Owner's Manual

CRRFTSHRN®

ALL-IN-ONE

CUTTING TOOL

Model No.

183.172540

Important Safety Notice

[_, WARNING I

Always have one hand firmly

placed on the tool body while

operating, Never operate the

tool by holdingonlythe tool

handle.

• Safety Instructions

CAUTION:

Before using this Cutting

Tool, read this manual

and follow all its Safety

Rules and Operating

Instructions,

• Accessories

• Assembly

• Operation

• Maintenance

• Parts List

• Espanol

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Part, No, 183172540001 Rev. 0 07/21/03

Safety and Assembly Instructions

CRRFTSMRN®

FLEX SHAFT for

ALL-IN-ONE

CUTTING TOOL

Model No.

183.287660

IAWA.N,.GJ

ALWAYS WEAR EYE PROTECTION. Any power

standard Z87.1. Everyday glasses have only

impact resistant lenses. They ARE NOT safety

glasses, Safety goggles are available at most

hardware stores,

Glasses or goggles not in compliance with ANSI

Z87.1 could cause serious injury when they

break.

USE FACE OR DUST MASK along with safety

goggles if cutting or routing operation is dusty.

Make sure work area is well ventilated.

NEVER PLACE HANDS IN THE PATH OF THE

CUTTER or under the workpiece.

USE HEARING PROTECTION, particularly

during extended periods of operation,

ALWAYS RE-TIGHTEN COLLET before starting

the tool after a cutting bit or accessory has

been changed. Loose bits and accessories can

cause unexpected shifting of the tool, resulting

in loss of control and injury from the bit or

cutting tool being thrown.

NEVER TOUCH THE CUTTING BIT

IMMEDIATELY AFTER USE. The bit will be too

hot to be handled with bare hands and will burn

your fingers.

tool can throw foreign

which could cause

permanent eye damage.

ALWAYS wear safety

objects into your eyes

goggles (not glasses) that

comply with ANSI safety

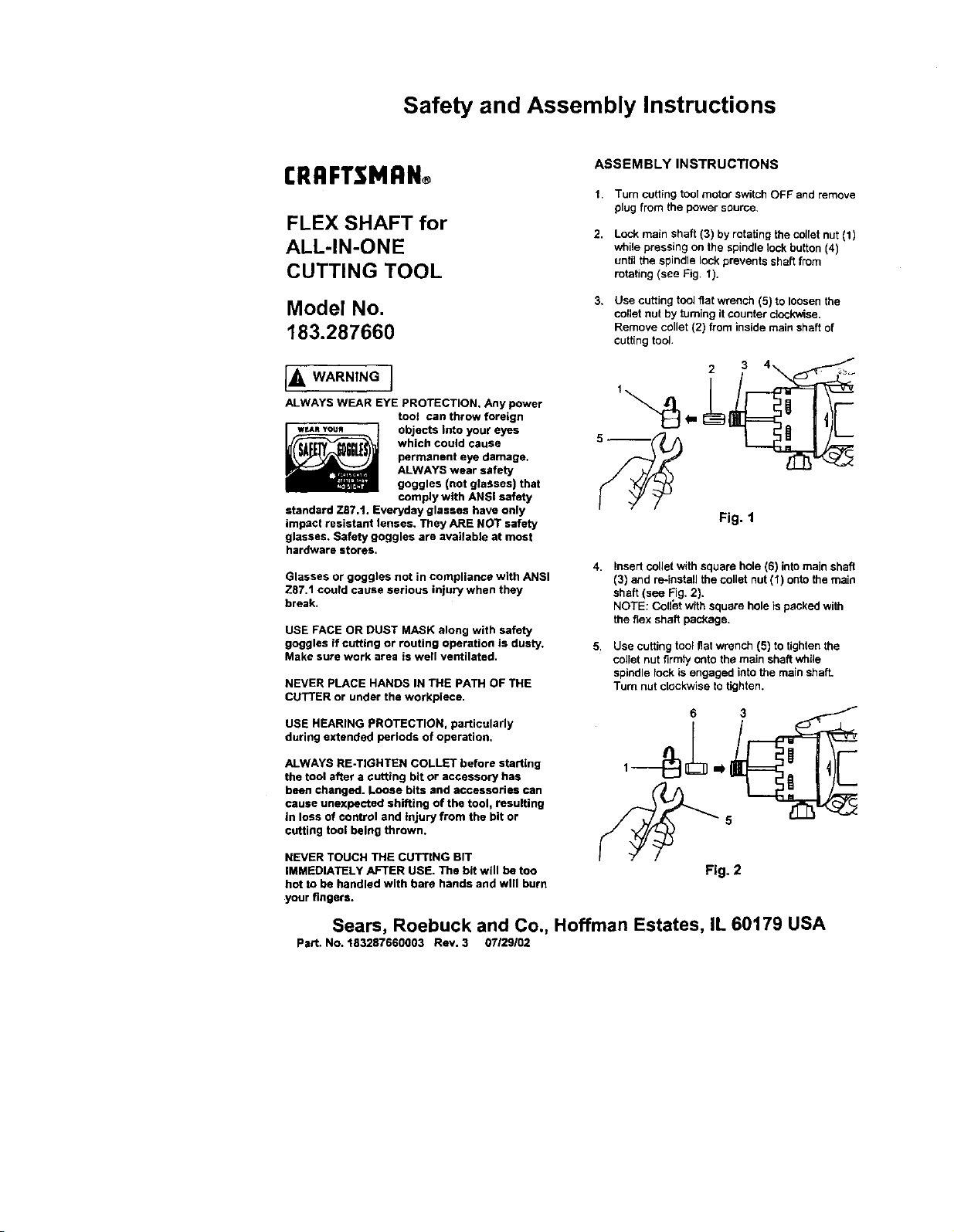

ASSEMBLY INSTRUCTIONS

t.

Turn cutting toolmotor switch OFF and remove

plugfrom the power source.

2.

Lock mainshaft (3) by rotatingthecollet nut(1)

while pressing on the spindle lockbutton (4)

untilthe spindlelock preventsshaftfrom

rotating (see Fig 1).

3.

Use cutting toolfiat wrench (5) to loosenthe

collet nut by turningit counter clockwise.

Remove collet(2) from insidemain shaft of

cutting tool.

2 3

Fig. 1

4. Insert collet withsquare hole (6) intomain shaft

(3) and re-installthe collet nut(1) onto the main

shaft(see Fig. 2).

NOTE: Coll_t with square hole ispackedwith

the flex shaft package.

5. Use cutting tool fiatwrench (5) to tightenthe

colletnut firmty onto the main shaftwhile

spindle lock is engaged into the main shaft,

Turn nut clockwise to tighten.

Fig. 2

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Part. No. 183287660003 Rev. 3 07129102

SECTION PAGE

Warranty........................................ 2

ProductSpecifications...................... 2

PowerToolSafety ............................ 3

CuttingToct&AccessorySafety ......... 4

ElectricalRequirement&Safety .......... 5

CuttingTootSymbols........................ 6

SECTION PAGE

ACCSS_ .................................... 7

Carton Contents .............................. 7 - 8

Know Your Cutting Toct .................... 9 - 10

Assembly & Operation ...................... 11 - 23

Maintenance ................................... 24

Repair Parts ................................... 25 - 36

FULL ONE YEAR WARRANTY

If this Cutting Tool fails due to a defect in material or workmanship within one year of date of

purchase, Sears will at its optionrepair or replace itfree of charge.

Return this Cutting Tool to a Sears Service Center for repair, or to place of purchase for

replacement.

This warranty gives you specific legal rights, and you may also have other dghts which may vary

from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

[A WARNINGJ

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well ventilated area and work with approved safety equipment such as

those dust masks that are specially designed to filter out microscopic particles,

Motor Rating ...................... 120 V, 60 Hz, AC

Amperes ........................... 5.0 A

Two Speeds (no load) ......... 20,000 & 30,000 RPM

Motor Horsepower ...... 3/4HP (Maximum Developed)

Weight ..................... 3 lb. 12 oz, (1.7 kg)

Maximum Disc SiZe .... 4" Diameter

J_ WARNING I

To avoid electrical hazards, fire hazards or damage to the tool, use proper circuit protection.

This power tool is wired at the factory for 110-120 V operation. It must be connected to a 110-120 V 115 A time

delayed fuse or circuit breaker. To avoid shock or fire, replace power cord Immediately if it is worn, cut or

damaged in any way.

Before using your cutting tool, it Is critical that you read and understand these safety rules, Failure to follow

these rules could result in serious Injury to you or damage to the cutting tool.

2

Safety and Assembly Instructions

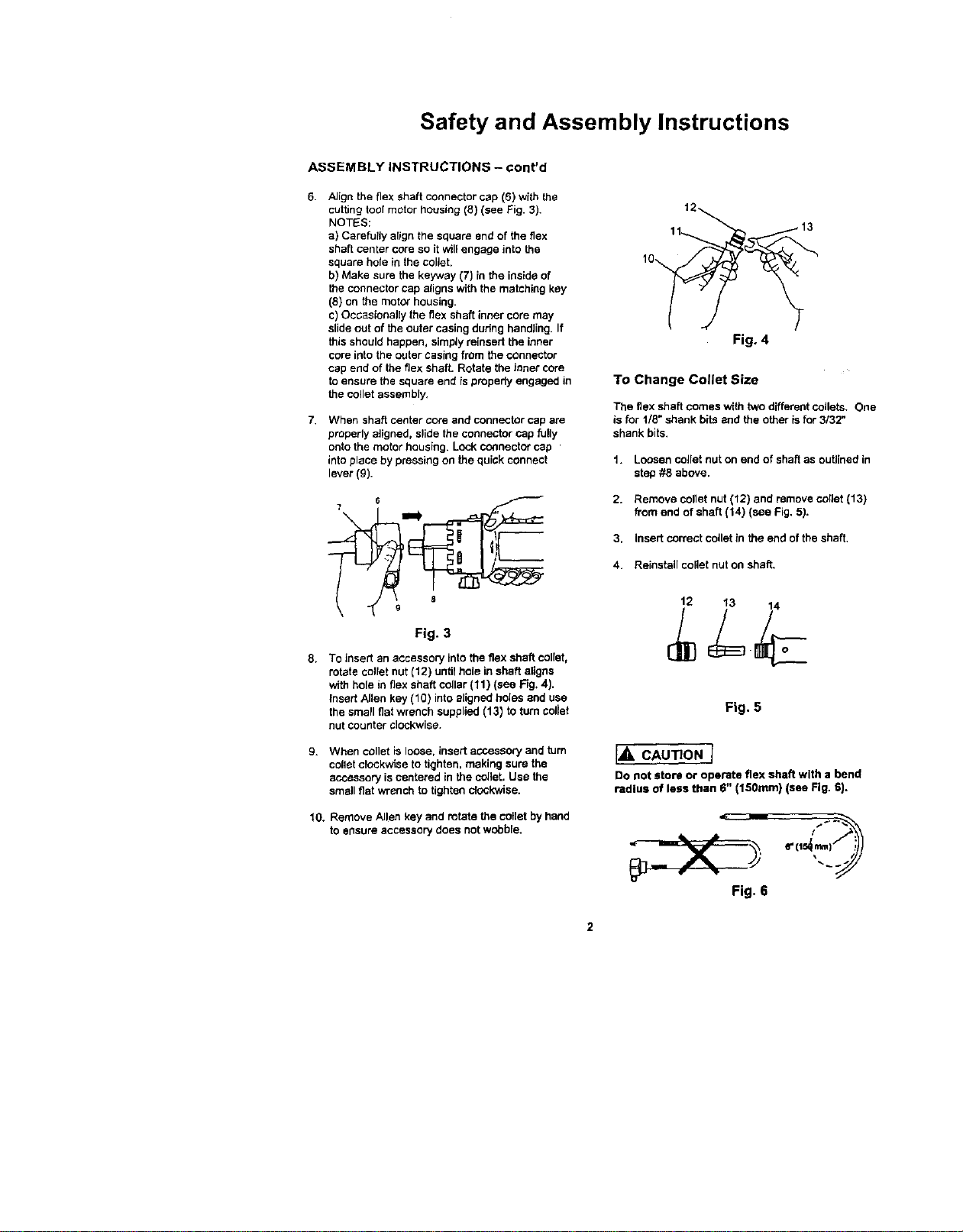

ASSEMBLY INSTRUCTIONS - cont'd

6. Align the flex shaft connector cap (6) wfth the

cutting tool motor housing (8) (see Fig. 3).

NOTES:

a) Carefully align the square endof the flex

shaft center core so it will engage into the

square hole in the collet.

b) Make sure the keyway (7) in the inside of

the connector cap alignswith the matching key

(8) on the motor housing.

c) Oocasionally theflex shaft inner core may

slide out of the outer casing durthg handling. If

this should happen, simply reinsert the inner

coreinto the outer casing from the connector

cap end of the flex shaft. Rotate the ironercore

to ensure the square end is properlyengaged in

the collet assembly.

7. When shaft center coreand connector cap are

properly aligned,slidethe connectorcap fully

ontothe motor housing. Lock connectorcap

intoplace by pressing on the quick connect

lever (g).

9

Fig. 3

8. To insert an accessory intothe flex shaft collet,

rotate collet nut (12) untilhole in shaft aligns

with hole in flexshaft collar (11) (see Fig. 4).

insert Allen key (10) intoaligned holes and use

the small fiat wrench supplied (13) to turn toilet

nutcounter clockwise.

9. When collet is loose, insert accessory and turn

col)atclockwise to tighten, making sure the

accessoryis centered in the collet, Use the

smallfiat wrench to tighten clockwise.

10. Remove Allen key and rotate the ¢otlet by hand

to ensure accessory does notwobble.

t2

11 13

Fig. 4

To Change Cotlet Size

The flex shaft comes with two differentcollets+ One

is for 1/8"shank bits and the otheris for 3/32"

shank bits.

1. Loosen colletnut on end of shaftas outlinedin

step #8 above.

2. Remove collet nut (12) and remove collet(13)

from end of shaft(14) (see Fig. 5).

3. Insert correct collet in the end of the shaft.

4. Reinstall collet nut on shaft.

12 13 14

,o

Fig. 5

Ih,CAU ONI

Do not store or operate flex shaft with a bend

radius of less than 6" (150ram) (see Fig. 6).

Fig. 6

[_ WARNING--]

Before using your cutting tool, it is critical

that you read and understand these safety

rules. Failure to follow these rules could

result in serious injury to you or damage to

the cutting tool

Good safety practices are a combination of common

sense, staying alert and understanding how to use your

power tool. To avoid mistakes that couldcause serious

thjuty, do not pJugin your cuing tooJuntil you have read

and understoo_ the follOWing safety rules:

READ and become familiar with thisentire Owner's

Manual. LEARN the tool's applications, limitationsand

possible hazards.

t-,_ WARNING_

LOOkfor this symbo_that identifies important safety

precautions. Itmeans CAUTIONI BECOME ALERTt,

YOUR SAFETY IS INVOLVEDI

GENERAL SAFETY RULES

KEEP GUARDS IN PLACE and in working order.

ALWAYS WEAR EYE PROTECTION. Any powertool

can throw foreign objects into your eyes

damage. ALWAYS wear safety goggles

which cOUldcause permanent eye

(not glasses) that comply with ANSI

glasses have only impactresistant lenses. *l_heyARE

NOT safety glasses. Safety goggles are available at

Sears.

safety standard Z87.1. Everyday

IA,WARN'NGI

Glasses or goggles not in compliance with ANSI

Z87,1 could cause serious injury when they break.

WORK AREA

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gasses or dust. Power toolscreate sparks

which may lgnttethe dust or fumes.

Keep bystanders, children and visitors away while

operating the tool. Distractions can cause you to lose

control

PERSONAL SAFETY

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use the toot while tired or under the influence of

drugs, alcohol or medication. A moment of inattention

while operatingpower tools mey result in serious

person_ injury.

SAVE THESE INSTRUCTIONS FOR REFERENCE

Dress properly. Do not wear loose clothing or jewelry

Contain long hair. Keep your hair, clothing and

gloves away from moving parts. Loose clothing.

jewelry or long hair can be caught In moving parts.

Avoid accidental starting. Re sure switch is OFF

before plugging in. Carting too_swith yourfinger on

the switch or plugging in tools that have the switch ON

invites accidents.

Remove adjusting keys or wrenches before turning

the tool ON. A wrench or key that is left attached to a

rotating part of the tool may result in personal injury

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables better

control of the toct in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat or

hearing protection must be used for appropriate

conditions.

TOOL USE AND CARE

Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and

may lead toJossof control.

Do not force the tool Uae the correct tool for your

application. The correct tooIwilldo the job better and

safer at the rate for which it is designed.

Do not use the tool it the switch does not turn it ON

or OFF. Any tool that cannot be controlledwith the

switch is dangerous and must be repaired.

Disconnect the plug from the power source before

making any adjustments, changing accessories or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Store idfa toots out of reach of children and other

untrained persons. Tools are dangerous in the hands of

untrained users.

Maintain tools with care, Keep cutting tools sharp

and clean. Preper/y maintained cuttingtools with sharp

cuttingedges are less likely to bind and are easier to

control.

Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may

affect the tool's operation. If damaged, have the tool

serviced before using. Many accidents are caused by

poorly maintained too!s.

Use only accessories that are recommended by the

manufacturer for your model Accessories that maybe

suitable for one toolmay become hazardous when used

on another tool

SERVICE

Tool service must be performed only by qualified

personnel Service or maintenance performed by

unqualified personnel could result in risk of injury.

When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance

instructions may create a dsk of electric shock or injury.

ANGLE GRINDER ATTACHMENT SAFETY

L='wAr.J.GI

Always wear safety goggles with side shields or a

face mask when using the angle grinder attachment.

High speed grinding and sanding will throw hot

sparks and dust particles that could cause serious

injury to your eyes.

Always wear hearing protection when using the angle

grinder attachment.

SPECIFIC SAFETY RULES

Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with a

"live" wire will make exposed metal parts of the tool "live"

and shock the operator.

Always make sure the work surface is free from nails

and other foreign objects, Cutting into a nail can cause

the bit and the tool to jump and damage t_e bit.

Never hold the workpiece in one hand and the tool in

the other hand when in use. Never place the hands

near or below the cutting surface. Clamping the

mateda[ and guiding the tool with both hands is much

safer,

Never lay workpiece on hard surfaces like concrete,

stone, etc. Protruding cutting bit may cause tool tojump.

Always wear safety goggles, hearing protection and

dust mask. Use only in well ventilated area. Using

personal safety devices and working in a safe

environment reduces risk of injury.

After changing the bits or making adjustments, make

sure the collet nut end any other adjustment devices

are securely tightened. Loose adjustment devices will

be violently thrown.

Never use dull or damaged bits. Sharp bits must be

handled with care, Damaged bits can snap during use.

Dull bits require more force to push the tool, possibly

causing the bit to break.

Never touch the bit during or Immediately after use.

After use the bit is too hot to be touched by hare hands.

Always use appropriate dust mask when using the

angle grinder attachment.

Use ONLY grinding wheels and sanding discs rated

for speeds greater than 18,000 RPM, as the angle

grinder attachment runs st speeds from 12,000 -

18,000 RPM.

Inspect the grinding wheel before each use to make

sure it is tightly fastened and free from cracks or any

other damages.

Rotate the guard to a position where it will protect the

operator from sparks and dust. The guard should be

positioned immediately in front of the side handle to

protect the operator's hand.

Do not over tighten the nut holding the grinding

wheel in place. Excessive tightening may cause the

grinding wheel to crack and possibly shatter dudng

operation.

Do not clamp the angle grinder attachment in a vice

or usa as a fixed grinder.

Hold the angle grinder attachment securely with two

hands at ell times while it is running.

Never turn the motor switch ON with the grinding

wheel or sanding disc touching the work surface.

FLEXIBLE SHAFT SAFETY

When using the flexible shaft accessory, always

hang the motor unit on a hook using the hanging loop

at the top of the motor housing.

Always use safety glasses, hearing protection and a

dust mask.

Never hold the workplace with your hand while using

a cutting biL Clamp the wofkpiece in a vice or to a

workbench to permit using two hands on the flex shaft.

Never place hands in the path of the cutter or under

the wod(piece.

Do not store or operate the flex shaft with a bend

radius of less than g" (150 ram).

SAVE THESEINSTRUCTIONS FOR REFERENCE

4

IZolUl;pie;il_ F;ll IIP'_,IIIfe__

This cutting tool is double insulated to protect you from

el_l shock,

WARNIN N

Double Insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug

will fit Into a polarized outlet only one way. If the plug

does not fit fully into the outlet, reverse the plug, If it

still does not fit, contact a qualified electrician to

install a polarized outleL Do not alter the plug In any

way. Double insulation eliminates the need for the three

wire grounded power cord and grounded power supply

system.

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is grounded.

Do not expose power tools to rain or wet conditions,

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carry

the tool or pull the plug from the outlet. Keep cord

away from heat, oil, sharp edges and moving parts.

Replace damaged cords immediately. Damaged cords

increase the dsk of electric shock.

When operating a power tool outdoors, use an

outdoor extension cord marked '_N-A" or "W". These

cords are rated for outdoor use arm reduce the risk of

• e]ecfric shock,

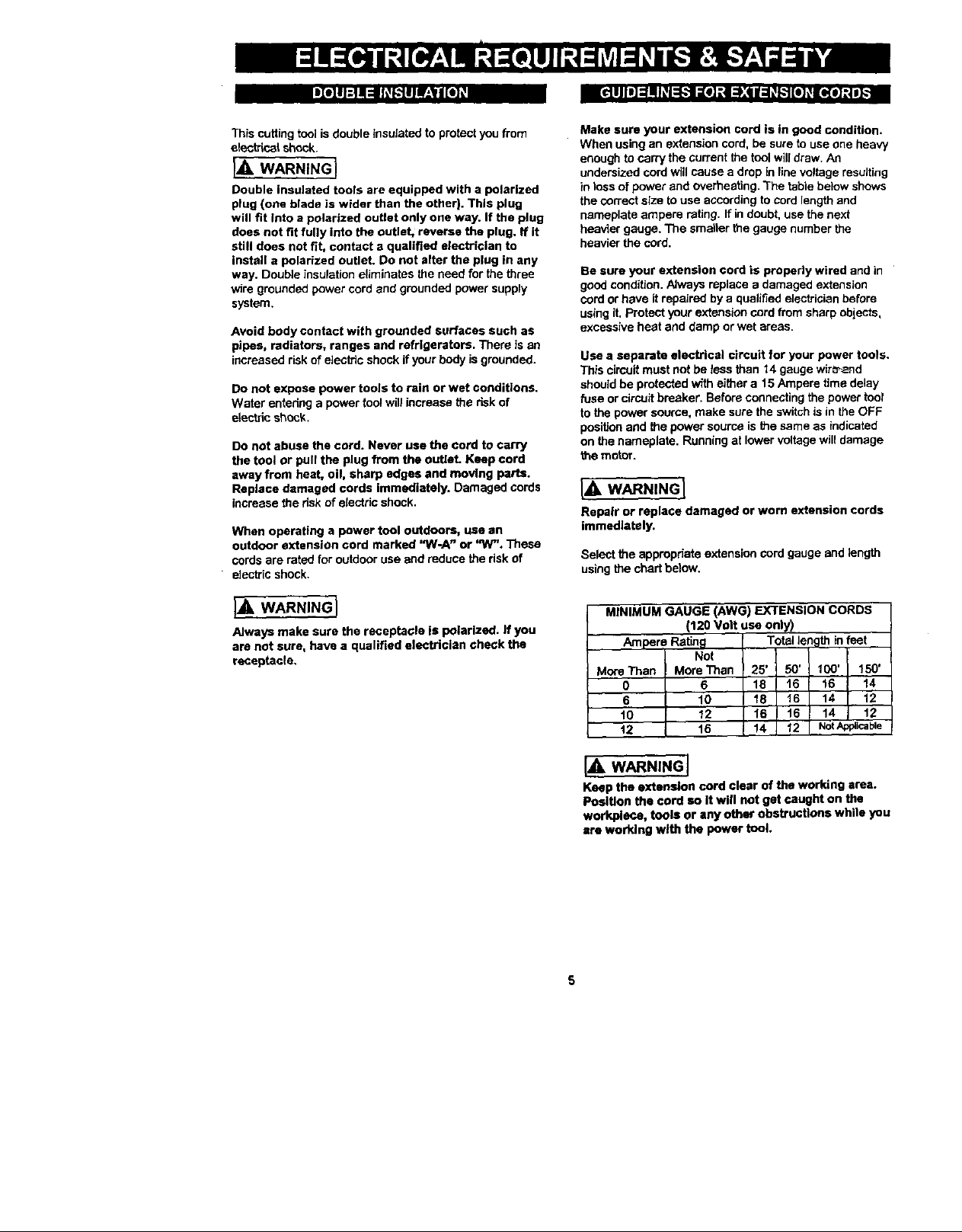

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current the tool will draw. An

undersized cord will cause a drop in line voltage resulting

in loss of power and overheating, The table below shows

the correct size to use according to cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number the

heavier the cord.

Be sure your extension cord is propedy wired and in

good condition. Always replace e damaged extension

cord or have it repaired by a qualified electrician before

using it. Protect your extension cord from sharp objects,

excessive heat and damp or wet areas.

Use a separate electrical circuit for your power tools.

This circuit must not be loss than 14 gauge wir_nd

should be protected with either a 15 Ampere time delay

fuse or circuit breaker. Before connecting the power tool

to the power source, make sure the switch is in the OFF

position and the power source is the same as indicated

on the nameplate. Running at lower voltage will damage

the motor.

IA WARNING I

Repair or replace damaged or worn extensioncords

immediately.

Select the appropriate extension cord gauge and length

using the chart below.

I_ WARNING I

Always make sure the receptacle is polarized. If you

are not sure, have a qualified electrician check the

receptacle.

MINIMUM GAUGE (AWG) EXTENSION CORDS

(120 Volt use only)

Ampere Rating Total length in feet

Not IMore Than More Than 25' 50' 100' 150'

O 6 18 16 I 16 14

6 10 18 16 I 14 12

t0 12 I 16 16 14 12

t2 16 I,_14 12 NotApplicable

[,_. WARNING J

Keep the extension cord clear of the working area,

Position the cord so it will not get caught on the

workplece, tools or any other obstructions while you

ere worklng with the power tool.

IA WARNING I

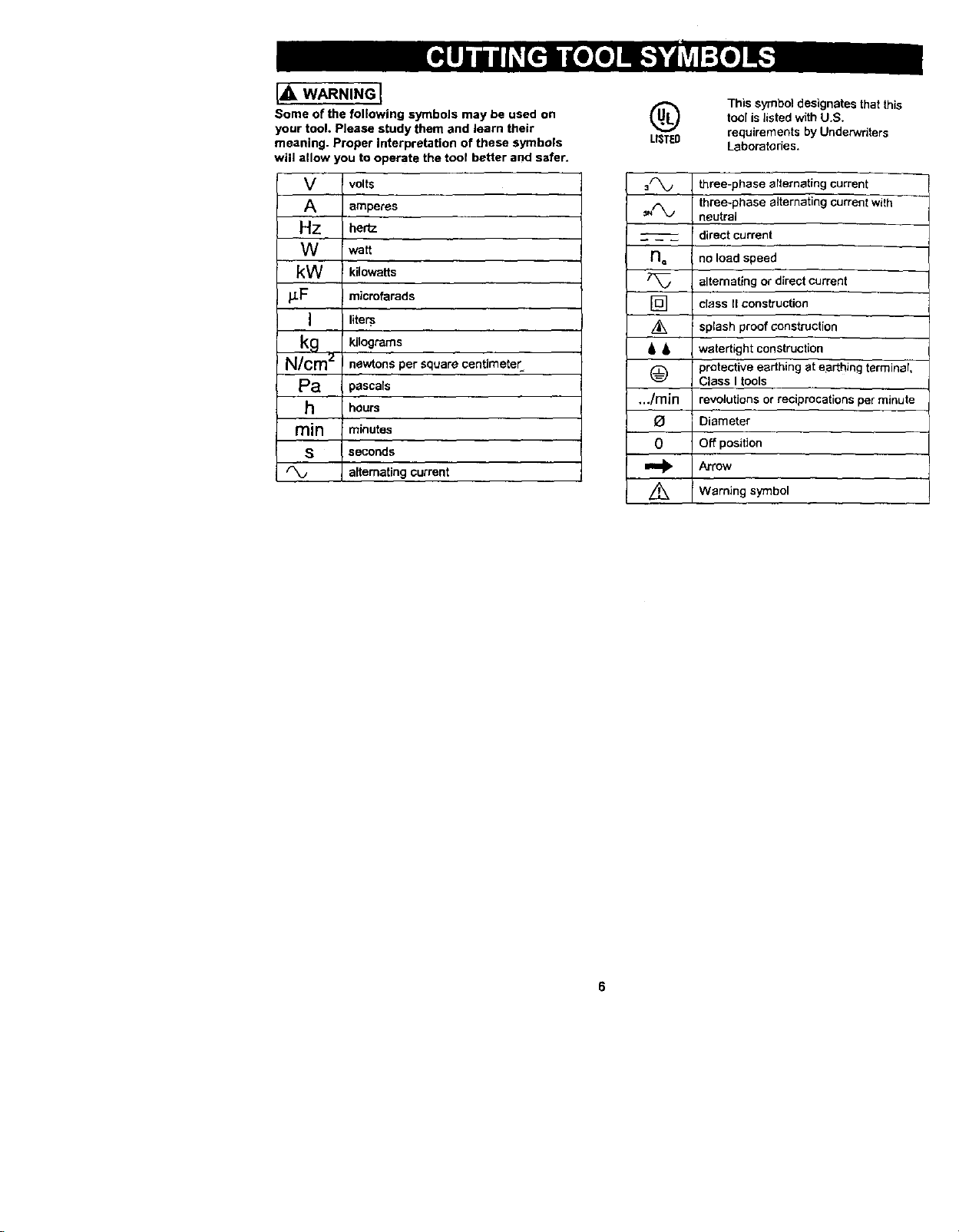

Some of the following symbols may be used on

your tool. Please study them and learn their

meaning. Proper interpretation of these symbols

will allow you to operate the tool better and safer.

V

volts

A

amperes

Hz

W

kW

#F

kg

N/cm z

Pa

min

hertz

watt

kilowatts

micro farads

I

liters

kilograms

newtons per square centimeter

pascals

h

hours

minutes

seconds

S

altemating current

®

LISTED

no

[]

z_

iA

@

,..Imin

o

0

This symbol designates that this

tool is listed with U.S.

requirements by Underwriters

Laboratories.

three-phase alternating current

three-phase alternating current with

neutral

direct current

no load speed

alternating or direct current

class II construction

splash proof construction

watertight construction

protective earthing at earthing terminal,

Class I tools

revolutions or reciprocations per minute

Diameter

Off position

Arrow

Warning symbol

AVAILABLEACCESSORIES

IA WARNING J

Use only accessories recommended for this cutting

tool. Follow instructions that accompany

accessories. Use of improper accessortes may cause

injury to the operator or damage to the Cutting Tool.

Visit your Sears Hardware Department or see the

Sears Power and Hand Tool Catalog for an assortment

of accessories recommended for use with this cutting tool:

_/_"Cutting Bits

_la"& 3132"Hobby Rotary Tool Accessories

_, Cutters

> Polishers

Sanders

> Grinders

Most '/4"Shank Router Bits

3 '/="Grinding Disks

4" Sanding Disks

)f:_;_l(I]_l [e[o]ll i :1_11[,;

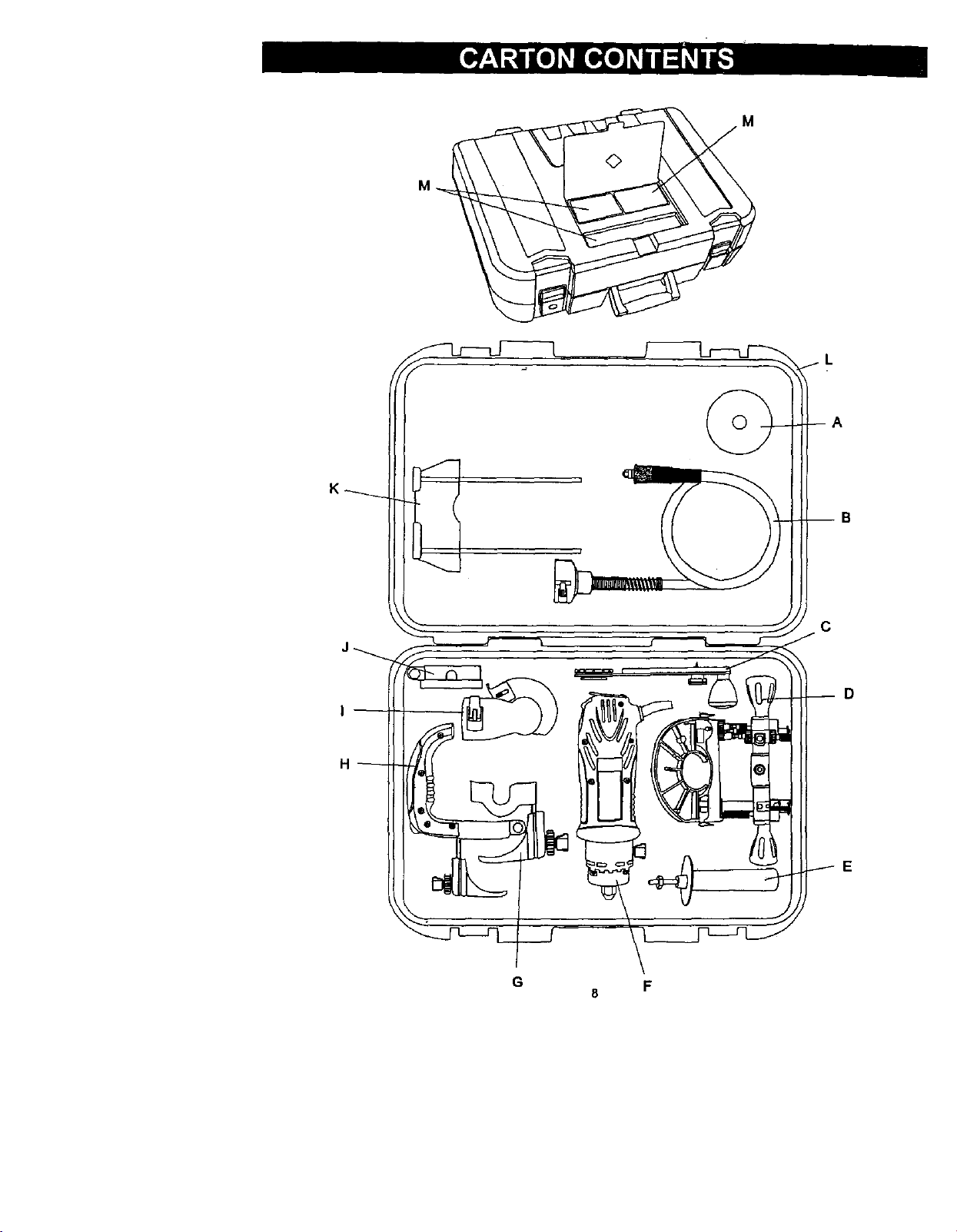

UNPACKING AND CHECKING CARTON CONTENTS

IA WARNINGJ

If any part is missing or damaged, de not plug the

Cutting Tool into the power aource until the missing

or damaged part is replaced and assembly is

complete.

Carafully unpack the Cutting Tool and all its components.

Compare against the =Cutting Tool Components" chart.

NOTE: See Page 8 & 9 for illustration of components.

J_. WARNING I

To avoid fire or toxic reaction, never use gasoline,

naphtha, acetone, lacquer thinner or similar highly

volatile solvents to clean the cutting tool.

LATERAL STYLE DRYWALL CUTTING BIT

This cutting bit has a fine spiral for removing high

volumes of fine particles when cutting (see right).

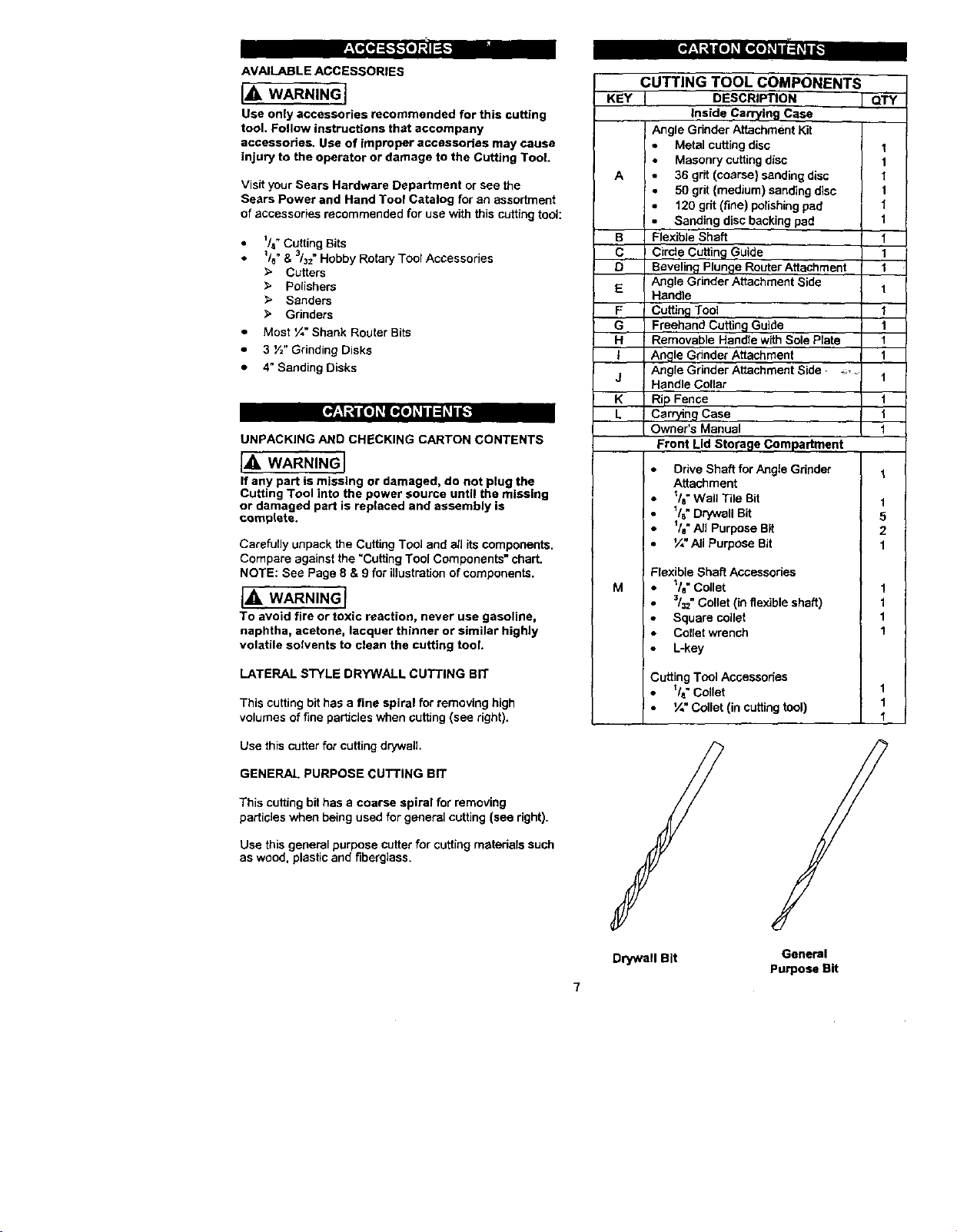

CUTTING TOOL COMPONENTS

KEY J DESCRIPTION I QI;Y

A 36 grit (coarse} sanding disc 1

B Flexible Shaft 1

C Circle Cutting Guide 1

D Beveling Plunge Router Attachment 1

E Angle Grinder Attachment Side 1

F Cuffing Tool

G Freehand Cutting Guide 1

H Removable Handle with Sole Plate t

t Angle Gdnder Attachment 1

j Angle Grinder Attachment Side • "" t

K Rip Fence t

L Carr_ng Case I

M

Inside Carrying Case

Angle Grinder Attachment Kit

Metal cutting disc 1

Masonry cutting disc 1

50 grit (medium) sanding disc 1

120 grit (fine) polishing pad 1

Sanding disc backing pad 1

Hendle

Handle Collar

Owner's Manual t

Front Lid Storage Compartment

Drive Shaft for Angle Grinder 1

Attachment

_/8"Wall Tile Bit 1

1/8"Drywall Bit 5

lie" All Purpose Bit 2

¼" All Purpose Bit 1

Flexible Shaft Accessories

l/e" Collet 1

3/==.Collet (in flexible shaft) 1

Square coilet 1

Coflet wrench 1

• L-key

Cutting Tool Accessories

_/a"Collet 1

¼" Collet (in cutting tool) 1

1

Use this cutter for cutting drywall

GENERAL PURPOSE CUTTING BIT

Thiscutting bithas acoarse spiral for removing

particles when beingusedfor generalcutting(see right).

Use this general purpose cutter for cutting materials such

as wood, plastic and fiberglass,

Drywall Bit General

Purpose Sit

7

M

K_

D

H

G F;

8

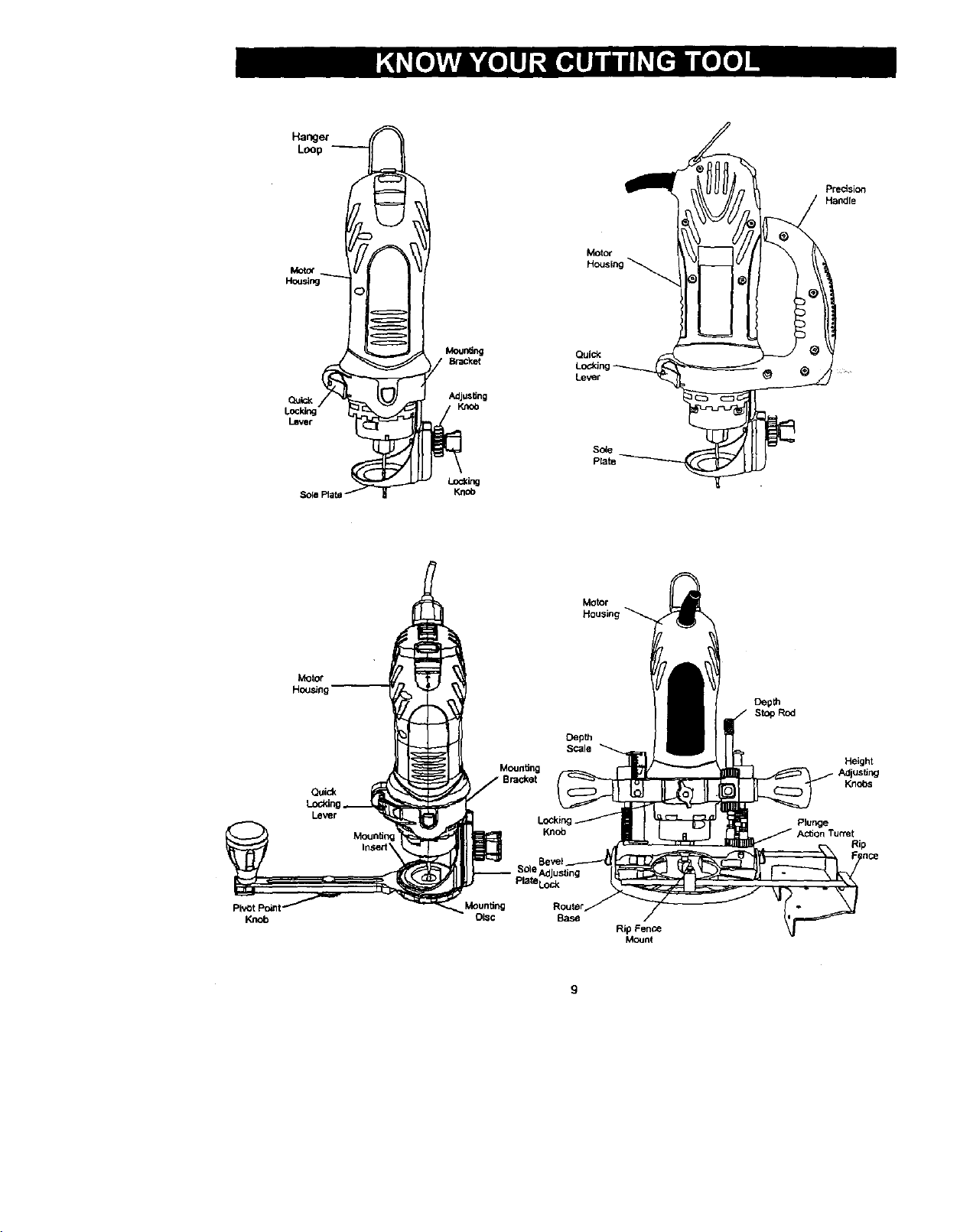

Loop

H_ng C:) <

I_ver

Adjusting

KnOb

Motor

Housir

Quick

Lod_ng

Le_r

,So4e

Prate

precision

Handle

Knob

Motor

Housing

Quick

Lever

Mounting

OLSC

Mounting

Sole Adjusting

Pla_eLoc_

Knob

Base

DepUl

SCale

Motor

Housir

Rip Fence

Mount

Depth

StopRod

PSunge

Action Turret

Height

Knobs

Rip

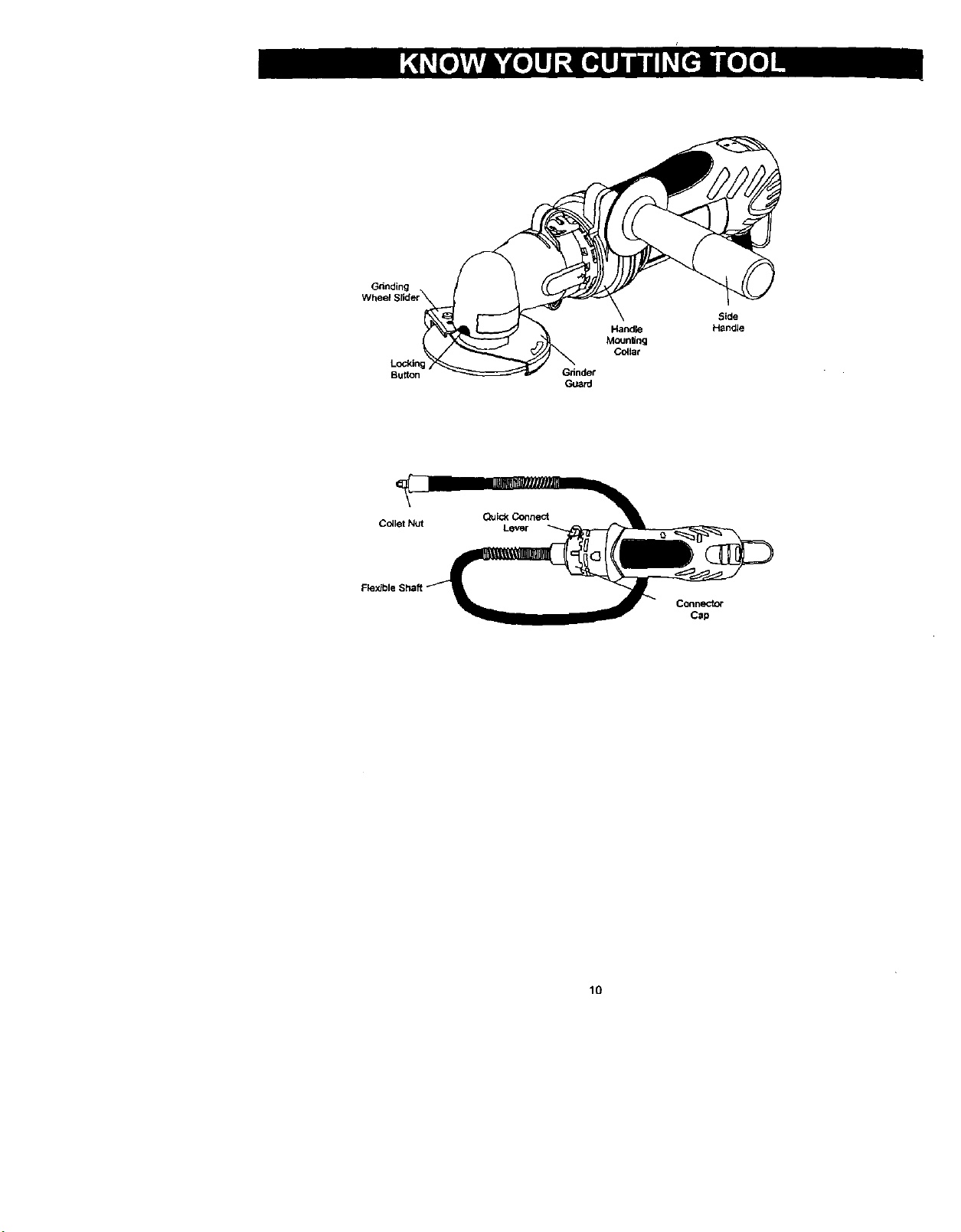

Grinding

Lockln

Button

Handle

Mounting

Colla¢

Cc41etNut Lever

Qulc_Connect

Connector

Cap

lO