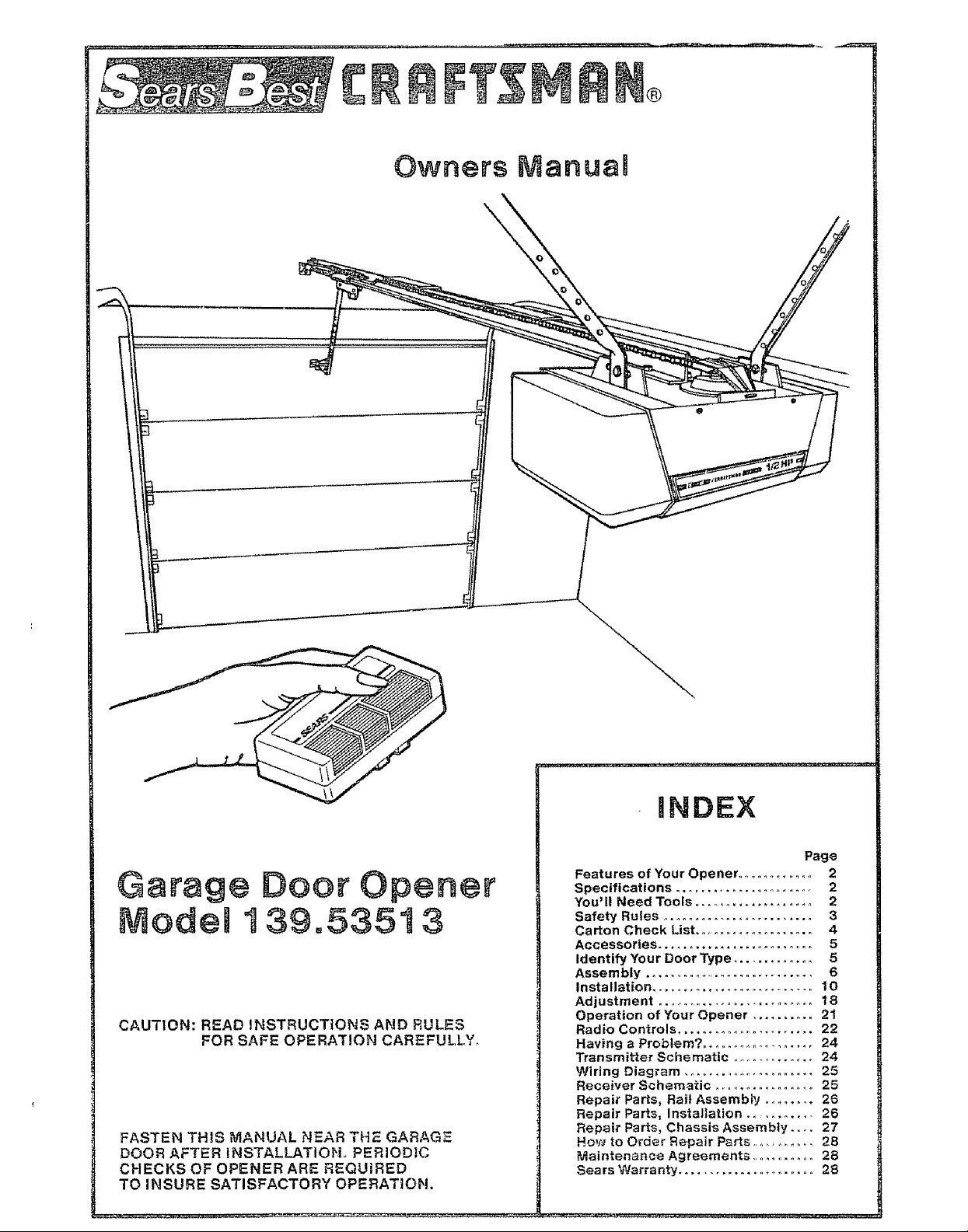

Craftsman 13953513 Owner’s Manual

Owners ManuaR

°° _ O/l/ °

Garage Door Opener

Modem 139.535t 3

CAUTION: READ INSTRUCTIONS AND RULES

FOR SAFE OPERATION CAREFULLY_

FASTEN THIS MANUAL NEAR THE GARAGE

DOOR AFTER INSTALLATIOH. PERIODIC

CHECKS OF OPENER ARE REQUIRED

TO INSURE SATISFACTORY OPERATIOH.

mNDIEX

Page

Features of Your Opener .............. 2

Specifications ........................ 2

You'll Need Tools ................... 2

Safety Rules ........................ 3

Carton Check List .................... 4

Accessories ......................... 5

Identify Your Door Type ............. 5

Assembly ............................. 6

Installation .......................... 10

Adjustment ........................... 18

Operation of Your Opener .......... 21

Radio Controls ....................... 22

Having a Problem? ..................... 24

Transmitter Schematic .............. 24

Wiring Diagram ...................... 25

Receiver Schematic .................. 25

Repair Parts, Rail Assembly .......... 26

Repair Parts, Installation ........... 26

Repair Parts, Chassis Assembly .... 27

How to Order Repair Parts ............. 28

• ]aintenance Agreements ........... 28

Sears Warranty ...................... 28

FEATURES OF YOUR OPENER

1. Opener Lights: Turn on and off automaticaflywith

4-1/2 minute illumination for your safety and con-

venience Provide constant light when Work Light

control button is pressed

2. Safety System: Independent up and down force

adjustment Door reverses automatically when ob-

structed in DOWN direction Door STOPS when

obstructed in UP direction.

3o Emergency Disconnect: Pull cord disconnect

permits manual door operation,

4_ Automatic Reconnect: Trolley halves reconnect

for automatic operation when opener is energized

after emergency discon nect.

5, Motor Power, 1/2 horsepower permanently lubri-

cated motor with automatic reseL

SPECIFICATIONS

MOTOR SAFETY

Type .....

Speed

Volts

Current

Gear reduction

Drive

Lubrication

Length of Travel

Travel rate

Lamp

Door linkage

1t2 horsepower, permanent split capacitor

1500 rpm

120 Volts AC- 60 Hz Only

4 5 amperes

DRIVE MECHANISM

!6:1

Chain & cable with two-piece trolley on

steel Tee rail

Motor is self-lubricated, Drive shaft bronze

oil-fit e bearings

Adjustable to 7-1/2 feet

6 to 8 inches per second

On when door starts in travel, oft 4-t/2

minutes after stop, Also separate Work

Light push button

Adjuslable doer arm Pull cord Irotley

release

6. Digital Radio Controls: 19,683 codes from which to

choose Can be changed easily by the owner

7.3-Channel Transmitter: Three push buttons, Each

button can activate one or more remote control

devices, The large transmitter button is factory

preset to operate the garage door opener_

8. Easy Limit Adjustment: Limits of door opening

and closing adjusted by turning screws without re-

moving chassis cover

9. Vacation Push Button: When the Vacation Push

Button is ON,the opener will not operate from the

transmitter The door will operate in the UP direc-

tion ONLY from the Wall Control (or optional Key

Switch accessory, Page 5).

Persona! Push button & automalic reversal in down

Electronic

Electrical

Limit device .

Limit adjustment

Start circuit

Length (overall) . 12!-t/2 inches

Headroom required 2 inches

Shipping Weight 43 pounds

direction Push button & automatic step tn

up direction

Independent up & down force adjustment

screws

Motor overload protector and low voltage

push button wiring

Circuil actuated by limit nut

Screwdriver adjustment on side panel

Low voltage push button or radio control

DIMENSIONS

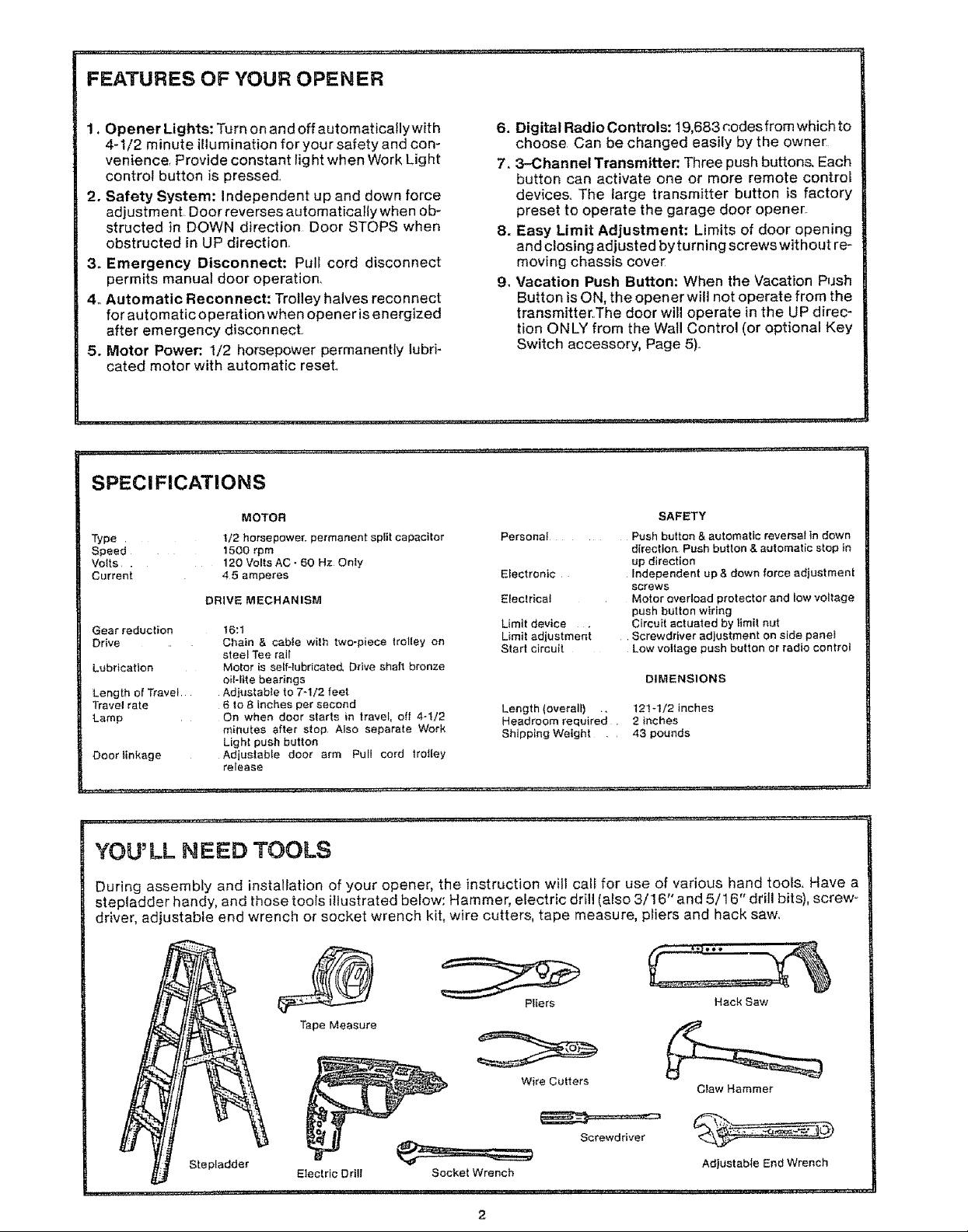

YOU' LL N EED TOOLS

During assembly and installation of your opener, the instruction will call for use of various hand tools. Have a

stepladder handy, and those tools illustrated below: Hammer, electric drill (also 3/16" and 5/16" drill bits), screw-

driver, adjustable end wrench or socket wrench kit, wire cutters, tape measure, pliers and hack saw.

Hack Saw

Claw Hammer

Adlustable End Wrench

Stepladder

Pliers

Tape Measure

Wire Cutters

Screwdriver

Electric Drill Socket Wrench

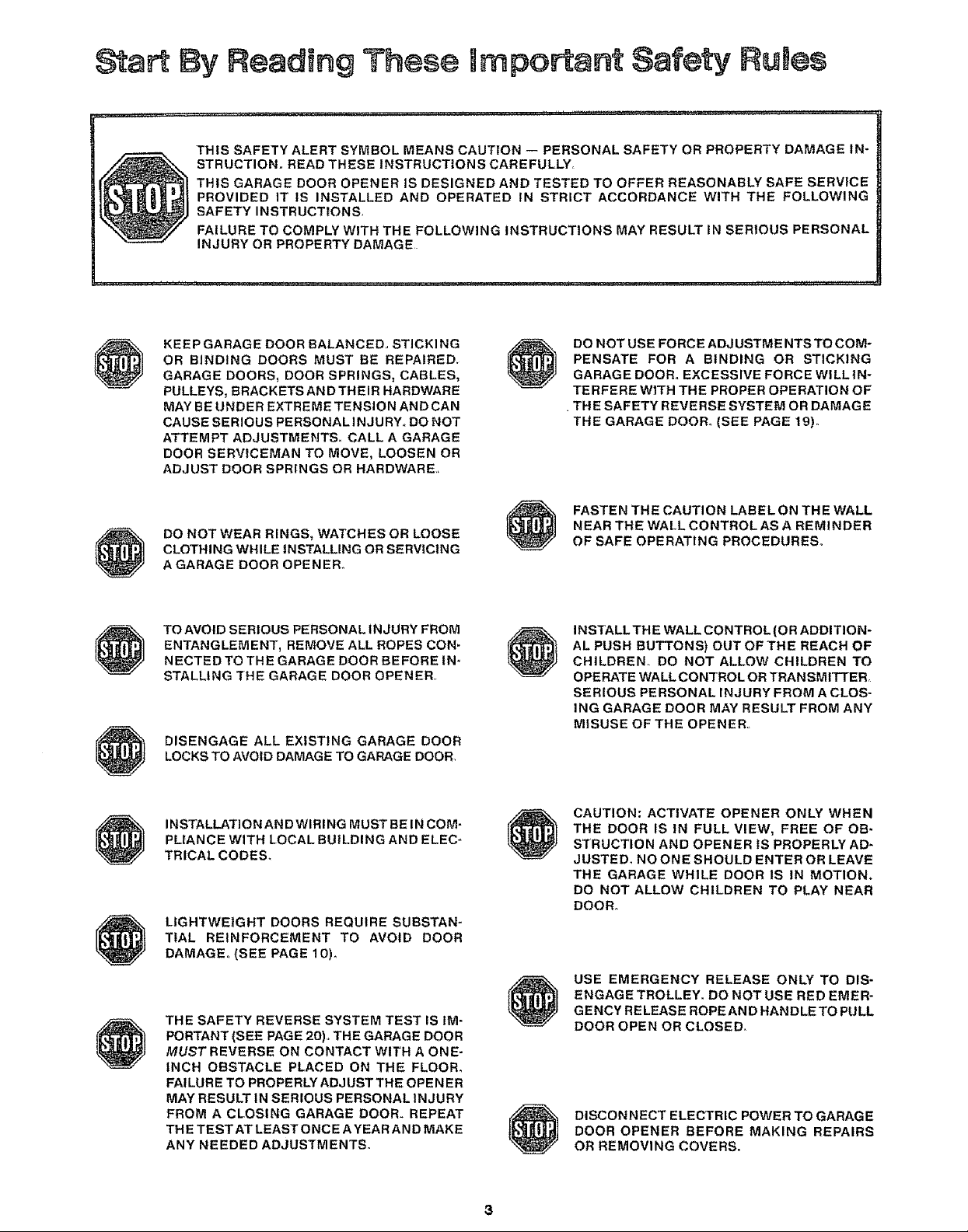

THIS SAFETY ALERT SYMBOL MEANS CAUTION -- PERSONAL SAFETY OR PROPERTY DAMAGE IN"

STRUCTION,, READ THESE INSTRUCTIONS CAREFULLY,

THIS GARAGE DOOR OPENER IS DESIGNED AND TESTED TO OFFER REASONABLY SAFE SERVICE

PROVIDED IT IS INSTALLED AND OPERATED tN STRICT ACCORDANCE WITH THE FOLLOWING

SAFETY INSTRUCTIONS,

FAILURE TO COMPLY WITH THE FOLLOWING INSTRUCTIONS MAY RESULT IN SERIOUS PERSONAL

INJURY OR PROPERTY DAMAGE

KEEP GARAGE DOOR BALANCED. STICKING

OR BINDING DOORS MUST BE REPAIRED.

GARAGE DOORS, DOOR SPRINGS, CABLES,

PULLEYS, BRACKETS AND THEIR HARDWARE

MAY BE UNDER EXTREME TENSION AND CAN

CAUSE SERIOUS PERSONAL INJURYo DO NOT

ATTEMPT ADJUSTMENTS.. CALL A GARAGE

DOOR SERVICEMAN TO MOVE, LOOSEN OR

ADJUST DOOR SPRINGS OR HARDWARE..

DO NOT WEAR RINGS, WATCHES OR LOOSE

CLOTHING WHILE INSTALLING OR SERVICING

A GARAGE DOOR OPENER°

TO AVOID SERIOUS PERSONAL INJURY FROM

ENTANGLEMENT, REMOVE ALL ROPES CON"

NECTED TO THE GARAGE DOOR BEFORE IN-

STALLING THE GARAGE DOOR OPENER.

DISENGAGE ALL EXISTING GARAGE DOOR

LOCKS TO AVOID DAMAGE TO GARAGE DOOR

DO NOT USE FORCE ADJUSTME NTS TO COM-

PENSATE FOR A BINDING OR STICKING

GARAGE DOOR. EXCESSIVE FORCE WILLtN-

TERFERE WITH THE PROPER OPERATION OF

. THE SAFETY REVERSE SYSTEM OR DAMAGE

THE GARAGE DOOR° (SEE PAGE 19)o

FASTEN THE CAUTION LABEL ON TH E WALL

NEAR THE WALL CONTROL AS A REMINDER

OF SAFE OPERATING PROCEDURES.

INSTALL THE WALL CONTROL (OR ADDITION-

AL PUSH BUTTONS) OUT OF THE REACH OF

CHILDREN, DO NOT ALLOW CHILDREN TO

OPERATE WALL CONTROL OR TRANSMITTER,

SERIOUS PERSONAL INJURY FROM A CLOS-

ING GARAGE DOOR MAY RESULT FROM ANY

MISUSE OF THE OPENER.

INSTALLATION AND WIRING MUST BE IN COM-

PLIANCE WITH LOCAL BUILDING AND ELEC-

TRICAL CODES.

LIGHTWEIGHT DOORS REQUIRE SUBSTAN-

TIAL REINFORCEMENT TO AVOID DOOR

DAMAGE° (SEE PAGE 10)o

THE SAFETY REVERSE SYSTEM TEST IS tM-

PORTANT (SEE PAGE 20),, THE GARAGE DOOR

MUST REVERSE ON CONTACT WITH A ONE-

INCH OBSTACLE PLACED ON THE FLOOR,

FAI LUR E TO PROPERLY ADJ UST THE OPE N E R

MAY RESULT IN SERIOUS PERSONAL INJURY

FROM A CLOSING GARAGE DOOR. REPEAT

TH E TEST AT LEAST ONC E A YEAR AN D MAKE

ANY NEEDED ADJUSTMENTS°

CAUTION: ACTIVATE OPENER ONLY WHEN

THE DOOR IS IN FULL VIEW, FREE OF OB-

STRUCTION AND OPENER IS PROPERLY AD _

JUSTED, NO ONE SHOULD ENTER OR LEAVE

THE GARAGE WHILE DOOR 1S tN MOTION.

DO NOT ALLOW CHILDREN TO PLAY NEAR

DOOR.

USE EMERGENCY RELEASE ONLY TO DIS"

ENGAGE TROLLEY. DO NOT USE RED EMER-

GENCY RE LEASE ROPE AND HANDLE TO PULL

DOOR OPEN OR CLOSED°

DISCONNECT ELECTRIC POWER TO GARAGE

DOOR OPENER BEFORE MAKING REPAIRS

OR REMOVING COVERS°

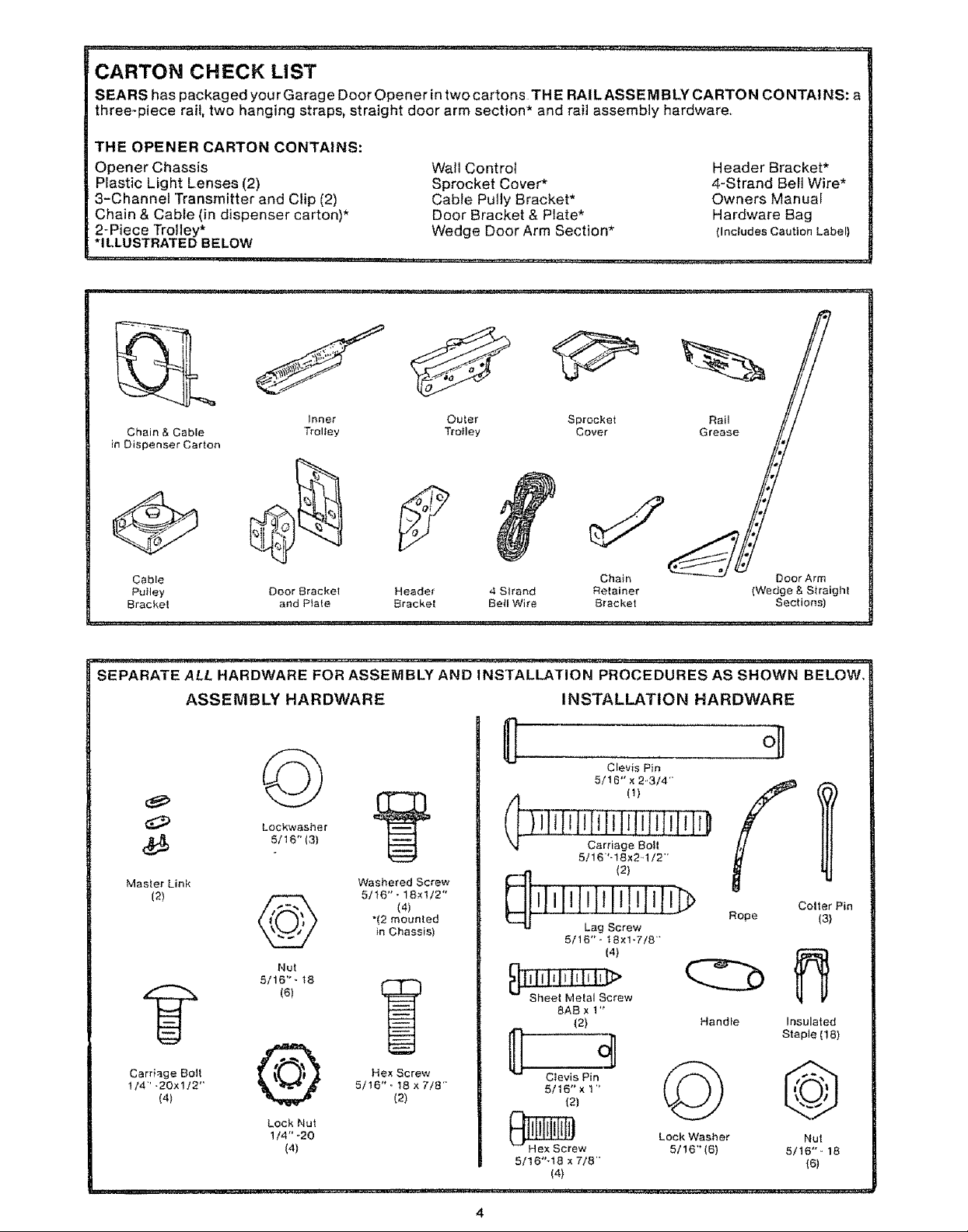

CARTON CHECK LiST

SEARS has packaged your Garage Door Opener in two cartons THE RAILASSEMBLY CARTON CONTAINS: a

three-piece rail, two hanging straps, straight door arm section* and rail assembly hardware

THE OPENER CARTON CONTAINS:

Opener Chassis

Plastic Light Lenses (2)

3-Channel Transmitter and Clip (2)

Chain & Cable (in dispenser carton)*

2-Piece Trolley*

*ILLUSTRATED BELOW

Wall Control

Sprocket Cover*

Cable Pully Bracket*

Door Bracket & Plate*

Wedge Door Arm Section*

Header Bracket*

4-Strand Bell Wire*

Owners Manual

Hardware Bag

(Inetudes Caution Label)

Chain & Cable Trolley

Inner

in Dispenser Carton

Outer

Trolley

Sprocket

Cover

J

Cable

Pulley Door Bracket

Bracket and Plate

SEPARATE ALL HARDWARE FOR ASSEMBLY AND INSTALLATION PROCEDURES AS SHOWN BELOW,

Header 4 S_rand

Bracket Bell Wire

ASSEMBLY HARDWARE

]lqTF[iiilili illD

(_ 5/16" (3)

Master Link

(2)

Lockwasher

@

5/16" - 18

Nut

(e)

Washered Screw

5/16" - 18xl/2"

(4)

"(2 mounted

in Chassis)

"%,[ Carriage Bolt

Chain Door Arm

Retainer (Wedge & Straight

Bracket Sections)

INSTALLATION HARDWARE

Clevis Pin

5/16" x 2,3/4"

(1)

5/16'-18x2,1/2""

(2)

Rope (3)

5/16 "° 18xl-7/8"

(4)

BAB x 1"

(2)

Handle Insulated

Coller Pin

Staple (18)

Carriage Bolt

1/4"-20xl/2"

(4)

@

Lock Nut

1/4"-20

(4)

Hex Screw

5/16 "_ 18 x 7/8'

(2)

Clevis Pin

5/16" x 1 "

(2)

5/16"-18 × 7/8'"

(4)

© @

Lock Washer Nut

5/16"(6) 5/16"- 18

(6)

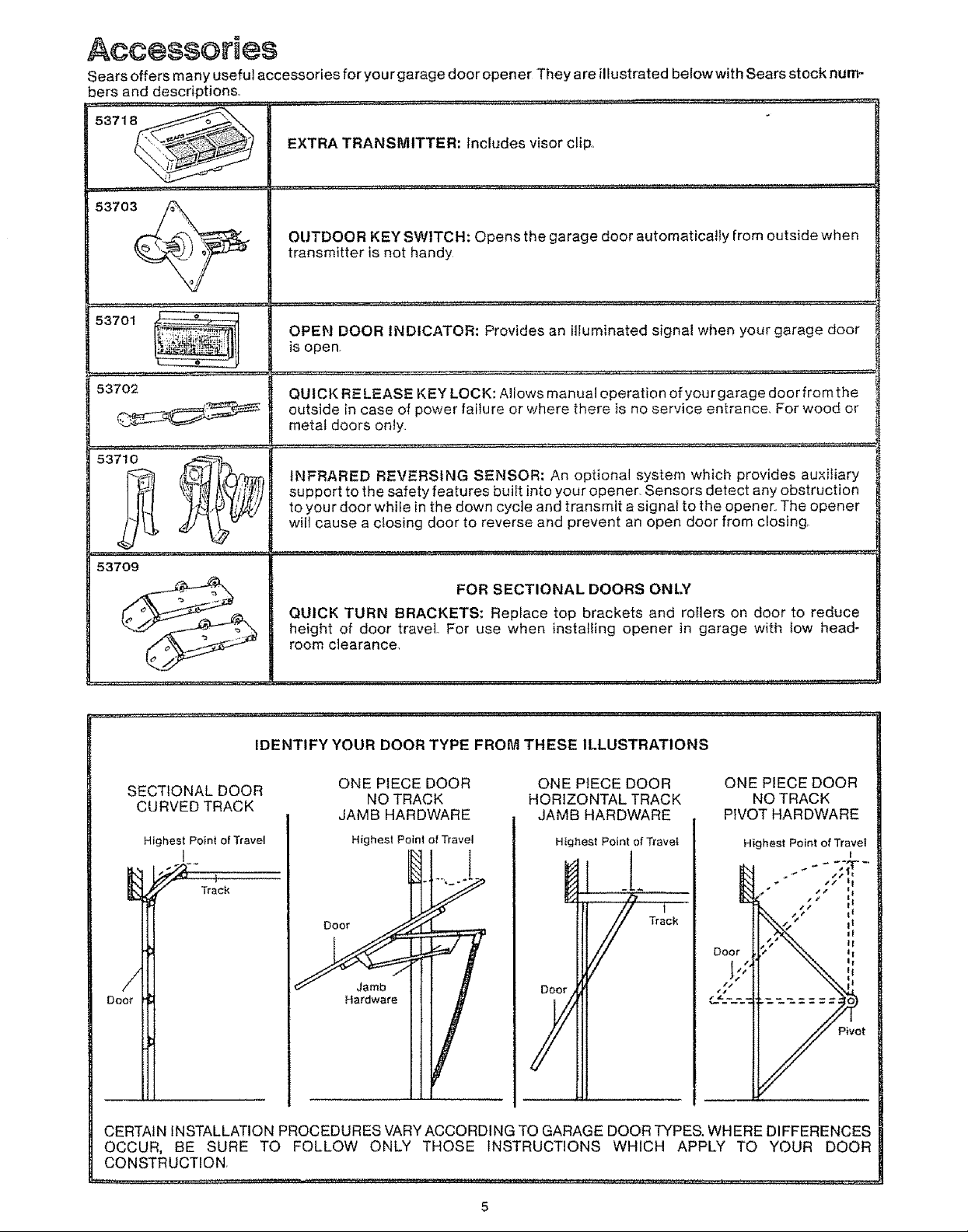

Acc÷ssGries

Sears offers many useful accessories for your garage door open er They are illustrated below with Sears stock num-

bers and descriptions.,

EXTRA TRANSMITTER: Includes visor clip

5371

5370_/C.__r_/_ OUTDOOR KEY SWITCH: Opens the garage door automatically from outside when

transmitter is not handy

53701 _--

....... , ,z. _..........

53702

53709

....... , ,,,,,,,........

OPEN DOOR INDICATOR: Provides an illuminated signal when your garage door

is open,

QUICK RELEASE KEY LOCK: Allows manual operation of your garage door fromthe

outside in case of power failure or where there is no service entrance, For wood or

metal doors only,

INFRARED REVERSING SENSOR: An optional system which provides auxiliary

support to the safety features built into your opener, Sensors detect any obstruction

to your door whi_e in the down cycle and transmit a signal to the opener, The opener

wilt cause a closing door to reverse and prevent an open door from closing,

FOR SECTIONAL DOORS ONI.Y

QUICK TURN BRACKETS: Replace top brackets and rollers on door to reduce

height of door travel, For use when installing opener in garage with Iow head-

room clearance,

IDENTIFY YOUR DOOR TYPE FROM THESE ILLUSTRATIONS

SECTIONAL DOOR

CURVED TRACK

Highest Point of Travel

I

ONE PIECE DOOR

NO TRACK

JAMB HARDWARE

Highest Point of Travel

ONE PIECE DOOR

HORIZONTAL TRACK

JAMB HARDWARE

Highest Point of Travet

Track

ONE PIECE DOOR

NO TRACK

PIVOT HARDWARE

/,

Hardware

t

CERTAIN iNSTALLATION PROCEDURES VARY ACCORDING TO GARAGE DOOR TYPES. WHERE DIFFERENCES

OCCUR, BE SURE TO FOLLOW ONLY THOSE INSTRUCTIONS WHICH APPLY TO YOUR DOOR

CONSTRUCTION,

Door

AssembUy

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE GARAGE DOOR OPENER UNTIL YOU HAVE

COMPLETED STEP 8, PAGE ! 5.

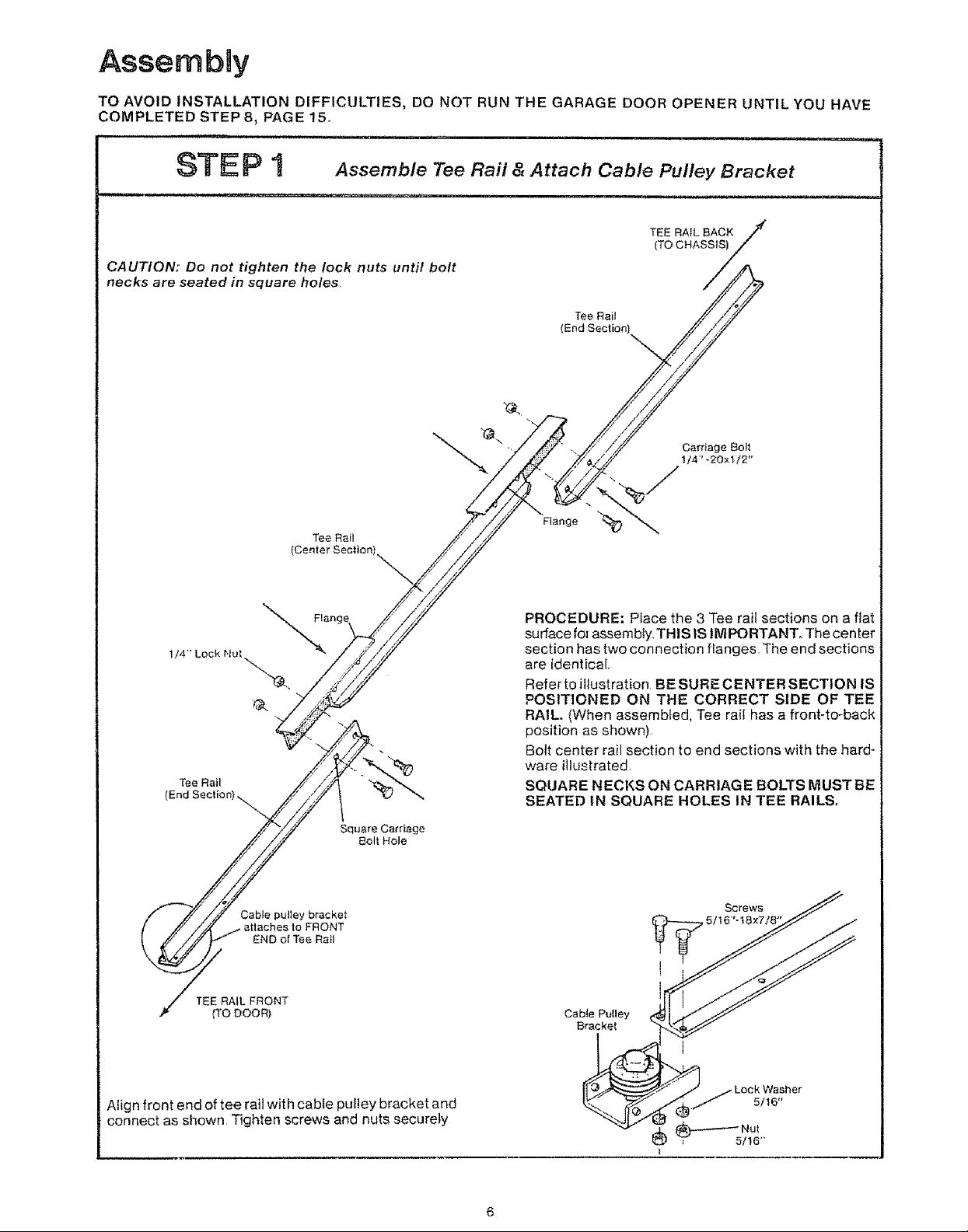

STE P 1 AssemblereoRa,_AttachCabl_P.,_yBr_okot

, ,=_==,,,,,= ,=, ,,,= .... =,,

TEE RAIL BACK

(TO CHASSIS)

CA UTtON: Do not tighten the lock nuts until bolt

necks are seated in square holes.

TeaRail

(End Section)

\

Carriage Bolt

!/4" -20×1/2"

I14""Lock Nut

Tee Rail

(End Sectior

Tee Rail

(Center

Cable pulley bracket

attaches to FRONT

END of Tee Rail

Square Carriage

Bolt Hole

Flange

PROCEDURE: Ptace the 3 Tee rail sections on a flat

surface fol assembly.. THIS lS IMPORTANT. The center

section has two connection flanges. The end sections

are identical.

Refer to illustration BE SURE CENTER SECTION IS

POSITIONED ON THE CORRECT SIDE OF TEE

RAIL. (When assembled, Tee rail has a front-to-back

position as shown)

Bott center rail section to end sections with the hard-

ware illustrated,

SQUARE NECKS ON CARRIAG E BOLTS MUST BE

SEATED IN SQUARE HOLES IN TEE RAILS,

Screws

TEE RAIL FRONT

(TO DOOR) Cabie Pulley

Align front end of tee rait with cable puItey bracket and

connect as shown Tighten screws and nuts securely

Bracket

Assembmy

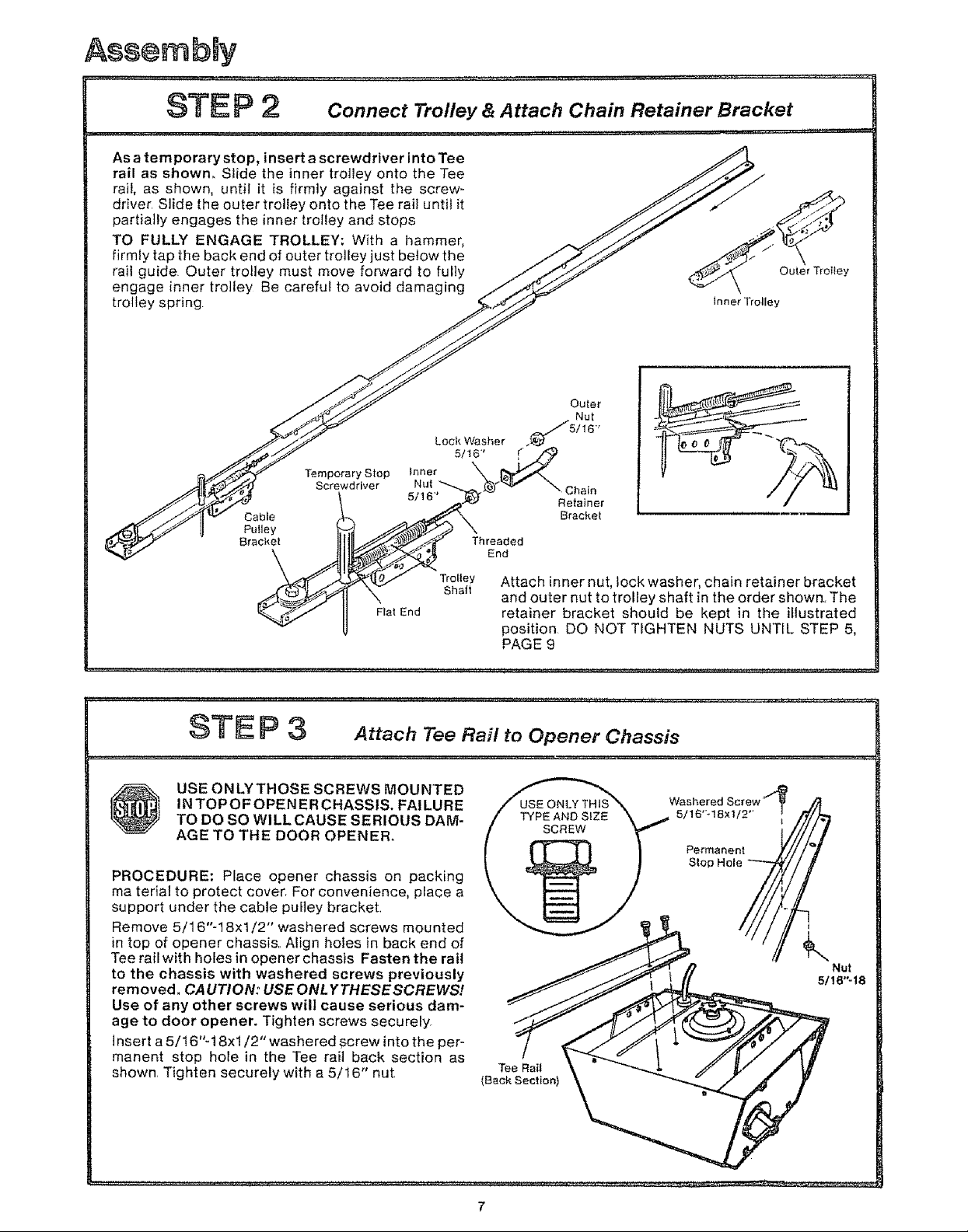

STE P 2 connect Trolley & Attach Chain Retainer Bracket

, ..... , _,_,,u,,

As a temporary stop, insert a screwdriver into Tee

rail as shown° Siide the inner trolley onto the Tee

rail, as shown, until it is firmly against the screw-

driver Slide the outer trolley onto the Tee rail until it

partially engages the inner trolley and stops

TO FULLY ENGAGE TROLLEY; With a hammer,

firmly tap the back end of outer trolley just below the

rail guide Outer trolley must move forward to fully

engage inner trolley Be careful to avoid damaging

trolley spring

_ Outer TrotleY

_nner Trolley

Outer

Nut

Lock Washer ._//5/16"

Cable

PuIley

Bracket

Temporary Stop

Screwdriver

Inner 5/1_

Nut _ Chain

\

Trolley

Shaft

Flat End

USE ON LY THOSE SCREWS MOUNTED

@

PROCEDURE: Place opener chassis on packing

ma terial to protect cover, For convenience, place a

support under the cable pu[]ey bracket.

Remove 5/16"-t 8xt/2" washered screws mounted

in top of opener chassis. Align hotes in back end of

Tee rail with holes in opener chassis Fasten the rail

to the chassis with washered screws previously

rein eve& CA UTION: USE ONLY THESESCREWS!

Use of any other screws will cause serious dam-

age to door opener. Tighten screws securely_

insert a 5/16"-18xl/2" washered screw into the per-

manent stop hole in the Tee rail back section as

shown Tighten securely with a 5/16" nut

IN TOPOF OPENER CHASSIS. FAILURE

TO DO SO WiLL CAUSE SERIOUS DAM-

AGE TO THE DOOR OPENEE

Retainer

Bracket

Threaded

End

Attach inner nut, lock washer, chain retainer bracket

and outer nut to trolley shaft in the order shown.. The

retainer bracket should be kept in the illustrated

position DO NOT TIGHTEN NUTS UNTIL STEP 5,

PAGE 9

Washered Screw 4

5/16"d 8xt/2" _

Permanent _/

Slop Hole_

Nut

5/16"-18

Tee Rail

(Back Section)

7

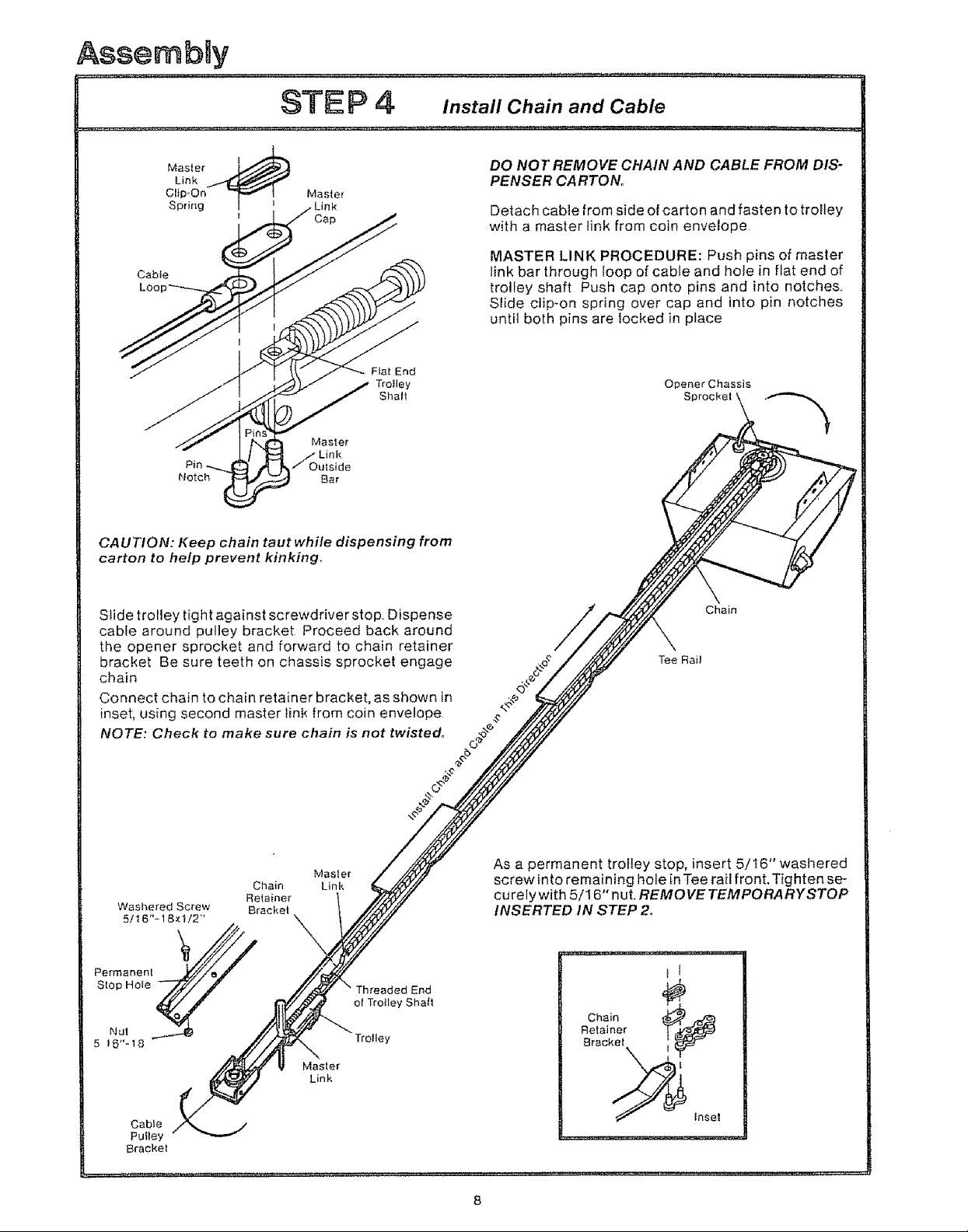

AssembBy

Cable

LOOl

Notch

Masle_

Master

Outside

B,3r

Flat End

Trofley

ShaN

DO NOT REMOVE CHAIN AND CABLE FROM DIS-

PENSER CA RTON.

Detach cable from side of carton and fasten to tro!ley

with a master link from coin envelope

MASTER LINK PROCEDURE: Push pins of master

link bar through loop of cable and hole in flat end of

trolley shaft Push cap onto pins and into notches,

Slide clip-on spring over cap and into pin notches

until both pins are locked in place

Opener Chassis

Sprocket

CAUTION: Keep chain taut while dispensing from

carton to help prevent kinking,

Stide trolley tight against screwdriver stop. Dispense

cable around pulley bracket Proceed back around

the opener sprocket and forward to chain retainer

bracket Be sure teeth on chassis sprocket engage

chain

Connect chain to chain retainer bracket, as shown in

inset, using second master link from coin envelope.

NOTE: Check to make sure chain is not twisted.

Chain

Washered Screw Bracket

5/16"_18×1/2"'

Retainer

Masler

Link

Threaded ;End

of Trolley Shaft

Chain

Tee Rail

As a permanent trolley stop, insert 5/16" washered

screw into remaining hole in Tee rail front, Tighten se-

curely with 5/16" nut. REMOVE TEMPORARYSTOP

INSERTED IN STEP 2_

5 t 6"_18

Cable

Pulley

Bracket

Trolley

Master

Link

AssembRy

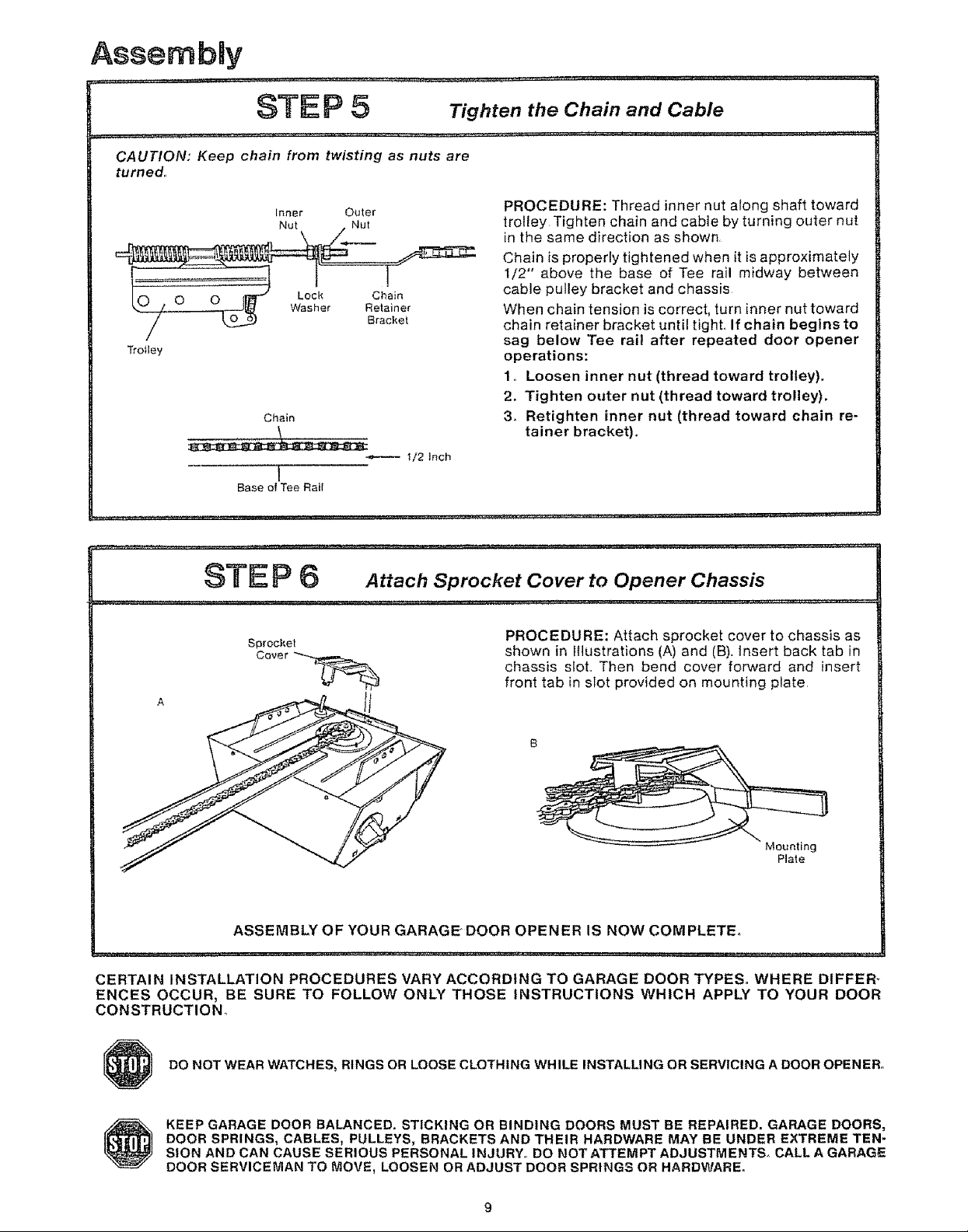

STEP 5 tightenthe Chain and Cable

CAUTION: Keep chain from twisting as nuts are

turned,

Trolley

Inner Outer

-T

_ Bracket

Chain

\

-,*------ 1/2 Inch

1

Base of Tee Rail

,r ,, , ,, ,,, ,'_' h/, ' '"'" '"'*"_'"'"""' *H' ............. n'

PROCEDURE: Thread inner nut along shaft toward

trolley Tighten chain and cable by turning outer nut

in the same direction as shown,

Chain is properly tightened when it is approximately

1/2" above the base of Tee rail midway between

cable pulley bracket and chassis

When chain tension is correct, turn inner nut toward

chain retainer bracket until tight, If chain begins to

sag below Tee rail after repeated door opener

operations:

1, Loosen inner nut (thread toward trolley).

2. Tighten outer nut (thread toward trolley).

3, Retighten inner nut (thread toward chain re-

tainer bracket)°

STE P 6 Attach Sprocket Cover to Opener Chassis

Sprocket

Cover _-_

PROCEDURE: Attach sprocket cover to chassis as

shown in Illustrations (A) and (B). Insert back tab in

chassis slot,, Then bend cover forward and insert

front tab in slot provided on mounting plate

Mounting

Plate

ASSEMBLY OF YOUR GARAGE" DOOR OPENER IS NOW COMPLETE°

CERTAIN INSTALLATION PROCEDURES VARY ACCORDING TO GARAGE DOOR TYPES. WHERE DIFFER _

ENCES OCCUR, BE SURE TO FOLLOW ONLY THOSE INSTRUCTIONS WHICH APPLY TO YOUR DOOR

CONSTRUCTION°

DO NOT WEAR WATCHES, RINGS OR LOOSE CLOTHING WHILE INSTALLING OR SERVICING A DOOR OPENER.

KEEP GARAGE DOOR BALANCED. STICKING OR BINDING DOORS MUST BE REPAIRED. GARAGE DOORS,

DOOR SPRINGS, CABLES, PULLEYS, BRACKETS AND THEIR HARDWARE MAY BE UNDER EXTREME TEN-

S|ON AND CAN CAUSE SERIOUS PERSONAL INJURY. DO NOT ATTEMPT ADJUSTMENTS° CALL A GARAGE

DOOR SERVICEMAN TO MOVE, LOOSEN OR ADJUST DOOR SPRINGS OR HARDWARE.

Loading...

Loading...