Page 1

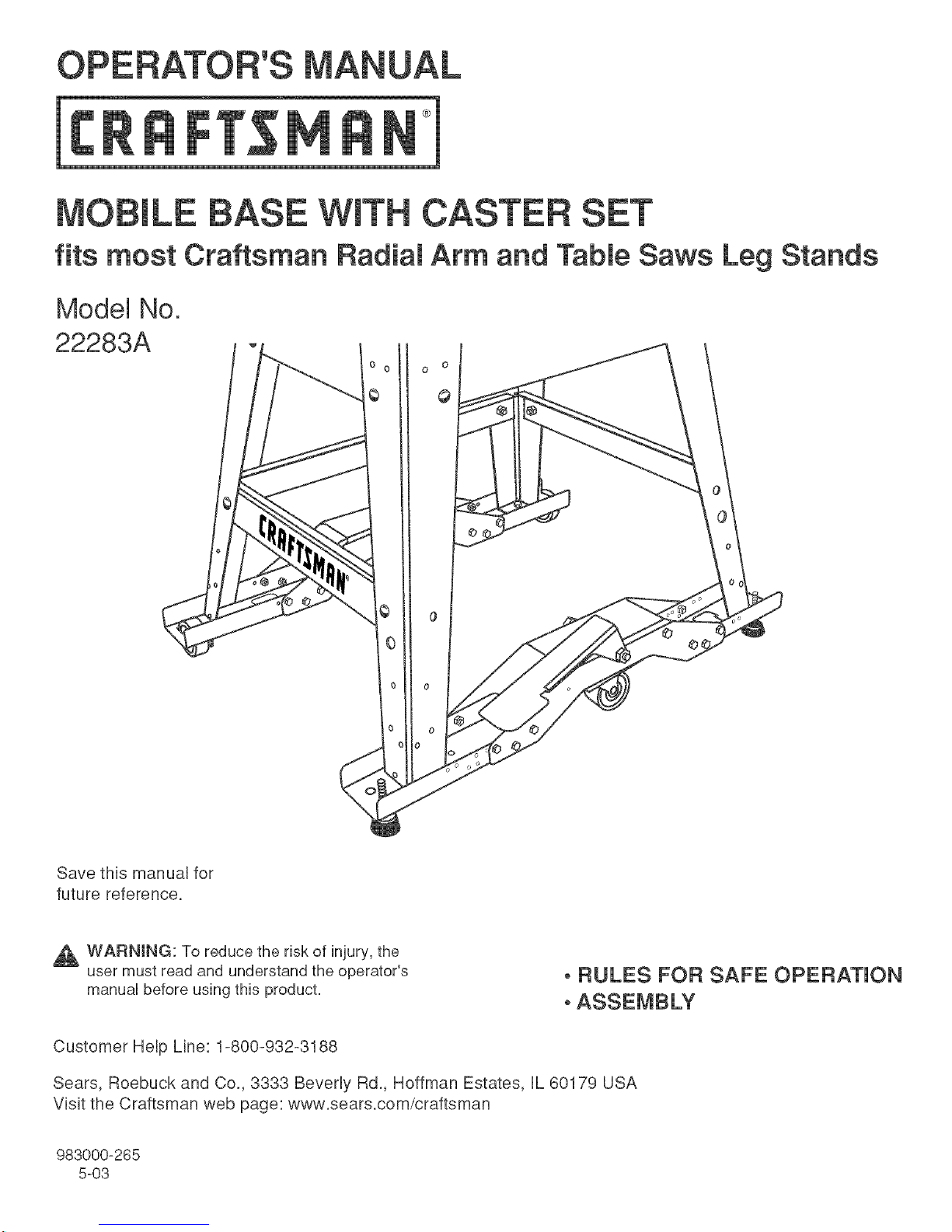

fits most Craftsman

Model No.

22283A

Radial Arm and Table Saws Leg Stands

©

Save thb manual for

future reference.

,_ WARNING: To reduce the risk of injury, the

user must read and understand the operator's

manual before using this product.

oRULES FOR SAFE OPERATION

oASSEMBLY

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, IL 60179 USA

Vbit the Craftsman web page: www.sears.com/craftsman

983000-265

5-03

Page 2

Thepurposeof safetysymboisis to attractyourattentionto possibiedangers.Thesafetysymbois,andthe

expianafionswiththem,deserveyourcarefuiattentionandunderstanding.Thesafetywarningsdonotbythemseives

eliminateanydanger.Theinstructionsorwarningstheygivearenotsubstitutesforproperaccidentprevention

measures.

SYMBOL MEANmNG

DANGER:hdbatesanimminentiyhazardoussituation,which,if notavoided,wHiresuitindeathor

WARNING:Undbatesapotentialiyhazardoussituation,which,ifnotavoided,couidresuitindeathor

seriousinjury.

CAUTION:Indicatesa potentiallyhazardoussituation,which,ifnotavoided,mayresultinminoror

moderateinjury.Itmayalsobeusedtoalertagainstunsafepracticesthatmaycausepropertydamage.

mmportant:Advisesyouofimportantinformationorinstructionsvitaltotheoperationormaintenanceof

Note:Advisesyouofadditionalinformationconcerningtheoperationormaintenanceoftheequipment.

,_ WARNmNG: Read and understand aH instructions.

Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious personal

injury.

SAVE THESE INSTRUCTIONS

[] Know your power tool Read the operator's manuai for

your Table Saw or Radial Arm Saw carefully. Learn the

saw's applications and limitations as well as the specific

potential hazards related to this tool.

Safety instructions For Mobile Bases

[] Never install mobile base with saw mounted to leg

stand.

[] Be careful when moving to avoid any finger pinch

points.

[] Remove the dust bag before moving the tool or when

placing the leg stand on the mobile base.

[] Place base on a level surface and adjust leveling feet

before placing your saw in position. This should keep

saw from rocking, while testing it for stability.

[] Test for stability in both the up (on the caster) and the

down positions. Exercise caution when testing the

stability of top heavy machines such as your saw.

[] Never lift the saw onto the leg stand without help.

[] Unplug your saw before moving or repositioning your

tool.

[] Always test your setup for stability and safety after

repositioning and before plugging the saw into an outlet.

[] Care should be taken when planning the orientation of

your saw onto the mobile base. Transfer of weight off of

the leveling feet to the caster will result in the saw tilting

1/2 in. toward the fixed wheels. When repositioning top

heavy tools such as your saw, take advantage of the

center of gravity, and position so that it will remain

stable while on caster.

[] Never use your saw while it is suspended on the swivel

caster. Always lower saw onto the nonskid leveling feet

before operating.

[] When moving, always push the leg stand, not the saw.

[] Think Safety. Safety is a combination of operator

awareness, common sense and alertness at aii times.

[] Save these instructions. Refer to them frequently and

use them to instruct others who may use this tool If you

loan someone this tool, loan them these instructions also.

_ WARNING: Secure leg stand to mobile base before

moving the tool. Failure to secure the leg stand could

cause the saw to fall resulting in serious personal

injury.

[] Measure the leg stand from the leveling foot hobs at

one side to the leveling foot hobs on the other side.

This measurement is needed to determine which hobs

in the lower support bracket and wheel support bracket

are to be used when assembling the mobile base. The

hobs must align properly for the leg stand and mobile

base to be secured.

_, WARNING: Do not engage or disengage the

release lever while the support brace is still attached

to the leg stand and never use your hand to operate

the release lever. Failure to heed this warning could

result in serious personal injury.

[] Unpack and identify all components and hardware

before attempting to assemble this unit.

Page 3

The items incUuded in this kit are:

m Large caster (1)

m Oenter support (2)

m Lower support bracket (2)

m WheeU support bracket (2)

m Oaster bracket (1)

m Release Rever (1)

WheeU Hardware Bag:

m WheeU (2)

m Hex bout, 1/4x 1 3/4 (2)

m Lock nut, 1/4 - 20 (2)

m Large bout, 3/8 x 4 1/2 (1)

m Washer, 3/8 (1)

m Lock nut, 3/8 - 16 (1)

Hardware Baq:

m Hex bout, 1/4 x 5/8 (24)

m Hex nut, flanged, 1/4 - 20 (24)

m Large hex bout, 5/16 x 3/4 (10)

m Large hex nut, 5/16 - 18 (8)

m Washer, 5/16 (18)

m LeveUing feet (2)

m Washer, 3/8 (4)

m Nut, 3/8-16(4)

m Lock nut, 5/16 - 18 (2)

MOSTTABLE

SAWS

MOSTRADIAL

ARMSAWS

CENTER

SUPPORT

WHEEL

SUPPORT

BRACKET

_° ° ° ooO_

WHEEL

WHEEL RELEASELEVER

SUPPORTBRACKET @_%\

WHEEL

CENTER

LOWER ÷ !41

SUPPORT ...__[%/

BRACKET °°°_--

_._ LEVEUNG

® FEET

LOWERSUPPORT

BRACKET

®

@

@

CASTER

BRACKET

LEVEUNGFEET

LARGECASTER

Fig. 1

Page 4

ASSEMBLY (NSTRUCT(ONS

To assemble first side (side with two wheels):

m Remove wheels, hex bolts, and lock nuts from the bag.

m Place wheel in slot of the wheel support bracket and

insert hex bolt through both the bracket and the wheel.

[] Secure with the lock nut and tighten.

[] Place center support (without the slot) upside down on

a fiat surface. Align the wheel support brackets with the

hobs previously determined to fit the saw. Using the

small hex bolts and hex nuts from the hardware bag,

place hex bolts through the hobs of both the wheel

support bracket and the center support.

[] Tighten using hex nuts.

Note: Repeat above steps for other side.

To assemble remaining side (side with two leveling feet

and caster):

m Mount caster to the caster bracket using large hex

bolts. Secure using lock nuts.

m Attach leveling feet to lower support bracket using hex

nuts and washers as shown in figure 3. Leveling feet

must touch the floor when the caster is in the raised

position.

m Secure bracket to underside of center support using the

remaining large hex bolts and hex nuts.

m Place center support (with slot and attached caster)

upside down on a fiat surface. Align the lower support

brackets with the hobs previously determined to fit the

saw. Using the small hex bolts and hex nuts from the

hardware bag, place hex bolts through the hobs of

both the lower support bracket and the center support.

[] Tighten using hex nuts.

[] Turn assembly upright onto leveling feet.

[] (nsert release lever into slot. Using the large bolt,

washer, and lock nut, secure release lever. Tighten.

[] (f saw is mounted to a leg stand, remove the saw from

the leg stand before installing the mobile base.

[] Remove leveling feet from leg stand. Secure the mobile

base to the leg stand using the large hex bolt and large

hex nut.

[] Mount the saw and remove support brace from the leg

stand (the support above the release lever). Do not

discard the support brace and hardware. (n the event

the saw is ever removed from the mobile base the

support brace must be installed.

,_ WARN(NG: Obtain help when lifting the saw to

place on the leg stand. Once the saw is mounted,

remove the support brace from the leg stand (the

support above the release lever). Failure to remove

the support brace, could result in injury.

TO RA(SE WHEEL:

Step down firmly on release lever.

TO LOWER WHEEL:

Place foot under the release lever and lift up.

Note: Never use your hand to raise or lower the wheel.

CENTERSUPPORT HEXBOLT

HEXHUT,

FLANGED_

HEXBOLT

_WHEEL

SUPPORTBRACKET

LOCKNUT

WHEEL

LARGEBOLT

J

LOCKHUT

WHEEL

Fig. 2

RELEASE

LEVER

WA_

NUT

@

@

SLOT

LOCKNUT

CASTER

BRACKET

LARGE

HEXBOLT_WASHER CASTER

HEXNUT

LEVEUNGFEET

TO

RA(SE

LARGE

HEXBOLT

&

Fig. 3

TO

Fig. 4

Loading...

Loading...