Page 1

Owner’s

Manual

Model No.

139.53662SRT

139.5367SSRT

For Residential Use

Only

CRAFTSMAN^

Caution:

Read and follow all

safety rules and

operating instructions

before first use of this

product.

Fasten the manual

near the garage door

after installation.

GARAGE DOOR OPENER 1/2 HP

@ Safety Precautions

и Assembly

Ш Installation

a Adjustment

a Care and Maintenance

m Operation

m Troubleshoc^tji^^'i;

H Parts List

Complies wilii UL 325 /^1 li \

refiiiations effective I )

Januaiy 1, t993

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Page 2

Contents

A review of safety alert symbols

Youll need tools

Safety information reqardinq qaraqa door

locks and ropes

Testing your garage door for sticking,

binding and balance

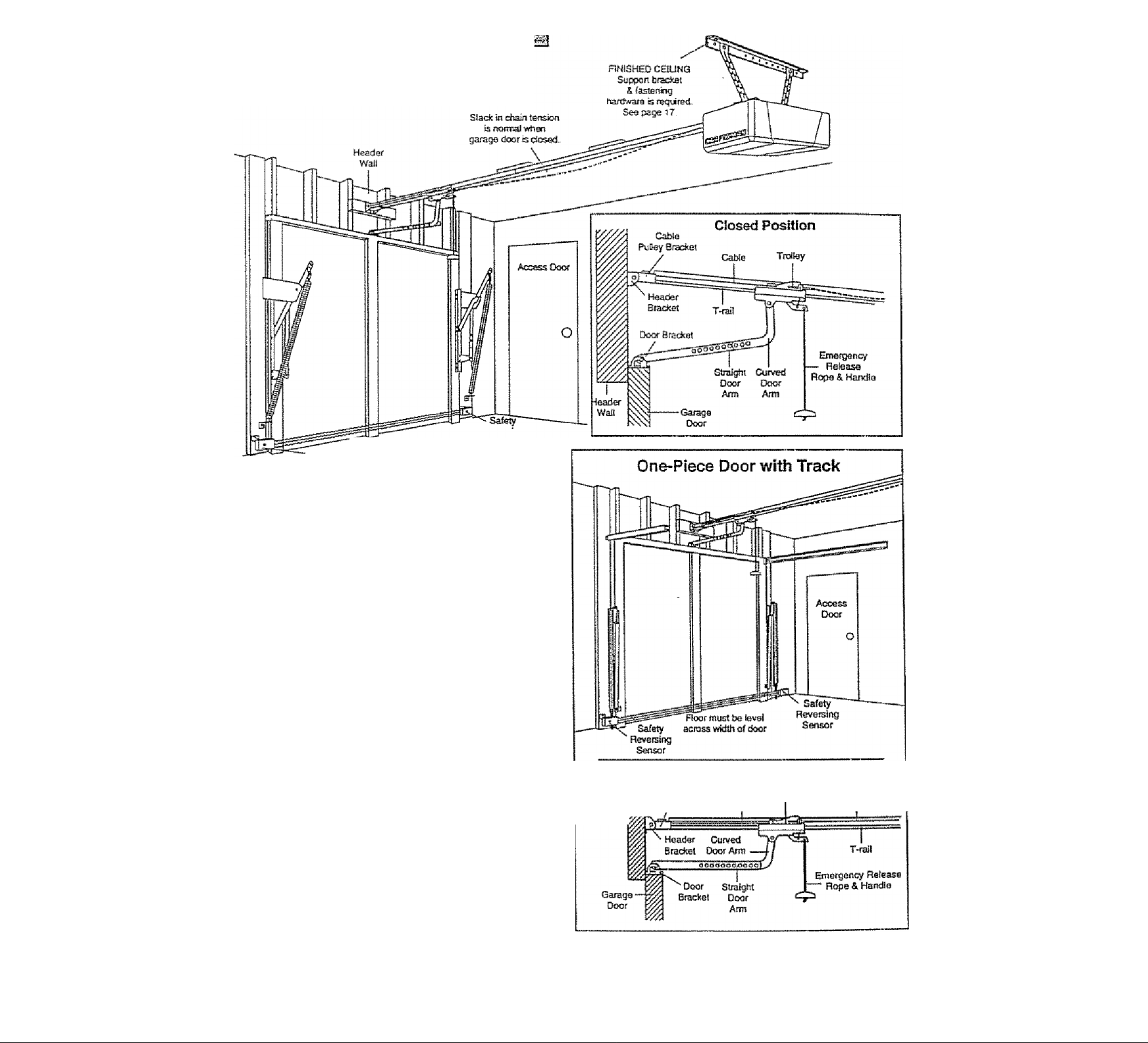

Illustration of sectional door instailadQn ....

Illustration of one-piece door installation...

Carton inventory...................

Hardware inventory.....................

Assembly section - pages 8 -11

Assemble T-raiL...

Attach cable pulley bracket............

Install trolley

Fasten T-rai! to opener...................

install chain/cabie

Attach sprocket cover.,,.,.

Tighten the chain and cable

Installation section * pages 11-27

Installation safety instructions..__....

Determine header bracket location

Sectional door ...........,

One-piece door,.,..

Install the header bracket

Attach the T-ral to header bracket

Position the opener

Hang the opener............................

Install the door control

...........................................

.........

....

.....

.

.......

..................

.........

........................

...................

............

.........

.....

.........

.

......

................

..

.

.

Page

.....

___4

......5

......7

.

.....

...10

™10

,..11

,...11

....12

.13

.....

14

......15

......

16

......17

.....

.18

3

.6

9

Corrients

.

___ig

„..,...19

.......

.....

.

,.22,23

........24

.

......

........26

„„....27

........28

.

......29

........

....... .^10

........31

____

.

........

.„.„..32

____

..34,35

........36

........37

.„....,39

........

........40

Install the lights and lenses...,..............

Attach emergency release rope and handle „

F*lcu'''ÍTir't3i f'oni ti rs3mí3rsic

t«№lvtrwUi « Bv.|wl E iB I ItiO • >11^ nn-. Kirn*, ,no»FT,r'.Vr<t ■'|‘I T , f ,

Safety reversing sensor information

Install the safety reversing sensor

i—iscrtcsn í*ír*i/^í*

i cUaLcíi i UwvJi Ul i-cil tiJwVJi I

Fasten door bracket (one-piece door)

Connect door arm to trolley (sectional door)

Connect door arm to trolley (one-piece door).

Adjustment section - pages ^ - 30

Travel limit adjustments ...............................

Force adjustments............................................

Test the safety reversing serrsor...........

Test the safety reverse system

Operation safety instructions............................

Care of your opener ............................................

Maintenance schedule

Operation of your opener ............................

Receiver and remote control programming ......

Having a problem?...

Repair parts, rail assembly

Repair parts, installation...,

Repair parts, opener assembly

Accessories

Index..........................

How to order repair parte

Maintenance agreement

Warranty.............

.......................................

...........................................

________________

..

.........

...........................

.............

.

.

.................

.

Page

20

,.21

25

30

31

31

33

36

38

40

40

Start by Reviewing these Important Safety Alert Symbols

When you see these Safety Symbols on the following pages, they will alert you to the possibility of

serious Injury or death if you do not compiy with the corresponding instructions. The hazard may

come from something mechanical or from electric shock. Head the instructions carefully.

ÉñechmTi©all)4iA.7. cj

When you see^this sSf^^Symb^l-On the following pages, it will alert you to the possibility of damage

■dxLygur garage'3o”0T anti/oli the garage tioor opener if you do not comply with the corresponding

instriiction'SrHead.ifte^msfruc|/OTdcarefui/^^

This garage door opener is designed and tested to offer safe service provided it is installed, operated,

maintained and tested in strict accordance with the safety instructions contained in this manual.

Electrical

Page 3

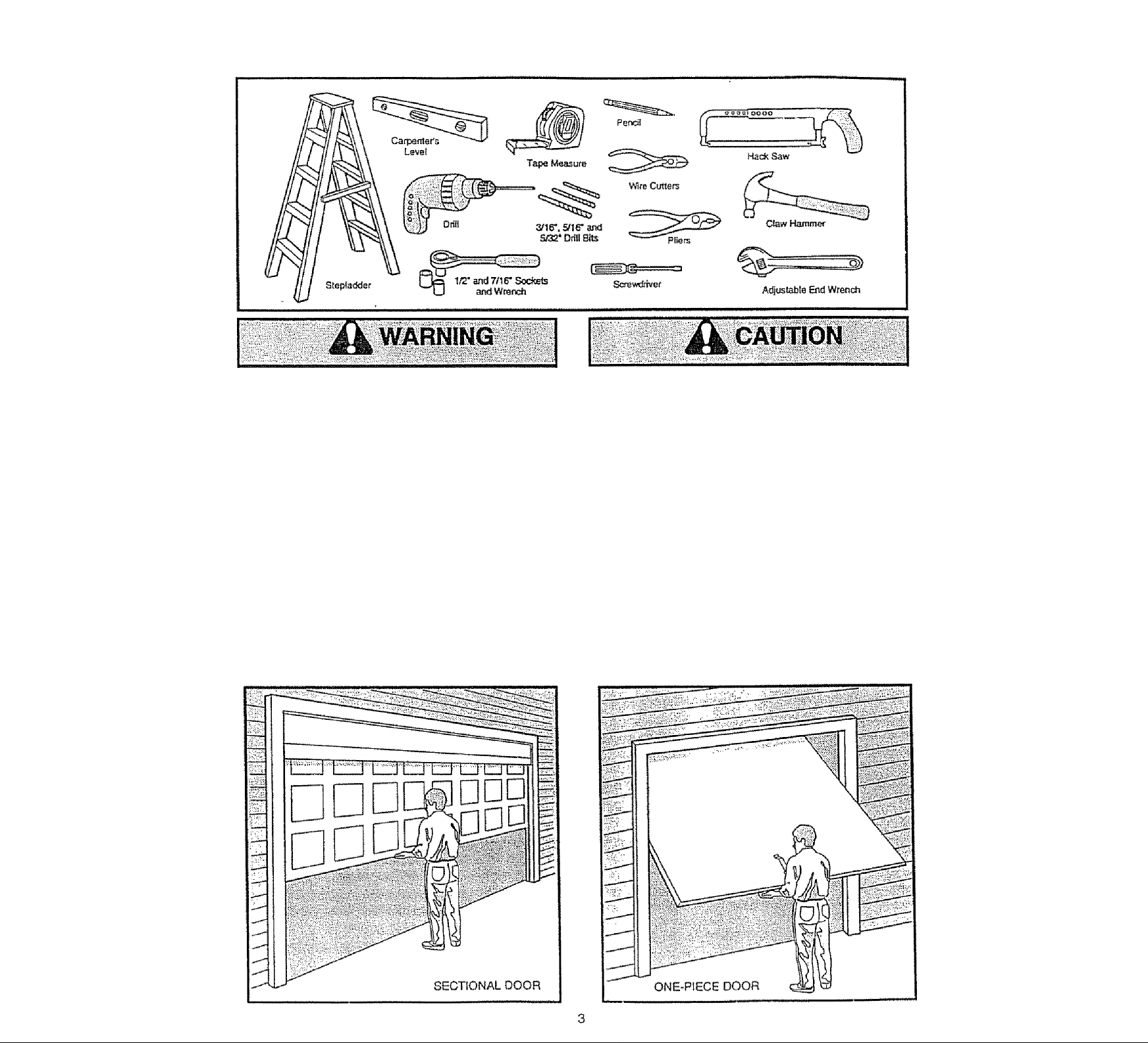

You'll Need Tools

During assembiy, instaliation and adjustment of the opener, instructions wili cail for hand ioois shnwrs below.

An unbalanced garage door might not reverse

when required and someone under the door

could be seriously injured or killed.

If your garage door binds, sticks or is out of

balance, caii for professionai garage door

service. Garage doors, door springs, cables,

pulleys, brackets and their hardware are under

extreme tension and can cause serious injury

or death. Do not try to ioosen, move or adjust

them yourself!

Bopes left on a garage door could cause

someone to become entangled and killed.

Remove ail ropes connected to the door before

installing and operating the opener.

Identify the type and height of your door and any

special conditions that exist and any additional

materials that may be required by referring to the lists

on page 4 or page 6.

To avoid damage to the garage door and

opener, disable locks before Installing and

operating the opener. Use a wood screwr or nail

to hold locks in the "open" (unlocked)

position.

Operation at other than 120V 60 Hz will cause

opener malfunction and damage.

Before you begin, complete the following test to

make sure your door is balanced, and is not

sticking or binding:

• Lift the door about halfway as shown. Release the

door, it should stay in place, supported entirely by

its springs.

• Raise and lower the door to see if there is any

binding or sticking. •

Page 4

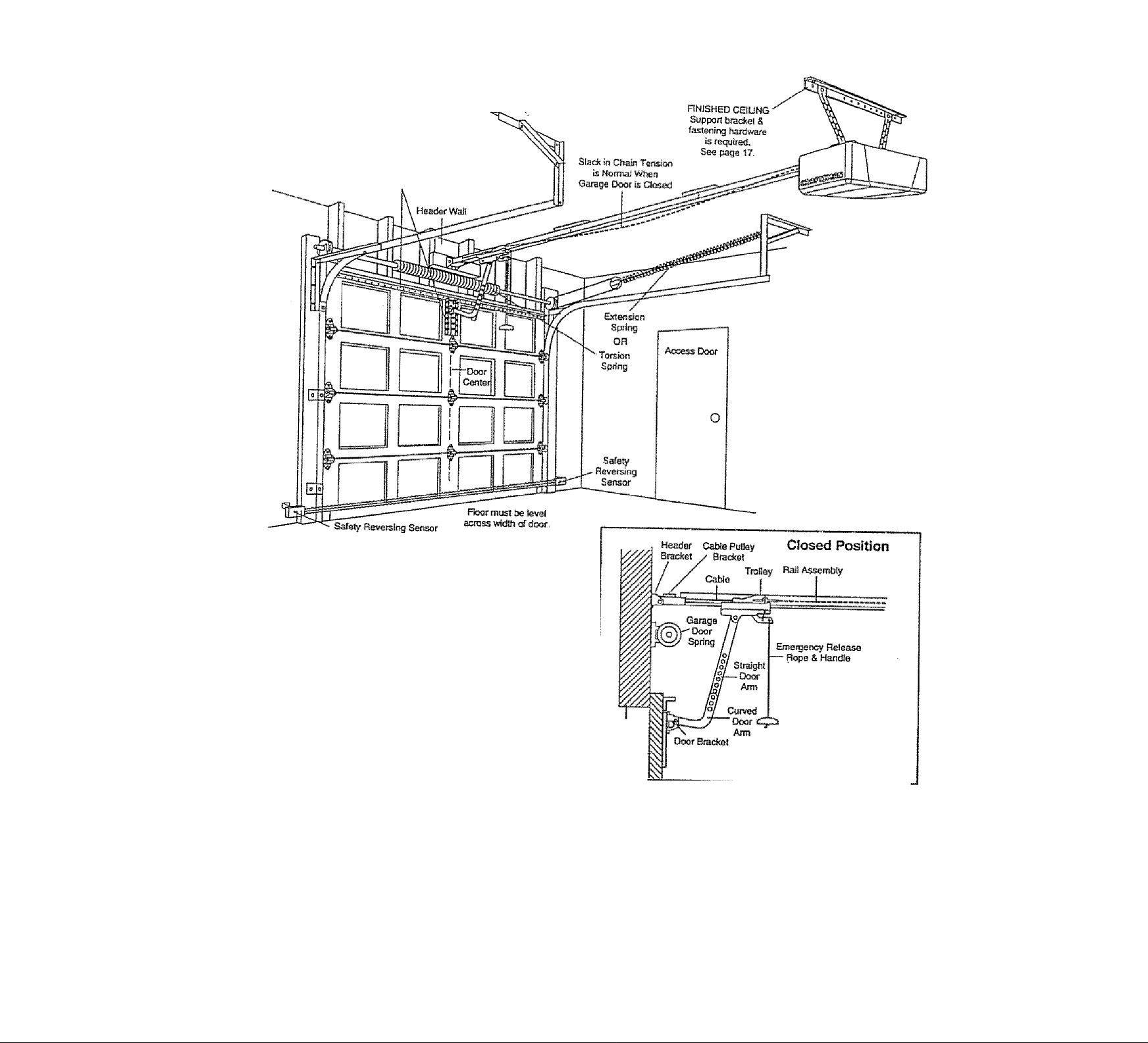

Before you begin, survey your garaoe area to

see whether any of the conditions fallow apply

to your installation.

^ Hofizofita] and vafiicsii reintotcameni

is needed for fighiweigW garage doors

¡fibergiass, stesi, aluminum, door

wtBi glass panels, etc.).

See page 24 for details.

Based on your particular requirements, there are

sever^ installation steps which might call for

materiaJs and/or hardware not included in the carton

* Step 1, page 12 - Look at the wail or ceiling above

the garage door. The header bracket must be

securely fastened to structural supports.

■ Step 5, page 17 ~ Do you have a finished ceiling in

your garage? It so, a support bracket and

additionai fastening hardware may be required.

‘ Safety reversing sensor, page 21 - Depending

upon garage construction, wood blocks may need

to be fastened to mounting locations before

sensors are Installed.

' Step 10, page 22 - Alternate floor mounting of the

safety reversing sensor will require hardware not

provided.

■ Step 11, page 24 - Do you have a steel, aiuminum,

fiberglass or glass pane! door? If so, horizontal

and vertical reinforcement is required.

* Look at the garage door where it meets the floor.

It must close on the floor ail the way across.

Otherwise, the safety reverse system may not

work properly. See page 30. Roor or door should

be repaired.

Hsadsf

Willi

Garage -

Door

* TTie opener can be fnstalied within 2 feet to the left

or right of the door center if there is a torsion spring

or center bearing plate In the way of the header

bracket or door bracket area. If your door has

extension springs, the opener must be installed

in the center of the door. See pages 12 and 24.

> Do you have an access door in addition to the

garage door? if not. Mode! 53702 Emerqencv

Key Release is required. See page 38.

■ if your door is more than 7 feet high, see the raíl

extension kits listed on page 38,

You may find it helpful to refer back to this page as you proceed with the installation of your opener.

Page 5

i :,,CiQN E'PiH©Es00Qiilia§ta|№iil

Be'fore you begin, survey your garage area to

see whether any of the conditions below apply

to your installation.

One-Piece Door without Track

'Esp between Hoor and boBom Sensor

Safely of door must not eiOeed 1 /4*.,

Reversing Sensor

Based on your particuiar requirements, there are

several installation steps which might caJl for

materials and/or hardware not included in the carton.,

• Step 1, page 13 - Look at the wall or ceiling above

the garage door. The header bracket hicsf be

securely fastened to struciuial supports,

• Step 5, page 17 - Do you have a finished ceiling in

your garage? If so, a support bracket arrd

additional fastening hardware (not supplied) may

be required.

• Safety reversing sensor, page 21 - Depending on

garage constmction, wood blocks may need to be

securely fastened to mounting locations before

sensors are installed.

• Step 10, page 22 - Alternate floor mounting of the

safety reversing sensor will require hardware that

is not provided.

• Step 11, page 25 - Generally, a one-piece door

does not require reinforcement. If your door is

lightweight, you can refer to the information

relating to sectional doors on page 24.

• Step 11, page 25 - Depending on your door's

constmctlon, you might need additional mounting

hardware for the door bracket.

• Do you have an access door in addition to the

garage door? If not, Model 53702 Emergency Key

Release is required. See page 38.

• The gap between the bottom of the garage

door and the floor cannot exceed 1/4".

Otherwise, the safety reverse system may not

work properly. See page 30. The floor or the door

should be repaired.

Reverang

Closed Position

Headar — w PuHey Brackai

Gabte

Cable

Gbain

Was

You may find it helpful to refer back to this page

as you proceed with the installation of your

opener.

Page 6

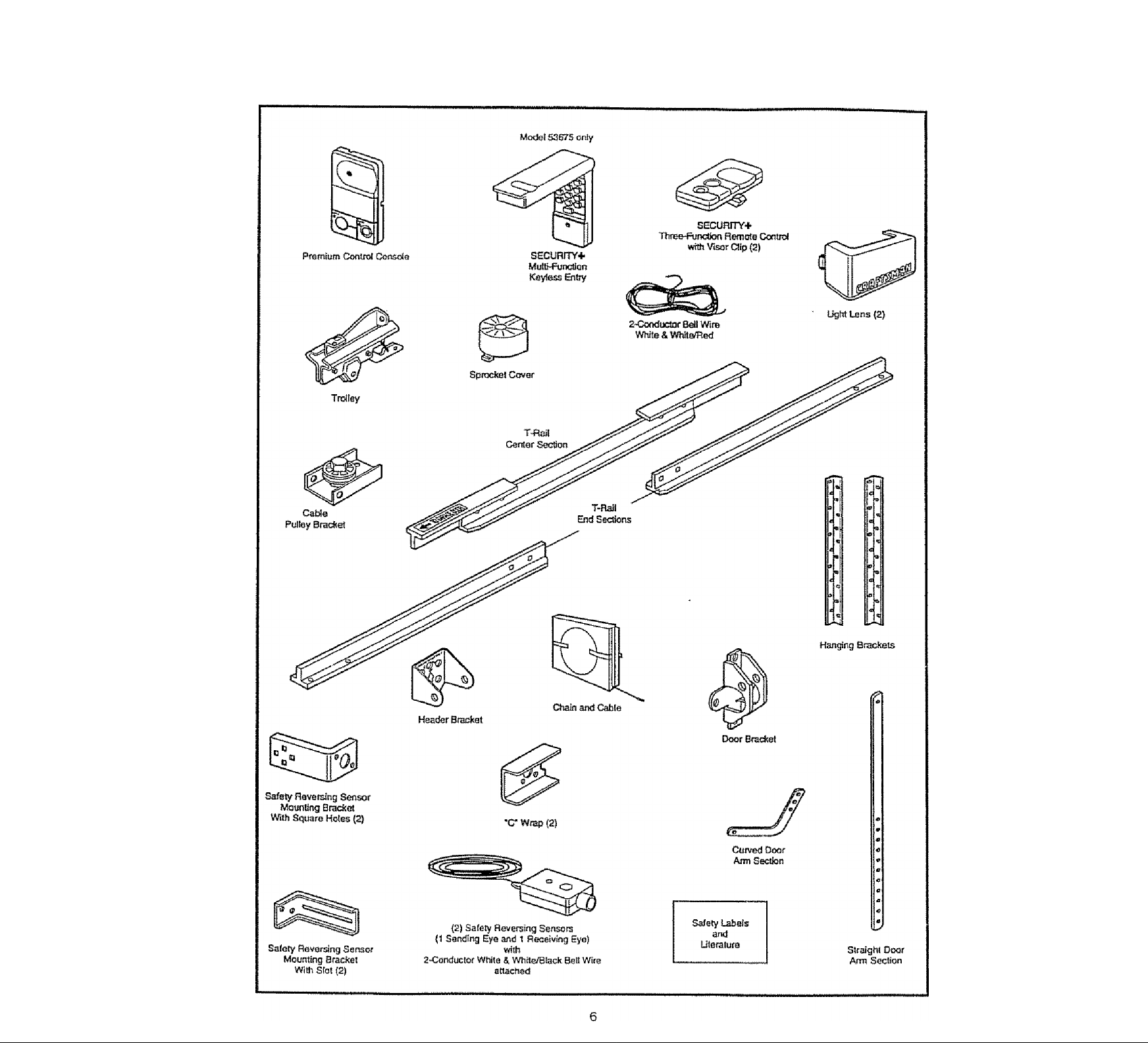

Carton Inventory

Your garage door opener is packaged in two cartons which contain aii parts illustiated below. If anything is

missing, carefully check the packing material. Parts may be ‘stuck* in the foam. Hardware for assembly and

installation is shown on page 7,

Page 7

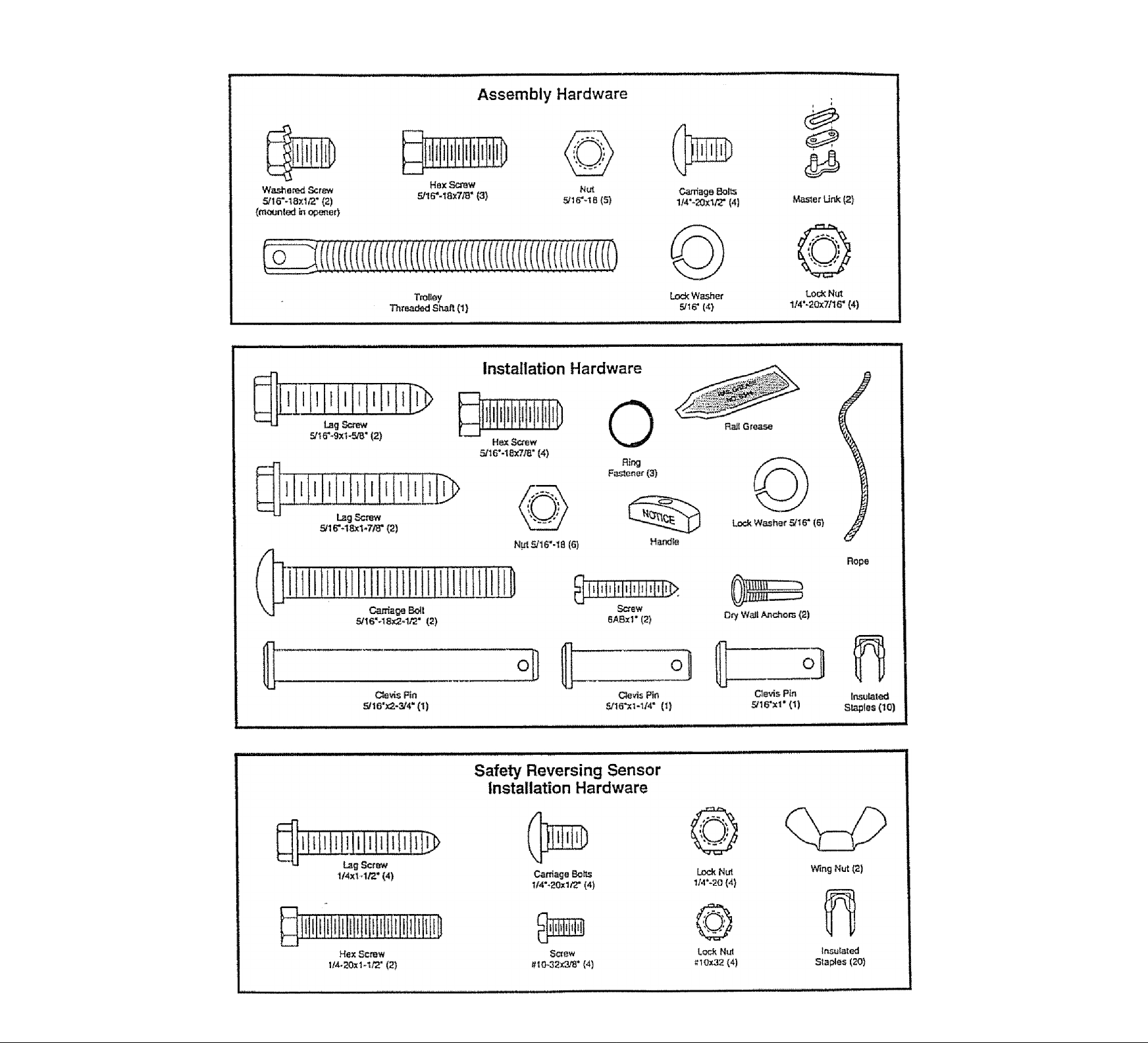

Separate all hardware from the packages in the rail carton and the opener carton, as

shown below, for the assembly and installation procedures.

Page 8

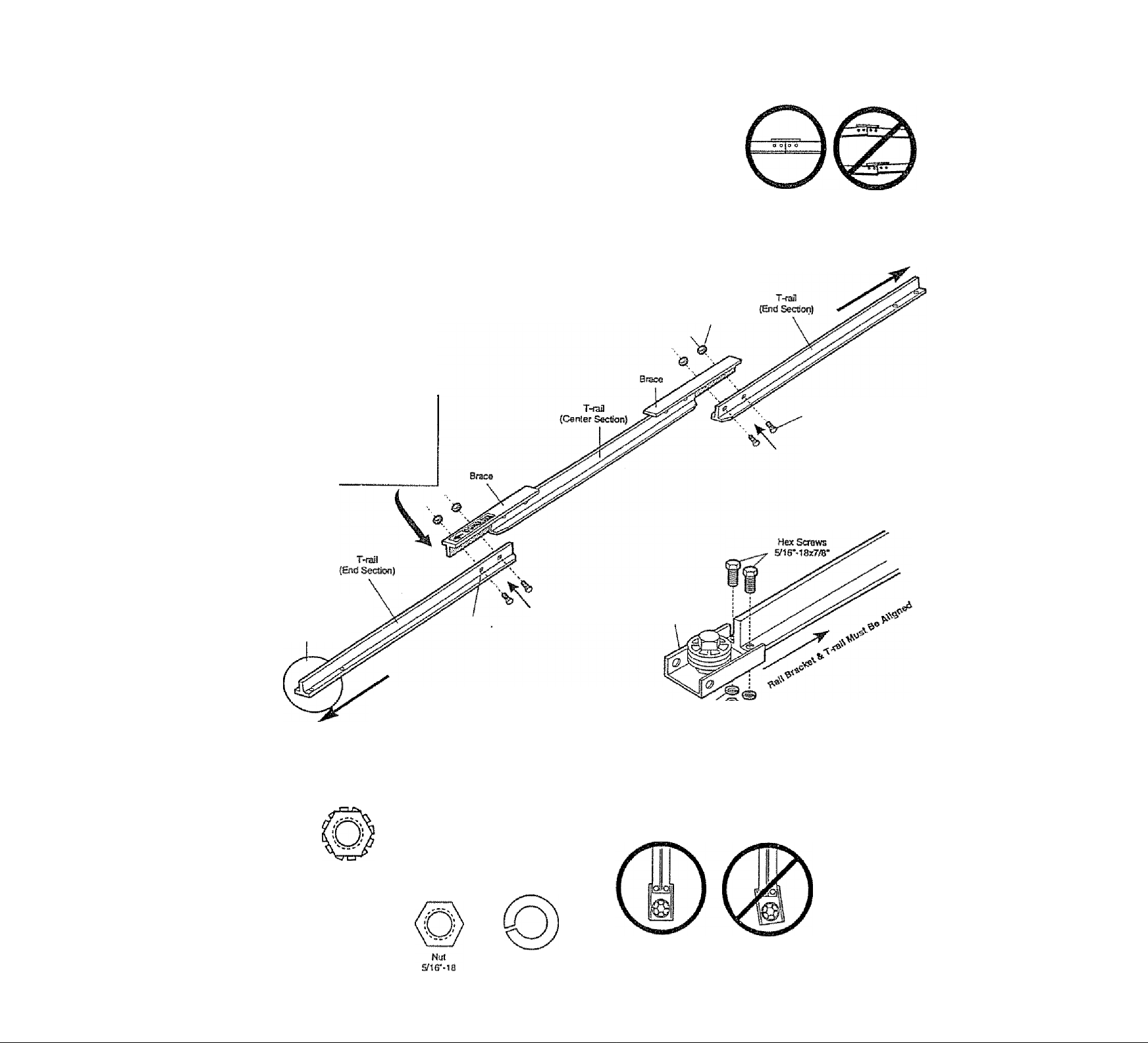

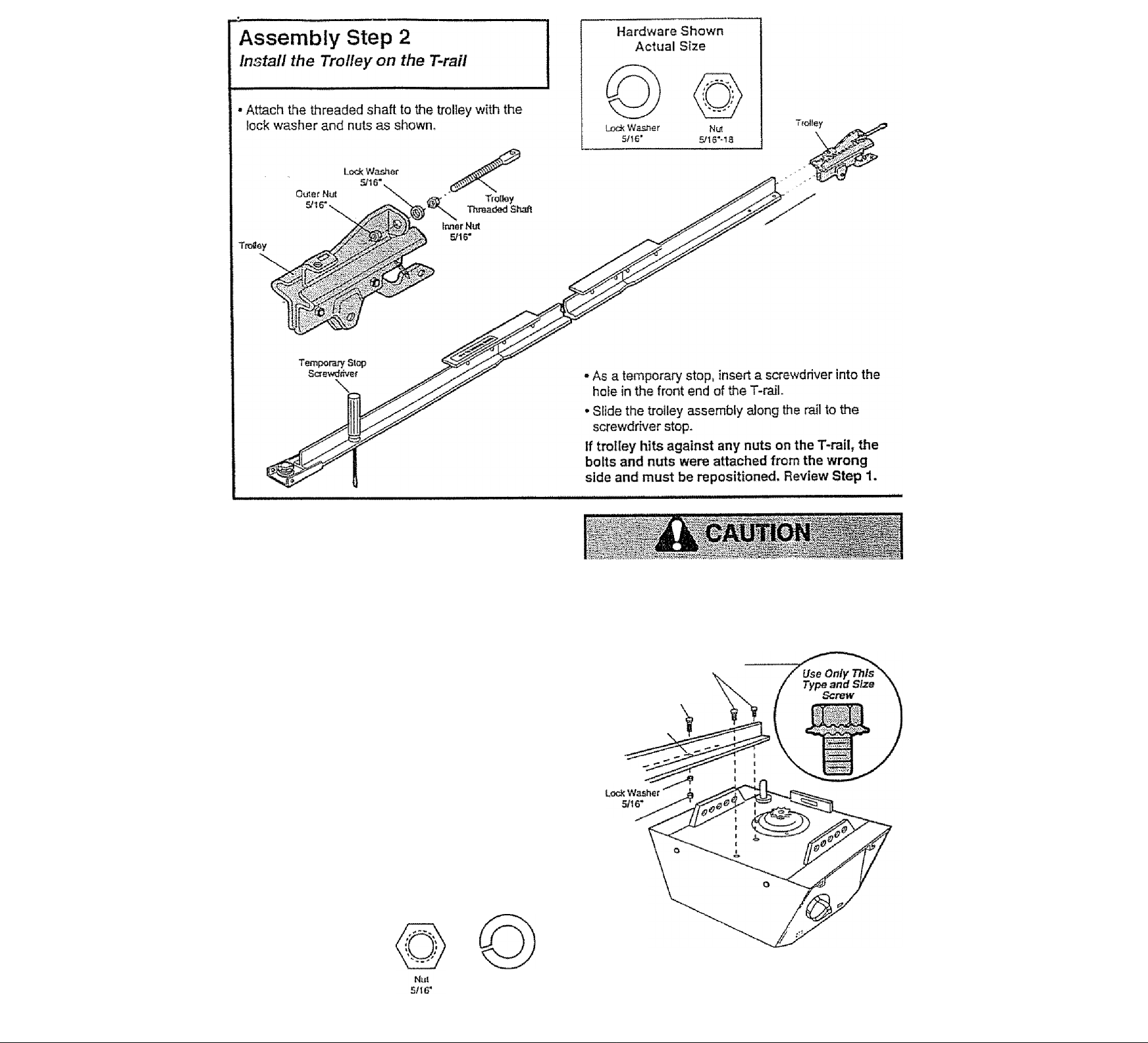

Assembly Section: Pages 8-11

To avoid installation difficulties, do not run the garage door opener until Instructed to do so.

Assembly Step 1

Assemble the T-rail &

Attach the Cable Pulley Bracket

* Place the 3 T-rail sections on a flat surface for

assembly. The end sections are idenficai. Make

sure the "arrow label" on the center section is

pointing toward the door.

• Insert the carriage bolts so the square boit necks

seat in the square holes in the T-rafI end sections

and pass through the round holes in T-rafi center

section. Assemble lock nuts, ensure alignment and

tighten.

If T-raii is not assembled

EXACTLY as shown,

trolley Will not travel

smoothly along length of

rail or It will hit against

the nuts.

Make sure bait necks are

seated In the square

holes and rails are

aligned before you

tighten lock nuts. (See

right and wrong views).

Improper assembly can

E^use jerky troJIey

operation, noise and/or

nuisance door reversals.

1M* Look Nu!

T-RAlLaACK

(Tooparsî)

Carnage Soit

Wrong

Cabio pulley bracket

attaches lo f^ONT

dl'lli« Ul I (cUt

Hardware Shown Actual Size

Lock Nut

1M*-20xr/16*

Hex Screw

stir-iaxT/B"

T-RAIL FRONT

(TO OOOR)

Square Carnage

Bolt Holes

Catiiage Bolts

Lock Washer

5/1 g-

Cable FuUey

Bracket

Lock Washer © 0..,

S/16' > !

SiW

► Position the rable pulley bracket on the tont end of the

T-rail as shown. Fasten securely with the hardware.

When

tightening the

screws, be

sure to keep

bracket parallel

to the rail.

Otherwise, the

rail may bow

Right

Wrong

when opener is

opsrstsd.

Page 9

Assembly Step 3

Fasten the T-rail to the Opener

• Place the opener on packing material to protect

the cover. For convenience, put a support under

the cable pulley bracket

• Remove the (2) 5/16"-18x1/2* washered screws

mounted in the top of the opener.

• Align the holes in the back section of the T-raii with

the holes in the opener,

• Fasten the rati with the (2) washered screws

previously removed, tighten securely.

Ftemember to use only these screws! Any other

screws will cause serious damage to the opener.

• Insert a S/16“-18x7/8* hex screw into the cover

protection bolt hole in the T-rail as shown. Tighten

securely with a 5/16" lock washer and nut

NOTE: This screw prevents trolley over-travel.

Keep a 2“ minimum between the trolley and this

screw when adjusting travel limits {see page 28).

Hardware Shown Actual Size

To fasten rail, use only those screws mounted

in the top of the opener. Any other screws will

cause serious damage to the opener.

Washered Screw

S/IS’-iaxt/r

Hex Screw

5/16*-1Sx7/B'

Cover

Protecijon

Bolt Hole

T-raB

{Sack Section)

Nut

S/16*-18

Hex Screw

S/)6'-iax7/8*

Lock Washer

S/16*

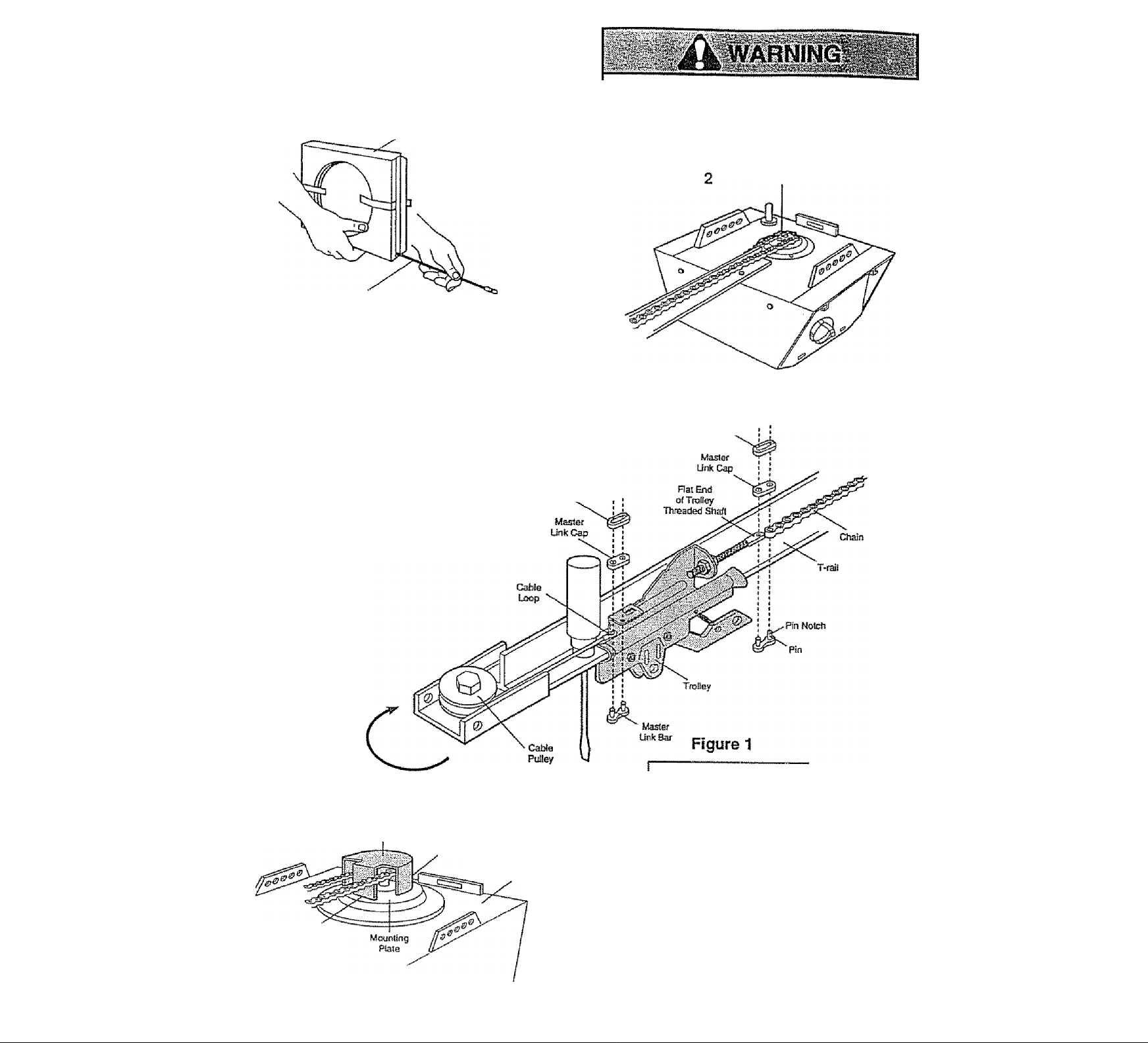

Page 10

Assembly Step 4

install the Chain/Cable &

Attach the Sprocket Cover

Dispensing Carton

Leava Chain and Cable

inside OispensETsg

Carton to Prevail Kjnidng.

Keep Chain and Cabla

Tay| When Dispensing

• Detach the cable loop from the carton and fasten It

to the trolley with a master link from the hardware

bag. See master link procedure, Rgure 1.

• yyith the trolley against the screwdriver, dispense

the cable around the pulley.

® Proceed back around the opener sprocket,

Rgure 2, Be sure sprocket teeth engage the chain.

Continue forwant to the trolley threaded shaft,

Rgure 3.

• Use the second master link to connect the

chain to the flat end of the shaft Check

to make sure the chain is not

twisted.

" Remove the screwdriver.

DipOn Spring

Master Unk

Serious Infury can resuit If fingers become

entangled in moving opener sprocket. Attach

sprocket cover securely. Never operate opener

while your hand Is near the opener sprocket.

Opener

Figure

Spfodtat

Figure 3

MasierUnic

Ciip-On Spring

Frani Tab Slot

Instait Cha'n teid Cabla

in This Direction

Sprocket

Cover

Back Tab Slot

Top of Qpenar

Master Link Procedure;

Push pifis of raasier link bar

through cable loop and ho!e in

front end of troiley. Posh rap

over pins and past notchesSlide clip-on spring over cap

and into notches until both

pins are securely tocked.

To attach the sprocket cover:

• Insert the back tab in the opener slot. Squeeze the

cover slightly and insert the front tab in the slot on

the mounting plate.

10

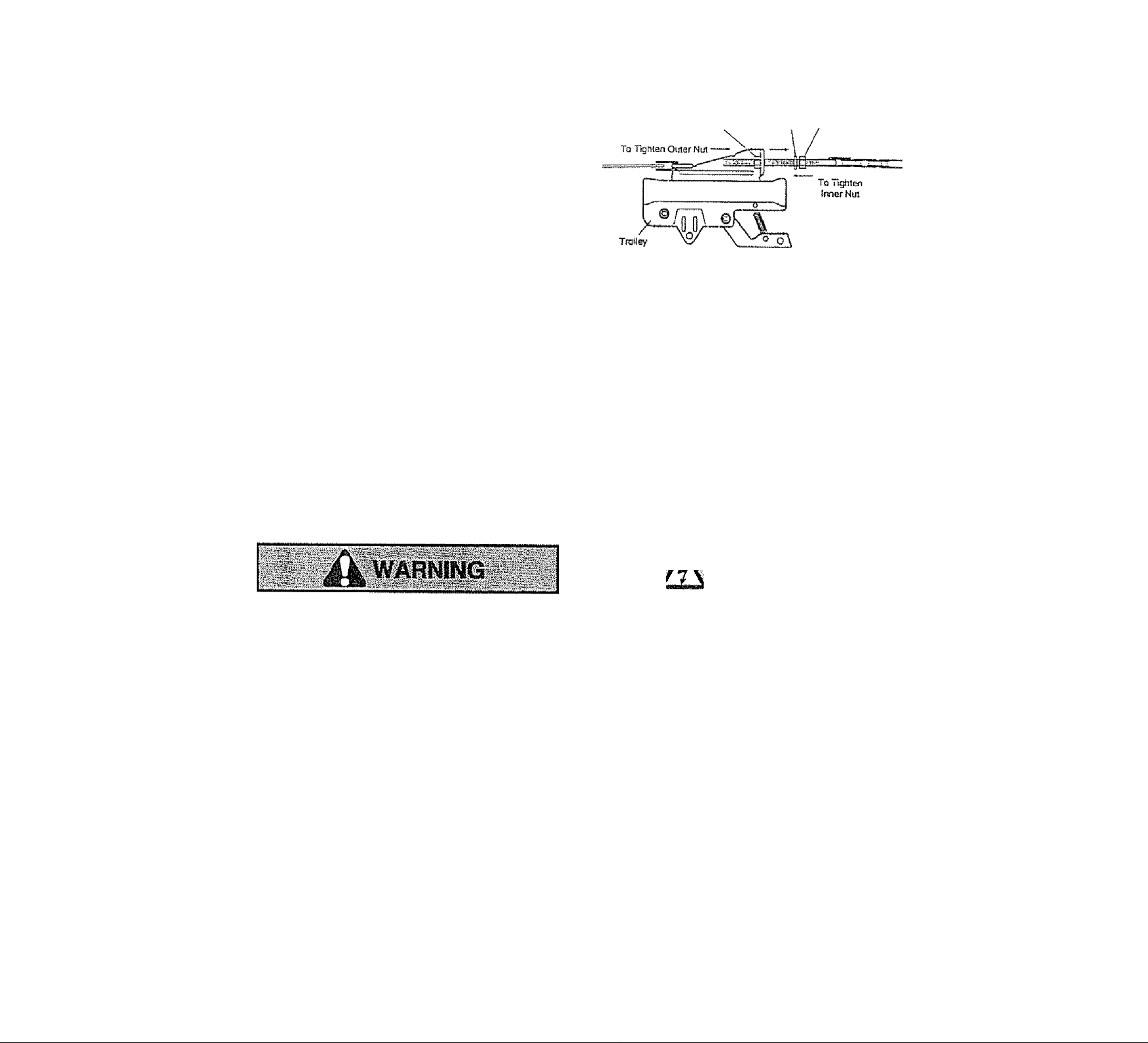

Page 11

Assembly Step 5

Tighten the Chain & Cable

* Spin the inner ntft and lock washer down the

threaded shaft, away from the troiley.

* To tighten the chain, turn outer nut in the direction

shown. As you turn the nut, keep the chain

from twisting.

* When the chain is approximately 1/2' above the

base of the T-raii at its midpoint, re-tighien the

inner nut to secure the adjustment

Sprocket noise can result if chain Is either too

loose or too tight

When instaJlation is complete, you may notice some

chain droop with the door closed. This is normal. If

the chain returns to the position shown when the

door is open, do notre-adjust the chain.

NOTE: During future maintenance, ALWAYS

pull the emergency release handle to disconnect

trolley before adjusting chain.

Otrte/ Nut Wa^fier

~i ГТ T t I

Lock

Chain

ia Inch

i

O* I "TBlf

You have now finished assembling your garage door opener. Please read the following warnings before proceeding to the installation section;

IMPORTANT INSTALLATION INSTRUCTIONS

> “ , ■ у #c\

/V

WARNING

To reduce the risk of severe injury or death to persons:

1. READ AND FOLLOW ALL INSTALLATiON INSTRUCTIONS.

2. install only on a properly balanced and lubricated garage door. An improperly balanced door

may not reverse and could result in severe injury or death. Repairs to cables, spring assemblies

and other hardware must be made by a professional service person before installing opener.

3. Disable all locks and remove all ropes connected to the garage door before installing the opener.

Ropes connected to a garage door can cause entanglement and death.

4. If possible, install door opener 7 feet or more above floor with the emergency release handle

mounted 6 feet above the floor.

5. Do not connect the opener to power source until instructed to do so,

6. Locate the Door Control within sight of the door at a minimum height of 5 feet where small

children cannot reach, and away from ail moving parts of the door,

7. Install the User Safety Instruction Label on the wall adjacent to the door control and the

Maintenance Instruction Label in a prominent location on the inside of the garage door.

8. Upon completion of the installation, the door must reverse when it comes in contact with a

one-inch high object or a 2x4 laid flat on the floor.

9. Do not wear watches, rings or loose clothing while installing or servicing an opener. Jewelry or

loose clothing can be caught in the mechanism of the garage door or the opener.

11

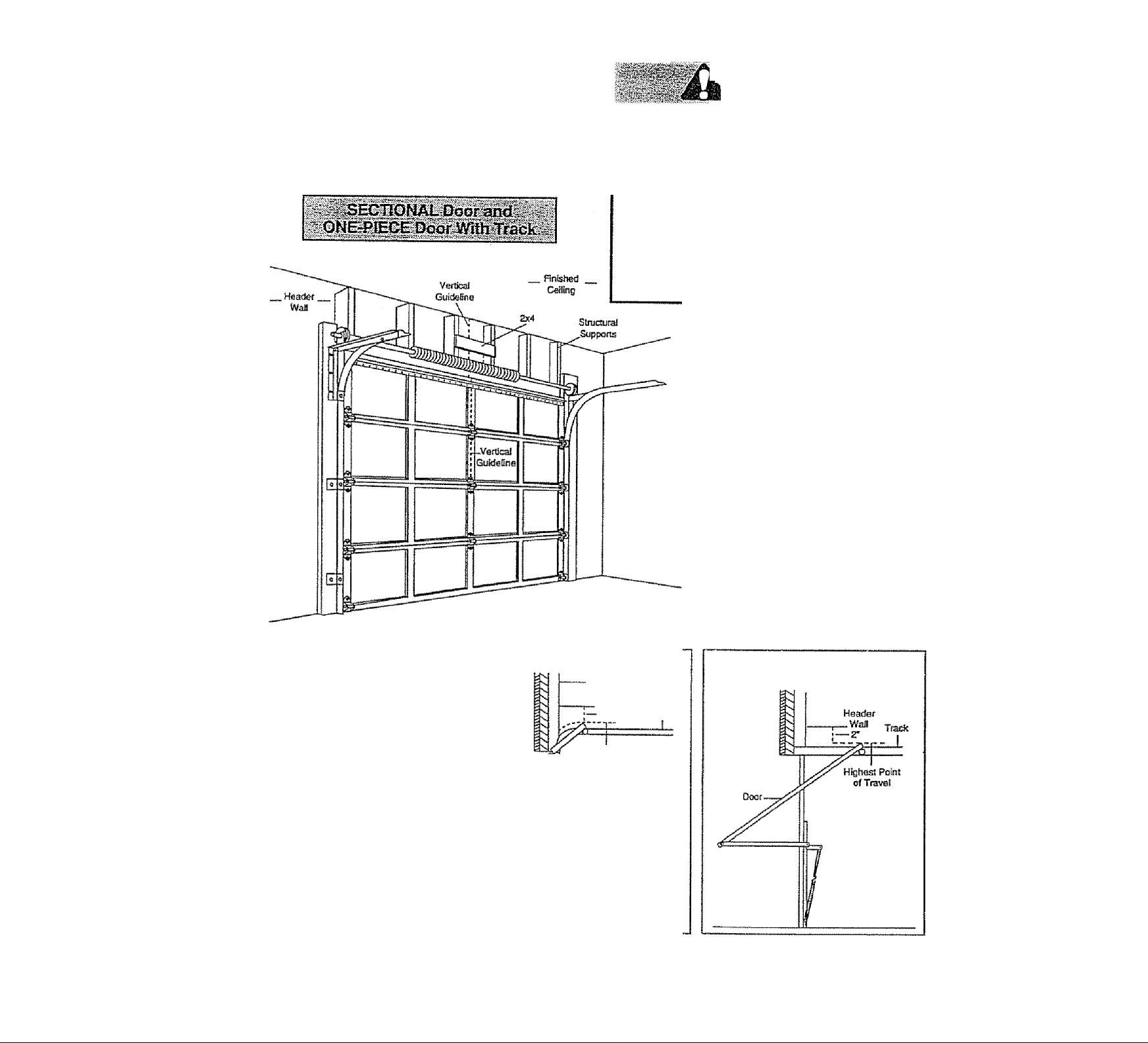

Page 12

Installation Section: Pages 12 - 27

Installation Step 1

Determine HeBder Bracket LocBtion

Installation procedures vary according to

garage door types. Follow the instructions

which apply to your door.

If the header bracket is not rigidly fastened to

a structural support on the header wall or

ceiling, the safety reverse system may not

work properly (see page 30). The door might

not reverse when required, end could cause

serious injury or death.

The garage door springs, cables, pulleys,

brackets and their hardware are under extreme

tension. Do not attempt to loosen, move or

adjust them yourself. Serious personal Injury

or death could result. Cal! for professional

garage door service.

* Close the door and mark the inside

vertical centerline of the garage door.

• Extend the line onto the header wail

above the door.

Remember, you can fasten the

header bracket within 2 feet of the

left or right of the door center only if

a torsion spring or center bearing

plate is in the way; or you can attach

it to the ceiling (refer to page 14)

when clearance is minimal- (It may

be mounted on the wall upside down

If necessary, to gain approximately

1/2".)

If you need to install the header bracket

on a 2x4 (an wall or ceiling), use lag

screws (not supplied) to securely fasten

•the 2x4 to structural supports as shown

here and on page 13.

• Open your door to the highest

point of travel as shown. Draw

an intersecting horizontal line

on the header wall 2" above

the high point This height will

provide travel clearance for the

top edge of the door.

Door clearance brackets are

available for sectional doors

when headroom clearance is

less than 2* *. See accessory

page 38.

Proceed to Step 2, page 14.

Door ■

Ceffing

Header

-Wall

-2* Track

Higliesi Pdnt

of Travel

Sectional door

with curved track

12

One-piece door

with horizontal track

Page 13

Read the Safety instructions on page 12. They also apply to doors without tracks.

' Close the door and mark the

inside verticaJ centeriine of

your garage door. Extend the

line onto the header wall

above door.

if headroom clearance Is

minimal, you can install the

header bracket on the ceiling.

See page 14.

► ¡fyou need to instail the

header bracket on a 2x4 (on

wall or ceiling). use lag screws

(not supp/Ied) to securely

fasten the 2x4 to structural

supports as shown.

One-piece door without track

jamb hardware

• Open your door to the highest point of travel as

shown. Measure the distance from the top of the

door to the floor. Subtract the actual height of the

door. Add 8* to the remainder. (See Example).

* Close the door and draw an Intersecting horizontai

line on the header wall at the determined height.

If the total number of inches exceeds the height

availabie in your garage, use the maximum

height possible, or refer to page 14 for ceiling

instailation.

Proceed to Step 2, page 14.

pivot hardware

EXAMPLE

Distance from top of door

(at highest point of travel) to floor........

Actual height of door

Remainder.,,..,..,,,,,.,....,.,,.,,,............,..,,

Add

....................................................................... ..-r-8"

Bracket height on header wail...,.............„„.,„=12“

(Measure UP from top of CLOSED door.)

....................................—..■.....-SB"

...............

13

...

....................

,.„,......,4"

92"

Page 14

Installation Step 2

Install the Header Bracket

You can attach the header bracket either to the

wall above the garage door, or to the ceiling.

Follow the Instructions which will work best for

your particuiar requirements.

Fasten the Header Bracket to the Wall

' Center the bracket on the vertical guideline with

the bottom edge of the bracket on the horizontal

line as shown (with the arrow pointing toward the

ceiling).

2X4

Slrucsural

ЗиррюЯ

'1

Highest

Point of Travel

(of Garage Door]

Verttcai

Center

Line

' Mark either set of bracket holes (do not use the

holes designated for ceiling mount). Drill 3/16’ pilot

holes and fasten the bracket securely to a structural

support with the hardware provided.

Lag Screws

Sn6*xax1-5/8*

onfy. You must use ¿g scraws to

The nai! hole is for posHionirtg

mount the header btaelteL

Hardware Shown Actual Size

LagSaew

S/IS'-BXI-SB*

Optionai

Wsif Moontiog

Holes

Wai!

Mooniing Holes

[i>

Fasten the Header Bracket to the Ceiling

’ Extend the vertical guideline onto the ceiling as

shown.

’ Center the bracket on the vertical mark, no more

than 6“ from the wail. Make sure the arrow is

pointing toward the wall. The bracket can be

mounted flush against the ceiling when clearance

is minimal

' Mark holes designated for ceiling mount only. Drill

3/16" pilot holes and fasten bracket securely to a

structural support with the hardware provided

CeiSng Mounting Holes

The nail hole is for positioning only

You musl use lag screws So mouns

She header bractes.

Rnishetl

Coiilng

Lag Screws

s/i6’xsxi'Sra'

Header

■ Wall "

1

Page 15

Installation Step 3

Attach the T-rail to the Header Bracket

Hsacfer Wal

• Position the opener on the garage floor below the

header bracket Use packing materiaJ as a

protective base.

If the door spring is in the way you'll need help.

Have someone hold the opener securely on a

temporary support to allow the T-rall to dear the

spring.

• Posrtion the cable pulley bracket against the header

bracket

• Align the bracket holes and ¡oin with a clevis pin as

shown.

• Insert a ring fastener to secure.

Hardware Shown Actual Size

Clevis Pin

S/56‘x2-3/4-

IS

O

o

Ring Fassener

Page 16

Installation Step 4

Position the Opener

Follow Instructions which apply to your door

type as illustrated.

A 2x4 laid flat Is convenient for setting an ideal

door-to-T-rail distance.

• Raise the opener onto a stepladder.

You will need help at this paint if the ¡adder is

not tail enough.

♦ Open the door all the way and place a 2x4 laid flat

on the top section beneath the T-rail.

if the top panel hits the traiiey when you raise

the door, puH dawn on the trolley release arm to

disconnect the inner and outer sections. The

trolley can remain disconnected until Step 12 is

completed.

To prevent damage to steel, aluminum,

fiberglass or glass panel doors, do not rest the

opener on №e door without using a 2x4.

laid Flat

Tmiley

ONE-PIECE Door without Trnck

• With the door fuily open and parallel to the floor,

measure the distance from the floor to the top of

the door.

• Using a stepladder as a support, raise the opener

to the same distance as the door from the floor (it

wifi be at a slight angle as shown).

• The top of the door should be level with the top of

the opener. Do not position the opener more than

2" above this point

Top of Opener

16

Page 17

Installation Step 5

Häng the Opener

Two representative installations are shown.

Yours may be different Hanging brackets shouid

be angled, Rgure 1, to provide rigid support On

finished ceilings, Rgure 2, attach a sturdy metal

bracket to structural supports before installing the

opener. The bracket and fastening hardware are not

supplied. See accessory page 38.

• Measure the distance from each side of the opener

to the structural support

• Cut both pieces of the hanging bracket to required

lengths.

• Drill 3/16' pilot holes in the structurai supports.

• Attach one end of each bracket to a support with

5/16'-18x1*7/8' iag screws.

• Fasten the opener to the hanging brackets with

5/16“-18x7/8“ screws, lock washers and nuts.

• Check to make sure the T*rail is centered over the

door (or in line with the header bracket if the

bracket is not centered above the door).

• Remove the 2x4. Operate the door manually. If the

door hits the rail, raise the header bracket.

The opener coutd fait and Injure someone If ft

is not properly secured. Fasten the opener

securely to structural supports of the garage.

Figure 1

Moäsuro

Dismnca

S/16'-iax7/B’ Scfflw,

5/16" Look Washar

S/16M8 Niit

Figure 2

Stiuctoral

Suppofts

Grease the top and underside of the

rail surface where the trolley

slides. A tube of grease is

supplied.

Hardware Shown Actual Size

Lag Screw

5/ie*-t8x1.7/8*

PI)

Hex Screw

S/16*-16x7/8* NUI5/16--18

Lock Washer 5/16*

Bracket

(Nat SuppiteP) .

S/t 6*-18x7/8* Screw

S/16* Lode Washer

5/16*.18 Nut

HWden

Support

Rrished Ceiling-

:■ (Not Supplied)

S/ie*-18x7/8* Screw

5f16" Lock Wa^r

Page 18

Installation Step 6

Instai! the Premium Control Console

Locate the door control within sight of the door

at a minimum height of 5 feet where small

children cannot reach, and away from all moving

parts of the door and door hardware.

The door control is typically attached directly to the

wall If installing into drywall, drill 5/32" holes and

use the anchors provided. For pre-wired insiaJiaiions

(as In new home œnstrucîian), Console models

may be mounted to a standard single gang box

(Figure 2).

1 .Strip 1/4‘ of insulation from one end of the bell

wire and connect it to the two screw terminals on

the back of the door control: white to 2, and

white/red to 1.

2, Pry off cover along one side with a screwdriver

blade (see Figure 1). Fasten with 6ABx1-1/4‘ self

tapping screws (standard installation) or 6-32x1*

machine screws (pre-wired instaliation) as follows:

• Install bottom screw, allowing 1/8* to protrede

above wall surface.

• Position bottom of door control on screw head and

slide down to secure. Adjust screw for snug fit.

• Drill and install top screw with care to avoid

cracking plastic housing. Do not overtighten.

• Insert top tabs and snap on cover.

3. (For standard installation) Run ttie bell wire up the

Do not connect to live electncal wiring. Connect

only to 24 Volt low voltage wires. Connection to

live wires or higher voltage may cause serious

injury from shock, bum or electrocution.

Children operating or piaying with a garage

door opener can Injure themselves or others.

The garage door could close and cause

serious injury or death.

instail the door control (or any additional push

buttons) out of the reach of children and away

from all moving parts of the door and door

hardware, but H*ere the garage door is visible.

Do riot allow children to operate the push

button(s) or the remote control(s).

A moving garage door could.injure someone

under it Activate the opener only when the

door is properly adjusted, you can see it

clearly, and there are no obstructions to door

travel.

Hardware Shown Actual Size

NMjilriiHIijiHIIïïro

SA0 X1-1M* Screw

CofTtroi Cansofe (std instailalk«)

nm

^ 6-32 xT Screw

Contttsl Console (pre-wired)

11

OiyWaltAnetiore

insuiatect

Stapies

18

Page 19

6. Attach tie User Safety Instruction iabei to the wall

near the door control, and the Maintenance

Instruction label in a prominent location on the

inside of the garage door.

Page 32 explains how to use the door controL

Instsllstton Stsp 7

Instail the Lights and the Lenses

• Instali a 75 watt maximum light bulb in each

socket. The lights wtl! turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the lights will hjm OFF.

• If the bulbs bum out prematurely due to vibration,

replace them with standard neck 'Garage Door

Opener* * bulbs.

Do NOT connect the power and operate the

opener at this time. The trolley will travel to the

full open position but will not return to the

close position until the sensor beam Is

connected and properly aligned.

See Safety Reversing Sensor Instructions

beginning on page 21.

75 Wa« Ma*.

Guida

Install the lenses:

• Apply slight pressure on the sides of each lens

and slide the tabs into the slots in the side panels.

• For convenience, the lenses may be installed

after Adjustment Step 4 on page 30.

• Reverse the procedure to remove the lenses.

Instailation Step 8

Attach the Emergency

Release Repe and Randie

• Thread one end of the rope through the hole in

the top of the red handle so "NOTICE" reads right

side up as shown. Secure with an overhand knot.

The knot should be at least 1" from the end of

the rope to prevent slipping.

• Thread the other end of the rope through the hole

in the release arm of the outer troiley.

• Adjust rope length so the handle Is 6 feet above

the floor. Secure with an overhand knot.

If it is necessary to cut the rope, heat seal the

cut end with a match or lighter to prevent

unraveling.

Lens

Tab

Lens'

Tab

Do not use the red handle to pull the door

open or closed. The rope knot could become

untied and you could fall. Use the emergency

release only to disengage the troHey and, if

passible, only when the door is closed.

Garage doors are heavy. If the door is open

when the handle is puiied, the door could

close inadvertently if it is not properly

balanced. Serious injury may result to persons

under the door. Make sure the doorway is clear

of persons and obstructions before pulling

handle when door is open.

Overiiarxi

Kjio!

19

Trolley

Ovettiand

Knot

Trolley

Release Arm

Emergency

flelease Handle

Page 20

Instaiiation Step 9

Electrical Requirements

Tq reduce the risk of electric shock, your garage

door opener has a grounding type plug with a third

grounding pin. This plug will on/y fit into a grounding

type outlet,

if the plug doesn't fit into the outlet you have,

contact a qualified electrician to instaii the proper

outlet.

To avoid instaiiation difftcuities,

do not run the opener at this time.

To prevent electrocution or fire, Installation

and wiring must be in compliance with local

electrical and building codes.

Do NOT use an extension cord, 2-w!re adapter

or change the plug in any way to make It fit

your outlet.

Right

Wrong

if permanent wiring is required by your local code, refer to the following procedure:

To prevent electrocution, remove power from

the garage door opener and from the circuit

you plan to use for the permanent connection.

Permanent

To make a permanent connection through the

T/8" diameter hole in the top of the opener

(according to local code):

Remove the opener cover screws and set the

cover aside.

Remove the attached 3-prong cord.

Connect the black (fine) wire to the screw on the

brass terminal; the white (neutral) wire to the

screw on the silver terminal; and the ground wire

to the green ground screw. The opener must be

grounded.

Reinstall the cover.

Connections

Wiring

To avoid insta nation difficulties,

do not run the opener at this time.

Biade

WIra

20

Page 21

The Safety Reversing system

Information you'll need before you begin the Installation of the safety reversing sensor.

The safety reversing sensor must be connected

and aligned correctly before the garage door

opener will move in the down direction. This is a

required safety device and cannot be disabled.

Imiallathn procedures are the same for sectiana!

and one-piece doors.

Without a properly working safety reversing

sensor, persons (particularly children) could

be injured or killed by a closing garage door.

Read and follow all Instructions.

To protect small children, Install the safety

reversing sensor so that the beam will be no

higher than 4“*6'‘ above the garage floor.

Disconnect power to the garage door opener

before Installing the safety reversing sensor.

Be sure power to the opener is disconnected.

The sending eye transmits an invisible light beam to

the receiving eye* The units can be instaJled on

either side of the garage door as long as the sun

never shines directly into the receiving eye lens.

Look at the label on the connector end of each case

to identify the sensors.

The brackets must be connected and fastened so

that the sending and receMng eyes face each other

as shown in Rgure 1.

If an obstruction breaks the light beam while the

garage door is closing, the door will stop and

reverse to full open position and the opener lights

will flash for 5 seconds.

The brackets must be securely fastened to a solid

surface such as the studs on either side of the door,

or add a piece of wood at each location if installing in

masonry construction.

The invisible light beam path must be unobstructed*

No part of the garage door (or door tracks, springs,

hinges, rollers or other hardware) can interrupt the

beam while the door is closing. If it does, use a piece

of wood to build out each sensor mounting locaton to

the minimum depth required for light beam clearance.

Figure 1: Facing the door from inside the garage

21

Page 22

installation Step 10

Instai! the Safety Reversing Sensor

Rgures 2 and 3 show assembly of brackets and

'C* wrap based on the recommended installation of

the sensors as shown on page 21.

However, Figures 4 and S are variations which may

fit your insiallaiion requirements better. Make sure

the wraps and brackets are aligned so the

sensors will face each other across the garage

door.

• Fasten the “C* wraps to the mounting brackets

having square holes, using the hardware shown

in Rgure 2.

• Connect each assembly to a slotted bracket, using

the hardware shown in Rgure 3.

Note the alignment of the brackets for left and

right sides of the door.

• Roger tighten the lock nuts,

• Use bracket mounting holes as a template to

locate and dril! (2) 3/16" diameter pitot holes on

both sides of the garage door, 4‘-6” above the

floor but not exceeding 6*. (See warning on

page 21.)

• Attach bracket assemblies with 1/4*x1-1/2* lag

screws as shown in Rgure 3.

• Adjust right and left side bracket assemblies to the

same distance out from the mounting surface.

Make sure all door hardware obstructions are

cleared. Tighten the nuts securely,

Figure 2

UKkNuts

Figure 3

-Ci:o3s —

War

#10-32

a.

Mounting B tacket

With Square Hotos

1/4X1-1Ä*

Lag Screws

MounSrtg Bracket

with Slot

Mouneig Staoket

with Square Hates

G'Wrafj

#10-32x3/6*

Screws

1/4-20x1/2* CaiTíago Boits

{wHh square shoulder)

mwrap

#10-32x3/8*

Screw

Figure 4

#10x32

Lock Nut

Alternate Wall Mount

Mounting Bracket

With Slot

Hardware Shown Actual Size

11

__

Mtxtnling Bracket

1

Square Hotos

C* Wrap

Sensor

with wire

tndicatar Light

I I III

1^

IMxl-1/2*

Lag Screw

D

Figure 5

1/4'-20x1/2*

Caiiiaga Bafts

Alternate Floor Mount

Sensor with wire

InsScatar Ught

Mourning Bracket

wlh Square Holes

MounSfrsg Bracket

vwth Slot

concrete anchors

(not provided)

1/4'-20

Lock Nut

Attach witti

22

Page 23

» Center each sensor unit in a 'C* wrap with tenses

pointing toward each other across the door (see

Hgure 6).

• Secure sensors with the hardware shown. Roger

tighten the wing nut on the receiving eye to aliow

for final adjustment. Securely tighten the sending

eye wing nut

• Run the wires from both sensors to the opener.

Use insulated staples to secure wire to waJ! and

ceiling,

«Strip 1/4“ of insulation from each set of wires.

Separate white and whiie/black wires sufficiently to

connect to the opener terminal screws: white to 2

and white/black to 3.

Aligning the Safety Sensors

• Plug in the opener. Green indicator lights in both

the sending and receiving eyes will glow steadily il

wiring connections and alignment are correct

The sending eye indicator light will giow regardless

of alignment or obstruction. If the indicator light is

off, dim, or flickering in the receiving eye (and the

invisible light beam path is not obstructed),

alignment is required.

• Loosen the sending eye wing nut and readjust,

aiming directly at the receiving eye. Lock in place.

• Loosen the receiving eye wing nut and adjust

sensor vertically and/or horizontally untii it receives

the sender^s beam. When the green indicator light

glows steadily, tighten the wing nut.

Rgure 6

¡mficator

Ugh!

1/4-23x1-1/2*

Hex Boil

'C'Wrap

Trouble Shooting

1. if the sending eye indicator light does not glow

steadily after installation, check for

• Bectric power to the opener.

• A short in the white or white/black wires. These

can occur under staples or at screw terminal

connections.

• Incorrect wiring between sensors and opener,

• An open wire (wire break).

2. if the sending eye indicator light glows steadily but

the receiving eye indicator light doesn*t

■ Check alignment.

• Check for an open wire to the receiving eye,

3. If the receiving eye indicator light is dim, realign

either sensor.

NOTE: When the invisible beam path is obstructed or

misaligned while the door is closing, the door wilt

reverse. If the door is already open, it will not dose.

The opener fights will flash 10 times. (Ifbutbs are not

instalied, 10 dicks are audible.) See page 21.

Hardware Shown Actual Size

l/4-20xM/a* _

He* Soft

Sonspr

InvistbS« Light Beam

Protection Afea

Sensor

23

Page 24

Installation Step 11

Fasten Door Bracket

I lUINIi

Foilow Instructions which apply to your door

type as illustrated below or on page 25.

A horizontal brace should be long enough to be secured to 2 vertical supports. A vertical brace should

cover the height of the top panel.

The Illustration shows one piece of angle iron as the horizontal brace. For the vertical brace, 2 pieces of

angle iron are used to create a "IF-shaped support The best solution Is to check with your garage door

manufacturer for an opener instailatlon door reinforcement kit

To prevent damage to steel, aluminum,

fiberglass or glass pane! doors, always

reinforce the inside of the door both vertically

and horizontally with an angle iron.

Figure 1

* Center the door bracket on the previousiy marked

vertical guideline used for the header bracket

installation, Nate correct UP placement, as

stamped inside the bracket

* Position the bracket on the face of the door within

the following limits:

A) The top edge of the bracket 2“-4" below the top

edge of the door.

8) The top edge of the bracket directly below any

structural support across the top of the door.

* Mark and drill 5/16" left and right fastening holes.

Secure the bracket as shown in Rgure 1 if there is

vertical reinforcement.

If your installation doesn’t require verticai reinforce

ment but does need top and bottom fastening holes

for the door bracket, fasten as shown in Figure 2

Figure 2

Hardware Shown Actual Size

Nut 5/16-1 a Lode Washei S/16"

Camags Bel!

S/!6".l8x2-t/2‘

24

Page 25

"

............

P!ease read and comply with the warnings and reinforcement instructions on page 24.

They apply to one-piece doors also.

• Center the bracket on the top of the door, in line

with the header bracket as shown. Mark holes.

• Dtiil 5/16" pilot holes and fasten the door bracket

with hardware supplied.

if the door has no exposed framing, drill 3/16* pilot

holes and fasten the bracket with sh6"x1-1/2* lag

screws (not supplied) to the top of the door.

The door bracket may be installed on the top

edge of the door If required for your instailation.

(Refer to the dotted line optional placement

drawing.) Drill 3/16" pilot holes and substitute

5/16"x1-1/2" lag screws (not supplied) to fasten

the bracket to the door.

25

Page 26

Installation Step 12

Connect Door Arm to Trolley

Follow Instructions which apply to your door

type as Illustrated below and on page 27,

Make sure garage door is fully closed. Pull the emergency release handle to disconnect the outer trolley

from the inner trolley. Slide the outer trolley back (away from the door) aboirt 2" as shown In

Rgures 1,2 and 3.

Rgure 1:

• Fasten straight door arm section to outer trolley

with the the 5/16*xr clevis pin. Secure the

connection with a ring fastener.

« Fasten curved door arm to the door bracket in the

same way, using the S/IS'xl-IM" clevis pin.

inner Troilsy

Rgure 2:

• Bring arm sections together. Rnd two pairs of holes

that line up and join sections. Select holes as far

apart as possible to increase door arm rigidity.

Straight

Door Arm

Cle«a Pin

S/16M-1/4'

Cusved

i3oor Arm

igure 1

Hole Alignment Alternative

Figure 3:

• If holes In curved arm are above holes in straiaht

arm, disconnect straight arm. Cut about 6** from

the solid end. Reconnect to trolley with cut end

down as shown.

• Bring arm sections together.

• Rnd two pairs of holes that line up and join with

screws, lock washers and nuts.

Hardware Shown Actual Size

O

Nutsns'-IB Lock Washer S/1 S' Ring Fastener

Door Bracket

Eni0f||ency

Heiease

Handle

Scmws

sne'-iew/s*

Figure 2

Cut This End

o

' CieHs Pin

m e 'xV {Trolley)

Proceed to Adjustment Step 1, page 28, Trolley will re-engage automatically when the opener is operated.

Clevis Pin Hex Screw

o

(Door Bracket) 5/l6‘-iax7/B*

26

Figure 3

Page 27

Assemble the Door Arm:

• fasten the straight and curved door arm sections

together to the longest possible length, with a 2 or 3

hole overlap.

• With the door dosed, connect the straight door arm

section to the door bracket with the 5-16" x 1 -1/4"

clevis pin.

• Secure with a ring fastener.

On one-piece doors, before donnecfing the door arm to the trolley the travel limits must be adjusted. Limit adjust

ment screws are located on the left side panel as shown on page 28. Follow adjustment procedures below.

Door

aitig

Ad}ustment Procedures for One-Piece Doors

open Door Adjustment:

Decrease UP limit

' Turn the UP limit adjustment screw counter-

dockwise 5-1/2 turns,

- Press the Wait Control push bar. The trolley will

travel to the fully open position.

> Manually raise the door to the open position

(parailel to the floor), and lift the door arm to the

trolley. The arm ahouid touch the trolley just in

back of the door aim connector hole. Refer to the

fully open troliey/door arm positions in the

illustration. If the arm does not extend far enough,

adjust the limit further. One full turn equals 2* of

trolley travel.

Connect the door arm to the trolley.

• Close the door and join the curved arm to the connector hole in the trolley with the remaining clevis pin. It may

be necessary to lift the door slightly to make the connection.

• Secure with a ring fastener.

• Run the opener through a complete travel cycle. If the door has a slight “backward" slant in full open position

as shown in the Illustration, decrease the UP limit until the door is parallel to the floor.

'Turn the DOWN limit adjustment screw clockwise

5 complete turns.

‘ Press the Wall Controi push bar. The trolley will

travel to the fully closed position.

> Manually dose the door and lift the door arm to the

trolley. The aim should touch the trolley just ahead

of the door arm connector hole. Refer to the fully

closed trolley/door aim positions in the illustration. If

the arm is behind the connector hole, adjust the limit

further. One full turn equals 2" of trolley travel.

Closed Door Adjustment:

Decrease DOWN limit '

27

Page 28

Adjustment Section: Pages 28 - 30

Adjustment Step 1

Adjust the UP and DOWN Limits

Do not make any limit adjustments until the

safety reversing sensors are completely

installed.

Umit adj'ustment settings reguiate the points at

whidi the door will stop when moving up or down.

The door wiii stop in the up direction if anything

interferes with door travel The door will reverse in

the down direction if anything interferes with the

dooriravei (including binding or unbalanced doors).

To operate the opener, press the Door Ckinirol push

button. Run the opener through a complete travel

cycle.

• Does the door open and close completely?

• Does the door stay closed and not reverse

unintentionally when fully closed?

If your door passes both of these tests, no limit

adjustments are necessary unless the reversing test

fails (See page 30).

Adjustment procedures are outifned below. Riin

the opener through a complete travel cycle after

each adjustment.

Repeated operation of the opener during

adjustment procedures may cause the motor to

overheat and shut off. Simply wait 15 minutes

and try again.

Read the procedures carefully before proceeding to

Adjustment Step 2. Use a screwdriver to make limit

adjustments.

Improper adjustment of the travel limits will

interfere with the proper operation of the

safety reverse system. The door might not

reverse properly when required and could

seriously injure or kill someone under it Test

the safety reverse system following all

adjustments to the travel limits. See page 30.

r—

....—ussa.

Cover y

PtDtedjan

Bdt

iCZCs

CD CD O CD rp

"'ciJ'""'"""'“"

.........

.............. ............................

Left Side Panel °

X /

Limit Adjustm^t

Scrsws

© ^

Adjustaent Label

How and When to Adjust the Limits

• If the door does not open completely, but

opens at least five feet:

Increase up travel Turn the UP limit adjustment

screw clockwise. One turn equals 2* of travel.

NOTE: To prevent the trolley from hitting the

cover protection bait, keep a minimum distance

of 2-4*' between the trolley and the bolt

• If door does not open at least 5 feet:

Adjust the UP (open) force as explained in

Adjustment Step 2,

• If the door does not close completely:

Increase down travel Turn the DOWN limit

adjustment screw counterclockwise. One turn

equals 2“ of travel.

If the door still won't close completely and the trolley

bumps into the pulley bracket (see page 4 or 5), try

lengthening the door arm, (see page 26).

If you have adjusted the door arm to the maximum

length and the door stiil will not dose completely,

lower the header bracket. See Installation Step 1,

pages 12 and 13.

• If the opener reverses in fully closed position:

Decrease down travel. Turn the DOWN limit

adjustment screw clockwise. One turn equals 2" of

travel.

V If the door reverses when closing and there is

no visible interference to travel cycle:

if the opener lights are flashing, the Safety Reversing

Sensors are either not installed, misaligned, or

obstructed. See Troubleshooting, page 23, ,

Test the door for binding; Pull the manual release

handle. Manually open and close the door. If the door

is binding, call for garage door service. If the door is

not binding or unbalanced, adjust the DOWN (dose)

force. See Adjustment Step 2.

28

Page 29

Adjustment Step 2

Adjust the Force

Force adjtjsirnent contrais are located on the right

Side рале1 of the opener. Force adjustment settings

regulate the amount of power required to open and

dose the door.

The door wifi stop in the up direction if anything

interferes with its travel. The door wii! reverse in the

down direction if anything interferes with its travel

(including binding or unbalanced doors).

If the forces are set too light, door travel may be

intemipted by nuisance reversals in the down

direction and stops in the ф direction. Weather

conditions can affect the door movement, so

occasional adjustment may be needed.

The maximum force adjustment range is 260 degrees,

about 3/4 of a complete turn, Oo not force controls

beyond that point. Turn force adjustment controls

with a screwdriver.

Too much force on the door will Interfere with

the proper operation of the safety reverse

system. The door might not reverse properly

when required and could seriously Injure or

kill someone under it Do not increase the

force beyond the minimum amount required

to close the door. Do not use the force

adjustments to compensate for a binding or

sticking garage door. Test the safety reverse

system following all adjustments to force

levels. See page 30.

Forea Adjussment

Contrais,

Acflustmem taba!

How and When to Adjust the Forces

Test the DOWN (close) force

Grasp the door bottom when the door is about

halfway through DOWN (close) travei. The door

should reverse. Reversal halfway through down

travel does not guarantee reversal on a one-inch

obstruction. See page 30. If the door is hard to

hold or doesn’t reverse, decrease the DOWN (close)

force by turning the control counterclockwise.

Make 10 degree turn adjustments until the door

reverses normally. After each adjustment, run the

opener through a complete cycle.

Test the UP (open) force

Grasp the door bottom when the door is about

halfway through UP (open) travel. The door should

stop, if the door is hard to hold or doesn't stop,

decrease UP (open) force by turning the control

counterclockwise.

Right Sida Panel

Make 10 degree turn adjustments unffl the doorstops

easily. After each adjustment, run the opener through

a complete travel cycle.

if the door doesn’t open af least 5 feet

Increase UP (Open) force by turning the control

clockwise. Make 10 degree turn adjustments until

door opens completely. Re-adjust the UP limit if

necessary. After each adjustment, run the opener

through a complete travel cycle.

If the door reverses during the down (close) cycle

and the opener lights aren’t flashing

increase DOWN (close) force by turning the control

clockwise. Make 10 degree turn adjustments until the

door completes a close cycie. After each adjustment,

run the opener through a complete travel cycle. Do

not increase the force beyond the minimum

amount required to close the door.

29

Page 30

Adjustment Step 3

T&st The Safety Reversing Sensor

* Press the remote control push button to open the

door.

* Place the opener carton in the path of the door,,

* Press the remote control push button to dose the

door. The door will not move more then an inch,

and the opener lighifs) will flash.

Professional service is required if the opener

doses the door when the safety reversing

sensor is obstructed.,

The garage door opener will not close from a

remote control If the Indicator light in either

sensor Is off (alerting you to the fact that the

sensor Is misaligned or obstructed).

The garage door can be dosed by pressing and

holding the Door Control push button until down

travel is completed.

Adjustment Step 4

Test the Safety Reverse System

Without a properly working safety reversing

sensor, persons (joarticu/arfy chiidren) could be

seriously injured or killed if trapped by a closing

garage door. Repeat this test once a month.

N

I

a

Safety RevBEStng Sensor

Safely Revarsirig Sensor

Test:

«Place a one-inch board {or a 2x4 laid fiat) on the

floor, centered under the garage door.

• Operate the door in the down direction. The door

must reverse on striking the obstruction.

Adjustment;

If the door stops on the obstruction, it is not traveling

far enough in the down direction.

• Increase the DOWN limit by turning the DOWN

limit adjustment screw counierciockwise 1/4 turn.

• Repeat the test.

On a sectional door, make sure limit

adjustments do not force the door arm beyond a

straight up and down position. See the

illustration on page 26.

• When the door revetses on the one-inch board,

remove the obstruction and am the opener through

3 or 4 complete travel cycles to test adjustment.

If the door will not reverse after repeated

adjustment attempts, call for professional

garage door service.

Failure to test and adjust the safety reverse

sysfem may result in serious injury or death to

persons trapped by a closing garage door.

Repeat this test once a month and adjust as

needed.

6ARAGE DOOR

Onwodi SoanJ

■ (or a 2x4 iaid na!)

Important safety check

Repeat Adjustment Steps 1, 2 and 4 after:

• Each adjustment of door ami length, force controls

or limit controls.

• Any repair to or adjustment of the garage door

(including springs and hardware),

• Any repair to or buckling of the garage floor.

• Any repair to or adjustment of the opener.

30

Page 31

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of severe injury or death to persons:

1. READ AND FOLLOW ALL INSTRUCTIONS,

2. Do not permit children either to operate or to

play with the opener. Keep remote control in a

location inaccessible to children.

3. Operate opener only when the door is in full

view and free from any obstnictlon. Keep the

door in sight until it is completely closed. NO

ONE SHOULD CROSS THE PATH OF THE

MUViNQ DOORm

4. Check safety reversal system monthly. See

page 30. The garage door Afí/STreverse on

contact with a one-inch {or a 2x4 board laid

flat) object placed on the floor. If an adjustment

is made to either the force or the Hml of travel,

both adjustments may be needed and the

safety reversal system must be checked.

Failure to properly adjust the opener may

result in severe injury or death.

Care of Your Opener

Limit and force adjustment controls

Limit Controls Force Controls

Adfustment Label

{Locased on the leli side panel)

Weather conditions may cause some minor

changes in door operation requiring some re

adjustments, particularly during the first year of

operation.

Pages 28 and 29 refer to the limit and force

adjustments. Only a screwdriver is required. Follow

the instructions carefully.

Repeat the safety reverse test (page 30) after any

adjustment of limits or force.

Ai^usiment labe)

(Localed on the right side panei)

'é'

6. if possible, use the emergency release only

when the door is in a closed position. Caution

should be taken whenever the disconnect cord

is actuated with the door open. Weak or broken

spnngs may cause the door to fail rapidly,

causing injury or death to persons.

6. KEEP GARAGE DOORS PROPERLY

BALANCED. See page 3. An improperly

balanced door may not reverse when required

and could result In severe injury or death.

Repairs to cables, spring assemblies and other

hardware must he made by a professional

garage door person.

7. Disconnect the electric power to the garage

door opener before maidng any repairs or

removing the covers.

8. SAVE THESE INSTRUCTIONS.

The remote control

The lithium batteries should

produce power for up to

5 years. To replace batteries,

use the visor clip or screwdriver

blade to pry open tfie case as

shown, {“Open" location is

stamped on back of remote

contro! case.) insert batteries positive side down.

Replace cover as follows. S-Function remote: Insert

the 3 tabs at the opposite end and snap shut

3-rUNCnON

Oped tftfa end

Jiistto

aacJctng

housing

COMPACT

Twist hem,

xo open

Compact 3-Function remote: Snap shut along both

sides.

Dispose of old batteries properly.

Keep batteries away from small children. If

swallowed, promptly notify doctor.

Maintenance Schedule

Once 3 Month

Manually operate door. If it is unbalanced or

binding, caí! for professional garage door service.

Check to be sure door opens and closes fuHy.

Adjust limits and/or force if necessary.

{See pages 28 and 29.)

Repeat the safety reverse test Make any

necessary adjustments (See page 30).

Twice a Year

Check chain tension. Disconnect trolley first

Adjust if necessary (See page 11),

Once a Year

Oil door rollers, bearinqs and hinoes. The opener

does not require additional lubrication. Do not

grease the door tracks.

31

Page 32

Operation of Your Opener

Activate the opener with any of the following:

• The Remote Control; Hold push button down until

the door starts to move,

" The Door Control; Hold push button down until

the door starts fn move

w V-l WWI O LCiAi um? i-W t f c\^ w VC 4«

« The Outdoor Key Switch or Keyless Entry: (See

Accessories)

When the opener is activated with the safety

reversing sensor installed and correctly aligned:

1. If open, the door will close. If closed, the door will

open,

2. If closing, the door will reverse.

3. If opening; the door will stop (allowing space for

entry and exit of pets and for fresh air).

4- If the door has been stopped in a partially open

position, it will close.

5. If obstaicted while closing, the doorwii! reveree.

6. If obstructed while opening, the doorwiit stop.

7. The garage door will reverse Irr the closing cycle

when the invisible beam is broken. If fully open,

the door will not close when the beam is broken.

"TTiD CDnCAf* hiSC nA rSuffOAf tn AAOAlAA

111^ is-c#I i-oim«I I Itd.w i 11«# iL sI I IJ 1x5 xJLa/lu«I ill ix^ w$x5•

If the sensor is not Installed, or is not aligned

rniTArtiv fhA dnnf rln<5A finrn pnv rpinnti^

luw t i wx<xi Y i w 1x7 SJ \JxJi wYXJi t i 11 wl 1 c OJ IV I x#l 1

transmitter. You can close the door with the Door

Control, the Outdoor Key Switch, or Keyless Entry,

however, if you activate them until down travel Is

complete. If you release them too soon, the door will

f/a t/yi j"gy <3

# *

The opener lights will blink for S seconds when the

safety reversing sensor causes the door to reverse.

The Opener Lights wii! turn on under the following

conditions: When the opener is initially plugged in;

when the power is inteirupted; when the opener is

activated. They will turn off automatically after 4"1/2

minutes or provide constant light when the Light

feature on the Premium Control Console is activated.

SECURITY+ models: Lights will also turn on when

someone walks through the open garage door. Bulb

size is 75 watts maximum.

Weak or broken springs could allow an open

door to fall (either rapidly or unexpectedly)t

resulting in serious in}ury, death or property

damage. If possible, use the emergency

release rope and handle only when the door is

fully closed.

To open the door

manually:

Release Arm

Tfoiley

The door should be

fully closed If possible.

Pull down on the red

emergency release

handle and lift the door

manually. To

Einefigency

Release Handle

<Pun Down)

Manual disconnect

fpnnnnpcf thA rfnnr tn

the opener, press the

Door Control push

button.

position

The lockout feature

prevents the trolley from

reconnecting automatically., ¡ ^

Pull the emergency handle

Release Airn

down and back (toward the

opener). The door can then

be raised and lowered

manually as often as

FtAAoeciiaA/ Та Hícíaaaíüaíi

níívAÍoocli у» *w и1хэЦ1 iUcÍUt5

the Lockout Feature, pull

the emergency handle

straight down. The trolley

Emergency

Balease Haridfe

(PüÜ Dovm & Back

Towards Opener)

will reconnect on the next Lockout position

UP or Down operation.

Operation of trie Door

(SECURiTY’i* models: See additional

Press the lighted push button to open or close the

door.

Press again to reverse the door during the dosing

cycle or to stop the door while ifs opening.

Premium Console:

L/ghfFeatore- Press the large round Light button,

the opener lights are off, they will turn on. If the

opener lights are on, (even in the 4*1/2 minute

automatic cycle) they will turn off.

But if you use the Light button to turn the lights on

and then activate the opener, the lights will turn off

after 4-1/2 minutes,

The Light button will not control the opener lights

when the door is in motion.

Controls (see page 18)

programming features, next page,)

Premium Console (cont):

Lock Feature - The Lock feature is designed to

prevent operation of the door from remote controls.

However, the door will open and close from the Door

Control, the Outdoor Key Switch and the Keyless Entry

Accessories,

If

To Activate; Press and held the small round Lock

button for 2 seconds. The push button light will flash

as long as the Lock feature is on.

To turn off: Press and hold the Lock button again

for 2 seconds.The push button light will stop

flashing. The Lock feature wii! also turn off whenever

the "SRT" button on the opener pane! is activated.

32

Page 33

Receiver and Remote Control Programming

SE€URnT+

Your garage door opener receiver and remote control

have been pre-set at the factory. The door will open

when you press the LARGE remote control push

button. The code between the remote control and the

receiver changes with each use, randomly accessing

over 100 billion new oades.

The 3-function remote control can also activate

additional SECURITY*®» garage door openers and/or

light controls.

Your SECURrTY-f opener will operate with:

• several SECURITY*® remote controls (with blue

push buttons) utilizing up to 8 functions.

• one SECURITY*® Keyless Entry System (Mode!

139.53684).

Follow the instructions beiow to program your opener

to match any additional remotes you may purchase.

See Accessories on page 38.

To comfW with FCC nites, ac^usttnent or m«£iicau'ahs of this recoiver

andior JransmitSef ara po5ii33fted, except for diangasg trio ccda seUitKi «

replacing tha taSety, THEHE ABE NO OmSB USER SERVICEABLE

PARTS.

Children operating or playing with a garage

door opener can injure tftemseives or others.

The garage door could dose and cause serious

Injury or death. Do not allow children to operate

the door push button(s) or remote control's).

A moving garage door could Injure or kill

someone under It Activate the opener only

when you can see the door clearly, it is free of

obstructions, and Is properly adjusted.

Figure 1

Seteci a remoia ссп&Ы posh

btittan w operate openar

To Add A Remote Control

If you have a Premium Control Console:

1. With the door closed, press and hold a remote

Gontroi push button. See Rgure 1.

2. Press and hold the Light button on the door

control.

3. Press and hold the door control push button.

4. After the opener light flashes, release all buttons.

Test by pressing the remote push button.

If you do not have a Premium Control Console:

1. Press and /ю/d the selected remote control push

button. See Rgure 1.

2. Then press and release the SRT (leam) button on

the back panel of the opener, Rgure 2„ The

indicator light on ttie panel will begin to blink and

the opener light will ffash once.

3. Release the remote push button.

Test by pressing the remote push button.

To Erase All Remote Control Codes

Press and hold the SRT button on the opener panel

until the indicator light turns off (about 6 seconds). All

remote control codes are now erased. Then follow

the steps above to re-program each remote control.

SECURlTY-i"

3-Function

Remote Control

To Control the Opener Light (Premium Consoles)

With SECURfTY-® remote controls, a push button can

be programmed to operate the opener light without

opening tie door.

1. With the door dosed, press and bold the remote

button that you want to control the light.

2. Press and hold the Light button on the door

control.

3. Press and hold the Lock button on the door control.

4. After the opener light flashes, release ail buttons.

Test by pressing the remote push button. The opener

light should turn on or off but the door should not move.

SECURITY*®

Garage Door Opener

Figure 2

33

Page 34

Having a Problem?

Situation

The opener doesn't

operate from either

the Door Control or

the remote control:

Opener apemtes

from the remote

control, but not from

the Door Control: -

The door operates

horn the Door

Control, but not ft'om

the remote control:

Probable Cause and Solution

1. Does the opener have electric power? Plug a lamp into the outlet. If it doesn't light,

check the fuse box or the dncuit breaker. (Some outlets are controlled by a door switch,)

2. Have you disabled all door locks? Review installation instruction warnings on Page 11,

3. Is there a buHd-up of ice or snow under the door? The door may be frozen to the

ground. Remove any restriction,

4. The garage door spring may be broken. Have it replaced,

5. Repeated operation may have tripped the overload protector in the motor. Wait

IS minutes. Try again.

1. Is the Door Control lit? Jf not, remove the bell wire from the opener terminal screws.

Short the red and white terminals by touching both terminals at the same time with a

piece of wire, if the opener runs, check for a faulty wire connection at the Door

Control, a short under the staples, or a broken wire.

2. Are the wiring connections correct? Review Step 6, page 18.

1. Is any door push button flashing? If your model has the Lock feature, make sure the

lock is Off.

2. Your opener needs to re-leam a remote control code. Refer to Instructions on the

AfliSnOi* nonol

wijtSi ttSi Ucu itSK

3. Program the receiver to match the remote control code,

4. Repeat the receiver programming procedure with ail remote controls.

The remote control

has short range:

Opener noise is

disturbing in living

quarters of home:

The garage door

opens and closes

by itself:

The door doesn't

open completely:

1. Change the location of the remote control in your car.

2. Check to be sure the antenna on the side or back pane! of opener extends fully

downward.

3. Some installations may have shorter range due to a metal door, foil backed

insulation, or metal garage siding. (Antenna Extender Kit 41A3504)

If operational noise is a problem because of proximity of the opener to the living

quarters, the Vibration Isolator Kit 41A3263 can be installed. This kit was designed to

minimize vibration to the house and is easy to install.

1. Be sure that all remote control push buttons are off.

2. Remove the bel! wire from the Door Control terminals and operate from the remote

control only, if this solves the problem, the Door Control is faulty (replace), or there is

an intermittent short on the wire between the Door Control and the opener,

3. Clear memory and reprogram ail remote controls.

1. is something obstructing the door? Remove the obstruction or repair the door.

2. if the door has been working property but now doesn't open all the way, increase the

up force. See page 29.

3. If door opens at least 5 feet, the travel limits may need to be increased. One turn

equals 2 inches of travel. See page 28.

Repeat the safety reverse test añer the adjustment is complete.

The door stops but

doesn't close

completely:

Review the travel limits adjustment procedures on page 28.

Repeat the safety reverse test añer any adjustment of door arm length, close

force or down limit.

34

Page 35

Having a Problem? (continued)

Situation

The door opens but

woni dose:

The door reverses for

no ^parent r^son

srtd opener liphts

don't blink:

The door reverses for

no apparent reason

and opener lights

blink for S seconds

Ci» Xi eSr 1 W fcr J ¿y f t ■

Probable Cause & Solution

1. if the opener lights blink, check the safety reversing sensor. See page 23.

2. If the opener lights do not biink and it is a new installation, check the down force.

See Adjustment Step 2, page 29, For an existing installation, see below.

Repeat the safety reverse test añer the adjustment is complete.

1. Is something obstructing the door? Pull the red emergency release handle. Operate

the door manually. If it is unbalanced or binding, cal! for professional garage door

service.

2. Clear any ice or snow from the garage floor area where the door closes.

3. Review the force adjustment procedures on page 29.

4. If door reverses in the fully c/osedposition, decrease the travel limits (page 28).

Repeat safety reverse test after adjustments to force or travel limits. The need

for occasional adjustment of the force and limit settings is normal. Weather

conditions in particular can affect door travel

Check the safety reversing sensor. Remove any obstruction or align the receiving eye.

See page 23.

The opener lights:

The opener strains or

maximum forcé is

needed to operate

door:

The opener motor

hums briefly, then

won't work:

The opener won’t

operate due to

power failure:

.., don’t turn on;

Replace the fight bulbs (75 watts maximum). Use a standard neck garage door opener

buib if regular bulb bums out.

... don’t turn off:

is tie Light feature on? Turn it off.

The door may be out of balance or the springs are broken. Close the door and use the

emergency release to disconnect the trolley. Open and dose the door manually, A properly

balanced door will stay in any point of travel while being supported enflrely by Ks springs, if it

does not, disconnect tie opener and call a professional garage door serviceman. Do not

increase the force to operate the opener

1. The garage door springs are broken. See above.