Craftsman 183172500 Owner’s Manual

Owner's Manual

CRRFTSMANe

CUTTER

Model No.

183.172500

CAUTION:

Before using this Cutter,

read this manual and

follow all its Safety Rules

and Operating

Instructions.

• SafIty Instructions

• Accessories

• Assembly

• Operation

• Maintenance

• Parts List

• Espenol

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

ParL No. 149277480001 Rev. 1 07/13/01

SECTION PAGE

warranty ........................................ 2

Product Specifications ....................... 2

Power Tool Safety ............................ 3

Cutter Safety ..................................4

Elech'icalRequirements & Safety........5

Accessories ....................................5

SECTION PAGE

Carton Contents .............................. 6, 7

Know Your Cutl_. ............................. 8

Assembly & OpemUon ...................... 9 - 17

Maintenance ................................... 17

Repair Parts ................................... 18 - 22

Parts & Service Availability ................ 23

llllJ

FULL ONE YEAR WARRANW

If this Cutter fails due to a defect in material or workmanship within one year of date of

purchase,Sears will at itsoptionrepair orreplace itfree of charge.

Returnthis Cutterto a Sears Service Center for repair,or to place of purchase for replacement.

This warranty gives you specific legal fights, and you may also have other rights which may vary

from state to state.

Seam, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

l& WARNING I

Some dust created by power sanding, sawing, grinding, drilling and other coaMructlon activities contains

chemlcaia known (to the State of California) to cause cancer, birth defects or olther reproductive harm. Some

exampfes of these chemicals are:

• Lead from iaad-based paints

• Crystalline silica Wont bricks, cement and other masonry products

• Arsenic and chrominm from chem..ally treated lumber

Your risk from these exposure varies, depending on how often you do this type of work. To reduce your

expo6ure to these chemicals, work In a well ventliated area and wod( _ approvad safety equipment such as

those dust masks that ere specially designed to filter out microscopic parl_.

l;,l [o] lU[oM

Motor Rating ...................... 120V, 60Hz, AC Motor Horsepower ...... tl3 HP (Ma_mum Developed)

Amperes ........................... 4.0 Amperes Weight ..................... 3.75 kg

Speed (no load) .................. 30000 RPM

I,_, WARNINGI

To avoid electrical hazards, fire hazards or damage to the cutter, use proper circuit protection.

This cutter is wired atthe factory for110-120 Volt operation. It must be connecl_d to a 110-120 Voit115 Ampere

time delay fuse or curcuit breaker. To avoid shock or fire, replace power cord immediately If It is worn, cut or

damaged in any way.

Before using your cutter, It is crltinal that you read and undemtand these mlGety rules. Failure to follow these

miss could result in serious injury to you or damage to the cutter.

[A WARNINGJ

Before using your cutter, it is critical that you read and understand these safety rules. Failure

to follow these rules could result in serious injury to you or damage to the cutter.

15,

Good safe_ practices are a combina_n of common

sense, staying alert and undemtanding howto use your

power tool. To avoid mistakes that could cause sedous

mJury, do not plug in your cutter until you have read and

understood the following safety rules:

1. READ and become familiar with this entire Owner's

Manual. LEARN the tool's applications, limitations and

possible hazards.

2.IA WARNINGJ

Look for this symbol that identif'ms important safety

precautions. It means CAUTIONI BECOME ALERTt

YOUR SAFETY IS INVOLVEDI

3. KEEP GUARDS IN PLACE and in working order.

4. DO NOT USE IN A DANGEROUS ENVIRONMENT

such as damp orwet locations or exposure to rain.

Keep work area well lighted.

5. DO NOT use power toolsinthe presence of

flammable liquidsor gases.

6. KEEP WORK AREA CLEAN. Cluttered areas and

workbenches invite accidents.

7. KEEP CHILDREN AWAY. All visitors should be kept

at a safe distance from the work area.

8. DO NOT FORCE THE TOOL ItwHIdothejobbetter

and safer at the rate for which if was designed.

9. USE THE RIGHT TOOL. Do not force the tool or

attachment to do a job for which it is not designed.

10. WEAR PROPER APPAREL. DO NOT wear loose

clothing, gloves, neckties, rings, bracelets or other

jewelry that may get caught in moving pans. Non-slip

footwear is recommended. Wear protective hair

covering to contain long hair.

11. WEAR A FACE MASK OR DUST MASK. Sawing,

cutting, drilling and sanding operations produce

hazardous dust.

12. DIe, CONNECT TOOLS FROM THE POWER

SOURCE before servicing and when changing

accessories such as blades, bits, cutters, etc.

13. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure the switch is in the "OFF"

position before plugging into the power source.

14. USE ONLY RECOMMENDED ACCESSORIES.

Consult the Owner's Manual for recommended

accessories. The use of improper accessories may

cause injury to you or damage to the tool.

REMOVE ADJ_ KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning "ON'.

16.

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER "OFF". Do not leave the tool

before it comes to a complete stop.

17.

NEVER STAND ON TOOL. Serious injury could

occur ifthe tool is tipped or if the cutting tool is

unintentionally contacted.

18.

DO NOT OVERREACH. Keep proper footing and

balance at all times.

19. MAINTAIN TOOt_ WITH CARE. Keep tools sharp

and clean for molt efficient and safest performance.

Follow instruc_ofls for lubricating and changing

accessories.

20. CHECK FOR D_Mt, GED PARTS. Before further use

of the tool, a guaed or other part that is damaged

should be carefuNy checked to ensure it will operate

properly and perfoml its intended function. Check for

alignment of moving parts, binding of moving parts,

mounting and any _her conditions that may affect its

safe operation. Aguard or other part that is damaged

should be properly repaired or replaced.

21. MAKE WORKI_IOIP CHLD PROOF with padlocks,

master switches or by removing starter keys.

22. DO NOT operate the tool if you are under the

influence of any drugs, alcohol or medication that

could impair your abHify to use the tool safely.

23. USE DUST COLLECTION SYSTEM wherever

ossible. Dust generstod from certain materials can

e hazardous to your health and in some cases, a fire

hazard. Always operate the power tool in a well

ventilated area with adequate dust removal.

24.

ALWAYS WEAR EYE PROTECTION. Any power

ANSI safety stenderd Z87.1. Everyday glasses have

only impact reststont lenses. They ARE NOT safety

glasses. Safety goggles are available at Sears.

tool can throw foreign objects

into your eyes which could

cause permanent eye damage.

ALWAYS wear safety goggles

(not glasses) that comply with

I& WARNll_I

Glasses or gollIlII not In compliance with ANSI

Ztt7.1 could cI I_dous injury when they break.

SAVE THESE INSTRUCTIONS FOR REFERENCE

_ARNING_

For your safety, do not plug in your cutter or try to

use any accessory until it is complemly assembled

and installed according to these Instructions, and

until you have read and understood this Owner's

Manual.

Failure to follow these safety rules will result in risk of

serious injury.

1. WEAR EYE PROTECTION. This high speed tool will

throw particles from the workpiece during operation.

Make sure safety glasses have side shields.

2. USE FACE OR DUST MASK along with safety

goggles if cutting or routing operation is dusty. Make

sure work area is well ventilated.

3.

USE HEARING PROTECTION, particularly during

extended periods of operation.

4.

NEVER USE DULL OR DAMAGED BITS. Damaged

bits can break without warning. Dull bits may ovedoad

the motor, cut slowly and are difficult to control. They

will also overheat and possibly break.

ALWAYS MAKE SURE THE WORKPIECE IS FREE

OF NAILS AND OTHER FOREIGN OBJECTS. If the

bit strikes a nail it will jump sideways and possibly

break.

6. DO NOT USE THIS TOOL FOR DRILLING HOLES.

It is NOT intended to be used as a ddll.

ALLOW CLEARANCE UNDER WORKPIECE for bit

to b'avel. Never place workpiece on hard surfaces

such as concrete etc. The bitmay jump or break

when contacting a surface other than the one being

cut.

ALWAYS SET THE DEPTH GUIDE TO THE

APPROPRIATE DEPTH. Use tool with the depth

guide flat against the work surface for better control of

the tool.

9. NEVER USE THE TOOL wrrHOUT THE SOLE

PLATE, PRECISION HANDLE OR ROUTER BASE

attached and appropriately adjusted.

10. ALWAYS CLAMP WORKPIECE TO HOLD IT

STEADY WHEN CUTTING. This will free both hands

for operating the tool.

11. NEVER HOLD THE WORKPIECE IN ONE HAND

while operating the fool with the other hand.

12. NEVER PLACE HANDS IN THE PATH OF THE

CUTTER AND UNDER THE WORKPIECE.

13. NEVER START THE TOOL WHEN THE BIT IS

TOUCHING THE WORKPECE. The bit may catch

the workpiece causing loss of control.

14. ALWAYS HOLD THE TOOL WITH TWO HANDS

DURING START-UP AND OPERATION. When

starting, motor torque will cause the tool to twisL

15. TURN OFF ALL CIRCUIT BREAKERS AND

REMOVE ALL FUSES in the work area when cutting

into walls or blind areas.

16. ALWAYS HOLDTHE TOOL BY THE INSULATED

GRIPPING _UlIRFACES ON THE BODY OF THE

TOOL where fllere is any possibility of the cutter

contacting hidden elecb'ical wires or the cord of the

tool. Contectwith "live" wires will make exposed

metal parts of the tool _live" causing an electrical

shock to the operator.

17.

WHEN CUTTING DRYWALL ELECTRICAL OUTLET

OPENINGS using the outlet as a guide, always cut in

a counter c_ direction. The natural tendency

of the tool to pull to the left will cause a "hugging"

action toward the outlet box, resulting in a heater cut.

18. NEVER LAY THE TOOL DOWN UNTIL THE

CUTTER COB TO A COMPLETE STOP. A

spinning bit (:an come in contact with the surface and

pull it out of yqmr con_ol.

19. NEVER TOU_H THE BIT IMMEDIATELY AFTER

USE. The bit!will be too hot to be handled with bare

hands and _dll bum your fingers.

20. ALWAYS RI_TI_HTEN COLLET AND ALL

ADJUSTMIENT8 before starting the tool after a bit or

accessory h_ been changed. Loose bits and

adjuskneolB_ cause unexpected shifting of the tool,

resulting in I_ bf control and injury from the bit or

cutter being thmt_.

SAVE THESE INSTRUCTIONS FOR REFERENCE

[lJli=|ilPl_k_._--"'Jllll].

This cutter is double insulated to protect you from

electrical shock.

IA WARNING I

Double insulated tools am equipped with a polarized

plug (one blade is wider than the other). This plug will

f_ into a polarized outlet only one way. If the plug

does not fit fully into the outlet, reverse the plug. If it

still does not fit, contact a qualified etacITIclan to

install a polarized outlet. Do not alter the plug in any

way. Double insulation eliminates the need for the three

wire grounded power cord and grounded power supply

system.

Avoid body contact wlth grounded surfaces such as

pipes, radiators, ranges and refrlgerators. There is an

increased riskof electric shock if your body is grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carry

the tool or pull the plug from the outteL Keep cord

away from heat, oil, sharp edges and moving parts.

Replace damaged cords immediately. Damaged cords

increase the risk of electhc shook.

When operaUng a power tool outdoors, use an

outdoor exteesfon cord marked "W-A" or"W". These

cords are rated for outdoor use and reduce the risk of

electric shock.

IA, WARNING I

Always make sure the receptacle Is polarized. If you

are not sure, have a qualified electllclsn check the

receptacle.

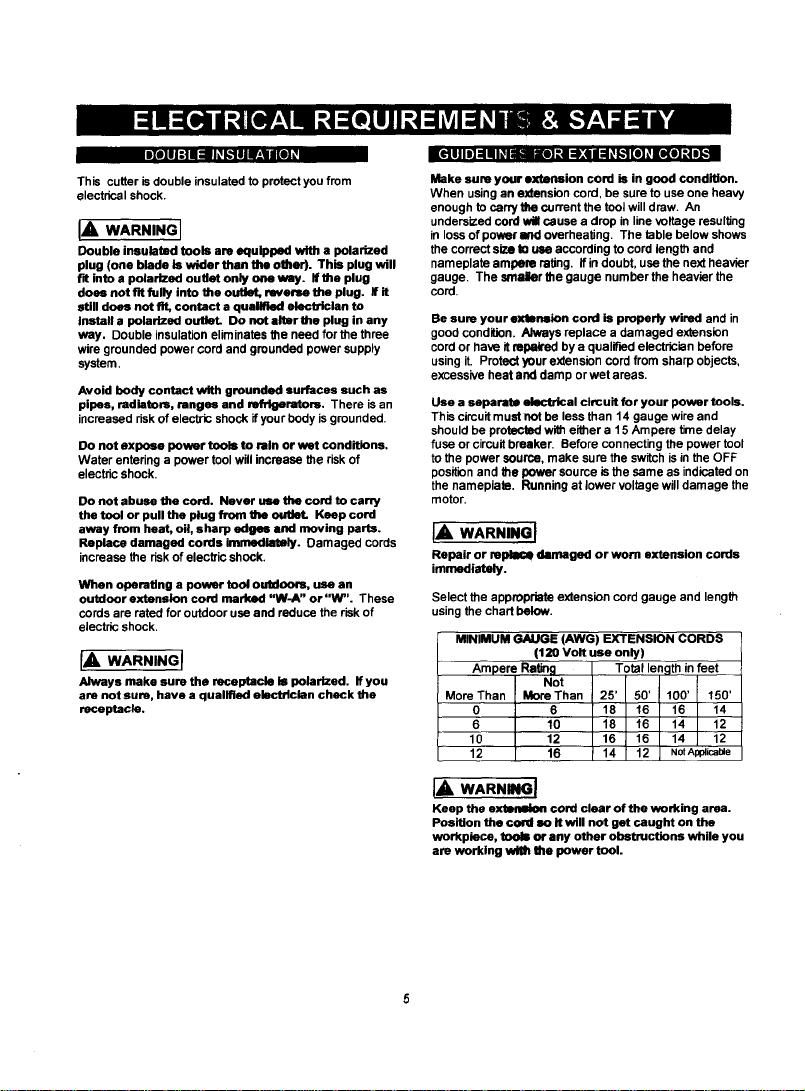

[ellJll]illl_lile]:l 1:l)[41l:ll_k'l[I]_: [ata];llk

Make sure your extension cord is in good condWon.

When using an extension cord, be sure to use one heavy

enough to carry the current the tool will draw. An

undersized cord will cause a drop in line voltage resulting

in loss of power told overheating. The table below shows

the correct size to use according to cord length and

nameplate ampere rating. If in doubt, use the next heavier

gauge. The smager the gauge number the heavier the

cord.

Be sure your extension conS is properly wired and in

good condition, Always replace a damaged extension

cord or have it repaked by a qualified electrician before

using it. Proteet your extension cord from sharp objects,

excessive heat and damp or wet areas.

Use a separate electrical circuit for your power tools.

This circuit must not be less than 14 gauge wire and

should be protected with either a 15 Ampere time delay

fuse or circuit breaker. Before connecting the power tool

to the power source, make sure the switch is in the OFF

position and the power source is the same as indicated on

the nameplate. Running at lower voltage will damage the

motor.

IA WARNINOI

Repair or rspla¢l) damaged or worn extension cords

immediately.

Select the appropriate extension cord gauge and length

using the chart below.

MINIMUM GAUGE (AWG) EXTENSION CORDS

Ampere Rating Total length in feet

More Than More Than 25' 50' 100' 150'

0 6 18 16 16 14

12 16 14 12 NOtApplicable

(120 Volt use only)

Not

0 10 18 16 14 12

12 16 16 14 12

_A WARNINGI

Keep the extm_ cord clear of the working area.

Position the coRl so It will not get caught on the

workptace, too_ or any other obstructions while you

are working w#h the power tool.

_Xo(o] II.$'_o] =]i;i_'

AVAILABLE ACCESSORIES

I r II _J_mn1_i_

UNPACKING _ CHECKING CARTON CONTENTS

!i !

[A WARNING I

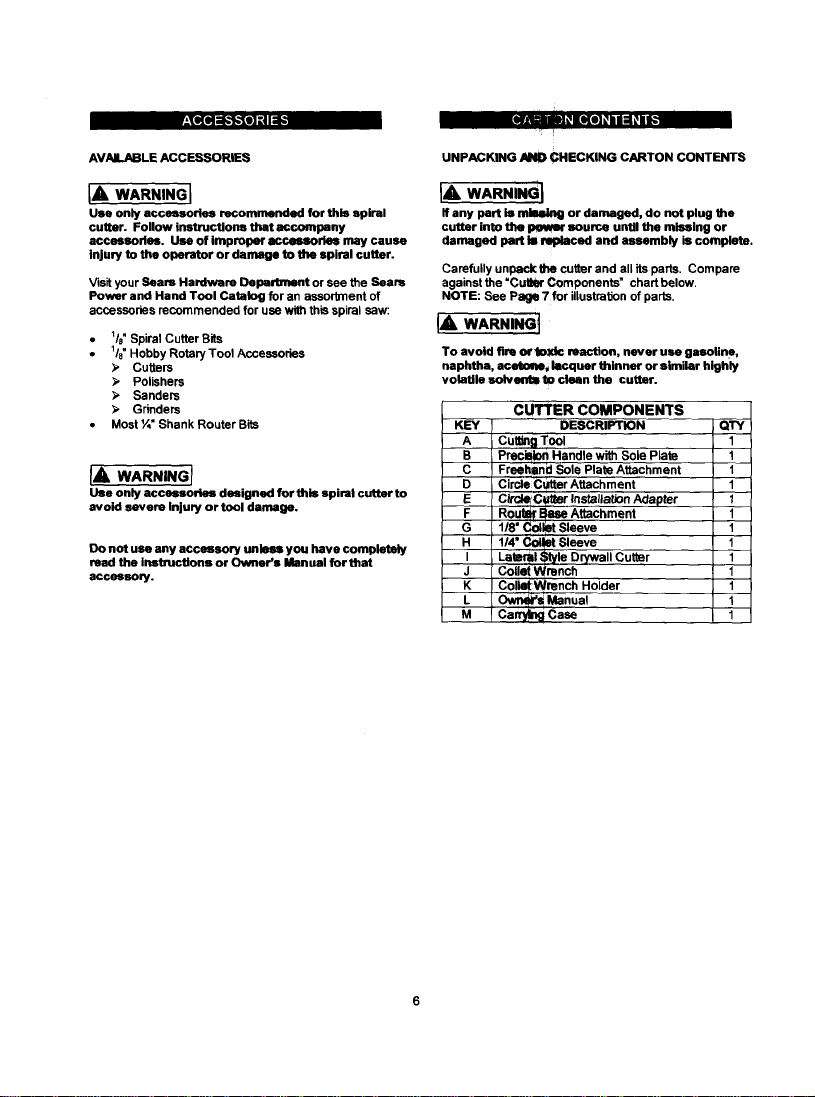

Use only accessories recommended for this spiral

cutter. Follow instructions that accompany

accessories. Use of improper accessories may cause

Injury to the operator or damage to the spiral cutter.

Visit your Sears Hardware Department or see the Seam

Power and Hand Tool Catalog for an assorbllent of

accessories recommended for use with this spiral saw:

• _/e" Spiral Cutter Bits

• 1/8"Hobby Rotary Tool Accessories

;, Cutters

_, Polishers

Sanders

;, Grinders

• Most ¼" Shank Router Bits

IA wAe.,.o]

Use only accessories designed for this spiral cutter to

avoid severe Injury or tool damage.

Do not use any accessory unless you have completely

read the Instructions or Owner's Manual for that

accessory.

IA WARNmGI

If any part is mlsek!tg or damaged, do not plug the

cutter into the PoWer source until the missing or

damaged part Is replaced and assembly is complete.

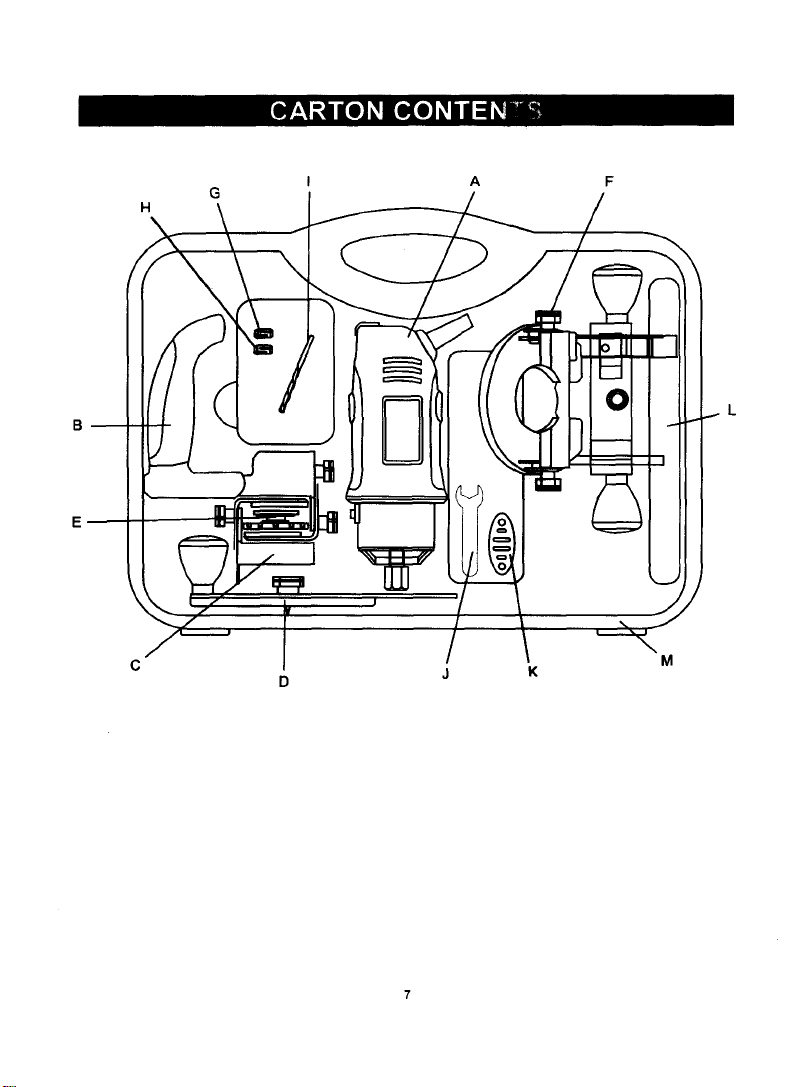

Carefully unpackthe cutter and all its parts. Compare

against the =Cutm" Components" chart below.

NOTE: See Page 7 for illustm'don of parts.

IA, WARNING I

To avoid fire or, toxic reaction, never use gasolin e,

naphtha, acetolm_ lacquer thinner or similar highly

volatile solvents to clean the cutter.

CUTTER COMPONENTS

KEY DESCRIPTION QTY

A CuWn_ Tool 1

_C B-- Precil_k:)n Handlewith Sole Plata 1

Freehand Sole Plate Attachment 1

D Circle Cutter Attachment 1

c_€_ Instaita=nAdepter 1

R0U _t_TBase Attachment 1

G 118" Col_t Sleeve t

1/4" Co41_t Sleeve 1

Lateral Style Drywall Cutter 1

J Collet Wrench I

K Coll_Wrench Holder 1

Owr_, _! Manual 1

Canyll_ Case 1

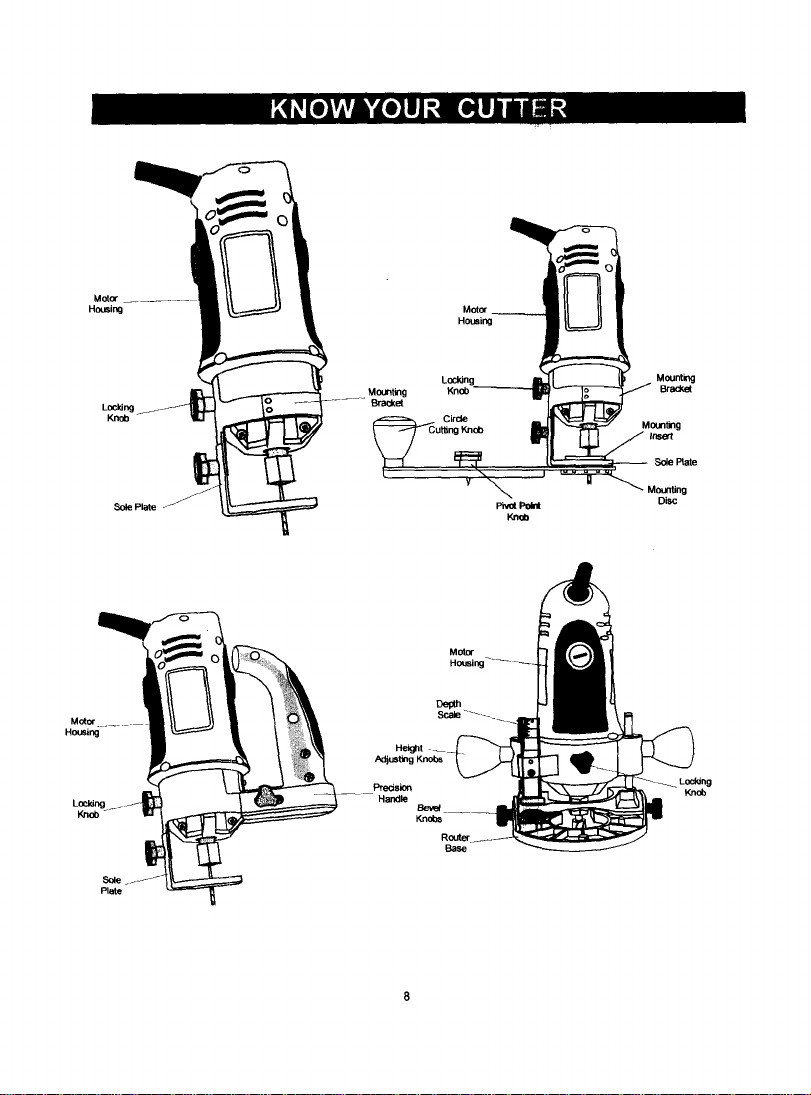

[_ [o,Io_

C

K41_e]vAvJk_e]l_ [e,]l]lil_l

Loddng

Knob

Motor .... _

Housing

Sole _/

Plate

Sole Plate _F_

|

Mou_ting L / MBr°Ua_

Circle

CutBng Knob Mir_g

Sole Plate

Y'_ J _'-_'"_ Mounting

Pi_ _ Disc

Adjusting Knobs

P_dsior_

Handle

eev_

KnObs

Router

Base

Locking

KnOb

IA WARNINGI

Remove the plug from the power source before

assembly, changing accessorkm or cutters and

making adjustments. This safety action wftl help

prevent accidental etarting of the tool which could

result In eertous Injury.

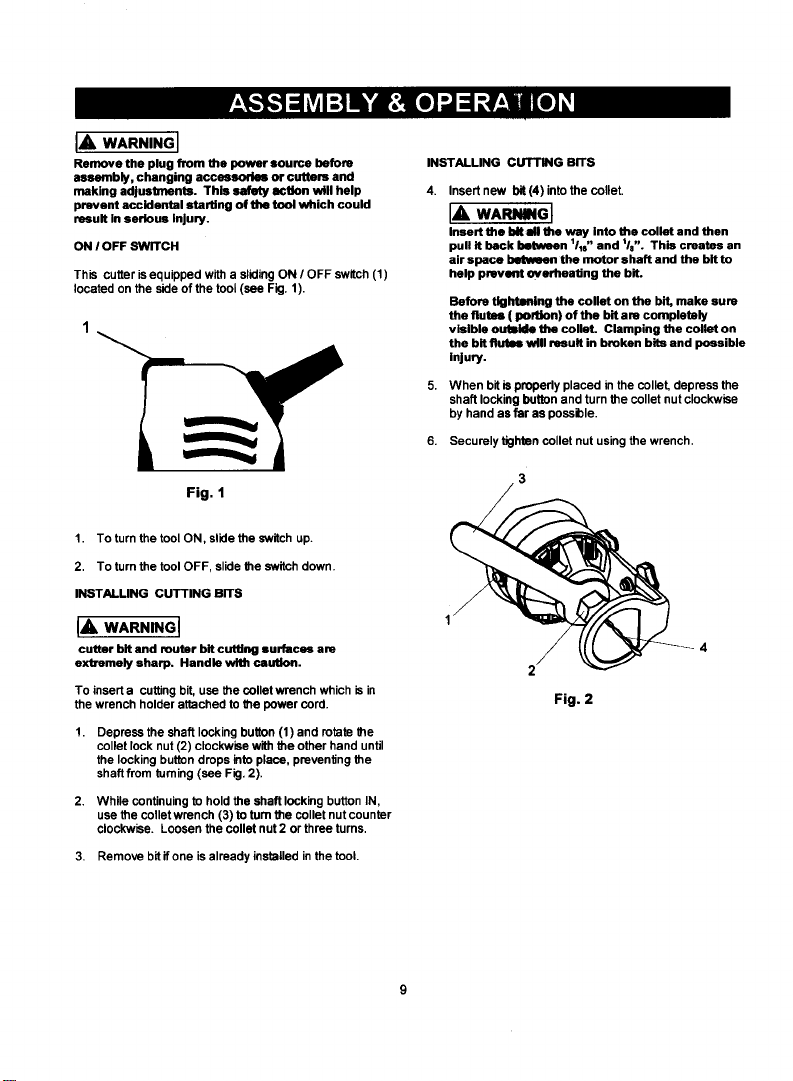

ON I OFF SWITCH

This cutter is equipped with a sliding ON / OFF switch (1)

located on the side of the tool (see Fig. 1 ).

Fig. 1

1. To turn the tool ON, slide the switch up.

2. To turn the tool OFF, slide the switch down.

INSTALLING CUTTING BITS

IA WARNING]

cutter bit and router bit cutting surfaces am

extremely sharp. Handle with caution.

To insert a cutting bit, use the collet wrench which is in

the wrench holder attached to the power cord.

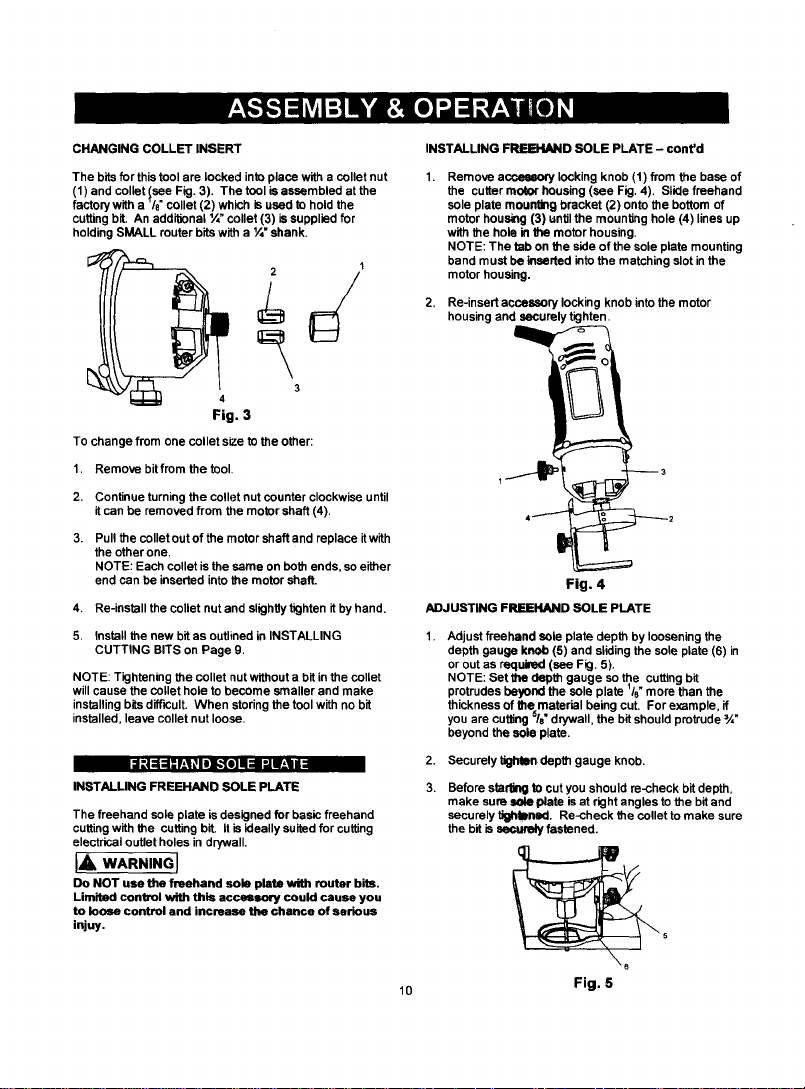

Depress the shaft locking button (1) and rotate the

collet lock nut (2) clockwise with the other hand until

the locking button drops into place, preventing the

shaft from turning (see Fig. 2).

2. While continuing to hold the shaft locking button IN,

use the collet wrench (3) to turn the collet nut counter

clockwise. Loosen the collet nut 2 or three turns.

3. Remove bit ifone is already installed in the tool.

INSTALLING CUTTING BITS

4. Insert new bit (4) into the colleL

I_ WARNING I

Insert the bit all the way Into the collet and then

pull it back between 111s"and tla". This creates an

airspace between the motor shaft and the bltto

help prevent overheating the bit.

Before tight=ruing the collet on the bit, make sure

the flutes (poItion) of the bit are completely

visible outside the colleL Clamping the collet on

the bit flutsl w#l result in broken bits and possible

injury.

5. When bit ispropedy placed in the collet, depress the

shaft locking button and turn the collet nut clockwise

by hand as far as possible.

6. Securely tighten collet nut using the wrench.

Fig. 2

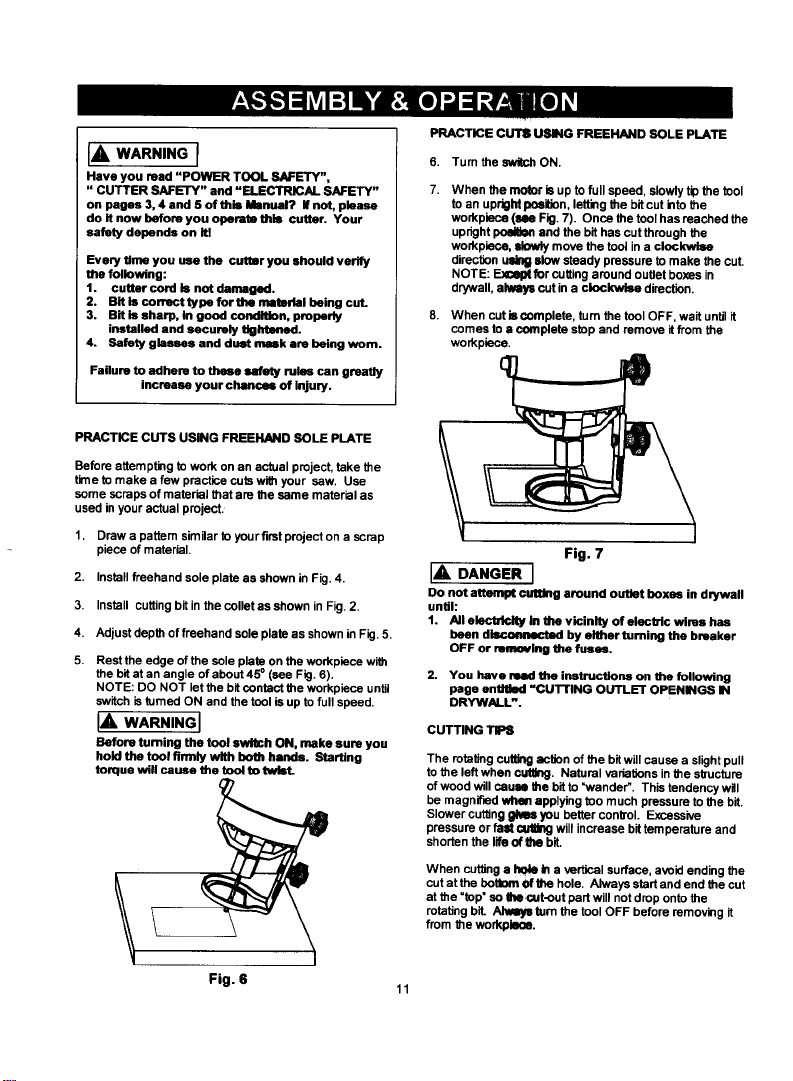

CHANGING COLLET INSERT

The bits for this tool are locked into place with a collet nut

(1) and collet lsee Fig. 3). The tool is assembled at the

factory with a "/8"collet (2) which is used to hold the

cutting bit. An addil_onal ¼" collet (3) issupplied for

holding SMALL router bits with a I/4" shank.

Fig. 3

To change from one collet size to the other:

1. Remove bit from the tool.

2. Continue turning the collet nut counter clockwise until

it can be removed from the motor shaft (4).

3. Pull the collet out of the motor shaft and replace it with

the other one.

NOTE: Each collet is the same on both ends, so either

end can be inserted into the motor shaft.

4. Re-install the collet nut and slighity tighten it by hand.

5. Install the new bit as outlined in INSTALLING

CUTTING BITS on Page 9.

NOTE: Tightening the collet nut without a bit in the collet

will cause the collet hole to become smaller and make

installing bits difficult. When storing the tool with no bit

installed, leave collet nut loose.

l:|=Izl==f±_l_li_ fo]II=l I'nI_II

INSTALLING FREEHAND SOLE PLATE

The freehand sole plate is designed for basic freehand

cutting with the cutting bit. It is ideally suited for cutting

electrical outlet holes in drywall.

IA WARNiNGJ

Do NOT use the freehand sole plate with router bits,

Limited control with this accessory could cause you

to loose control and increase the chance of serious

injuy.

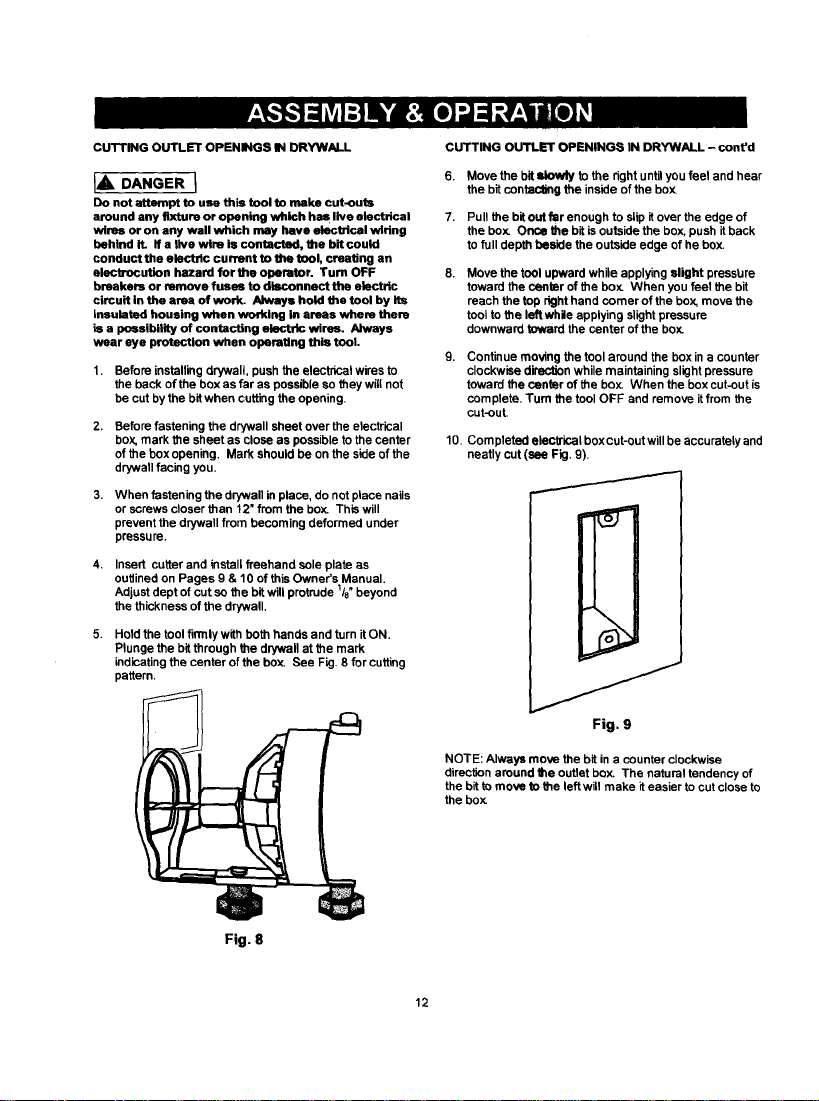

INSTALLING FREEHAND SOLE PLATE - cont'd

Remove a_ locking knob (1) from the base of

the cutter motor housing (see Fig. 4). Slide freehand

sole plate mounting bracket (2) onto the bottom of

motor housing (3) until the mounl_ng hole (4) lines up

with the hole in the motor housing.

NOTE: The tab on the side of the sole plate mounting

band must be inserted into the matching slot inthe

motor housing.

2. Re-insert accessorylocking knobintothe motor

housingand securelytighten.

Fig. 4

ADJUSTING FREEItAND SOLE PLATE

Adjust freehand sole plate depth by loosening the

depth gauge knob (5) and sliding the sole plate (6) in

or out as required (see Fig. 5).

NOTE: Bet the depth gauge so the cutting bit

protrudes beyond the sole plate '/8" more than the

thickness of the material being cut. For example, if

you are cutting 5/8" drywall, the bif should protrude ¾"

beyond the sole plate.

2. Securely tighfan depth gauge knob.

Before starting to cut you should re-check bitdepth,

make sure sole plate is at right angles to the bit and

securely t_ned. Re-check the collet to make sure

the bit is sec_ fastened.

10

Fig. 5

IAWARN,NOr

Have you read "POWER TOOL 8AI=ETY",

"CUTTER SAFETY" and "ELECTRICAL SAFETY"

on pages 3, 4 and 5 of thto Manual? If not, please

do It now before you operate thto cutter. Your

safety depends on ttl

Every time you use the cutmr you should verify

the following:

1. cutmr cord Is not damaged.

2. BIt is correct type for the matarlal being cut.

3. Bit to sharp, In 9God cond#lon, properly

installed and securely tighlMitted.

4. Safety glasses and dust mask are being wom.

Failure to adhere to these safety rules can greatly

increase your chances of Injury.

PRACTICE CUTS USING FREEHAND SOLE PLATE

Before attempting to work on an actual project, take the

time to make a few practice cuts with your saw. Use

some scraps of material that are the same materisl as

used in your actual project.

1. Draw a pattom similar to your f'wstproject on a scrap

piece of material.

2. Install freehand sole plato as shown in Fig. 4.

3. Install cutting bit in the collet as shown in Fig. 2.

4. Adjust depth of freehand sole plate as shown in Fig. 5.

Rest the edge of the sole plate on the workpiece with

the bit at an angle of about 45 ° (see Fig. 6).

NOTE: DO NOT let the bit contact the workpiece until

switch is tumed ON and the tool is up to full speed.

IA WARNINGI

Before turning the tool switch ON, make sure you

hold the tool flnnty with both hands. Starting

torque will cause the tool to twtot.

PRACTICE GUTS USING FREEHAND SOLE PLATE

6. Turn the switch ON.

7.

When the motor is up to full speed, slowly tip the tool

to an upright position, letting the hit cut into the

workpiece (lee Fig. 7). Once the tool has reached the

upright pceil_n and the bit has cut through the

workpiac.e, slowly move the tool in a clockwk_

diraction ulll_ slow steady pressure to make the cut,

NOTE: E._e_ for cutting around outlet bo_es in

drywall, always out in a clockwise direction.

When cut is cumpleto, turn the tool OFF, wait until it

comes to a complete stop and remove it from the

workpiece.

Fig. 7

IA DANGER I

Do not attempt ©uttlng around outlet boxes in dwwall

until:

1. All electricity lit the vicinity of electric wires has

been disr.olmectad by either turning the breaker

OFF or remmtlng the fuses.

2. You have mind the instructlous on the following

page entitled =CU'I-FING OUTLET OPENINGS IN

DRYWALL".

CUTTING TIPS

The rotating cuffing aclJon of the bit will cause a slight pull

to the left when cut_g. Natural vedatJons in the structure

of wood will cause the bit to "wander'. This tendency will

be magnified when applying too much pressure to the bit.

Slower cutting _ you better control. Excessive

pressure or fa_ _ will increase bit temperature and

shorten the life oflhe bit.

When cutting a hole b a vertical surface, avoid ending the

cut at the betll_it el' the hole. Always start and end the cut

at the "top" so ate cut.out part will not drop onto the

rotating bit. Alway= turn the tool OFF before removing it

from the workpleoe.

Fig. 6 I_

[,:][oT

CUTTING OUTLET OPENINGS IN DRYWALL CUTTING OUTLET OPENINGS IN DRYWALL - cont'd

IA DANGER I 6.

Do not attempt to use this tool to make cut-outa

around any fixture or opening which has live electdcal 7.

wires or on any wall which may have elect]rlcal wiring

behind it. If a live wire is contacted, the bit could

conduct the electric current to the tool, cresting an

electrocution hazard forths operator. Tum OFF 8.

breakers or remove fuses to disconnect the electric

circuit in the area of work. Aliways hold the tool by its

insulated housing when working In areas where there

is a possibility of contacting electric wires. Always

wear eye protection when operating this tool.

Before installing drywalH, push the electrical wires to

the back of the box as far as possible so they will not

be cut by the bit when cutting the opening.

Before fastening the drywall sheet over the electrical

box, mark the sheet as close as possible to the center

of the box opening. Mark should be on the side of the

drywall facing you.

3. When fastening the drywall in place, do not place nails

or screws closer than _2" from the box. This will

prevent the drywall from becoming deformed under

pressure.

Insert cutter and install freehand sole plate as

outlined on Pages 9 & 10 of this Owner's Manual.

Adjust dept of cut so the bit will protrude _/e" beyond

the thickness of the drywall.

Hold the tool firmly with both hands and turn it ON.

Plunge the bit through the dq/wall at the mark

indicating the center oF the box. See Fig. 8 for cutting

pattern.

Move the bit slowly to the right until you feel and hear

the bit contacting the inside of the bo_

Pull the bit out far enough to slip it over the edge of

the bo_ Onoe the bit isoutside the box, push it back

to full depth beside the outside edge of he box.

Move the tool upward while applying slight pressbre

toward the cenler of the bo_ When you feel the bit

reach the top right hand comer of the box, move the

tool to the left while applying slight pressure

downward toward the center of the bo:_

Continue moving the tool around the box in a counter

clockwise direc_n while maintaining slight pressure

toward the center of the box. When the box cut-out is

complete, Turn the tool OFF and remove it from the

cut-out.

10. Completed elec_ical box cut-out will be accurately and

neatly cut (see Fig. 9).

Fig. 8

Fig. 9

NOTE: Always move the bit in a counter clockwise

directten around the outlet box. The natural tendency of

the bitto move tothe left will make it easier to cut close to

the bo_

12

I-) lS"d5:][o)"-.] iOD]

•J_(_k,"l[e] _1I_"f__l_l|]ll III In= [qgiianil=l"

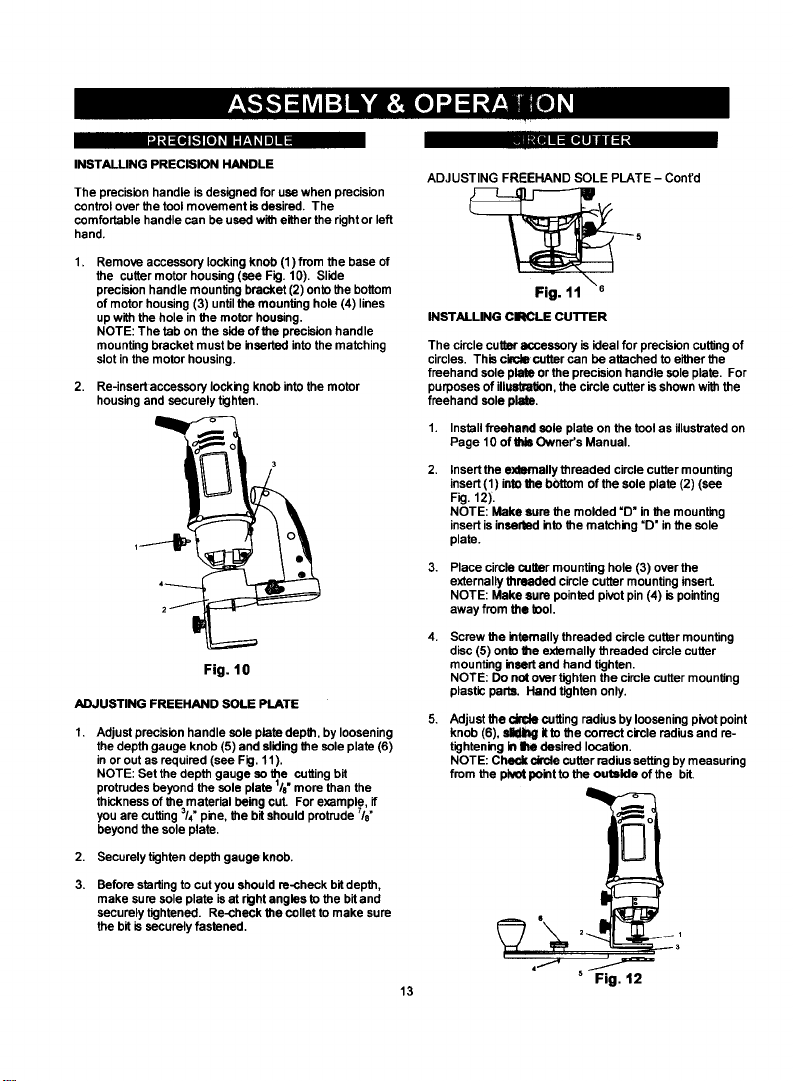

INSTALLING PRECISION HANDLE

The precision handle is designed for use when precision

control over the tool movement is desired. The

comfortable handle can be used with either the right or left

hand.

Remove accessory locking knob (1) from the base of

the cutter motor housing (see Fig. 10). Slide

precision handle mounting bracket (2) onto the bottom

of motor housing (3) until the mounting hole (4) lines

up with the hole in the motor housing.

NOTE: The tab on the side of the precision handle

mounting bracket must be inserted into the matching

slot in the motor housing.

2. Re-insert accessory locking knob into the motor

housing and securely tighten.

Fig. 10

ADJUSTING FREEHAND SOLE PLATE

Adjust precision handle sole plate depth, by loosening

the depth gauge knob (5) and sliding the sole plate (6)

in or out as required (see Fig. 11).

NOTE: Set the depth gauge so the cutting bit

protrudes beyond the sole plate Is" more than the

thickness of the material being cut. For example, if

you are cutting /4" pine, the bit should protrude Is"

beyond the sole plate.

2. Securely tighten depth gauge knob.

Before starting tocut you should re-check bitdepth,

make sure sole plate is at right angles to the bit and

securely tightened. Re-check the collet to make sure

the bit is securely fastened.

3 7

1

ADJUSTING FREEHAND SOLE PLATE - Cont'd

INSTALLING CIRCLE cU'rFER

The circle cutter accessory is ideal for precision cutttng of

circles. This cbcle cutter can be attached to either the

freehand sole plate or the precision handle sole plate. For

purposes of illustralten, the circle cutter is shown with the

freehand sole plate.

1. installfieeharKI sole plate on the toolas illustratedon

Page 10 of_ Owner's Manual.

insert the externally threaded circle cutter mounting

insert (1) into Ute bottom of the sole plate (2) (see

Fig, 12),

NOTE: Make sure the molded "D" in the mounting

insert is inserted into the matching "D" in the sole

plate.

Place circle cutter mounting hole (3) over the

externally threaded circle cutter mounting insert.

NOTE: Make sure pointed pivot pin (4) is pointing

away from the tool.

Screw the internally threaded circle cutter mounting

disc (5) onto the externally threaded circle cutter

mounting insert and hand tighten.

NOTE: Do not over tighten the cimle cutter mounting

plastic parts, Hand tighten only.

Adjust the dr{de cutting radius by loosening pivot point

knob (6), _ It to the correct circle radius and re-

tightening In Ire desired location.

NOTE: C_ drcte cutter radius setting by measuring

from the pivot point to the outside of the bit,

13

Fig. 12

I]I _MII mR[_-_--- --

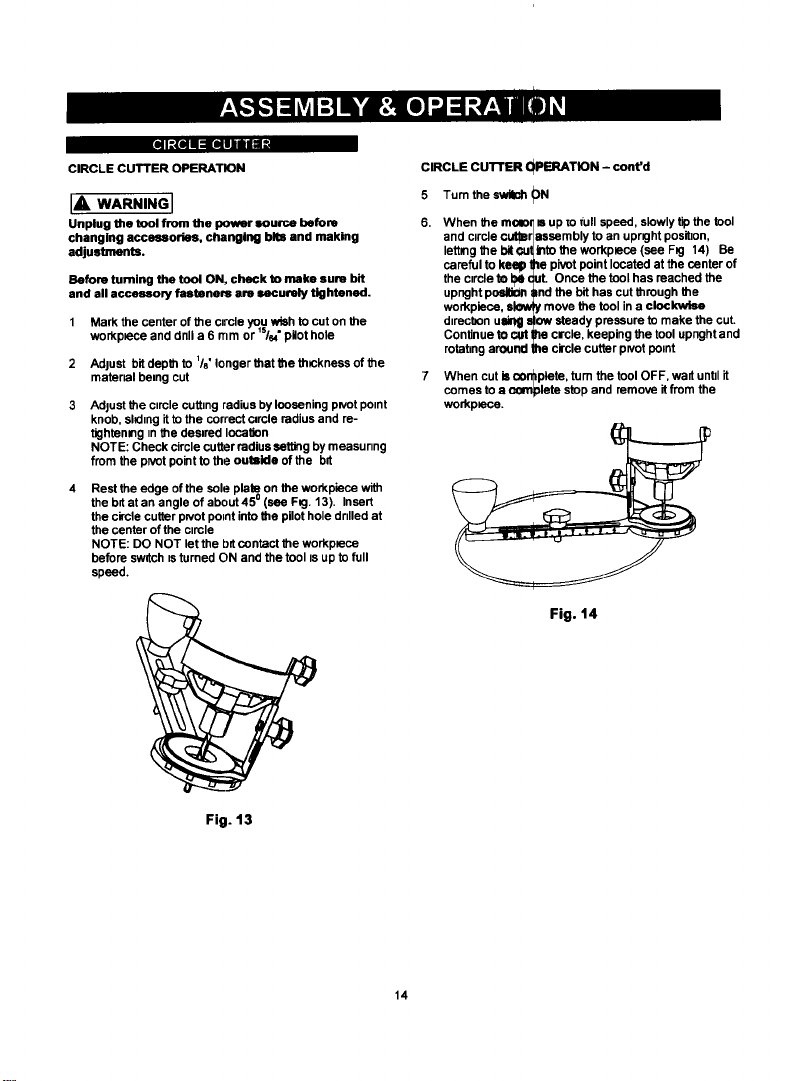

CIRCLE CUTTER OPERATION

IA WARNINGI

Unplug the tool from the power source before

changing accessories, changing bits and making

adjustments.

Before turning the tool ON, check to make sum bit

and all accessory fasteners are securely tightened.

1 Mark the center of the circle you wish to cut on the

workplace and dnll a 6 mm or s/, pilot hole

2 Adjust bit depth to l/o" longer that the thlckness of the

material being cut

Adjust the ctmle cuitmg radius by loosening pivot pomt

knob, sl_tng itto the correct c_rcle radius and re-

tightemng tn the desired Iocafion

NOTE: Check circle cutter radius setting by measunng

from the pNot point to the outside of the bit

Rest the edge of the sole plato on the workplace with

the bd at an angle of about 450 (see F_j. 13). Insert

the circle cutter p_votpotnt into the pilot hole drilled at

the center of the circle

NOTE: DO NOT let the bit contact the workptece

before switch tsturned ON and the tool is up to full

speed.

CIRCLE CUTTER QPERATION - cont'd

5 Tumthe_0N

6. When the molo_ m up m full speed, slowly tip the tool

and circle cuter assembly to an uprK3ht position,

letting the bitcu_lnto the workpiace (see FK3 14) Be

careful to keep the pivot point located at the center of

the ctrcle to N Cut. Once the tool has reached the

upnght posl_n and the bit has cut through the

workpiece, ak_ move the tool in a clockwise

dtrecbon ulblg slow steady pressure to make the cut.

Continue tO c,_ _ circle, keeping the tool upnght and

rotating around the circle cutter pivot potnt

7 When cut is con_ptete, tom the tool OFF, wa_ unttl it

comes to a ocmplete stop and remove it from the

workpN_3e.

Fig. 14

Fig. 13

14

;|O|IPlll = =4I-'f_-_-_

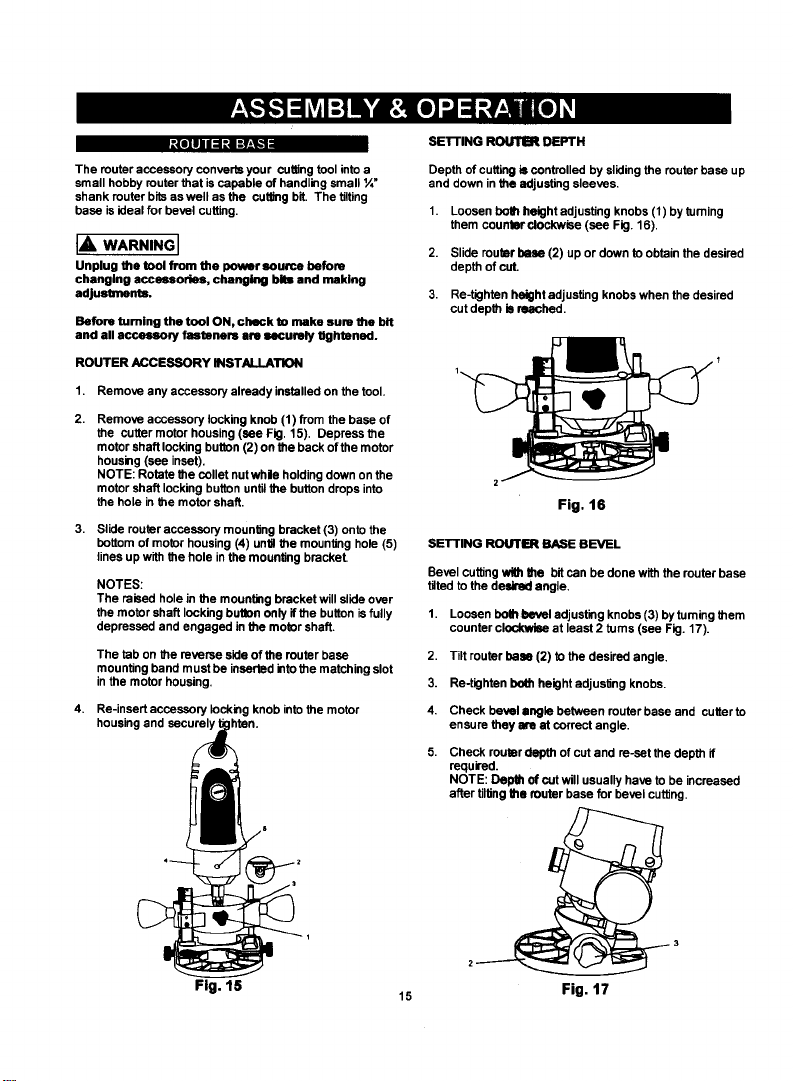

The router accessory converts your cuffing tool into a

small hobby router that is capable of handling small 1/4,

shank router bits as well as the cuffing bit. The tilting

base isideal for bevel cutting.

IA WARNiNGI

Unplug the tool from the powor source before

changing accessories, changing bits and making

adjustments.

Before tuming the tool ON, check to make sure _e bit

and all accessory fastonere ere securely tightened.

ROUTER ACCESSORY INSTALLATION

1. Remove any accessory already installed on the tool.

Remove accessory locking knob (1) from the base of

the cutter motor housing (see Fig. 15). Depress the

motor shaft locking button (2) on the back of the motor

housing (see inset).

NOTE: Rotate the collet nut whle holding down on the

motor shaft locking button until the button drops into

the hole in the motor shaft.

3. Slide router accessory mounitng bracket (3) onto the

bottom of motor housing (4) unUl the mounting hole (5)

lines up with the hole in the mounting bracket.

NOTES:

The raised hole in the mounting bracket will slide over

the motor shaft locking button only if the button is fully

depressed and engaged in the motor shaft.

The tab on the reverse side of the router base

mounting band must be inserted into the matching slot

in the motor housing.

4. Re-insert accessory locking knob into the motor

housing and securely I hten.

SETFING ROUTIER DEPTH

Depth of cutting is controlled by sliding the router base up

and down in the adjusting sleeves.

1. Loosen both height adjusting knobs (1) by turning

them countm'clockwise (see Fig. 16).

2. Slide router bose (2) up or down to obtain the desired

depth of cut.

3. Re-tighten height adjusUng knobs when the desired

cut depth is reached.

Fig. 16

SETTING ROUTER BASE BEVEL

Bevel cuffing with the bit can be done with the router base

ti/ted to the deldred angle.

1. Loosen both bevel adjusting knobs (3) by tuming them

counter clockwise at least 2 turns (see Fig. 17).

2,

Tilt router base (2) to the desired angle,

3.

Re-tighten both height adjusitng knobs.

4,

Check bevel angle between router base and cutter to

ensure they are at correct angle.

Check router depth of cut and to-set the depth if

required.

NOTE: Depth of cut will usually have to be increased

after tilting the router base for bevel cuffing.

Fig. 15

15

Fig. 17

Loading...

Loading...