Page 1

Owner's Manual/Manual del Propietario

GARAGE DOOR OPENER

ABRIDOR DE PUERTA DE COCHERA

For Residential Use Only/Sblo para uso residencial

Model/Modelo 139.53990

Read and follow all safety rules

and operating instructions before

first use of this product.

Fasten the manual near the garage

door after installation.

Periodic checks of the opener are

required to ensure safe operation.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

www.sears.com/craftsman

Lea y siga todas las reglas de

seguridad y las instrucciones de

operaci6n antes de usar este

producto por primera vezo

Guarde este manual cerca de la

puerta de la cochera.

Se deben realizar revisiones

peribdicas del abridor de puertas

para asegurar su operaci6n

segura.

Z_

O

I-"

Page 2

TABLE OF CONTENTS

Introduction 2. 7

Safety symbol and signalword review........................ 2

Prepadng your garage door........................................ 3

Toolsneeded............................................................... 3

Planning .................................................................. 4-5

Carton inventory.......................................................... 6

Hardware inventory..................................................... 7

Assembly 8.11

Assemble the rail and installtrolley............................. 8

Fasten railto motorunit and installidler pulley..........9

Install chain/cable...................................................... 10

"nghtenthe chain....................................................... 11

Installation 11.27

Installationsafety instructions.................................... 11

Determine the header bracketlocation................12-13

Installthe header bracket.......................................... 14

Attach the railto the header bracket......................... 15

Positionthe opener ................................................... 16

Hang the opener ....................................................... 17

Installthe door control............................................... 18

Installthe lightsand lens........................................... 19

Attach the emergency release ropeand handle.......19

Electricalrequirements.............................................. 20

Installthe safety reversingsensor ....................... 21-23

Fasten the door bracket....................................... 24-25

Connect the doorarm to the trolley..................... 26-27

Adjustment 28-30

Adjustthe travel limits............................................... 28

Adjustthe force......................................................... 29

Testthe safety reversal system................................. 30

Testthe safety reversingsensor............................... 30

Operation 31.34

Operationsafety instructions..................................... 31

Using yourgarage door opener ................................ 31

Using the wall-mountedDoor Control....................... 32

To open the door manually........................................ 32

Care of yourgarage door opener.............................. 33

Havinga problem?.................................................... 34

Programming 3.5-36

To add a hand-held remote control........................... 35

To erase all codes..................................................... 35

3-Function Remotes.................................................. 35

To add or change a Keyless Entry PIN ..................... 36

Repair Parts 37-38

Railassembly parts................................................... 37

Installationparts........................................................ 37

Motor unitassembly parts......................................... 38

Accessories 39

Warranty

Service Numbers

Back Cover

39

INTRODUCTION

Safety Symbol

and Signal Word Review

This garage door opener has been designedand testedto offer safe serviceprovided it is installed,operated,

maintainedand tested in strictaccordancewith the instructionsandwarningscontainedinthis manual.

When you see these Safety Symbols and Signal

Words on the followingpages, they willalert you to

Mechanical

Electrical

the possibilityof serious injury or death if you do

not complywith the warnings that accompany them.

The hazardmay come from something mechanical

or from alectdc shock. Read the warningscarefully.

When you see this Signal Word on the following

pages, it willalert you tothe possibility of damage to

yourgarage door and/or the garage dooropener if

you do not complywith the cautionary statements

that accompany it. Read them carefully.

2

Page 3

Preparing your Garage Door

Beforeyou begin:

• Disable locks.

• Remove any ropesconnectedto garage door.

• Complete the following test to make sure your

garage door is balanced and is not stickingor

binding:

1. Liftthe door about halfwayas shown. Release

the door.If balanced, itshould stay in place

supportedentirelyby its spdngs.

2. Raise and lower the door to see if there is any

bindingor sticking.

If your door binds,sticks,or isout of balance, cell

a trained door systemstechnician.

TopreventpossibleSERIOUSINJURYORDEATH:

• ALWAYScallatraineddoorsystemstechnicianif

garagedoorbinds,sticks,or is outofbalance.An

unbalancedgaragedoormaynotreversewhen

required.

• NEVERtryto loosen,moveoradjust garagedoor,door

springs,cables,pulleys,bracketsor theirhardware,all

ofwhichareunderEXTREMEtension.

• DisableALLlocksandremoveALLropesconnectedto

garagedoorbeforeinstallingandoperatinggarage

dooropenerto avoidentanglement.

Topreventdamageto garagedoorandopener:

• ALWAYSdisablelocksbeforeinstallingandoperating

theopener.

• ONLYoperategaragedooropenerat 120V,60Hzto

avoidmalfunctionanddamage.

Sectional Door

One-Piece Door

Level

Dda 3/16", 5/16"

Tape Measure

Drill Bits

and 5/32"

Tools Needed

During assembly, installationand adjustmentof the

opener,instructionswillcall for hand tools as

illustratedbelow.

PencJ

Wk'e Cutters

Screwdriver

1/2",5/8", 7/16", 9/16" end

LJ_ 1/4" Sockets and Wrench

Adjustable End Wrench

Page 4

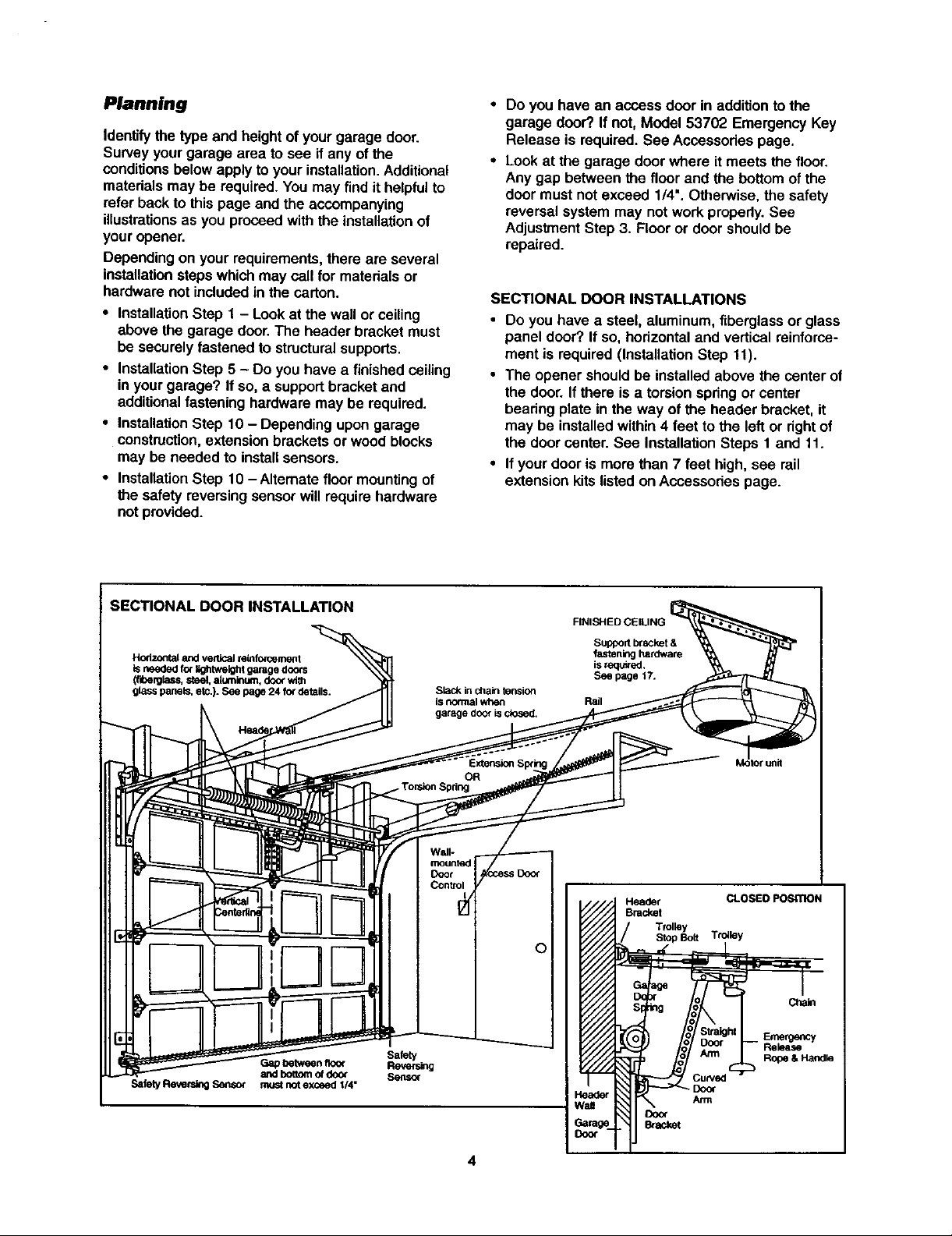

Planning

Identifythe type and height of yourgarage door.

Survey yourgarage area to see if any of the

conditionsbelow apply to your installation.Additional

materialsmay be required.You may find ithelpful to

refer backto thispage and the accompanying

illustrationsas you proceedwith the installationof

your opener.

Dependingon your requirements,there are several

installationstepswhichmay call for materialsor

hardware not includedin the carton.

• InstallationStep 1 - Lookat the wall or ceiling

above the garage door.The header bracket must

be securely fastened to structuralsupports.

• InstallationStep 5 - Do you have a finished ceiling

in yourgarage? If so, a supportbracketand

additionalfastening hardware may be required.

• InstallationStep 10- Depending upongarage

construction,extensionbrackets or woodblocks

may be needed to installsensors.

• InstallationStep 10 -Alternate floor mountingof

the safety reversingsensor willrequire hardware

not provided.

Do you have an access door in additionto the

garage door? If not, Model 53702 Emergency Key

Release is required.See Acoessodes page.

Lookat the garage door where itmeets the floor.

Any gap between the floor and the bottom of the

door must notexceed 1/4". Otherwise, the safety

reversal system may notwork properly.See

AdjustmentStep 3. Flooror door shouldbe

repaired.

SECTIONAL DOOR INSTALLATIONS

• Do you have a steel, aluminum, fiberglass or glass

panel door? Ifso, horizontaland vertical reinforce-

ment is required (InstallationStep tl).

• The opener shouldbe installed above the center of

the door. If there isa torsionspdng or center

beadng plate in the way of the header bracket,it

may be installedwithin4 feet to the left or rightof

the door center. See Installation Steps 1 and 11.

• Ifyour door is more than 7 feet high, see rail

extensionkitslisted on Accessories page.

SECTIONAL DOOR INSTALLATION

Hodz.ordalendverticalreinforcement

isneededforI_htweightgaragedoors

(fiberglass,steel,aluminum,doorwith

glasspanels,etc.).Seepage24 fordetails.

Gap between floo_

Safety Reve_g Sensor must not exceed I/4"

aed bottomof door

Safety

Reversing

Sensor

Slack in chain fension

ISnormal when

garage door is closed.

Wall-

mounted

Door

Control V

FINISHED CEILING

Suppod Ixacket &

fastening hardware

is requ_ed,

See page 17.

Rail

Header CLOSED POSITION

Bracket

Door

Bracket

Trolley

Stop Bolt Trolley

_Door

Arm

Chale

Emergency

Release

Rope & Handle

Page 5

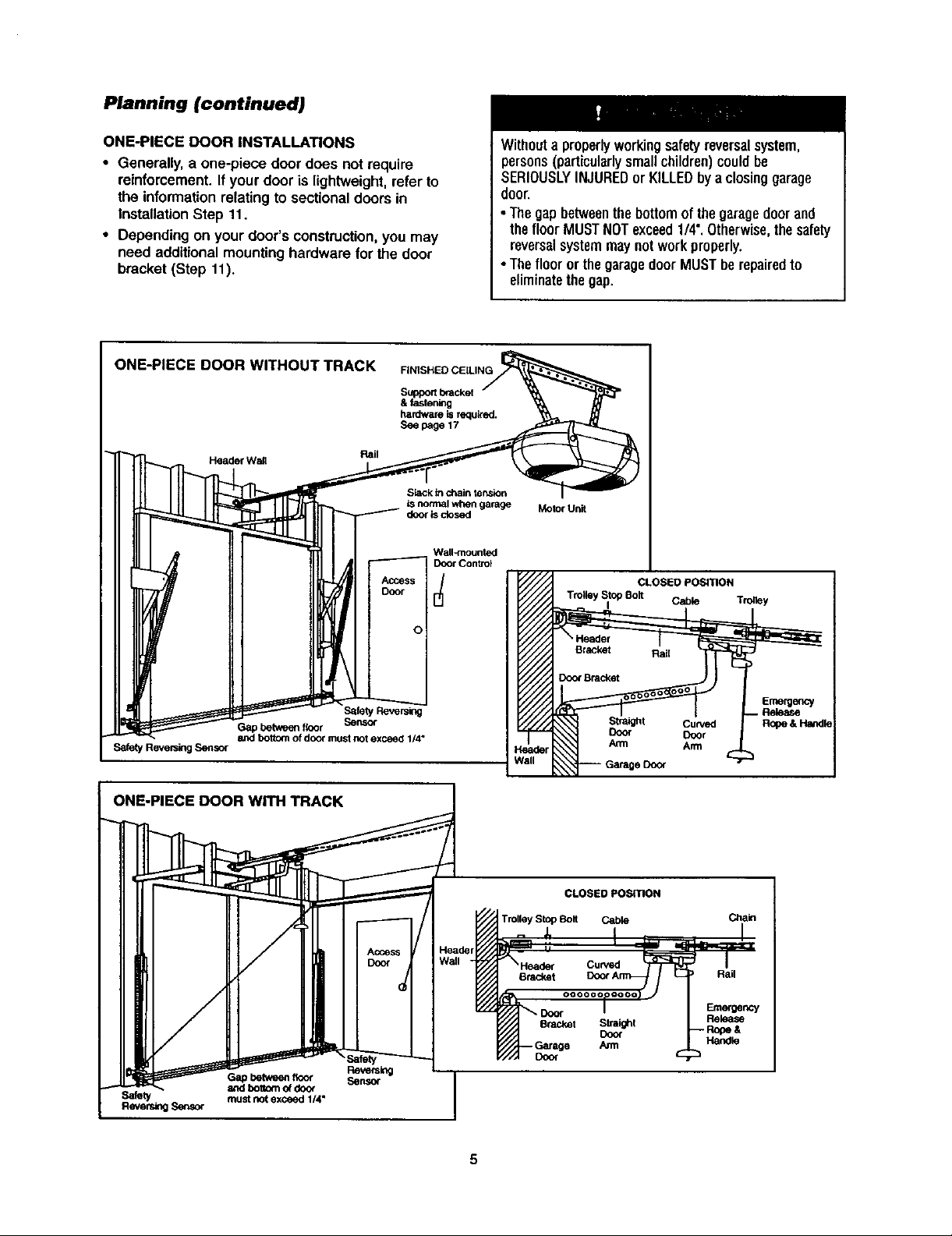

Planning (continued)

ONE-PIECE DOOR INSTALLATIONS

• Generally,a one-piece door does not require

reinforcement.If your door is lightweight,refer to

the informationrelatingto sectional doorsin

InstallationStep 11.

• Depending on your door's construction,you may

need additionalmountinghardwarefor the door

bracket (Step 11).

ONE-PIECE DOOR WITHOUT TRACK

Header Wail

FINISHED CEILING

Supportbracket

& fastening

hardware is requk'ab.

See page 17

Rail

DOOr

,cc.s

Slack inchain ter_sinn

isnormal when garage

door isclosed

o

Wall-mounted

Door Control

Withouta properlyworkingsafetyreversalsystem,

persons(particularlysmallchildren)couldbe

SERIOUSLYINJUREDor KILLEDbya closinggarage

door

•Thegapbetweenthebottomofthegaragedoor and

thefloor MUSTNOTexceed1/4".Otherwise,thesafety

reversalsystemmaynotworkproperly.

•Thefloor orthe garagedoorMUSTberepairedto

eliminatethegap.

Motor Unit

Trolley Stop Bolt

CLOSED POSITION

I Cable Trolley

Gap between floor Sensor

Safety Reversing Sensor

and bottom of door must not exceed 1/4"

ONE-PIECE DOOR WITH TRACK

Gapbetwee_floor Sensor

and boBom o_doo_

ReversingSensor

must not exceed 1/4"

.----.__.__

Safety Reversing

%

Reversing

Curved R_oe & HaiKIle

Door

eDd_r

/all

CLOSED POSITION

Trolley Stop Bolt Cable Chain

Dracket Rail

Door

Curved

Bracket Straight

Co<x

Arm

Handle

Emmgency

Rek_se

Emergency

. Release

5

Page 6

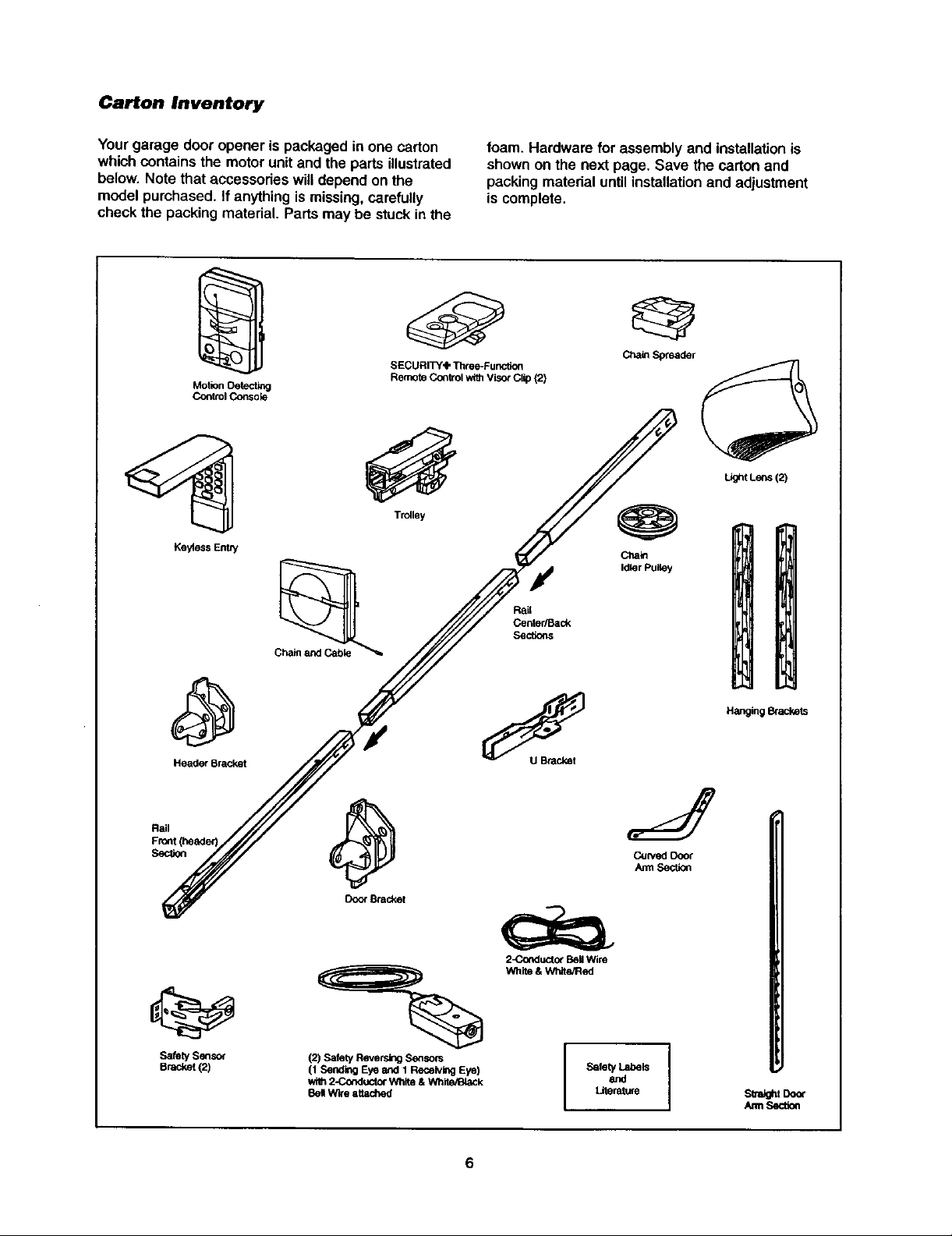

Carton Inventory

Yourgarage door opener is packaged in one carton

which containsthe motor unitand the parts illustrated

below. Note that accessodes willdepend on the

modelpurchased. If anythingismissing,carefully

check the packing material. Parts may be stuck inthe

SECURITY'IP Three-Func6on

Motion Oetectl_l

Co_trol Consok3

Ke_ess EnW

Remote Control with Visor Clip (2)

Trolley

foam. Hardware for assembly and installationis

shownon the next page. Save the carton and

packing materialuntil installationand adjustment

is complete.

Light Lens (2)

Ctlaio

Idler Pulley

Header Bracket

SafetySensor

Bracket{2)

Door Bracket

=%

(2) Safety Reversing S6_sors

(1 Sending Eye and 1 Receiving Eye)

wi_ 2-Co_luctor Wllite& White/IBiaCk

8el Wire attached

6

2_rKlucto_ BellWire

White & White/Red

SafetyandLabels I

LJtenMure

Hanging _ackets

sua_t Door

/um Sectk_

Page 7

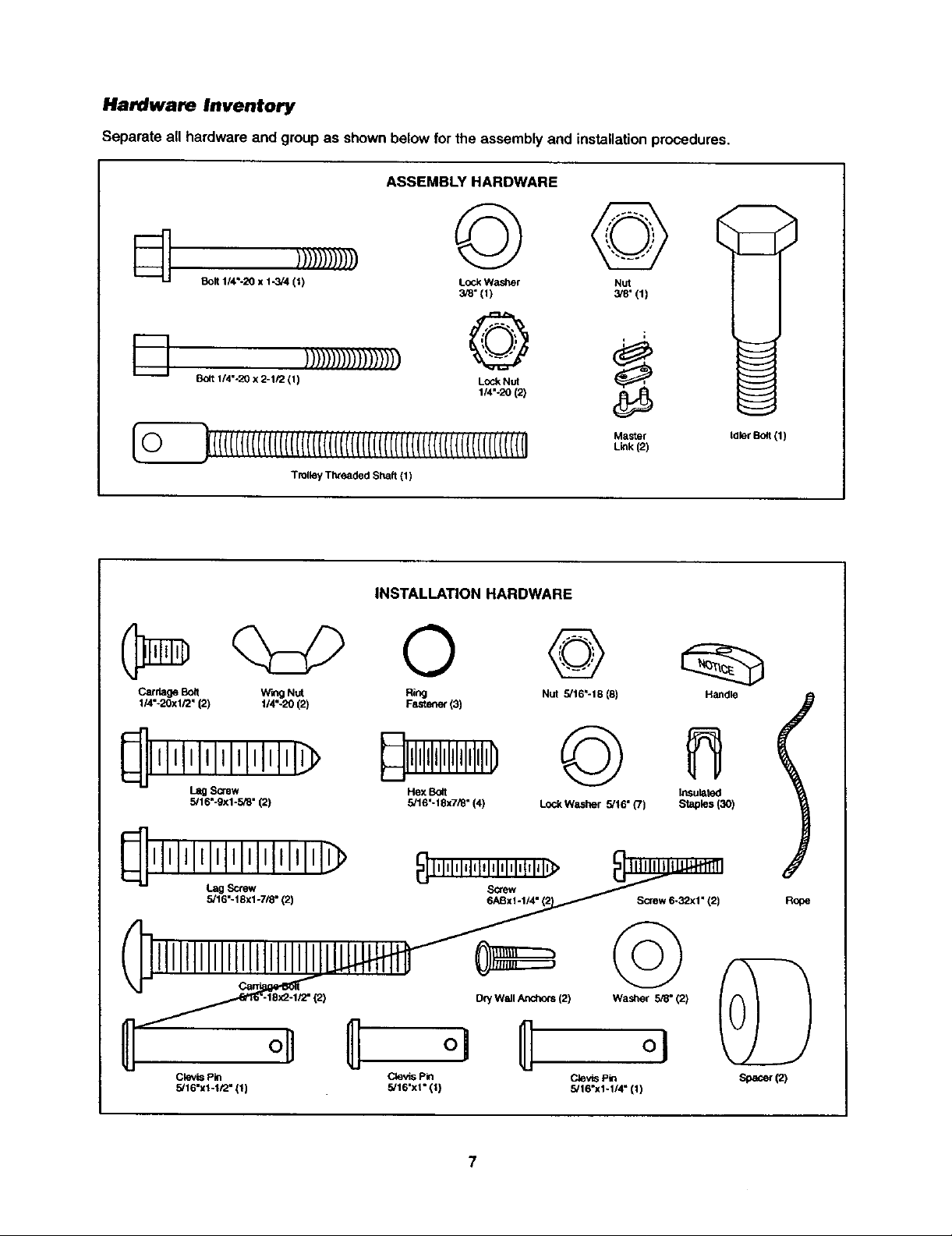

Hardware Inventory

Separate all hardware and groupas shownbelow forthe assembly and installationprocedures.

ASSEMBLY HARDWARE

© ©

Lock Washer Nut

3/8" (1) 3/8"(1)

I---!, ))))))))))))))))))

Bolt 1/4%20 x 2-1/2 (1)

Lock Nut

o

1/4"-20 (2)

Master

_(((((((((((((((((((((('('('('((((((((((('('('('('('('(('((l(((((r('('('('(i

Trolley Threaded Shaft (1)

INSTALLATION HARDWARE

Link (2)

0 @

Carriage Boit Wing Nut Ring Nut 5/16"-18 (8)

114"-20xl/2" (2) 114"-20 (2) FaStener (3)

_lllllllllllllllllll_

L_ Screw

5,'16"-9xi-5/8" (2)

Hex Bo4t

5/16"- 18x7/_" (4)

©

LockWashar 5/16" (7)

Handle

Insulated

Staples (3O)

tdler Bolt (1)

I

Clevis Pin

5/16"x1-1/2" (1)

[2) Dry Wall Anchors (2) Washer ,5_" (2)

oU

Clevis Pin Clevis Pin

5,'16"xl" 111 5/16"x1-1/4" (11

Screw 6-32xl" (2)

Rooe

Page 8

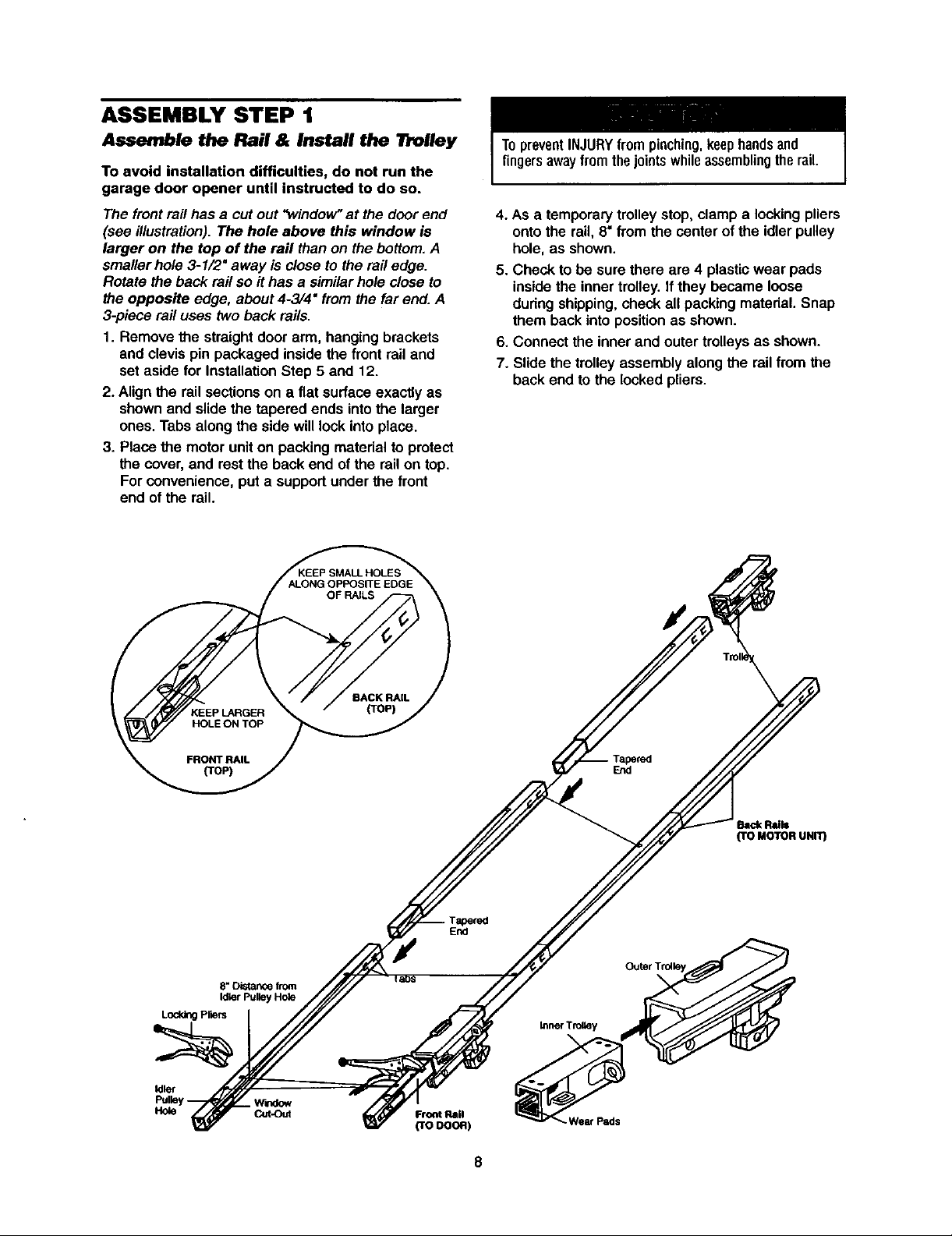

ASSEMBLY STEP 1

Assemble the Rail & Install the Trolley

To avoid installation difficulties, do not run the

garage door opener until instructed to do so.

The frontrail has a cut out "window"at the door end

(see illustration).The hole above this window is

larger on the top of the rail than on the bottom.A

smaller hole 3-1/2" away is close to the rail edge.

Rotate the back rail so it has a similarhole close to

the opposite edge, about 4-3/4" from the far end.A

3-piece rail uses two back rails.

1. Remove the straightdoor arm, hangingbrackets

and clevispin packaged inside the front rail and

set aside for InstallationStep 5 and 12.

2. Align the railsections on a flat surfaceexactly as

shownand slidethe tapered ends intothe larger

ones. Tabs along the side willlock into place.

3. Placethe motoruniton packing material to protect

the cover, and rest the back end of the railon top.

Forconvenience, put a supportunderthe front

end of the rail.

TopreventINJURYfrompinching,keephandsand

fingersawayfromthejointswhileassemblingtherail.

4. As a temporarytrolley stop,clamp a lookingpliers

ontothe rail, 8" from the center of the idler pulley

hole, as shown.

5. Check to be sure there are 4 plastic wear pads

insidethe inner trolley.If they became loose

during shipping,check all packing material. Snap

them backinto positionas shown.

6. Connect the inner and outer trolleysas shown.

7. Slidethe trolleyassembly along the rail from the

back end to the locked pliers.

e, Distance from

Ididr Pulley H(_e

Lodd_ P,ars

Idler

Hole Cut-Out

_lrtdow

Tapered

End

Front Rail

(reoooR)

End

hick R'=I=

(TO MOTOR UNIT)

Wear Pads

8

Page 9

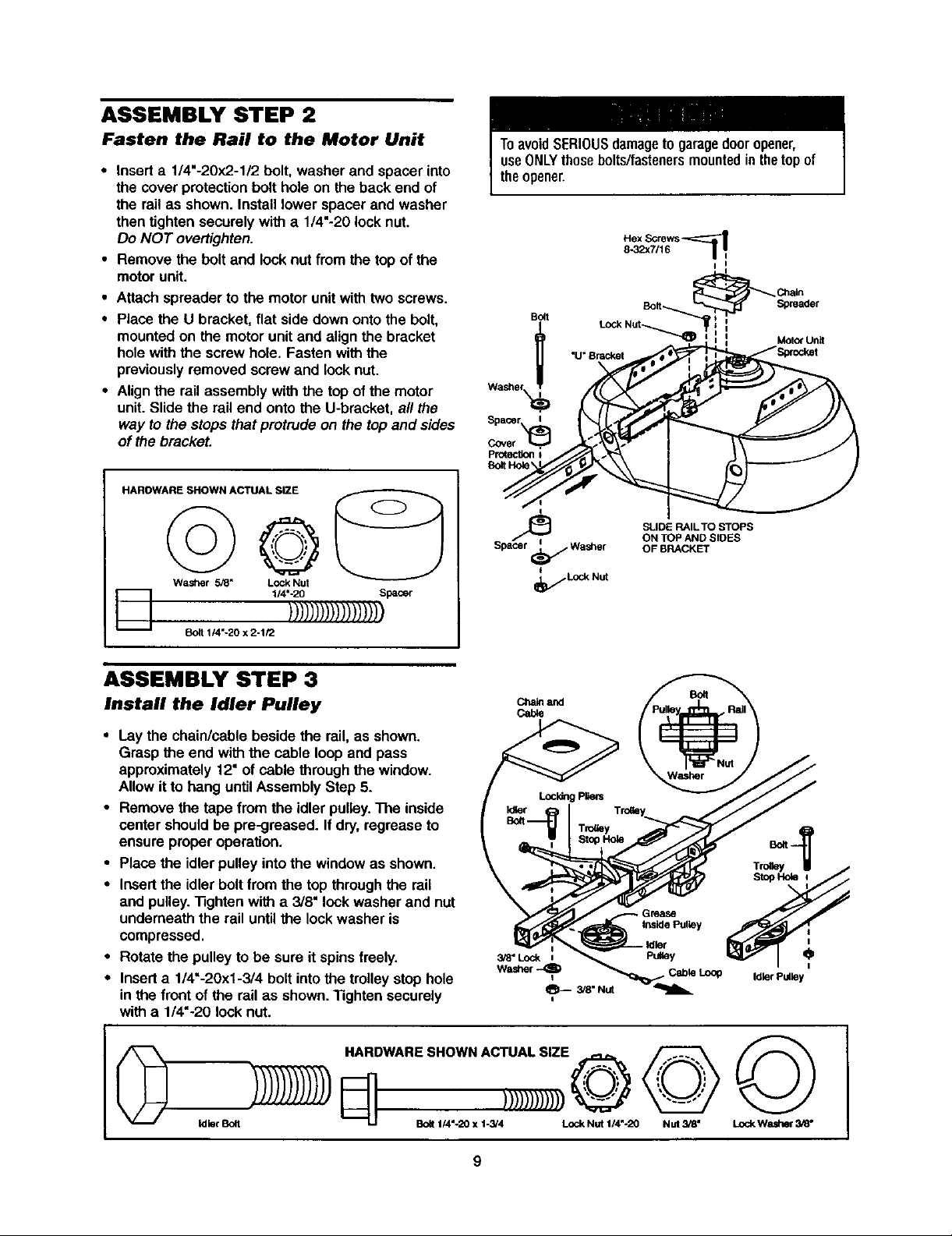

ASSEMBLY STEP 2

Fasten the Rail to the Motor Unit

• Insert a 1/4"-20x2-1/2 bolt, washer and spacer into

the cover protection bolt hole on the back end of

the rail as shown. Install lower spacer and washer

then tighten securely with a 1/4"-20 lock nut.

Do NOT overtighten.

• Remove the bolt and lock nut from the top of the

motor unit.

• Attach spreader to the motorunit with twoscrews.

• Place the U bracket, flat side down ontothe bolt,

mountedon the motor unit and align the bracket

holewith the screw hole. Fasten with the

previouslyremoved screw and lock nut.

• Alignthe rail assembly with the top ofthe motor

unit. Slidethe railend ontothe U-bracket, al/the

way to the stops that protrude on the topand sides

of the bracket.

ToavoidSERIOUSdamageto garagedooropener,

useONLYthosebolts/fastenersmountedinthetopof

theopener.

I

I

Bo_I

_r_)_ LOCkNut -......,_ : MOtOrUnit

Bolt-.._ Spreader

_ Ctnain

=

HAROWARE SHOWN ACTUAL SIZE

©

Washer 5_" Lock Nut

D

1/4"-20 x 2-1/2

ASSEMBLY STEP 3

Install the Idler Pulley

• Laythe chain/cable beside the rail, as shown.

Grasp the end with the cable loop and pass

approximately 12"of cable through the window.

Allow it to hang untilAssemblyStep 5.

• Remove the tape from the idler pulley.The inside

center should be pre-greased. If dry,regrease to

ensure proper operation.

• Place the idler pulley intothe windowas shown.

• Insertthe idler boltfrom the top throughthe rail

and pulley."13ghtenwitha 3/8" lockwasher and nut

underneath the railuntil the lock washer is

compressed.

• Rotate the pulley to be sure it spinsfreely.

• Inserta 1/4"-20xl-3/4 bolt intothe trolley stop hole

in the front of the rail as shown."Rghten securely

with a 1/4"-20 lock nut.

1/4"-20 Spacer

)))1))))))))))))))

__Spacer Ii

SLIDE RAIL TO STOPS

ON TOP AND SIDES

Spacer _ Wasi3er OF BRACKET

I

_f Lod_ Nut

C_aleand

Cable

Grease

Inside Pulley

3/8" Lock i PuUey O

Washer

Idler Pulley

©

Idler Bolt

HARDWARESHOWNACTUALSIZE -- _ / _--_ _

LJ BOlt1/4 -20 X 1-3/4 Lock Nut 114"-20 NUt 3/8" LockWasher 3/8"

9

Page 10

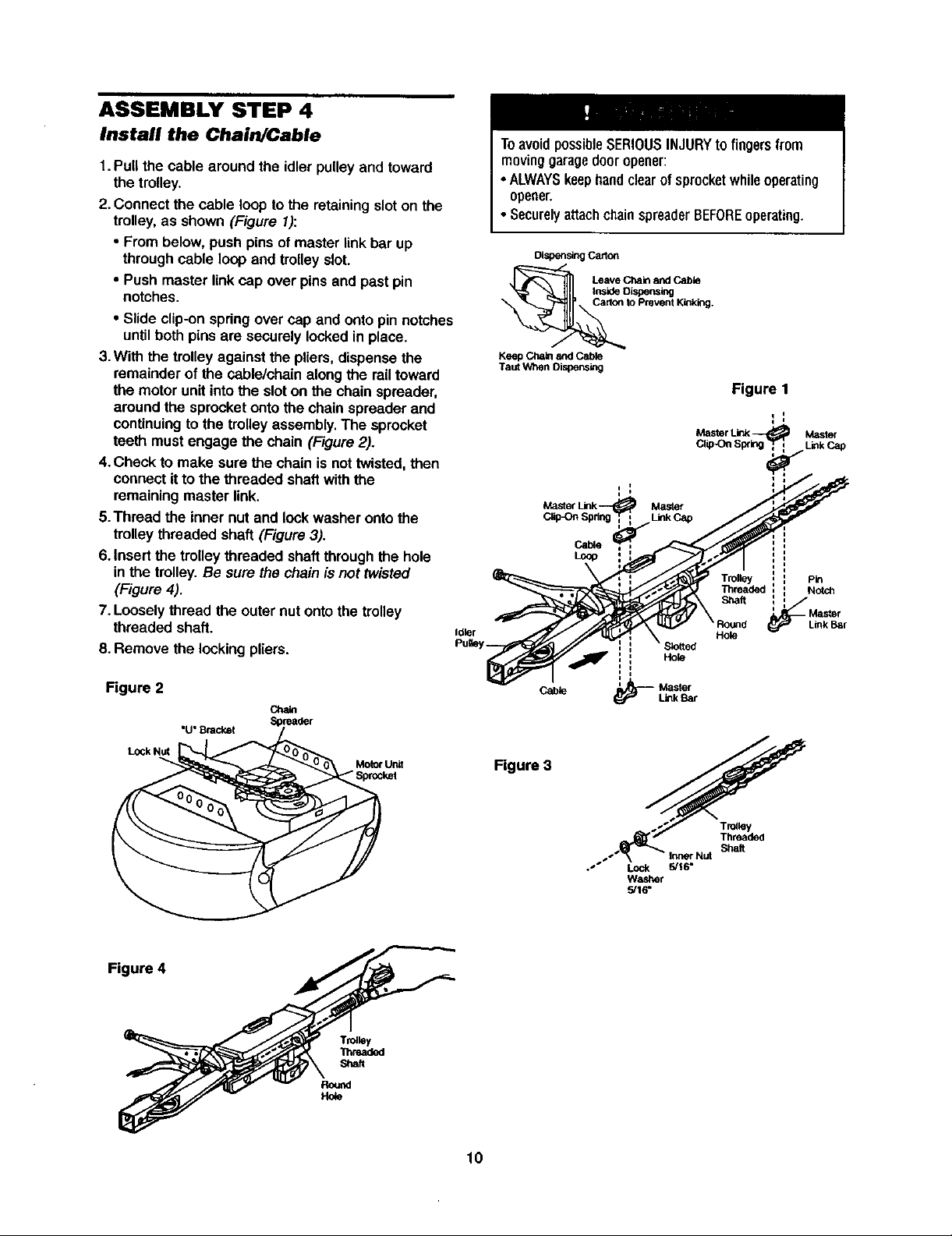

ASSEMBLY STEP 4

Install the Chain/Cable

1.Pull the cable aroundthe idler pulley and toward

the trolley.

2. Connect the cable loop to the retainingsloton the

trolley,as shown (Figure 1):

• From below, push pins of master linkbar up

through cable loopand trolleyslot.

• Push master link cap over pins and past pin

notches.

• Slide clip-onspringover cap and ontopin notches

until both pins are securely locked in place.

3.With the trolley against the pliers,dispense the

remainder of the cable/chain along the rail toward

the motor unitinto the slot on the chainspreader,

around the sprocketonto the chain spreader and

continuing to the trolley assembly. The sprocket

teeth must engage the chain (Figure 2).

4.Check to make sure the chain is not twisted, then

connect it to the threaded shaft with the

remaining master link.

5.Thread the inner nut and lock washer onto the

trolley threaded shaft (Figure 3).

6. Insert the trolley threaded shaft through the hole

in the trolley. Be sure the chainis not twisted

(Figure 4).

7. Loosely thread the outer nut onto the trolley

threaded shaft.

8. Remove the locking pliers.

Figure 2

Cha_

"U"Bracket

ToavoidpossibleSERIOUSINJURYtofingers from

moving garagedooropener:

•ALWAYSkeephandclearof sprocketwhileoperating

• Securelyattach chainspreaderBEFOREoperating.

Keep Chain and Cable

Taut When Dispensing

Idler

opener.

Dispensing Carton

Leave Chain and Cable

Inside OLspens_g

Clip-On S Link Cap

Cable

Loop

i

Cable ' Master

te Prevent Kinking.

CiipOn 8p¢ LinkCap

Master Link_ Master

Master

Hole

Link Bar

Figure 1

i I

q I

i

Threaded : Notch

Shaft l_

Hole

: Pin

Master

Link Bar

Figure 4

Motorunit

"Sprocket

Trolley

Thruded

Shaft

10

Figure 3

_._ Threaded

_.-"_ \ - InnerNut Shaft

.'" Lock 5/16*

Washer

.5/16"

Page 11

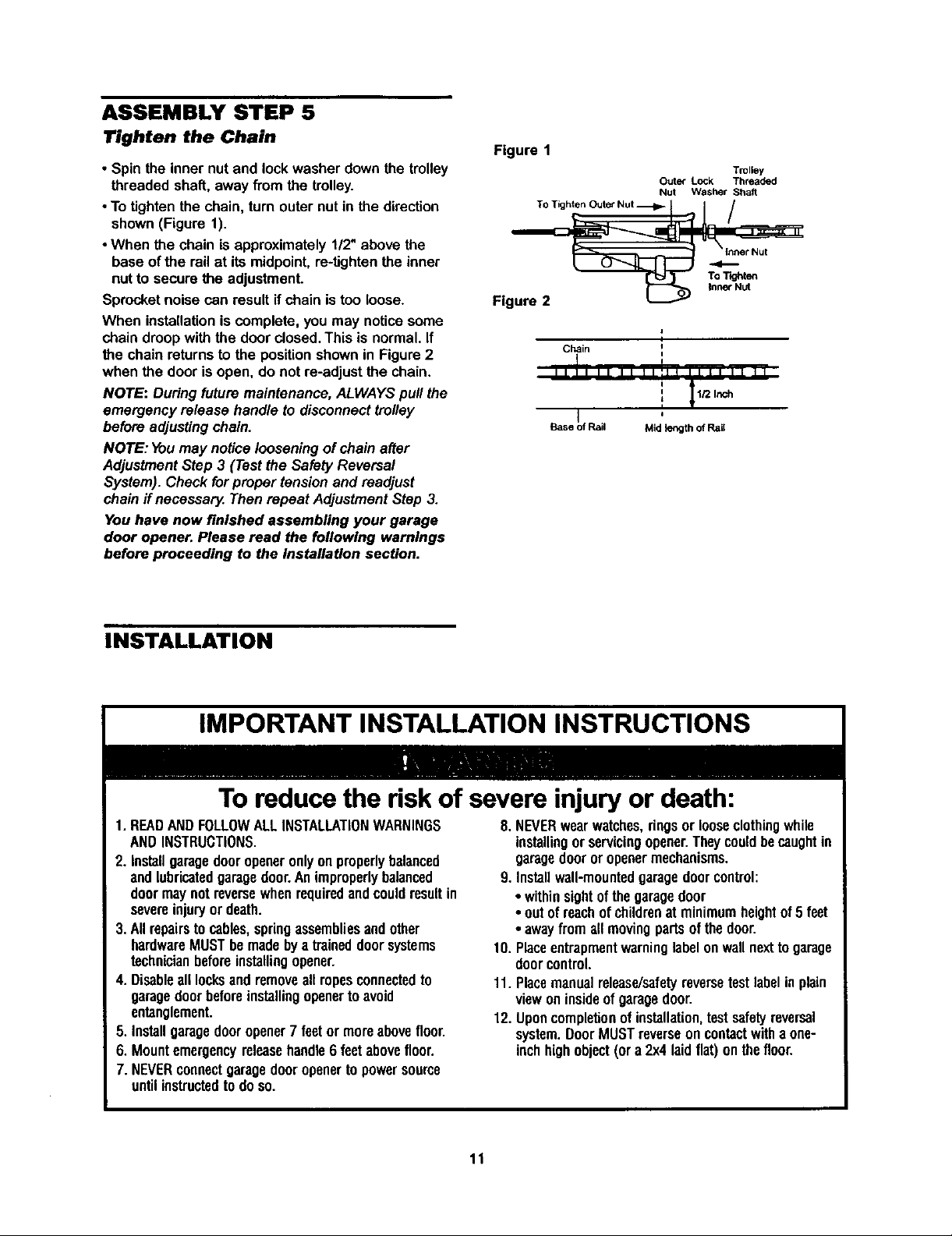

ASSEMBLY STEP 5

Tighten the Chain

• Spin the inner nut and lockwasher down the trolley

threaded shat_,away from the trolley.

• To tighten the chain, turn outernutinthe direction

shown(Figure 1).

•When the chain is approximately112"above the

base of the railat its midpoint,re-tightenthe inner

nut to secure the adjustment.

Sprocketnoise can resultif chain is too loose.

When installationis complete, you may noticesome

chain droop withthe doorclosed.Thisis normal.If

the chain returnsto the positionshownin Figure2

when the door isopen, do not re-adjust the chain.

NOTE: Duringfuture maintenance,ALWAYSpull the

emergency release handle to disconnecttrolley

before adjustingchain.

NOTE: Youmay noticelooseningof chain after

AdjustmentStep 3 (Testthe Safety Reversal

System). Check forproper tension and readjust

chainif necossary.Then repeat AdjustmentStep 3.

You have now finished assembling your garage

door opener. Please read the following warnings

before proceeding to the Installation section.

Figure 1

Figure 2

Outer Lock Threaded

Nut Washer Shaft

Chain i

II ]1 II II Ilill II II II

: _ 1/2 Inch

f

I

Base Rail Mid length of Rail

,

Trolley

I I

INSTALLATION

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of severe injury or death:

1.READANDFOLLOWALLINSTALLATIONWARNINGS

ANDINSTRUCTIONS.

2. Installgaragedooropeneronlyon properlybalanced

and lubricatedgaragedoor.Animproperlybalanced

doormaynotreversewhenrequiredandcouldresultin

severeinjuryordeath.

3.All repairsto cables,springassembliesandother

hardwareMUSTbemadebya traineddoorsystems

technicianbeforeinstallingopener.

4. Disableall locksandremoveallropesconnectedto

garagedoorbeforeinstallingopenerto avoid

entanglement.

5. Installgaragedooropener7 feetor moreabovefloor.

6. Mountemergencyreleasehandle6 feetabovefloor.

7. NEVERconnectgaragedooropenerto powersource

untilinstructedtodoso.

8.NEVERwearwatches,ringsor looseclothingwhile

installingor servicingopener.Theycouldbecaughtin

garagedooror openermechanisms.

9. Installwall-mountedgaragedoorcontrol:

• withinsightofthegaragedoor

• outofreachofchildrenat minimumheightof5 feet

• awayfrom all movingparts ofthedoor.

10. Placeentrapmentwarninglabelonwallnexttogarage

doorcontrol.

11. Placemanualrelease/safetyreversetestlabelinplain

viewoninsideofgaragedoor.

12. Uponcompletionof installation,testsafetyreversal

system.DoorMUSTreverseoncontactwitha one-

inchhighobject(or a 2x4laid flat)onthefloor.

11

Page 12

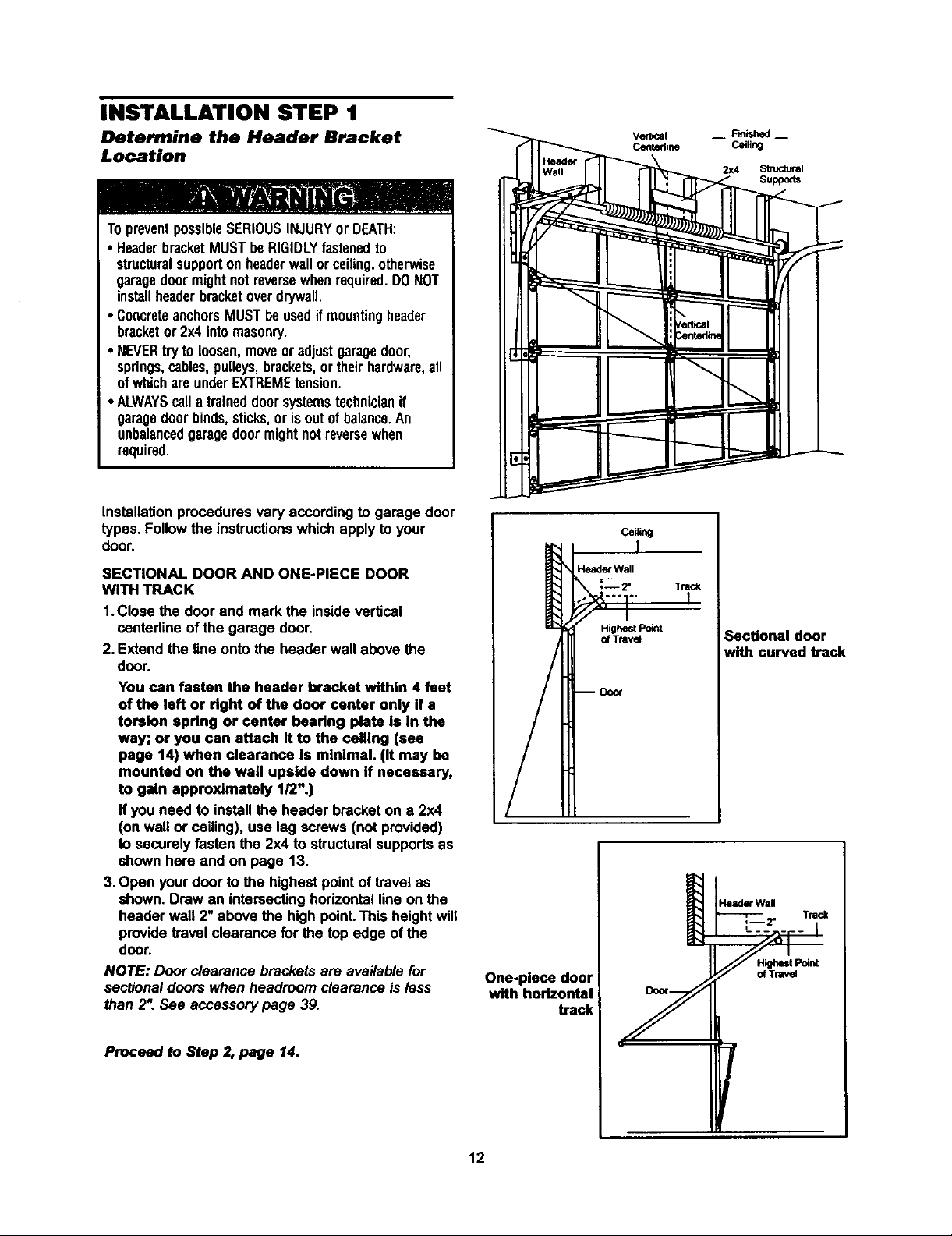

INSTALLATION STEP 1

Determine the Header Bracket

Location

TopreventpossibleSERIOUSINJURYor DEATH:

• HeaderbracketMUSTbe RIGIDLYfastenedto

structuralsupportonheaderwallorceiling,otherwise

garagedoormightnotreversewhenrequired.DONOT

installheaderbracketoverdrywall.

• ConcreteanchorsMUSTbeusedifmountingheader

bracketor2x4 intomasonry.

• NEVERtryto loosen,moveoradjustgaragedoor,

springs,cables,pulleys,brackets,or theirhardware,all

ofwhichare underEXTREMEtension.

• ALWAYScalla traineddoorsystemstechnicianif

garagedoorbinds,sticks,orisoutof balance.An

unbalancedgaragedoormightnot reversewhen

required.

Installation procedures vary according to garage door

types. Follow the instructions which apply to your

door.

SECTIONAL DOOR AND ONE-PIECE DOOR

WITH TRACK

1.Close the door and mark the insidevertical

centerlineof the garage door.

2. Extend the line onto the header wall above the

door.

You can fasten the header bracket within 4 feet

of the left or right of the door center only If a

torsion spdng or center bearing plate is in the

way; or you can attach It to the ceiling (see

page 14) when clearance is minimal. (It may be

mounted on the wall upside down if necessary,

to gain approximately 1/2".)

If you need to installthe header bracketon a 2x4

(on wall or ceiling), use lag screws (not provided)

to securely fasten the 2x4 to structuralsupportsas

shown here and on page 13.

3.Open your door to the highest pointof travel as

shown. Draw an intersectinghorizontal lineon the

header wall 2" above the high point.This heightwill

providetravel clearance for the top edge of the

door.

NOTE: Door clearance brackets are availablefor

sectionaldoors when headroom clearance is less

than 2". See accessory page 39.

One-piece door

with horlzontal

track

Header Wall

Highest Point

of Ttavst

Trac_

Sectional door

with curved track

Proceed to Step 2, page 14.

12

Page 13

ONE-PIECEDOORWITHOUTTRACK

1.Closethedoorandmarkthe insidevertical

centadine of your garage door.Extend the line

onto the header wall above door, as shown.

If headroom clearance is minimal, you can install

the header bracket on the ceiling. See page 14.

If you need to install the header bracket on a 2x4

(on wall or ceiling), use lag screws (not provided)

to securely fasten the 2x4 to structural supports

as shown.

2. Open your door to the highest point of travel as

shown. Measure the distance from the top of the

door to the floor. Subtract the actual height of the

door. Add 8" to the remainder. (See Example).

3.Close the door and draw an intersecting horizontal

line on the header wall at the determined height.

NOTE: ff the total number of inches exceeds the

height available in your garage, use the maximum

height possible, or refer to page 14 for ceiling

installation.

EXAMPLE

Distancefrom top of door

(at highest pointof travel)to floor...................... 92"

Actualheight of door.......................................... -88"

Remainder.......................................................... 4"

Add..................................................................... +8"

Bracketheight on header wall............................ =12"

(Measure UP from top of CLOSED door.)

VerUcst

Centedine

2x4

Header Wall

J

HighestPoint

of Tr=vst

HEADER BRACKET

FOR

Proceed to Step 2,page 14.

One-piece door without track: jamb hardware

Highest Point

Header Wall

of Travel

One-piece door without track:

13

pivot hardware

Fkxx

Page 14

INSTALLATION STEP 2

Install the Header Bracket

You can attach the header bracket either to the wall

above the garage door, or to the ceiling. Follow the

instructions which will work best for your particular

requirements. Do not install the header bracket

over drywall. If installing into masonry, use

concrete anchors (not provided).

WALL HEADER BRACKET INSTALLATION

• Center the bracket on the vertical centadinewith

the bottomedge of the bracketon the horizontal

line as shown (with the arrow pointingtowardthe

ceiling).

• Mark the vertical set of bracketholes. Ddll 3/16"

pilotholes and fastenthe bracket securelyto a

structuralsupport with the hardware provided.

2)(4

Sb_mturai

Suppo_

Wall Mount

Optional

Mounting Hole_

Vedk_l

Centedlne

Lag Screws

5/16"xgx1-SJS"

HAROWARE SHOWN ACTUAL SiZE

lll IIIIIlllllIJl

Lag Screw

5/16"-9x1-518"

CEIUNG HEADER BRACKET INSTALLATION

• Extend the vertical centerline ontothe ceilingas

shown.

• Center the bracket on the vertical mark, no more

than 6"from the wall.Make sure the arrow is

pointing awayfrom the wall. The bracket can be

mounted flush againstthe ceiling when clearance

is minimal.

• Mark the side holes. Drill 3/16" pilotholes and

fasten bracket securelyto a structuralsupportwith

the hardware provided.

Highest Point of

Garage Door Travel

Heade_ _

Bracket

Door

Sp_ng

/

/

- Finished Celllng -

I

Garage

Centedine

5/16"xgx1-5/8"

14

Page 15

Header Bracket

INSTALLATION STEP 3

Attach the Rail to the

Header Bracket

NOTE: (Optional) Withan existing Craftsman

installation,you may re-use the old header bracket

withthe twoplastic spacers includedin the hardware

bag. Place the spacers inside the bracket on each

side of the rail, as illustrated.

• Positionthe opener on the garage floor below the

header bracket. Use packing material as a

protectivebase. NOTE: If the door spring isin the

way you'llneed help. Have someone hold the

opener securelyon a temporary supportto allow

the raft toclear the spring.

• Positionthe front rail end withinthe header bracket

and join with a 5/16"x1-1/2" clevispin as shown.

• Inserta ring fastener to secure.

Door

Mounting

Hole

HARDWARE SHOWN ACTUAL SIZE

Header Bracket

Mounting

Hole

EXISTING CRAFTSMAN

INSTALLATION

OpenerCart_ of

Suppeft

Clevis Pin 5/16"x1-1/2" Ring fastener

15

Page 16

INSTALLATION STEP 4

Position the Opener

Follow instructions which apply to your door type as

illustrated.

SECTIONAL DOOR OR ONE-PIECE DOOR WITH

TRACK

A 2x4 laidflat is convenientfor setting an ideal door-

to-rail distance.

• Raise the opener onto a stepladder You will need

help at this point if the ladder is not tall enough.

• Open the door all the way and place a 2x4 laid flat

on the top section beneath the rail.

• If the top section or panel hits the trolley when you

raise the door, pull down on the trolley release arm

to disconnect inner and outer sections. Slide the

outer trolley toward the motor unit. The trolley can

remain disconnected until Installation Step 12

is completed

Topreventdamageto garagedoor,restgaragedoor

openerrailon2x4placedontopsectionofdoor

ONE-PIECE DOOR WITHOUT TRACK

• With the door fully openand parallelto the floor,

measure the distancefrom the floorto thetop of

the door.

• Using a stepladder as a support,raise the top of

the opener to this height.

• The top of the door shouldbe levelwith the top of

the motor unit. Do not positionthe opener more

than 2" above this point.

Header

Top of Motor

Top of Door

16

Page 17

INSTALLATION STEP 5

Hang the Opener

Two representative installations are shown. Yours

may be different. Hanging brackets should be angled

(Figure 1) to provide rigid support. On finished

ceilings (Figure 2), attach a sturdy metal bracket to

structural supports before installing the opener. This

bracket and fastening hardware are not provided.

(See Accessories).

1.Measure the distancefromeach side of the motor

unitto the structuralsupport.

2. Cut bothpieces of the hanging bracketto required

lengths.

3. Drill 3/16" pilot holes in the structuralsupports.

4. Attach one end of each bracketto a supportwith

5/16"-18xl -7/8" lag screws.

5. Fasten the opener to the hangingbrackets with

5/16"-18x7/8" hex bolts,lock washers and nuts.

6. Check to make sure the rail is centered overthe

door(or in line withthe header bracketif the

bracketis not centered above the door).

7. Remove the 2x4. Operate the door manually.Ifthe

door hitsthe rail,raisethe header bracket.

NOTE: DO NOT connectpower to opener at this

time.

ToavoidpossibleSERIOUSINJURYfromafalling

garagedooropener,fastenit SECURELYtostructural

supportsofthegarage.ConcreteanchorsMUSTbeused

ifinstallinganybracketsintomasonry.

Figure 1

• Lag Screws

Bolt 5,'16"-18x718"

Nut 5/16"-18

5/16"-18xl-7/8"

Figure 2

-- Finished Ceiling --

__.+ 5/16=*18xl-718 - _._"

Lag Screws

HARDWARE SHOWN ACTUAL SIZE

5/16"-18xl-7/8"

Hex Bolt

5/16"- 18X7/8" Nut 5/16%18

Nut 5/16"-18

©

Lock Washer 5/16"

17

Page 18

INSTALLATION STEP 6

Install the Door Control

Locate door control within sight of door, at a

minimum height of 5 feet where small children

cannot reach, away from moving parts of door and

door hardware. If installing into drywall, drill 5/32"

holes and use the anchors provided. For pre-wired

installations (as in new home construction), it may be

mounted to a single gang box (Figure 2).

1. Skip 7/16" of insulation from one end of bell wire

and connect to the two screw terminals on back of

door control by color: white wire to 2 and white/red

wire to the 1.

2.Remove white cover by gentlyprying at slot in top

ofthe cover with a small fiat head screwdriver.

Fasten with 6ABx1-l/4%elf-tapping screws

(drywall installation)or6-32x1" machinescrews

(intogang box) as follows:

• Installbottomscrew, allowing 1/8"to protrude

above wall surface.

• Positionbottom of door control onscrew head

and slidedown to secure.Adjust screw

for snugfit.

• Ddll and installtop screw with care to avoid

cracking plastichousing.Do not over tighten.

• Inserttop tabs and snap on cover.

3. (For standard Installation only) Run bell wire up

wall and across ceilingto motorunit.Use insulated

staplesto secure wire in several places.Do not

piercewire with a staple,creatinga shortor open

circuit.

4. Skip 7/16" of insulationfrom end of bell wire.

Connect bell wire to the quick-connect terminals

as follows: white to white and white/redto red.

NOTE: When connecting multiple door controls to

the opener, twist same color wires together. Insert

wires into quick-connect holes: white to white and

redhNhite to red.

5. Positionthe antenna wire as shown.

6. Use tacks orstaplesto permanentlyattach

entrapment warninglabel to wall near door

control, and manual release/safety reverse

test label in a prominentlocationoninsideof

garage door.

NOTE: DO NOT connect power and operate

opener at thistime. The trolleywill travelto the

fullopen positionbut will not returnto the close

positionuntil thesensor beam is connected

and properly aligned.

To preventpossibleSERIOUSINJURYor DEATHfrom

electrocution:

• Besurepower isnotconnectedBEFOREinstallingdoor

• control.

ConnectONLYto 24 VOLTlowvoltagewires.

TopreventpossibleSERIOUSINJURYor DEATHfroma

closinggaragedoor:

Installdoorcontrolwithinsightofgaragedoor,outof

reachof childrenat a minimumheightof5feet,and

awayfromall movingpartsof door.

• NEVERpermit childrentooperateorplaywithdoor

controlpushbuttonsorremotecontroltransmitters.

•ActivatedoorONLYwhenitcanbeseenclearly,is

properlyadjusted,andthereareno obstructionstodoor

travel.

• ALWAYSkeepgaragedoorinsightuntilcompletely

closed,NEVERpermitanyoneto crosspathof closing

garagedoor.

Outside Keylock Accessory Connections

To opener quick-connectterminals:white to white;

white/red to red.

HARDWARE SHOWN ACTUAL SiZE

6AB x 1-114"Screw Insulated

{_I_lillltltllltltlt Ill,Ill>

Control Console (std Installation) Staples

ContrOl Console (pre-wired) Dry Wall Anchors

Figure 1

REMOVE & REPLACE COVER

To Replace,

Insefl Top

2-Conducto_

Push Bar Bert Wire

Figure 2

PRE-WIRED

INSTALLATION

Qu_Connect

TerminaLs

24 Volt

2-Coeductor

Sell Wire in

Gang Box

(BACK VIEW)

18

-_ur_dng

To release wire, push in tab Door Control

withscrewdriver tip Connections

Red

Strip wire 7116"

// White Grey J Antenna

Page 19

INSTALLATION STEP 7

Install the Lights

• Press the release tabs on both sides of lens. Gently

rotate lens back and downward until the lens hinge

is in the fully open position. Do not remove

the lens.

• install up to a 100 watt maximum light bulb in each

socket. The lights will turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the lights will turn OFF.

• Reverse the procedure to close the lens.

• If the bulbs burn out prematurely due to vibration,

replace with a Garage Door Opener bulb.

NOTE: Use only standard light bulbs. The use of

short neck or speciality light bulbs may overheat the

endpanel or light socket.

Release Tab

100 Watt (Max)

Light Bulb

Standard

IC0 Watt (Max) "--_-_ )

Standard Light Bulb

/

/

/

Lens

Hinge

INSTALLATION STEP 8

Attach the Emergency Release

Rope and Handle

• Thread one end of the rope through the hole inthe

top ofthe red handle so "NOTICE" reads rightside

up as shown. Secure with an overhandknotat

least 1"from the end of the ropeto

preventslipping.

• Thread the other end of the ropethrough the hole

inthe release arm of the outer trolley.

• Adjust rope lengthso the handle is 6 feet above

the floor.Secure with an overhand knot.

NOTE: flit is necessary to cut the rope, heat

seal the cut end with a match or lighter to

prevent unraveling.

• TopreventpossibleSERIOUSINJURYorDEATHfrom

a fallinggaragedoor:

- Ifpossible,useemergencyreleasehandleto

disengagetrolleyONLYwhengaragedooris

CLOSED.Weakor brokenspringsor unbalanced

doorcouldresultin anopendoorfalling rapidly

and/orunexpectedly.

- NEVERusaemergencyreleasehandleunlessgarage

doorwayisclearofpersonsandobstructions.

• NEVERusehandleto pulldooropenorclosed.If rope

knotbecomesuntied,youcouldfall.

T_y

Emergency' Knot

Ove_and

19

Page 20

INSTALLATION STEP 9

Electrical Requirements

To avoid installation difficulties, do not run the

opener at this time.

To reduce the risk of electric shock, your garage door

opener has a grounding type plug with a third

grounding pin. This plug will only fit into a grounding

type outlet. If the plug doesn't fit into the outlet you

have, contact a qualified electrician to install the

proper outlet.

If permanent wiring Is required by your local

code, refer to the following procedure.

To make a permanent connection through the 7/8"

hole in the top of the motor unit:

• Remove the motor unit cover screws and set the

cover aside.

• Remove the attached3-prong cord

• Connect the black (line) wire to the screw on the

brass terminal;the white (neutral) wire to the screw

on the silver terminal; and the groundwiretothe

green ground screw The opener must be

grounded.

• Reinstallthe cover.

TopreventpossibleSERIOUSINJURYor DEATHfrom

electrocutionor fire:

• Besurepowerisnotconnectedto theopener,and

disconnectpowertocircuitBEFOREremovingcoverto

establishpermanentwiringconnection.

• GaragedoorinstallationandwiringMUSTbein

compliancewithall localelectricalandbuildingcodes

• NEVERuseanextensioncord,2-wireadapter,or

changeplugin anywaytomakeit fitoutlet Besure

theopenerisgrounded

PERMANENT WIRING

CONNECTION

GroundTab

Green

2O

Page 21

INSTALLATION STEP 10

Install The Safety Reversing Sensor

The safety reversing sensor must be connected

and aligned correctly before the garage door

opener will move in the down direction.

IMPORTANT INFORMATION ABOUT

THE SAFETY REVERSING SENSOR

When properlyconnected and aligned, the sensor

will detect an obstacle in the path of its electronic

beam. The sendingeye (withan orange indicator

light)transmitsan invisiblelightbeam to the

receivingeye (with a green indicatorlight).If an

obstructionbreaksthe lightbeam while the door is

closing,the door will stop and reverse to fullopen

position,and the opener lightswill flash 10 times.

The units must be installedinsidethe garage so that

the sendingand receiving eyes face each other

acrossthe door,no higher than 6" above the floor.

Eithercan be installedon the left or dghtofthe door

as long as the sun never shines directlyintothe

receivingeye lens.

The mountingbrackets are designed to clip ontothe

track of sectionalgarage doors withoutadditional

hardware.

• Besurepoweris notconnectedto thegaragedoor

openerBEFOREinstallingthesafetyreversingsensor.

•TopreventSERIOUSINJURYor DEATHfroma closing

garagedoor:

- Correctlyconnectandalignthesafetyreversing

sensor.ThisrequiredsafetydeviceMUSTNOTbe

disabled.

- Installthesafetyreversingsensorso beamisNO

HIGHERthan6"abovegaragefloor.

If it is necessaryto mount the unitson the wall, the

bracketsmust be securely fastened to a solid

surface suchas the wall framing. Extensionbrackets

(see accessories)are available if needed, ff

installingin masonry construction,add a piece of

wood at each locationto avoid ddllingextraholes in

masonryif ropositioningis necessary.

The invisiblelightbeam path must be unobstructed.

No part of the garage door (or door tracks, springs,

hinges, rollersor other hardware) may interruptthe

beam whilethe door is closing.

Facing the door from Inside the garage

Senso(Beam

6"maximum

abovefloor

21

Page 22

INSTALLINGTHEBRACKETS

Besurepowertotheopenerisdisconnected.

Installandalignthebracketssothe sensors willface

each other acrossthe garage door,with the beam no

higherthan 6" above the floor.They may be installed

in one ofthree ways, as follows.

Garage door track installation (preferred):

• Slip the curved arms overthe rounded edge of

each door track, with the curved arms facing the

door.Snap into place against the side of the track.

Itshould lie flush,with the lip huggingthe back

edge ofthe track, as shown in Figure 1.

Ifyour door trackwillnot supportthe bracket

securely, wall installationis recommended.

Wall installation:

• Place the bracket againstthe wall withcurved arms

facingthe door. Be sure there isenough clearance

for the sensorbeam to be unobstructed.

• If additionaldepth isneeded, an extension bracket

(see Accessodes)or woodblocks can be used.

• Use bracket mountingholes as a template to locate

and ddll (2) 3/16" diameter pilotholes on the wall at

each side of the door,no higherthan 6"abovethe

floor.

• Attach brackets to wall with lag screws

(not provided).

• If usingextension brackets or wood blocks,adjust

rightand left assembliesto the same distance out

from the mountingsurface. Make sure all door

hardware obstructionsare cleared.

Floor installation:

• Use wood blocks or extension brackets (see

Accessories) toelevate sensor bracketsso the

lenses willbe no higher than 6"above the floor,

• Carefully measure and place dght and left

assembliesat the same distance out fromthe wall.

Be sure all door hardware obstructionsare cleared.

• Fasten to the floorwith concreteanchors as shown.

Figure 1

DOOR TRACK MOUNT (RIGHT SIDE)

, Track

Lip

_n_

Bme_l

Figure 2 WALL MOUNT (RIGHT SLOE)

Exte_on

Bracket

(See Accessories)

(Provided with

Extension '

Bracket)

Lens

Figure 3 FLOOR MOUNT (RIGHT SLOE)

Logs

Senso_

Bracket

Indicator

Light

(Providedwith

Extem_on Bracket)

indicator

Llghl

d with

Bracket)

(no_provided)

HARDWARE SHOWN AC1UAL SIZE

CardageBolt wingNut Staples

1/4"-20xl/2" 1/4"-20

Extension

(SeeAccesso_s)

22

Page 23

MOUNTINGANDWIRINGTHESAFETYSENSORS

• Slide a 114"-20x112"carriage bolthead intothe slot

on each sensor, Use wing nuts to fasten sensorsto

brackets, with lenses pointingtoward each other

across the door. Be sure the lens isnot obstructed

bya bracketextension(Figure 4).

• Finger tighten the wing nuts.

• Run the wires from both sensors tothe opener. Use

insulatedstaplesto secure wire to wall and ceiling.

• Strip 7/16" of insulationfrom each set of wires.

Separate white and white/black wires sufficientlyto

connectto the opener quick-connectterminals.

Twist like coloredwires together. Insert wires into

quick-connectholes:whiteto whiteand white/black

togrey (Figure 5).

AUGNING THE SAFETY SENSORS

• Plug in the opener. The indicator lightsin both the

sendingand receivingeyes will glowsteadily if

winng connectionsand alignmentare correct.

The sending eye orange indicatorlightwill glow

regardless of alignmentor obstruction.If the green

indicatorlight in the receiving eye is off, dim, or

flickering (and the invisiblelightbeam path is not

obstructed),alignment is required.

• Loosenthe sendingeye wing nut and readjust,

aimingdirectly at the receivingeye. Lock in place.

• Loosen the receiving eye wing nut and adjust

sensoruntil it receives the sender's beam. When

the green indicatorlight glowssteadily,tightenthe

wingnut.

Figure 4

Carnagebolt "_"

1/4"-20xl/2"

TROUBLESHOOTING THE SAFETY SENSORS

1. If the sendingeye indicatorlightdoes not glow

steadilyafter installation,check for:

• Electdcpower to the opener.

•A short in the white or white/black wires.These

can occurat staples,or at opener connections.

• Incorrectwiring between sensors and opener.

• Abrokenwire.

2. Ifthe sendingeyeindicatorlightglowssteadilybut

the receivingeye indicatorlightdoesn't:

• Check alignment.

• Check for an open wire to the receivingeye.

3. If the receivingeye indicatorlightis dim, realign

either sensor.

NOTE: When the invisiblebeam path is obstructed

or misalignedwhilethe door is closing,the door will

reverse.If the dooris already open, it willnot close.

The opener lightswillflash 10 times. See page 21.

Figure 5

BellWire Finished

-- Ceg_g --

Coflnect w'we to

1. Stdp wire 7n6"

wirestogether

2+ Twist _e colored

3. Inset into

appropriate terminals

Quk:k-ConnectTerrrdna_

23

Page 24

INSTALLATION STEP 11

Fasten the Door Bracket

Follow instructionswhich applyto your door type

as illustratedbelow or on the following page.

A horizontal reinforcement brace should be long

enough to be secured to two vertical supports. A

vertical reinforcement brace should cover the

height of the top panel.

The illustrationshowsone piece of angle ironas the

hodzontal brace. For the vertical brace, two pieces of

angle ironare used to create a "U'-shaped support

(Figure 1). The best solutionis to check with your

garage door manufacturerfor an openerinstallation

door reinforcementkit.

NOTE: Many verticalbrace installationsprovide for

directattachment of the clevis pin and door ann. In

this case you willnot need the doorbracket;proceed

to Installation Step 12.

SECTIONAL DOORS

• Center the door bracket on the previouslymarked

vertical centedine used for the header bracket

installation.Note correctUP placement, as

stamped insidethe bracket (Figure 2).

• Positionthe bracket on the face of the door within

the followinglimits:

A) The top edge of the bracket 2"-4" belowthe top

edge of the door.

B) The top edge of the bracket directlybelow any

structuralsupportacross the top of the door.

Topreventdamageto garagedoor,reinforceinsideof

doorwithangleironbothverticallyandhorizontally.

HAROWARE SHOWN ACTUAL SIZE

CantleSot

5/16"-18X2-1/2"

• Mark and ddll 5/16" leftand rightfasteningholes.

Secure the bracketas shownin Figure 1 ifthere is

verticalreinforcement.

If your installationdoesn'trequire vertical reinforce-

mentbut does need top and bottom fasteningholes

for the doerbracket, fastenas shown in Figure 2.

Head_ Bnv:ket

Hodzontala_l vetticalminfomement

Isneededfo(_*e_ht gaffe doors

doorswlm

24

Figure I

Page 25

ONE-PIECEDOORS

Pleasereadandcomplywiththewarningsand

reinforcementinstructionsonthe previouspage.

They apply to one-piece doors also.

• Center the door bracket on the top ofthe door, in

linewith the header bracket as shown. Mark either

the left and right,or the top and bottomholes.

• Ddll 5/16" pilotholes and fasten the bracket with

hardware supplied.

If the door has no exposed framing, drill3/16" pilot

holesand fasten the bracket with 5/16"xl -1,"2"lag

screws (notprovided) to the top of the door.

NOTE: The door bracketmay be installedon the top

edge of the door if required for your installation.

(Refer to thedotted line optionalplacement drawing.)

Drill3/16" pilot holes and substitute5/16"x1-1/2" lag

screws (notprovided) tofasten the bracket to the

door.

He_ Wall

2:<4Support

HARDWARE SHOWN ACTUAL SiZE

CantageBolt

5/16"-18x2-tPZ'

Horizontal and vertical

relnfo_ement is needed for

_tv,eight 0aragedocxs

(lit_ rglass,81um_um, steel,

doorwithglasspanel,etc.)

(notwovtde_.

FOra door with no exposed 1taming.

or for Ihe opUonal installa6on, use

5/16"xl -1/2" lag screws (not provided)

to fasten door brackeL

25

Page 26

INSTALLATION STEP 12

Connect Door Arm to Trolley

Followinstructionswhichapply to yourdoortype as

illustratedbelowand on the following page.

SECTIONAL DOORS ONLY

• Make sure garage door isfully closed. Pull the

emergency release handle to disconnectthe outer

trolleyfrom the inner trolley.Slide the outertrolley

back (away from the pulley) for 8" minimumas

shownin Figures 1, 2 and 3.

• Figure 1:

- Fasten straightdoor arm sectionto outertrolley

withthe 5/16"xl" clevis pin. Secure the

connectionwith a ringfastener.

- Fasten curved sectionto the doorbracket in the

same way, usingthe 5/16"x1-1/4" clevis pin.

• Figure 2:

- Bring armsections together. Find two pairsof

holesthat lineup and join sections. Select holes

as far apart as possibleto increase doorarm

rigidity.

• Figure 3, Hole alignment alternative:

- If holes in curved arm are above holes in straight

arm, disconnectstraightarm. Cut about6" from

the solidend. Reconnect to trolleywith cut end

down as shown.

- Bring arm sectionstogether.

- Find two pairs of holes that lineup andjoin with

bolts, lock washers and nuts.

• Pull the emergency release handle towardthe

opener at a 45° angle sothat the trolley release

arm ishorizontal. Proceed to AdjustmentStep 1,

page 28. Trolleywill re-engage automaticallywhen

opener isoperated.

Clevis pin

5/16"x1-1/4'

Figure I

Figure 2

P.,ey

Pulley

/L(-.-.--_ 8" MIN.__])'

- n

j

I

Trolley

s_ _

Nuts 5/16" fo_

W_

Cuwed Door Ann

_Bolts

5/16_18x7_"

Trolley

5/16"x1"

Emergency

- Release

Handle

Door Atrn

HARDWARE SHOWN ACTUAL SIZE

Nut 5/16"-18 Lock Washer 5/16" Ring Fastener

5/16'xl" {'Trolley) 5/16"xl -I/4" (Door Bracket) 5/16"-18x7/8"

i_'i_ 8" MIN, "_>i

__ rf _,- _ _ _

Figure 3

26

Page 27

ALLONE-PIECEDOORS

1.Assemble the door arm, Figure 4:

• Fasten the straight and curved door arm sections

together to the longest possible length (with a 2

or 3 hole overlap).

• With the door closed, connect the straight door

arm section to the door bracket with the

5/16"x1-1/4" clevis pin.

• Secure with a dng fastener.

2. Adjustment procedures, Figure 5:

• On one-piece doors, before connecting the door

arm to the trolley, the travel limits must be

adjusted. Limit adjustment screws are located on

the left side panel as shown on page 28. Follow

adjustment procedures below.

• Open door adjustment: decrease UP

travel limit

-Turn the UP limitadjustmentscrew

counter-clockwise4 turns.

- Press the DoorControlpushbutton.The trolley

willtravel tothe fullyopen position.

- Manually raise the door tothe open position

(parallelto the floor), and liftthe door arm to the

trolley.The arm shouldtouchthe trolleyjust in

back of the door arm connectorhole. Refer to

the fully open trolley/doorarm positionsinthe

illustration.If the arm does not extend far

enough, adjustthe limitfurther. One full turn

equals 3" of trolleytravel.

• Closed door adjustment: decrease DOWN

travel limit

- Turn the DOWN limitadjustment screwclockwise

4 complete turns.

Door

CtevLsPin

5/16" x 1-1/4" Arm

Botts

5/16"-18 x 7/8 Curved

Ring

Fastener

Lock

Washers

5/16"

Nuts

5/16"-1_

Figure 4 DoorArm

- Pressthe Door Control pushbutton.The trolley

willtravel to the fully closed position.

- Manually close thedoor and liftthe door arm to

the trolley.The arm should touchthe trolleyjust

ahead of the door arm connectorhole. Refer to

the fully closedtrolley/doorarm positionsin the

illustration.Ifthe arm is behindthe connector

hole, adjustthe limitfurther. One full turnequals

3"of trolleytravel.

3.Connect the door arm to the trolley:

• Close the door and join the curved arm to the

connectorhole in the trolleywith the remaining

clevispin. Itmay be necessaryto lift the door

slightlyto make the connection.

• Secure with a ringfastener.

• Run the opener through a complete travel cycle. If

the door has a slight"backward"slant in full open

positionas shownin the illustration,decrease the

UP limit untilthe door isparallel tothe floor.

NOTE: When settingthe up limitonthe following

page, the doorshouldnothave a "backward"slant

when fullyopen as illustratedbelow.A slight

backwardslant will cause unnecessary bucking

and/orjerking operation as the door isbeing opened

or closedfrom the futiyopen position.

Figure 5

Door An'n

Connector Hole

FullyClosed

Trolley

-- EmergencyReleaseHandle

FuayOp_

27

Page 28

ADJUSTMENT STEP 1

Adjust the UP and DOWN lr_avel

Limits

Limitadjustmentsettings regulatethe points at which

the door will stop when movingup or down.

To operate the opener, press the Door Controlpush

button. Run the opener through a complete

travel cycle.

• Does the door open and close completely?

• Does the doer stay closed and not reverse

unintentionallywhen fully closed?

If your door passes both of these tests,no limit

adjustmentsare necessary unlessthe reversingtest

fails (sea AdjustmentStep 3, page 30).

Adjustmentproceduresare outlinedbelow. Read the

procedures carefullybefore proceedingto

AdjustmentStep 2. Use a screwdriverto make limit

adjustments.Run the opener through a complete

travel cycle after each adjustment.

NOTE: Repeated operationof the opener dudng

adjustmentprocedures may cause the motorto

overheat and shutoff. Simplywa# 15 minutes and

tryagain.

NOTE: If anythinginterfereswith the door'supward

travel,it willstop. ff anythinginterfereswith the

door'sdownward travel (includingbindingor

unbalanceddoors), it will reverse.

Withouta properlyinstalledsafetyreversalsystem,

persons(particularlysmallchildren)couldbe

SERIOUSLYINJUREDor KILLEDbya closinggarage

door.

• Incorrectadjustmentofgaragedoortravellimitswill

interferewithproperoperationofsafetyreversal

system.

• Ifonecontrol(forceortravellimits)isadjusted,the

othercontrolmayalsoneedadjustment.

•AfterANYadjustmentsaremade,thesafetyreversal

systemMUSTbetested.DoorMUSTreverseon

contactwithone-inchhighobject(or 2x4laidflat)on

floor.

Topreventdamageto vehicles,be surefullyopendoor

providesadequateclearance.

Im

HOW AND WHEN TO ADJUST THE UMrFS

• If the door does not open completely but opens

at least five feet:

Increase up travel. Tum the UP limitadjustment

screwclockwise. One turn equals3" of

trolleytravel.

NOTE: Toprevent the trolleyfromhitting thecover

protectionbolt, keep a minimumdistanceof2-4"

between the trolleyand the bolt.

• If door does not open at least 5 feet:

Adjustthe UP (open) forceas explained in

AdjustmentStep 2.

• If the door does not close completely:

Increase down travel. Turnthe downlimit

adjustmentscrewcountemlockwise.One tum

equals3" of trolleytravel.

If door stillwon't close completely,try lengthening

the door arm (page 26) and decreasing the

downlimit.

• If the opener reverses in fully closed position:

Decrease down travel.Turn the down limit

adjustmentscrew clockwise,One turn equals 3"

oftrolley travel.

Covet

PIO_eC_O_

Bolt

• If the door reverses when closing and there is

no visible interference to travel cycle:

If the opener lightsare flashing, the Safety

Reversing Sensors are either not installed,

misaligned,or obstructed.See Troubleshooting,

page 23.

Testthe door for binding: Pullthe emergency

release handle. Manually open and closethe door.

Ifthe dooris binding,cell a trained doer systems

technician. If the door isnot bindingor unbalanced,

adjustthe DOWN (close) force. See Adjustment

Step 2,

28

Page 29

ADJUSTMENT STEP 2

Adjust the Force

Force adjustmentcontrolsare located on the right

side panel of the motorunit. Force adjustment

settingsregulatethe amountof power requiredto

open and closethe door.

If the forces are set too light, door travel may be

interruptedby nuisance reversalsinthe down

directionand stops in the up direction,Weather

conditionscan affectthe doormovement, so

occasionaladjustmentmay be needed,

The maximum force adjustment range is about

3/4 of a complete turn. Do not force controls

beyond that point. Turn force adjustmentcontrols

with a screwdriver.

NOTE: ff anything interfereswith thedoor's upward

travel, ffwillstop. Ifanything interferes withthe

door's downwardtravel (includingbindingor

unbalanced doors),it willreverse.

HOW AND WHEN TO ADJUST THE FORCES

1. Test the DOWN (close) force

• Grasp the door bottomwhen the door isabout

halfway throughDOWN (close)travel.The door

shouldreverse. Reversal halfway through down

travel does not guarantee reversalona one-inch

obstruction.See AdjustmentStep 3, page 30.

If the door is hard to hold or doesn't reverse,

DECREASE the DOWN (close)force by turning

the controlcounterclockwise.Make small

adjustmentsuntilthe door reverses normally.

After each adjustment, runthe opener through

a complete cycle.

• If the door reverses during the down (close)

cycle end the opener lights aren't flashing,

INCREASE DOWN (close) force by turningthe

controlclock'wise.Make smalladjustmentsuntil

the door completesa closecycle. After each

adjustment,run the opener through a complete

travel cycle. Do notincrease the force beyond

the minimumamount required to close the door.

2. Test the UP (open) force

• Grasp the door bottom when the door is about

halfwaythrough UP (open) travel. The door

shouldstop. If the door is hard to hold or

doesn't stop, DECREASE UP (open) force by

turningthe control counterclockwise. Make small

adjustmentsuntilthe door stops easily and

opens fully. After each adjustment,run the

opener through a completetravelcycle.

• If the door doesn't open at least 5 feet,

INCREASE UP (open) force by tuming the

controlclockwise. Make small adjustments until

door opens completely. Readjust the UP limitif

necessary.After each adjustment, run the

opener through a complete travel cycle.

Withouta properlyinstalledsafetyreversalsystem,

persons(particularlysmallchildren)couldbe

SERIOUSLYINJUREDor KILLEDbya closinggarage

door.

• Toomuchforceongaragedoorwillinterferewith

properoperationof safetyreversalsystem.

• NEVERincreaseforce beyondminimumamount

requiredto closegaragedoor.

• NEVERuseforceadjustmentstocompensatefor a

bindingorstickinggaragedoor.

• If onecontrol(forceortravellimits)isadjusted,the

othercontrolmayalsoneedadjustment.

• AfterANYadjustmentsaremade,thesafetyreversal

systemMUSTbetested.DoorMUSTreverseon

contactwithone-inchhighobject(or 2x4laidflat)on

floor,

Force Adjusknent

Co_tr_s

O O

Right Side Panel

Adjus_nent Label

29

Page 30

ADJUSTMENT STEP 3

Test the Safety Reversal System

TEST

• With the doorfully open, place a one-inchboard

(or a 2x4 laidfiat) on the floor, centered under the

garage door.

• Operate the door in the downdirection.The door

must reverseon stdkingthe obstruction.

ADJUST

• Ifthe door stops on the obstruction,itis not

travelingfar enough in the down direction.

Increase the DOWN limitby turningthe DOWN

limitadjustmentscrew counterclockwise1/4 turn.

NOTE: On a sectionaldoor,make sure limit

adjustments do not cause the trolleyto move

within2-1/2" of the trolleystop bolt. If necessary

lengthenstraightdoor arm to maintain this

minimumdistance.

• Repeat the test.

• When the door reverses on the one-inch board,

remove the obstructionand runthe opener through

3 or 4 complete travel cyclesto test adjustment.

IMPORTANT SAFETY CHECK:

Repeat AdjustmentSteps 1, 2 and 3 after.-

• Each adjustment of door arm length,limits,or

force controls.

• Any repair to or adjustment of the garage door

(includingspdngs and hardware).

• Any repairto or bucklingof the garage floor.

• Any repair to or adjustment of the opener.

Withouta properlyinstalledsafetyreversalsystem,

persons(particularlysmallchildren)couldbe

SERIOUSLYINJUREDor KILLEDbya closinggarage

door.

• SafetyreversalsystemMUSTbe testedeverymonth.

• If onecontrol(forceortravellimits)isadjusted,the

othercontrolmayalsoneedadjustment.

• AfterANYadjustmentsaremade,thesafetyreversal

systemMUSTbetested.DoorMUSTreverseon

contactwithone-inchhighobject(or 2x4laidflat) on

thefloor.

ADJUSTMENT STEP 4

Test the Safety Reversing Sensor

• Pressthe remote controlpush buttonto open

the door.

• Place the opener carton inthe pathof the door.

• Pressthe remote control push buttonto close the

door.The doorwill not move more than an inch,

and the opener lightswillflash.

The garage door opener will not close from a remote

if the indicatorlightin either sensor is off (alerting

you to the fact that the sensor is misaligned

or obstructed).

If the opener closes the door when the safety

reversing sensor is obstructed (and the sensors

are no more than 6" above the floor), call for a

trained door systems technician.

persons(particularlysmallchildren)couldbe

SERIOUSLYINJUREDorKILLEDbya dosinggarage

door.

o Io[ IJ _J,Ih

3O

Page 31

OPERATION

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of severe injury or death:

1. READANDFOLLOWALLWARNINGSAND

INSTRUCTIONS.

2. ALWAYSkeepremotecontrolsoutofreachofchildren.

NEVERpermitchildrento operateor playwithgarage

doorcontrolpushbuttonsor remotecontrols.

3. ONLYactivategaragedoorwhenitcanbeseenclearly,it

isproperlyadjusted,andtherearenoobstructionsto

doortravel.

4. ALWAYSkeepgaragedoorin sightuntilcompletely

closed.NOONESHOULDCROSSTHEPATHOFTHE

MOVINGDOOR.

5. Ifpossible,useemergencyreleasehandleto disengage

trolleyONLYwhengaragedoorisCLOSED.Weakor

brokenspringsor unbalanceddoorcouldresultinan

opendoorfalling rapidlyand/orunexpectedly.

6. NEVERuseemergencyreleasehandleunlessgarage

doorwayis clearofpersonsandobstructions.

7. NEVERusehandleto pullgaragedooropenorclosed.If

ropeknotbecomesuntied,youcouldfall.

Using Your Garage Door Opener

YourSecurity.I.opener and hand-held remote control

have been factory-set to a matchingcode which

changeswith each use, randomlyaccessingover

100 billionnew codes. Youropener will operate with

up to eight Security,l.remote controls and one

Secudty.l. Keyless Entry System. If you purchase a

new remote,or ifyou wish to deactivate any remote,

follow the instructionsinthe Programmingsection.

Activate your opener with any of the following:

• The hand-held Remote Control:Hold the large

pushbutton down untilthe door starts to move.

• The wall-mounted Door Control:Hold the push

buttondown untilthe door starts to move.

• TheKeylessEntry(SeeAcceasodea):lfprevided

with yourgarage door opener, it must be

programmed beforeuse. See Programming.

When the opener is activated (with the safety

reversing sensor correctly installed and aligned)

1. If open, the door will close. If closed, itwillopen.

2. If closing,the door will reverse.

3. If opening, the door willstop.

4. If the door has been stopped in a partially open

position, it will close.

5. If obstructedwhile dosing, the door will reverse. If

the obstructioninterruptsthe sensorbeam, the

opener lightswillblinkfor fiveseconds.

8. If onecontrol(forceortravellimits)isadjusted,the

othercontrolmayalsoneedadjustment.

9. Afteranyadjustmentsaremade,thesafetyreversal

systemMUSTbetested.

10.SafetyreversalsystemMUSTbe testedeverymonth.

GaragedoorMUSTreverseoncontactwithone-inch

highobject(ora 2x4 laidflat) onthefloor.

11.ALWAYSKEEPGARAGEDOORPROPERLYBALANCED

(seepage3). Animproperlybalanceddoormaynot

reversewhenrequiredandcouldresultin severeinjury

or death.

12.Allrepairsto cables,springassembliesandother

hardware,allofwhichare underEXTREMEtension,

MUSTbe madebya traineddoorsystemstechnician.

13.ALWAYSdisconnectelectricpowertogaragedoor

openerbeforemakinganyrepairsor removingcovers.

t4.SAVETHESEINSTRUCTIONS.

6.If obstructedwhile opening,the door willstop.

7.If fully open,the door willnot close when the beam

is broken. The sensor has no effect in the opening

cycle.

If the sensor is not installed, or is misaligned,the

door won'tclose from a hand-heldremote. However,

you can close the door with the Door Control,the

OutdoorKey Switch, or Keyless Entry, ifyou activate

them untildown travel is complete. If you release

them too soon, the door will reverse.

The opener lights willturn on underthe following

conditions: when the opener is initiallyplugged in;

when poweris restored after interruption;whenthe

opener isactivated.

They willturnoffautomaticallyafter 4-1_ minutesor

provideconstant lightwhen the Ught feature on the

MotionDetecting ControlConsole is activated.Bulb

size is 100 watts maximum.

Security,P Light Feature: Ughts will also turnon

when someone walksthrough the open garage door.

With a MotionDetecting Control Console, thisfeature

may be turnedoff as follows:With the opener lights

off, press and hold the light buttonfor 10 seconds,

untilthe lightgoes on and off again. To restorethis

feature, start with the opener lightson, then press

and holdthe light buttonfor 10 secondsuntilthe light

goes off, then on again.

31

Page 32

Using the Wall.Mounted Door Control

THE MOTION DETECTING CONTROL CONSOLE

Press the push bar to open or

close the door. Press again to

reverse the door during the

closingcycle or to stop the door

while it's opening.

This door controlcontains a

motiondetectorthat will

automaticallyturn on the light

when itdetects a person

enteringthe garage. This

feature can be easily turned off

for extended work light use.

Light Feature

Pressthe Ught button toturn the openerlightonor

off. It will not controlthe opener lightswhen the door is

in motion.If you turn it on and then activatethe

opener, the lightwill remain on for 4-1/2 minutes.

Pressagain to turn it off sooner. The 4-1/2 minute

intervalcan be changed to 1-1/2, 2-112,or 3-112

minutesas follows: Press and hold the Lock button

untilthe lightblinks (about 10 seconds).A singleblink

indicatesthat the timer is reset to 1-112minutes.

Repeat the procedure and the lightwill blinktwice,

resettingthe timer to 2-1/2 minutes.Repeat again for a

3-1/2 minuteinterval,etc., up to a maximumof four

blinksand 4-1/2 minutes.

When usingthe openerlightsas workinglights,we

recommend that youfirst disable the motionsensor.

See AutomaticLight Feature, below.

Automatic Light Feature: The opener lightwillturn

on automatically when a person entersthe garage.

When a person walks in front of the door control,the

lightwillcome on for five minutes,then shutoff. This

feature worksby detecting bodyheat and may not

work in temperatures around IO0"F.

To disable this feature, slidethe DetectorSwitch on

the dghtside of the door controldown (off).

We recommendthat you disable the motionsensor

when using the opener lightsas workinglights.

Otherwise, they willturn off automaticallyifyou are

workingbeyond the sensorsrange.

Lock Feature

Designed to prevent operation of the doorfrom hand-

held remote controls.However, the door will open and

close from the Door Control, the Outside Keylockand

the Keyless Entry Accessories.

To activate, press and hold the Lock buttonfor 2

seconds. The push bar lightwill flashas long as the

Lock feature ison.

To turnoff, press and hold the Lockbuttonagain for

2 seconds.The push bar lightwill stop flashing. The

Lockfeature willalsoturnoff wheneverthe =Smart"

(leam) button on the motorunitpanel isactivated.

Lighted

Additional feature when used with the 3-function

hand-held remote

To controlthe opener lights:

In additionto operating the door, you

may program the remote to operate

the lights.

1.With the door closed, press and holda small

remote buttonthat you want to controlthe light.

2.Press and held the Light buttonon the

door control.

3.While holding the Lightbutton,press and holdthe

Lockbutton on the door control.

4.After the opener lightsflash, release all buttons.

To Open the Door Manually

• TopreventpossibleSERIOUSINJURYor DEATHfrom

a falling garagedoor:

- If possible,useemergencyreleasehandleto

disengagetrolleyONLYwhengaragedooris

CLOSED.Weakorbrokenspringsorunbalanced

doorcouldresultin anopendoorfalling rapidly

and/orunexpectedly.

- NEVERuseemergencyreleasehandleunlessgarage

doorwayisclearofpersonsandobstructions.

• NEVERusehandleto pulldooropenorclosed.If rope

knotbecomesuntied,youcouldfall.

DISCONNECT THE TROLLEY:

The door should be fully closed

if possible.Pull down onthe

Trolley

_ I

emergency release handle (so

that the trolleyrelease arm

snaps intoa vertical position)

and liftthe door manually.The

lockout feature preventsthe

trolleyfrom reconnecting

Retease ann

(In Manual

DLsconnect

Posi_on)

automatically,and the door can

be raised and lowered manually

as often as necessary. Lockout )osition

(Manual disconnect)

TO RE-CONNECT THE TROLLEY:

Pullthe emergency release

Trolley

handle towardthe opener at

a 45° degree angle so that

the trolleyrelease arm is

horizontal.The trolley will

reconnecton the next UP or

DOWN operation,either

manually or byusingthe

door control or remote.

To reconnect

32

Page 33

Care of Your Opener

UMIT AND FORCE ADJUSTMENTS:

Weather conditions may

cause some minor FORCECONTROLS

changes in door

operation requiringsome

re-adjustments,

particularlydudng the

firstyear of operation.

uMrr CONTROLS

Pages 28 and 29 referto

the limitand fome

adjustments. Only a

screwdriveris required.

Followthe instructionscarefully.

Repeat the safety reverse test (page 30) after any

adjustment of limits or force.

MAINTENANCE SCHEDULE

Once a Month

• Manually operate door. If it is unbalanced or

binding,call a trained door systems technician.

• Check to be sure door opens & closes fully.Adjust

limitsand/or force if necessary. (See pages 28

and 29.)

• Repeat the safety reverse test. Make any

necessary adjustments. (See Adjustment Step 3.)

Twice a Year

• Check chaintension. Disconnecttrolley first. Adjust

if necessary (See page 11).

Once a Year

• Oil door rollers,beadngs and hinges.The opener

does not requireadditionallubdcafion.Do not

grease the door tracks.

THE REMOTE CONTROL BAI-rERY

The lithiumbattery should

producepower for up to

5 years. To replace battery,use

3-FUNCTION

Openmls end

the visor (dipor screwdriver

blade to pry open the case as

shown. Insertbatterypositive

side up.

Disposeof old battery properly.

NOTICE:TOcomplywith FCCand or Indue.,'./ Canada(IC) ru_;, _ or

modlllcatiorlsof thiseeceivefand/orb'ansmitMrate _xohl_4ted,exceptIo_ckangin0the

codesegingorrep_ackqthe bzge¢/.THERE_RENOOIHERLIS_ S_ PARTS.

Te:Stedto Contplywithrcc StandardsF0RHOME0R 0R:IC:EUSE_0perRioe_ subjectto

the_ W,Ocondition:(1) ridsdevicemaynotcsuseharmfulm, and

(2)thisde_cem_stacceptanyimderencereceive0,k_ inletfenmcethatmaycause

endesbedogeration.

33

Page 34

Having a Problem?

1. The opener doesn't operate from either the Door

Control or the remote control:

• Does the opener have electricpower? Plug a lamp into the

outlet. If it doesn't light, check the fuse box or the circuit

breaker, (Some outlets are controlledby a wall switch.)

• Have you disabled all door locks? Review installation

instructionwarningson page 11.

• Is there a build-up of ice or snow under the door? The door

may be frozen to the ground. Remove any restriction.

• The garage door spring may be broken. Have it replaced,

• Repeated operationmay have tripped the overload

protector in the motor. Wait 15 minutesand try again,

2. Opener operates from the remote, but not from the

Door Control:

• Is the door controllit? If not, reverse the wires. If the

opener runs, check for a faulty wire connection at the door

control, a short under the staples, or a broken wire.

• Are the wiring connectionscorrect? Review Instal/atioo

Step 6, page 18,

3. The door operates from the Door Control, but not from

the remote control:

• Is the door push button flashing? If yourmodel has the

Lockfeature, make sure it is off.

• Programthe opener to match the remote control code.

(Refer to instructionson the motorunit panel.) Repeat with

all remotes.

4. The remote control has short range:

• Change the location of the remote controlin yourcar.

• Check to he sure the antenna on the side or back panel of

mater unit extends fully downward.

• Some installationsmay have shorter range due to a metal

dour,foil backed insulation, or metal garage siding.

(Antenna Extender Kit 41A3504)

5. Opener noise is disturbing in living quarters of home:

• If operational noise is a problembecause of proximityof

the opener to the livingquarters, the Vibration IsolatorKit

41A3263 can be installed.This kit was designed to

minimize vibrationto the house and iseasy to install.