Page 1

Page 2

THE POWER ROUTER

..

ROUTER BITS

ROUTER ACCESSORIES.

GENERAL

CONTOUR WORK

STRAIGHT-LINE

CI

RCLES & FRAMES

ROUTING

INSTRUCTION'S

&

SURFACING

ROUTING & EDGING

...

. . .

CARVING & LETTERING ....

&

TAPER ROUTING

PATTERN

DOVETAIL

BUTT

&

TEMPLATE

JOINTING ............

HINGE & LOCK-FACE

LAMINATED

SHARPENING

33 WOOD

Two

Types

JOINTS

Homemade

of

End, Middl

Middle Lap on

FLUTING

ROUTING

PLASTICS

CUTTING

BITS & CUTTERS

- HOW TO

Holding

Cuts . . . . . . . . . . . .

e,

Tee and Half-Lap

Edge

With

Dovetail Lap

Cogged

Joint

Box

Joint

Dado

Joints

Mortise

Tongue and Groove

Mitered

Lock

THE

Joint ...... . .

SHAPER

and Tenon

Joints

TABLE

Joints

Joint

....

. .

ACCESSORY

. . . .

....

.

& EDGING

ROUTING ... .

& EDGING

.....

ROUT

THEM:

Fixtures . .

Joints

Groove

PAGE

3

4

5

6

9

10

12

13

14

16

.

18

19

20

.

21

22

22

26

27

27

27

27

28

29

30

30

31

32

DO

DO

DO

DO

All

operations explained

formed with any Sears Router equipped with the

cessories designed and sold for use with the router.

BE A CRAFTSMAN-LIKE

Disconnect the

when installing or removing

and tighten the chuck securely after in-

stalling a bit.

NOT

Make any adjustments

workpiece while the tool

Keep your tool,

NOT

Use

dull, rusted,

or

allow sawdust to clog the tool

air vents.

A MIDWEST

Catalog No.

too

l from power source

of

is

motor

and cutters clean.

bent

or gummed bits -

TECHNICAL

2948

router

your

tool

running.

PUBLICATION

bits-

or

motor

REV. 1972

NOTE

in

this book can be per-

TOOL

DO

DO

DO Keep a firm, two-handed hold on your

DO

Make certain that

move during an operation.

NOT

Attempt

hand while guiding the tool with your

other hand.

tool throughout each operation.

NOT

Let your attention stray,

tool carelessly.

ac-

"PILOT"

your

to hold workpiece with one

Copyr

igh

ted

ROEBUCK

Printed

1969

and

SEARS,

workpiece cannot

or

CO.

in

U .S .A

handle your

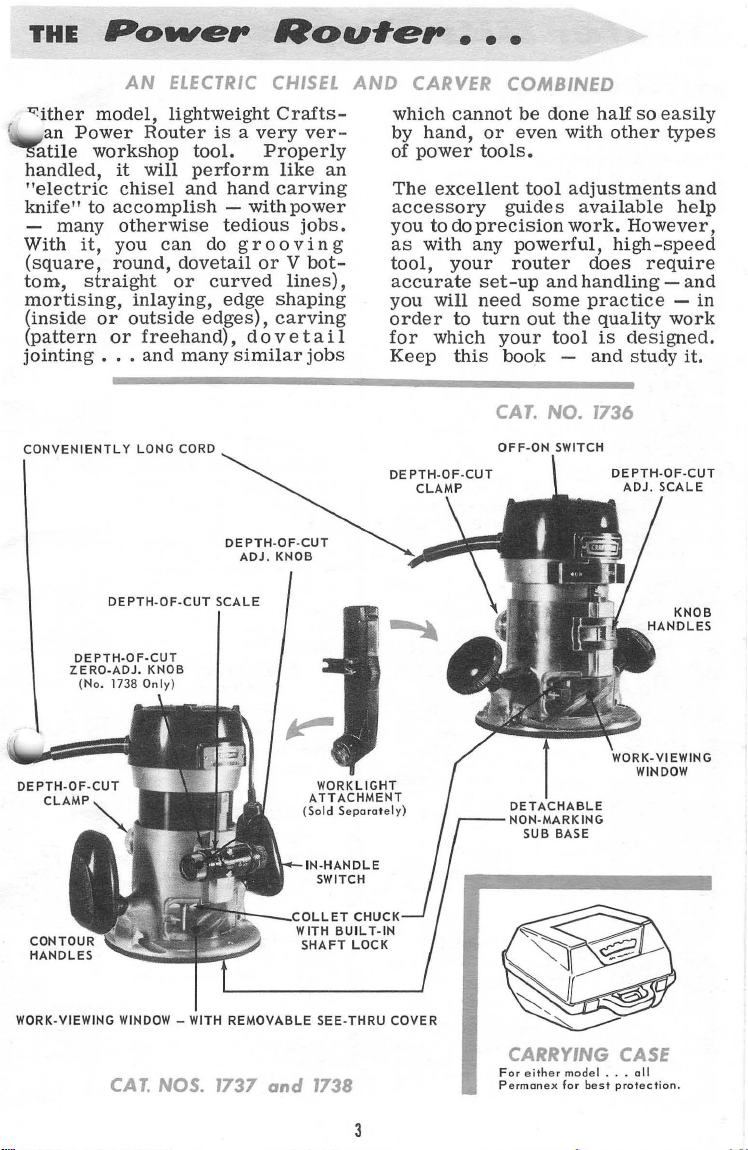

Page 3

THE

~ither

atile

an

Power

POlMer

model,

workshop

handled,

"electric

knife"

-

With

to

many

it,

(square,

tom,

straight

mortising,

(inside

(pattern

jointing

CONVENIENTLY

or

or

...

Rou#e,.

AN

ElECTRIC

lightweight

Router

tool.

it

will

chisel

perform

and

accomplish -with

otherwise

you

can

round,

do

dovetail

or

curved

inlaying,

outside

edges),

freehand),

and

many

LONG CORD

CHISEL

is a very

Properly

hand

tedious

grooving

or V bot-

edge

shaping

carving

do

vet

similar

DE

PTH-Of-CUT

ADJ_

KNOB

Crafts-

ver-

like

an

carving

power

jobs.

lines),

ail

jobs

AND

CARVER

which

cannot

by

hand,

of

power

The

excellent

accessory

you

to

as

tool,

do

with

your

accurate

you

will

order

for

Keep

to

which

this

..•

COMBINED

or

tools.

guides

precision

any

router

set-up

need

turn

your

book

CAT.

Off-ON

be

done

even

with

tool

adjustments

available

work.

powerful,

and

handling -and

some

out

the

tool

-

NO.

SWITCH

half

so

easily

other

types

and

help

However,

high-speed

does

require

practice -in

quality

is

and

work

designed.

study

it.

1736

DEPTH-OF-CUT

ZERO-ADJ_ KNOB

(No_ 1738

WORK-VIEWING

DEPTH-Of-CUT

Only)

WINDOW

CA

T.

SCALE

- WITH

REMOVABLE

NOS. 1737 and 1738

WORKLIGHT

ATTACHMENT

(Sold

Separately)

SEE-THRU

3

COVER

CARRYING

For

either

Permon

model ...

ex

for best

CASE

all

protection

.

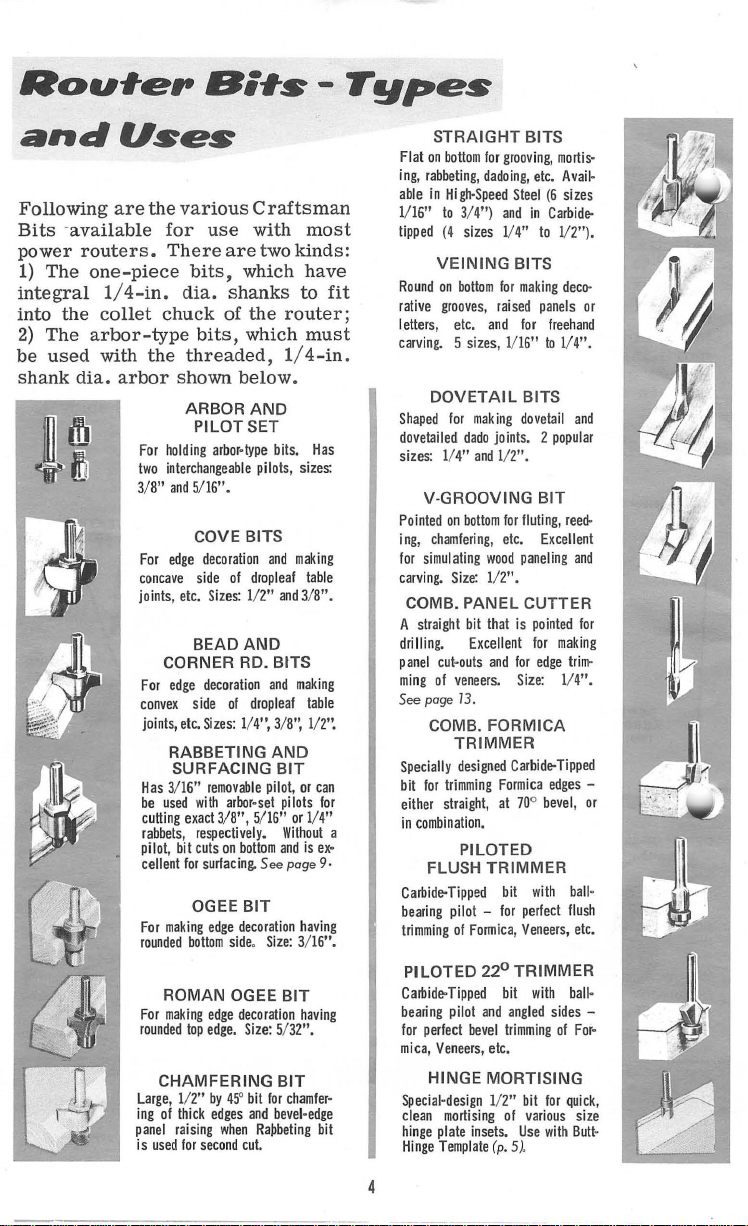

Page 4

Rou#e"

S;#s

-

Types

and

Following

Uses

are

the

Bits 'available

power

1)

The

routers.

one-piece

integral 1/4-in.

into

the

collet

2)

The

arbor-type

be

used

with

the

shank

dia.

arbor

For

two

3/8"

For

concave

joints,

F

or

convex

joints,

Has 3/16"

be

cutting

rabbets,

pilot, bit

cellent

For

rounded

For

rounded

Large,

ing

panel

is

used

various

for

There

bits,

dia.

chuck

use

of

bits,

Craftsman

with

are

two

which

shanks

the

which

router;

threaded, 1/4-in

shown

holding

interchangeable

and

edge

CORNER RD. BITS

edge

RABBETING

SURFACING

used

making

ROMAN OGEE

making

CHAMFERING

112"

of

thick

raising

below.

ARBOR

PILOT

arbor·type

S/ 16".

COVE BITS

decoration

side

of

etc.

Sizes:

BEAD

AND

decoration

side

of

etc.

Sizes:

1/4",3/

removable

with

arbor-set

exact

3/8",

respectively.

cuts

on

bottom

for

surfacing. See

OGEE

BIT

edge

decoration

boltom

side. Size: 3/16".

edge

decoration

top

edge.

by 4S'

edges

when

for

second

cut.

AND

SET

bits.

pilots,

and

drop

leaf

1/2"

and

and

drop

leaf

AND

BIT

pilot,

pilots

S/16"

Without

and

BIT

Size:

S/ 32".

BIT

bit

for

and

bevel-edge

Rapbeting

8",

page 9·

chamfer

most

kinds:

have

to

fit

must

Has

sizes

:

making

table

3/8".

making

table

1/2".

or

can

for

or

1/4"

a

is

ex-

having

having

-

bit

.

STRAIGHT

Flat

on

bottom

ing,

rabbeting,

able

in

High-Speed

1/16"

to

3/4")

tipped

(4

sizes

VEINING

Round

on

bottom

rative

grooves,

I

etters, etc.

carving

. S

sizes,

DOVETAIL

Shaped

for

dovetailed

sizes:

Pointed

ing,

for

carving.

COMB.

A

drilling.

panel

ming

See

Specially

bit

either

in

Carbide-Tipped

bearing

trimming

PILOTED

Carbide-Tipped

bearing

for

mica,

Special·design

clean

hinge

Hinge

mak

dado

114"

and

V-GROOVING

on

bottom for

chamfering, etc.

simulating

Size:

PANEL

straight

bit

Excellent

cut-outs

of

veneers.

page 1

3.

COMB. FOR

TRIMMER

designed

for

trimming

straight,

combination.

PILOTED

FLUSH

pilot -

of

Formica, Veneers,

pilot

perfect

bevel

Veneers, etc

HINGE

mortising

plate

insets.

Template

BITS

for

grooving, mortis·

dadoing,

etc.

Steel

(6

and

in

Carbide-

1/4"

to

1/ 2").

BITS

for

making

rai

sed

panels

and

for

freehand

1/16"

to

BITS

ing

dovetail

joints. 2

popular

1/2".

BIT

fluting,

Excellent

wood

paneling

112".

CUTTER

that

is

pointed

for

and

Formica

at 70°

TRIMMER

22°

and

MORTISING

1/2" bit

(p

making

for

edge

Size: 114".

MICA

Carbide-Tipped

edges

bevel,

bit

with

for

perfect

TRIMMER

bit

with

angled

sides

trimming

of

.

for

of

various

Use

with

. 5).

Avail

sizes

deco-

114".

and

reed-

and

for

trim

ball

flush

etc.

ball

For-

quick

size

Butt

·

or

·

-

or

-

-

-

,

-

4

Page 5

Raul-e,.

Aeeesso

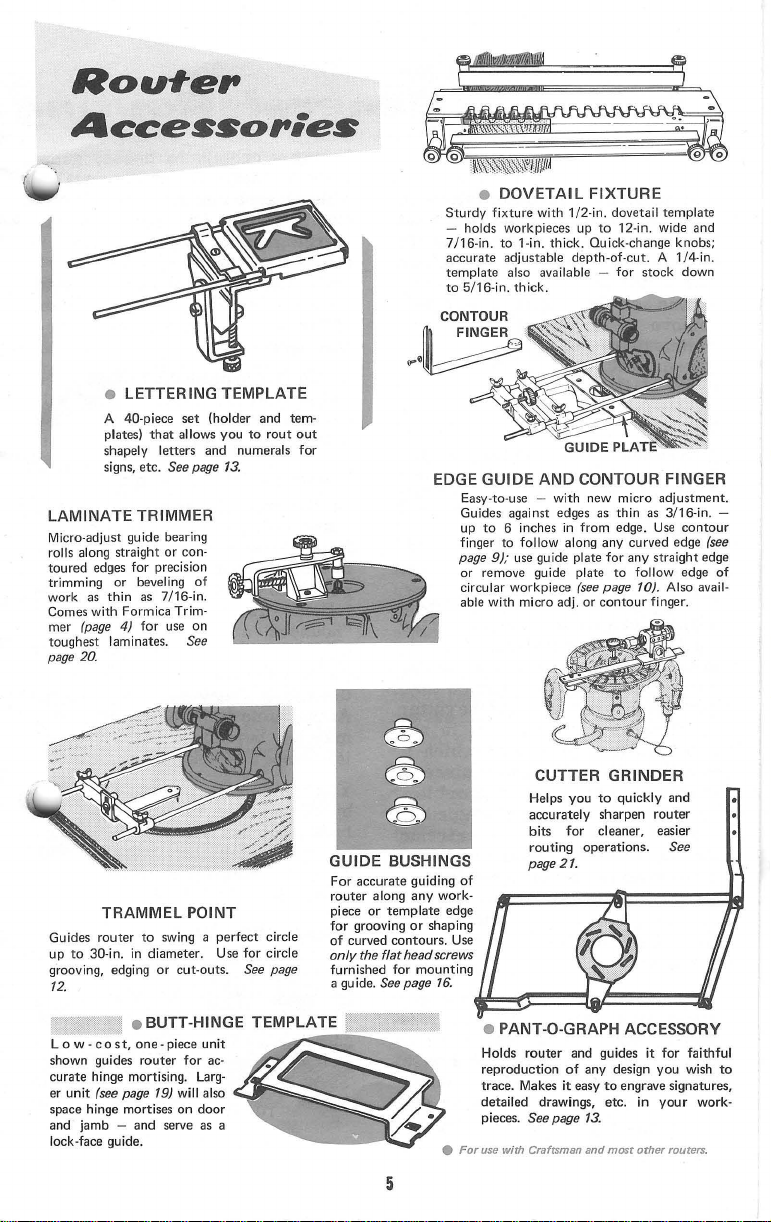

• LETTERING TEMPLATE

A 40-piece

plates)

shapely letters and numerals for

signs, etc.

LAMINATE

Micro-adjust guide bearing

rolls along straight

toured edges for precision

trimming or

work

as

thin as 7/16-in.

Comes with Formica

mer (page

toughest

page 20.

4)

laminates.

set

that

allows you

See

page

TRIMMER

or

con-

beveling

Trim-

for use on

See

·

,.;es

(holder and tem-

to

rout

13.

of

out

•

DOVETAIL FIXTURE

Sturdy

fixture with 1/2-in. dovetail template

- holds workpieces up

7/16-in.

to

accurate

template also available - for stock down

to

EDGE

page

1-in. thick. Quick-change knobs;

adjustable depth-of-cut. A l/4-in.

5/16-in. thick .

GUIDE

Easy-to-use - with new micro adjustment.

Guides against edges as thin

to

6 inches

up

finger to follow along any curved edge

9);

use guide plate for any straight edge

or remove guide

circular workpiece

able

with micro adj. or

to

12-in. wide and

AND

CONTOUR FINGER

in

from edge.

plate

to

(see

page 10). Also avail-

contour

as

3/16-in. -

Use

follow edge

finger.

contour

(see

of

TRAMMEL

Guides router

up

to

30-in.

grooving, edging

12.

low -cos

shown guides router for

curate hinge mortising . larger

space hinge mortises on

and jamb - and serve as a

lock-face guide.

unit

(see

t,

page 19) will also

POINT

to

swing a perfect circle

in

diameter. Use for circle

or

cut-outs.

one

-piece unit

ac-

door

See

page

GUIDE

only

BUSHINGS

For accurate guiding

router along

piece

for grooving

of

curved contours. Use

furnished for mounting

a

gu

the

ide.

or

template

flat

See

any

work-

edge

or

shaping

head

screws

page

16.

• For use with Craftsman and

5

CUTTER

Helps

you

accurately sharpen

bits

for

routing operations.

page

of

21.

• PANT-O-GRA

Holds

router

reproduction

trace. Makes

detailed drawings, etc. in

pieces. See page

and guides

of

any design you wish

it

easy

13.

GRINDER

to

quickly and

router

cleaner, easier

PH

to

most

See

ACCESSORY

it

for faithful

engrave signatures,

your

other routers.

to

work-

Page 6

General

THE

SUB-BASE

The

phenolic

to

the

base

screws)

surface

mar a fine

ditions

remove

tachments

RATE

•••••••••••••••••••••••••••••••••

:

:

The

:

:

~~i~:

: to

•••••••••••••••••••••••••••••••••

whole

routing

be

made.

or

OF

"Force

Clean,

shaping

cutting

atively

very

cleanly

revolves

lation

advances

must

. . .

a

slow-down

become

be

than

ant

workpiece.

smooth

can

tool

high

small

severed

to

necessarily

to

produce

rougher

so

partially

fully

splintering

sub-base

with

three

provides a glass-smooth

which

will

workpiece.

instructions

it

for

using

or

set-ups.

FEED

IMPORTANT

"secret"

and

shaping

/:~;:f:l

f::~~p

(attached

pan-head

not

scratch

When

con-

warrant,

certain

of

professional

lies

in

select-

fo·r~:

c~~

feeding"

routing

be

done only when

is

revolving

speed

bites

to

chips.

at a slower

the

speed

through

finish.

conditions

large

cut

the

take

bigger

that

knocked

off)

...

and

and

at a rel-

and

is

produce

If

the

rpm

with

which

workpiece,

bigger

chips

Under

extreme

the

bites

the

chips

off

with

result-

gouging of

edge

taking

tiny,

cutter

in

re-

bites

and

can

will

(rather

or

at-

the

it

it

the

having a certain

miness,

which

ficult.

"force

the

motor.

will

it

loses

of

holding

ably

In

addition

chipped)

overload

:

it

:

:

:

:

to

"Standstill

At

the

"standstill

from

is

not

cutter

lution. As a

''bounces''

made

the

sides

them

At

the

may

its

temper -and

You

by

listening

highly-pitched

or

by

which

in

its

Proper

Rou#;ng

hardness,

dampness

makes

sound

increased.

overheat,

feeding

. . .

. . .

same

be

can

the

cut.

cutting

You

can

feeding"

speed.

to

work,

the

by

Its

high-pitched

lower

the

tool

producing

"force

motor

and

Feeding"

opposite

enough new wood

to

bite

of

burned

detect

feeling

cutter

extreme

feeding".

so

slowly

into

result,

around

may

score

the

cut

may

even

time

so

"standstill

to

the

sound

the

is

in

the

Feeding

or

other

relatively

always

the

and

stronger

Also,

the

will

be

rough

feeding"

...

will

may

damage

This

that

with

each

the

the

cut

and

...

may

burn

cutter,

that

its

sharpness.

"runaway"

of

the

"wiggle"

bouncing

•••

gum-

qual

detect

sound

"whir"

strain

notice-

(even

cause

there

results

there

for

revo-

cutter

already

ripple

glaze

them.

itself,

it

loses

feedi"

motor;

with

around

d

of

as

will

it.

is

the

Your

router

speed

speed),

proportion

"Force

"Force

vance

cut

tool

but

feeding"

feeding"

too

being

is

an

(25,000

it

will

to

the

rapidly

taken

extremely

rpm

slow

load

placed

will

slow

is

trying

for

the

in a

high-

no-load

down

workpiece

it

down.

to

size

on

in

it.

ad-

of

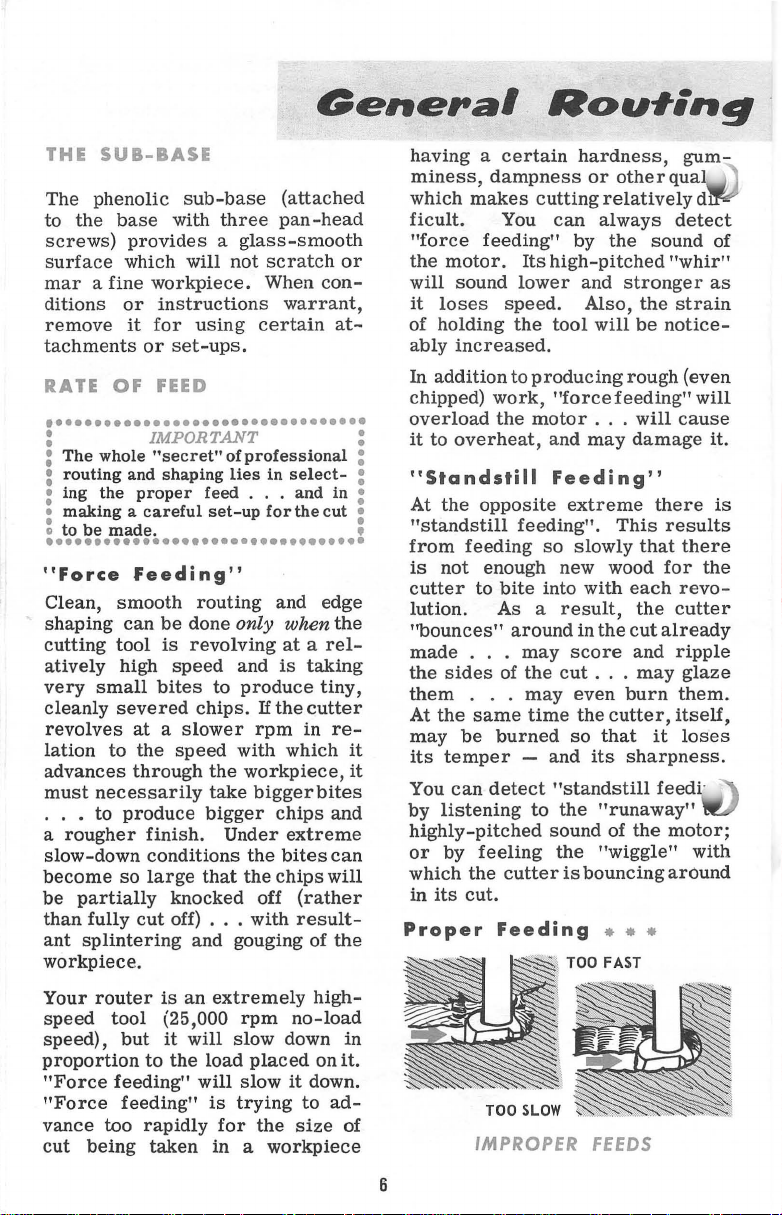

IMPROPER

6

FEEDS

Page 7

'ns",,.ue#/ons

The

right

feed

is

neither

.

"standstill".

hich

and

surely

noticeable

work.

diameter

wood, the

as

along

hand,

is

gummy

proper

There

have to

by

possible,

made

wood.

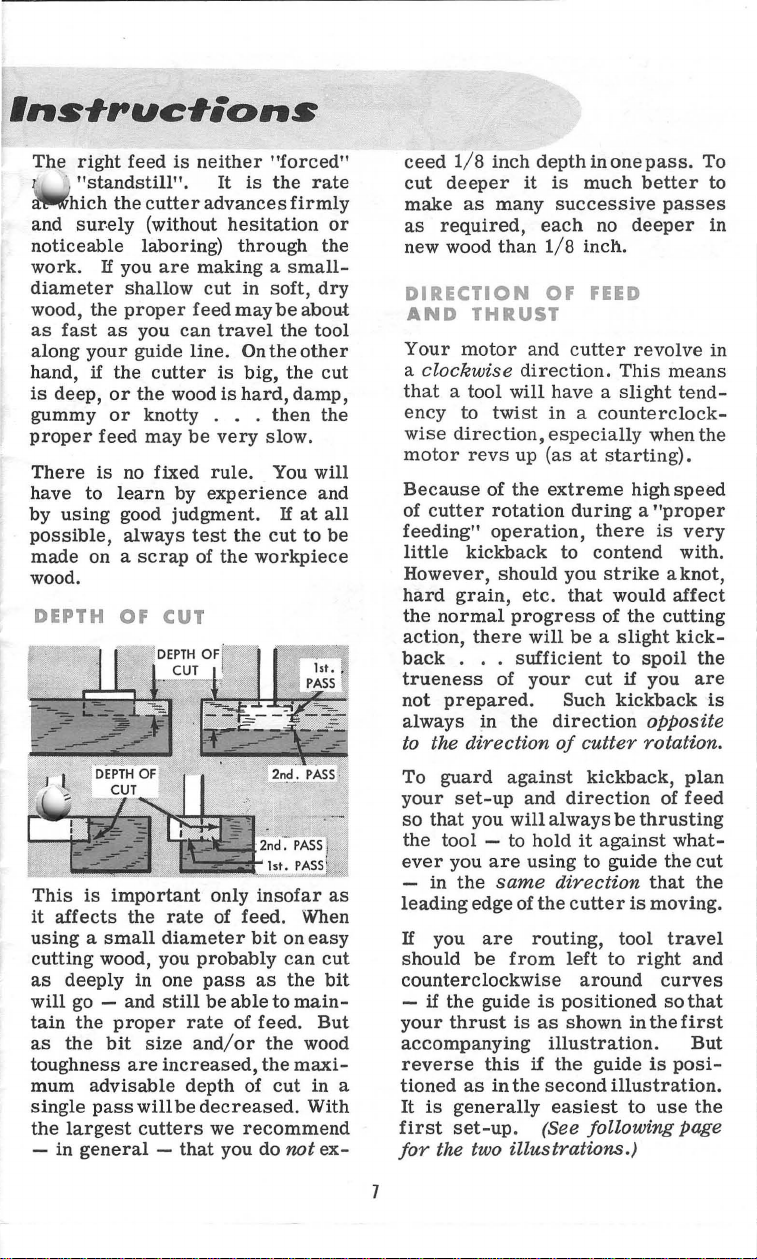

DEPTH

If

fast

your

if

deep,

feed

is

using

on a

the

cutter

(without

laboring)

you

shallow

proper

as

you

guide

the

cutter

or

the

or

knotty . . .

may

no fixed

learn

good judgment. If

always

scrap

OF

It

is

advances

hesitation

through

are

making a small-

cut

in

feed

may

can

travel

line.

On

is

big,

wood

is

hard,

be

very

rule.

by

experience

test

the

of

the

CUT

workpiece

"forced"

the

rate

firmly

the

soft,

dry

be

about

the tool

the

other

the

cut

damp,

then

the

slow.

You will

and

at

all

cut

to

or

be

ceed

1/ 8

inch

cut

deeper

make

as

required,

new wood

DIRECTION

AND

Your

motor

clockwise

a

that

a tool

ency

to

wise

direction, especially

motor

Because

of

cutter

feeding"

little

However,

hard

grain,

the

normal

action,

back

. . .

trueness

not

prepared.

always

to

the direction

it

as

many

than

THRUST

direction.

will

twist

revs

up (as

of

the

rotation

operation,

kickback

should

etc.

progress

there

sufficient

of

in

the

depthinonepass.

is

much

better

successive

each

no

1/8

inch

OF

FEED

and

cutter

have a slight

in a counterclock-

at

extreme

during a "proper

there

to

contend

you

that

of

will

be a slight

your

cut

Such

direction

of

cutter

passes

deeper

.

revolve

This

when the

starting).

high

is

strike

would

the

cutting

to

spoil

if

you

kickback

opposite

rotation.

To

to

in

in

means

tend-

speed

very

with.

aknot,

affect

kick-

the

are

is

This

is

important

it

affects

using a small

cutting

as

deeply

will

tain

as

the

toughness

mum

single

the

largest

- in

the

wood, you

in one

go - and

the

proper

bit

are

advisable

pass

will

general -that

rate

diameter

probably

still

rate

size

and/or

increased,

depth of

be

cutters

only

insofar

of

feed.

bit

pass

as

be

able

to

of

feed. But

the

the

cut

decreased.

we

recommend

you do not

When

on

can

the

main-

wood

maxi-

With

as

easy

cut

bit

in a

ex-

To

guard

your

set

-up and

so

that

you

the

tool

- to hold

ever

you

- in

the

leading

If you

should

counterclockwise

-

your

accompanying

reverse

tioned

It

first

for

edge

are

be

if

the

guide

thrust

this

as

is

generally

set-up.

the two illustrations.)

7

against

will

are

same

of

from

is

in

the

kickback,

direction

always

it

against

using

to guide

direction

the

cutter

routing,

left

around

is

positioned

as

shown in

illustration.

if

the

guide

second

easiest

(See following page

plan

of

feed

be

thrusting

what-

the

cut

that

the

is

moving.

tool

travel

to

right

and

curves

so

that

the

first

But

is

posi-

illustration.

to

use

the

Page 8

::::;=

~

_LEADING

ED(;E

3.

THRUSl

'#"IH,jtl

0"",",

~

_ ROTATION Inside

~

..

.,

LEADING

EDGE

-

"-1/

THRUST

/f\

...-FEED

THRUST

l ROTATION

~

,.-

...

FEED

..

\

A

"CHOPPING"

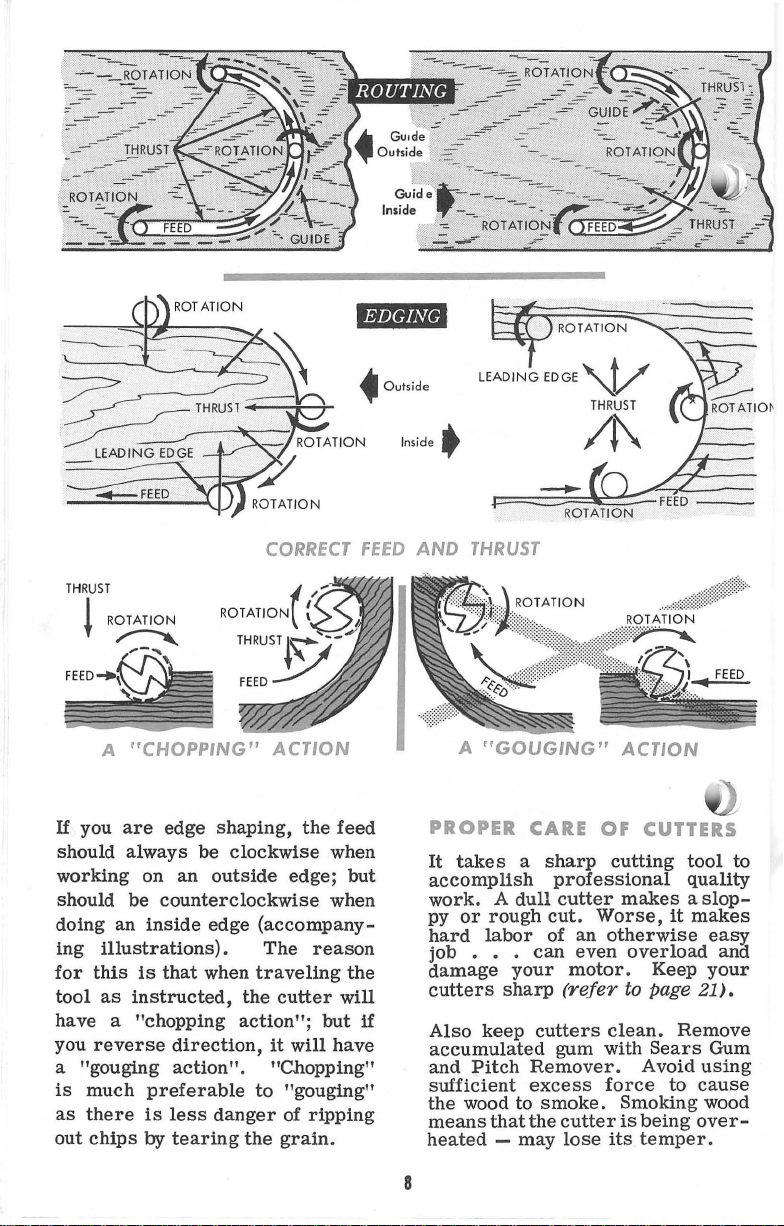

If

you

are

edge

should

working on

should be

doing an

ing

for

tool

have a "chopping

you

a "gouging

is

as

out

always

an

counterclockwise

inside

illustrations).

this

is

that

as

instructed,

reverse

much

there

chips

direction,

action".

preferable

is

less

by

tearing

be

outside

edge

when

danger

ROTAT

CORRECT

ACTION

shaping,

clockwise

(accompany-

The

traveling

the

cutter

action";

it

"Chopping"

to

the

grain.

ION

FEED

the

feed

when

edge;

but

when

reason

the

will

but

if

will

have

"gouging"

of

ripping

AND

THRUST

A

"GOUGING"

PROPER

It

takes a sharp

accomplish

work. A dull

py

or

rough

hard

labor

job

...

damage

cutters

Also

accumulated

and

sufficient

the

means

heated -may

your

sharp

keep

Pitch

wood to

that

ROTATION

···:·:::::ti(·~

CARE

can

OF

professional

cutter

cut.

Worse,

of

an

even

motor.

(refer

cutters

gum with

Remover.

excess

smoke.

the

cutter

lose

ROTATION

ACTION

CUTTERS

cutting

makes a slop-

otherwise

overload

to

clean.

force

Smoking wood

is

its

tool

quality

it

makes

Keep

page

21).

Remove

Sears

Avoid

to

cause

being

over-

temper.

your

using

to

easy

ana

Gum

8

Page 9

Con

#0

u,.

Wo,.kancl

~u,.#ae;ng

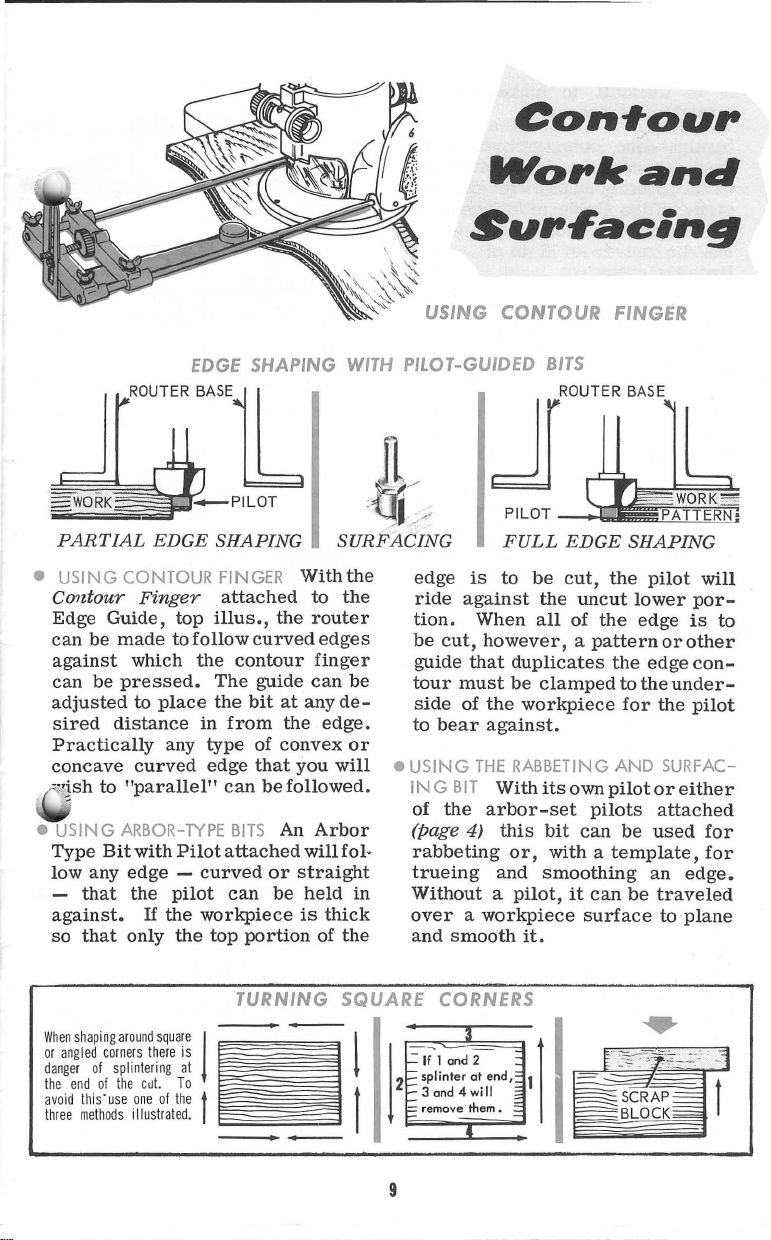

CONTOUR FINGER

PARTIAL

•

USING

Contour

Edge Guide, top

can

be

against

can

adjusted

sired

Practically

concave

--(lsh

EDGE

CONTOUR FINGER With

Finger

made

which

be

pressed.

to

distance

curved

to

"parallel"

"

•

USING

Type

low any

-

against.

so

ARBOR-TYPE

Bit

with

edge -curved

that

the

If

that

only

EDGE

SHAPING

attached

illus

to follow

the

contour

The

place

the

in

from

any type of

edge

can

BITS

Pilot

attached

pilot

can

the

workpiece

the

top

SHAPING WITH PILOT-GUIDED

PI

FULL

is

to

against

. When

however, a pattern

that

duplicates

must

be

of

the

against.

THE

RABBETING

BIT

Withitsownpilotoreither

arbor-set

this

or,

and

smooth

.,

the

curved

guide

bit

at

the

convex

that

you

be

followed.

An

or

straight

be

portion

SURFACING

the

to

the

router

edges

finger

can

be

any

de-

edge.

or

will

Arbor

will folheld

in

is

thick

of

the

&:

edge

ride

tion

be

cut,

guide

tour

side

to

bear

•

USING

ING

of

the

(Page 4)

rabbeting

trueing

Without a pilot,

over a workpiece

and

BITS

LOT

--.\...!IGl

EDGE

be

cut,

the

uncut

all

of

clamped

workpiece

pilots

bit

can

with a

smoothing

it

can

surface

it.

SHAPING

the

pilot

lower

the

edge

the

edge

to

the

for

the

AND

attached

be

used

template,

an

be

traveled

will

por-

is

or

other

con-

under-

pilot

SURFAC-

for

for

edge.

to

plane

to

When

shaping around

or

angled

danger

the end

avoid

this'

three

methods

square

corners

there

of splintering

of

the cot.

use

one

of

illustrated.

TURNING

--

1 1

is

lEI

at

To

the

t 1

--

SQUARE CORNERS

32

.:::

If 1 and

2::

splinter

at

4wiJJ

them.

end,

::

~

::

j

E.remove

3 and

•

9

1

1

Page 10

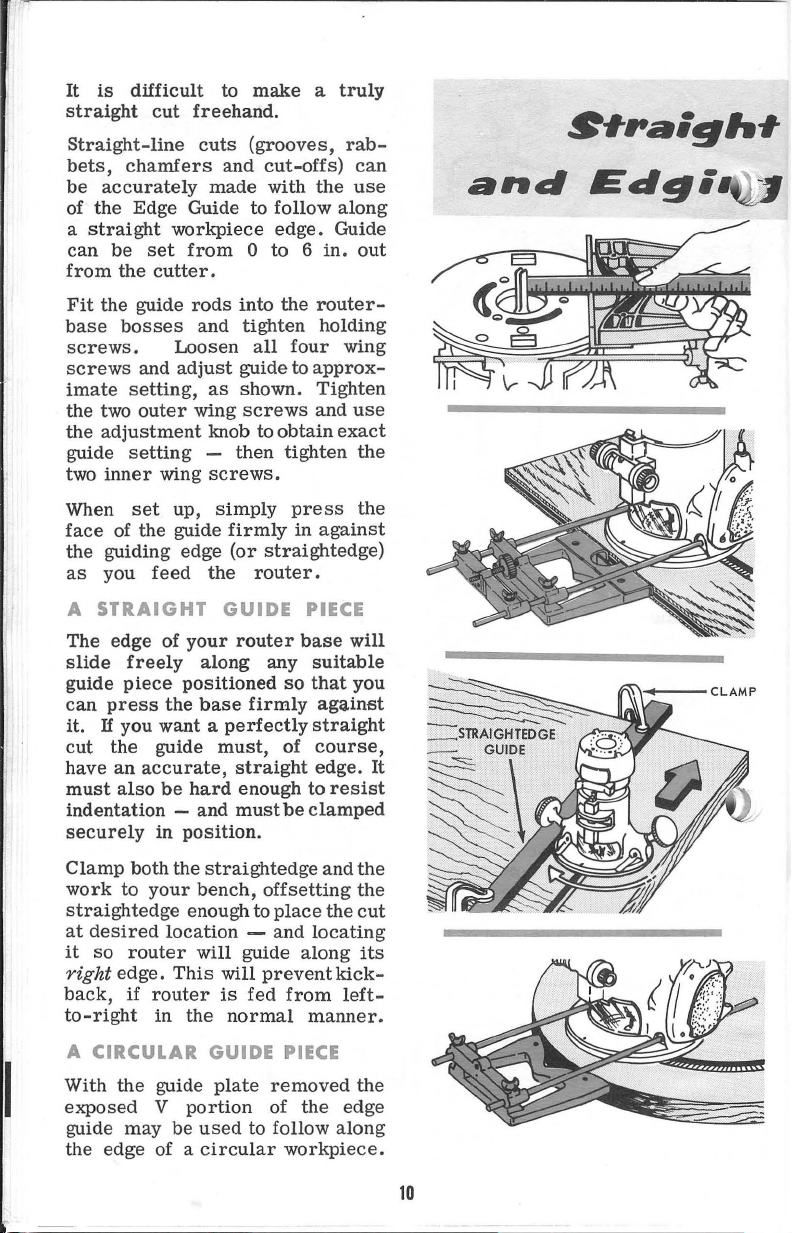

It

is

difficult

straight

Straight-line

bets,

be

of

a

straight

can

from

Fit

base

screws

screws

imate

the two

the

guide

two

cut

chamfers

accurately

the

Edge

be

set

the

cutter.

the

guide

bosses

.

and

setting,

outer

adjustment

setting

inner

wing

to

make a truly

freehand.

cuts

(grooves,

and

cut-offs)

made

with

Guide to

workpiece

from 0 to 6 in.

rods

and

Loosen

adjust

as

wing

knob to

screws.

follow

edge.

into

the

tighten

all

guide to

shown.

screws

obtain

then

tighten

four

rab-

can

the

use

along

Guide

out

router-

holding

wing

approx-

Tighten

and

use

exact

the

and

~",,.a;g"'"

Edg

...

I

When

face

the

as

A

The

slide

guide

can

it.

cut

have

must

indentation -and

securely

Clamp

work

straightedge

at

it

right

back,

to-right

A CIRCULAR

With

exposed

guide

the

set

up,

of

the

guide

guiding edge

you

feed

STRAIGHT

edge

of

freely

piece

press

the

If

you

want a perfectly

the

guide

an

accurate,

also

be

in

both

the

to

your

desired

so

edge

location -and

router

edge.

This

if

router

in

the

guide

V

may

be

of a

the

your

along

positioned

base

hard

position.

straightedge

bench,

enough to

will

the

GUIDE

plate

portion

used

circular

simply

firmly

(or

straightedge)

router.

GUIDE

router

any

firmly

must,

straight

enough

mustbe

offsetting

place

guide

will

prevent

is

fed

normal

removed

of

to follow

press

in

so

of

from

PIECE

workpiece.

against

PIECE

base

will

suitable

that

you

against

straight

course,

edge.

to

resist

clamped

and

the

the

the

locating

along

kick-

left-

manner.

the

the

edge

along

the

cut

its

It

10

Page 11

LIne

•

Rou""ng

••••

A

BOX

This

fastened

the

them

as

a guide

faces

router

with

while

guide.

necessary,

and

work

the

to

make

A

TEE

This

making

parallel

one

shown,

hardwood. Or

two

tersunk

angles

tained.

GUIDE

is

simply

with

router

workpiece

pieces

base

freely

for

it

speeds

can

be

one

hand

the

other

Clamping

if

firmly.

underside

this

easier.

SQUARE

simple

cuts

cuts)

preferably

together

bolt

other

but

(especially a series

and

two

straightedges

crosspieces

will

slide

without

routing

the

work

held

down

(on top of

hand

is

thus

you

can

hold

Sandpaper,

of

the

• • •

device

than

at

a 90°

edge.

of

you

wing

90°

is

aluminum

can

with a

nut,

so

between

slop.

on

flat

as

and

pushed

motor)

holds

made un-

the

guide,

useful

angle

Make

attach

so

can

be

that

Used

sur-

the

the

guide

glued

will

for

it

as

or

the

coun-

that

ob-

of

to

PARALLEL CUTS

A

GUIDE

If

you

have

and

wish

to

equally

(straight

a

three

serve

steady

slide

and

exactly

nor

spaced

or

socket-head

sub-base

as

a guide. Hold

so

that

in

the

so

that

opposite

behind).

11

• • •

WITHOUT

routed

the

make a series

identical

contoured),

bolt

for

screws

this

bolt

previous

the

bit

will

to

it

(neither

first

grooves

substitute

one

. . . to

the

head

groove

always

groove

of

of

the

router

will

-

be

ahead

Page 12

C;rcles

and

Fralnes

.........

:

:

,.

••

Round,

table

Har

objects

both

on

use

of

and

a few

bits

are

square

tops,

inner

the

used

and

trays,

can

and

Trammel

simple

the

rounded-corner

picture

be

outer

fixtures.

pilots

frames

cut

out

and

edges -with

Point,

If

are

omitted.

shaped

Edge

arbor

square

and

G

sim-

the

-

~,

'

'e

If you

can

quick,

ting.

be

shape a round

round

picture,

edge

beted,

same

have

be

used

easy

If

desired, a veining

used

to

disc

etc.

(or

chamfered

manner,

SQUARE

CONCAVE

CONVEX

the

method

cut

for

both

&

FULL

Trammel

as

shown

through

disc,

framing a mirror

Afterwards,

edges)

or

using

ROUNDED-CORNER

T h r e e

gu

trated.

the

the

guide

to

from

8-32x7/16-in.

Drill

through

e d g e

screws

block

used

der

block

The

cave

be

ture

can

piece

a

shaped

through

curvature.

Point,

to

afford

of

circle

the

stock

or

a hollow

the

can

be

shaped

the

proper

ide

blocks

Edge Guide,

contour

plate

the

inner

underneath

two 1/ 8 -

so

(or

is

- with

heads

to

cross

curvature

or

convex

the

same

to

be

be a

edge

pattern

edge

for

cut-

bit

outer

rab-

in

types

To

block

that

too thick)

followed - which

pre

or a pattern.

is

ROUND

it

a

can

to

or

the

bit.

of wooden

are

attach

finger

(which

cross

screws).

in.

near

these

longer

washers

- to

beam.

of

the

block

as

the

shaped

used,

can

shaping

12

WORK

(OR

illus-

one to

remove

and

the

is

held

beam

by two

holes

rear

two

ones

can

be

un-

secure

con-

should

curva-

work-

If

an

un-

be

cut

to

the

if

END)

WORK

Page 13

t::.",,'ng

I.e##e,,'ng

-

• USING

for

accessory.

or V _groove

to

your

etc.

size)

all

Start

desired

trace

graph

ingenious

depth-of-cut,

or

substituting a pencil

graph

bit

it,

for

ca

THE

PANT-O-GRAPH

setting-up

be

carved.

design

that

is

is

positioned

of

it

without

the

router

depth-of-cut

your

tracing

effects,

filling

of

point,

to

trace a design

you

can

use

in

carving

of

the

original.

Instructions

are

packaged

Use

any

straight,

bit

suitable

Before

(any

twice

design

or

the

and

create a double-size

flat

the

so

changing

and

with

point.

vary

use

finished

by

an

starting,

desired

lower

•..

contrast

for

using

fastened

exact-size

with

to

the

print,

drawing,

you

can

its

position.

the

then

the

For

additional

bits

coloring

engraving.

the

the

this

veining

design

be

sure

finished

trace

bit

to

simply

pant-o

and/or

By

pant-o-

router

beneath

print,

repli-

-

USING

AN

AUXILIARY

SASE

• USING

clamp

the

(or

be

guide

straight,

ply

feed

anyone

Using

be

•

embossing

V

be

latticework,

use

drills

draw,

to

freehand

When

forearms

trol.

on

be

supplied

workpiece

numeral)

fitted

bushing

veining

set

bit

it

through

of

1/S-in.

created

FREEHAND

-groove

done.

the

Combination

its

own

stencil

be

routed

guide

doing

on

If

router

surface, a piece

substituted

THE

LETTERING

and

guide

with a

(page

to

desired

the

40

hardboard,

for

additional

CARVING

use

any

bit

suitable

For

making

etc.

through

or

trace

onto

your

intricate

the

for

TEMPLATE

simultaneously

the

particular

in

use.

Router

5/S-in.

or V -groove

the

letters

straight,

clear

Panel

your

surface

base

the

or

5)

and a

depth-of-cut

guide to

or

numerals.

guides

figures

For

engraving

veining

for

the

panel

through

Cutter

hole).

Preferably

the

pattern

workpiece-then

bit

accordingly.

work,

of

sub-base.

rest

for

better

cannot

hardboard

The

holds

letter

must

smaller

suitable

bit.

Sim-

and

engrave

may

.

or

or

work

cut-outs,

the

work,

(which

lines

your

con-

rest

flat

may

to

TYPICAL SCROLL &

13

CARVING

WORK

Page 14

-

Taper

Rou#;ng

and

Flu#;ng

The

simple

of a

the

along

TAPERING

base

other

the

fixture

loose

tapering

such

with two

(to

tops

of

be

the

can

as

equal

held

two

projects

be

quickly

the

one

illustrated. This

straightedge

with

clamps

sides

(rails)

add

grace

as

tables,

and

neatly

sides,

as

shown) .

.

Make a

deep

rabbet

edge

of

tach

the

to

your

stall a 1/2-in.

Use

square

taper

lines

two

wedges

under

it

up

as

Position

ture

against

wedge

jacent

will

be

edge

of

(jig.

B).

in

place

curely

tain

that

matches

side

of

chairs,

done

fixture

one

1/4-in

each

5/8-in.

router

the

required

the

up

its

taper

exactly

the

Clamp

to

..•

its

the

the

workpiece

and

distinction

bed-steads,

with a router

simply

fixed

onto

The

router

. wide by

cut

along

fixture

a.D.

(Page

straight

stock

on

it

(fig.

which

workpiece

(jigs . B and

workpiece

the

fixed

ends

line

for

matched

rabbet

hold

and

check

rabbet

top

cut

the

the

taper

Tapered

the

the

side

guide

16),

bit.

and

A).

can

ends

on

side

so

that

the

in

moveable

workpiece se-

to

edge

line

.

to

consists

base

will

9/16-in.

top

inside

rail.

bushing

and

mark

Prepare

be

to

the

rail,

the

top

with

this

make

on

Ie

such

etc.

and

and

slide

At-

in -

the

used

lift

C).

fix-

and

ad-

side

the

cer-

also

this

~

a

/

r

Set

the

cut

at

then

slide

remove

above

remaining

way.

doing a taper

ready

positioned

14

the

the

Note,

cut,

router

low

it

along

all

top

side

the

(jig.

for

zero

workpiece

the

stock

however,

that

taper

tapers

opposite

wedges

C).

lines.

rail

in

the

that

to

must

depth

end

...

tops

projects

Do

the

same

when

one

al-

be

re-

of

to

Page 15

flutes

a

ridges, evenly

ridge

as

veining

dovetail

larger

evenly.

bit

edges

to

later

For

leave

spaced.

to

beading,

square

Sand

round

desired. A straight, V -groove

(round

bit

end)

can

or

even a smad

be

used

effect.

to

use

sided

the

them

good

FLUTE

DECORATING A SQUARE

RECTANGULAR

Fluting

moving

es)

is

The

show

two

the

end

fixture

(grooving)

enough

adds a decorative

easily

accompanying

flute

different

leg

is

and

rails

preceding).

pressing

, e

outer

other

of

grooves

will

result

parallel

wedges

the

rails

The

face

grooves

between

leg

and

will be

grooves

at

one

slanting

PATTERNS

WORKPIECE

or

beading

stock

to

leave

touch

done with above

illustrations

patterns

wedged

clamped

Plow

your

side

(to

make

at

in long

the

parallel

the

set-ups

between

(just

grooves,

Edge

of

first

an

each

Vs.

are

the

fixture

can

be

end,

leg

resulting

. In

up

at

as

for

Guide

one

equal

side

If

desired,

tapered

rails

to

each

made

if

-

desired,

slightly

set-up.

the

the

tapering,

made

rail

of

centered,

fixture.

Set

up and

the

four

For

adjust

fluting,

flute

sides

the

Edge Guide

or

bead

in

the

same

use a small

to

manner.

space

OR

(re-

ridg-

. . .

from

first,

small

the

two

by

against

then

number

the

leg)

place

end

of

so

the

other.

to

sur-

by

in

the

each

of

bit

and

the

DECORATING

WORKPIECE

If

you

have

you

have

turned a cylindrical

tapered

an

your

flutes

leg.

guide

you

to

with

actly

the

is

guide

through

the

indexing

beads

member,

ed,

ly

its

round

indexing

router

or

Two

tool

rail

need.

hold

the

the

centerline

parallel

leg.

Now, when

moved

rail,

the

groove

to

evenly

however,

the

grooves

spaced

large

end.

head

beads

(as

rail

horizontally

slot

to

space

at

A

a wood

leg

- you

and

lathe

for

posts

and a

illustrated)

Adjust

parallel

to

the

the

bit

at

be

cut.

the

around

if

will

its

small

ROUND

lathe

on

- and

can

to

if

combine

produce

decorating

homemade

are

the

tool

to

the

of

the

slot

centerline

the

router

along

will

travel

a 900 angle

Plan

grooves

the

leg.

leg

is

taper-

be

more

close-

end

than

which

or

it

has

the

all

posts

leg

ex-

of

base

the

to

your

or

Re-

at

15

Page 16

_

PATTERN

sign

and

areas,

of

assures

Since

against

DUPLICATING When

calls

for

"gentle"

and you

duplicates,

you

the

edge

the

pattern

illustration),

smaller

for

router

the

for

cut

a

pattern

than

the

distance

base

pattern

routing

it

off to

serves

can

workpieces

-USE

OF A GUIDE BUSHING

the

three

be

attached

three

as

illustrated.

7/16-,

guide

screws

5/8respectively,

and

templates.

bit

best

suited

type of

cut

you

an

curves

wish

use

of a

quick,

of

the

the

pattern

the

finished

between

edge.

clear

the

outline

also

to

duplicate

bushings

to

the

furnished

and

1-1/16-in.

for

use

Select

for

wish

outline

and/or

to

make a number

of a

pattern

simple

router

edge

(accompanying

must

work

the

Clamped

as

an

excellent

through

desired.

be

used

for

decorations.

Anyone

(page

router

with

The

bushings

with

different

the

your

template

to

make.

the

de-

having

long

straight

guide

method.

base

rides

be

enough

to

allow

bit

and

the

the

stock,

to

guide

the

stock

Such

grooving

5)

can

base

(with

bushings)

have

O.D.pilots,

bits

bushing

and

:lnd

to

of

Pa##ern

Duplicates

either

plate.

prepared

or

hardboard.

in

conjunction

Guide

lO-32x5/16 I 1 PILOT

FL-HD.

SUB-BASE

SCREW_~

..

----

are

by

use

of a

A

pattern

guide

Bushings

I I

I

rr~BUSHING

I~

SCREW

L----_

~I

==;:::::::::=----

Templates

with one of

(page

!

A

and

EXAMPLES

easily

pattern

made

GUIDE

prepared,

or a tem-

is a specially

of plywood

are

the

5)

available

ATTACHING

BUSHING

.,

used

three

A

SET-UP

BUSHING

GUIDE

TEMPLATE

16

Page 17

r~,~.,,,"'e

IF

TEMPLA

TE

•• •

Rou""ng

ROUTING AND

INLA

Y WORK

and

Edging

for

attachment

A

template

wood,

and

intricate

quired

is

_---

When

is

will hold

ly,

arrangement

for

duction type

hardboard,

is

for

to

be

---

-------------------------j

A

BOX

prepared,

hinged

as

illustrated.

clamps,

to

the

may

be

or

generally

design

inlaying

done.

' TEMPLATE

to a framework

the

and

work.

____________________

used

work

or

the

template

workpiece

avoids

speeds

Router

made

(such

Such

the

Base.

of

sheetmetal,

whenever

as

latticework)

that

firm-

an

need

pro-

ply-

re-

J

.MAKINGAND

in.

thick

plate

though plywood,

may

plate

saw

routing

pattern

making

set

of

the

preparing

it

to a piece

design

guide.

smallest

these

•

INLAY

of two

for

other

the

cupy.

for

be

be a

spaces

pare

through

1/4-inch

female

about

ness.

and,

face

lected

really

in

this

sheetmetal

is

best

be

used.

can

be done

or,

if

through

lines.

the

between

guide

the

using

If

bit

out

afterwards

WORK

templates,

preparing

(female

routed-out

The

only

each

used,

but

hair

line

into

the

male

appropriate

thickness

spaces

1/64-inch

Glue

when

finish.

for

beautiful

manner.

corners

male

dry,

USINGATEMPLATE A

or

for

production

hardboard,

Preparation

the

along

design

the

router

bushing

template,

of

stock

the

template

will

Inlaying

the

template)

spaces

template

of

the

these

smaller

which

pieces

into

deeper

the

male

sand

If

wood

colorings

workpieces

aluminum

with

an

material

carefully

Just

remember

to

allow

bit

you

and

sharper

make

are

with a chisel

requires

one

(male

inlay

pieces

these

different

must

than

they

will

by

stock

...

your

than

pieces

to a smooth

is

and

type

plastic,

of

electric

permits,

for

and

will

use.

simply

rout

edges

than

desired.

for

preparing

are

need

be

planned

the

cutting

of

then

workpiece

this

tastefully

grainings,

can

1/8-

tem-

work,

etc.

the

tem-

saber

by

traced

when

the

off-

the

edge

After

clamp

out

your

as

your

your

cut

•

the

use

template)

and

an-

to

oc-

provide

shapes

fIt.

route

female

Pre-

clear

1/8

thick-

in

place

sur-

be

made

to

to

to

the

se-

17

Page 18

Do~e#all

Jo/n#/ng

your

router

for

holding

one

use

of

it

invaluable!

For

1/2-in.

the

Dovetail

Bushings

Dovetail

Bit

dovetailing

and

the

nished

1/4-in.

The

so

joint

up

need

the

with guide

bit.

fixture

that

both

are

is

quick

do

is

comb-like

template.

is

the

ideal

the

bit.

the

router

dovetailing

Fixture

(Page 5),

(page

4).

you

need

1/4-in.

template

bushing),

holds

both

parts

cut

simultaneously.

and

simple.

guide

the

edge

power

Indeed,

alone

and

the

and

the

For

the

workpieces

of

the

bit

of

the

tool

this

makes

you

ne"~

Gui~

1/2-in.

1/4-in.

fixture

(fur-

and

the

dovetail

Set-

All

you

to follow

fixture

.

All fine

joints

(and

the

cabinetwork

for

sometimes

sides

requiring

strength.

impossible

highly

pare

skilled

such a joint

dovetail

KNOB

joining

...

and

the

best

But

for

anyone

cabinetmaker

bit

and

uses

drawer

the

backs,

for

other

of

neatness

it

is

practically

other

without

template.

Boards

o

RAWE

dovetail

fronts

too)

joints

than

to

pre-

using

flush

at

R SIDE

to

and

And

top.

a

a

Both

be

Detailed

with

I

nstall

and

the

shown.

edges

shown;

right

different

beted

dovetai I is

flush

quickly

the

THE

workpieces

drawer

For

dovetail

of

workpieces

for

right

side

of

holes

and

rabbeted

made

instructions

accessories.

SETTING

DOVETAIL

inside

out -the

side

in

front -and

at

left

against

side

dovetail,

template.

depending

to

be

made.

These

upon

joints

with

this

are

UP

TEMPLATE

drawer

clamp

side

of

drawer,

the

two

locating

use

locating

screws

are

whether a flush

can

set

un

packag

front

on

firm

ly

butt

screws

screws

placed

or

top

left

rab-

~

as

on

in

18

Page 19

Buff

H;nge

anel

~

LockFace

Roul-;ng

MORTISING

DOOR

HINGES

The

large

especially

having many

it

you

a

set-up

square

any

door

to

2-1/2-in.

can

then

jamb hinge

or

for

Also,

is

adjustable

standard-size

desirable

can

quickly

for 2 or 3 rounded

hinges

up to

be

hanging

anyone

(4-piece)

doors

and

up

to

B-ft.

thick.

used

for

mortises

other

of

the

for

mortising

lock

template

for

to

hang.

easily

5-in.

high

Same

making

to

match.

identical

three

faces

and

anyone

With

make

or

long

on

by

3/4

set-up

doordoors.

guides

for

all

plates.

is

.

The

small

excellent

it

you

can

at a time)

hinges.

router

bushing

Set-ups

door

mortises

tises,

following

aged

with

guides

in.

(for

and a 4-in.

19

(one-piece)

for a homeowner.

set-up

for

It

can

fitted

and a 1/2-in.

can

the

are

available:

most

(for

to

any

number

be

with a

be

made

and

the

instructions

guide.

inside

most

used

5/B-in.

outside

template

mortise

with any

straight

both

jamb

Two

sizes

The

door

hinges)

With

(one

of

door

guide

bit.

for

the

mor-

pack-

of

3-1/2-

doors).

is

Page 20

J.s",'ns"'ett:l

Plss""cs

Cuffing

an~

Laminated

laminates

agents

shaped

tools.

without

bide-tipped

and

the

guided in

Professional

be

accomplished

using

the

5)

and

Trimmer

with

the

using

Trimmer

mer

(Page

The

laminate

with

the

most

versatility.

bination

E~glng

plastics,

having

are

successfully

For

danger

bit

firm

Laminate

the

(Page

trimmer

either

or

4).

combination

1-flute

similar

much

fast,

of

chipping

bit

should

must

contact

quality

in two ways:

Combination

4)

attachment.

the

the

Piloted

trimmer

First,

bit

phenolics

too

hard

with

clean

be

be

with

trimming

Trimmer

that

is

Piloted

220Trim-

bit

offers

will

trim

edging

used

precisely

the

and

bonding

to

be

ordinary

- a

car-

•..

the

edge.

can

1)

By

(page

Formica

supplied

2)

By

Flush

together

the

com-

either

-

at

a 200 bevel

end

is

used

straight,

ered

Second, the

be

depth

means

can

more)

cut

off a

pass

If

you

bevel

type

and

these

faster

ball-bearing

Sible

any

With

practice

nating

hang

by

After

use

3/16-in.

faced

flush

to

use

adjusted

of

cut

that,

do

the

passes

settings,

sizeable

.

wish

trimming

bit

you

the

220 bevel

bits

and

type

edge

contour.

either

is

material

the

wood to

about 3/16-in.

the

the

router

to

edge.

angle

(if

for

cutting) ,

edge

(if

the

straight

cutter

to

will

do

smoother)

of guide

to

bonding

make a flush

attachment

in

or

out

as

desired

if

it

is

advisable,

trimming

at

staged

instead

overhang

have 2 flutes

pilot

above

do

both

with

need

bits.

is

the

for

pre-cut

so

that

which

on

agent

bit

to

of

both

method

trim

beveled

bit

is

portion).

to

set

•.•

in

two

depth-of

trimming

all

in

flush

the

piloted

the

However,

-

and

best

following

the

it

will

it

is

bonded

every

has

off

or

bevel-

bit

or

low-

can

the

which

you

(or

one

and

flush

(cut

the

pos-

best

lami-

over-

side.

set,

this

a

l

./

-

USING

TRIMMER

THE

LAMINA

ATTACHMENT

TE

20

USING A SALL-SEARING

PILOTED

TRIMMER

Page 21

VERTICAL

ADJUSTMENT

~

, A

makes

makes

to a true

...

gouging.

motor

lessen

together,

ped

omy,

to

sharp

ment.

~

A

in

A

adjustments

can

cutting

surface.

a two

these

align

all

identical

type feeding

ment)

exact

pass

ANGULAR

ADJUSTMENT

dull

or

fine

the

and

causes

and, if

the

the

cutter

especially

keep

your

with

special

the

router

full

range

accurately

edge with

Once

or

three

adjustments

the

edges

proportions,

allows

setting

of

an

ROTATING

ADJUSTMENT

chipped

work

router

line,

cutting

impossible.

difficult

makes

cutting

splintering

It

may

also

overload

used

too long,

life of

is

this

your

use

of a

extremely

when

bits

and

cutters

"foolproof"

dull

it

grinding wheel

chuck

of

circular

is

provided

is

align

the

grinding

set

for

edged

serve

remaining

will

screw

you to

for

edge

edges

be

sharpened

(vertical

establish

each

over

the

edge

It

to hold

slow

and/or

the

may

tool.

Al-

or

chip-

poor econ-

is

so

easy

razor

attach-

for

use

included.

and

angular

so

that

you

any

shape

wheel

one edge of

cutting

also

so

tool

to

that

to

A

vernier

adjust-

an

successive

grinding

wheel

blade

each

tion

Thus,

edges

vernier

the

... then

tional

to

Detailed

with

Since

side

avoid

face

sary.

20o~

edge in

for a pass

attachment

make

the

metal

of a

sharpening

more

"

.(

.

...

and a

stop

makes

turn

you

sharpen

of

the

setting

repeat

vernier

all

edges

instructions

attachment.

removed

bit

than

Also

sharpen

/'

taining

els

15°

Touch

round

faces

move

built-in

it

easy

into

over

the

cutting

(Simply

on

its

at

as

settings

equally

are

changes

on

the

absolutely

original

or

as

the

the

lightly to

burrs.

automatic

exact

the

two

tool

by

guide

many

as

from

outer

end,

illustrated

outer

•••••••••••••••••••••••••••••••

NOTE

All

router

bits

and

be

sharpened

-

excepting

bit

(page

cial-tipped

be

sharpened

only

20)

tools.

with

this

the

carbide-tipped

or

any

Such

on a

diamond

cutters

attachment

similar

bits

••••••••••••••••••••••••••••••••

to

rotate

posi-

whe.

el.

or

three

to one

sliding

rail)

addi-

required

sharp.

packaged

the

out-

its

size,

sur-

neces-

main-

bev-

edges

a-

sur-

re-

may

spe-

must

wheel.

.

21

Page 22

HOlM

#0

Rou#

.vooel

Jo/n#.

DADO,

GROOVE

RABBET CUTS

Description

Set-Ups

A dado

across

with

or

made

~---

SMALL

HOLDER

This

rout

piece

ing

use

. . . and

your

rabbets

the two

be

finishing

into

then

paints.

and the

is a square

the

grain,

the

grain

Plow

cuts.

in

the

TWO

WORKPIECE

adjustable

on the

it

1/2-

smooth

the

cut

surface

by

affording a means

securely

to

can

requirements.

on

the

rails

and

nails

sliding

off the

These

holes

can

and

Basic

and

are

called

These

workpiece

USEFUL

fixture

of a

to

the

two

that

free.

about

pieces

heads

be

bench.

lumber

the

sliding

Drive

grip

patched

I-in.

size

so

will

AND

groove

similar

grooves

cuts

may

surface,

HOMEMADE HOLDING FIXTURES

will

help

small

of

clamp-

You

as

desired

pieces

Make

adjustment

1-1/4-in.

to

the

to

identical

pieces

1-1/2-in.

as

shown -

leave

workpiece,

afterwards.

cut

cuts

be

in

you to

work-

can

suit

and

will

deep

sharp

its

end,

they

always

bottom

wood. If

made

piece

side

rabbet

The

close

edge

and a

cut.

methods

ON-EDGE

HOLDER

Preferably

should

in.

Make

width to

port

must

workpiece

bench

of

not

er

allow you

sure

of

be

lumber

the

suit

the

be

as

the

two

only

provide a support

base

to

in

accurately

the

workpiece

or

along

its

have

to

form a channel

either

enough to

so

that

bottom

of

making

WORKPIECE

make

and

your

slide

set

the

in

the

base

length

requirements.

rail

For

clamp

identical

along ...

your

edge

from

.

identical

fixture

stationary

rigid.

and

illustrated.

rails

to

edge ...

two

type

it

has

it

two

size)

of

I-in.

and

as

use,

the

fixture

Having

(and flat)

guide

the

sides

of

the

only

is

called

all

___

rails

of 1-to

the

shown -

clamp

for

the

it

will

two

but

and

in t

tlu

cut

work-

one

three

(which

lumber.

base

Sup-

in

the

to

your

the

tops

will

rout-

also

to

measides

-

is

a

...

2-

it

••••••••••••••••

: (Si

ze all

pi

eces

your

to

needs

:

meet

••••••••••••••••

:

.) :

22

Page 23

Through

and

Blind

Cuts

cuts

are

identical.

differences

to the

surface,

course,

piece

For

making

plows

piece

other

can't

Edge Guide, a

square,

able method

cut.

Shaper

between

locations

edge

or

determine

is

to

be

held.

surface

or

rabbets)

firmly,

flat

substantial

slide

or

wobble. Use

straightedge,

the box guide,

for

For

long,

Table

(page

of the

end) - which, of

how

secure

on

support,

making a

through

helpful.

For

making

dos,

plows

workpiece

end

or

rabbets)

in

an

or

edge

On-Edge

(preceding page) . . .

in a

vise

between two equal

ness

straightedge

which the

accurately.

essed

ne

guide

against

(or the other)

the

router

cut.

Use

scrap

base

the

the

scrap

The only

them

are

cuts

the

work-

cuts

(dados,

the

your

work-

bench

so

the

or

any

straight

cuts

32)

is

cuts

secure

Holder

or

clamp

thick-

pieces

will

Edge Guide

outer

side

block

real

due

(in

or

it

the

tee

suit-

most

(da-

the

it

on

slide

of

to

Dados

through

one

When making

the

piece

vent

the

applies

grain.

The

stops

called

and

make a half-blind

edge and have a

to the

desired.

a

stop

the

a

router

hole

as

for a half-blind

Wide

If a

largest

cessive

justing

cut

overlaps

about

deep

passes,

and plows

cuts

workpiece

grain,

back

with a

splintering

end

of

the

when

cut

is

called

short

of the

a blind

stops

work

To

short

to stop

make a blind

block

starting

at

cut

point - and

so

as

this

point.

and/or

is

to

bit,

do

passes -each

your

guide

1/16

to

cut

also