Page 1

Owner’s Manual/Manual Del Propietario

CRflFTSMBN

«315MHz GARAGE DOOR OPENER

ABRIDOR DE PUERTA DE COCHERA

For Residential Use Oniy/Sólo para uso residencial

Model/Modelo 139.53918D

iVi№

Q

00

5

Read and follow all safety rules

and operating instructions before

first use of this product.

Fasten the manual near the garage

door after installation.

Periodic checks of the opener are

required to ensure safe operation.

os

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

www.sears.com/craftsman

Leer y seguir todas las reglas de

seguridad y las instrucciones de

operación antes de usar este

producto por primera vez.

Guardar este manual cerca de la

puerta de la cochera.

Se deben realizar revisiones

periódicas del abridor de puertas

para asegurar su operación

segura.

Page 2

TABLE OF CONTENTS

Introduction 2-7

Safety symbol review and signal word review

Preparing your garage door............................................3

Tools needed...................................................................3

Planning ......................................................................4-5

Carton inventory .............................................................6

Hardware inventory.........................................................7

................

2

Assembly 8-11

Assemble the rail and Install the trolley

Fasten the rail to the motor unit

Install the idler pulley

Install the belt and attach the belt cap retainer

Set the tension..............................................................11

......................................................

..........................

.....................................

.............

8

9

9

10

Installation 11-26

Installation safety instructions

Determine the header bracket location.........................12

Install the header bracket

Attach the rail to the header bracket

Position the opener.......................................................15

Hang the opener

Install the control console

Install the battery...........................................................18

Install the lights

Attach the emergency release rope and handle

Electrical requirements

Install The Protector System® (safety sensors) . . . .20-22

Fasten the door bracket...........................................23-24

Connect the door arm to the trolley

..........................................................

............................................................

.....................................

............................................

.............................

............................................

...........

................................................

.........................

25-26

11

13

14

16

17

18

18

19

Adjustment 27-29

Program the travel limits ...........................................27

Setting the force

Test the safety reversal system.................................29

Test The Protector System® (safety sensors)

........................................................

.........

28

29

Operation 30-36

Operation safety instructions.....................................30

Using your garage door opener

Using the wall-mounted control console

Care of your opener

To open the door manually

Battery backup

Having a problem (Troubleshooting)

Diagnostic chart.........................................................35

LCD motion detecting control

console messages.....................................................36

..................................................

..........................................................

................................

....................

......................................

........................

30

32

32

33

34

Programming 37-38

To add or reprogram a hand-held remote control . . .37

To erase all codes from motor unit memory ..............37

3-Function remotes ...................................................37

To add, reprogram or change a

Keyless Entry PIN

....................................................

38

Repair Parts 39-40

Rail assembly parts ..................................................39

Installation parts

Motor unit assembly parts

........................................................

........................................

39

40

Accessories 41

Warranty 41

Repair Parts & Service Back Cover

31

INTRODUCTION

Safety Symbol Review

and Signal Word Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated,

maintained and tested in strict accordance with the instructions and warnings contained in this manual.

¿k WARNING

Mechanical

A WARNING

Electrical

CAUTION

When you see these Safety Symbols and Signal Words

on the following pages, they will alert you to the

possibility of serious injury or death if you do not

comply with the warnings that accompany them. The

hazard may come from something mechanical or from

electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it

will alert you to the possibility of damage to your garage

door and/or the garage door opener if you do not comply

with the cautionary statements that accompany it. Read

them carefully.

Page 3

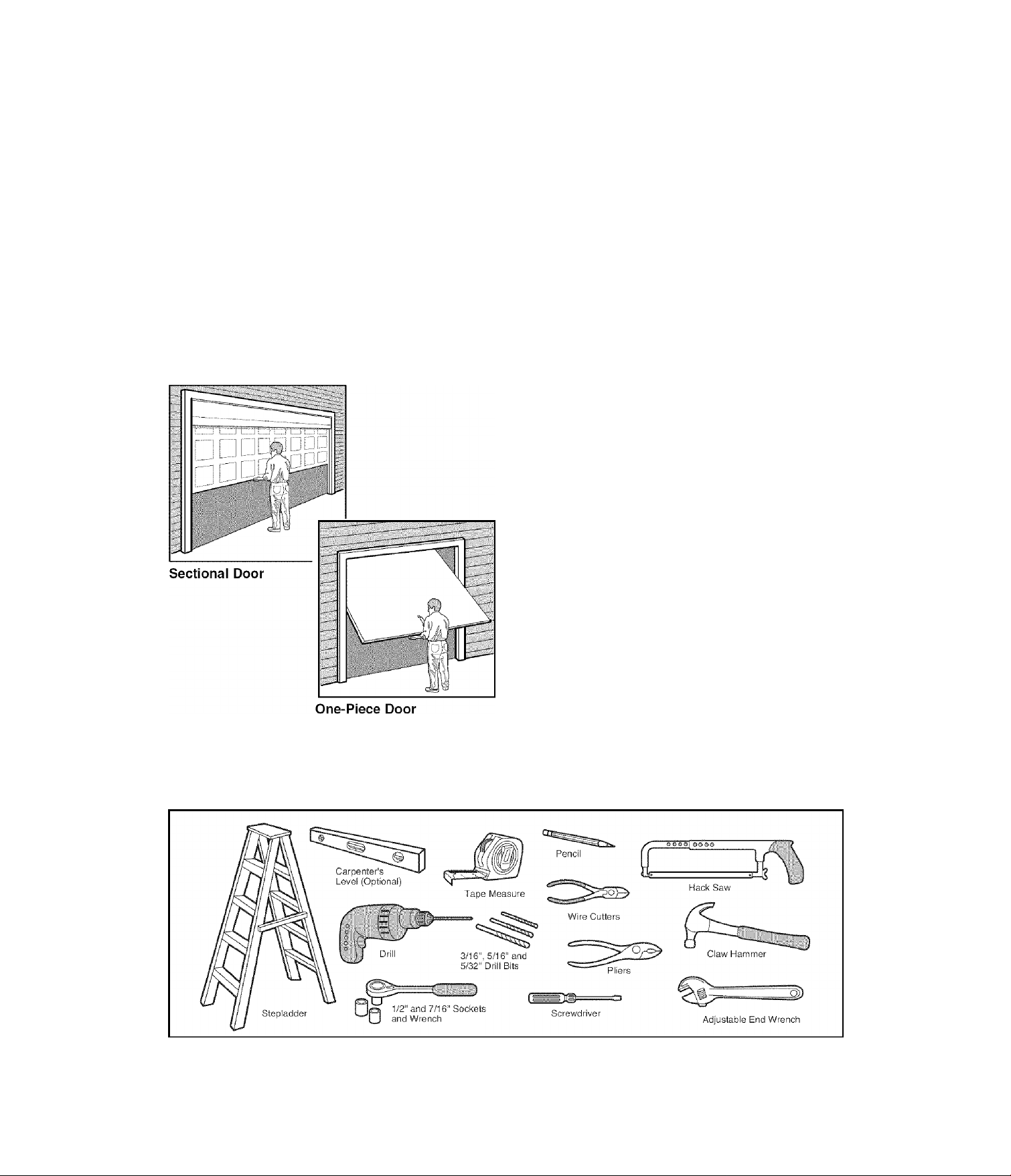

Preparing your garage door

Before you begin:

• Disable locks.

• Remove any ropes connected to garage door.

• Complete the following test to make sure your garage

door is balanced and is not sticking or binding:

1. Lift the door about halfway as shown. Release the

door. If balanced, it should stay in place, supported

entirely by its springs.

2. Raise and lower the door to see if there is any

binding or sticking.

If your door binds, sticks, or is out of balance, call a

trained door systems technician.

A WARNING

To prevent possible SERIOUS INJURY OR DEATH:

• ALWAYS call a trained door systems technician if garage

door binds, sticks, or is out of balance. An unbalanced

garage door may not reverse when required.

• NEVER try to loosen, move or adjust garage door, door

springs, cables, pulleys, brackets or their hardware, all of

which are under EXTREME tension.

• Disable ALL locks and remove ALL ropes connected to

garage door BEEORE Installing and operating garage door

opener to avoid entanglement.

CAUTION

To prevent damage to garage door and opener:

• ALWAYS disable locks BEFORE installing and operating the

opener.

• ONLY operate garage door opener at 120V, 60 Elz to avoid

malfunction and damage.

Tools needed

During assembly, installation and adjustment of the

opener, instructions will call for hand tools as

illustrated below.

Page 4

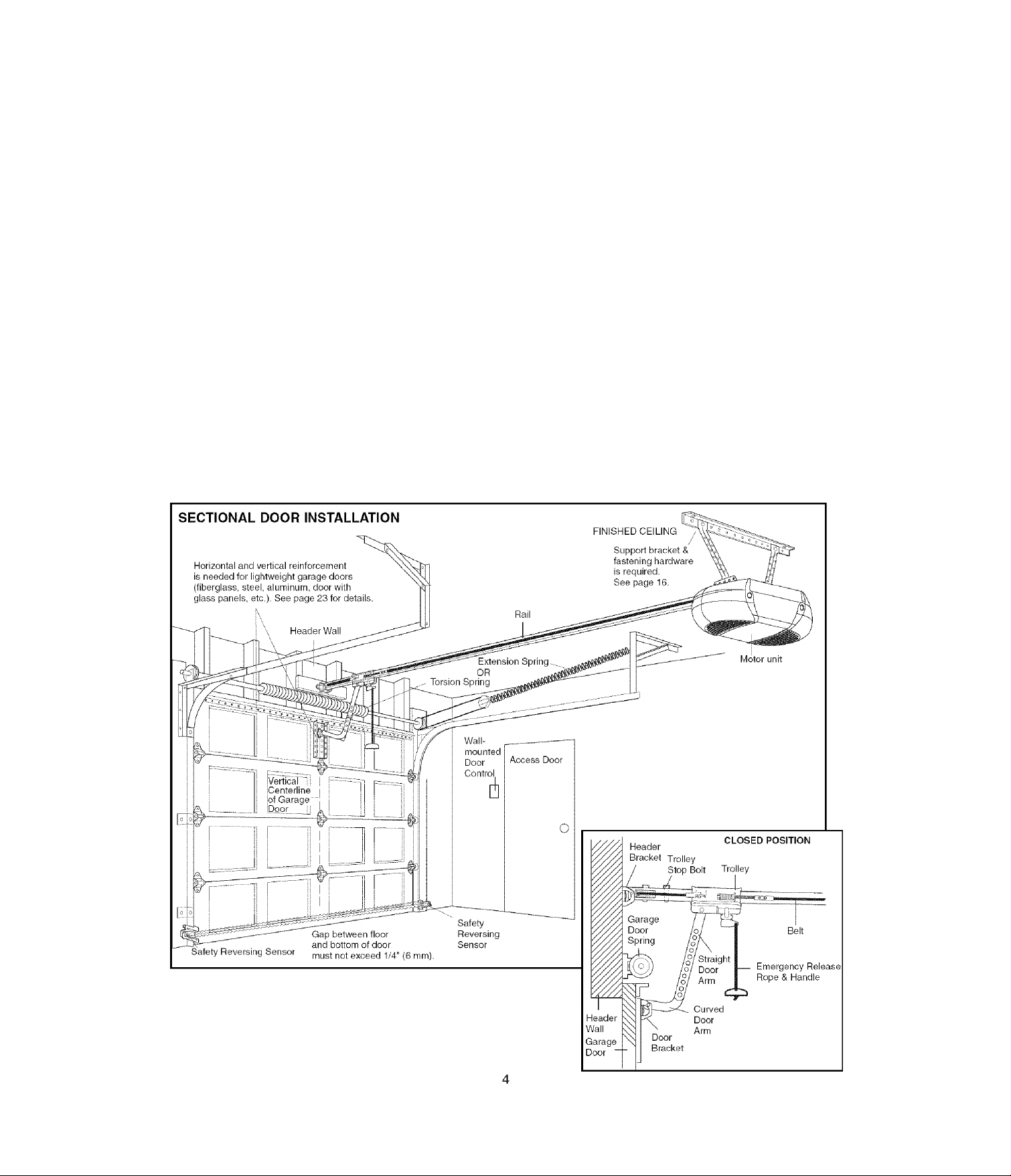

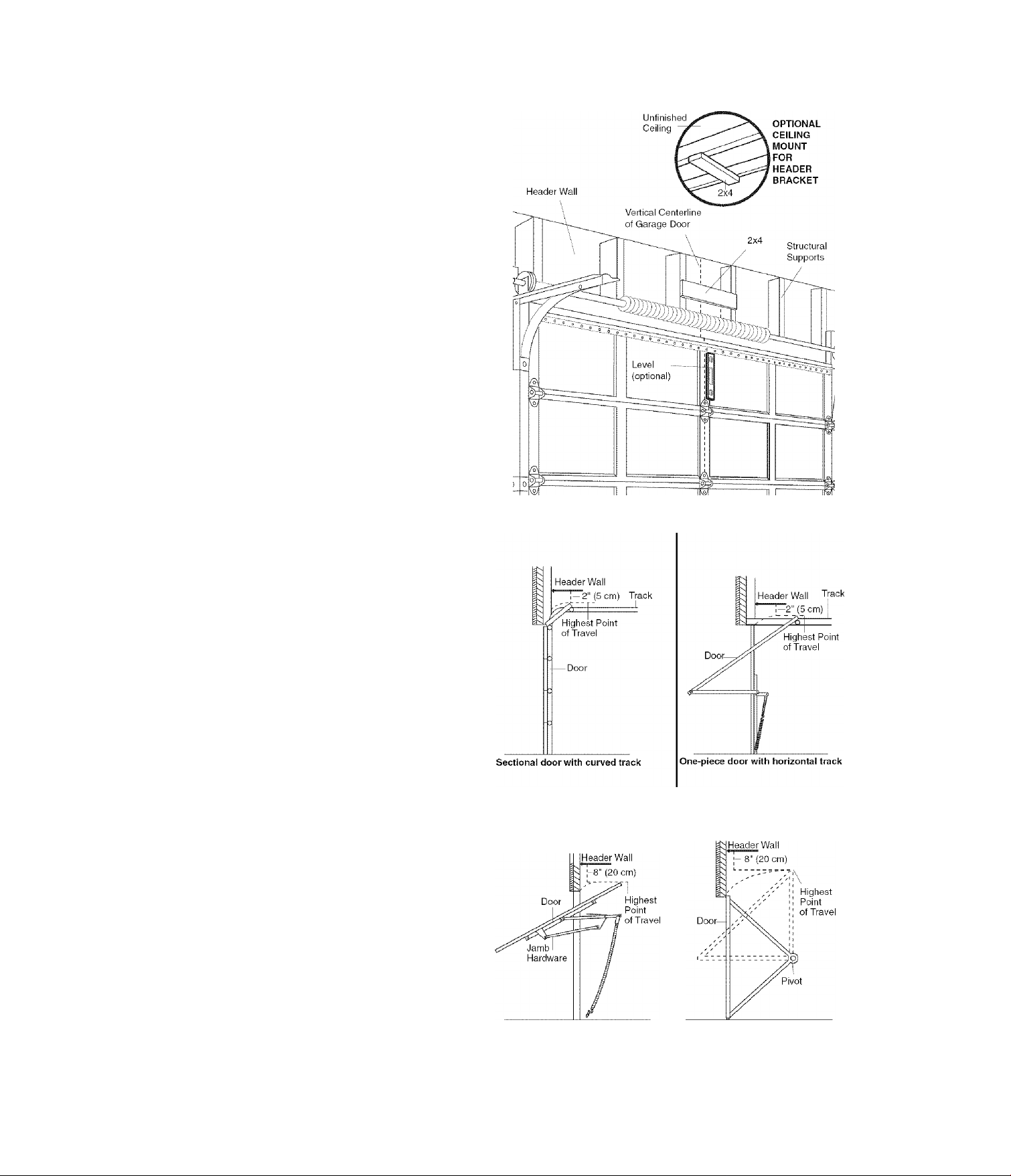

Planning

Identify the type and height of your garage door. Survey

your garage area to see if any of the conditions below

apply to your installation. Additional materials may be

required. You may find it helpful fo refer back to this page

and the accompanying illustrations as you proceed with

the installation of your opener.

Depending on your requirements, there are several

installation steps which may call for materials or

hardware not included in the carton.

• Installation Step 1 - Look at the wall or ceiling above

the garage door. The header bracket must be securely

fastened to structural supports.

• Installation Step 5 - Do you have a finished ceiling in

your garage? If so, a support bracket and additional

fastening hardware may be required.

• Installation Step 11 ™ Depending upon garage

construction, extension brackets or wood blocks may

be needed to install sensors.

• Installation Step 11 ~ Alternate floor mounting of the

safety reversing sensor will require hardware not

provided.

Do you have an access door in addition to the garage

door? If not, Model 139.53702 Emergency Key

Release is required. See Accessories page.

Look at the garage door where it meets the floor. Any

gap between the floor and the bottom of the door must

not exceed 1/4" (6 mm). Otherwise, the safety reversal

system may not work properly. See Adjustment Step 3.

Floor or door should be repaired.

SECTIONAL DOOR INSTALLATIONS

• Do you have a steel, aluminum, fiberglass or glass

panel door? If so, horizonfal and verfical

reinforcement is required (Installation Step 12).

• The opener should be installed above the center of fhe

door. If there is a torsion spring or center bearing plate

in the way of the header bracket, it may be installed

within 4 feet (1.22 m) to the left or right of the door

center. See Installation Steps 1 and 12.

• If your door is more than 7 feet (2.13 m) high, see rail

extension kits listed on Accessories page.

Page 5

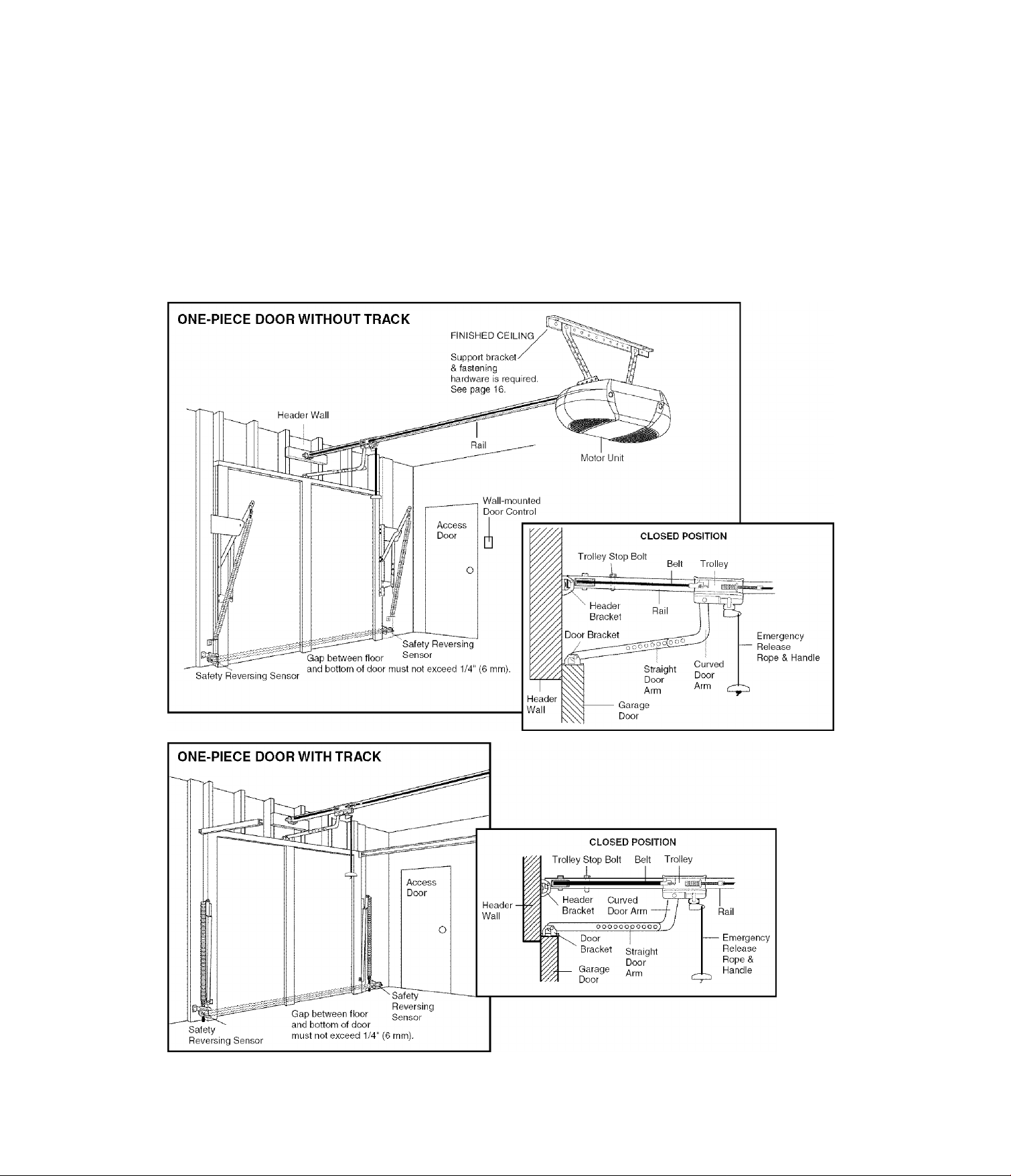

Planning (Continued)

ONE-PIECE DOOR INSTALLATIONS

• Generally, a one-piece door does not require

reinforcement, if your door is lightweight, refer to the

information reiating to sectional doors in Instailation

Step 12.

• Depending on your door’s construction, you may need

additional mounting hardware for the door bracket

(Step 12).

A WARNING

Without a properly working safehy reversal system, persons

(particularly small children) could be SERIOUSLY INJURED

or KILLED by a closing garage door.

• The gap between the bottom of the garage door and the

floor MUST NOT exceed 1/4" (6 mm). Otherwise, the safety

reversal system may not work properly.

• The floor or the garage door MUST be repaired to eliminate

the gap.

Page 6

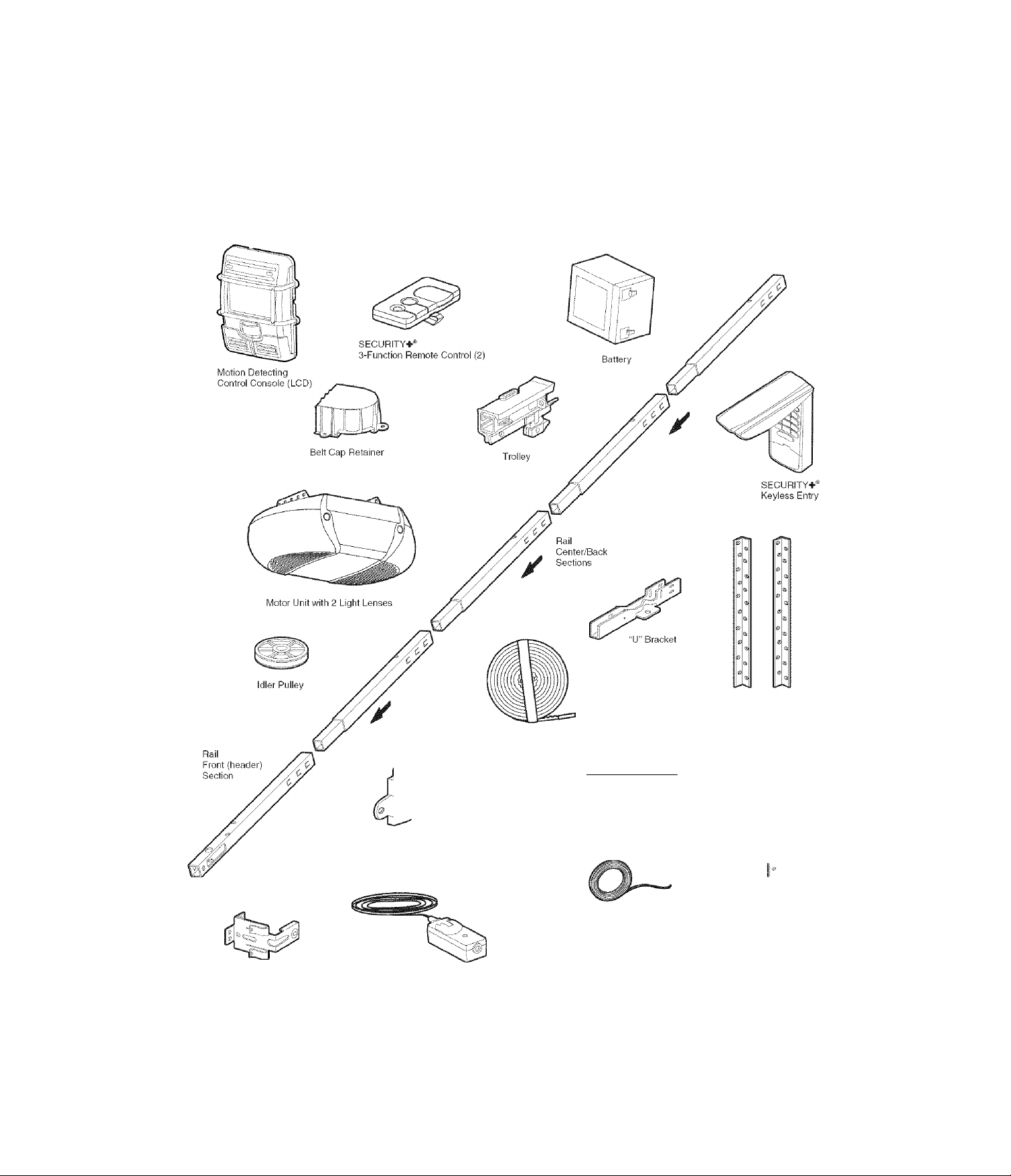

Carton Inventory

Your garage door opener is packaged in one carton

which contains the motor unit and all parts illustrated

below. Accessories will depend on the model purchased.

If anything is missing, carefully check the packing

material. Parts may be stuck in the foam. Hardware for

assembly and installation is shown on the next page.

Save the carton and packing material until installation

and adjustment is complete.

Safety Reversing

Sensor Bracket (2)

Header Bracket

The Protector System®

(2) Safety Reversing Sensors

(1 Sending Eye and 1 Receiving Eye)

with 2-Conductor White & White/Black

Bell Wire attached

Belt

10 IC jl

..

Door Bracket

Curved Door

Arm Section

2-Conductor Bell Wire

White & White/Red

Safety Labels

and

Literature

Hanging Brackets

/

/

i

Straight Door

Arm Section

Page 7

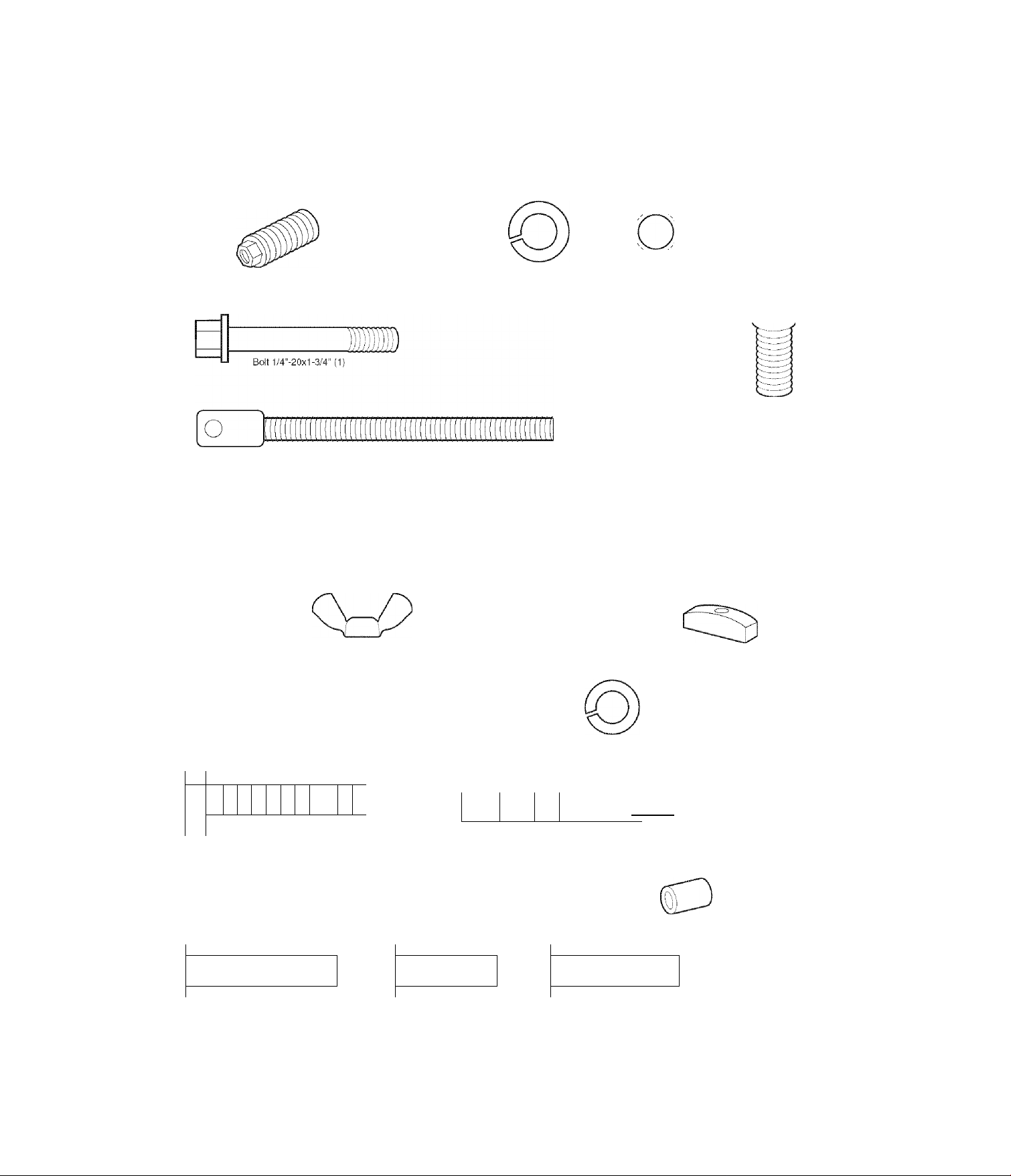

Hardware Inventory

Separate all hardware and group as shown below for the assembly and installation procedures.

ASSEMBLY HARDWARE

o

Sphng/Trolley Nut (1)

Carriage Bolt

1/4"-20x1/2" (2)

Lock Nut

1/4“-20 (2)

Trolley Threaded Shaft (1)

INSTALLATION HARDWARE

Wing Nut

1/4“-20 (2)

Lock Washer

3/8" (1)

o ®

Ring

Fastener (3)

Nut 5/16"-18(6)

Nut

3/8" (1)

Master

Link (2)

Idler Bolt (1)

Handle

1 1 1 1 1 1 1

L

jr

\j

Clevis Pin

5/16"x1-1/2" (1)

Lag Screw

5/16"-9x1-5/8“(2)

Lag Screw

Carriage Bolt

5/16"-18x2-1/2" (2)

I I

]>

Hex Bolt

5/16"-18x7/8" (4)

1 1

[i>

0

\

Clevis Pin

5/16“x1" (1)

MM 1 1 ! I

Screw

6ABX1-1/4" (2)

Drywall Anchors (2)

O

Lock Washer 5/16" (7)

1 1 17> £

/

y

Clevis Pin

5/16"x1-1/4" (1)

^llTiiniIìEIììIIiìIÌ

Screw 6-32x1 ■ (2)

Spacer (2)

o

Insulated

Staples (30)

Rope

Page 8

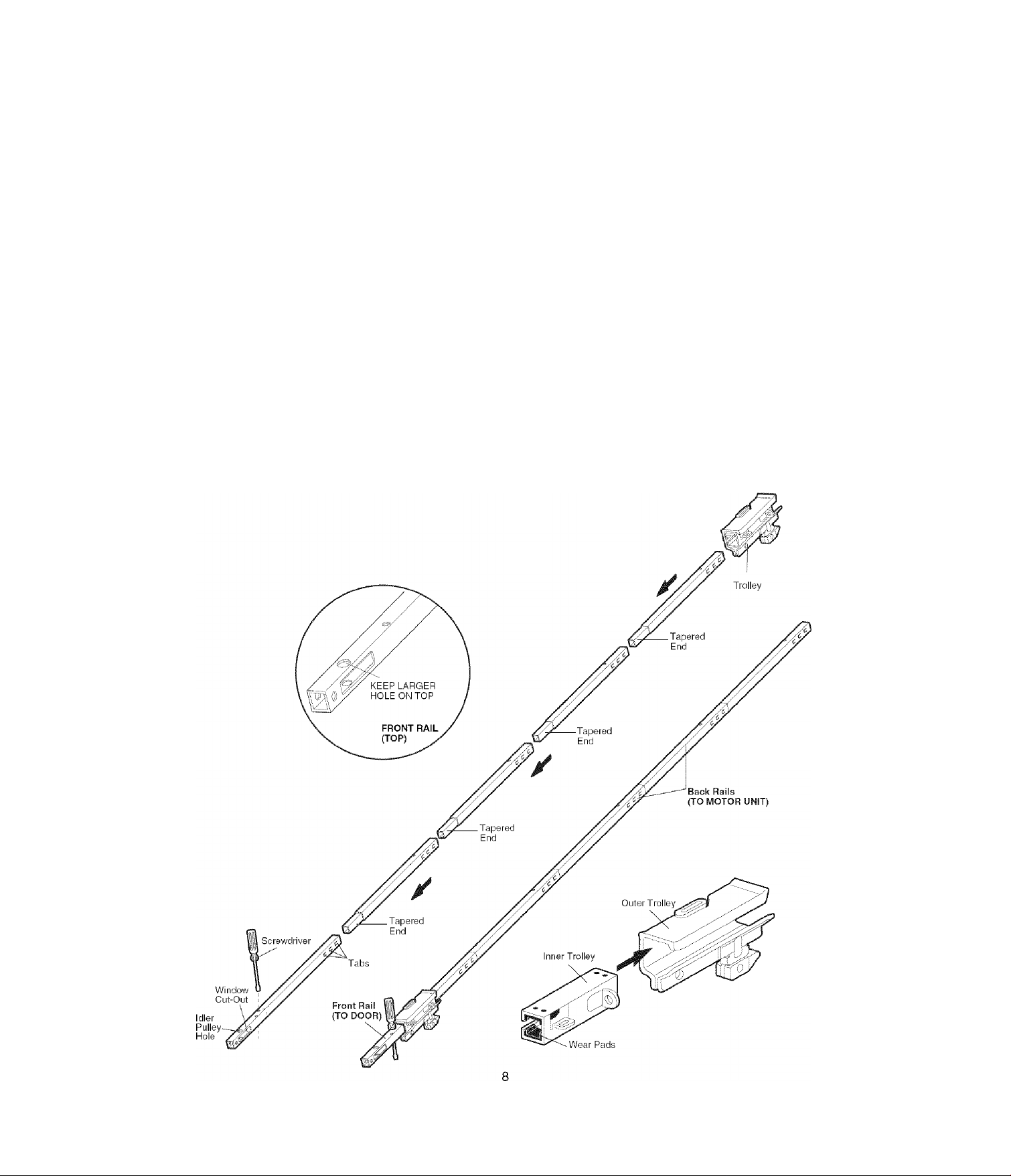

ASSEMBLY STEP 1

Assemble the Rail and Install the Th>//ey

To avoid installation difficulties, do not run the garage door opener until instructed to do so.

CAUTION

To prevent INJURY from pinching, keep hands and fingers

away from the joints while assembling the rail.

The front rail has a cut out “window”at the door end (see

illustration). The hole above this window is larger on

the top of the rail than on the bottom. A smaller hole

3-1/2" (8.9 cm) away is close to the rail edge. Rotate the

back rail so It has a similar hole close to the opposite

edge, about 4-3/4" (12 cm) from the far end.

1. Remove the straight door arm and hanging bracket

packaged inside the front rail and set aside for

Installation Steps 5 and 12. NOTE: To prevent

INJURY while unpacking the rail carefully remove the

straight door arm stored within the rail section.

2. Align the rail sections on a flat surface as shown and

slide the tapered ends into the larger ones. Tabs along

the side will lock into place.

3. Place the motor unit on packing material to protect the

cover, and rest the back end of the rail on top. For

convenience, put a support under the front end of

the rail.

4. As a temporary stop, insert a screwdriver into the hole

10" (25 cm) from the front end of the rail, as shown.

5. Check to be sure there are 4 plastic wear pads inside

the inner trolley. If they became loose during shipping,

check all packing material. Snap them back into

position as shown.

6. Slide the trolley assembly along the rail from the back

end to the screwdriver.

Page 9

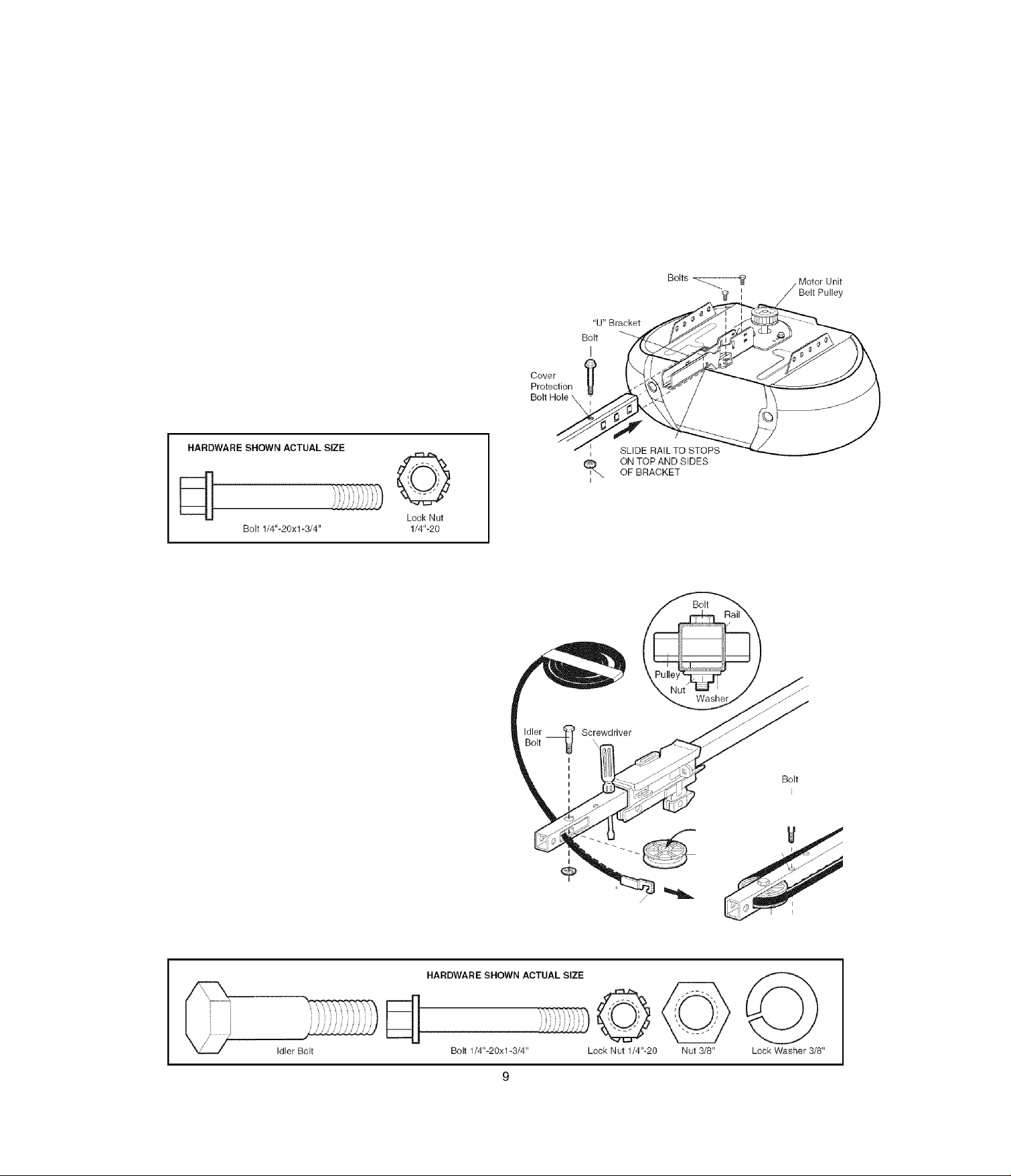

ASSEMBLY STEP 2

Fasten the Rail to the Motor Unit

• Insert a 1/4"-20x1 -3/4 bolt into the cover protection bolt

hole on the back end of the rail as shown. Tighten

securely with a 1/4"-20 lock nut. Do NOT overtighten.

• Remove the two bolts from the top of the motor unit.

• Place the “U" bracket, flat side down, on the motor unit

and align the bracket holes with the bolt holes. Fasten

with the previously removed bolts.

• Align the rail assembly with the top of the motor unit.

Slide the rail end onto the “U” bracket, all the way to

the stops that protrude on the top and sides of the

bracket

CAUTION

To avoid SERIOUS damage to garage door opener, use ONLY

those bolts/fasteners mounted in the top of the opener.

Lock Nut

ASSEMBLY STEP 3

Install the Idler Pulley

• Lay the belt beside the rail, as shown. Grasp the end

with the hooked trolley connector and pass

approximately 12" (30 cm) of belt through the window.

Keep the ribbed side toward the rail, and allow it to

hang until Assembly Step 5.

• Remove the tape from the idler pulley. The inside

center should be pre-greased. If dry, regrease to

ensure proper operation.

• Place the idler pulley into the window as shown.

• Insert the idler bolt from the top through the rail and

pulley. Tighten with a 3/8" lock washer and nut

underneath the rail until the lock washer is

compressed.

• Rotate the pulley to be sure it spins freely.

• Insert a 1/4"-20x1 -3/4 bolt into the trolley stop hole in

the front of the rail as shown. Tighten securely with a

1/4"-20 lock nut.

Lock Washer

3/8" ---

®- Nut 3/8'

I

T rolley

Connector

Trolley

Stop Hole

Grease \

Inside Pulley \

Idler Pulley '

Idler ^ Lock

Pulley I Llut

Page 10

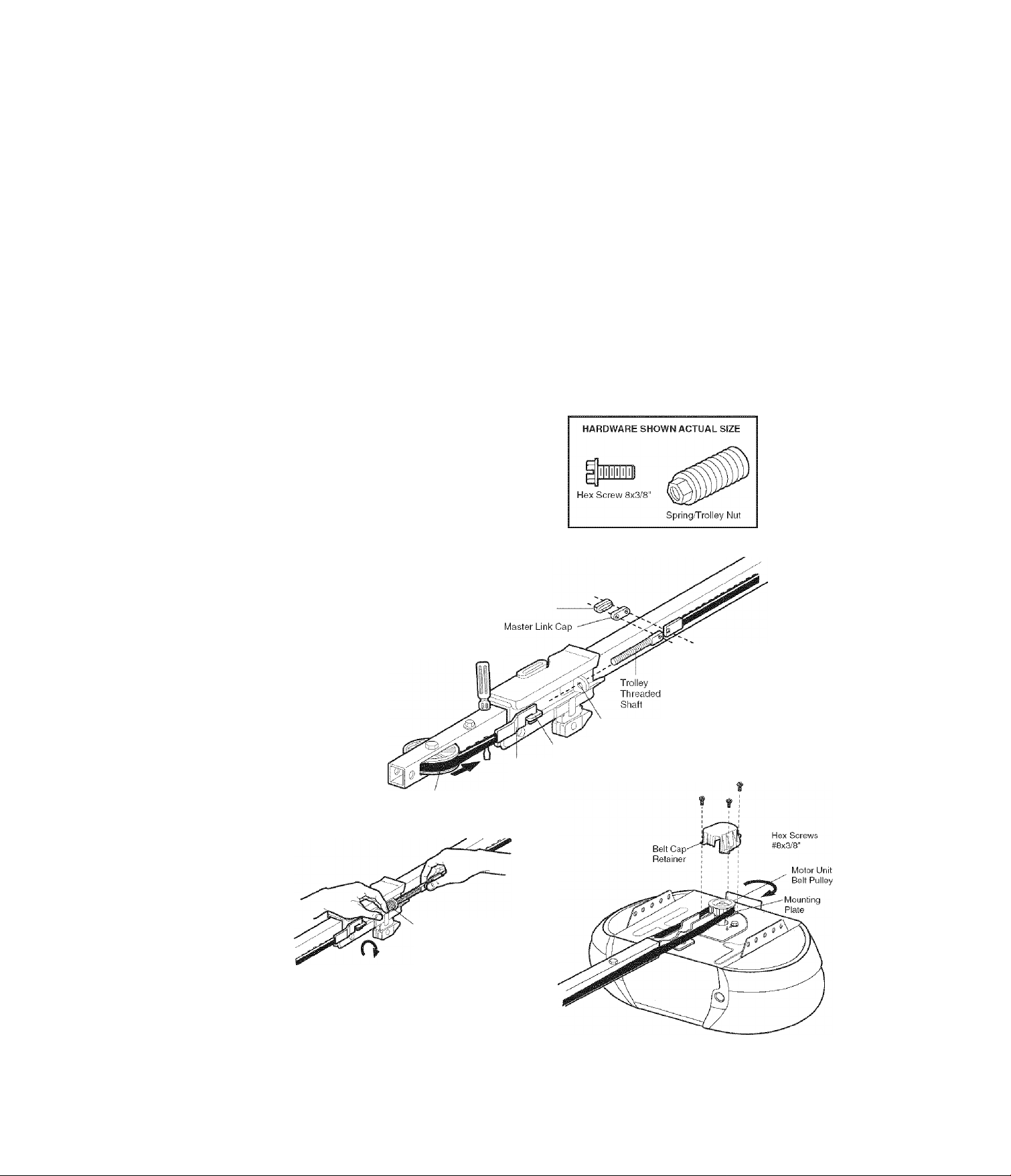

ASSEMBLY STEP 4

Install the Belt and Attach the Belt Cap Retainer

1. Pull the belt around the idler pulley and toward the

trolley. The ribbed side must contact the puiley.

2. Hook the trolley connector into the retaining siot on

the troiley as shown.

3. With the troiley against the screwdriver, dispense the

remainder of the beit along the rail length toward the

motor unit and around the sprocket. The sprocket

teeth must engage the belt.

4. Check to make sure the belt is not twisted, then

connect it to the flat end of the trolley threaded shaft

with the master link, as illustrated;

• Push pins of master link bar through holes in end of

belt and trolley threaded shaft.

• Push master link cap over pins and past

pin notches.

• Slide clip-on spring over cap and onto pin notches

until both pins are securely locked

in place.

5. Insert the trolley threaded shaft through the hole in

the trolley. Be sure the beit is not twisted, and the

ribbed side faces the rail.

6. Hold the belt at the trolley shaft as you thread the

spring nut by hand onto the shaft until finger tight

against the trolley. Do not use any tools.

7. Remove the screwdriver.

8. Position the belt cap retainer over the motor unit

sprocket as shown and fasten to the mounting plate

with 8x3/8" hex screws provided.

To avoid possible SERIOUS INJURY to fingers from moving

garage door opener:

• ALWAYS keep hand clear of belt pulley while operating

opener.

• Securely attach belt pulley cover BEFORE operating.

Master Link

Clip-On Spring

A WARNING

Pin

Notch

Master

Link Bar

Idler Pulley

Spring Nut

Trolley

Connector

10

Retaining

Slot

Round

Hole

Page 11

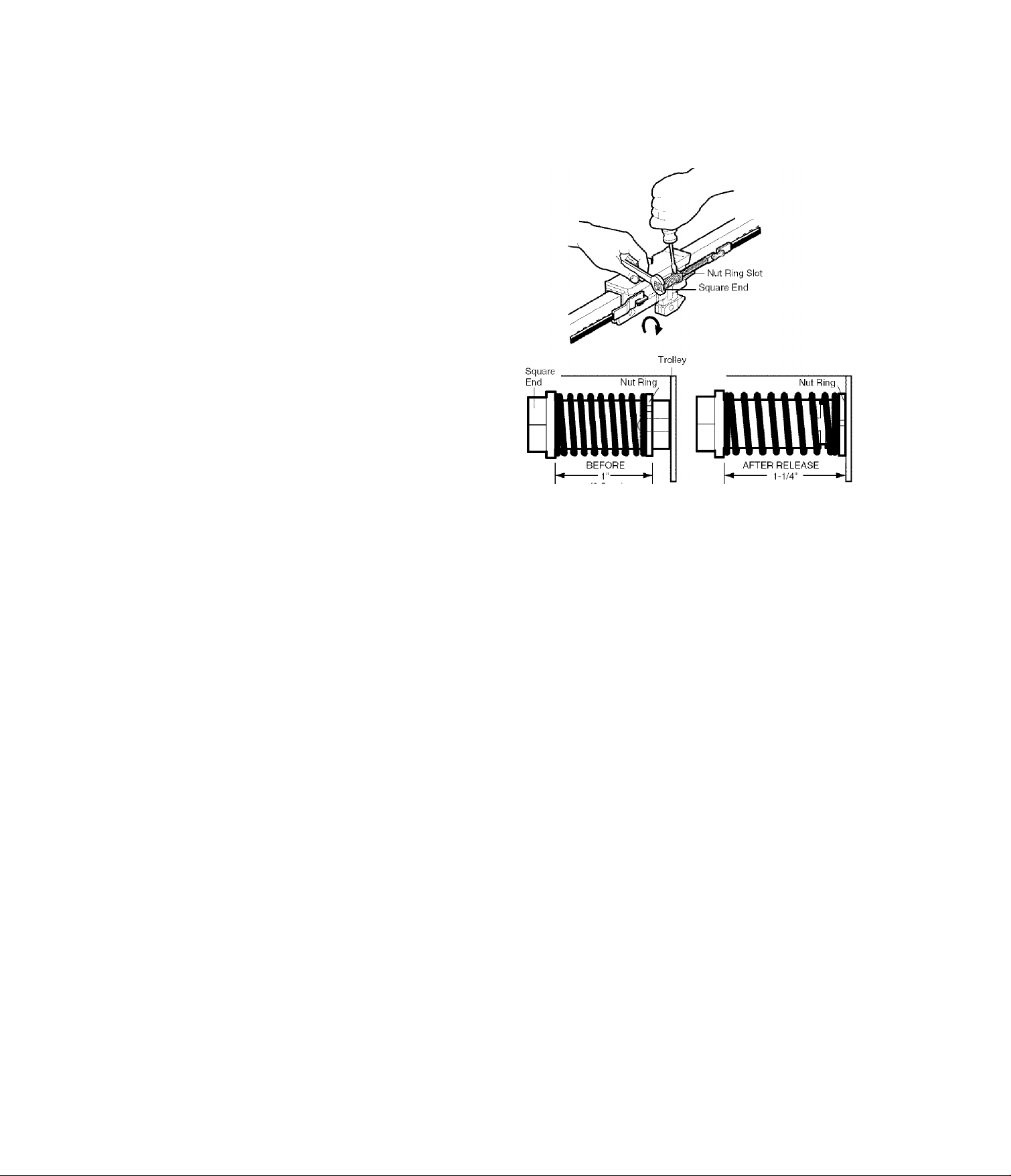

ASSEMBLY STEP 5

Set the Tension

• Insert a screwdriver tip into one of the nut ring slots

and brace it firmly against the trolley.

• Place a 7/16" open end wrench on the square end.

Rotate the nut about 1/4 turn until the spring releases

and snaps the nut ring against the trolley.

This sets the spring to optimum belt tension.

You have now finished assembiing your garage door

opener. Please read the following warnings before

proceeding to the installation section.

INSTALLATION

IMPORTANT INSTALLATION INSTRUCTIONS

A A WARNING

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTALLATION WARNINGS

AND INSTRUCTIONS.

2. Install garage door opener ONLY on properly balanced

and lubricated garage door. An improperly balanced door

may not reverse when required and could result in

SEVERE INJURY or DEATH.

3. ALL repairs to cables, spring assemblies and other

hardware MUST be made by a trained door systems

technician BEEORE installing opener.

4. Disable ALL locks and remove ALL ropes connected to

garage door BEFORE installing opener to avoid

entanglement.

5. Install garage door opener 7 feet (2.1 m) or more above

floor.

6. Mount emergency release handle 6 feet (1.8 m) above

floor.

7. NEVER connect garage door opener to power source until

instructed to do so.

(2.5 cm)

8. NEVER wear watches, rings or loose clothing while

installing or servicing opener. They could be caught in

garage door or opener mechanisms.

9. Install wall-mounted garage control console:

• within sight of the garage door.

• out of reach of children at minimum height of 5 feet

(1.5 m).

• away from ALL moving parts of the door.

10. Place entrapment warning label on wall next to garage

control console.

11. Place manual release/safety reverse test label in plain

view on inside of garage door.

12. Upon completion of installation, test safety reversal

system. Door MUST reverse on contact with a 1-1/2"

(3.8 cm) high object (or a 2x4 laid flat) on the floor.

13. To avoid SERIOUS PERSONAL INJURY or DEATH from

electrocution, disconnect ALL electric and battery power

BEFORE performing ANY service or maintenance.

(3.18 cm)

11

Page 12

INSTALLATION STEP 1

Determine the Header Bracket Location

WARNING

To prevent possible SERIOUS INJURY or DEATH:

• Header bracket MUST be RIGIDLY fastened to structural

support on header wall or ceiling, otherwise garage door

might not reverse when required. DO NOT install header

bracket over dry wall.

• Concrete anchors MUST be used if mounting header

bracket or 2x4 into masonry.

• NEVER try to loosen, move or adjust garage door, springs,

cables, pulleys, brackets, or their hardware, all of which are

under EXTREME tension.

• ALWAYS call a trained door systems technician if garage

door binds, sticks, or is out of balance. An unbalanced

garage door might not reverse when required.

Installation procedures vary according to garage door

types. Follow the instructions which apply to your door.

1 .Close the door and mark the inside vertical centerline

of the garage door.

2. Extend the line onto the header wall above the door.

You can fasten the header bracket within 4 feet

(1.22 m) of the left or right of the door center only

if a torsion spring or center bearing plate is in the

way; or you can attach it to the ceiling (see

page 13) when clearance is minimal. (It may be

mounted on the wall upside down if necessary, to

gain approximately 1/2" (1 cm).)

If you need to install the header bracket on a 2x4

(on wall or ceiling), use lag screws (not provided)

to securely fasten the 2x4 to structural supports as

shown here and on page 13.

3.0pen your door to the highest point of travel as

shown. Draw an intersecting horizontal line on the

header wall above the high point:

• 2" (5 cm) above the high point for sectional door

and one-piece door with track.

• 8" (20 cm) above the high point for one-piece door

without track.

This height will provide travel clearance for the top

edge of the door.

NOTE: If the total number of inches exceeds the

height availabie in your garage, use the maximum

height possibie, or refer to page 13 for ceiiing

insta nation.

One-piece door without track:

jamb hardware

12

One-piece door without track:

pivot hardware

Page 13

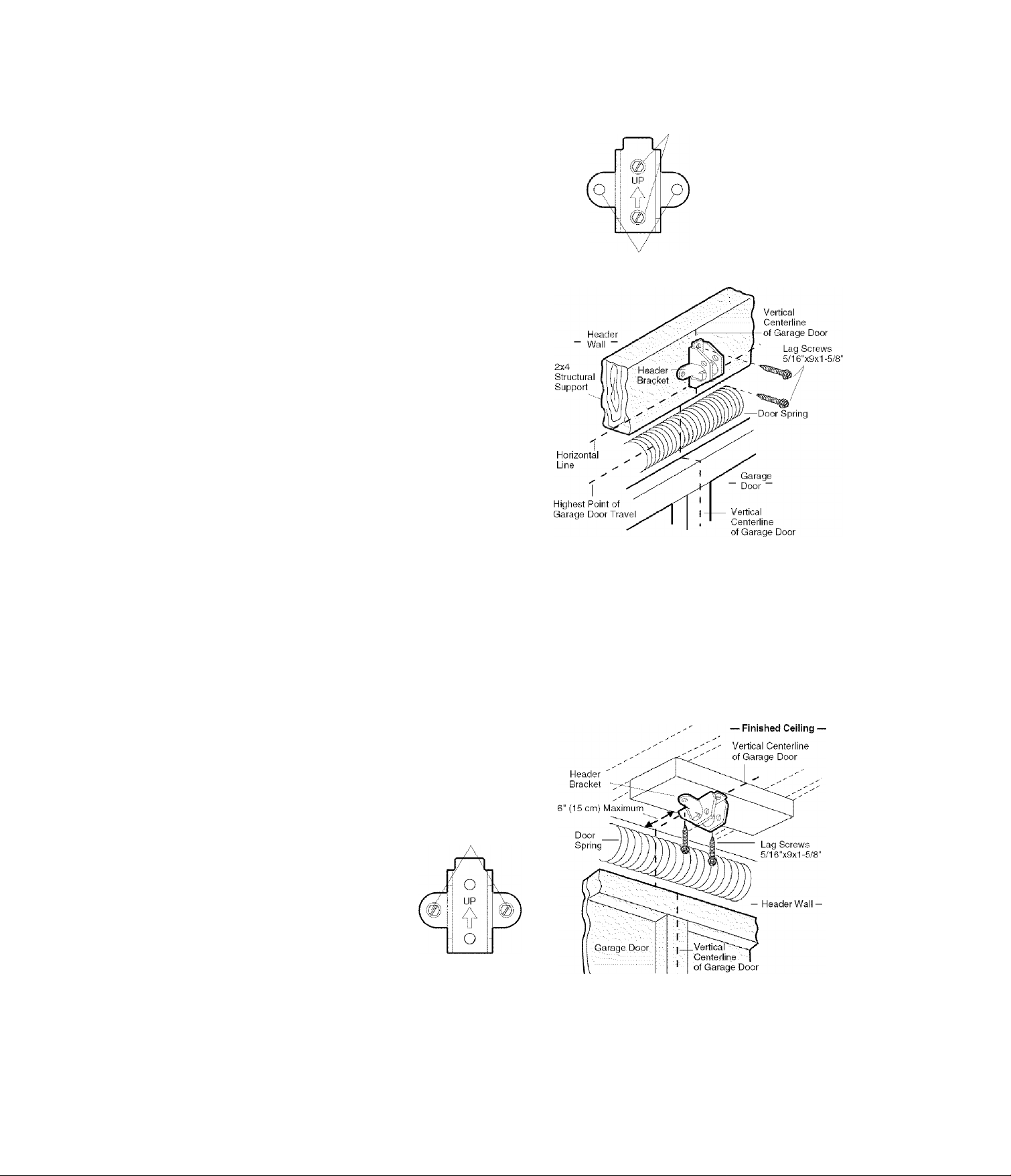

INSTALLATION STEP 2

Install the Header Bracket

You can attach the header bracket either to the wall

above the garage door, or to the ceiling. Follow the

instructions which will work best for your particular

requirements. Do not install the header bracket over

drywall. If installing into masonry, use concrete

anchors (not provided).

WALL HEADER BRACKET INSTALLATION

• Center the bracket on the vertical centerline with the

bottom edge of the bracket on the horizontal line as

shown (with the arrow pointing toward the ceiling).

• Mark the vertical set of bracket holes. Drill 3/16" pilot

holes and fasten the bracket securely to a structural

support with the hardware provided.

HARDWARE SHOWN ACTUAL SIZE

ID>

Lag Screw

5/16"-9x1-5/8"

Wall Mount

Optional

Mounting Holes

CEILING HEADER BRACKET INSTALLATION

• Extend the vertical centerline onto the ceiling as

shown.

• Center the bracket on the vertical mark, no more than

6" (15 cm) from the wall. Make sure the arrow is

pointing away from the wall. The bracket can be

mounted flush against the ceiling when clearance

is minimal.

• Mark the side holes. Drill 3/16" pilot holes and fasten

bracket securely to a structural support with the

hardware provided.

Ceiling Mounting Holes

13

Page 14

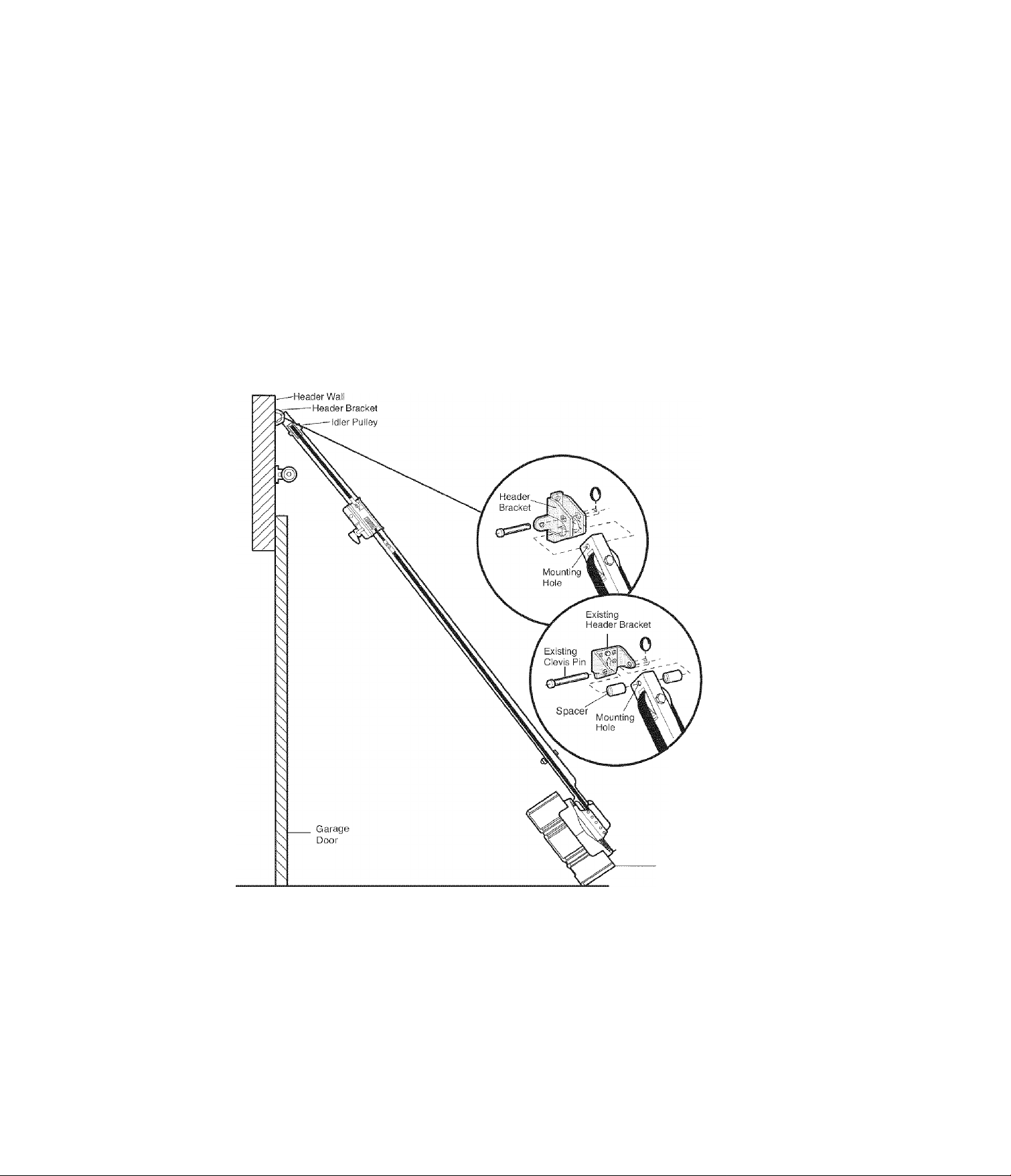

INSTALLATION STEP 3

Attach the Rail to the Header Bracket

NOTE: (Optional) With some existing installations, you

may re-use the old header bracket with the two plastic

spacers included in the hardware bag. Place the spacers

inside the bracket on each side of the rail, as illustrated.

• Position the opener on the garage floor below the

header bracket. Use packing material as a protective

base.

NOTE: If the door spring is in the way, you will

need help. Have someone hold the opener securely on

a temporary support to allow the rail to clear the

spring.

• Position the rail bracket against the header bracket.

• Align the bracket holes and join with a clevis pin

as shown.

• Insert a ring fastener to secure.

HARDWARE SHOWN ACTUAL SIZE

O

Clevis Pin 5/16''x1-1/2”

14

O

Ring Fastener

OPTION WITH

SOME EXISTING

INSTALLATIONS

Opener Carton or

Temporary

Support

Page 15

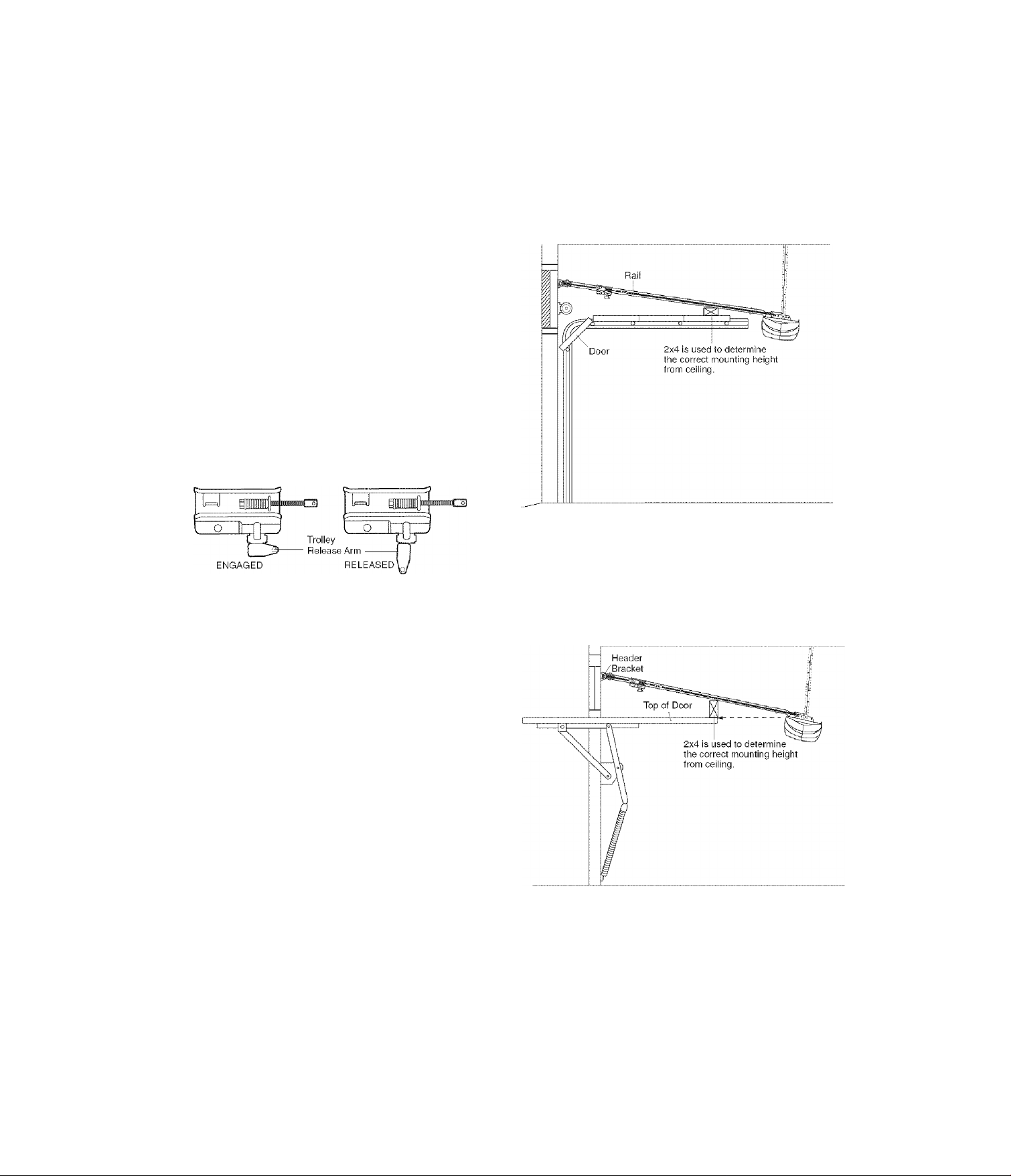

INSTALLATION STEP 4

Position the Opener

Follow instructions which apply to your door type

as illustrated.

SECTIONAL DOOR OR ONE-PIECE DOOR WITH TRACK

A 2x4 laid flat is convenient for setting an ideal

door-to-rail distance.

• Remove foam packaging.

• Raise the opener onto a stepladder. You will need help

at this point if the ladder is not tall enough.

• Open the door all the way and place a 2x4 laid flat on

the top section beneath the rail.

• If the top section or panel hits the trolley when you

raise the door, pull down on the trolley release arm

to disconnect inner and outer sections. Slide the outer

trolley toward the motor unit. The trolley can remain

disconnected until Installation Step 12 is completed.

CAUTION

To prevent damage to garage door, rest garage door opener

rail on 2x4 placed on top section of door.

ONE-PIECE DOORWITHOUTTRACK

A 2x4 on its side is convenient for setting an ideal

door-to-rail distance.

• Remove foam packaging.

• Raise the opener onto a stepladder. You will need help

at this point if the ladder is not tall enough.

• Open the door all the way and place a 2x4 on its side

on the top section of the door beneath the rail.

• The top of the door should be level with the top of the

motor unit. Do not position the opener more than 4"

(10 cm) above this point.

15

Page 16

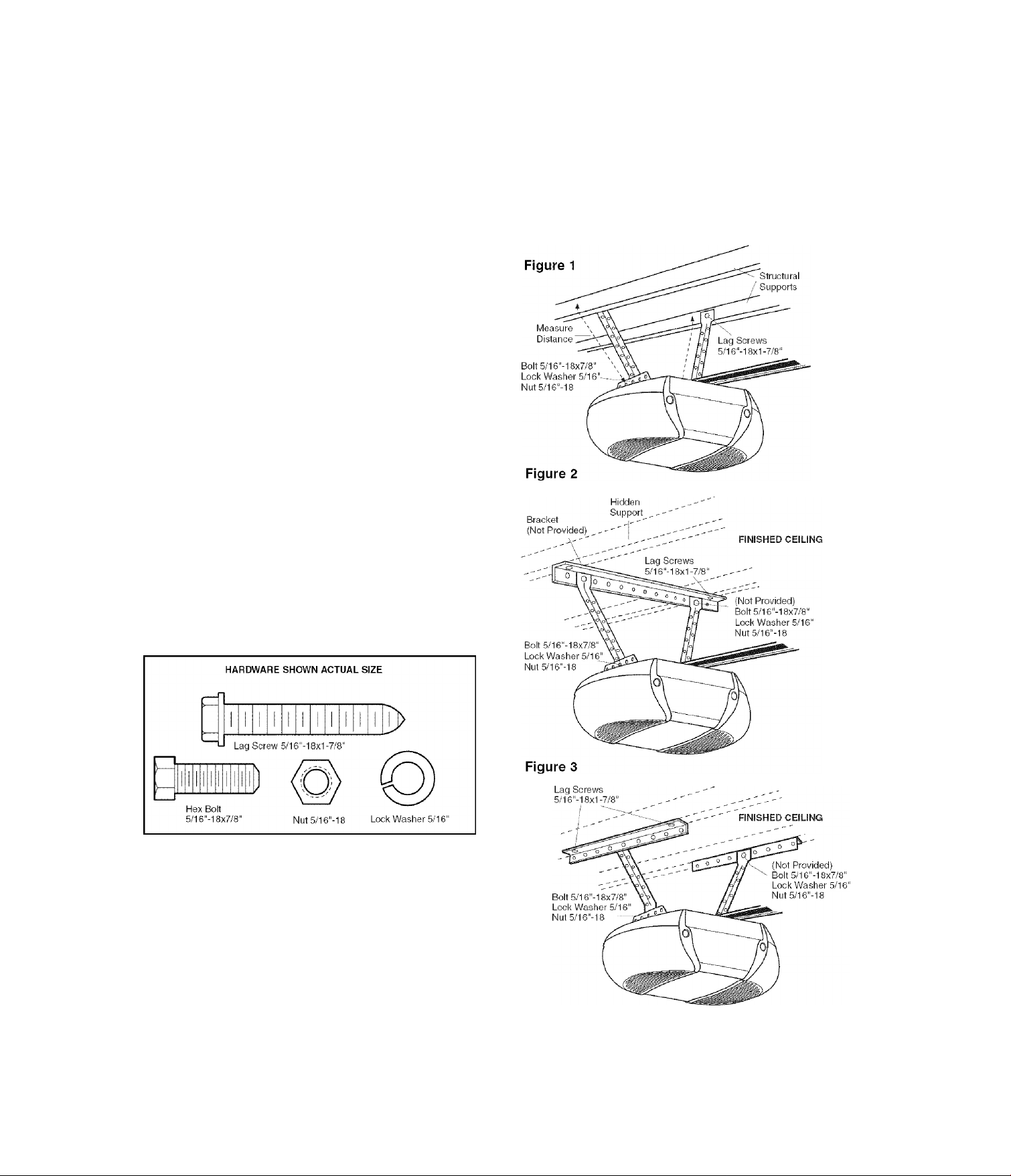

INSTALLATION STEP 5

Hang the Opener

Three representative installations are shown. Yours may

be different. Hanging brackets should be angled

(Figure 1) to provide rigid support. On finished ceilings

(Figures 2 and 3), attach a sturdy metal bracket to

structural supports before installing the opener. This

bracket and fastening hardware are not provided.

1. Measure the distance from each side of the motor unit

to the structural support.

2. Cut both pieces of the hanging bracket to required

lengths.

3. Drill 3/16" pilot holes in the structural supports.

4. Attach one end of each bracket to a support with

5/16"-18x1-7/8” lag screws.

5. Fasten the opener to the hanging brackets with

5/16"-18x7/8" hex bolts, lock washers and nuts.

6. Check to make sure the rail is centered over the door

(or in line with the header bracket if the bracket is not

centered above the door).

7. Remove the 2x4. Cperate the door manually. If the

door hits the rail, raise the header bracket.

NOTE: DO NOT connect power to opener at this time.

A WARNING

To avoid possible SERIOUS INJURY from a falling garage

door opener, fasten it SECURELY to structural supports of

the garage. Concrete anchors MUST be used if installing any

brackets into masonry.

16

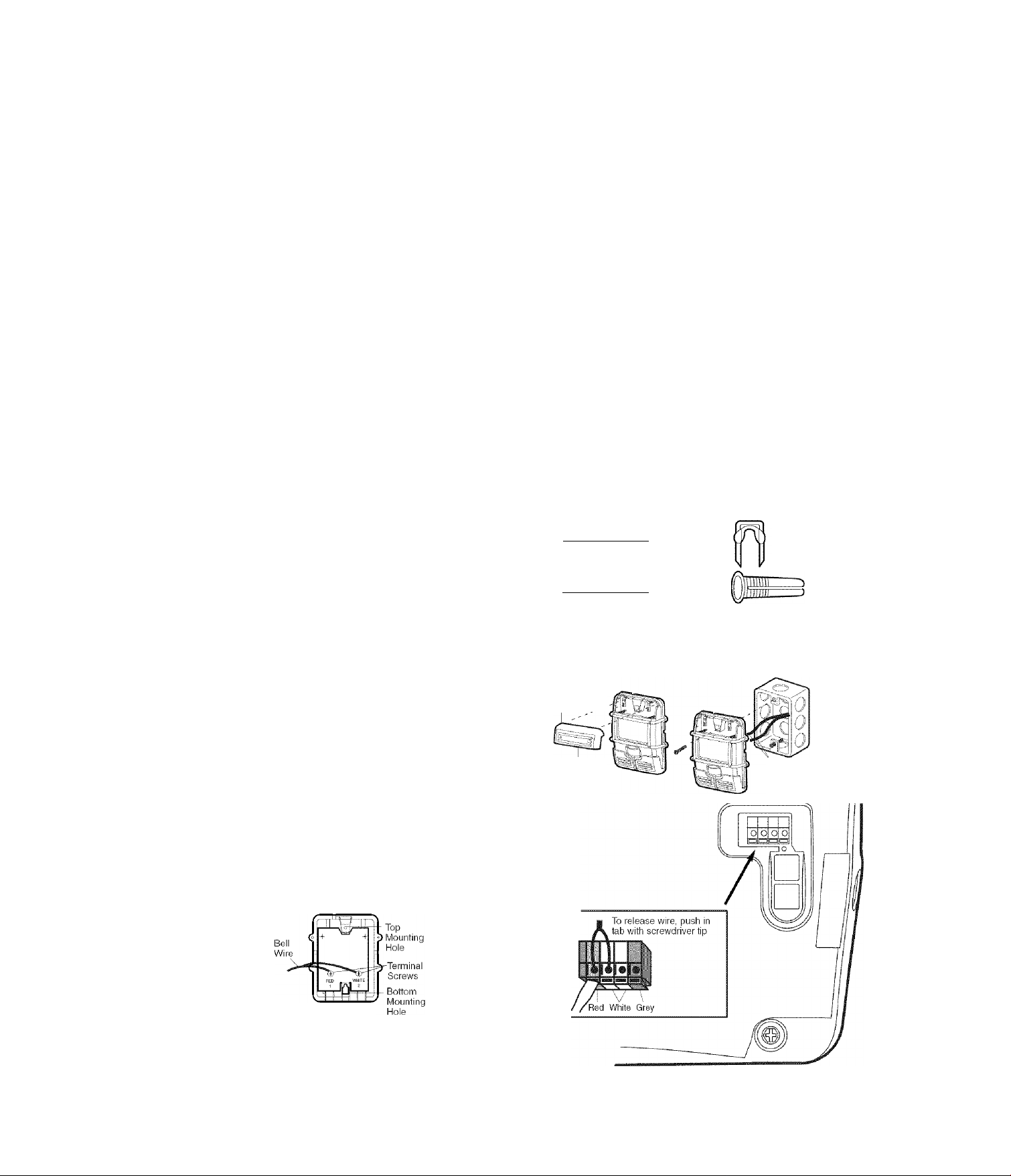

Page 17

INSTALLATION STEP 6

Install the Control Console

Locate control console within sight of door, at a minimum

height of 5 feet (1.5 m) where small children cannot

reach, away from moving parts of door and door

hardware. If installing into drywall, drill 5/32" holes and

use the anchors provided. For pre-wired installations

(as in new home construction), it may be mounted to a

single gang box (Figure 2).

1. Strip 7/16" (11 mm) of insulation from one end of bell

wire and connect to the two screw terminals on back of

control console by color: white wire to 2 and white/red

wire to the 1.

2. Remove cover by gently prying at slot in top of the

cover with a small flat head screwdriver. Fasten with

6ABx1-1/4" self-tapping screws (drywall installation) or

6-32x1" machine screws (into gang box) as follows:

• Install bottom screw, allowing 1/8" (3 mm) to protrude

above wall surface.

• Position bottom of control console on screw head

and slide down to secure. Adjust screw for snug fit.

• Drill and install top screw with care to avoid cracking

plastic housing. Do not overtighten.

• Insert top tabs and snap on cover.

3. (For standard installation only) Run bell wire up wall

and across ceiling to motor unit. Use insulated staples

to secure wire in several places. Do not pierce wire

with a staple, creating a short or open circuit.

4. Strip 7/16" (11 mm) of insulation from end of bell wire.

Connect bell wire to the quick-connect terminals as

follows: white to white and white/red to red.

5. Position the antenna wire as shown.

6. Use tacks or staples to permanently attach entrapment

warning label to wall near control console, and manual

release/safety reverse test label in a prominent

location on inside of garage door.

NOTE: DO NOT connect power and operate opener at

this time. The troliey wili travei to the fuil open position

but wilt not return to the close position until the sensor

beam is connected and properly aligned.

AA WARNING

To prevent possible SERIOUS INJURY or DEATH from

electrocution:

• Disconnect ALL electric and battery power BEFORE

performing ANY service or maintenance.

• Connect ONLY to 24 VOLT low voltage wires.

To prevent possible SERIOUS INJURY or DEATH from a

closing garage door:

• Install control console within sight of garage door, out of

reach of children at a minimum height of 5 feet (1.5 m), and

away from ALL moving parts of door.

• NEVER permit children to operate or play with control

console push buttons or remote controls.

• Activate door ONLY when it can be seen clearly, is properly

adjusted, and there are no obstructions to door travel.

• ALWAYS keep garage door in sight until completely closed.

NEVER permit anyone to cross path of closing garage door.

Outside Keylock Accessory Connections

To opener quick-connect terminals: white to white;

white/red to red.

HARDWARE SHOWN ACTUAL SIZE

|i|i|i|i|i|i|i|i|i|i|i|iT>

a

Screw 6ABx1-1/4‘

Control Panel (std installation)

IIIIIIIIIIIIIIIIIIH1

Screw 6-32x1"

Control Panel (pre-wired)

Figure 1

REMOVE & REPLACE COVER

To Replace

Insert Top

Tabs First

Push Bar Cover

PRE-WIRED INSTALLATION

Insulated

Staples

Drywall Anchors

Figure 2

24 Volt Bell Wire

(BACK VIEW)

Controi Console Connections

Strip wire 7/16“ (11 mm)

C^r'ie" (11 mmi>

17

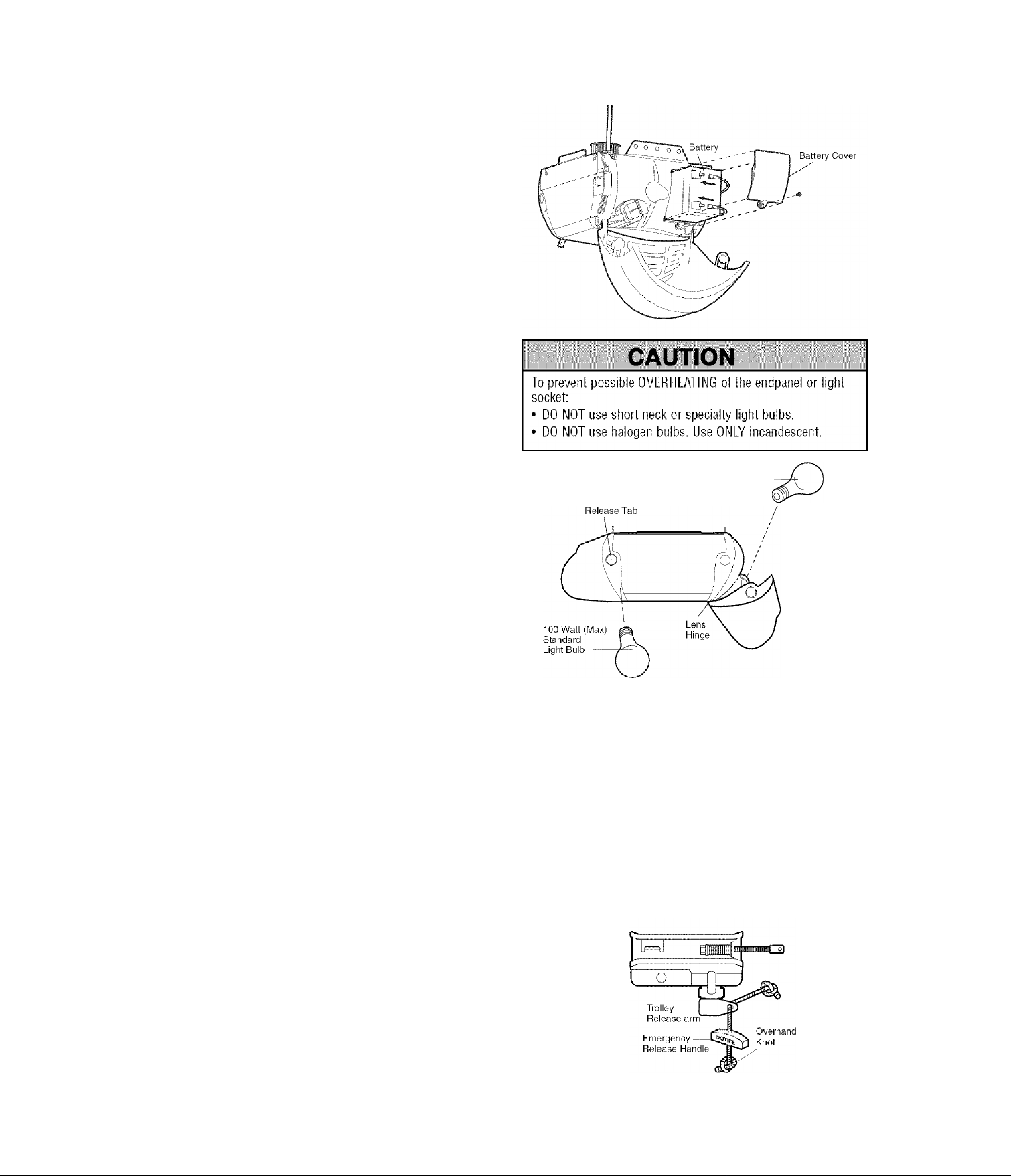

Page 18

INSTALLATION STEP 7

Install the Battery

• Make sure motor unit is unplugged.

• Using a Phillips head screwdriver, remove the battery

cover on the motor unit.

• Partially insert battery into motor unit with terminals

facing out.

• Connect the red {+) and black (-) wires from motor unit

to corresponding terminals on battery.

• Replace battery cover.

INSTALLATION STEP 8

Install the Lights

• Press the release tabs on both sides of lens. Gently

rotate lens back and downward until the lens hinge is

in the fully open position. Do not remove the lens.

• Install up to a too watt maximum light bulb in each

socket. The lights will turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the lights will turn OFR

• Reverse the procedure to close the lens.

• If the bulbs burn out prematurely due to vibration,

replace with a Garage Door Opener bulb.

NOTE: Use only standard light bulbs. The use of short

neck or speciality light bulbs may overheat the endpanel

or light socket.

100 Watt (Max) —

Standard Light Bulb

INSTALLATION STEP 9

Attach the Emergency Release Rope and Handle

• Thread one end of the rope through the hole in the top

of the red handle so “NOTICE” reads right side up

as shown. Secure with an overhand knot at least

1" (2.5 cm) from the end of the rope to prevent

slipping.

• Thread the other end of the rope through the hole in

the release arm of the outer trolley.

• Adjust rope length so the handle is 6 feet (1.83 m)

above the floor. Ensure that the rope and handle clear

the tops of all vehicles to avoid entanglement. Secure

with an overhand knot.

NOTE: If it is necessary to cut the rope, heat seal the cut

end with a match or lighter to prevent unraveling.

A WARNING

To prevent possible SERIOUS INJURY or DEATH from a

falling garage door:

• If possible, use emergency release handle to disengage

trolley ONLY when garage door is CLOSED. Weak or

broken springs or unbalanced door could result in an open

door falling rapidly and/or unexpectedly.

• NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

• NEVER use handle to pull door open or closed. If rope knot

becomes untied, you could fall.

Trolley

18

Page 19

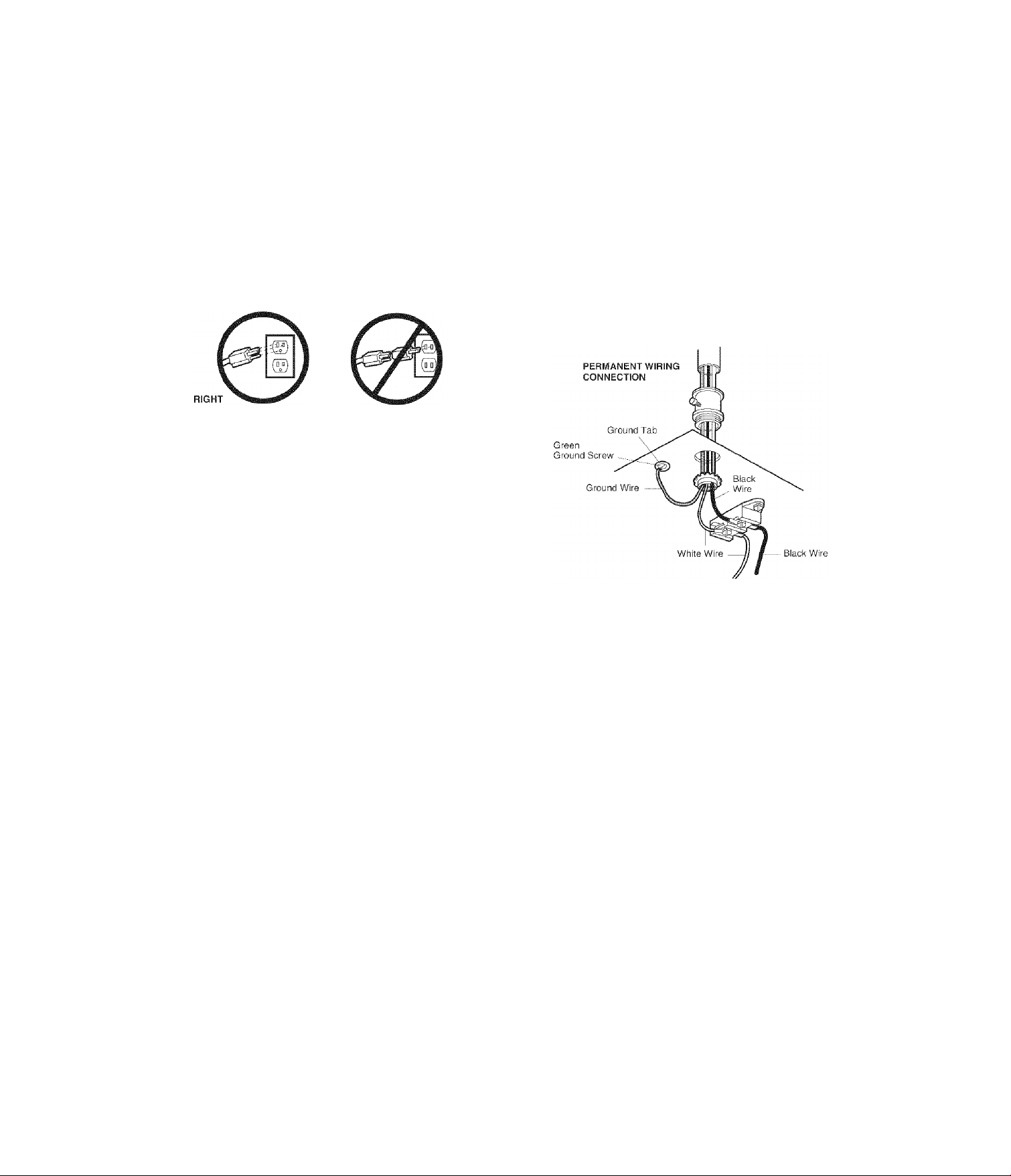

INSTALLATION STEP 10

Electrical Requirements

To avoid installation difficulties, do not run the opener at this time.

To reduce the risk of electric shock, your garage door

opener has a grounding type plug with a third grounding

pin. This plug will only fit into a grounding type outlet. If

the plug doesn’t fit into the outlet you have, contact a

qualified electrician to install the proper outlet.

WRONG

If permanent wiring is required by your local code, refer to the following procedure.

To make a permanent connection through the 7/8" (2 cm)

hole in the top of the motor unit:

• Remove the motor unit cover screws and set the cover

aside.

• Remove the attached 3-prong cord.

• Connect the black (line) wire to the screw on the brass

terminal; the white (neutral) wire to the screw on the

silver terminal; and the ground wire to the green

ground screw. The opener must be grounded.

• Reinstall the cover.

To avoid installation difficulties, do not run the

opener at this time.

A WARNING

To prevent possible SERIOUS INJURY or DEATH from

electrocution or fire:

• Disconnect ALL electric and battery power BEFORE

performing ANY service or maintenance.

• Garage door installation and wiring MUST be in compliance

with ALL local electrical and building codes.

• NEVER use an extension cord, 2-wire adapter, or change

plug in any way to make it fit outlet. Be sure the opener

is grounded.

19

Page 20

INSTALLATION STEP 11

Install The Protector System^

(Safety Sensors)

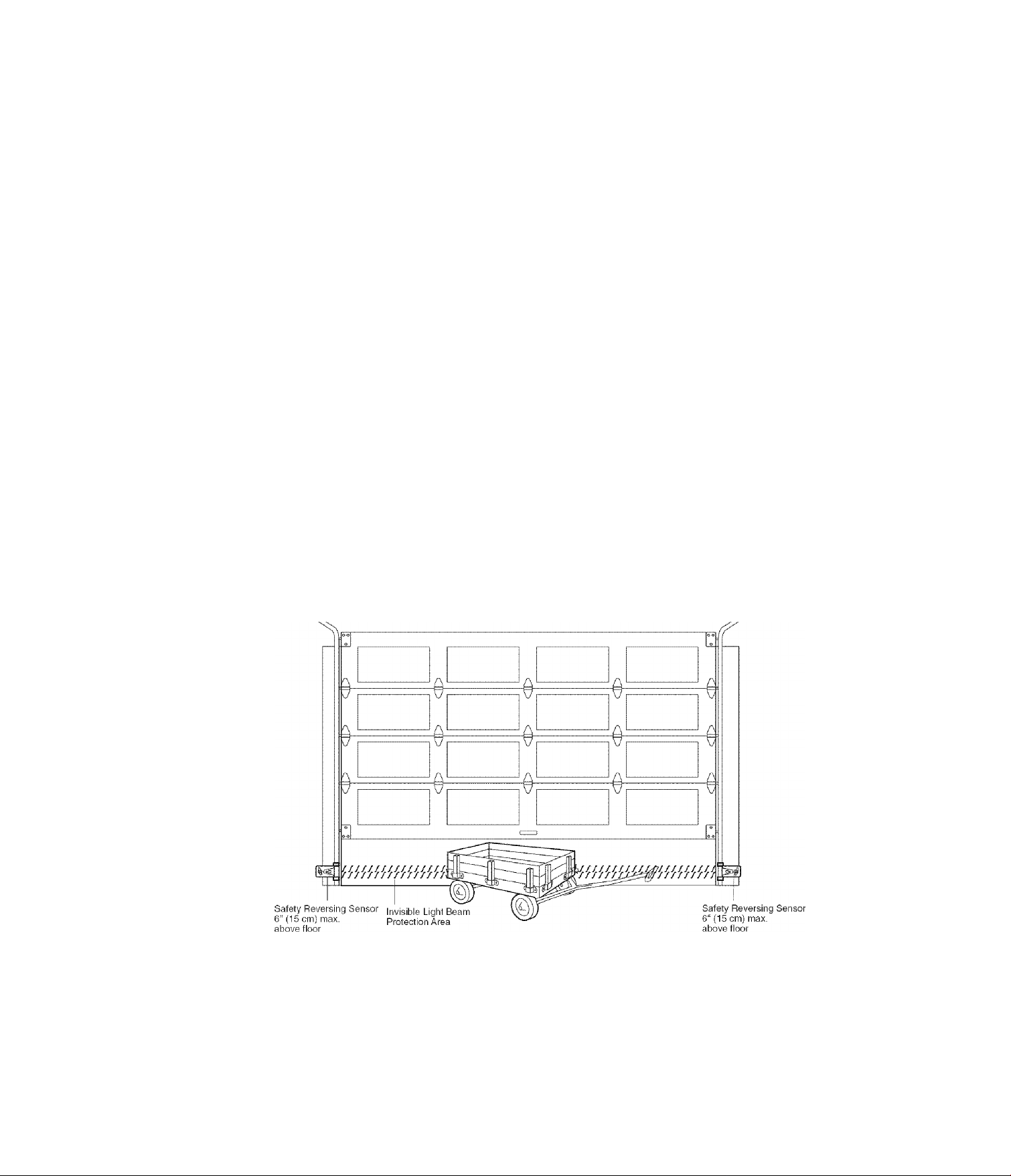

The safety reversing sensor must be connected and

aligned correctly before the garage door opener will

move in the down direction.

IMPORTANT INFORMATION ABOUT THE SAFETY REVERSING SENSOR

When properly connected and aligned, the sensor will

detect an obstacle in the path of its electronic beam. The

sending eye (with an amber indicator light) transmits an

invisible light beam to the receiving eye (with a green

indicator light). If an obstruction breaks the light beam

while the door is closing, the door will stop and reverse

to full open position, and the opener lights will flash

10 times.

The units must be installed inside the garage so that the

sending and receiving eyes face each other across the

door, no more than 6" (15 cm) above the floor. Either can

be installed on the left or right of the door as long as the

sun never shines directly into the receiving eye lens.

The mounting brackets are designed to clip onto the

track of sectional garage doors without additional

hardware.

ik WARNING

Be sure power is NOT connected to the garage door opener

BEFORE installing the safety reversing sensor.

To prevent SERIOUS INJURY or DEATH from a closing

garage door:

• Correctly connect and align the safety reversing sensor.

This required safety device MUST NOT be disabled.

• Install tbe safety reversing sensor so beam is NO HIGHER

than 6" (15 cm) above garage floor.

If it is necessary to mount the units on the wall, the

brackets must be securely fastened to a solid surface

such as the wall framing. Extension brackets (see

accessories) are available if needed. If installing in

masonry construction, add a piece of wood at each

location to avoid drilling extra holes in masonry if

repositioning is necessary.

The invisible light beam path must be unobstructed. No

part of the garage door (or door tracks, springs, hinges,

rollers or other hardware) may interrupt the beam while

the door is closing.

Facing the door from inside the garage

20

Page 21

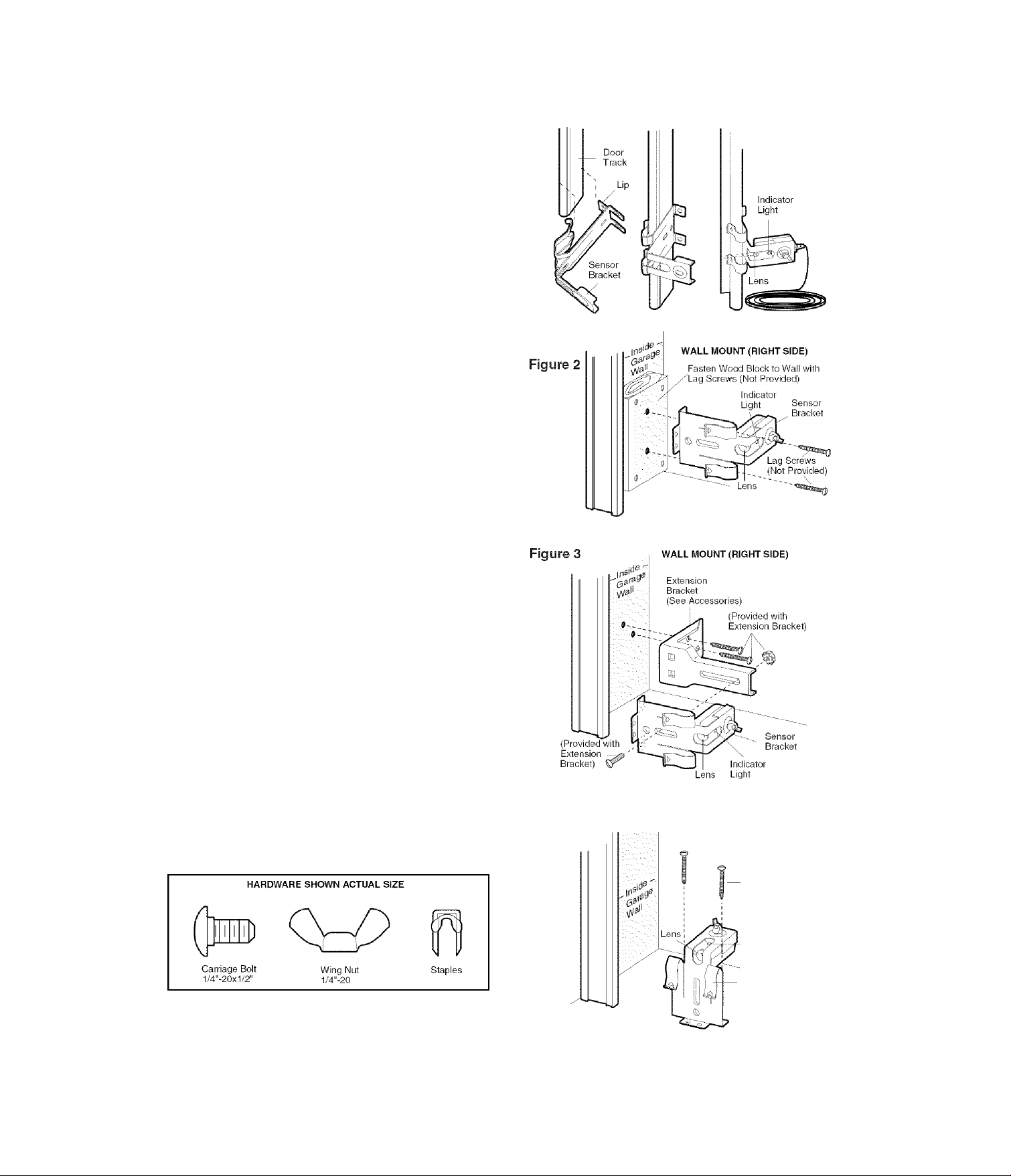

INSTALLING THE BRACKETS

Be sure power to the opener is disconnected. Install

and align the brackets so the sensors will face each

other across the garage door, with the beam no higher

than 6" (15 cm) above the floor. They may be installed in

one of three ways, as follows.

Garage door track installation (preferred):

• Slip the curved arms over the rounded edge of each

door track, with the curved arms facing the door. Snap

into place against the side of the track. It should lie

flush, with the lip hugging the back edge of the track

(Figure 1).

If your door track will not support the bracket securely,

wall installation is recommended.

Wall installation (Figures 2 and 3):

• Place the bracket against the wall with curved arms

facing the door. Be sure there is enough clearance for

the sensor beam to be unobstructed.

• If additional depth is needed, an extension bracket

(see Accessories) or wood blocks can be used.

• Use bracket mounting holes as a template to locate

and drill (2) 3/16" diameter pilot holes on the wall at

each side of the door, no higher than 6" (15 cm) above

the floor.

• Attach brackets to wall with lag screws (not provided).

• If using extension brackets or wood blocks, adjust right

and left assemblies to the same distance out from the

mounting surface. Make sure all door hardware

obstructions are cleared.

Floor installation (Figure 4):

• Use wood blocks or extension brackets (see

Accessories) to elevate sensor brackets so the lenses

will be no higher than 6" (15 cm) above the floor.

• Carefully measure and place right and left assemblies

at the same distance out from the wall. Be sure all

door hardware obstructions are cleared.

• Fasten to the floor with concrete anchors as shown.

Figure

1 door track mount (right side)

21

Figure 4

floor mount (RIGHT SIDE)

Concrete Anchors

(Not Provided)

Indicator

Light

- Sensor

Bracket

Page 22

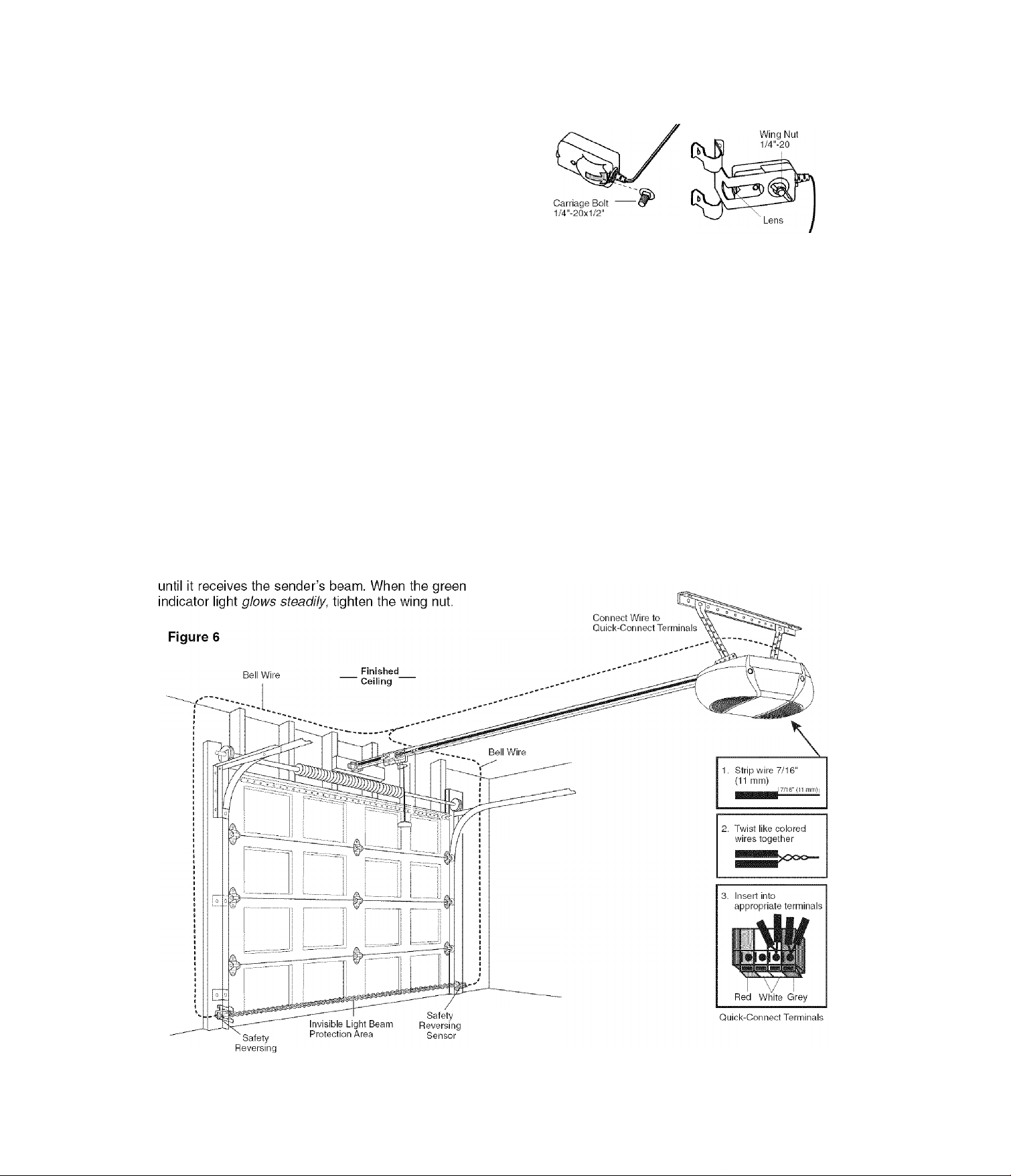

MOUNTING AND WIRING THE SAFETY REVERSING SENSORS

• Slide a 1/4"-20x1/2" carriage bolt head Into the slot on

each sensor. Use wing nuts to fasten sensors to

brackets, with lenses pointing toward each other

across the door. Be sure the lens is not obstructed by

a bracket extension (Figure 5).

• Finger tighten the wing nuts.

• Run the wires from both sensors to the opener. Use

insulated staples to secure wire to wall and ceiling.

• Strip 7/16" (11 mm) of insulation from each set of

wires. Separate white and white/black wires sufficiently

to connect to the opener guick-connect terminals. Twist

like colored wires together. Insert wires into

quick-connect holes: white to white and white/black

to grey (Figure 6).

ALIGNING THE SAFETY REVERSING SENSORS

• Plug in the opener. The indicator lights in both the

sending and receiving eyes m\\ glow steadily W wiring

connections and alignment are correct.

The sending eye amber indicator light will glow

regardless of alignment or obstruction. If the green

indicator light in the receiving eye is off, dim, or flickering

(and the invisible light beam path is not obstructed),

alignment is required.

• Loosen the sending eye wing nut and readjust, aiming

directly at the receiving eye. Lock in place.

• Loosen the receiving eye wing nut and adjust sensor

Figure 5

TROUBLESHOOTING THE SAFETY REVERSING SENSORS

1. If the sending eye indicator light does not glow steadily

after installation, check for:

• Electric power to the opener.

• A short in the white or white/black wires. These can

occur at staples, or at opener connections.

• Incorrect wiring between sensors and opener.

• A broken wire.

2. If the sending eye indicator light glows steadily but the

receiving eye indicator light doesn't:

• Check alignment.

• Check for an open wire to the receiving eye.

3. If the receiving eye indicator light is dim, realign either

sensor.

NOTE: When the invisible beam path is obstructed or

misaligned while the door is closing, the door will reverse.

If the door is already open, it will not close.

The opener lights will blink 10 times. See page 20.

Sensor

22

Page 23

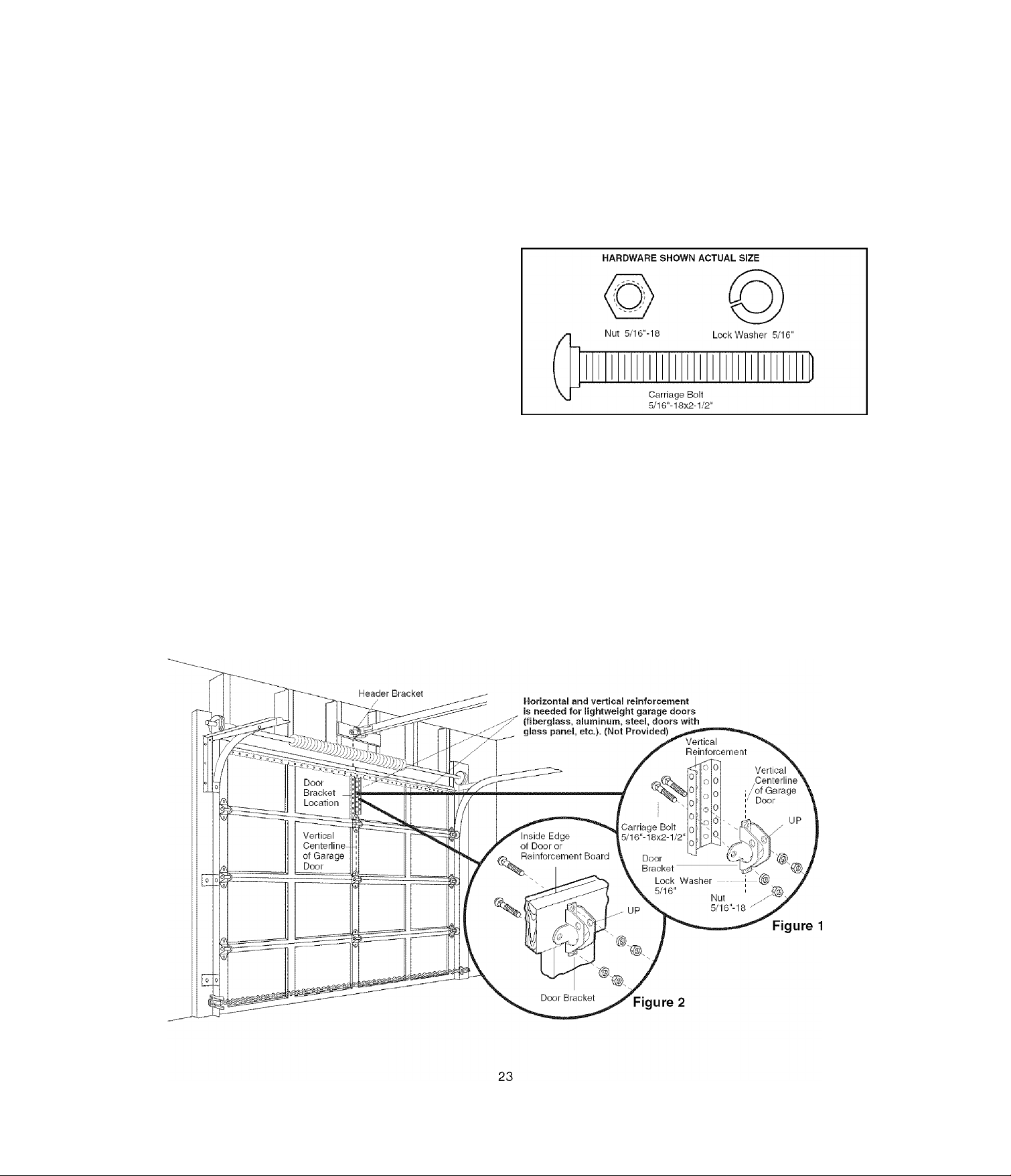

INSTALLATION STEP 12

Fasten the Door Bracket

Follow instructions which apply to your door type

as illustrated below or on the following page.

A horizontal reinforcement brace should be long

enough to be secured to two vertical supports. A

vertical reinforcement brace should cover the height

of the top panel.

The illustration shows one piece of angle iron as the

horizontal brace. For the vertical brace, two pieces of

angle iron are used to create a U-shaped support

(Figure 1). The best solution is to check with your

garage door manufacturer for an opener installation door

reinforcement kit.

NOTE: Many vertical brace installations provide for direct

attachment of the clevis pin and door arm. In this case

you will not need the door bracket; proceed to

Installation Step 13.

SECTIONAL DOORS

1. Center the door bracket on the previously marked

vertical centerline used for the header bracket

installation. Note correct UP placement, as stamped

inside the bracket (Figure 2).

2. Position the bracket on the face of the door within the

following limits:

• The top edge of the bracket 2"-4" (5-10 cm) below

the top edge of the door.

• The top edge of the bracket directly below any

structural support across the top of the door.

CAUTION

Fiberglass, aluminum or lightweight steel garage doors

WILL REQUIRE

bracket. Contact your door manufacturer for

reinforcement kit.

• Mark and drill 5/16" left and right fastening holes.

Secure the bracket as shown in Figure 1 if there is

vertical reinforcement.

If your installation doesn't require vertical reinforcement

but does need top and bottom fastening holes for the

door bracket, fasten as shown in Figure 2.

reinforcement BEFORE installation of door

Page 24

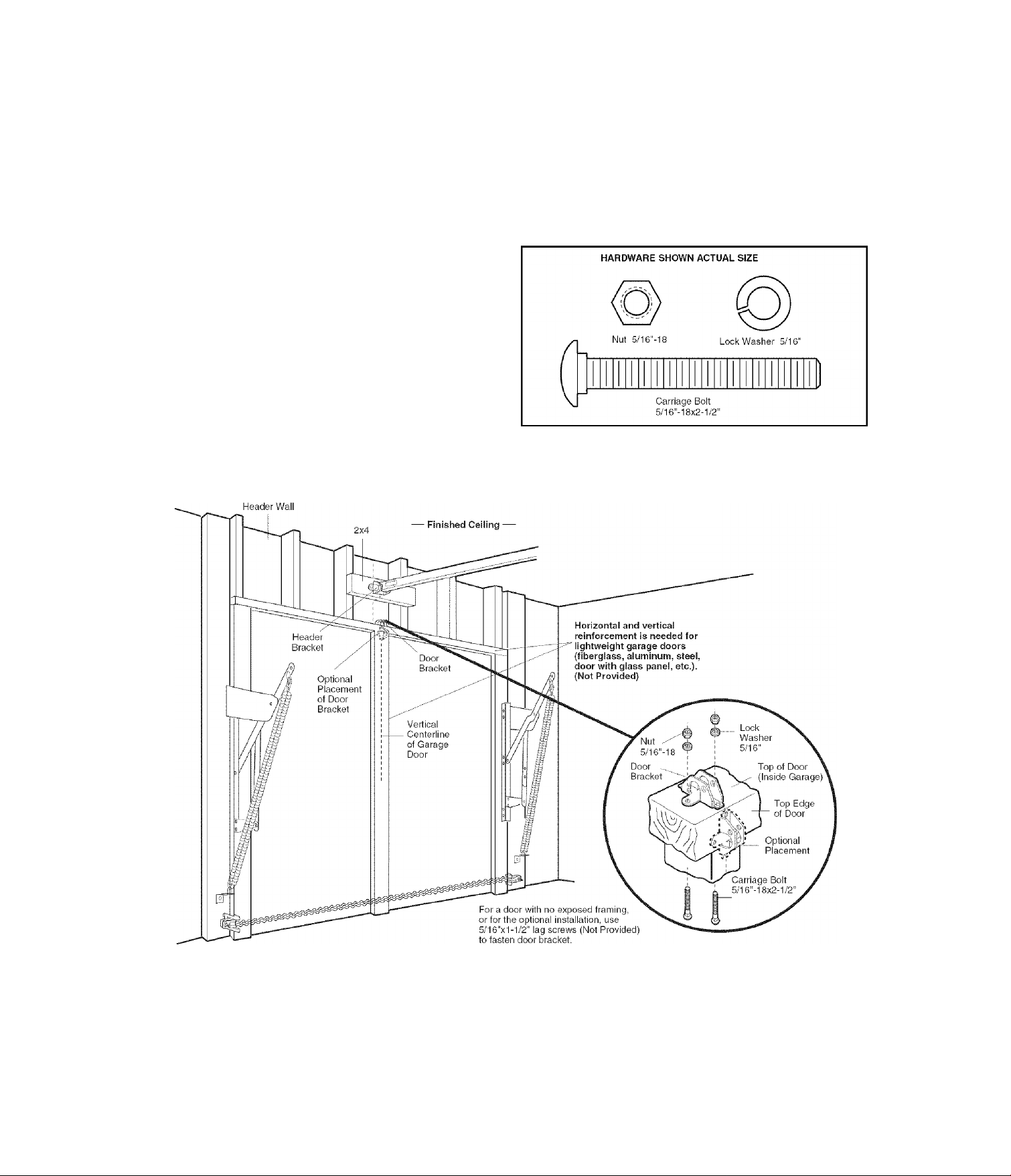

ONE-PIECE DOORS

Please read and comply with the warnings and

reinforcement instructions on the previous page. They

apply to one-piece doors also.

• Center the door bracket on the top of the door, in line

with the header bracket as shown. Mark either the left

and right, or the top and bottom holes.

• Drill 5/16" pilot holes and fasten the bracket with

hardware supplied.

If the door has no exposed framing, drill 3/16" pilot holes

and fasten the bracket with 5/16”x1-1/2" lag screws

(not provided) to the top of the door.

NOTE: The door bracket may be installed on the top

edge of the door If required for your instailation. (Refer to

the dotted line optional placement drawing.) Drili 3/16"

pilot holes and substitute 5/16"x1-1/2" lag screws (not

provided) to fasten the bracket to the door.

24

Page 25

INSTALLATION STEP 13

Connect Door Arm to Trolley

Follow Instructions which apply to your door type as

illustrated below and on the following page.

SECTIONAL DOORS ONLY

Make sure garage door is fully closed. Pull the

emergency release handle to disconnect the outer trolley

from the inner trolley. Slide the outer trolley back (away

from the pulley) about 8" (20 cm) (Figures 1,2 and 3).

Figure 1:

• Fasten straight door arm section to outer trolley with

the 5/16"x1'' clevis pin. Secure the connection with a

ring fastener.

• Fasten curved section to the door bracket in the same

way, using the 5/16"x1-1/4" clevis pin.

Figure 2:

• Bring arm sections together. Find two pairs of holes

that line up and join sections. Select holes as far apart

as possible to increase door arm rigidity.

Figure 3, Hoie alignment alternative:

• If holes in curved arm are above holes in straight arm,

disconnect straight arm. Cut about 6" (15 cm) from the

solid end. Reconnect to trolley with cut end down

as shown.

• Bring arm sections together.

• Find two pairs of holes that line up and join with bolts,

lock washers and nuts.

Pull the emergency release handle toward the opener at

a 45° angle so that the trolley release arm is horizontal.

Proceed to Adjustment Step 1, page 27. Trolley will

re-engage automatically when opener is operated.

Pulley

Figure 1

Pulley

Figure 2

25

Pulley

Figure 3

Page 26

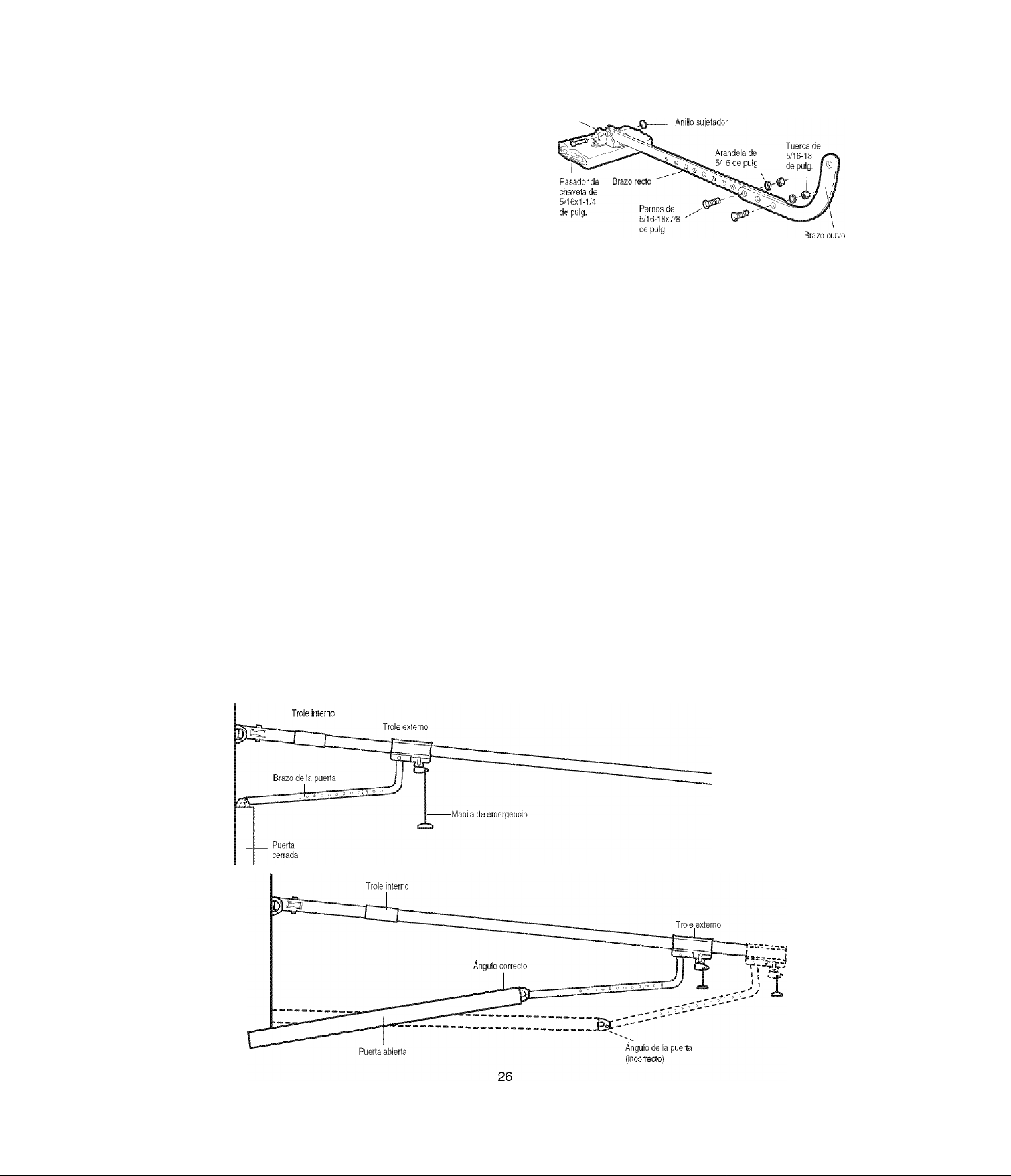

ALL ONE-PIECE DOORS

1. Assemble the Door Arm:

• Fasten the straight and curved door arm sections

together to the longest possible length (with a 2 or 3

hole overlap).

• Make sure the garage door is fully closed. Connect

the straight door arm section to the door bracket with

the 5/16"x1-1/4" clevis pin.

• Secure with a ring fastener.

• Pull the emergency release handle, disconnecting the

outer trolley from the inner trolley by pulling straight

down on the emergency release handle and sliding

the outer trolley back toward the motor unit.

• Connect the curved door arm section to the trolley

using the 5/16"x1-1/4" clevis pin and ring fastener.

NOTE: Adjusting the limits on the following page:

• The trolley will automatically connect If not, review

the trolley lockout feature on page 32.

• When setting the up limit on the following page, the

door should not have a “backward” slant when fully

open as Illustrated below. A slight backward slant will

cause unnecessary bucking and/or jerking operation

as the door is being opened or closed from the fully

open position.

Door

26

Page 27

ADJUSTMENT STEP 1

Program the Travel Limits

Travel limits regulate the points at which the door

will stop when moving up or down. Follow the steps

below to set the limits.

A WARNING

Without a properly installed safety reversal system, persons

(particularly small children) could be SERIOUSLY INJURED

or KILLED by a closing garage door.

• Incorrect adjustment of garage door travel limits will

interfere with proper operation of safety reversal system.

• NEVER use force adjustments to compensate for a binding

or sticking garage door.

• After ANY adjustments are made, the safety reversal system

MUST be tested. Door MUST reverse on contact with 1-1/2"

(3.8 cm) high object (or 2x4 laid flat) on floor.

CAUTION

To program the travel limits:

Adjust the position of the door by using the black and

purple buttons. Black moves the door UP (open) and

purple moves the door DOWN (close).

1. Setting the UP position: Press and hold the black

button until the yellow indicator light starts flashing

slowly then release.

2. Push and hold the black button until the door reaches

the desired UP (open) position (Figure 2).

NOTE: Check to be sure the door opens high enough for

your vehicle.

3. Push the remote control or door control (Figure 3).

This sets the UP (open) limit and begins closing the

door.

NOTE: Excessive movement of the motor unit will cause

premature wear. See Troubleshooting section.

4. Immediately when the door begins to move down,

press and release either the black or purple button.

This will stop the door.

5. Setting the DOWN position: Push and hold the

purple button until the door reaches the desired

DOWN (closed) position (Figure 4).

6. Once the door is closed, if there appears to have too

much pressure on the door, you may toggle the door

back and forth using the black and purple buttons to

reach the desired closed position.

7. Push the remote control or the door control (Figure 3).

This sets the DOWN (close) limit and should bring the

door to the open position.

• If the opener is not stopping exactly where you

would like it, repeat steps 1 through 8 and program

the limits again.

• When the unit stops in both the desired up (open)

and down (close) positions, proceed to

Adjustment Step 2, Setting the Force.

To prevent damage to vehicles, be sure fully open door

provides adequate clearance.

Figure 3

27

Page 28

ADJUSTMENT STEP 2

Setting the Force

The force setting button is located on the left panel

of the motor unit. The force setting measures the

amount of force required to open and close the door.

1. Locate the purple button on the left panel of the motor

unit (Figure 1).

2. Push the purple button twice to enter the opener Into

Force Adjustment Mode (Figure 2). The LED (Indicator

Light) will flash quickly.

3. Push the remote control or control console (Figure 3).

The door will travel to the DOWN (close) position.

Push the remote control or control console again, the

door will travel to the UP (open) position. Push the

remote control or control console a third time to send

the door to the DOWN (close) position.

The LED (Indicator Light) will stop flashing when the

force has been learned.

The opener has learned the forces required to open and

close your door.

The door must travel through a complete cycle, UP and

DOWN, in order for the force to be set properly. If the

opener cannot open and close your door fully, inspect

your door to insure that it is balanced properly and is not

sticking or binding. See page 3, “Preparing your

garage door.”

A WARNING

Without a properly installed safety reversal system, persons

(particularly small children) could be SERIOUSLY INJURED

or KILLED by a closing garage door.

• Too much force on garage door will interfere with proper

operation of safety reversal system.

• NEVER use force adjustments to compensate for a binding

or sticking garage door.

• After ANY adjustments are made, the safety reversal system

MUST be tested. Door MUST reverse on contact with 1-1/2"

(3.8 cm) high object (or 2x4 laid flat) on floor.

Figure 1

28

Page 29

ADJUSTMENT STEP 3

Test the Safety Reversal System

TEST

• With the door fully open, place a 1 -1/2" (3.8 cm) board

(or a 2x4 laid flat) on the floor, centered under the

garage door.

• Operate the door in the down direction. The door must

reverse on striking the obstruction.

ADJUST

• If the door stops on the obstruction, it is not traveling

far enough in the down direction. Complete Adjustment

Steps 1 and 2.

NOTE: On a sectional door, make sure limit

adjustments do not force the door arm beyond a

straight up and down position. See Figure 3, page 25.

• Repeat the test.

• When the door reverses on the 1 -1/2" (3.8 cm) board

(or 2x4 laid flat), remove the obstruction and run the

opener through 3 or 4 complete travel cycles to test

adjustment.

• If the unit continues to fail the Safety Reverse Test, call

for a trained door systems technician.

ik WARNING

Without a properly installed safety reversal system, persons

(particularly small children) could be SERIOUSLY INJURED

or KILLED by a closing garage door.

• Safety reversal system MUST be tested every month.

• After ANY adjustments are made, the safety reversal

system MUST be tested. Door MUST reverse on contact

with 1-1/2" high (3.8 cm) object (or 2x4 laid flat) on

the floor.

IMPORTANT SAFETY CHECK:

Test the Safety Reverse System after;

• Each adjustment of door arm length, limits, or force

controls.

• Any repair to or adjustment of the garage door

(including springs and hardware).

• Any repair to or buckling of fhe garage floor.

• Any repair fo or adjusfment of the opener.

ADJUSTMENT STEP 4

Test The Protector System®

(Safety Sensors)

• Press the remote control push button to open the door.

• Place the opener carton in the path of the door.

• Press the remote control push button to close the door.

The door will not move more than an inch (2.5 cm),

and the opener lights will flash.

The garage door opener will not close from a remote if

the indicator light in either sensor is off (alerting you to

the fact that the sensor is misaligned or obstructed).

If the opener closes the door when the safety

reversing sensor is obstructed (and the sensors are

no more than 6" (15 cm) above the floor), call for a

trained door systems technician.

29

Page 30

OPERATION

IMPORTANT SAFETY INSTRUCTIONS

A ik WARNING

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS.

2. ALWAYS keep remote controls out of reach of children.

NEVER permit children to operate or play with garage

control console push buttons or remote controls.

3. ONLY activate garage door when it can be seen clearly, it is

properly adjusted, and there are no obstructions to door

travel.

4. ALWAYS keep garage door in sight until completely closed.

NO ONE SHOULD CROSS THE PATH OE THE MOVING

DOOR.

5. NO ONE SHOULD GO UNDER A STOPPED, PARTIALLY

OPEN DOOR.

6. If possible, use emergency release handle to disengage

trolley ONLY when garage door is CLOSED. Weak or broken

springs or unbalanced door could result in an open door

falling rapidly and/or unexpectedly.

7. NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

8. NEVER use handle to pull garage door open or closed. If

rope knot becomes untied, you could fall.

9. If one control (force or travel limits) is adjusted, the other

control may also need adjustment.

10. After ANY adjustments are made, the safety reversal

system MUST be tested.

11. Safety reversal system MUST be tested every month.

Garage door MUST reverse on contact with 1-1/2" high

(3.8 cm) high object (or a 2x4 laid flat) on the floor.

12. ALWAYS KEEP GARAGE DOOR PROPERLY BALANCED

(see page 3). An improperly balanced door may not

reverse when required and could result in SEVERE INJURY

or DEATH.

13. ALL repairs to cables, spring assemblies and other

hardware, all of which are under EXTREME tension, MUST

be made by a trained door systems technician.

14. To avoid SERIOUS PERSONAL INJURY or DEATH from

electrocution, disconnect ALL electric and battery power

BEFORE performing ANY service or maintenance.

15 SAVE THESE INSTRUCTIONS.

Using Your Garage Door Opener

Your Security+® opener and hand-held remote control

have been factory-set to a matching code which changes

with each use, randomly accessing over 100 billion new

codes. Your opener will operate with up to ten Security+®

remote controls, one Security+® Keyless Entry System,

and one accessory wall control. If you purchase a new

remote, or if you wish to deactivate any remote, follow

the instructions in the Programming section.

Activate your opener with any of the foiiowing:

• The hand-held Remote Control: Hold the large push

button down until the door starts to move.

• The wall-mounted control console: Hold the push

button or bar down until the door starts to move.

• The Keyless Entry (see Accessories): If provided with

your garage door opener, it must be programmed

before use. See Programming.

When the opener is activated (with the safety

reversing sensor correctly installed and aligned)

1. If open, the door will close. If closed, it will open.

2. If closing, the door will reverse.

3. If opening, the door will stop.

4. If the door has been stopped in a partially open

position, it will close.

5. If obstructed while closing, the door will reverse. If the

obstruction interrupts the sensor beam, the opener

lights will blink for five seconds.

6. If obstructed while opening, the door will stop.

7. If fully open, the door will not close when the beam is

broken. The sensor has no effect in the opening cycle.

If the sensor is not installed, or is misaligned, the door

won’t close from a hand-held remote. However, you can

close the door with the control console, the Outdoor Key

Switch, or Keyless Entry, if you activate them until down

travel is complete. If you release them too soon, the door

will reverse.

The opener lights will turn on under the following

conditions: when the opener is initially plugged in; when

power is restored after interruption; when the opener is

activated.

They will turn off automatically after 4-1/2 minutes or

provide constant light when the Light feature on the

Control Console is activated. Bulb size is 100 watts

maximum.

Security4^ light feature: Lights will also turn on when

someone walks through the open garage door. With a

Motion Detecting Control Console, this feature may be

turned off as follows: With the opener lights off, press

and hold the light button for 10 seconds, until the light

goes on, then off again. To restore this feature, start with

the opener lights on, then press and hold the light button

for 10 seconds until the light goes off, then on again.

30

Page 31

Using the Wall-Mounted

Control Console

THE MOTION DETECTING CONTROL CONSOLE

Press the push button to open or close the door. Press

again to reverse the door during the closing cycle or to

stop the door while it’s opening.

This control console contains a motion detector that will

automatically turn on the light when it detects a person

entering the garage. This feature can be easily turned off

for extended work light use.

Light Feature

Press the Light button to turn the opener light on or off. It

will not control the opener lights when the door is in

motion. If you turn it on and then activate the opener, the

light will remain on for 4-1/2 minutes. Press again to turn

it off sooner. The 4-1/2 minute interval can be changed to

1-1/2, 2-1/2, or 3-1/2 minutes as follows: Press and hold

the Lock button until the light blinks (about 10 seconds).

A single blink indicates that the timer is reset to 1-1/2

minutes. Repeat the procedure and the light will blink

twice, resetting the timer to 2-1/2 minutes. Repeat again

for a 3-1/2 minute interval, etc., up to a maximum of four

blinks and 4-1/2 minutes.

When using the opener lights as working lights, we

recommend that you first disable the motion sensor.

Motion Detecting Light Feature: The opener light will

turn on automatically when a person walks in front of the

wall-mounted control console. This feature works by

detecting motion and body heat and may not work in

temperatures around 100°F, 37.7C. The opener light will

come on for 5 minutes, then shut off automatically if no

additional motion or heat differential is calculated.

To disable this feature, press the Automatic Light On/Off

button on the left side of the control console.

We recommend that you disable the motion sensor when

using the opener lights as working lights. Otherwise, they

will turn off automatically if you are working beyond the

sensor’s range.

Lock Feature

Designed to prevent operation of the door from hand-held

remote controls. However, the door will open and close

from the control console, the Outside Keylock and the

Keyless Entry Accessories.

To activate, press and hold the Lock button for 2

seconds. The push bar light will flash as long as the Lock

feature is on.

To turn off, press and hold the Lock button again for

2 seconds.The push bar light will stop flashing. The Lock

feature will also turn off whenever the “learn” button

is activated.

Learn Feature

The control console is equipped with a LEARN button to

assist in learning remote controls to the unit. Press the

LEARN button once to initiate LEARN mode and the

display will show learn Remote Control - Press Learn

Button Again to Confirm.’ Press the LEARN button a

second time and the display will show learn Mode -

Press Remote Control Button to Learn Remote.’ Press

the button of the remote control to be learned and the

worklight will blink to confirm the remote control has

been learned.

Hour and Minute Feature

Press or hold either of these side buttons to increment

the hour or minute displayed on the LCD display.

Language Feature

Press this side button to toggle between the three

languages - English, Spanish, and French.

Degrees F/C Feature

Press this side button to toggle the temperature units

between Fahrenheit and Celsius.

Additionai feature when used with the 3-Function

hand-heid remote

To control the opener lights:

1. With the door closed, press and

hold a small remote button that you

want to control the light.

2. Press and hold the Light button on

the control console.

3. While holding the Light button, press and hold the Lock

button on the control console.

4. After the opener lights flash, release all buttons.

31

Page 32

Care of Your Opener

THE REMOTE CONTROL BATTERY

MAINTENANCE SCHEDULE

Once a Month

• Manually operate door. If it is unbalanced or binding,

call a trained door systems technician.

• Check to be sure door opens and closes fully. Adjust

limits and/or force if necessary (see pages 27 and 28).

• Repeat the safety reverse test. Make any necessary

adjustments (See Adjustment Step 3).

Once a Year

• Oil door rollers, bearings and hinges. The opener does

not require additional lubrication. Do not grease the

door tracks.

To Open the Door Manually

DISCONNECT THE TROLLEY:

The door should be fully closed if

possible. Pull down on the

emergency release handle (so

that the trolley release arm snaps

into a vertical position) and lift the

door manually. The lockout

feature prevents the trolley from

reconnecting automatically, and

the door can be raised and

lowered manually as often as

necessary.

TO RE-CONNECT THE TROLLEY:

Pull the emergency release

handle toward the opener at an

angle so that the trolley release

arm is horizontal. The trolley will

reconnect on the next UP or

DOWN operation, either

manually or by using the control

console or remote.

Trolley

Lockout position (Manual disconnect)

Trolley

A WARNING

To prevent possible SERIOUS INJURY or DEATH:

• NEVER allow small children near batteries.

• If battery is swallowed, immediately notify doctor.

The lithium battery should

produce power for up to

5 years. To replace battery,

use the visor clip or

Open this end

first to avoid

cracking

housing

screwdriver blade to pry open

the case as shown. Insert

battery positive side up (+).

Dispose of old battery properly.

NOTICE: To comply with FCC and or Industry Canada rules (iC), adjustment or modifications of

this receiver and/or transmitter are prohibited, except for changing the code setting or replacing

the battery. THERE ARE NO OTHER USER SERVICEABLE PARTS.

Tested to Comply with FCC Standards FOR HOME OR OFFICE USE. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired operation.

A WARNING

To prevent possible SERIOUS INJURY or DEATEI from a

falling garage door:

• If possible, use emergency release handle to disengage

trolley ONLY when garage door is CLOSED. Weak or

broken springs or unbalanced door could result in an open

door falling rapidly and/or unexpectedly.

• NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

• NEVER use handle to pull door open or closed. If rope knot

becomes untied, you could fall.

32

Page 33

Battery Backup

OPERATING INSTRUCTIONS

1. Test the installed battery with the motor unit.

To test the battery, disconnect the motor unit power cord

from the electrical outlet.

• A solid orange LED indicates the battery is operating

on battery power.

• A flashing orange LED with beep indicates the unit is

operating on battery power and that the battery charge

is low.

• To test the battery is functioning properly, open and

close the garage door.

• Re-connect the motor unit power cord back into the

electrical outlet.

• Verify that the green LED is flashing on the BBU

(indicates that the battery is now charging).

• Test completed.

2. Charge the battery.

• Battery will take 24 to 48 hours to fully charge.

A fully charged battery supplies 12V DC to the motor unit

for one to two days of normal operation during an

electrical power outage. If the battery voltage drops too

low, the batteries will disconnect and the motor unit will

no longer operate under battery power.

After the electrical power has been restored, the battery

will recharge within 48 hours. Under normal usage

batteries will last 3 to 5 years.

A WARNING

To reduce the risk of FIRE or INJURY to persons:

• Disconnect ALL electric and battery power BEFORE

performing ANY service or maintenance.

• Use only Craftsman part #41A822 for replacement battery.

• Do NOT dispose of battery in fire. Battery may explode.

Check with local codes for disposal instructions.

Battery

Status LED

NOTE: LED is most visible with worklight off.

GREEN LED:

All systems are normal.

• A solid LED light indicates the battery is fully charged.

• A flashing LED indicates the battery is being charged.

NOTE: Battery does not have to be fully charged to

operate the motor unit.

To obtain maximum battery life and prevent damage,

disconnect the battery when the motor unit is

unplugged for an extended period of time.

NOTE: Door operation may be limited until battery is fully

charged. The motor unit’s lights will not turn on during

battery mode.

ORANGE LED:

The motor unit has lost power and is operating off of the

battery.

• A solid LED with beep, sounding approximately every

2 seconds, indicates the motor unit is activating the

door and is operating off of the battery.

• A flashing LED with beep, sounding every 30 seconds,

indicates battery is low.

• Once the power is restored the battery will recharge.

This is indicated by a flashing green LED.

RED LED:

• If a red LED remains on when the power is restored,

and is accompanied by a beep sounding every 30

seconds, please call for service.

• To obtain maximum battery life and prevent damage,

also disconnect the battery if you unplug the motor unit

while on vacation or any other extended period of

time.

33

Page 34

Having a Problem (Troubleshooting)

NOTE: Always unplug battery prior to troubleshooting.

1. My door will not close and the light bulbs blink on

my motor unit: The safety reversing sensor must be

connected and aligned correctly before the garage

door opener will move in the down direction.

• Verify the safety reversing sensors are properly

installed, aligned and free of any obstructions. Refer

to Installation Step 11: Install The Protector Systenf.

• Check diagnostic LED for flashes on the motor unit

then refer to the Diagnostic Chart on the

following page.

2. My remotes will not activate the door:

• Verify your Motion Detecting Control Console does

not display “Lock Mode.” If it does, deactivate the

Lock Mode following the instructions for Using the

Motion Detecting Control Console.

• Reprogram remotes following the programming

instructions. Refer to Programming.

• If remote will still not activate your door, check

diagnostic LED for flashes on motor unit then refer to

Diagnostic Chart on the following page.

Sending Eye Safety

Reversing Sensor

(Amber Indicator Light)

Receiving Eye

Safety Reversing Sensor

(Green indicator Light)

3. My door reverses for no apparent reason: Repeat

safety reverse test after adjustments to force or travel

limits. The need for occasional adjustment for the force

and limit settings is normal. Weather conditions in

particular can affect door travel.

• Manually check door for balance or any binding

problems.

• Refer to Adjustment Step 2, Setting the Force.

4. My door reverses for no apparent reason after fully

closing and touching the floor: Repeat safety

reverse test after adjustments to force or travel limits.

The need for occasional adjustment for the force and

limit settings is normal. Weather conditions in particular

can affect door travel.

• Refer to Adjustment Step 1, Program the

Travel Limits.

5. My lights will not turn off when door is open:

• The garage door opener is equipped with a security

light feature. This feature activates the light on when

the safety reversing sensor beam has been

obstructed. Refer to Operation section; Using the

Wall Mounted control console, Light Feature.

6. My motor unit hums briefly:

• First verify that the trolley is against the stop bolt.

• Release the door from the opener by pulling the

Emergency Release Rope.

• Manually bring the door to a closed position.

• Loosen the belt by adjusting the outer nut 4 to 5

turns. This relieves the tension.

• Run the motor unit from the remote control or control

console. The trolley should travel towards the door

and stop. If the trolley re-engages with the door, pull

the Emergency Release Rope to disengage.

• Decrease the UP travel.

Trolley-

(3.18 cm)

• Re-Tighten the outer nut until the trolley spring is

approximately 1-1/4" (3.18 cm) in length.

• If the trolley does not move away from the bolt,

repeat the steps above.

7. Battery status LED is not lit properly:

• Check battery connections.

34

Page 35

Safety Reversing Sensor

Diagnostic Chart

Safety reversing sensors

wire open (broken

or disconnected).

OR

Safety reversing sensors

wire shorted or

biack/white wire

reversed.

Control console or wire shorted.

rAmmvAmmmmmmVfmmmmVfi

Your garage door opener is programmed with

seif-diagnostic capabiiities. The “Learn” button/diagnostic

LED win fiash a number of times then pause signifying it

has found a potentiai issue. Consult Diagnostic Chart below.

Symptom: One or both of the Indicator lights on the safety reversing sensors

do not glow steady.

• Inspect sensor wires for a short (staple in wire), correct wiring polarity

(biack/white wires reversed), broken or disconnected wires, replace/attach

as needed.

• Disconnect all wires from back of motor unit.

• Remove sensors from brackets and shorten sensor wires to 1-2 ft (30-60 cm) from

back each of sensor.

• Reattach sending eye to motor unit using shortened wires. If sending eye indicator

light giows steadily, attach the receiving eye.

• Align sensors, if the indicator lights glow replace the wires for the sensors. If the

sensor indicator lights do not light, replace the safety reversing sensors.

I

Symptom: LED is not lit on control console.

• Inspect control console/wires for a short (staple in wire), replace as needed.

• Disconnect wires at control console, touch wires together. If mofor unit activates,

replace control console.

• If motor unit does not activate, disconnect control console wires from motor unit.

Momentarily short across red and white terminals with jumper wire. If mofor unit

activates, replace control console wires.

Safety reversing sensors

slightly misaligned

(dim or flashing LED).

Possible RPM sensor

failure. Unplug to reset.

I

Symptom: Sending indicator light glows steadily, receiving indicator light is

dim or flashing.

• Realign receiving eye sensor, clean lens and secure brackets.

• Verify door track is firmly secured to wall and does not move.

I

Symptom: RPM Sensor = Short travel 6-8" (15-20 cm).

• Unplug unit to reset. Try to operate motor unit, check diagnostic code.

• If it is still flashing 5 times and motor unit moves 6-8" (15-20 cm), replace RPM

sensor.

• If motor unit doesn’t operate, motor unit is overheated. Wait 30 minutes and retry. If

motor unit still will not operate replace logic board.

35

Page 36

LCD Motion Detecting Control Console Messages

The following messages are contained within the LCD

Motion Detecting Control Console and may appear

during the operations of the unit:

Meaning: This message wiii appear if the Safety Reversing Sensors are out of

SAFETY SENSORS

CHECK ALIGNMENT,

BLOCKAGE OR

MISWIRING SEE

OWNER’S MANUAL

SAFETY SENSORS

MALFUNCTION

CHECK MISWIRING

SEE OWNER’S

MANUAL

atignment, if they are biocked or if the wiring is disconnected. To dear message from

Controi Consoie do the foiiowing:

• Check to see that area is clear between the Safety Reversing Sensors.

• Check to see that the Safety Reversing Sensors are not misaligned.

• Realign receiving eye sensor, clean lens and secure brackets.

• Verify door track is firmly secured to wall and does not move.

• Check to see that the Safety Reversing Sensors’ wires are connected to the motor unit.

• If message has not cleared after the above checks, refer to message #2.

Meaning: This message wiii appear if the Safety Reversing Sensors are miswired.

To dear the message, do the foiiowing:

• Inspect the safety reversing sensor wires for a short (staple in wire), correct wiring

polarity (black/white wires reversed), replace/attach as needed.