Owner's Manual

rRRFTSMAN®

ALL-IN-ONE

CUTTING TOOL

Model No.

183,172520

Important Safety Notice

[& WARNING I

Always have one hand firmly

placed on the tool body while

operating, Never operate the

tool by holding only the tool

handle.

CAUTION:

Before using this Cutting

Tool, read this manual and

follow all its Safety Rules

and Operating

Instructions.

®

• Safety Instructions

• Accessories

• Assembly

• Operation

• _aintenance

• Parts List

• Espanol

Seam, Roebuck and Co., Hoffman Estates, IL 60179 USA

Part. No. 183172520001 Rev. 1 04/29102

SECTION PAGE

Warranty ..... 2

ProductSpec_lcations 2

PowerTool Safety . .. 3

CuttmgToolSafety ...... 4

ElectricalRequirements& Safety 5

Accessooes 6

SECTION PAGE

Carton Contents 6, 7

Know Your Cutting Tool ..... 8

Assembly & Operation 9 - 18

Mamtenance .... 18

Repatr Parts .. 19 - 25

Parts &Servtce Avaiiabtl_ .... 26

FULL ONE YEAR WARRANTY

If this Cutting Tool fails due to a defect in material or workmanship within one year of date of

purchase, Sears will at its option repair or replace tt free of charge.

Return this Cutting Tool to a Sears Service Center for repair, or to place of purchase for

replacement.

This warranty gives you specific legal rights,and you may also have other rightswhich may vary

from state to state.

Seam, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

IA WARNINGI

Some dust created by power sanding, sawing, grinding, drilling andother construction activities contains

chemicals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals ere:

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures vadsa, depending on how often you do this type of work. To reduceyour exposur_

to these chemicals, work ina well ventilated area and work with approved safety equipment such as these dust

masks that are specially designed to filter out microscopic particles.

Motor Rating...................... 120V, 60Hz, AC

Amperes................ 5 0 Amperes

2 Speeds (noload)..... 20000 & 30000 RPM

Motor Horsepower ..... 3/4HP (Maximum Developed)

Weight ................. 1.7 kg

IA WARNINGI

To avoid electrical hazards, fire hazards or damage to the cutting tool, usa proper circuit protection.

This cutting tool Is wired st the factory for 1t0-t20 Volt operation. It must be connected to a t10-120 Volt115

Ampere Ume delay fuse of ourcult breaker. To avoid shock or fire, replace power cord Immedistaly ff It Is worn, cu

or damaged In any way.

Before using your cuffing tool, it Is critical that you reed and understand these safety rules. Failure to follow these

rules could result in serious Injury to you or damage to the cutting tool.

2

IA WARNING I

Before using your cutting tool, it is critical that you read and understand these safety rules.

Failure to follow these rules could result in serious injury to you or damage to the cutting tool.

15

Good safety practices are a combination of common

sense, staying alert and understanding how to use your

power tool To avoid mistakes that could cause senous

inJury,do not plug in your cutting tool until you have read

and understood the following safety rules:

1 READ and become famikar with this entire Owner's

Manual LEARN the tool's applications, hmttahons and

possible hazards.

2 I& WARNINGI

Lookforthtssymbolthat identtfies importantsafety

precautionsIt means CAUTIONI BECOME ALERT!

YOUR SAFETY IS INVOLVED!

REMOVE ADJUSTING KEYS AND WRENCHES

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning "ON"

16

NEVER LEAVE TOOL RUNNING UNAI"rENDED.

TURN THE POWER "OFF" Do not leave the tool

before it comes to a complete stop

17.

NEVER STAND ON TOOL Serious injury could occur

if the tool is tipped or if the cutting tool ts

unintenhonally contacted

18

DO NOT OVER REACH Keep properfoohngand

balanceat all times

3

KEEP GUARDS IN PLACE and in workingorder

4.

DO NOT USE IN A DANGEROUS ENVIRONMENT

such as damp or wet locations or exposure to ram

Keep work area well lighted

5

DO NOT usa power tools m the presence of

flammable hquJdsor gases.

6

KEEP WORK AREA CLEAN Clutteredareas and

workbenchesmwteacozdents

7.

KEEP CHILDREN AWAY All visitorsshouldbe kept

at a safe d_stancefromthe workarea

8.

DO NOT FORCE THE TOOL Itwill do thejob better

and saferat the ratefor whichitwas desHgned

9

USE THE RIGHT TOOL. Do not forcethe toolor

attachmentto do a job for whichit is notdesigned

10. WEAR PROPER APPAREL. DO NOT wear loose

clothing,gloves,neckttes,nngs,braceletsor other

jewelrythat maygetcaughtin movingparts Non-skp

footwearis recommendedWear protectivehatr

coveringtocontainlonghair.

11. WEAR A FACE MASK OR DUST MASK. Sawing,

cutting,dnllingand sandingoperationsproduce

hazardousdust

12. DISCONNECT TOOLS FROM THE POWER

SOURCE before servicing and when changing

accessones such as blades, bits, cutters, etc

13 REDUCE THE RISK OF UNINTENTIONAL

STARTING Make sure the switch is _nthe "OFF"

position before plugging into the power source

14 USE ONLY RECOMMENDED ACCESSORIES

ConsulttheOwner's Manualfor recommended

accesaones The use of=mproperaccessonesmay

causeinJuryto youor damage to the tool.

19

MAINTAIN TOOLS WITH CARE Keep tools sharp

and clean for most effioient and safest performance

Follow mstruchons for lubricating and changing

accessories

20.

CHECK FOR DAMAGED PARTS Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to ensure it wdl operate

properly and perform its intended function Check for

alignment of mowng paris, binding of moving parts,

mounting and any other condihons that may affect its

safe operation. A guard or other part that Is damaged

should be properly repaired or replaced

21 MAKE WORKSHOP CHILD PROOF wdhpadlocks,

masterswitchesor by remowngstarterkeys

22. DO NOT operate the tool if you are under the

influence of any drugs, alcohol or medicehon that

could impair your ability to usa the tool safely

23 USE DUST COLLECTION SYSTEM wherever

posstble Dustgeneratedfrom certain materialscan

be hazardousto yourhealthand in somecases,a fire

hazard Alwaysoperate the powertool=na well

ventilatedareawith adequate dustremoval.

24. ALWAYS WEAR EYE PROTECTION Any power tool

your eyes which could cause

permanent eye damage.

can throw foreign objects into

ALWAYS wear safety goggles

(not glasses) that comply with

ANSI safety standard Z87 1 Everyday glasses have

only =mpact res=stant lenses They ARE NOT safety

glasses Safety goggles are available at Sears.

iA WARNINGI

Glasses or goggles not in compliance with ANSI

Z87.1 could cause serious injury when they break.

SAVE THESE INSTRUCTIONS FOR REFERENCE

3

For your safety, do not plug in your cutting tool or try

to use any accessory until It Is completely assembled

and installed according to these instructions, and

until you have read and understood this Owner's

Manual.

11. NEVER HOLD THE WORKPIECE IN ONE HAND

whale operating the tool wnth the other hand

12 NEVER PLACE HANDS iN THE PATH OF THE

CUTTER AND UNDER THE WORKPIECE.

Failure to follow these safety rules will result in risk of

serious injury.

1 WEAR EYE PROTECTION This hnghspeed tool wnll

throw particles from the workpnece during operatnon

Make sure safety glasses have sfde shields

2 USE FACE OR DUST MASK along wtth safety

goggles If cutting or reutmg operatnon nsdusty Make

sure work area _swell venhlatad

3 USE HEARING PROTECTION, particularly dunng

extended periods of operahon

4

NEVER USE DULL OR DAMAGED BITS Damaged

bits can break without warning Dull bits may ovedoad

the motor, cut slowly and are difficult to control They

will also overheat and possrbly break

5 ALWAYS MAKE SURE THE WORKPIECE IS FREE

OF NAILS AND OTHER FOREIGN OBJECTS Ifthe

butstrikesa nailit wnlljumpsudewaysand possibly

break

6 DO NOT USE THIS TOOL FOR DRILLING HOLES

It usNOT intended to be used as a droll

7 ALLOW CLEARANCE UNDER WORKPIECE for bit

to travel Never placeworkpnecaon hardsurfaces

suchas concreteetc The bitmay jump or breakwhen

contactinga surfaceotherthan the one beingcut

ALWAYS SET THE DEPTH GUIDE TO THE

APPROPRIATE DEPTH Use tool wnththe depth

guide fiat agaunst the work surface for better control of

the tool

9 NEVER USE THE TOOL WITHOUT THE SOLE

PLATE, PRECISION HANDLE OR ROUTER BASE

attachedand apprepnatelyadjusted

10 ALWAYS CLAMP WORKPIECE TO HOLD IT

STEADY WHEN CUTTING Thts wnllfree both hands

for oberatnngthe tool

13 NEVER START THE TOOL WHEN THE BIT IS

TOUCHING THE WORKPIECE. The butmay catch

the workpaece causing loss of control.

14 ALWAYS HOLD THE TOOL WITH TWO HANDS

DURING START-UP AND OPERATION When

starting, motor torque w=llcause the tool to twist

15 TURN OFF ALL CIRCUIT BREAKERS AND

REMOVE ALL FUSES =nthe work area when cutting

untowalls or blind areas

16 ALWAYS HOLD THE TOOL BY THE INSULATED

GRIPPING SURFACES ON THE BODY OF THE

TOOL where there usany possnbnhtyof the cutting but

contacting hidden electrncalworesor the cord of the

tool Contact wth "live"wureswill make exposed meta

parts of the tool "lave"causing an electrical shock to

the operator.

17 WHEN CUTTING DRYWALL ELECTRICAL OUTLET

OPENINGS usnngthe outlet as a guile, always cut =n

a counter clockwise darectlon.The natural tendency o_

the tool to pull to the left wdl cause a "huggnng"acbon

toward the outlet box, resulting =na nearer cut.

18 NEVER LAY THE TOOL DOWN UNTIL THE

CUTrING BIT COMES TO A COMPLETE STOP A

spnnnmgbit can come m contactwiththe surfaceand

pullItout of yourcontrol

19 NEVER TOUCH THE CUTTING BIT IMMEDIATELY

AFTER USE. The bit will be too hot to be handled wltt

bare hands and wnllburn your fingers

2O ALWAYS RE-TIGHTEN COLLET AND ALL

ADJUSTMENTS before starting the tool after a cuttan_

bd or accessory has been changed Loose batsand

adjustments can cause unexpected shdtmg of the tool

resuitung m loss of control and unlury from the butor

cutting tool being thrown

SAVE THESE INSTRUCTIONS FOR REFERENCE

4

BZo)gl:! N:il_ k.'l_gliF_,1II[o]_

I[Clli I"] :1III _,I:kl ;[o] :l _;,q 1:1_i,.-![el_I[o[e] _,|-,_

This cutting tool is double insulated to protect you from

electrical shock

IA WARNINGI

Double insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug will

fit into a polarized outlet only one way. if the plug

does not fit fully into the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to

install a polarized outlet. Do not alter the plug in any

way. Double insulation ehmmates the need for the three

wire grounded power cord and grounded power supply

system

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is grounded

Do not expose power tools to rain or wet conditions.

Water entenng a power tool will increase the nsk of

electric shock

Do not abuse the cord. Never use the cord to carry the

tool or pull the plug from the outleL Keep cord away

from heat, oil, sharp edges and moving parts.

Replace damaged cords immediately. Damaged cords

increase the risk of electnc shock

When operating a power tool outdoors, use an

outdoor extension cord marked "W-A" or "W". These

cords are rated for outdoor use and reduce the risk of

electric shock

IA WARNING I

Always make sure the receptacle is polarized. If you

are not sure, have a qualified electrician check the

receptacle.

Make sure your extension cord is in good condition.

When using an extenslon cord, be sure to use one heavy

enough to can_ the current the tool will draw An

undersized cord will cause a drop m llne voltage resulbng

=nloss of power and overheahng The table below shows

the correct s_.e to usa eccordmg to cord length and

nameplate ampere rating If m doubt, use the next heawer

gauge The smaller the gauge number the heavier the

cord

Be sure your extension cord is properly wired and m

good conditton Always replace a damaged extension cord

or have it repatred by a quahfied electnclan before using it

Protect your extanston cord from sharp objects, excesstve

heat and damp or wet areas

Use a separate electrical circuit for your power tools.

Th=sctrcult must not be less than 14 gauge wlra and

should be protected wtth either a 15 Ampere hme delay

fuse or clroutt breaker Before connecting the power tool to

the power source, make sure the switch ts m the OFF

pos_honand the power source _sthe same as mdtcated on

the nameplate Running at lower voltage wdl damage the

motor

IA WARNING I

Repair or replace damaged or worn extension cords

immediately.

Select the appropriate extension cord gauge and length

using the chart below

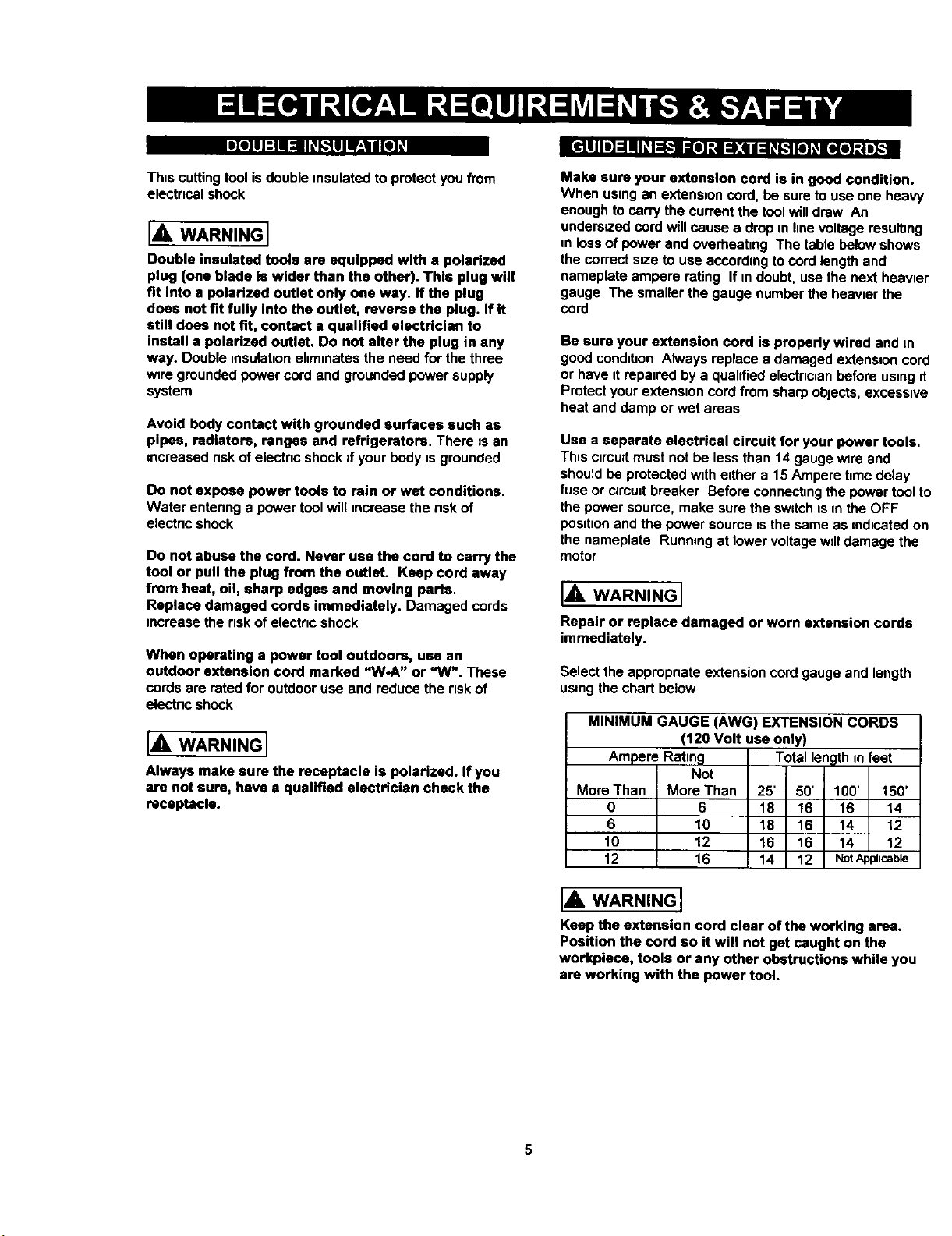

MINIMUM GAUGE (AWG) EXTENSION CORDS

(120 Volt use only)

Ampere Rating

Not

More Than More Than

0 6

6 10

10 12

12 16

Totallength m feet

25' 50' 100' 150'

18 16 16 14

18 16 14 12

16 16 14 12

14 12 NotApphcable

IAWARNINGI

Keep the extension cord clear of the working area,

Position the cord so it will not get caught on the

workpiece, tools or any other obstructions while you

are working with the power tool.

5

:le[o,]:l,,"[,,,_o];,11:1_

AVAILABLE ACCESSORIES

I,A, WARNINGI

Use only accessories recommended for this cutting

tool. Follow instructions that accompany accessories.

Use of improper accessories may cause injury to the

operator or damage to the cutting tool.

Visit your Sears Hardware Department or see the Sears

Power and Hand Tool Catalog for an assortment of

accessornes recommended for use wuththis cuttnngtool

• Flex Dnve

• Rip Gunde

• I/e" Cutting Bnts

• I/s" Hobby Rotary Tool Accessones

Cutters

_" Polishers

Sanders

_' Gnndem

• Most ¼" Shank Router Bds

Use only accessories designed for this cutting tool to

avoid severe injury or tool damage.

Do not use any accessory unless you have completely

read the instructions or Owner's Manual for that

accessory.

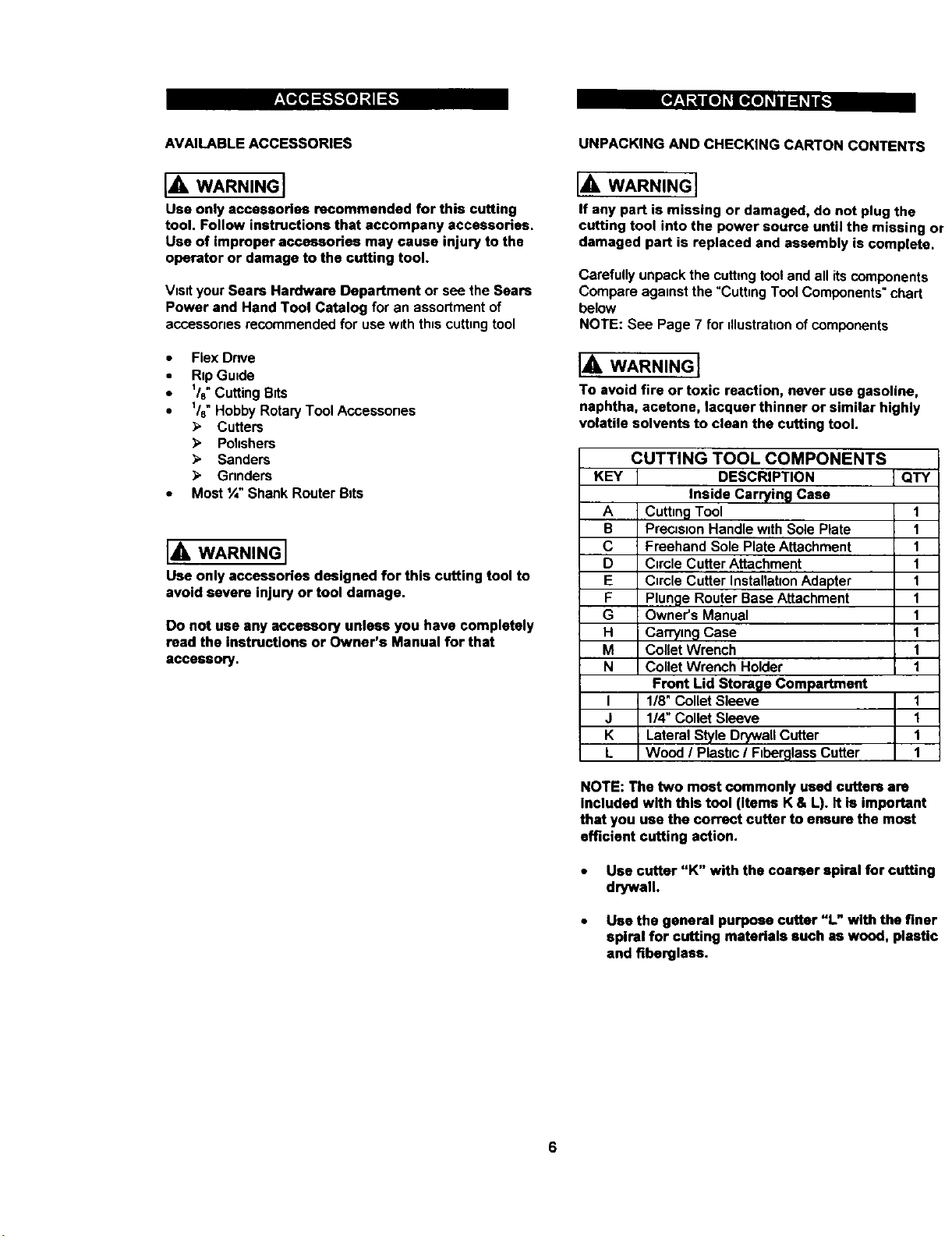

UNPACKING AND CHECKING CARTON CONTENTS

IA WARNING I

If any part is missing or damaged, do not plug the

cutting tool into the power source until the missing or

damaged part is replaced and assembly is complete.

Carefully unpack the cuttmg too! and all its components

Compare against the "Cutting Tool Components" chart

below

NOTE: See Page 7 for illustration of components

I_, WARNING I

To avoid fire or toxic reaction, never use gasoline,

naphtha, acetone, lacquer thinner or similar highly

volatile solvents to clean the cutting tool.

CUTTING TOOL COMPONENTS

KEY I DESCRIPTION ] QTY

Inside Carrying Case

A Cutting Tool

B PrecJsuonHandle with Sole Plate

C Freehand Sole Plate Attachment

D Circle Cutter Attachment

E CnrcleCutter Installahon Adapter

F Plunge Router Base Attachment

G Owner's Manual

H i Carrying Case

M Collet Wrench

N Collet Wrench Holder

Front Lid Storage Compartment

I 1/8" Collet Sleeve

J 114" Collet Sleeve

K Lateral Style Drywall Cutter

L Wood / Plastic / Fiberglass Cutter

1

1

1

1

1

1

1

1

1

1

1

1

1

1

NOTE: The two most commonly used cutters are

Included with this tool (items K & L). It is important

that you use the correct cutter to ensure the most

efficient cutting action.

• Use cutter "K" with the coarser spiral for cuffing

drywall.

• Use the general purpose cutter "L" with the finer

spiral for cutting materials such as wood, plastic

and fiberglass.

f_

/

f

[]

E

H

c

7

D

F

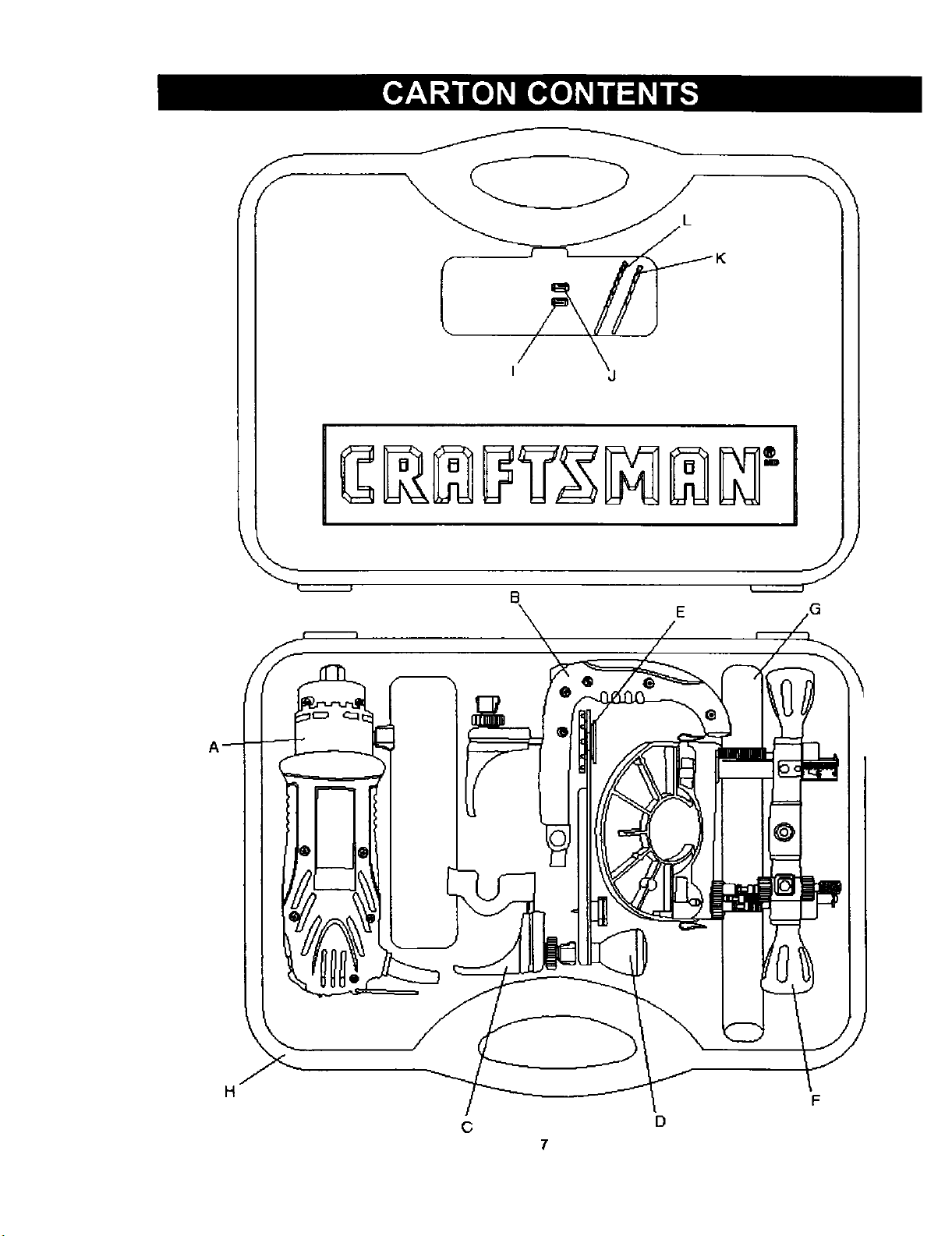

Motor

Housing

Motor

HOUSIng

Qu_k

Locking

Level

Motor

Housqng

Mounting

/ Bracket

Adlushng

Knob

Locking

Knob

Pma_on

Handle

C1r_

Cuthn(

Qu_k

Lever

Mounhng

Insed

Motor

Hous,ng--_-" \

Depth

Scale" ..

Depth

Rod

Mounta_

Bracket

D_sc

He,hi

Knobs

Qumk

Lockm

Lever

Plate

Lockm

Knob

Router

Base

plunge

Ac_on

Turret

Bevel

Adlushng

Lock

IA WARNINGI

Remove the plug from the power source before

assembly, changing accessories or cutters and

making adjustments. This safety action will help

prevent accidental starting of the tool which could

result in serious injury.

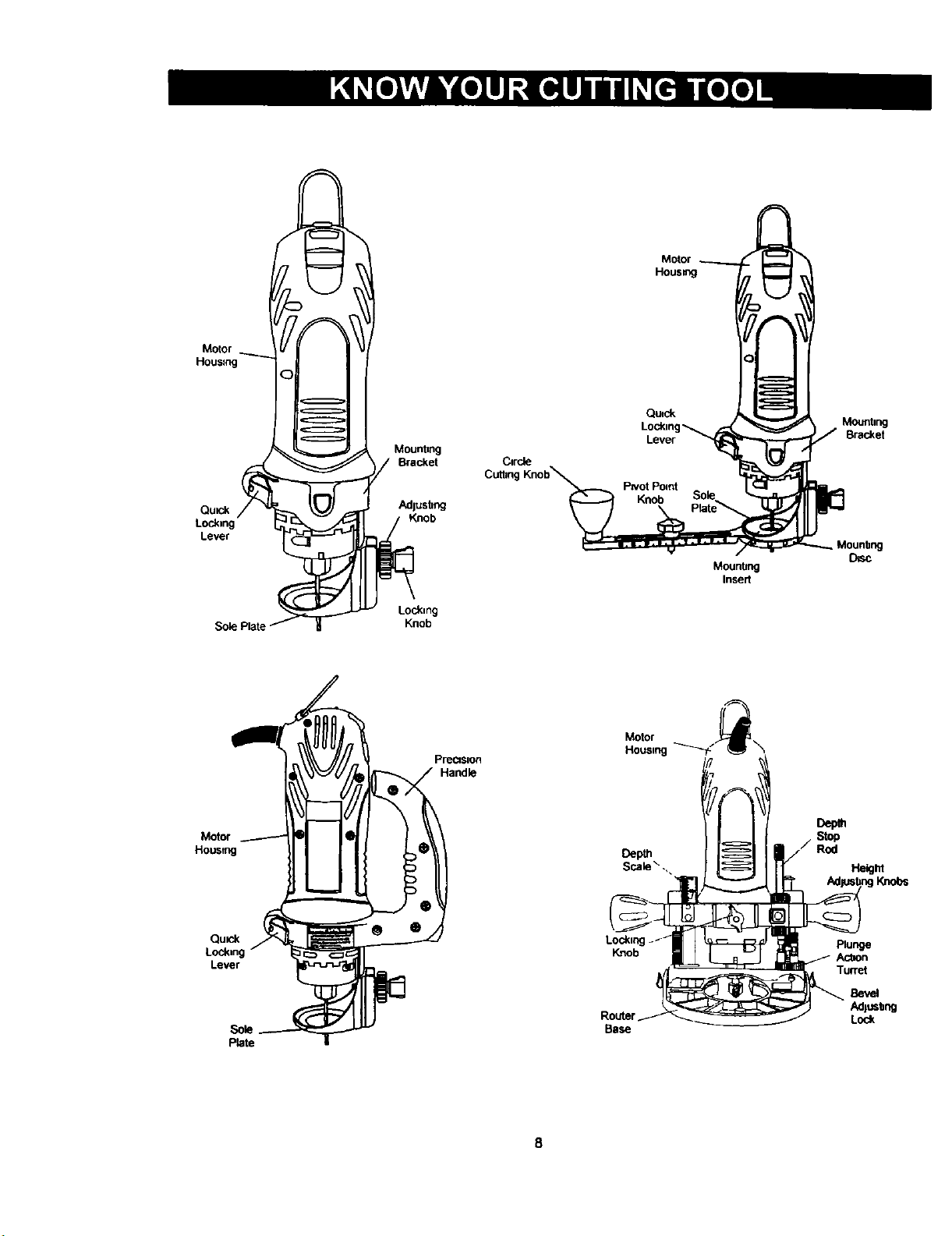

ON I OFF & SPEED CONTROL SWITCHES

Thrs cutting tool is equipped w=tha sliding ON / OFF

switch (1) located on the side of the tool and a speed

control switch (2) located on top of the tool (see Fig 1)

2

INSTALLING CUTTING BITS - Cont'd

Insert new cutting bit (4) into the collet

IA WARNING I

Insert the bit all the way into the collet and then

pull it back between 111e"and 1Is". This creates an

air space between the motor shaft and the bit to

help prevent overheating the bit.

Before tightening the collet on the bit, make sure

the flutes (spiral portion) of the bit are completely

visible outside the colleL Clamping the collet on

the bit flutes will result In broken bits and possible

injury.

When bit is properly placed in the collet, depress the

shaft locking button and turn the collet nut clockwise

by hand as far as possible

6 Securely tighten collet nut using the wrench

Fig. 1

1 To turn the tool ON, slide the switch (1) up

2 To turn the tool OFF, slide the swltch down

3 To set speed to high speed, slide speed control switch

(2) away from the ON / OFF switch

4. To set the speed control switch to low speed, slide the

speed control sw_tch (2) toward the ON I OFF switch

INSTALLING CUTTING BITS

IA WARNINGI

Cutting bit and router bit cutting surfaces are

extremely sharp. Handle with caution.

To insert a cutting btt, use the collet wrench which IS in the

wrench holder attached to the power cord

Depress the shaft locking button (1) and rotate the

collet look nut (2) clookwme with the other hand until

the locking button drops into place, preventing the

shaft from turning (see Fig 2)

2 Whdecontmuingto holdthe shaft lockingbuttonIN,

usethe colletwrench(3) to turnthe colletnutcounter

clockwiseLoosenthe colletnuttwo or three turns

3 Removebit if one isalready installedinthe tool

5

Fig. 2

WORK LIGHTS

The motor umt has two built-in work 1_3hts(5) (see F_g 2)

These work hghts automatically hghtup when the motor

switch m turned ON. Patterns or drawings m the

immedtate vicinity of the bitwill be dlummated for better

vtstbthtyand tmproved cutting accuracy

SELECT APPROPRIATE MOTOR SPEED

Selectingthe appropriatemotorspeedwdlensure

smoother,more efficientcuttingaction ChooseLOW

speed forgnndmg,cuttingplastics,polishingandwhen

usingw_reor bristlebrushes Choose HIGH speedwhen

cuttingwood. usingcut-offwheelsand to reduce"chatter"

thatmaydevelopwhen cuttingsomematerialsat LOW

speed

CHANGING COLLET INSERT INSTALLING FREEHAND SOLE PLATE - cont'd

The cutting bits for this tool are locked into ptace with a

collet nut (1) and collet (see Fig 3) The tool is assembled

at the factory with NO collet insta!led Both the l/s" and ¼"

collets can be found in the carrying case front lid storage

compartment The 1/8" collet (2) is used for holding hobby

tool accessory bits The ¼" collet (3) is supplied for

holding SMALL router bits with a ¼" shank

3

4 2 1

Fig. 3

To change from one collet s=ze to the other

1 Remove bit from the tool

2 Continue turning the collet nut counter clockwise untd

it can be removed from the motor shaft (4)

3 Pull the collet out of the motor shaft and replace it with

the other one

NOTE Each collet is the same on beth ends, so either

end can be inserted into the motor shaft

4 Re-install the collet nut and slightly tighten it by hand

5. Install the new bit as outhned in INSTALLING

CUTTING BITS on Page 9.

NOTE Tightening the collet nut without a bit in the collet

will cause the collet hole to become smaller and make

installing bits difficult When storing the tool with no bit

installed, leave collet nut loose

_1;.|=1=1-"F_.I_10_F,._[e]N =11_1W_,III

INSTALLING FREEHAND SOLE PLATE

The freehand sole plate is designed for basic freehand

cutting with the cutting bit. It is ideally suited for cutting

electrmal outlet holes in dr/wall

Shde freehand sole plate mounting bracket (1) onto

the bottom of motor housing (2) untilthe slot in the

bracket (3) lines up with the shaft locking button (4) in

the motor housing

NOTE The mounting bracket must be pushed onto

the motor housing as far as it wdl go

Lock the sole plate to the motor housing by snapping

the quick locking lever (5) firmly against the motor

housing

2

4

3

5

Fig. 4

ADJUSTING FREEHAND SOLE PLATE

Adjust freehand sole plate depth by loosening the

depth gauge locking knob (6) and rotating the

adjusting knob (7) to move the sole plate in or out as

required (see FK3 5)

NOTE" Set the depth gauge so the cutting bit

protrudes beyond the sole plate 1Is more than the

thickness of the material being cut For example, if

you are cutting 5/8"drywall, the bit should protrude %"

beyond the sole plate

2 Securely tighten depth gauge knob

Before starting to cut you should re-check bitdepth

Make sure sole plate is at right angles to the bit and

securely tightened Re-check the collet to make sure

the bit is securely fastened

IA WARNINGI

Do NOT use the freehand sole plate with router bits.

Umlted control with this accessory could cause you

to loose control end Increase the chance of serious

injury.

Fig. 5

10

PRACTICE CUTS USING FREEHAND SOLE PLATE

IA wAR.I.GI

Have you read =POWER TOOL SAFETY",

"cuTrlNG TOOL SAFETY" and "ELECTRICAL

SAFETY" on pages 3, 4 and 5 of this Manual? If

not, please do it now before you operate this

cutting tool. Your safety depends on Itl

Evew time you use the cutting tool you should

verify the following:

1. Cutting tool cord is not damaged.

2. Bit is correct type for the material being cut.

3. Bit is sharp, in good condition, properly

installed and securely tightened.

4. Safety glasses and dust mask are being worn.

Failure to adhere to these safety rules can greatly

increase your chances of Injury.

PRACTICE CUTS USING FREEHAND SOLE PLATE

Before attempting to work on an actual proJect, take the

time to make s few practuce cuts with your cutting tool

Use some scraps of matenal that are the same maternal as

used nnyour actual project.

1. Draw a patternsumulartoyour firstprojecton a scrap

p_eceofmaterial

6 Set the speed control switch to the appropriate speed

7 Turn the swntchON

When the motornsupto fullspeed, slowiyttp thetool

toan upnghtposttnon,lettnngthe bitcut nntothe

workpnece(see F=g7) Once thetoolhas reached the

uprightpesubonandthe bithas cutthroughthe

workplece,slowlymovethe toolin a clockwise

dnrectionusnngslow steadypressuretomake thecut

NOTE"Exceptfor cuttnngaroundoutletboxes in

drywall,alwayscut ma clockwise durectlon

9 When cut nscomplete, turn the tool OFF, want untd it

comes to a complete stop and remove it from the

workpuece

Fig. 7

2. Installfreehandsoleplateas shownin Fig 4

3 Installcuttingb=tin thecolletas shownin Fig 2

4 Adjust depth of freehand sole plate as shown in Fng 5

5

Rest the edge ofthe sole plateon the workpiecevath

the bntat an angleofabout45° (see Fug 6).

NOTE DO NOT let the bitcontactthe workpleceuntil

switchnsturnedON and the toolis up tofull speed.

IAWARNINGI

Before tuming the tool switch ON, make sure you

hold the tool firmly with both hands. Starting

torque will cause the tool to twlsL

L

IADANGER I

Do not attempt cutting around outlet boxes in drywall

until:

t. All electricity in the vicinity of electric wires has

been disconnected by either turning the breaker

OFF or removing the fuses.

2. You have read the Instructions on the following

page entitled "CUTTING OUTLET OPENINGS IN

DRYWALL".

cUTrlNG TIPS

The rotatingcuttungactionofthe bitvailcausea skghtpull

tothe left when cutting.Naturalvariationsinthe structure

ofwoodwillcause the 10ftto"wander'.This tendencywill

be magnifiedwhen applyingtoo muchpressuretothe bit

Slowercuttinggivesyou bettercontrol. Excessive

pressureor fast cuttingwill increasebittemperatureand

shortenthe hfeof the bit

When cuttinga holeina verticalsurface,avo_lendingthe

cutat the bottomofthe hole AJwaysstartand endthe cut

at the"top"sothe cut-outpartwillnotdropontothe

rotatingbit.Alwaystumthe toolOFFbefore removingd

fromthe workpisce,

Fig. 6

11

CUTTING OUTLET OPENINGS IN DRYWALL

CUTTING OUTLET OPENINGS IN DRYWALL - cont'd

I,_ DANGER I

Do not attempt to use this tool to make cut-outs

around any fixture or opening which has live electrical

wires or on any wall which may have electrical wiring

behind it. If a live wire is contacted, the bit could

conduct the electric current to the tool, creating an

electrocution hazard for the operator. Turn OFF

breakers or remove fuses to disconnect the electric

circuit in the area of work. Always hold the tool by its

insulated housing when working in areas where there

is a possibility of contacting electric wires. Always

wear eye pretection when operating this tool.

Before mstalhng drywall, push the electncel wires to

the back of the box as far as possible so they will not

be cut by the bit when cutting the opening

2

Before fastening the drywall sheet over the electncal

box, mark the sheet as close as possible to the center

of the box opening Mark should be on the side of the

dr/wall facing you

When fastening the drywall In place, do not place nads

or screws closer than 12" from the box Thsswilt

prevent the drywall from becoming deformed under

pressure

6 Move the bit slowly to the nght until you feel and he;

the bit contacting the mstde of the box

7 Pull the btt out far enough to shp tt over the edge of

the box Once the bit is outside the box, push it back

to full depth bestde the outside edge of the box

8

Move the tool upward whde applying alight pressure

toward the center of the box When you feel the bit

reach the top nght hand comer of the box. move the

tool to the left whde applying shght pressure

downward toward the center of the box

Continue moving the tool around the box in s counter

clockwtse d=rocbonwhde maintaining shghtpressure

toward the center of the box When the box cut-out t._

complete Turn the tool OFF and remove d from the

cut-out

10 Completedelectricalboxcut-outwillbe acouratelya_

neatlycut(see Fag9)

4

Insert cutbng b_tand install freehand sole plate as

outlined on Pages 9 & 10 of this Owner's Manual

AdJustdepth of cut so the bit wdl protrude _/8"beyond

the thickness of the drywall

Hold the tool firmly with both hands and turn it ON

Plunge the bd through the drywall at the mark

mdlcahng the center of the box See Fig 8 for cutting

pattern

Fig. 8

\

Fig. 9

NOTE: Alwaysmovethe cuttingbitina counter

clockwise directionaroundthe outletbox.The natural

tendencyof thecuthngba to moveto the leftwillmake it

eas_erto cutclosetothe box

12

INSTALLING PRECISION HANDLE

The prectslon handle is desogned for use when prec0sion

control over the tool movement 0sdesired The

comfortable handle can be used with either the right or left

hand

1 Shde precls0on handle mounting bracket (1) onto the

bottom of motor housmg (2) until the slot under the

handle (3) hnes up with the shaft locking button (4) in

the motor housing (see Fig 10).

NOTES

a) The mounting bracket must be pushed onto the

motor housing as far as it will go

b) The shaft locking button (5) can now be activated

by your thumb while holding on to the precision

handle

ADJUSTING FREEHAND SOLE PLATE - Cont'd

Fig. l l

::::(ql= [141111:1;

INSTALLING CIRCLE CUTTER

The circle cutter accessory is ideal for precision cuttmg of

clmles Th=s circle cutter can be attached to either the

freehand sole plate or the precision handle sole plate. For

purposes of dlustration, the circle cutter is shown with the

freehand sole plate

2 Lockthe precisionhandleto the motorhousingby

snappingthequncklockinglever(6) firmlyagainstthe

motor housing

2

6 4

5

Fig, 10

'ADJUSTING FREEHAND SOLE PLATE

AdJustprecision handle sole plate depth by loosening

the depth gauge locking knob (7) and rotating the

adjusting knob (8) to move the sole plate (9) in or out

as required (see Fig 11)

NOTE Set the depth gauge so the cuttmg bit

protrudes beyond the sole plate 1/8"more than the

thtckness of the matenal being cut For example} d

you are cutting 3/4"pine, the bit should protrude /e

beyond the sole plate

1

Install freehand sole plate on the tool as illustrated on

Page 10 of this Owner's Manual

2

Insert the extemally threaded circle cutter mounting

insert (1) into the bottom of the sole plate (2) (see

Fog 12).

NOTE' Make sure the molded "D" in the mounting

insert is inserted into the matching "D" in the sole

plate

Place circle cutter mountmg hole (3) over the

externally threaded circle cutter mounting nnsert

NOTE: Make sure pointed ptvot pm (4) is pointing

away from the tool

Screw the internally threaded circle cutter mounting

disc (6) onto the externally threaded circle cutter

mounting insert and hand t0ghten.

NOTE" Do not over tighten the circle cutter mounting

plasbc parts. Hand tighten only

Adjustthe circle cuttingradiusby looseningpivotpoint

knob(5), slidingitto the correctcircle radiusand re-

tighteninginthe desired location

NOTE Check circlecutterradiussettingby measuring

from the ptvotpomttothe outside of thecuttmgbit

2 Securely tighten depth gauge knob

3.

Beforestartingto cutyou shouldre-checkbitdepth,

make suresole plate is at rightanglesto thebitand

securelytightened Re-check the colletto make sure

the bit is securelyfastened.

1

5 2

Fig. 12

13

s]I_-{qil _[_eil illi1"_:

CIRCLE CUTTER OPERATION

CIRCLE CUTTER OPERATION - cont'd

IA WARNINGI

Unplug the tool from the power source I_fore

changing accessories, changing bits and making

adjustments.

Before turning the tool ON, check to make sure bit

and all accessory fasteners are securely tightened.

1 Mark the center of the circle you wish to cut on the

workplece and dntt a 6 mm or _s/e4"pdothole

2 AdJuStcutting b=tdepth to l/s" longer than the

thickness of the matenal being cut (see Fig 5)

3

Adjust the circle cutting radtus by loosening pivot point

knob. shdmg ttto the correct circle radius and re-

tightemng in the deaoredlocation

NOTE Check circle cutter radius setting by measuring

from the p=votpoint to the outside of the sptral bR

4

Rest the edge of the sole plate on the workptece with

the btt at an angle of about 450 (see Fog 13) Insert

the circle cutter pivot point into the pilot hole dnlled at

the center of the ctrcle

NOTE DO NOT let the b_tcontact the workptece

before swttch ts turned ON and the tool is up to full

speed

5 Turn the switch ON

When the motor is up to full speed, slowly hp the t_

and clrole cutter assembly to an upright posdlon,

letting the bit cut into the workpiece (see Fig 14) I

careful to keep the pivot point located at the centel

the circle to be cut Once the tool has reached the

upnght posttton and the b=thas cut through the

workplace, slowly move the tool m a clockwise

d_rection using slow steady pressure to make the c_

Continue to cut the circle, keaplng the tool upright

rotating around the circle cutter pivot point

7 When cut fs complete, turn the tool OFF, wait untd

comes to a complete stop and remove it from the

workptece

\

Fig. 13

Fig. 14

14

_tLIJ_[¢]=l I='TO]IInlI;:I,41:Y,JI.']

SETTING ROUTER DEPTH FOR SINGLE DEPTH ONLY

The router accessory converts your cuttnngtool Into a

small hobby plunge router that uscapable of handling

small '/," shank router butsas well as the spiral cutting but

The tnltnngbase is ideal for bevel cutting The plunge

feature allows you to pre-set up to three ddferent cuttnng

depths

IA WARNINGI

Unplug the tool from the power source before

changing accessories, changing bits and making

adjustments.

Before turning the tool ON, check to make sure the bit

and all accessory fasteners are securely tightened.

ROUTER ACCESSORY INSTALLATION

1 Remove any accessory already unstalled on the tool

Slide router accessory mounting bracket (1) onto the

bottom of motor housnng(2) until the mounting hole (3)

hnes up wuththe hole nnthe mountung bracket (see Fig

15)

NOTE The raised hole in the mounting bracket will

shde over the motor shaft locking button

3 Re-nnsert accessory locking knob (4) into the motor

housnngand securely tighten

Depth of cutting os controlled by sliding the router base up

and down on the gutde rods and locking dun place

Rause plunge router depth stop rod by turning the

lower depth stop lock nut (1) counter clockwise untul=t

is posutnonedat the bottom of the depth stop rod (2)

(see Fig 16) Push depth stop quick release button (3

and reuse the depth stop rod to Its maximum height

and then release the button

2 Rotate plunge actuonturret (4) untilthe shortest stop

screw usunder the depth stop rod (2)

3

Loosen both height adjushng knobs (5) by turning

them counter clockwtse

NOTE" Only loosen height edjustmg knobs enough to

release the tension on the guide rods (6).

4 Shde muter base (7) up or down to obtannthe desured

depth of cut

5 Re-hghtenbothheughtadjustnngknobswhenthe

desiredcutdepth tsreached.

Fig. 15

Fig. 16

SETTING PLUNGE DEPTH

Up to three different plunge depths can be preset by

using the depth stop rod and plunge action turret This

provides for qutck changes between depth setbngs

1

Turn lowerdepth stop locknut (1) to thebottomof

depthstop rodand upperdepthstoplocknut(2)to

the top of depthstoprod(3) (see Fig 17)

2. Pushdepthstopquick releasebutton(4) and raisethe

depthstoprodto its maximumheightandthen

releasethe button.

3. Rotate plungeactionturret(5) untilthe shorteststop

screwis underthe depth stoprod

15

SETTING PLUNGE DEPTH - cont'd

SETTING ROUTER BASE BEVEL

Loosen both height adjust=ng knobs (6) by tummg

them counter clockw=se

NOTE Only loosen height adjushng knobs enough to

release the tens=on on the gutde rods (7)

5 Shde router base (8) up or down to obta=nthe des=red

depth of cut

6 Re-hghten he=ghtadjusting knobs when the desfred

cut depth is reached

Push the depth stop qu=ck release button and lower

depth stop rod untdit contacts the turret stop screw

(9) After releas=ng the qu=ckrelease button, finer

adjustments can be made by turning the depth stop

rod

Lock both the lower (1) and upper (2) depth stop lock

nuts against the router body to lock the depth stop rod

m place

NOTE Do not use pliers to hghten lock nuts Turn

lock nuts by hand only

9 Lock shortest turret stop screw by t_ghtenlng lock nut

(10)

NOTE Do not over tighten lock nut

10 Loosen both he=ght adjusting knobs just enough to

allow router to freely sltde up and down on the guide

rods

Bevel cutting with the cutting bit can be done with the

router base tilted to the desired angle

1 Loosen both bevel adjustmg locks (1) by pulhng them

outward from the router base (2) (see Fig 18)

Tilt router base to the desired angle

NOTE There are detents for Iockmg the router base

at 0°, 15°, 30° and 45° These are the four most

common angles for bevel cutt=ng

3 Lock both bevel adjusting locks by pushing them

firmly back into pos=honagamst the router base.

4 Check bevel angle between router base and router bit

to ensure they are at correct angle

5

Check routerdepthof cutand re-setthe depthif

required

NOTE Depth ofcut w=llusuallyhaveto be increased

afterbitingtherouterbase for bevelcutt=ng

11 Two add=t=onaldepths can be pre-set =na s=milarway

setting the other two turret stop screws to the desired

depth

NOTE To select pre-set plunge depth, simply rotate

the turret until the correct turret stop screw is aligned

under the depth stop rod

Fig. 17

Fig. 18

16

|lUJ _,[l'] :11=|o]ll 1:1:| I:T'_

FREEHAND CUTTING AND ROUTING

When the router base accessory is installed on the cutting

tool, it will function as a small router to be used for

freehand cutting of irregular shaped patterns You can cut

patterns out of the workpnese with the cutting bit or route

pettems into the workplece with small router bvts

FREEHAND CUI-I'ING

1 Adjust the cutting batdepth to lie" longer then the

thickness of the material being cut

2 Turn the switch ON while firmly holding the tool

3 When starting the cut ms=dethe workplece, place the

bit at an angle to allow the bit to cut its way into the

workpuece (see Fig 6)

4 Use the two height adjusting knobs to guide the bit

through the workplece

FREEHAND ROUTING

Use the routerbasew0thsmall routerbitstoperform

variousfreehandroutingprojects(see Fig 19)

1 Remove 1/8"collet and insert ¼" collet (see Fig 3)

CU'I-rlNG STRAIGHT LINE WITH STRAIGHT EDGE

To cuta straightline,youcan usea straightedge

templateto guidethe routerbase

1

Draw a hne on the workplece where you wushto make

the cut (see Fig 20)

2

Draw a parallel second line approxtmately 21/e"back

into the workpaeco (away from the cutting line)

3 Clamp the straight edge onto the larger portion of the

workpuece that msto be clamped while cutting

Place the fiat side of the router base against the

straight edge with the bit near the start of the cutting

line

NOTE Check bit Iocateonto ensure cut wnllbe made

in the correct Iocabon

5 Turn the switch ON whde firmly holding the tool

6 Slidethe routerplateagainstthe stra=ghtedge whde

makingthe cut

2 Install router bit and securely tighten

3 Adjust router base height to the con'ect routing depth

4. Turn the swutchON making surethe routerbutis not

touchinganything.

5. Holding the tool by the two height adjusting knobs,

carefully lower the bit onto the workplece and guide

the bit around the desired pattern

Fig. 19

Fig. 20

17

i ii[IJ_,[€.]1 Z(o]II I :l:i I:Y:I-_

IZff._1l_i_l_ _a]l_l

CUTTING CURVED LINE WITH A TEMPLATE

To cut a curved line, you can use a curved template to

guide the router base

Make a template from hardboard or other similar

material to the shape you require (see Fig 21)

NOTE Radius of curve must be greater than 2½" for

router base to propedy follow the curved template

2 Mark the location of the cut to be made

3 Mark the workplece approximately 27/1e"back into the

workplece (away from the cutting line)

4 Clamp the template onto the larger port_onof the

workplece that is to be clamped while cutting

5

Place the curved portion of the router base against the

template with the b_tnear the start of the cutting line

NOTE. Check bit Iocatnonto ensure cut will be made

in the correct location

6 Turn the switch ON while firmly holding the tool

7 Slndethe router plate against the template while

making the cut

EXTERNAL CLEANING

IA WARNINGI

DO NOT use solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged by

their use. Usa clean cloth to remove dirt, dust, oil,

grease, etc.

Do not at any time allow brake fluids, gasoline,

petroleum-based products, penetrating oils, etc. to

come in contact with plastic parts. They contain

chemicals that can damage, weaken or destroy plastic

INTERNAL CLEANING

It has been foundthatelectnctoolsare subjectedto

acceleratedwear and possibleprematurefailure when

theyare usedonfiberglassbeats and sportscars,

wallboard,spacklingcompoundsor plaster.The chipsand

gnndingsfrom these materialsare highlyabrasiveto

electrictoolpartssuch as beanngs,brushes,commutators

etc Dunnganyuse on thesematedalsit is extremely

importantthatthetool iscleaned frequently by blowingout

witha compressed anrJet

Fig. 21

IvN:lI_I l =1_r:l _[11

IADANGER I

For your own safety, turn the switch OFFand remove

the plug from the power source before maintaining

your cutting tool.

When servicing, use only Identical Craftsman parts.

Use of any other part may create a hazard or cause

product damage.

IADANGERI

it is critical that you wear safety gogglesor safety

glasses with side shields and a dust mask while

blowing dust out of the cutting tool with a

compressed air jet. Failure to take these safety

precautions could result in permanent eye or lung

damage.

POWER CORD MAINTENANCE

IAWARNINGI

To avoid shock or fire hazard, replace the cord

immediately If it Is wom or damaged In any way.

LUBRICATION

Allof the bearingsInthiscuttingtoolare lubricatedwitha

sufficientamountof highgradelubricantforthe lifeof the

undundernom_l conditions.Therefore,nofurther

lubricationisrequired

18

Main Unit

19

I_, WARNING I

When servicing use only CRAFTSMAN replacement parts. Use of anyother parts may create a HAZARDor cause

damage to your Cutting Tool.

Any attempt to repair or replace electrical parts on this Cutting Tool may create a hazard unless repair is

performed by a qualified technician, Repair service is available by contacting your nearest Seam Service Center.

Always order by PART NUMBER, not by key number.

Main Unit

Key# Part# Part Name

1 01AR-000032-00 BeanngSleeve

2 01AR-000035-00 Switchpresser

3 01AT-000014-A0 Bushingtube

5 01AT-000031-00 Bushingtube

10 02AE-000060-00 Frontbeanng

11 02AE-000061-00 Rear beanng

12 02AK-000022-00 Rivet

13 02AH-000088-00 Brushspring

14 02AH-000089-00 Spindlespdng

15 02AH-000112-00 Hanger

16 02AN-000012-00 Screw nut

17 02AS-000199-A0 Case screw

18 02AS-O00201-A0 Screw

19 02AS-000260-00 Machinescrew

19 02AS-000260-10 Machinescrew

22 02AW-000055-00 Retainingring

22 02AW-000055-10 Retainingring

23 03AA-000279-00 Transformer

24 03AC-00001l-F0 Capacity

25 03AC-000043-00 Capacity

28 03AD-000009-A0 Diode

29 03AD-000040-00 Dlac

29 03AD-000040-10 Diac

30 03AD-000074-00 LED

31 03AD-000075-00 Tnac

34 03AM-000104-00 Stator

35 03AM-000105-00 Rotor

36 03AP-000073-00 i PCB

36 03AP-000073-10 PCB

37 03AP-000076-00 PCB

37 03AP-000076-10 PCB

38 03AR-000013-AO Resistor

39 03AR-000015-D0 Resistor

40 03AR-000109-A0 R_=_i_tnr

Qty Key# Part#

1 41 03AS-000135-00

1 42 03AS-000140-00

2 44 03AT-000033-00

2 48 03AT-000040-00

1 49 03AT-000046-00

1 50 03AW-000131-00

4 50 or03AW-000131-10

2 53 03AY-000020-00

1 55 03AY-000073-00

1 56 03AY-000074-00

1 59 04AP-000068-00

8 62 2203-MA0003-00

3 62 2203-MA0004-00

1 63 2203-MA0007-00

1 67 2207-MA0003-00

1 70 2213-MA0002-00

1 71 2213-MA0005-00

1 72 2213-MA0006-00

1 * 2213-SAM001-00

1 73 2213-MA0011-00

4 74 2213-MA0012-00

1 76 2213-MA0014-00

1 76 2213-MA0014-01

2 79 2203-PA0008-00

1 80 2207-PA0007-00

1 81 2213-PA0022-00

1 82 2213-PA0023-00

1 83 2213-PA0024-00

1 84 2213-PA0025-O0

1 85 2213-PA0026-00

1 87 2213-PA0028-00

1 91 9866-PA0004-00

1 92 9920-PA0011-00

3

Part Name

Microswdch

Switch

Termmalblock

Terminal(female)

Carbonbrush

: Powercord

Powercord

W_re

Wire

Wire

Fibra

1/4"collet

1/8"collet

Lock plate

Spindlelock

Conductor

Chuck cap

Spanner

Brushassembly

Metal conductor

Brushcase

Wire cover

Wire cover

Spannerbelt

ScrewlockB

Bottomcabinet

Topcabinet

Switchcover

Lockbutton

Cover

2P-Switch

Pressplata

Cord Sleeve

at,/

1

1

1

2

2

1

1

1

2

2

1

1

1

1

1

2

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

20

Freehand Soleplate Assembly

Key # Part #

201 02AF-000041-10

202 02AF-000076-00

203 02AS-000287-00

208 2213-MA0010-00

211 2213-PA0010-00

212 2213-PA0011-00

213 2213-PA0012-00

214 2213-PA0013-00

215 2213-PA0014-00

216 2213-PA0015-00

Part Name

F[xlngshaft

Releaselock pin

Screw

Freecutmetal round guide

Lock

Fixbase

Piast=cguide base

AdjustmentGear 15T

Sleeve

Sclew lockF

21

Qty

1

1

1

1

1

1

1

1

1

1

Handle Assembly

Key # Part #

301 02AF-000041-10

302 02AF-000076-00

304 02AH-000106-00

305 02AS-000148-00

306 02AS-000287-00

307 02AS-000288-00

310 02AW-000067-00

312 2213-MA0013-00

321 2213-PA0010-00

323 2213-PA0012-00

324 2213-PA0013-00

325 2213-PA0014-00

326 2213-PA0015-00

327 2213-PA0016-00

328 2213-PA0017-00

329 2213-PA0018-00

330 2213-PA0019-00

331 2213-PA0020-00

332 2213-PA0021-00

Part Name Qty

Fixingshaft 1

Releaselockpin 1

Compressivespnng 1

Screw 2

Screw 1

Screw 3

Washer 1

S-roundguideholder 1

Lock 1

Plasbcguidebase 1

AdjustmentGear 15T 1

Sleeve 1

ScrewlockF 1

Anx righthandle 1

Anx lefthandle 1

Anx handlesoftgrip(outs=de) 1

Anx handlesoftgnp(inside) 1

Simplelock 1

ShaftF5-5 1

22

Circle Cutter Assembly

Key # Part #

401 02AN-000017-00

402 02AN-000018-00

403 02AS-000258-00

404 02AS-000272-00

405 02AW-000022-00

410 2206-MA0001-00

410 2206-MA0005-00

411 2206-MA0002-00

412 2206-MA0003-00

415 2206-PA0001-00

416 2206-PA0003-00

417 2206-PA0004-00

418 2213-PA0007-00

419 2213-PA0008-00

Part Name Qty

I Square nut 1

Hexagon thin nut 1

Machine screw 1

Screw 1

Spdng washer 1

Cimular arm (metric) 1

Cimular arm (inch) 1

Washer 1

Handle bush 1

Dgstance lock w=thcenter pin 1

Locking base 1

Round guide mount 1

Handle cuplike base 1

Handle cuplike cover 1

23

Router Assembly

24

Router Assembly

Key# Part #

101 02AF-000041-10

102 02AF-000077-00

103 02AF-000078-00

104 02AG-000145-.00

105 02AJ-000016-00

107 02AH-000107-00

108 02AH-000108-00

109 02AH-000109-00

111 02AN-000001-A0

112 02AN-000013-00

113 02AN-000019-00

115 02AQ-000001-A0

117 02AS-000020-A0

118 02AS-000048-A0

119 02AS-000276-00

120 02AS-000258-00

121 02AS-000238-00

122 02AS-000290-00

123 02AS-000291-00

124 02AS-000292-00

128 02AW-000068-00

129 02AW-000070-00

131 2213-MA0001-00

133 2213-MA0003-00

134 2213-MA0004-00

138 2213-MA0007-00

139 2213-MA0008-00

151 2213-PA0001-00

152 2213-PA0002-00

153 2213-PA0003-00

154 2213-PA0004-00

155 2213-PA0005-00

156 2213-PA0006-00

157 2213-PA0007-00

158 2213-PA0008-00

159 2213-PA0009-00

164 2205-PA0004-00

165 2205-PA0007-00

Part Name

Fixingshaft

Baserelease lockpin

; Heightrod

Guidebush

Routertile base

Spring

Spring

Spring

Screw nut

Squarenut

M4 fixing nut

Steelball

Screw

Machinescrew

Basescrew

Machinescrew

Screw

Screw

Screw

Screw

Wave washer

Externalretainingdngs

Guiderod

Knockhead

Indexguide

Washer plate 1

Washer plate2

Routerfixbase

Routermovablebase

Routerquick heightlock

Memorypostdial

Lock

Bellow

Handlecuplike base

Handlecuplike cover

Heightadjustknob

Lens

Locking disc

aty

2

2

1

2

1

2

2

1

5

2

3

1

1

3

6

2

1

1

1

1

1

2

2

2

1

2

2

1

1

1

1

2

2

2

2

2

1

2

25

For repair of major brand appliances in your own home... _

no matter who made it, no matter who sold it! _

1-800.4-MY-HOME ® Anybrne,dayornight

(1-800-469-4663) (U S.A. and Canada) _,-_

www.sears.com www.sears.ca _;

For repair of carry-in products likevacuums, lawn equipment,

and electronics, call for the location of your nearest ?:"

Sears Parts and Repair Center. _

1-800-488-1222 Any_me,dayornight(USA one)

www.sears.com _-_

For the replacement parts, accessories and owners manuals _\

that you need to do-it-yourself, call Sears PartsDirectSM! :

1-800-366-PART 6 a m - 11 p rn. CST, 7 days a week --

(1-800-366-7278) (U.S.A. only) _:

www.sears.comlpartsdirect

To purchase or inquire about a Sears Service Agreement

or Sears Maintenance Agreement:

1-800-827-6655 (usA.)

7 a m. - 5 p.m CST, Mon- Sat.

Para ped=rserwciode reparacibna

domzcilio,y para ordenarpiP_s

1-888-SU-HOGAR sM

(1-888-784-6427)

® Regmtmed Trademark I _ Trademark I m Se_'k_ Mark of Sea_, RoebuCk andco

® Marca Rel_sVada I _ Marca de F_d:=ric=I m Mama de Setvido de See#l, Roebuck and Co

UCMm de commeme I m Marque d_ de Sun=, Roet_ck and Co

1-800-361-6665 (Canada)

9am.-8p.m. EST, M-F, 4 p.m Sat

Au Canada pourse_ce en franqais

1-800-LE-FOYER _'_c

(1-800-533-6937)

wwwsearsca

O Seam,RoebucklindCo

26

Loading...

Loading...