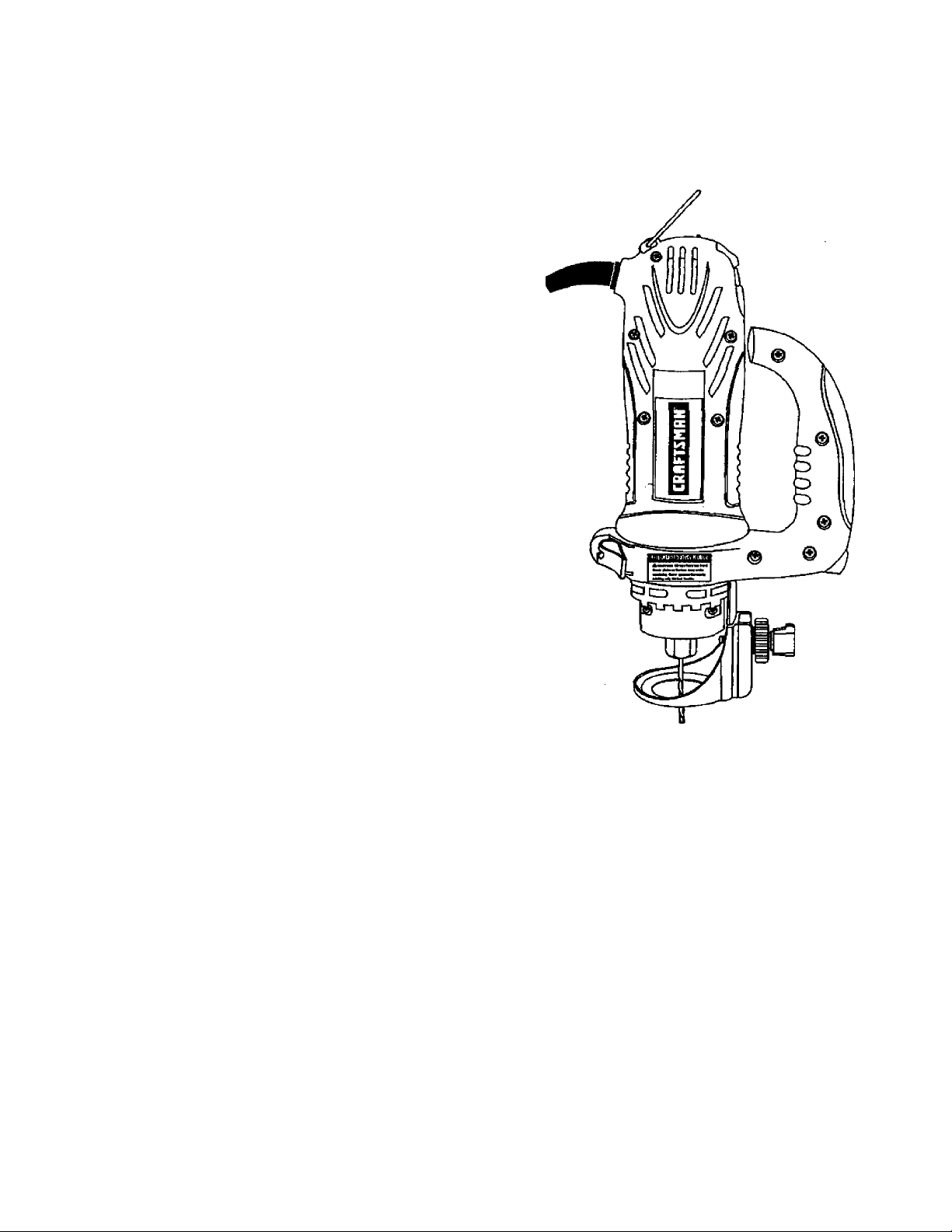

Page 1

Owner’s Manual

CRAFTSMAN

ALL-IN-ONE

CUTTING TOOL

Model No.

183.172530

Important Safety Notice

A WARNING

Always have one hand firmly

placed on the tool body

while operating. Never

operate the tool by holding

only the tool handle.

CAUTION:

Before using this Cutting

Tooi, read this manual and

follow all its Safety Rules

and Operating

instmctions.

• Accessories

• Assembiy

• Operation

• Maintenance

• Parts List

• Espanol

Sears, Roebuck and Co., Hoffman Estates, iL 60179 USA

Part. No. 183172530001 Rev.O 12/25/02

•* Safety Instructions

Page 2

TABLE OF CONTENTS

SECTION

Warranty

Product Specifications

Power Tool Safety

Cutting Totri Safety

Electrical Requirements & Safety

Accessories

.........................................................

...............................

........................................

......................................

..................................................

.............

PAGE SECTION

. 2

.

. 2

. 3

. 4

.

. 5

. 6

Carton Contents

Know Your Cutting Tool

Assembly & Operation

Maintenance............................................

Repair Parts............................................

Parts & Service Availabifity

....................................

......................

........................

................

.

.......

.

.

.......

PAGE

8

18

WARRANTY

FULL ONE YEAR WARRANTY

If this Cutting Tool fails due to a defect in material or workmanship within one year of date of

purchase, Sears will at its option repair or replace it free of charge.

Return this Cutting Tool to a Sears Service Center for repair, or to place of purchase for

replacement.

This warranty gives you specific legal rights, and you may also have other rights which may vary

from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

A WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are;

• Lead from lead-based paints

■ Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from friese exposures varies, depending on how often you do this type of work. To reduce your exposun

to these chemicals, work in a well ventilated area and work with approved safety equipment such as those dust

masks that are specially designed to filter out microscopic particles.

PRODUCT SPECIFICATIONS

Motor Rating

Amperes

2 Speeds (no load)

.................................

........................................

......................

12CA/. 60Hz, AC

5.0 Amperes

20000 & 30000 RPM

Motor Horsepower

Weight

................................

..........

% HP (Maximum Developed)

1-7 kg

A WARNING

To avoid electrical hazards, fire hazards or damage to the cutting tool, use proper circuit protection.

This cutting tool is wired at the frictory for 110-120 Volt operation. It must be connected to a 110-120 Volt /15

Ampere time delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately if it is worn, cut

or damaged in any way.

Before using your cutting tool, it is critical that you read and understand these safety rules. Failure to follow these

rules could result in serious Injury to you or damage to the cutting tool.

Page 3

POWER TOOL SAFETY

▲ WARNING

Before using your cutting tool, it is critical that you read and understand these safety rules. Failure to follow these rules could result in serious injury to you or damage to the cutting tool.

Good safety practices are a combination of common

sense, staying alert and understanding how to use your

power tool. To avoid mistakes that could cause serious

injury, do not plug in your cutting tool until you have read

and understood the following safety rules:

1.

READ and become familiar with this entire Owner’s

Manual. LEARN the tool’s applications, limitations and

possible hazards.

2.

A WARNING

Look for this symbol that identifies important safety

precautions. It means CAUTIONI BECOME ALERTI

YOUR SAFETY IS INVOLVEDI

3. KEEP GUARDS IN PLACE and in working order.

4. OO NOT USE IN A DANGEROUS ENVIRONMENT

such as damp or wet locations or exposure to rain.

Keep woik area well lighted.

5. DO NOT use power tods in the presence of

flammable liquids or gases.

6. KEEP WORK AREA CLEAN. Cluttered areas and

workbenches invite accidents.

7. KEEP CHILDREN AWAY. All visitors should be kept

at a safe distance from the work area.

8. DO NOT FORCE THE TOOL. It will do the job better

and safer at the rate for which it was designed.

9. USE THE RIGHT TOOL. Do not force the tool or

attachment to do a job for which it is not designed.

10. WEAR PROPER APPAREL DO NOT wear loose

Clothing, gloves, neckties, rings, bracelets or other

jewelry that may get caught in moving parts. Non-slip

footwear is recommended. Wear protective hair

covering to contain long hair.

11. WEAR A FACE MASK OR DUST MASK. Sawing,

cutting, drilling and sanding operations produce

hazardous dust.

12. DISCONNECT TOOLS FROM THE POWER

SOURCE before servicing and when changing

accessories such as blades, bits, cutters, etc.

13. REDUCE THE RISK OF UNINTENHONM.

STARTING. Make sure the svritch is in the “OFP

position before plugging into the power source.

14. USE ONLY RECOMMENDED ACCESSORIES.

Consult tite Ovmer's Manual for recommended

accessories. The use of improper accessories may

cause injury to you or damage to tiie tool.

15. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning "ON".

16. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER “OFF", Do not leave the tool

before it comes to a complete slop.

17. NEVER STAND ON TOOL. Serious injury could occur

if the tool is tipped or if the cutting tool is

unintentionally contacted.

18. DO NOT OVER REACH. Keep proper footing and

balance at all times.

19. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and dean for most efficient and safest performance.

Follow instructions for lubricating and changing

accessories.

20. CHECK FOR DAMAGED PARTS. Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to en^re it will operate

' property and perform its intended function. Check for

alignment of moving parts, binding of moving parts,

mounting and any other conditions that may affect its

safe operation, A guard or other part that is damaged

should be properly repaired or replaced.

21. MAKE WORKSHOP CHILD PROOF wth padlocks,

master switches or by removing starter ke]^.

22. DO NOT operate the tool If you are under the

influence of any drugs, alcohot or medication that

could impair your abili^ to use the tool safely.

23. USE OUST COLLECTION SYSTEM wherever

possible. Dust generated from certain materials can

be hazardous to your health artd In some cases, a fire

hazard. Always operate the power tod in a well

ventilated area with adequate dust removal.

ALWAYS WEAR EYE PROTECTION. Any power tool

24,

ANSI safety standard Z87.1. Everyday glasses have

only impact resistant lenses. They ARE NOT safety

glasses. Safety goggles are available at Sears.

can throw foreign objects into

your eyes which could cause

permanent eye damage.

alw ays wear safety goggles

(not glasses) that comply with

A WARNING

Glasses or goggles not In compliance with ANSI

Z87.1 could cause serious Injury when they break.

SAVE THESE INSTRUCTIONS FOR REFERENCE

Page 4

CUTTING TOOL SAFETY

A WARNING

For your safety, do not plug in your cutting tool or try

to use any accessory until It is completely assembled

and installed according to these instructions, and

until you have read and understood this Owner’s

Manual.

11. NEVER HOLD THE WORKPIECE (N ONE HAND

while operating the tool with the other hand.

12. NEVER PLACE HANDS IN THE PATH OF THE

CUTTER AND UNDER THE WORKPIECE.

Failure to follow these safety rules will result in risk of

serious Injury. ’

1. WEAR EYE PROTECTION. This high speed tool will

throw particles from the workpiece during operation.

Make sure safety glasses have side shields.

2. USE FACE OR DUST MASK along with safety

goggles if cutting or routing (deration is dusty. Make

sure work area is well ventilated.

3. USE HEARING PROTECTION, particularly during

extended periods of operation.

4. NEVER USE DULL OR DAMAGED BITS. Damaged

bits can break without warning. Dull bits may overload

the motor, cut slowly and are difficult to control. They

will also overheat and possibly break.

5. ALWAYS MAKE SURE THE WORKPIECE IS FREE

OF NAILS AND OTHER FOREIGN OBJECTS. If the

bit strikes a nail It will jump sideways and possibly

break.

6. DO NOT USE THIS TOOL FOR DRILUNG HOLES.

It is NOT intended to be used as a drill.

7. ALLOW CLE/UIANCE UNDER WORKPIECE for bit

to travel. Never place workpiece on hard surfaces

such as concrete etc. The bit may jump or break when

contacting a surface other than the one being cut.

8. ALWAYS SET THE DEPTH GUIDE TO THE

APPROPRIATE DEPTH. Use tool vrith the depth

guide flat against the work surface for better control of

the tool.

9. NEVER use THE TOOL WITHOUT THE SOLE

PLATE, PRECISION HANDLE OR ROUTER BASE

attached and appropriately adjusted.

10. ALWAYS CLAMP WORKPIECE TO HOLD IT

STEADY WHEN CUTTING. This will free both hands

for operating the tool.

13. NEVER START THE TOOL WHEN THE BIT IS

TOUCHING THE WORKPIECE. The bit may catch

the workpiece causing loss of control.

14. ALWAYS HOLD THE TOOL WITH TWO HANDS

DURING START-UP AND OPERATION. When

starting, motor torque will cause the tool to twist,

15. TURN OFF ALL CIRCUIT BREAKERS AND

REMOVE ALL FUSES in the work area when cutting

into walls or blind areas.

16. ALWAYS HOLD THE TOOL BY THE INSULATED

GRIPPING SURFACES ON THE BODY OF THE

TOOL where there is any possibility of the cutting bit

contacting hidden electrical wires or the cord of the

tool. Contact with "live” virires will make exposed metal

parts of the tool "live” causing an electrical shock to

the operator.

17. WHEN CUTTING DRYWALL ELECTRICAL OUTLET

OPENINGS using the outlet as a guide, always cut in

a counter clockwise direclloo. The natural tendency of

the tool to pull to the left will cause a "hugging” action

toward the outlet box, resulting in a neater cut.

18. NEVER LAY THE TOOL DOWN UNTIL THE

CUTTING BIT COMES TO A COMPLETE STOP. A

spinning bit can come in contact with the surface and

pull it out of your control,

19. NEVER TOUCH THE CUTTING BIT IMMEDIATELY

AFTER USE. The bit will be too hot to be handled with

bare hands and wii bum your fingers.

20. ALWAYS RE-TIGHTEN COLLET AND ALL

adjustments before starting the tool after a cutting

bit or accessory has been changed. Loose bits and

adjustments can cause unexpected shifting of the tool

resulting in loss of control and injury from the bit or

cutting tool being thrown.

SAVE THESE INSTRUCTIONS FOR REFERENCE

Page 5

ELECTRICAL REQUIREMENTS & SAFETY

DOUBLE INSULATION

This cutting tool is double insulated to protect you from

electrical shock.

A WARNING

Double insulated tools are equipped with a polarized

plug (one blade is wider than the Other). This plug will

ht into a polarized outlet only one way. If the plug

does not fit fully into the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to

install a polarized outlet Do not alter the plug in any

way. Double insulation eliminates the need for the three

wire grounded power cord and grounded power supply

system.

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shodc if your body is grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to cany

the tool or pull the plug from the outlet Keep cord

away from heat oil. sharp edges and moving parts.

Replace damaged cords immediately. Damaged cords

Increase the risk of electric shock.

When operating a power tool outdoors, use an

outdoor extension cord marked "WA" or “W”. These

cords are rated for outdoor use and reduce the risk of

electric shock.

A WARNING

Always make sure the receptacle is polarized. If you

are not sure, have a qualified electrician check the

receptacle.

GUIDELINES FOR EXTENSION CORDS

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the cument the tool will draw. An

undersized cord will cause a drop in line voltage resulting

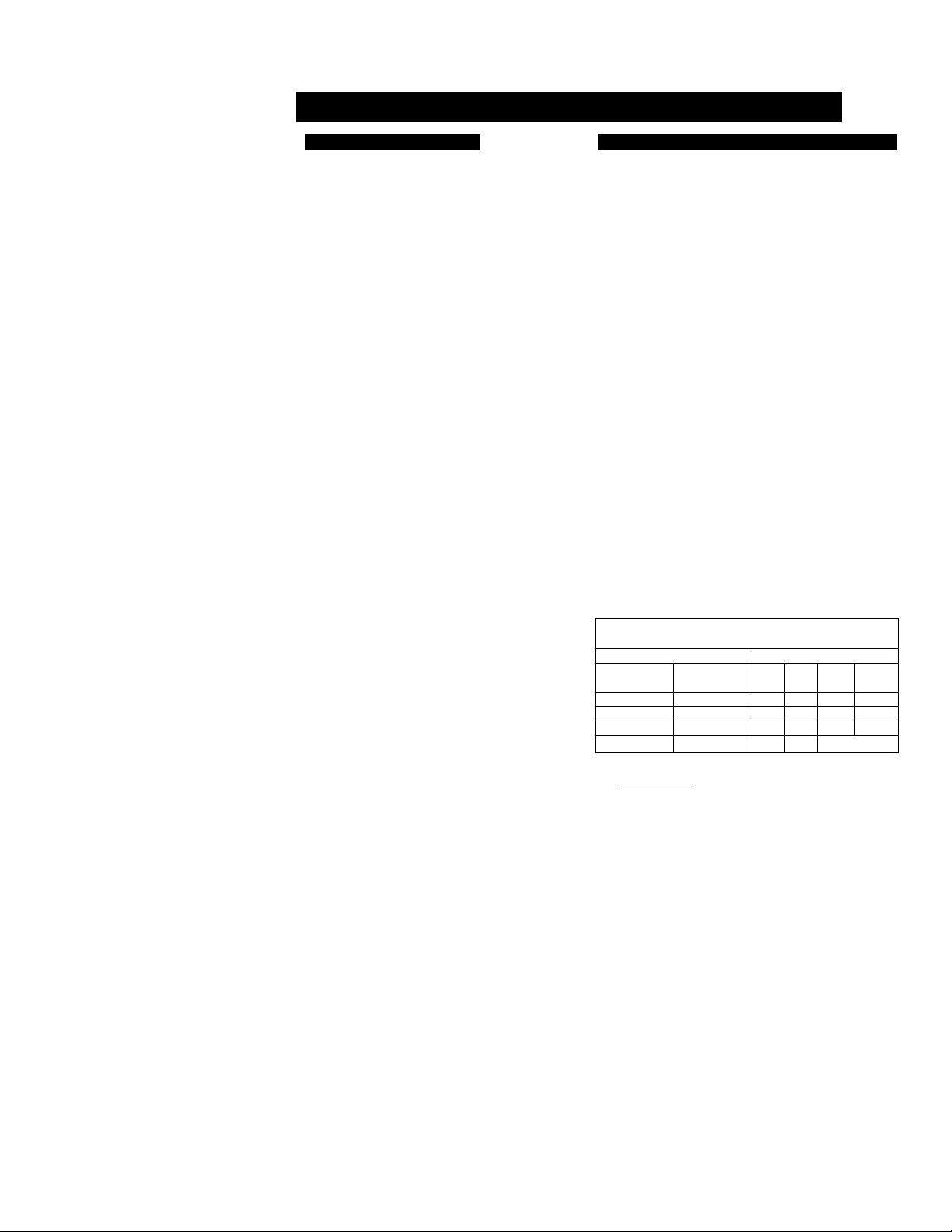

in loss of power and overheating. The table below shows

the correct size to use according to cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number the

heavier the cord.

Be sure ^ur extension cord is ¡properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified electrician before

using if. Protect your extension cord from sharp objects,

excessive heat and damp or wet areas.

Use a separate electrical circuit for your power tools.

This circuit must not be less than 14 gauge wre and

should be protected with either a 15 Ampere time delay

fuse or circuit breaker. Before connecting the power tool

to the power source, make sure the switch is in the OFF

position and the power source is the same as indicated

on the nameplate. Running at lower voltage will damage

the motor.

A WARNtNG

Repair or replace damaged or worn extension cords

immediately.

Select the appropriate extension cord gauge and length

using the chart below.

MINIMUM GAUGE (AWG) EXTENSION CORDS

Ampere Rating

More Than

0

6

10

12

(120 Volt use only)

Not

More Than

6

10 18 16

12 16 16

16

Total length in feet

25' 50’ 100'

16 16 14

18

14 12

14

14

NotAppHcable

150'

12

12

A WARNING

Keep №e extension cmd clear of the working area.

Position the cord so it will not get caught on the

workpiece, to^s or any other obstructions while you

are working with the power tool.

Page 6

ACCESSORIES CARTON CONTENTS

AVAILABLE ACCESSORIES

A WARNING

Use only accessories recommended for this cutting

tool. Follow instructions that accompany accessories.

Use of improper accessories may cause injury to the

operator or damage to the cutting tool.

Visit your Sears Hardware Department or see the Sears

Power andftand Tool Catalog for an assortment of

accessories recommended for use with this cutting tool:

Flex Drive

Rip Guide

Router

Circle Cutter

Cutting Bits

Hobby Rotary Tool Accessories

Cutters

Polishers

Sanders

Grinders

A WARNING

Use only accessories designed for this cutting tool to

avoid severe injury or tool damage.

Do not use any accessory unless you have

completely read the instructions or Owner's Manual

for that accessory.

UNPACKING AND CHECKING CARTON CONTENTS

A WARNING

If any part is missing or damaged, do not plug the

cutting tool into the power source until the missing

or damaged part is replaced and assembly is

complete.

Carefully unpack the cutting tool and all its components.

Compare against the “Cutting Tool Components" chart

below.

NOTE: See Page 7 for illustration of components.

A WARNING

To avoid fire or toxic reaction, never use gasoline,

naphtha, acetone, lacquer thinner or similar highly

volatile solvents to clean the cutting tool.

CUTTING TOOL COMPONENTS

"KEYHI DESCRIPTION | QTY

Cutting Tool 1

A

Collet Wrench 1

B

Collet Wrench Holder 1

C

Owner's Manual

D

Precision Handle with Soie Plate I 1

E

Freehand Sole Plate Attachment 1

F

1/8" Collet Sleeve 1

G

1/4" Collet Sleeve 1

H

Lateral Style Drvwall Cutter 1

1

Wood / Plastic / Fiberglass Cutter | 1

J

Cutting Tool Box

Accessory Box

1

NOTE: The two most commonly used cutters are

included with this tool (items I & J). It is Important

that you use the correct cutter to ensure the most

efficient cutting action.

• Use cutter T’ with the finer spiral for cutting

drywatl.

• Use the general purpose cutter “J” with the

coarser spiral for cutting materials such as wood,

plastic and fiberglass.

Page 7

CARTON CONTENTS

Cutting Toot Box

Accessory Box

Page 8

KNOW YOUR CUTTING TOOL

Page 9

ASSEMBLY & OPERATION

A WARNING

Remove the plug from the power source before

assembly, changing accessories or cutters and

making adjustments. This safety action will help

prevent accidental starting of the tool which could

result in serious injury.

ON / OFF & SPEED CONTROL SWITCHES

This cutting tool is equipped with a sliding ON / OFF

switch (1) located on the side of the tool and a speed

control switch (2) located on top of the tool (see Fig. 1 ),

Fig, 1

1. To turn the tool ON, slide the switch (1) up.

INSTALLING CUTTING BITS - Cont’d

4. Insert new cutting bit (4) into the collet.

A WARNING

Insert the bit all the way into the collet and then

pull it back between and 'it". This creates an

air space between the motor shaft and the bit to

help prevent overheating the bit.

Before tightening the collet on the bit, make sure

the flutes (spiral portion) of the bit are completely

wsible outside the collet. Clamping the collet on

the bit flutes will result in broken bits and possible

injury.

When bit is properly placed in the collet depress the

5.

shaft locking button and turn the collet nut clockwise

by hand as far as possible.

6. Securely tighten collet nut using the wrench.

2. To turn the tool OFF, slide the switch down,

3. To set speed to high speed, slide speed control switch

(2) away from the ON / OFF switch. ■

4. To set the speed control switch to low speed, slide the

speed control switch (2) toward the ON / OFF switch.

INSTALLING CUTTING BITS

A WARNING

Cutting bit and router bit cutting surfaces are

extremely sharp. Handle with caution.

To insert a cutting bit, use the collet wrench which is in the

wrench holder attached to the power cord,

1. Depress the shaft locking button (1) and rotate the

collet lock nut (2) clockwise with the other hand until

the locking button drops into place, preventing the

shaft from turning (see Rg, 2).

2. While continuing to hold the shaft locking button IN,

use the collet wrench (3) to turn the collet nut counter

clockwise. Loosen the collet nut two or three turns.

3. Remove bit if one is already Installed in the tool.

Fig. 2

WORK LIGHTS

The motor unit has two built-in work lights (5) (see Fig, 2).

These work lights automatically light up when the motor

switch is turned ON. Patterns or drawings in the

immediate vicinity of the bit will be illuminated for better

visibility and improved cutting accuracy.

SELECT APPROPRIATE MOTOR SPEED

Selecting the appropriate motor speed will ensure

smoother, more efficient cutting action. Choose LOW

speed for grinding, cutting plastics, polishing and when

using wire or bristle bnjshes. Choose HIGH speed when

cutting wood, using cut-off wheels and to reduce “chatter"

that may develop when cutting some materials at LOW

speed.

Page 10

ASSEMBLY & OPERATION

CHANGING COLLET INSERT

The cutting bits for this tool are locked into place with a

collet nut (1) and collet (see Fig. 3). The tool is assembled

at the factory with NO collet installed. Both the Ve" and VS"

collets can be found in the carrying case front lid storage

compartment. The 1/8" collet (2) is used for holding hobby

tool accessory bits. The Vi’ collet (3) is supplied for

holding SMALL router bits with a V*” shank.

To change from one collet size to the other

1. Remove bit from ttie tool.

2. Continue turning the collet nut counter clockwse until

it can be removed (torn the motor shaft (4).

3. Pull the collet out of the motor shaft and replace it with

the other one.

NOTE; Each collet is the same on both ends, so either

end can be inserted into the motor shaft.

4. Re-install the collet nut and slightly tighten it by hand.

5. Install the new bit as outlined in INSTALLING

CUTTING BITS on Page 9. .

NOTE: Tightening the collet nut without a bit In the collet

will cause the collet hole to become smaller and make

installing bits difficult. When storing the tool with no bit

installed, leave collet nut loose.

FREEHAND SOLE PLATE

INSTALUNG FREEHAND SOLE PLATE

The freehand sole plate is designed for basic freehand

cutting with the cutting bit. It is idesdiy suited for cutting

electrical outlet holes In drywall.

▲ WARNING

Do NOT use the freehand sole plate with router bits.

Limited control with this accessory could causa you

to loose control and Increase the chance of serious

Ipjury.

INSTALLING FREEHAND SOLE PLATE - cont’d

1.

Slide freehand sole plate mounting bracket (1) onto

the bottom of motor housing (2) until the slot in the

bracket (3) lines up with the shaft locking button (4) in

the motor housing.

NOTE: The mounting bracket must be pushed onto

the motor housing as far as it will go.

2.

Lock the sole plate to the motor housing by snapping

the quick locking lever (5) firmly against the motor

housing.

Fig. 4

ADJUSTING FREEHAND SOLE PLATE

1. Adjust freehand sole plate depth by loosening the

depth gauge locking knob (6) and rotating the

adjusting knob (7) to move the sole plate in or out as

required (see Rg. 5).

NOTE; Set the depth gauge so the cutting bit

protrudes beyond the sole plate V«’ more than the

thickness of the material being cut. For example, if

you are cutting %' drywall, the bit should protmde V*"

beyond the sole plate.

2. Securely tighten depth gauge knob.

3. Before starting to cut you should re-check bit depth.

Make sure sole plate is at right angles to the bit and

securely tighten^. Re-check the collet to make sure

the bit is securely fastened.

10

Page 11

ASSEMBLY & OPERATION

A WARNING

Have you read "POWER TOOL SAFETY”,

“CUTTING TOOL SAFETY" and “ELECTRICAL

SAFETY" on pages 3,4 and 5 of this Manual? If

not, please do it now t>efore you operate this

cutting tool. Your safety depends on ftl

Every time you use the cutting tool you should

verify the following:

1. Cutting tool cord is not damaged.

2. Bit is correct type for the material being cut

3. Bit is sharp. In good condition, properly

installed and securely tightened.

4. Safety glasses and dust mask are being worn.

Failure to adhere to these safety rules can greatly

increase your chances of injury.

PRACTICE CUTS USING FREEHAND SOLE PLATE

Before attempting to work on an actual project, take the

time to make a few practice cuts with your cutting tool.

Use some scraps of material that are the same material as

used in your actual project.

1. Draw a pattern similar to your first project on a scrap

piece of material.

PRACTICE CUTS USING FREEHAND SOLE PLATE

6. Set the speed control switch to the appropriate speed.

7. Turn the switch ON.

8.

When the motor is up to full speed, slowly tip the tool

to an upright position, letting the bit cut into the

workpiece (see Fig, 7). Once the tool has reached the

upright position and the bit has cut through the

workpiece, slowly move the tool in a clockwise

direction using slow steady pressure to make the cut.

NOTE: Except for cutting around outlet boxes in

drywall, always cut In a clockwise direction.

When cut is complete, turn the tool OFF, wait until it

9.

ccOTies to a complete stop and remove it from the

workpiece.

2. Install freehand sole plate as shown in Fig. 4.

3. Install cutting bit in ttie collet as shown in Fig. 2.

4. Adjust depth of freehand sole plate as shown In Rg. 5.

5. Rest the edge of the sole plate on the workpiece with

the bit at an angie of about 45° (see Rg. 6].

NOTE: DO NOT let the bit contact the workpiece untii

svwtch is turned ON and the tool is up to full speed.

A^arning

Before turning the tool switch ON, make sure you

hold the tool firmly wHh both hands. Starting

torc|ue will cause the tool to twist

A DANGER

Do not attempt cutting around outlet boxes in drywall

until:

1. Ail electricity in the vicinity of electric wires has

been disconnected by either turning tile breaker

OFF or removing the fuses.

2. You have read the instructions on the following

page entitled “CUTTING OUTLET OPENINGS IN

DRYWALL”.

CUTTING TIPS

The rotating cutting action of the bit will cause a slight pull

to the left when cutting. Natural variations in the structure

of wood will cause the bit to "wander". This tendency will

be magnified when applying too much pressure to the bit.

Sower cutting gives you better control. Excessive

pressure or fast cutting will increase bit temperature and

shorten the life of the bit

When cutting a hole in a vertical surface, avoid ending the

cut at the bottom of the hole. Always start and end the cut

at the *top’ so the cut-out part wiH not drop onto the

rotating bit Always turn tiie tool OFF before removing it

from the workpiece.

11

Page 12

ASSEMBLY & OPERATION

CUTTING OUTLET OPENINGS IN DRYWAU.

A DANGER

Do not attempt to use this tool to make cut-outs

around any fixture or opening which has live eiectrical

wires or on any wall which may have electrical wiring

behind it if a iive wire is contacted, the bit couid

conduct the eiectric current to the tool, creating an

electrocution hazard for the operator. Turn OFF

breakers or remove fuses to disconnect the electric

circuit in the area of work. Always hold the tool by its

insulated housing when working in areas where there

is a possibiiity of contacting electric wires. Always

wear eye protection when operating this tool.

1. Before installing drywall, push the electrical wires to

the back of the box as far as possible so they will not

be cut by the bit when cutting the opening.

2. Before fastening the drywall sheet over №e electrical

box, mark the sheet as close as possible to the center

of the box opening. Mark should be on the side of the

drywall facing you.

3. When fastening the drywali in place, do not place nails

or screws closer than 12” from the box. This will

prevent the drywall from becoming deformed under

pressure.

4. Insert cutting bit and install freehand sole plate as

outlined on Pages 9 & 10 of this Owner's Manual.

Adjust depth of cut so the bit wiil protrude Vj" beyond

the thickness of the drywall.

CUTTING OUTLET OPENINGS IN DRYWALL - cont’d

6. Move the bit slowly lo the right until you feel and hea

the bit contacting the inside of the box.

7. Pull the bit out far enough to slip it over the edge of

the box. Once the bit is outside the box. push it back

to full depth beside the outside edge of the box.

8. Move the tool upward while applying slight pressure

toward the center of the box. When you feel the bit

reach the top right hand comer of the box, move the

tool to the left while applying slight pressure

downward toward the center of the box,

9. Continue moving the tool around the box in a counter

clockwise direction while maintaining slight pressure

toward the center of the box. When the box cut-out is

complete. Turn the tool OFF and remove it from the

cut-out

10. Completed electrical box cut-out will be accurately ant

neatly cut (see Fig. 9).

5. Hold the tool firmly with both hands and turn it ON.

Plunge the bit through the drywall at the mark

indicating the center of the box. See Fig. 8 for cutting

pattern.

Fig. 8

NOTE; Always move the cutting bit in a counter

clockwise direction around №e outlet box. The natural

tendency of the cutting bit to move to the left will make it

easier to cut close lo the box.

12

Page 13

ASSEMBLY & OPERATION

PRECISION HANDLE

INSTALLING PRECISION HANDLE

The precision handle is designed for use when precision

control over the toot movement is desired. The

comfortable handle can be used wth either the right or left

hand.

1, Slide precision handle mounting bracket (1) onto the

bottom of motor housing (2) until the slot under the

handle (3) lines up with the shaft locking button (4) in

the motor housing (see Rg. 10).

NOTES:

a) The mounting bracket must be pushed onto the

motor housing as far as it will go.

b) The shaft locking button (5) can now be activated

by your thumb while holding on to the precision

handle

2, Lock the precision handle to the motor housing by

snapping the quick locking lever (6) firmly against the

motor housing.

Fig. 10

ADJUSTING FREEHAND SOLE PLATE

M'AINTENA'NCE

A DANGER

For your own safety, turn the switch OFF and remove

the plug from the power source before maintaining

your cutting tool.

When servicing, use only identical Craftsman parts.

Use of any other part may create a hazard or cause

product damage,

EXTERNAL CLEANING

A WARNING

DO NOT use solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged by

their use. Use clean cloth to remove dirt, dust, oil,

grease, etc.

Do not at anytime allow brake fluids, gasoline,

petroleum-based products, penetrating oils, etc. to

come in contact with plastic parts. They contain

chemicals that can damage, weaken or destroy plastic

INTERNAL CLEANING

It has been found that electric tools are subjected to

accelerated wear and possible premature failure when

they are used on fiberglass boats and sports cars,

wallboard, speckling compounds or plaster. The chips and

grindings from these materials are highly abrasive to

electric tool parts such as bearings, brushes, commutatons,

etc. During any use on these materials it is extremely

important that the tool is cleaned frequently by blowing out

with a compressed air jet.

1. Adjust precision handle sole plate depth by loosening

the depth gauge locking knob (7) and rotating the

adjusting knob (8) to move the sole plate (9) in or out

as required (see Rg. 11).

NOTE: Set Ihe d^th gauge so the cutting bit

protrudes beyond the sole plate Vt" more than the

thickness of the material being cuL For example, if

you are cutting ^U“ pine, the bit should protrude '/#"

beyond the sole plate.

2. Securely tighten depth gauge knob.

3. Before starting to cut you should re-check bit depth,

make sure sole plate Is at right angles to the bit and

securely tightened. Re-check the collet to make sure

the bit is securely fastened.

Fig. 11

A DANGER

It is critical that you wear safety goggles or safety

glasses with side shields and a dust mask while

blowing dust out of the cutting tool with a

compressed air jet. Failure to take these safety

precautions could result in permanent eye or lung

damage.

POWER CORD MAINTENANCE

A WARNING

To avoid shock or fire hazard, replace the cord

immediately If it is worn or damaged in anyway.

LUBRICATION

Ail of the bearings in this cutting tool are lubricated with a

sufficient amount of high grade lubricant for the life of the

unit under normal conditions. Therefore, no further

lubrication is required.

13

Page 14

PARTS DIAGRAM - MODEL 183.172530

Main Unit

14

Page 15

PARTS LIST - MODEL 183.172530

(A WARNING

When servicing use only CRAFTSMAN replacement parts. Use of any other parts may create a HAZARD or cause

damage to your Cutting Tool.

Any attempt to repair or replace electrical parts on this Cutting Tool may create a hazard unless repair is

performed by a qualified technician. Repair seit^ce is available by contacting your nearest Sears Service Center.

Always order by PART NUMBER, not by key number.

Main Unit

Key#

Part#

1

01AR-000032-00 Bearing Sleeve

2

01AR-000035-00

3 01AT-000014-AO Bushing tube

5 01AT-000031-00 Bushing tube

10 02AE-000060-00 Front bearing 1 53 03AY-000020-00

11 02AE-000061-00

_12

02AK-000022-00

13

02AH-000088-00 Brush spring 2 59

14 02AH-000089-00

15 02AH-000112-00 Hanger

17

02AS-000199-AO

18 02AS-000201-AO

22 02AW-000055-00

23

03AA-000279-00 Transformer

24

03AC-000011-FO Capacity

25 03AC-000043-00 Capacity 1

28 03AD-000009-AO Diode 4 73 2213-MA0011-00

29

03AD-000040-00 Diac

30

03AD-000074-00 LED

31 03AD-0000754)0 Triac 1

34 03AM-000104-00 Stator 1 79 2203-PAOd08-00

35 03AM-000105-00 Rotor 1 81 2213-PAOCQ2-00

36

03AP-000073-00 PCB

37 03AP-000076-00 PCB 1 83

38

03AR-000013-AO

39

03AR-000015-DO

40 03AR-000109-AO Resistor 3

41

03AS-000135-00 Micro switch 1 91

42 03AS-000140-00 Switch 1

Part Name Qty

Switch presser

Rear bearing

Rivet

Spindle spring 1

Case screw

Screw

Retaining ring

Resistor 1 84

Resistor 1 85

Key# Part#

44 03AT-000033-00

1

1 48 03AT-000040-00

49

2

50 03AW-000131-00 Power cord

2

1 55 03AY-000073-00

56

4

62

1 62 2203-MA0004-00 1/8" collet 1

8 63 2203-MA0007-00 Lock plate 1

3 67 2207-MA0003-00 Spindle lock 1

1 70 2213-MA0002-00

1 71 2213-MA0005-00 Chuck cap

1 72

1 74 2213-MA0012-00 Brush case 2

2 76 2213-MAO014-00

77 2213-MA0015-00 Stop plate 1

1 82 2213-PA0023-00 Top cabinet 1

87 2213-PA0028-00

92 9920-PA0011-00 Cord Sleeve 1

03AT-000046-00

03AY-000074-00 Wire 2

04AP-000068-00 Fibra

2203-MA0003-00 1/4" collet 1

2213-MA0006-00 Spanner 1

*

2213-SAM001-00 Brush assembly 2

2213-PA0024-00

2213-PA0025-00 Lock button 1

2213-PA0026-00

9866-PA0004-00 Press ptate 1

Part Name

Terminal blocR

Terminal (femaie)

Carbon brush

Wire

Wire 2

Conductor

Metal conductor

Wire cover

Spanner belt

Bottom cabinet

Switch cover .

Cover

2P-Switch 1

Qty

1

2

2

1

1

1

2

1

2

1

1

1

1

1

15

Page 16

PARTS - MODEL 183.172530

Freehand Soleplate Assembly

211.

201

K«y«

201

202

203

208 2213-MA0010-00 Freecut metal round guide

211

212

213

214

215

216

Part*

O2AF-OOO041-IO

02AF-0000764)0

02AS-000287-00 Screw

2213-PA0010-00 Lock

2213-PA0011-00

2213-PA0012-00 Plastic guide base

2213-PA0013-00

2213-PA0014-00 Sleeve

2213-PA001&00

Fixing shaft

Release lock gin

Fixbase

Adjustment Gear 15T

Screw lock F

Part Name

16

Qty

1

1

1

1

1

1

1

1

1

1

Page 17

PARTS - MODEL 183.172530

Handle Assembly

Key#

301 02AF-O00041-I0 Fixing shaft

302 02AF-000076-00

304 02AH-000106^

305 02AS-000148-00

306

307 02AS-OOCQ87-00 Screw

308 O2AS-O0Q288-0O Screw

310 02AW-000067-00

312 2213-MA00134»

321 2213-PAOOIOeO

323 2213-PA0012-00

324

325

326 2213-PA001SO0

327 2213-PA00164»

328 2213-PA0017-00

329 2213-PA0016-00

330 2213-PA00l9e0

331 2213-PAOQ20-00

332 22134>A0021-00

Part#

Release lock oln 1

Compressive spring

Screw

02AS-000199^

2213-PA0013-00

2213-PA0014-00 Sleeve

Screw

Washer

S-round guide hoider

Lock 1

Plastic guide base

AdKistment Gear 1ST

Screw lock F

Anx right handle

Anx left hanrfle

Anx handle softgrip (outsklel

Anx handle softgrip Ònslde)

Slmolelock

Shaft F5-5

17

Part Name Qty

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

Page 18

.^urs!

If

M-S:

w,

MS

fe

p

il

For repair of major brand appliances in your own home

no matter who made it, no matter who sold it!

1-800-4-MY-HOME®

(1 •800-469^63)

www.sears.com

Anytime, day or night

(U.S A and Canada)

www.sears.ca

For repair of cany-in products like vacuums, lawn equipment,

and electronics, call for the location of your nearest

Sears Parts and Repair Ceriter.

1-800-488-1222 Anytime, day or night (U,S a only)

www.seafs.com

For the replacement parts, accessories and owner’s manuals

that you need to do-it-yourself, call Sears PartsDirect^^I

1 -800-366-PART 6 a.m, -11 p.m. CST, 7 days a week

(1-800-366-7278) (U.SAonly)

www.sears.com/partsdirect

To purchase or inquire about a Sears Serxice Agreement

or Sears Maintenance Agreement

1 -800-827-6655 (U.S A) 1 -800-361 ^665 (Canada)

7 ajn. - 5 p.m. CST, Mon. - Sat 9 am, - 8 p.ra EST. M - F. 4 p.m. Sat

Para pecfr servido de reparación a

domidiio, y paa oidenar plazas:

1-8ie-SU-HOGAR®“

<1-888-784-6427) ^

« RaoWerad Tmdmi« / ^ TiBdMWk / Secvk» Uailt Saaii. Rofbucfc fend Ca

• Malts Ragistnda / ^ Marea da Fábrici/*** hlarca da Safvido da Saart, RotbucA and Ca

^Mwxjuadacoftnmarea/^^MarquadapQtéadaSaaii, RoabuefcandCo-

18

Au Canada pour service en fiangais:

1-800-LE-FOYER**

(1-800-533-8937)

www,sear8.ca

C Saan, Roebuck and C<L

Loading...

Loading...