Craftsman 20057983 Owner’s Manual

SEOMU06A-1

Table of Contents

Introduction

Symbols and Icons 2

Inventory 3

Preparation / Tools Required 4

Assembly

Rail and Trolley Assembly 5

Installing the Belt 6-7

Important Installation Instructions 8

Mounting Header Bracket 9

Installation

Attaching Rail to Header Bracket and Mounting Door Bracket 10

Mounting Opener to Ceiling 11

Attaching Door Arms 12

Installing Light and Emergency Release Handle 13

Wiring

Wiring Instructions 14

Connecting Photo Eye Safety System 15

Connecting Door Control Console 16

Connecting Power 17

Adjustment

Aligning the Photo Eye Safety System 17

Travel Limit Adjustment– I. UP Limit 18

Travel Limit Adjustment– II. DOWN Limit 19

Auto Force Adjustment 20

Final Adjustment and Testing 21

Operation

Programming 3-Button Remote 22

Programming Keyless Entry Pad 23

Important Safety Instructions 24

Operating the Opener 25

Door Status vs. Activation 26

Backup Battery Installation / Battery and Status Indicator 27

Backup Battery Features / Motion-Sensing Light 28

Maintenance 29

Troubleshooting 29-30

Repair Parts and Service

Rail Assembly Parts / Installation Parts / Accessories 31

Opener Assembly parts 32

Warranty 33

Symbols and Icons

!

WARNING

DO NOT connect power

*See Accessories in Repair Parts section of this manual for purchase information.

2

READ WARNINGS CAREFULLY to prevent SERIOUS INJURY or DEATH caused by

electrocution or mechanical hazard.

Please connect power

Beeps from built-in buzzer of the opener

Installation hardware are

shown in actual size

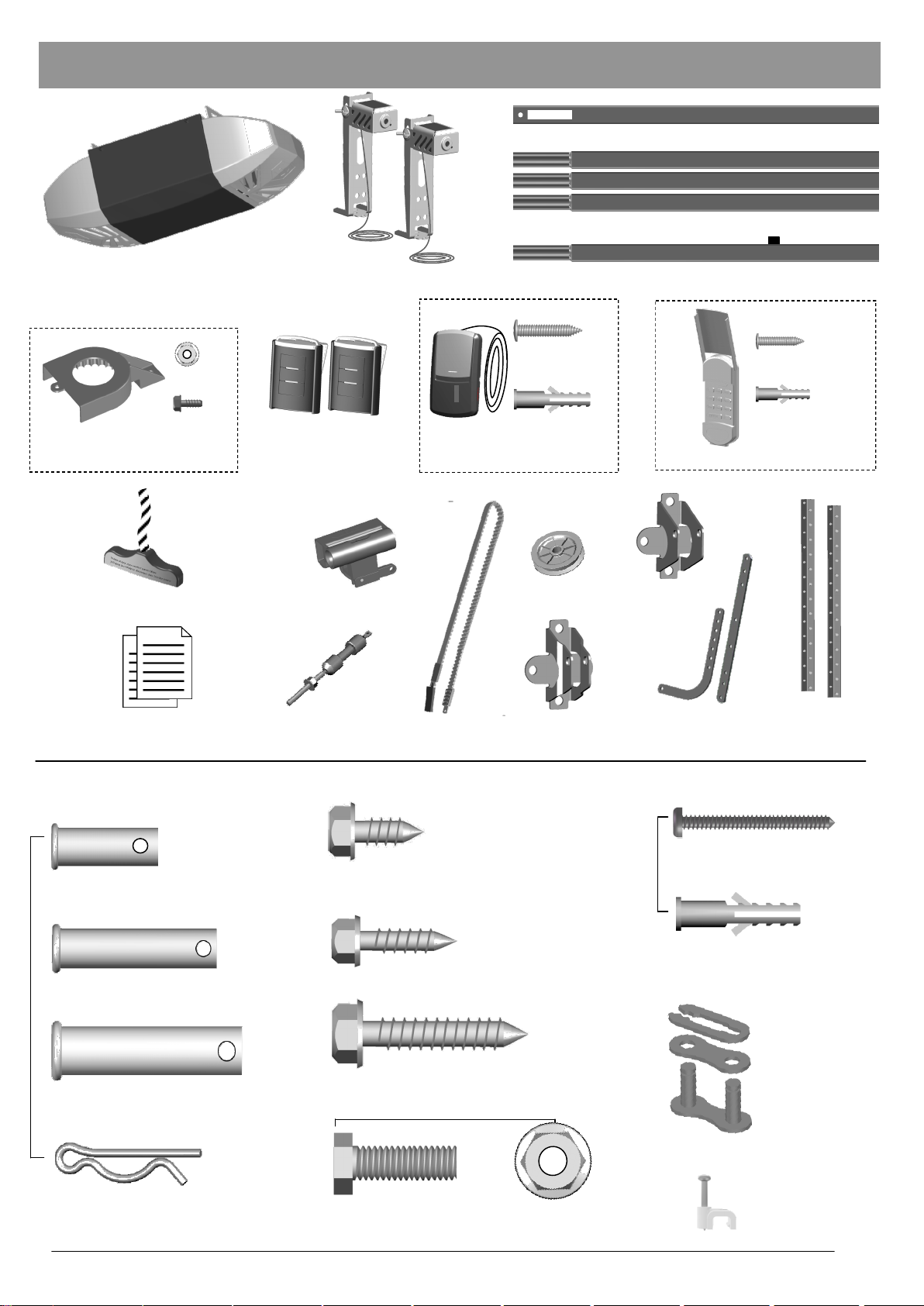

Inventory

Rail — Header Segment

Rail — Middle Segments x3

Opener Unit + Light Lens Cover

x 1

x 1

Sprocket Cover

Emergency Release Handle + Rope

Literature + Safety Labels

Photo Eye Safety System

Two 3-Button

Mini Remotes

Trolley

Trolley Shaft

Rail — End Segment with Trolley Stop Bolt

Screw #6 x 1”

Drywall Anchor

Door Control Console

Pulley

Belt

Door Bracket

Screw #6 x 1”

Drywall Anchor

Wireless Keyless Entry Keypad

Header

Bracket

Hanging

Door Arms

Brackets

x 2

x 2

INSTALLATION HARDWARE, LOCATED IN HARDWARE BAG (SHOWN IN ACTUAL SIZE)

x 2

x 2

Clevis Pin — Door arms

5/16” x 1”

x 1

Self-Threading Screw 1/4” x 5/8”

Door Bracket

x 4

Screw #6 x 1-1/4”

- Push Button

Drywall Anchor

- Push Button

Clevis Pin — Header Bracket

Lag Screw #12 x 1”— Photo Eye System

5/16” x 1-1/2”

x 4

x 1

Lag Screw 5/16” x 1-1/2”

Clevis Pin — Pulley

— Header Bracket / Mounting Opener

3/8” x 1-3/4”

x 5

Hitch Pin — Locking Clevis Pins

Bolt 5/16” x 1”

x 4

5/16” Flange Nut

x 4

— Door arms / Mounting Opener

x 2

x 2

x 1

Master Link Set

—Trolley Shaft

Insulated Staples

— Securing wires

3

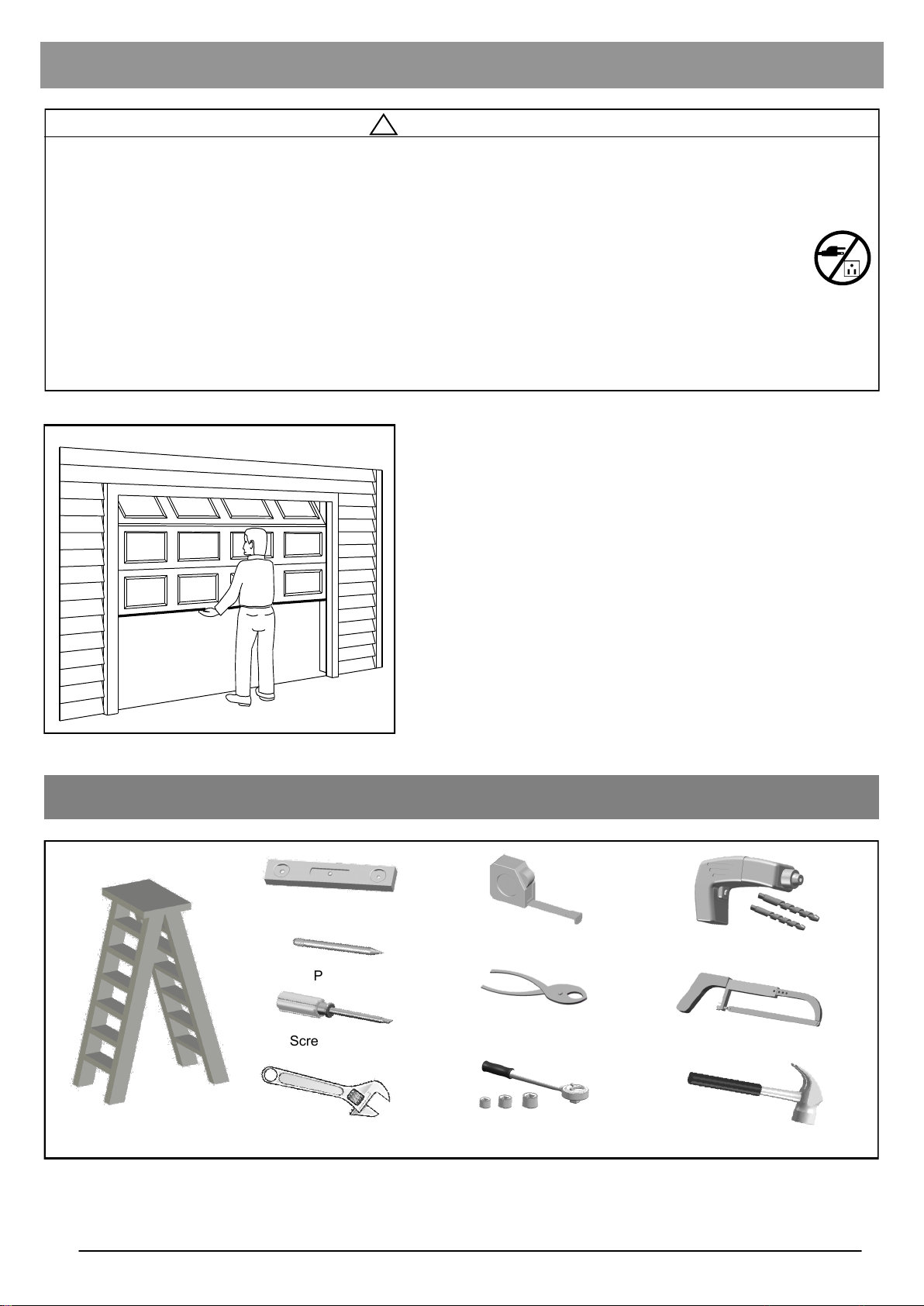

Preparation

!

WARNING

To prevent SERIOUS INJURY or DEATH:

- Before beginning installation of the opener please complete the following test to ensure that your door is

balanced and in good working condition.

- A poorly balanced door can cause serious injury and damage to the opener.

- Always have a qualified garage door service technician make any required adjustments and/or repairs to

your door before proceeding with installation.

- DISABLE ALL LOCKS and REMOVE ALL ROPES connected to the garage door BEFORE installing

and/or operating the opener.

To prevent damage to the door and opener:

- DO NOT connect power until instructed.

- Operate this opener with AC 120V/60Hz power supply ONLY.

DO NOT REUSE PARTS FROM ANOTHER BRAND OF OPENER!!!

Sectional Garage Door

Tools Required

BEFORE beginning Installation:

1. Disable locks and remove all ropes connected to the

garage door.

2. Perform the following door test to ensure your door is

balanced and in good working condition.

To Test Your Garage Door

1. Raise and lower the door to check if there is any sticking or

binding.

2. Check for loose hinges, damaged rollers, frayed cables and

damaged or broken springs.

3. Lift the door approximately halfway and release. The door

should stay at the point under proper spring tension.

Call a qualified garage door service technician if your door binds,

sticks or is unbalanced.

4

Step Ladder

Level

Pencil

Screwdriver

Adjustable Wrench

Tape Measure

Pliers

Ratchet with

5/16”, 7/16” and 1/2” sockets

Drill, 3/16” and 5/16” Drill Bits

Hack Saw

Hammer

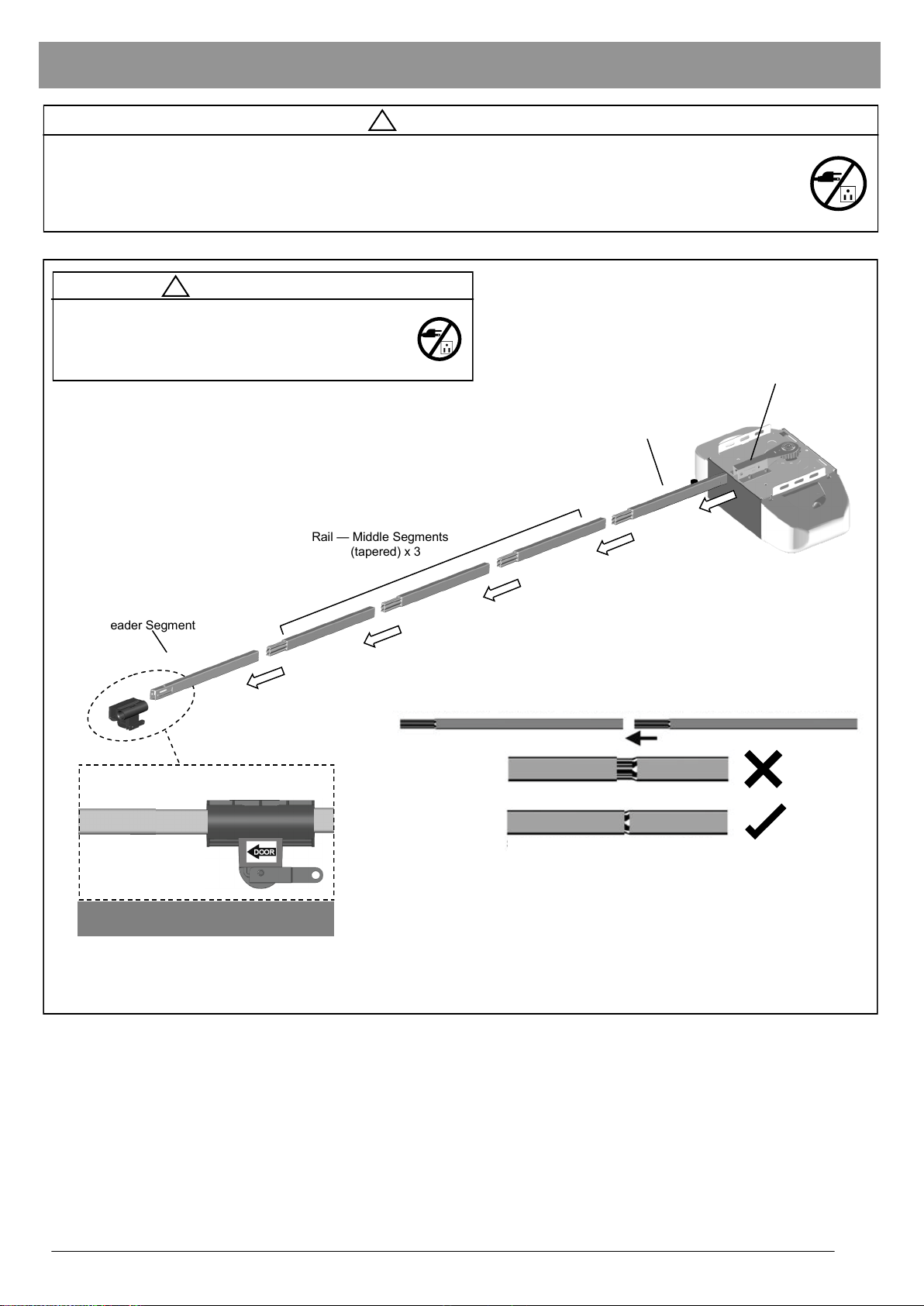

Rail and Trolley Assembly

!

WARNING

To prevent SERIOUS INJURY:

- DO NOT connect power until instructed.

- Keep hands and fingers clear from sprocket during operation.

- Wear gloves when installing belt.

- Keep hands and fingers away from joints and possible sharp edges.

!

CAUTION

- DO NOT connect power until instructed.

- To prevent INJURY, keep hands and fingers

away from joints and possible sharp edges.

- Wear gloves when installing chain/belt and cable.

Rail Bracket

Rail — End Segment (tapered)

with Trolley Stop Bolt

Rail — Header Segment

Trolley direction (Top View)

* VERY IMPORTANT! *

Rail — Middle Segments

(tapered) x 3

Wrong

Loosely connected

Right

Securely connected by applying force

When connecting the rails ensure they are securely connected as shown

above. To apply additional force tap gently on the end of the rail with a

rubber mallet*.

*Only use a soft rubber mallet to tap on the end of the rails as other tools

may damage the rail.

Fig.1

To Assemble Rail and Opener

1. Prepare the rails as shown in Fig.1.

2. Connect the rails starting with the Header Segment. Insert the tapered ends into open ends, apply any additional

force necessary by tapping the Rail on padded flooring. Ensure the End Segment has Trolley Stop Bolt facing up.

Make sure the rails are securely joined together as shown.

3. Slide the Trolley onto the rail from the Header Segment. Make sure the arrow is pointing towards the door as shown .

4. Insert the Rail - End Segment into the Rail Bracket on the Opener. Secure End Segment to Bracket as described on

next page.

5

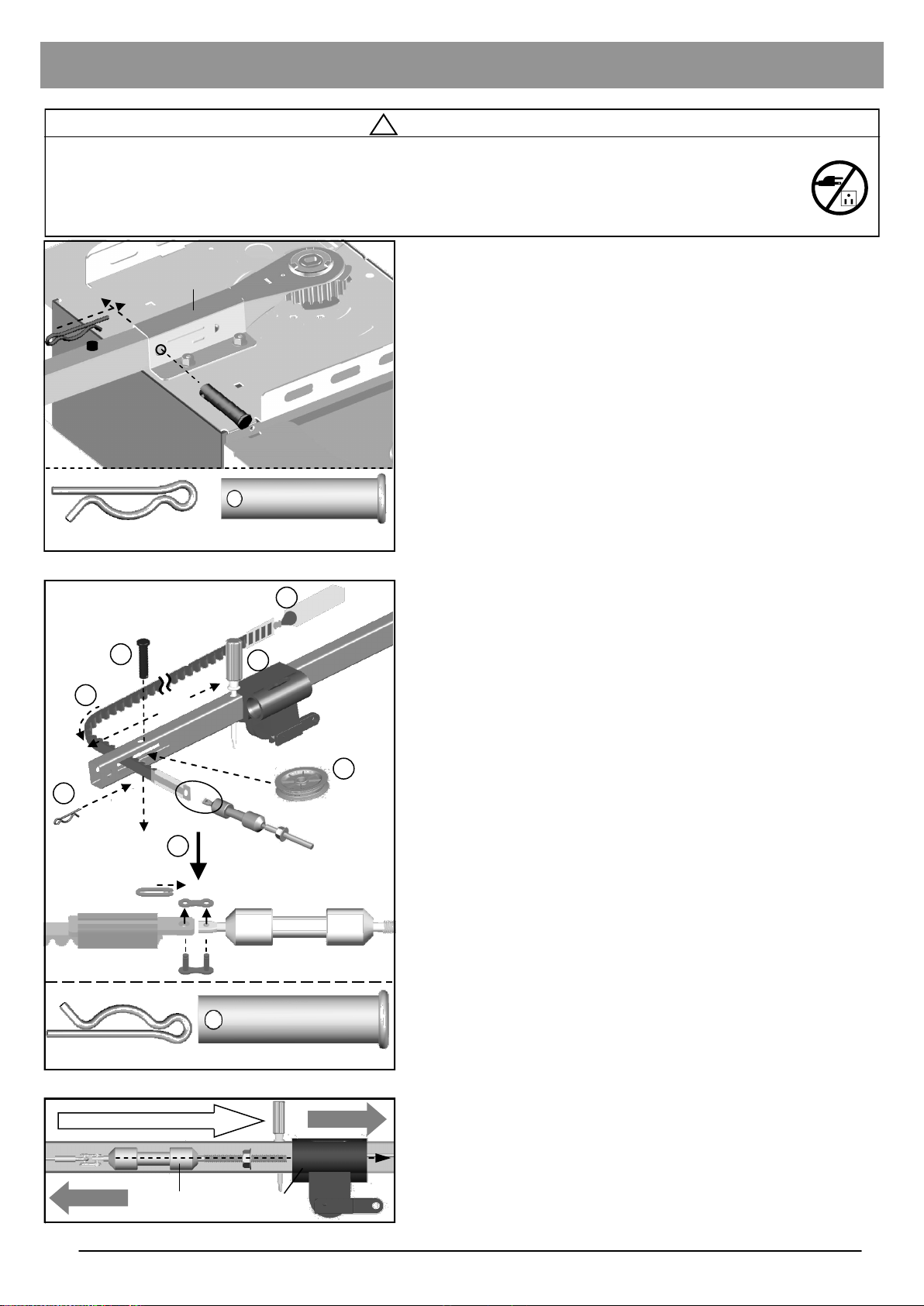

Installing the Belt

!

WARNING

To prevent SERIOUS INJURY:

- DO NOT connect power until instructed.

- Keep hands and fingers clear from sprocket during operation.

- Wear gloves when installing the belt.

- Keep hands and fingers away from joints and possible sharp edges.

To Secure the Rail on the Opener

With the End Segment of the rail fully inserted into the Rail

Bracket, insert a 5/16” x 1-1/2” Clevis Pin through the hole and

lock it into position with a Hitch Pin as shown in Fig.1.

To Assemble the Header Section of Rail

See Figure 2 for steps 1 through 7.

1. Place the belt beside the rail as shown

2. Insert a screwdriver into the hole approximately 10-1/4” from

the end of the Rail - Header Segment. Slide the trolley

against this screw driver. The trolley must stay in this position for proper alignment of the belt.

3. Pass the belt end with Trolley Shaft Connector through the

slot on the Rail - Header Segment.

4. Insert the Pulley into the slot to the right of the belt.

5. Secure the Pulley by inserting the 3/8” x 1-3/4” Clevis Pin

through the top of the rail.

6. Lock the Clevis Pin with a Hitch Pin. Rotate the Pulley to

ensure it spins smoothly.

7. Connect the Trolley Shaft to the Trolley Shaft Connector on

the belt, using the Master Link Set.

8. Slide the Trolley Shaft into the Trolley until you hear a "click"

when they lock together. See Fig. 3.

Hitch Pin

3

Hitch Pin

Clevis Pin

5

Rail Bracket

Fig.1

Screwdriver

10-1/4”

Clevis Pin

Clevis Pin - 5/16” x 1-1/2”

1

2

Trolley

6

Hitch Pin

Trolley Shaft Connector

Hitch Pin

Slide trolley shaft into trolley to lock

Garage Door

7

Trolley Shaft

2

Trolley Shaft

Clevis Pin — 3/8” x 1-3/4”

Fig.2

Trolley

4

Pulley

Opener Unit

6

Fig.3

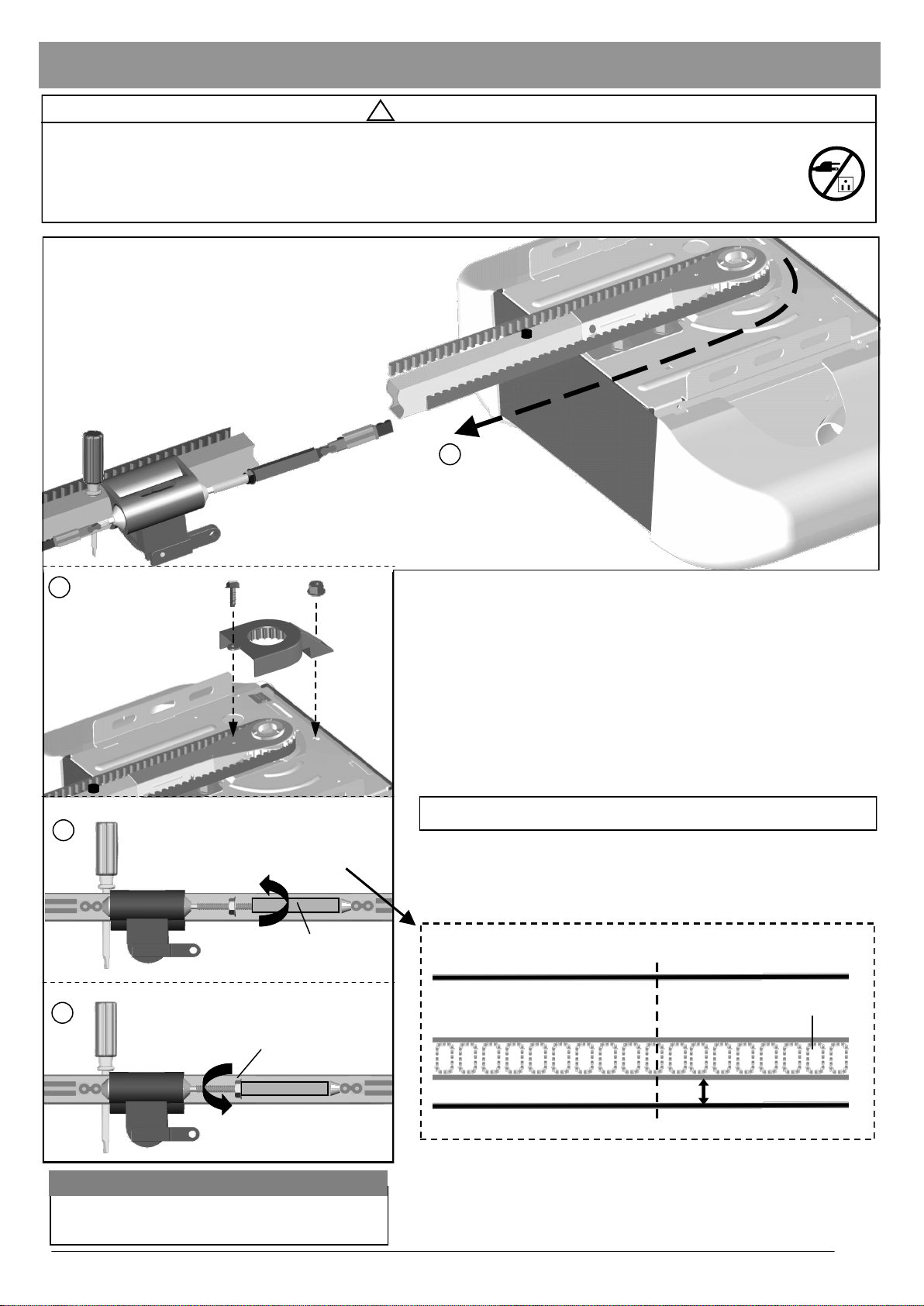

Installing the Belt

!

WARNING

To prevent SERIOUS INJURY:

- DO NOT connect power until instructed.

- Keep hands and fingers clear from sprocket during operation.

- Wear gloves when installing chain/belt and cable.

- Keep hands and fingers away from joints and possible sharp edges.

1

2

Sprocket Cover

3

4

Tighten until...

Belt Connector

Flange Nut

To Connect and Tension the Belt

1. With the trolley positioned against the screwdriver, pull the

remaining belt straight along the rail and engage belt teeth

around the sprocket. (Make sure the belt is not twisted

around the rail.) See Fig. 1.

2. After the belt is connected, attach the Sprocket Cover to the

opener with the screw and nut provided. See Fig. 2.

* VERY IMPORTANT! *

THE SPROCKET COVER MUST BE SECURELY INSTALLED!!

3. Rotate the Belt Connector towards the Trolley Shaft until the

belt is slightly loose about 1/4” (6mm) above the base of the

rail. Refer to the actual-sized illustration below for proper belt

tension. See Fig. 3.

Mid-point of rail assembly

Top of Rail

Actual Size

Belt

Tighten nut

NOTE: FOR HEAVY DOORS

For heavier doors an additional half turn to the belt

connector may be required to eliminate belt slippage.

1/4” (6mm)

Base of Rail

4. Tighten the Flange Nut on Trolley Shaft against the Belt

Connector. See Fig. 4.

Remove the screwdriver holding the trolley in position on the Rail Header Segment.

7

Important Installation Instructions

IMPORTANT INSTALLATION INSTRUCTIONS

!

WARNING

To reduce the risk of severe injury or death:

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2. Install only on a properly balanced garage door. An improperly balanced door has the potential to inflict severe

injury. Have a qualified service person make repairs to cables, spring assemblies, and other hardware before

installing the opener.

3. Remove all ropes and remove or make inoperative all locks connected to the garage door before installing

opener.

4. Where possible, install the door opener 7 feet or more above the floor. For products having an emergency

release, mount the emergency release within reach, but at least 6 feet above the floor and avoiding contact

with vehicles to avoid accidental release.

5. Do not connect the opener to source of power until instructed to do so.

6. Locate the push button: (a) within sight of door, (b) at a minimum height of 5 feet so small children are not able

to reach it, and (c) away from all moving parts of the door.

7. Install the Entrapment Warning Label next to the wall-mount push button in a prominent location. In case the

adhesive does not adhere on the surface, the label should be attached to the surface by mechanical means.

Place entrapment warning label on wall next to garage door control.

8. After installing the opener, the door must reverse when it contacts a 1-1/2-inch high object (or a 2 by 4 board

laid flat) on the floor.

8

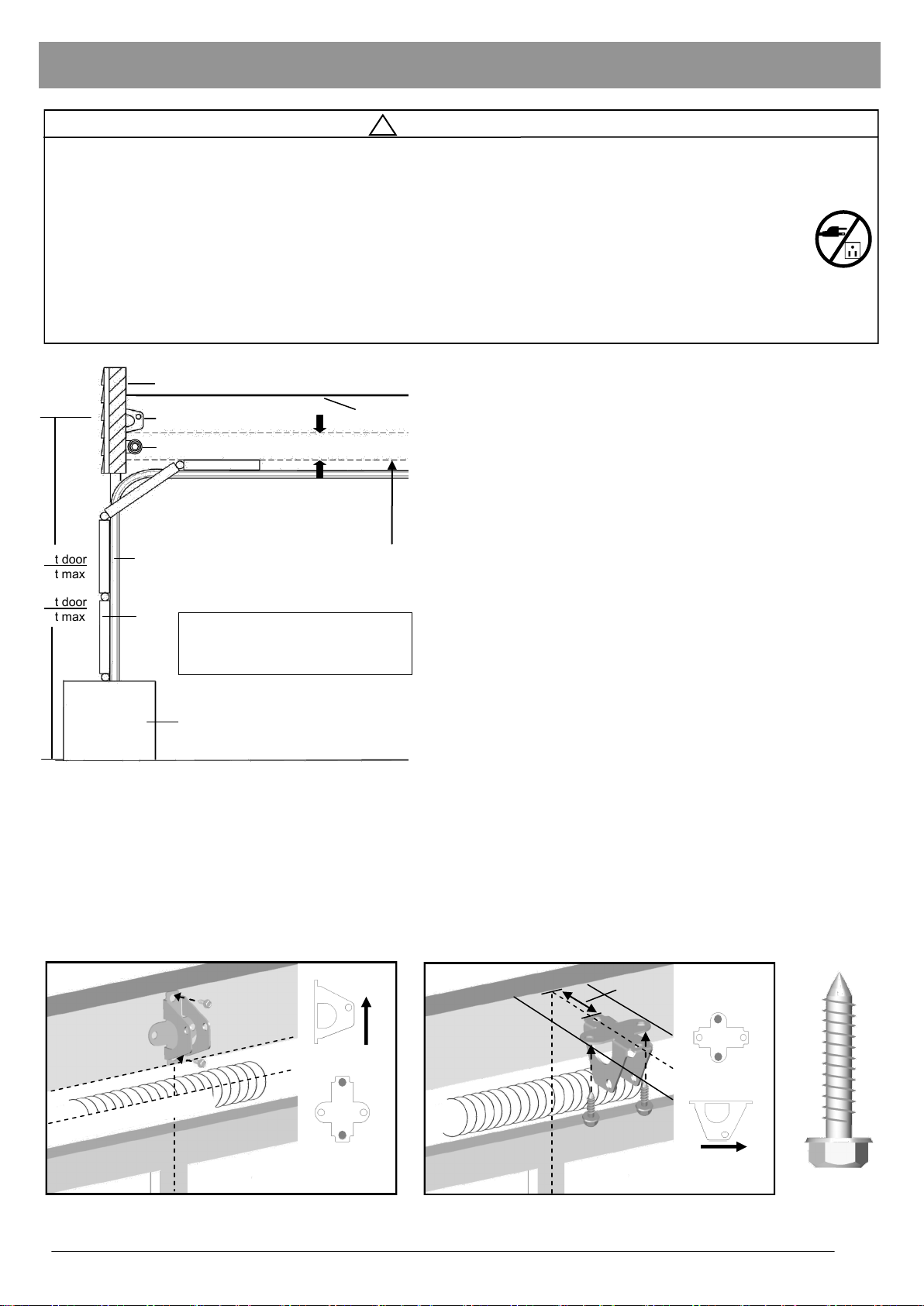

Mounting Header Bracket

!

WARNING

To prevent SERIOUS INJURY:

- DO NOT connect power until instructed.

- The header bracket MUST be SECURELY fastened to the structural support on the mounting wall or

ceiling, otherwise the door may not reverse when required. DO NOT install the header bracket over drywall.

- Concrete anchors MUST be used when mounting the header bracket into masonry.

- NEVER try to loosen, move or adjust garage door springs, cables, pulleys, brackets, or hardware.

- Contact a qualified garage door service technician if your door binds, sticks or is unbalanced. An unbal-

anced door might not reverse when required.

7ft door

8ft max

8ft door

9ft max

Header Wall

Header Bracket

Door Spring

Ceiling

2” (5cm) clearance

To Install Header Bracket

Note: Installation procedures may vary according to door

type.

1. While inside your garage, close the door and mark the

vertical centerline of the garage door. Extend the line onto

the header wall above the door spring.

2. Open the door to the highest point of travel. Mark a line on

MAX RAIL HEIGHT

Door Track

Highest Point of Door Travel

* VERY IMPORTANT! *

Door

Max recommended rail height from floor

7ft door = 8ft max height

8ft door = 9ft max height

the header wall 2“ (5cm) above the highest point of travel.

Note: DO NOT install the header bracket over drywall. In some

installations, it may be necessary to install a 2x4 across two wall

studs to create a suitable location for the header bracket.

If installing into masonry, use concrete anchors (not provided).

Wall-Mounting

As shown in Fig.2, place the header bracket on the vertical

centerline in direction shown.

Support block on floor

Floor

Fig.1

Mark and drill two 3/16” holes. Fasten the header bracket

securely to a structural support using two 5/16” x 1-1/2” lag

screws.

Alternative Ceiling-Mounting

Ceiling-mounting is suggested ONLY when clearance is minimal.

Horizontal Line

Highest Point of Door Travel

Fig.2 (Wall-Mounting) Fig.3 (Ceiling-Mounting)

Vertical Centerline

UP

Extend the vertical centerline onto the ceiling as shown in Fig.3.

Center the header bracket on the vertical mark, no more than

6” (15cm) from the header wall. Mark and drill holes to fasten the

header bracket securely to a structural support.

Finished Ceiling

Vertical Centerline

MAX. 6” (15cm)

OPENER

Lag Screw

5/16” x 1-1/2”

9

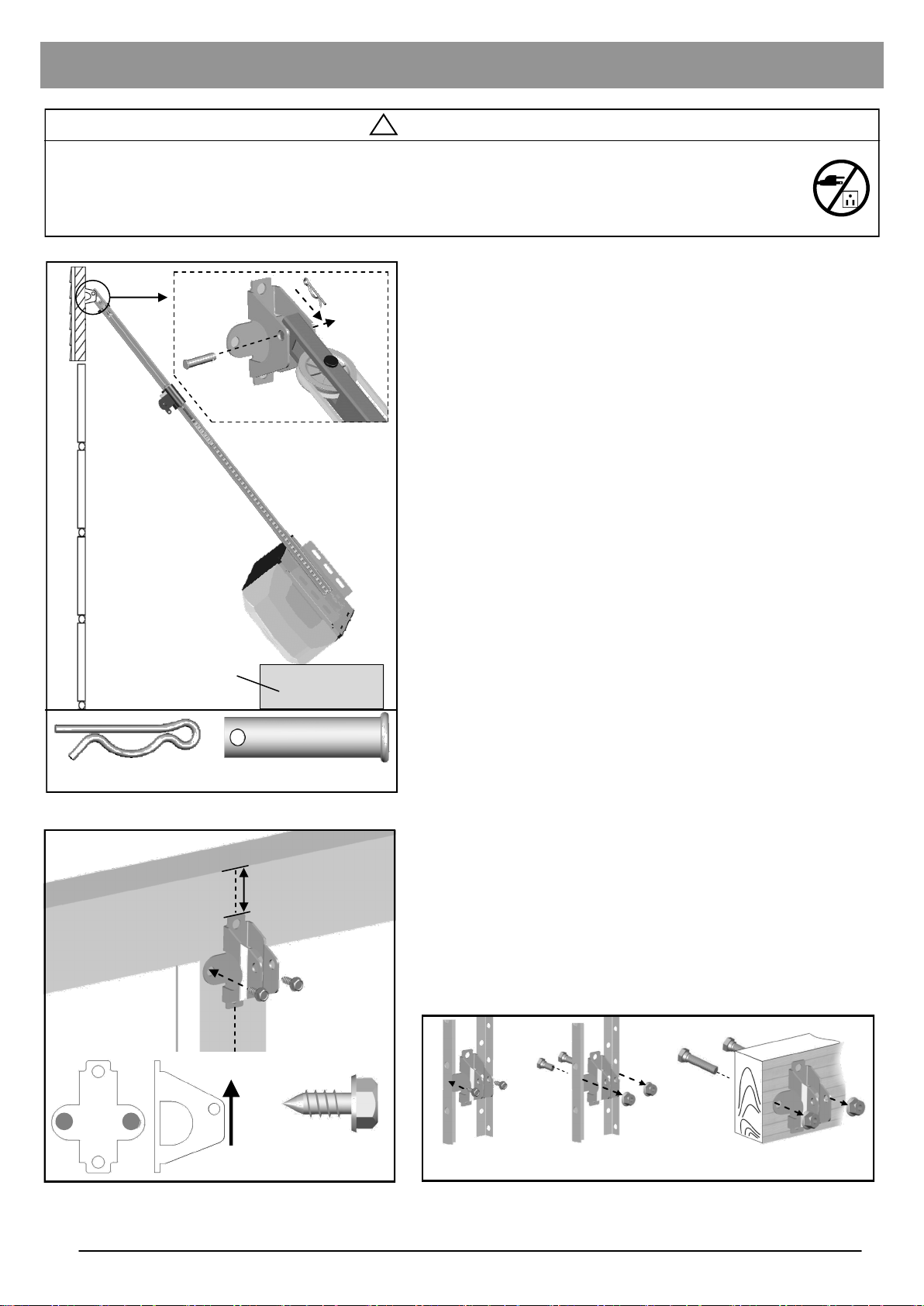

Attaching Rail to Header Bracket and Mounting Door Bracket

!

CAUTION

To prevent SERIOUS INJURY:

- DO NOT connect power until instructed.

- Horizontal and vertical REINFORCEMENT is needed for fiberglass, aluminum or lightweight steel garage

doors BEFORE installing the door bracket. Contact your door manufacturer for reinforcement options.

To Attach the Opener to the Header Bracket

1. As shown in Fig.1, use the packaging carton as temporary

support for the opener. Place the opener on carton to

prevent damage.

2. Align the mounting hole on the header rail to the mounting

hole on the Header Bracket.

3. Connect the header rail and the door bracket together with

a 5/16” x 1-1/2” clevis pin and lock it in place with a hitch

pin.

To mount the Door Bracket

Note: Some door reinforcement kits may provide direct

attachment of the door arm to the reinforcement bracket. If you

have a door reinforcement bracket with this option, skip this step

and proceed with the next step “mounting opener to ceiling”.

Hitch Pin

Carton

Clevis Pin - 5/16” x 1-1/2”

Fig.1

Top Edge of Door

2-4” (5-10cm)

1. Position the door bracket on the centerline of the door

approximately 2” - 4” (5-10cm) below the top edge of the

door, as shown in Fig.2.

2. Depending on the construction of your door, install using

one of the steps shown if Fig. 3 below:

For lightweight steel doors, with factory equipped

vertical steel reinforcement and horizontal strut.

(a) Mark and drill two 3/16” holes. Make sure not to drill

through the garage door. Secure the door bracket with two

1/4” x 5/8” self-threading screws (provided) as shown in

Fig.3(a).

(b) Alternative installation: Drill two 5/16” holes through the

door. Secure the door bracket using two 5/16” bolts, lock

washers and nuts (not provided) as shown in Fig.3(b). The

length of bolts will depend on the thickness of your door.

Wood door

(c) Mark and drill two 5/16” holes through the garage door.

Secure the door bracket using two 5/16” carriage bolts,

washers and nuts (not provided) as shown in Fig.3(c). The

length of bolts will depend on the thickness of your door.

Note: DO NOT use Self-Threading Screws on a wood door.

10

UP

Fig.2

Vertical Centerline of Door

Self-Threading

Screw - 1/4” x 5/8”

(a) (b) (c)

Fig.3

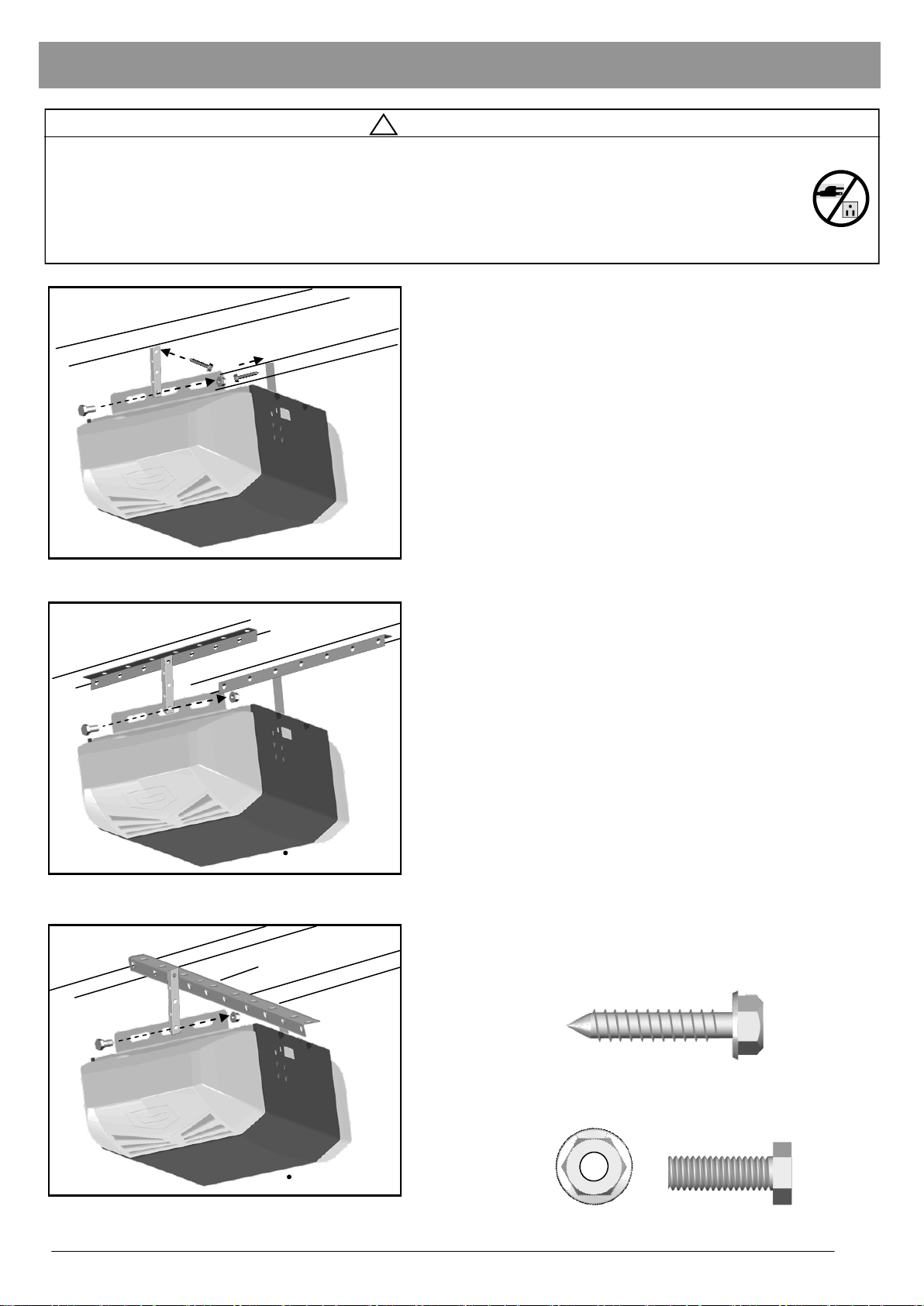

Mounting Opener to Ceiling

!

WARNING

To prevent SERIOUS INJURY or DEATH:

- DO NOT connect power until instructed.

- Install the opener at least 7 feet (2.13m) above the floor.

- Fasten the opener SECURELY to STRUCTURAL SUPPORTS of the garage to prevent falling.

- If installing brackets to masonry, concrete anchors (not provided) MUST be used.

Finished ceiling

Structural support

Fig.1

Angle Iron not provided

To Mount the Opener to Ceiling

The three most common installation options are shown in

Fig.1-3.

Fig.1 shows mounting the opener directly to structural

support on the ceiling. Fig.2 and 3 show mounting on a

finished ceiling, with heavy duty angle iron*.

*(angle iron not included)

Determine the mounting option that works best for your

application and follow installation steps below:

1. Raise the opener and rail assembly and temporarily place it

on a stepladder.

2. Position the opener and rail assembly so that it is aligned to

the center line of the garage door. If the header bracket was

mounted off center, align the opener with the header

bracket.

3. Measure the distance from each side of the opener to the

structural supports.

4. Cut both hanging brackets to appropriate length.

5. Drill 3/16” holes in the structural supports.

6. Secure one end of each of the hanging brackets to the

structural supports using 5/16” x1-1/2” lag screws

(provided).

Finished ceiling

Fig.2

Angle Iron not provided

Fig.3

Bolt / Lock Washer / Nut

not provided

Bolt / Lock Washer / Nut

not provided

7. Secure the opener to the hanging brackets and secure each

side with a 5/16” x 1” bolt and flange nut (provided).

8. Move the door manually to check clearance between

highest point of travel of the door and rail. If the door hits the

rail, raise the header bracket or adjust the mounting of

opener.

9. Remove the ladder ONLY when the opener is securely

mounted to the structural supports.

Fastening Hanging Brackets to structural supports

Lag Screw 5/16” x 1-1/2”

Securing Opener to Hanging Brackets

Bolt 5/16” x 1” Flange Nut

11

Loading...

Loading...