Page 1

Owner'sManual/ManualDelPropietario

I:RRFI"$MRN

GARAGEDOOROPENER

ABRIDORDEPUERTADE COCHERA

ForResidentialUse0nly/S61oparausoresidencial

Model/Modelo139.30437

I"11

Z

Read and follow all safety rules and operating

instructions before first use of this product.

Fastenthemanualnearthe garagedoorafter

installation.

Periodic checksofthe openerare requiredto

ensuresafeoperation.

DONOTenablethe Timer-To-Closefeatureif

you are installingthe garagedooropenerona

one-piecedoor.TheTimer-To-Closeisto be

usedONLYwithsectionaldoors.

oOus

I"11

'13

:=,

Z_

Leery seguirtodas lasreglasdeseguridady las

instruccionesdeoperaci6nantesdeusareste

productoporprimeravez.

Guardareste manualcercadela puertadela

cochera.

Se debenrealizar revisionesperi6dicas del

abridorde puertas para asegurarsuoperaci6n

segura.

NOusoel caracteristicaTemporizadorpara

cierrase el abridorde la puerta es instaladoen

unpuertadeunsola pieza. Elcaracteristica

temporizadorparacierraesSOLOpara usocon

puertasseccionales.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.craftsman.com

Page 2

TABLE OF CONTENTS

Introduction 2-7

Safetysymbol and signal word review..................... 2

Preparing your garagedoor ............................. 3

Tools needed ........................................ 3

Planning ........................................... 4-5

Carton inventory ...................................... 6

Hardware inventory.................................... 7

Assembly 8-11

Assemblethe rail andinstall the trolley .................... 8

Fastenthe rail to the motor unit .......................... 8

Install the idler pulley .................................. 9

Install the chain/cable................................. 10

Tighten the chain .................................... 11

Installation 11-27

Installation safetyinstructions .......................... 11

Determinethe headerbracket location .................... 12

Install the headerbracket .............................. 13

Attach the railto the headerbracket...................... 14

Position the opener................................... 15

Hangthe opener..................................... 16

Install the lights ..................................... 17

Attach the emergencyreleaserope and handle ............. 17

Fastenthe door bracket ............................. 18-19

Connectthe door arm to trolley ....................... 20-21

Attach the warning labels .............................. 21

Install the door control ................................ 22

Install The Protector System®......................... 23-26

Electrical requirements ................................ 26

Aligning the safety reversingsensors................... 26-27

Adjustment 27-29

Introduction ........................................ 27

Program the travel ................................... 28

Testthe safety reversalsystem.......................... 29

TestThe Protector System®............................ 29

Operation 30-34

Operationsafety instructions ........................... 30

Features ......................................... 30-31

Door control ........................................ 31

Motion-detecting control panelsetup ..................... 32

Programming ....................................... 33

To erasethe memory ................................. 33

To open the door manually............................. 34

Careof your opener .................................. 34

Troubleshooting 35-36

Repair Parts 37-38

Rail assembly parts .................................. 37

Installation parts..................................... 37

Motor unit assembly parts ............................. 38

Accessories 39

Warranty 39

Repair Parts and Back Cover

Service

INTRODUCTION

SafetySymboland SignalWordReview

This garage door openerhas beendesignedand tested to offer safe serviceprovided it is installed, operated,maintained and tested in

strict accordancewith the instructions and warnings contained inthis manual.

Whenyou seethese SafetySymbols and Signal Words on the

following pages,they will alertyou to the possibility of serious

Mechanical

Electrical

injury or deathif you do not comply with the warnings that

accompanythem. Thehazard may come from something

mechanicalor from electric shock. Readthe warnings carefully.

Whenyou seethis Signal Word on the following pages, it will

alertyou to the possibility of damageto your garagedoor and/or

the garagedoor opener if you do not comply with the cautionary

statements that accompanyit. Readthem carefully.

Page 3

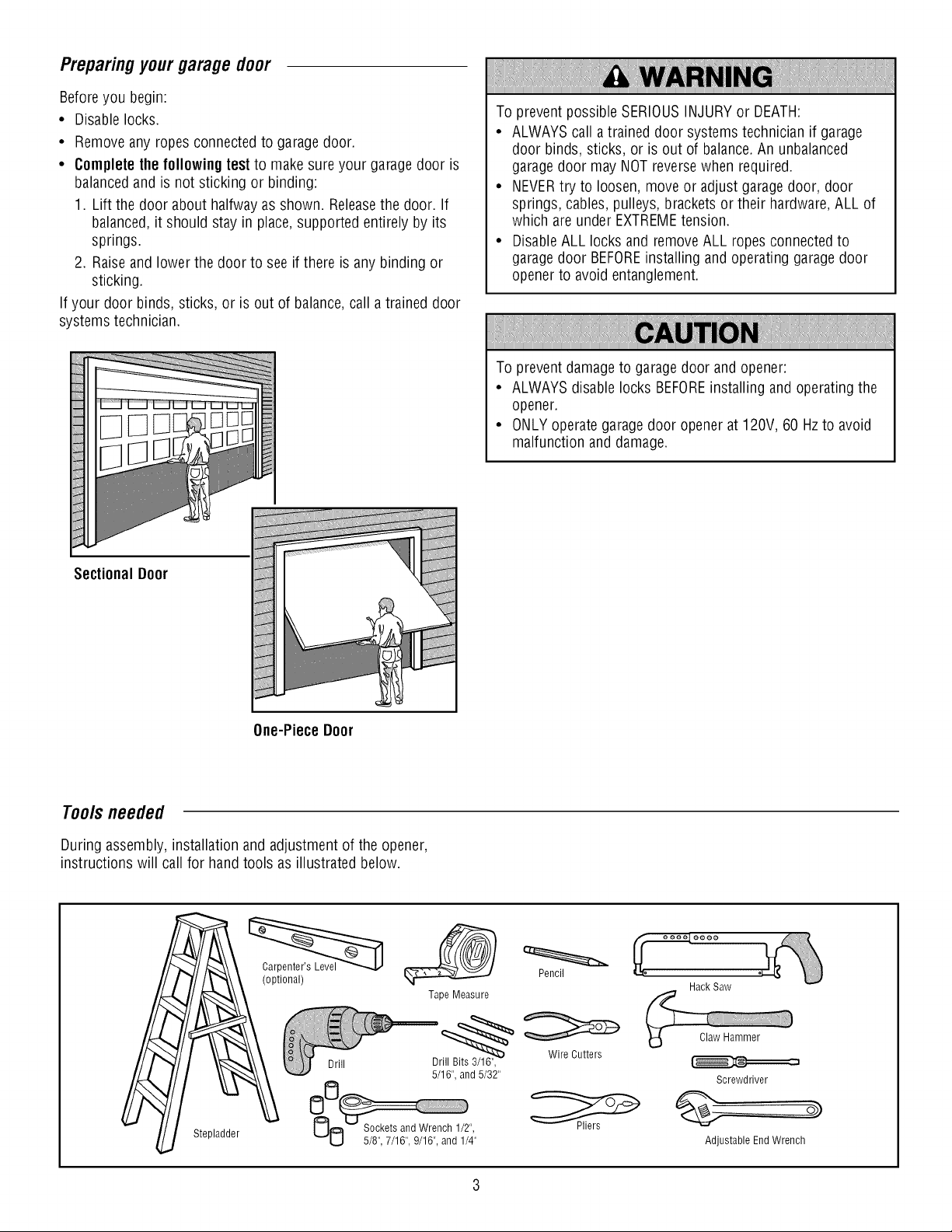

Preparingyourgaragedoor

Beforeyou begin:

• Disable locks.

• Removeany ropesconnected to garage door.

• Completethe followingtest to make sureyour garage door is

balancedand is not sticking or binding:

1. Lift the door about halfwayas shown. Releasethe door. If

balanced,it should stay in place,supported entirelyby its

springs.

2. Raiseand lower the door to see if there is any binding or

sticking.

If your door binds, sticks, or is out of balance,call atrained door

systems technician.

To prevent possible SERIOUSINJURYor DEATH:

• ALWAYScall atrained door systems technician if garage

door binds, sticks, or is out of balance.An unbalanced

garagedoor may NOTreversewhen required.

• NEVERtry to loosen, move or adjust garagedoor, door

springs, cables,pulleys, brackets or their hardware,ALL of

which areunder EXTREMEtension.

• DisableALL locks and removeALL ropes connectedto

garagedoor BEFOREinstalling andoperating garagedoor

opener to avoidentanglement.

To prevent damage to garage door and opener:

• ALWAYSdisable locks BEFOREinstalling and operatingthe

opener.

• ONLYoperate garagedoor openerat 120V, 60 Hzto avoid

malfunction and damage.

Sectional Door

One-Piece Door

Tools needed

During assembly, installation and adjustment of the opener,

instructions will call for hand tools as illustrated below.

(optional)

Tape Measure

Pencil

Hack Saw

Stepladder

Screwdriver

Adjustable EndWrench

Page 4

P_nnmg

Identify the type and height of your garagedoor. Surveyyour

garage areato see if any of the conditions below apply to your

installation. Additional materials may be required. You mayfind it

helpful to refer back to this page andthe accompanying

illustrations asyou proceedwith the installation of your opener.

Dependingon your requirements,there areseveralinstallation

steps which may call for materialsor hardware not included in the

carton.

• Installation Step 1 - Lookat the wall or ceiling abovethe

garagedoor. Theheader bracket must be securelyfastenedto

structural supports.

• Installation Step 5 - Doyou havea finished ceiling in your

garage? If so,a support bracket and additional fastening

hardware may be required.

• Installation Step 12- Dependingupon garageconstruction,

extension brackets or wood blocks may be neededto install

sensors.

• Installation Step 12- Alternatefloor mounting of the safety

reversingsensor will require hardwarenot provided.

Doyou havean access door in addition to the garagedoor? If

not, Model 139.53702 Emergency KeyReleaseis required. See

Accessoriespage.

Lookat the garage door where it meetsthe floor. Any gap

betweenthe floor andthe bottom of the door must not exceed

1/4" (6 mm). Otherwise,the safety reversalsystem may not

work properly. SeeAdjustment Step 2. Floor or door should be

repaired.

SECTIONALDOORINSTALLATIONS

• Doyou havea steel, aluminum, fiberglass or glass panel door?

If so, horizontal andvertical reinforcement is required

(Installation Step8).

• Theopenershould be installed abovethe center of the door. If

there is atorsion spring or centerbearingplate in theway of

the header bracket, it may beinstalled within 4 feet (1.22 m) to

the left or right of the door center.See Installation Steps 1

and 8.

• If your door is more than 7 feet (2.13 m) high, seerail

extension kits listed onAccessories page.

SECTIONALDOORINSTALLATION

Horizontal and vertical reinforcement is

neededfor lightweight garage doors

(fiberglass, steel, aluminum, door with glass

panels, etc.) Seepage 18 for details.

Header Wall

Vertical Centerline

of Garage Door

Gap between floor and bottom

of the door must not exceed

Safety Reversing Sensor

1/4" (6 mm).

Slack in chain tension is

normal when garage door

is closed.

Torsion Spring

Wall-mounted

Door Control

Safety Reversing Sensor

OR

Access Door

Sprin,

0

FINISHEDCEILING

Support bracket

& fastening

hardware is required. See

page 16.

Header CLOSEDPOSITION

Bracket

Trolley Stop Bolt Trolley

Garage Door

Spring

Door

Bracket

Motor Unit

Curved

Door Arm

Chain

Emergency

Release

Rope & Handle

Page 5

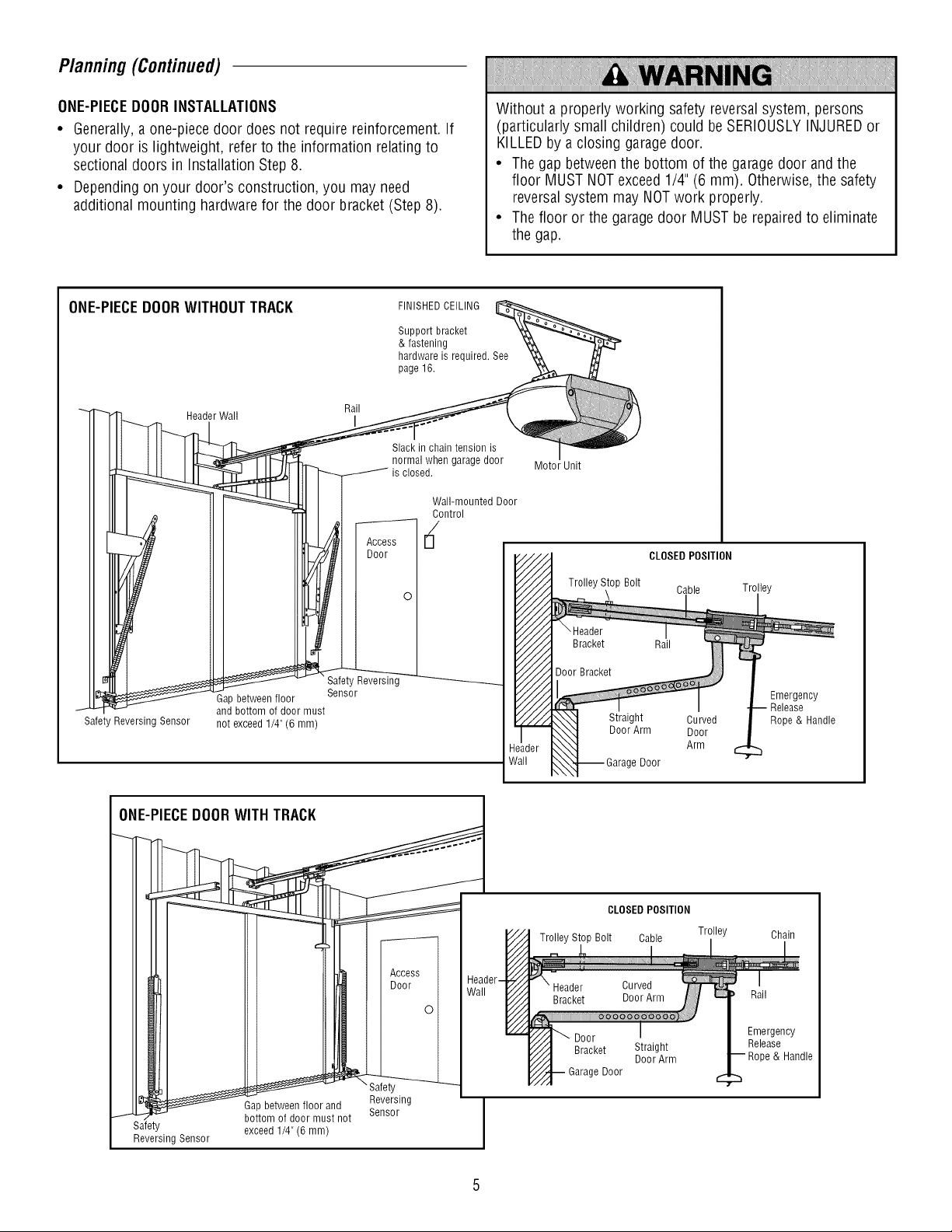

Planning(Continued)

ONE-PIECEDOORINSTALLATIONS

• Generally,a one-piecedoor does not require reinforcement. If

your door is lightweight, refer to the information relatingto

sectional doors in Installation Step 8.

• Dependingon your door's construction, you may need

additional mounting hardware for the door bracket (Step8).

ONE-PIECEDOORWITHOUTTRACK

Rail

Header Wall I

FINISHEDCEILING

Support bracket

& fastening

hardware is required. See

page 16.

Slack in chain tension is

normal when garage door

is closed.

Wall-mounted Door

Without a properly working safety reversal system, persons

(particularly small children) could beSERIOUSLYINJUREDor

KILLEDby a closing garagedoor.

• Thegap betweenthe bottom of the garagedoor andthe

floor MUST NOTexceed1/4" (6 mm). Otherwise,the safety

reversalsystem may NOTwork properly.

• Thefloor or the garage door MUSTbe repairedto eliminate

the gap.

Motor Unit

CLOSEDPOSITION

I and bottom of door must

Safety Reversing Sensor not exceed 1/4" (6 mm)

Gap between floor

Safety Reversing

Sensor

Trolley Stop Bolt

CLOSED POSITION

Trolley Stop Bolt Cable Trolley

e Door

Door

Straight

DoorArm

Cable Trolley

Curved

Door

Arm

Emergency

Release

Rope & Handle

Chain

Rail

Emergency

Release

& Handle

_-°nruass _dnot _!!!sing _ I

Safety

Reversing Sensor J

Gap between floor and ..... I

exceed 1/4" (6 mm)

Reversing

S_HbU/

Page 6

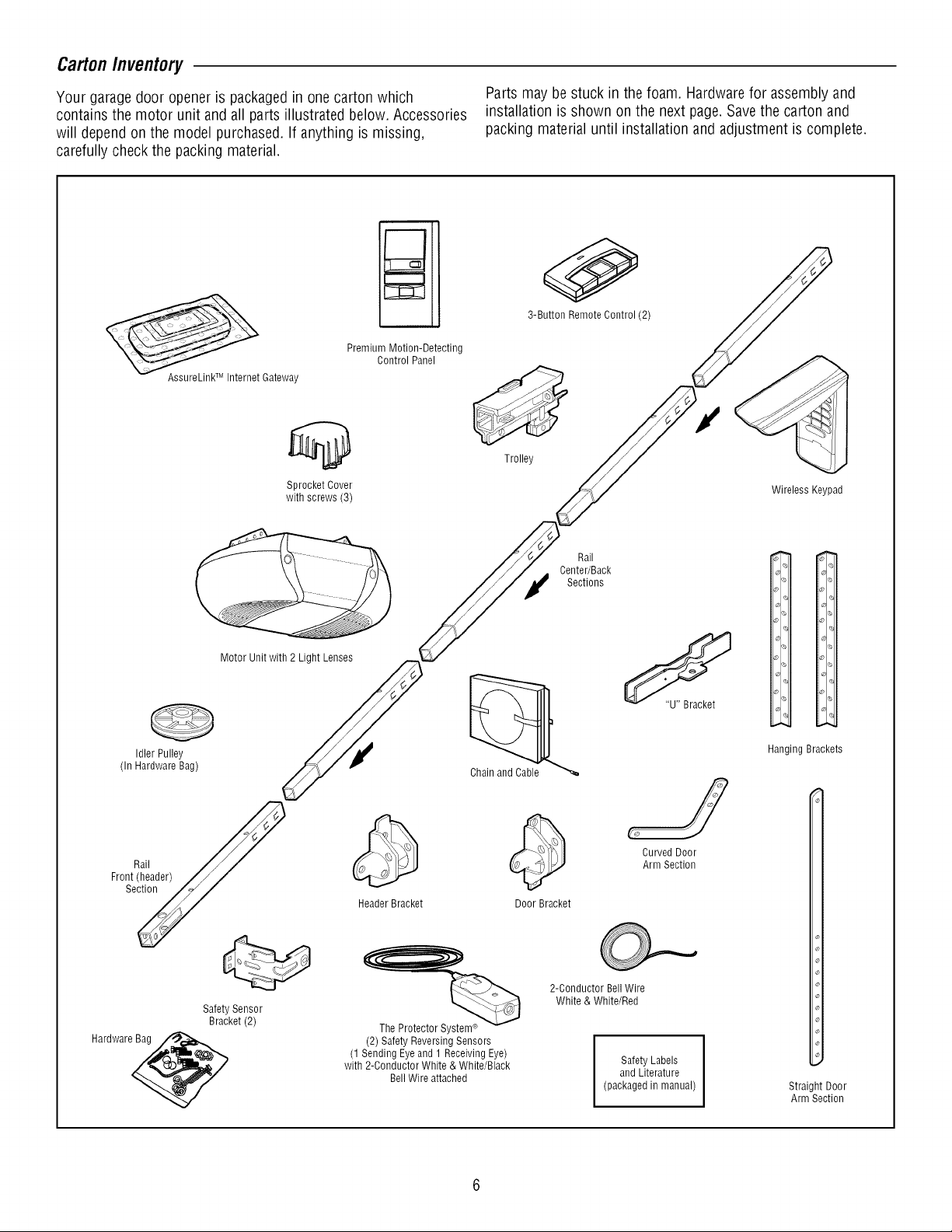

CartonInventory

Your garagedoor openeris packagedin onecarton which

contains the motor unit andall parts illustrated below. Accessories

will depend on the model purchased. If anything is missing,

carefully check the packing material.

Premium Motion-Detecting

Control Panel

AssureLinkTM Internet Gateway

Sprocket Cover

with screws (3)

Parts maybestuck in the foam. Hardwarefor assembly and

installation is shown on the next page.Savethe carton and

packing materialuntil installation and adjustment is complete.

0

3-Button Remote Control (2)

Trolley

Wireless Keypad

(In Hardware Bag)

Front_i_ader)

Hardware_

Idler Pulley

Motor Unit with 2 Light Lenses

Safety Sensor

Bracket (2)

Chain and Cable

Header Bracket

The Protector System®

(2) Safety Reversing Sensors

(1 Sending Eyeand 1 Receiving Eye)

with 2-Conductor White & White/Black

BellWire attached

Center/Back

Door Bracket

2-Conductor BellWire

White & White/Red

Rail

Sections

(packaged in manual)

CurvedDoor

ArmSection

Safety Labels

and Literature

i.

_)1 ,,,

% _l_

Ol

io

I%

I<_

% <

Ol o] c_

Hanging Brackets

Straight Door

Arm Section

Page 7

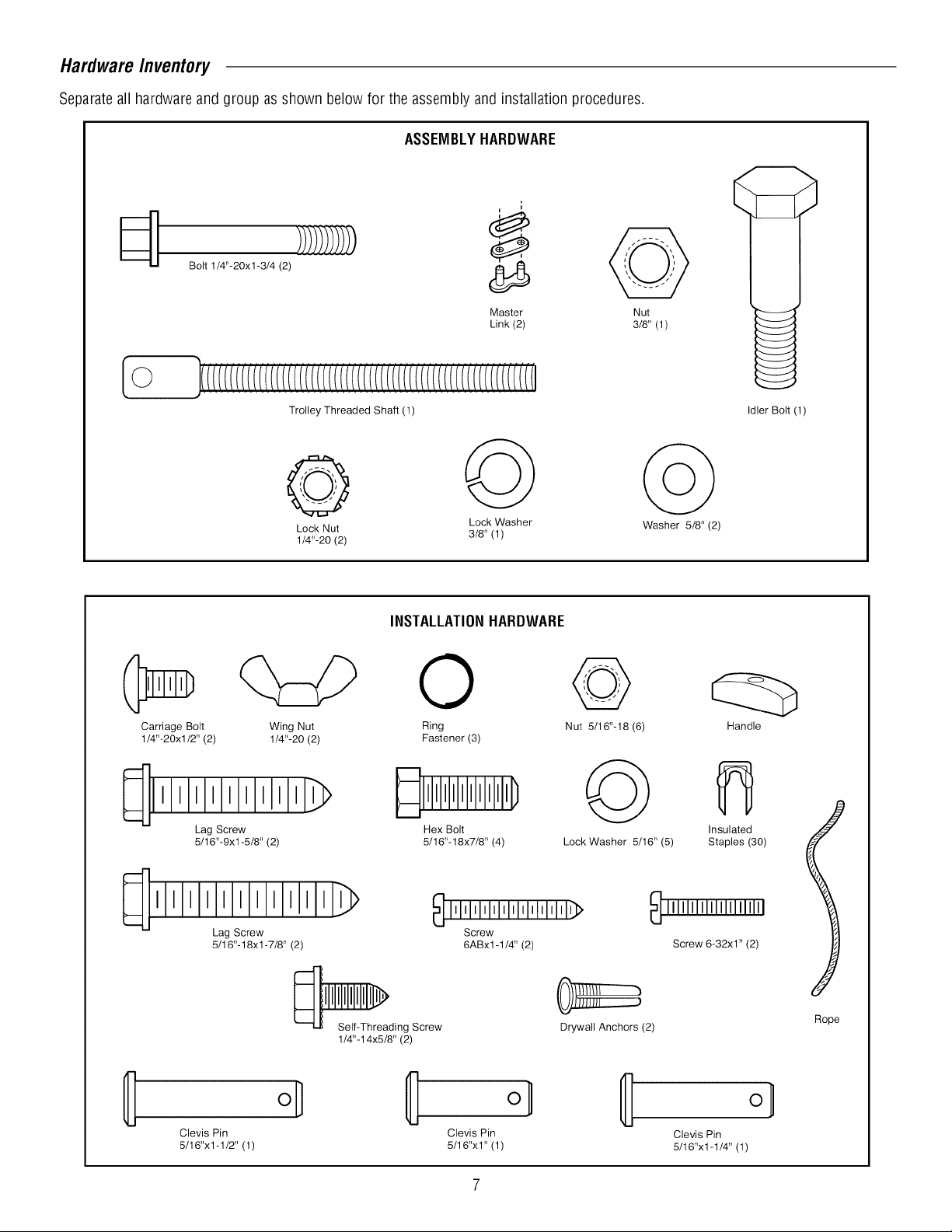

HardwareInventory

Separateall hardwareandgroup as shown below for the assembly andinstallation procedures.

ASSEMBLYHARDWARE

Bolt 1/4"-20xl-3/4 (2)

Master

Link (2)

Trolley Threaded Shaft (1)

Lock Nut 3/8' (1)

1/4"-20 (2)

Lock Washer Washer 5/8' (2)

INSTALLATIONHARDWARE

0

Carriage Bolt Wing Nut Ring Nut 5116"-18 (6)

1/4"-20xl/2" (2) 1/4"-20 (2) Fastener (3)

Nut

3/8' (1)

Idler Bolt (1)

Handle

Lag Screw Hex Bolt

5/16"-9xl-5/8" (2) 5/16"-18x7/8" (4) Lock Washer 5/16" (5)

111111111111_>

Lag Screw

5/16"-18xl -7/8" (2)

Self-Threading Screw

1/4"-14x5/8" (2)

Clevis Pin Clevis Pin

5/16"x1-1/2" (1) 5/16"x1" (1)

_ IMIMl'l'lllllllllllllll'l_

Screw

6ABx1-1/4" (2)

JIH/I J

Drywall Anchors (2)

Insulated

Staples (30)

_ IIIIIIIIIIIIIIIIIIIII

Screw 6-32x1" (2)

Rope

o_

Clevis Pin

5/16"x1-1/4" (1)

Page 8

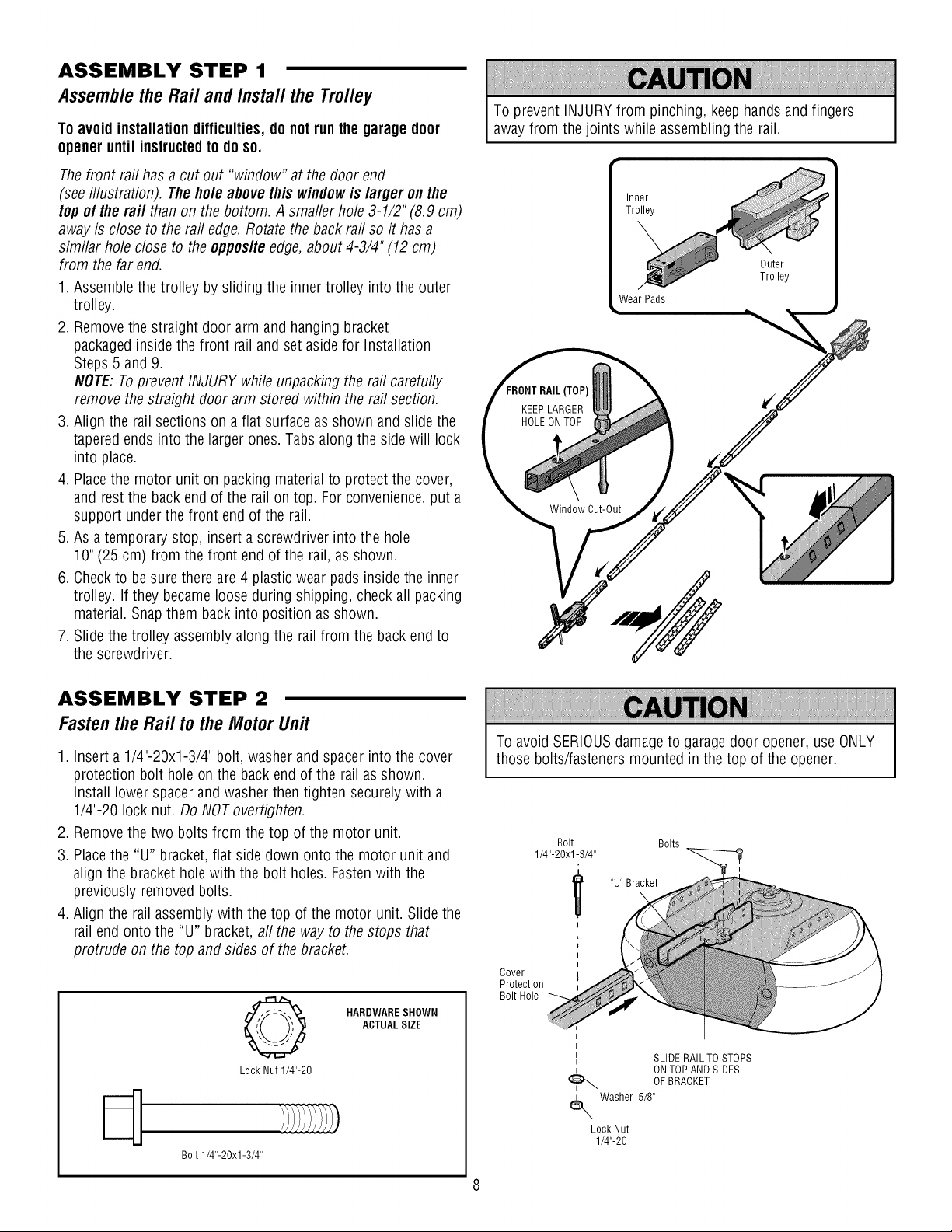

ASSEMBLY STEP 1

Assemblethe Rail andInstal/the Trolley

To avoidinstallation difficulties,do not runthe garagedoor

opener until instructedto doso.

Thefront rail has acut out "window" at the door end

(seeillustration). Theholeabove this windowis larger onthe

top of the raft than on the bottom. Asmaller hole3-1/2" (8.9 cm)

away is close to the rail edge.Rotatethe backrail so it has a

similar hole closeto the oppositeedge,about 4-3/4" (12 cm)

from the far end.

1. Assemble the trolley by sliding the inner trolley into the outer

trolley.

2. Removethe straight door arm and hanging bracket

packagedinside the front rail and set asidefor Installation

Steps 5 and9.

NOTE:Toprevent INJURY while unpacking the rail carefully

remove the straight door arm stored within the rail section.

3. Align the rail sections on a flat surface as shown and slide the

taperedends into the larger ones. Tabs along the sidewill lock

into place.

4. Placethe motor unit on packing material to protect the cover,

and restthe back end of the rail ontop. For convenience,put a

support under the front end of the rail.

5. As atemporary stop, insert a screwdriver into the hole

10"(25cm) from the front end of the rail, as shown.

6. Checkto besure there are4 plastic wear pads insidethe inner

trolley. If they becameloose during shipping, check all packing

material.Snap them back into position as shown.

7. Slide the trolley assemblyalong the rail from the back endto

the screwdriver.

To prevent INJURYfrom pinching, keephandsand fingers

away from the joints while assembling the rail.

Inner

Trolley

Outer

Trolley

Wear Pads

[TOP)

KEEPLARGER

HOLEON TOP

Window Cut-Out

ASSEMBLY STEP 2

Fastenthe Rail tothe MotorUnit

1. Inserta 1/4"-20xl-3/4" bolt, washerand spacerinto the cover

protection bolt hole on the back end of the rail as shown.

Install lower spacerandwasherthen tighten securelywith a

1/4"-20 lock nut. DoNOT overtighten.

2. Removethe two bolts from the top of the motor unit.

3. Placethe "U" bracket,flat side down onto the motor unit and

align the bracketholewith the bolt holes. Fastenwith the

previously removed bolts.

4. Align the rail assemblywith the top of the motor unit. Slidethe

rail end onto the "U" bracket,aft the way to the stops that

protrude on the top andsides of the bracket.

HARDWARESHOWN

ACTUALSIZE

Q

Lock Nut 1/4"-20

Bolt 1/4"-20xl-3/4"

To avoid SERIOUSdamageto garagedoor opener, use ONLY

those bolts/fasteners mounted in the top of the opener.

Bolt Bolts

1/4"-20xl-3/4"

"U" Bracket

Cover

Protection

Bolt Hole

l

l

I SLIDE RAIL TO STOPS

t ONTOP AND SIDES

Washer 5/8"

Lock Nut

1/4"-20

OFBRACKET

Page 9

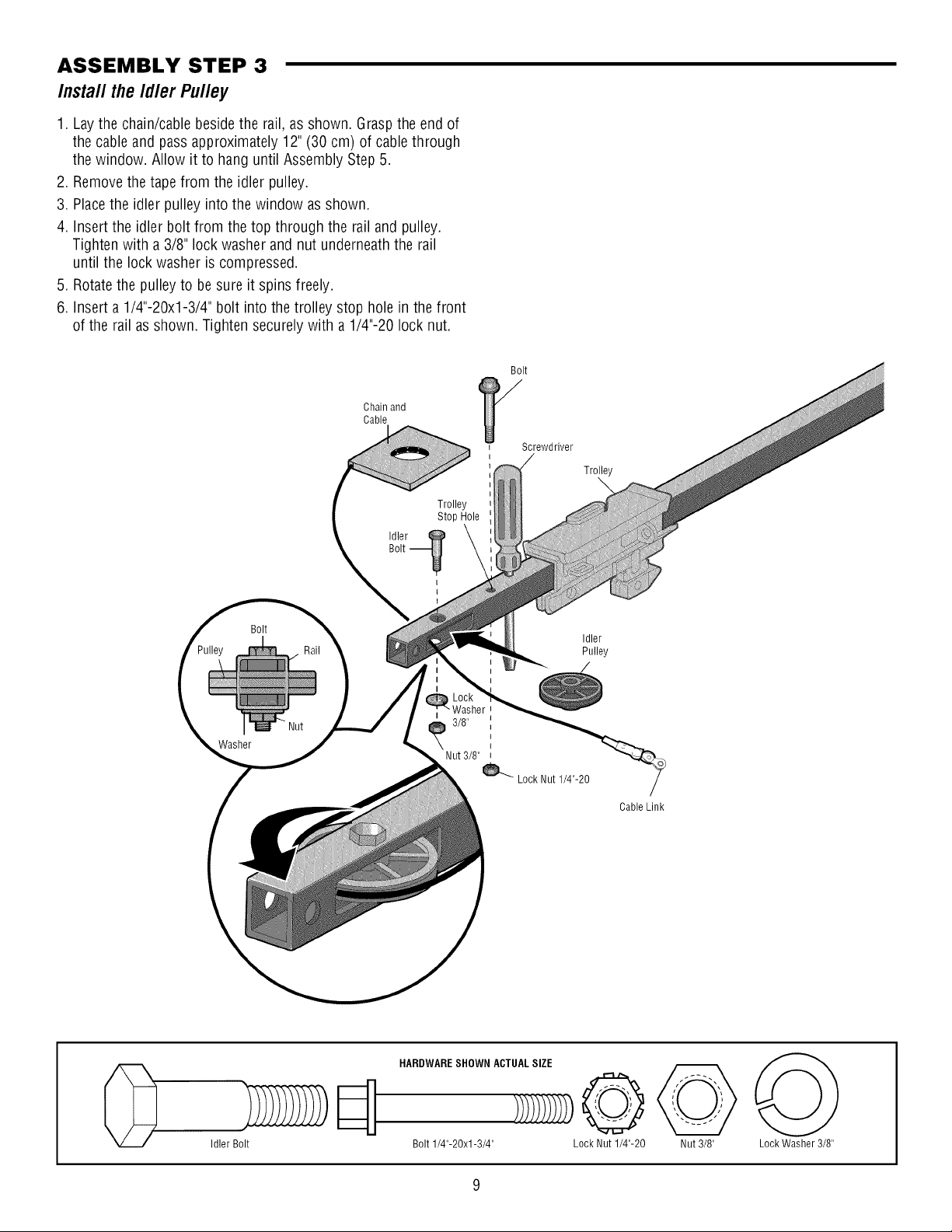

ASSEMBLY STEP 3

Insta// the Id/er Pu//ey

1. Lay the chain/cable besidethe rail, as shown. Graspthe end of

the cable andpassapproximately 12"(30 cm) of cablethrough

the window. Allow it to hanguntil Assembly Step 5.

2. Removethe tape from the idler pulley.

3. Placethe idler pulley into the window asshown.

4. Insert the idler bolt from the top through the rail andpulley.

Tighten with a 3/8" lock washer and nut underneaththe rail

until the lock washer is compressed.

5. Rotatethe pulley to besure it spins freely.

6. Insert a1/4"-20xl-3/4" bolt into the trolley stop hole inthe front

of the rail as shown. Tighten securely with a 1/4"-20 lock nut.

Chain and

Cable

Trolley

Stop Hole

Idler@

Bolt

Screwdriver

Trolley

\

Washer

Bolt

Bolt -_

I

t

Nut 3/8"

Idler

Pulley

3/8"

Lock Nut 1/4"-20

Cable Link

Idler Bolt

HARDWARESHOWN ACTUALSIZE

Bolt 1/4"-20xl-3/4" Lock Nut 1/4"-20 Nut 3/8" Lock Washer 3/8"

Page 10

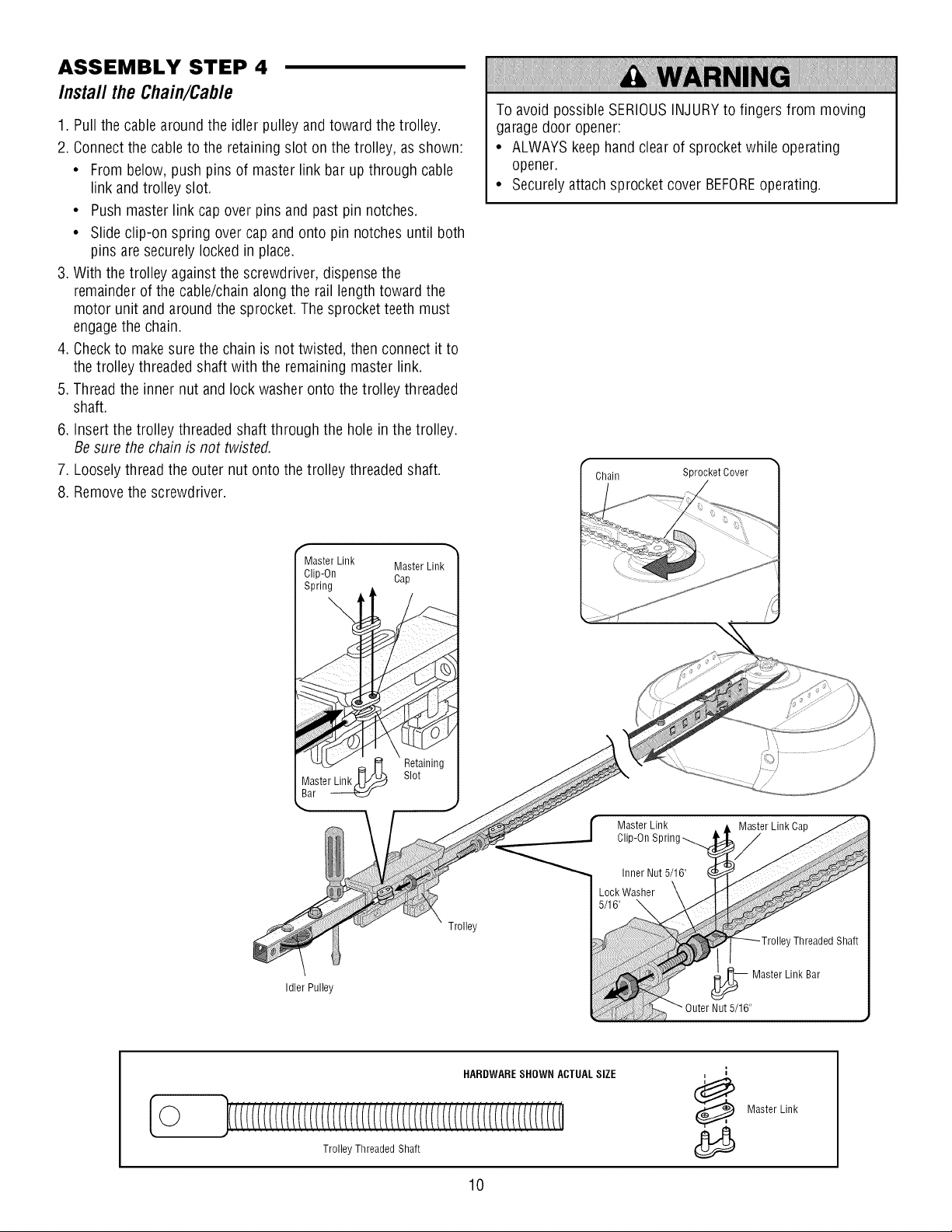

ASSEMBLY STEP 4

Install the Chain/Cable

1. Pull the cablearound the idler pulley andtoward the trolley.

2. Connect the cable to the retaining slot on the trolley, asshown:

• From below,push pins of master link barup through cable

link and trolley slot.

• Pushmaster link cap over pins and past pin notches.

• Slide clip-on spring over capand onto pin notches until both

pins aresecurely lockedin place.

3. With the trolley against the screwdriver, dispensethe

remainderof the cable/chainalong the rail length toward the

motor unit and around the sprocket. Thesprocket teeth must

engagethe chain.

4. Checkto make sure the chain is not twisted, then connect it to

the trolley threadedshaft with the remaining master link.

5. Thread the inner nut and lock washer onto the trolley threaded

shaft.

6. Insertthe trolley threaded shaft through the hole in the trolley.

Besure the chain is not twisted.

7. Looselythread the outer nut onto the trolley threaded shaft.

8. Removethe screwdriver.

To avoid possibleSERIOUSINJURYto fingers from moving

garagedoor opener:

• ALWAYSkeep handclearof sprocket while operating

opener.

• Securely attachsprocket cover BEFOREoperating.

Chain Sprocket Cover

Master Link Master Link

Clip-On Cap

Spring

Idler Pulley

Retaining

Slot

Trolley

Master Link

Clip-On Sprin

Master Link Cap

©

HARDWARESHOWN ACTUALSIZE

Master Link

Trolley Threaded Shaft

10

Page 11

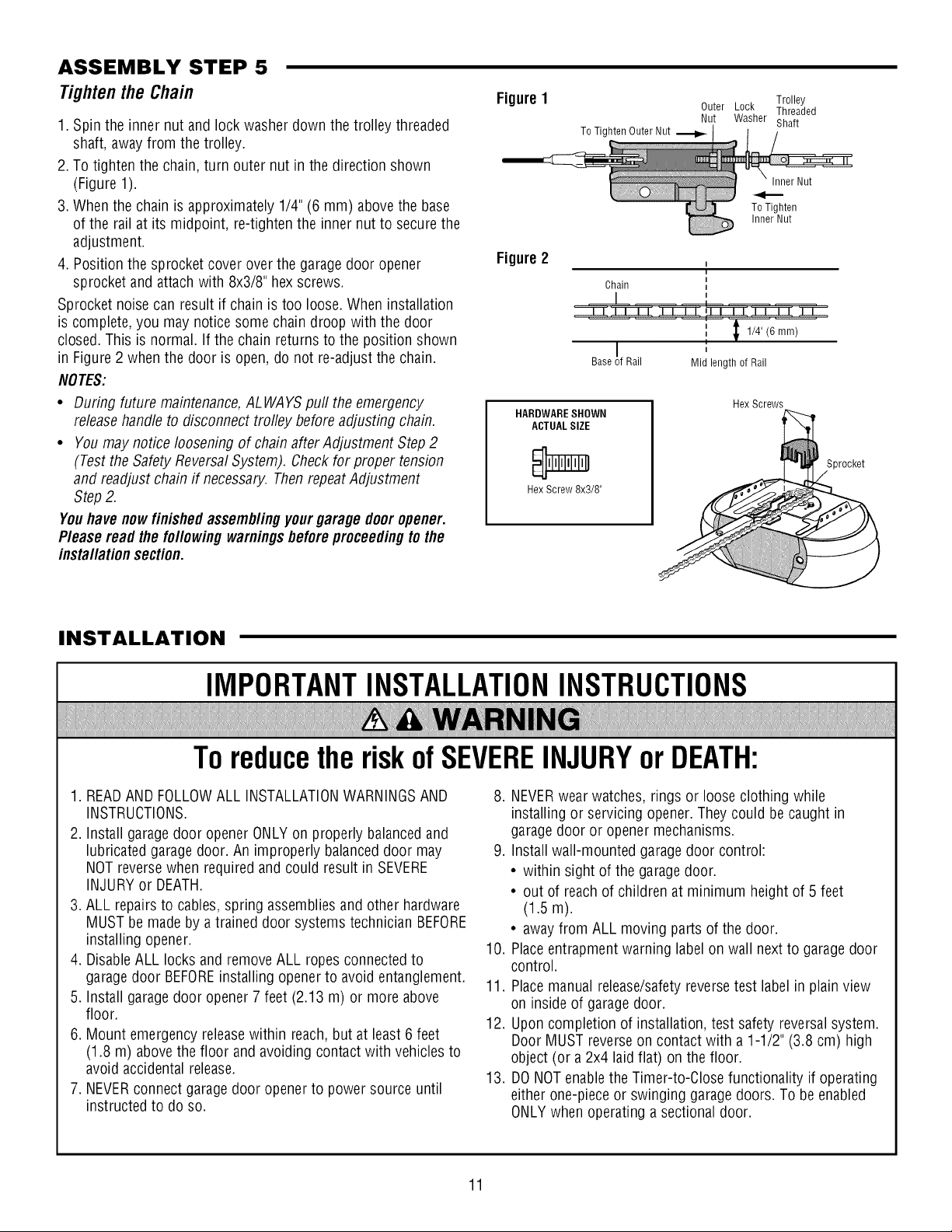

ASSEMBLY STEP 5

Tightenthe Chain

1. Spin the inner nut and lock washer down the trolley threaded

shaft, awayfrom the trolley.

2. To tightenthe chain, turn outer nut in the direction shown

(Figure 1).

3. When the chain is approximately 1/4" (6 mm) above the base

of the rail at its midpoint, re-tighten the inner nut to securethe

adjustment.

4. Position the sprocketcover over the garagedoor opener

sprocket andattachwith 8x3/8" hex screws.

Sprocket noise can result if chain is too loose. When installation

is complete, you may noticesomechain droop with the door

closed.This is normal. If the chain returns to the position shown

in Figure2 whenthe door is open, do not re-adjust the chain.

NOTES:

• During future maintenance,ALWAYSpull the emergency

releasehandle to disconnect trolley before adjusting chain.

• You may notice loosening of chain aflerAdjustment Step 2

(Testthe SafetyReversalSystem). Checkfor proper tension

and readjustchain if necessary. ThenrepeatAdjustment

Step2.

Youhave nowfinished assemblingyourgaragedoor opener.

Please read thefollowingwarningsbeforeproceedingto the

installationsection.

Figure1 Trolley

To Tighten Outer Nut

Figure2

Chain

Base !f Rail

HARDWARESHOWN

ACTUALSIZE

Hex Screw 8x3/8"

Outer Lock Threaded

Nut Washer Shaft

Inner Nut

ToTighten

Inner Nut

I

1/4" (6 mm)

,,

Mid length of Rail

Hex Screws

Sprocket

INSTALLATION

IMPORTANTINSTALLATIONINSTRUCTIONS

ToreducetheriskofSEVEREINJURYorDEATH:

1. READAND FOLLOWALL INSTALLATIONWARNINGSAND

INSTRUCTIONS.

2. Install garagedoor opener ONLYon properly balancedand

lubricated garagedoor. An improperly balanceddoor may

NOT reversewhen required and could result in SEVERE

INJURYor DEATH.

3. ALL repairsto cables,spring assembliesand other hardware

MUST be made by a trained door systems technician BEFORE

installing opener.

4. DisableALL locks and removeALL ropesconnectedto

garagedoor BEFOREinstalling openerto avoid entanglement.

5. Install garagedoor opener 7 feet (2.13 m) or more above

floor.

6. Mount emergency releasewithin reach, but at least 6 feet

(1.8 m) abovethe floor and avoiding contactwith vehicles to

avoid accidental release.

7. NEVERconnect garagedoor openerto power source until

instructed to do so.

8. NEVERwearwatches, rings or looseclothing while

installing or servicing opener. They could be caught in

garage door or openermechanisms.

9. Install wall-mounted garage door control:

• within sight of the garagedoor.

• out of reachof children at minimum height of 5 feet

(1.5 m).

• away from ALL moving parts of the door.

10. Placeentrapment warning labelon wall nextto garage door

control.

11. Placemanual release/safetyreversetest labelin plain view

on inside of garagedoor.

12. Upon completion of installation, test safety reversalsystem.

Door MUST reverseon contactwith a 1-1/2" (3.8 cm) high

object (or a2x4 laid flat) on the floor.

13. DONOTenablethe Timer-to-Close functionality if operating

either one-piece or swinging garagedoors. To beenabled

ONLYwhen operating a sectionaldoor.

11

Page 12

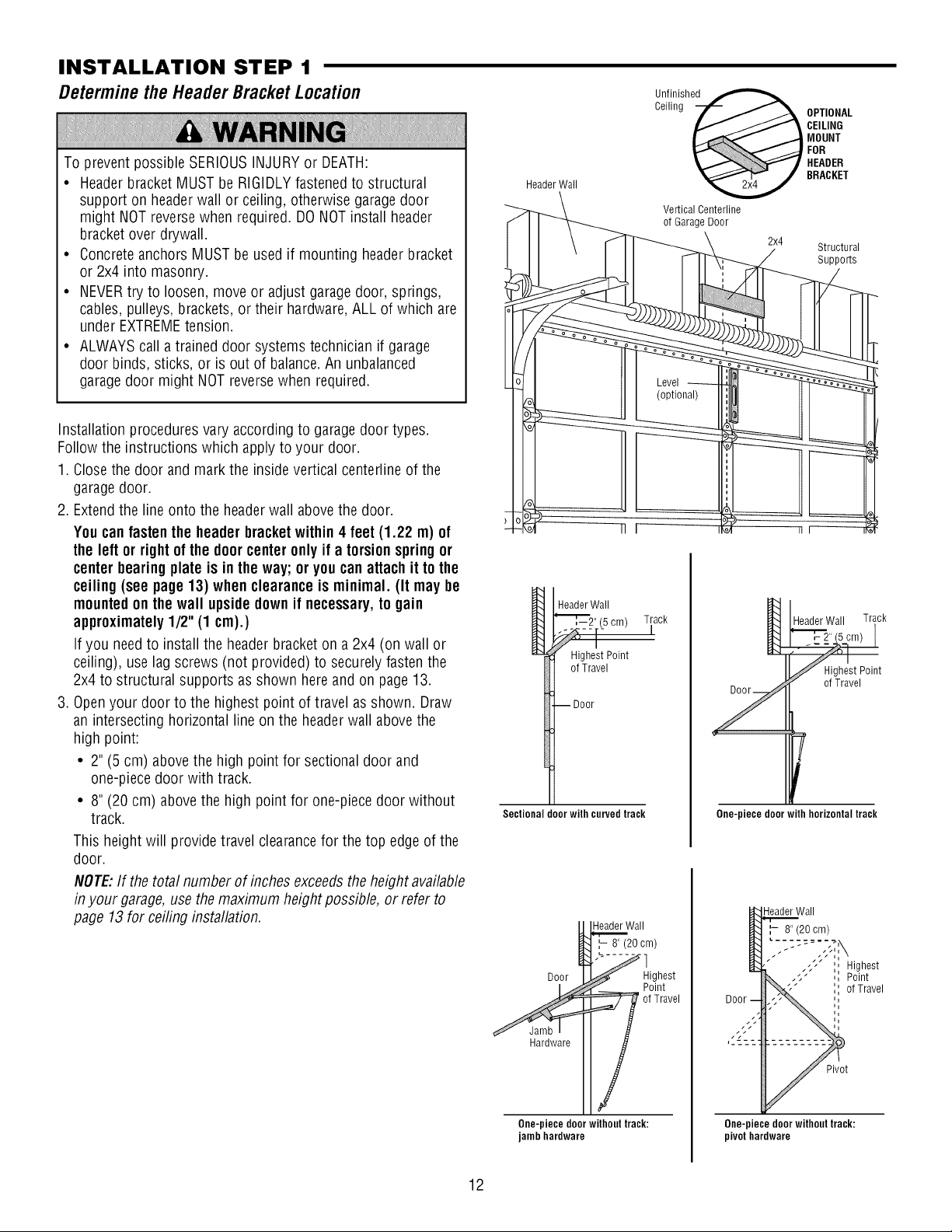

INSTALLATION STEP 1

Determinethe HeaderBracketLocation

Un.f!nished

To prevent possible SERIOUSINJURYor DEATH:

• Headerbracket MUST be RIGIDLYfastenedto structural

support on headerwall or ceiling, otherwise garagedoor

might NOTreversewhen required. DONOTinstall header

bracket over drywall.

• ConcreteanchorsMUSTbe usedif mounting headerbracket

or 2x4 into masonry.

• NEVERtry to loosen, move or adjust garagedoor, springs,

cables, pulleys, brackets, or their hardware,ALL of which are

under EXTREMEtension.

• ALWAYScall a trained door systems technician if garage

door binds, sticks, or is out of balance.Anunbalanced

garagedoor might NOTreversewhen required.

Installation proceduresvary accordingto garagedoor types.

Follow the instructions which applyto your door.

1. Closethe door and mark the insidevertical centerline of the

garagedoor.

2. Extendthe lineonto the headerwall abovethe door.

Youcanfasten the header bracketwithin 4 feet(1.22 m) of

the left or rightof thedoorcenteronly if a torsion springor

center bearingplate is inthe way; or youcanattach itto the

ceiling (see page 13) whenclearanceis minimal. (It may be

mountedon thewall upsidedown if necessary,to gain

approximately1/2" (1 cm).)

If you needto install the headerbracket on a 2x4 (on wall or

ceiling), use lag screws (not provided) to securelyfasten the

2x4 to structural supports as shown hereand on page13.

3. Openyour door to the highest point of travel asshown. Draw

an intersectinghorizontal lineon the headerwall abovethe

high point:

• 2" (5 cm) abovethe high point for sectionaldoor and

one-piecedoor with track.

• 8" (20 cm) abovethe high point for one-piecedoor without

track.

This heightwill provide travel clearancefor the top edgeof the

door.

NOTE:If the totalnumber of inches exceedsthe heightavailable

in your garage,use themaximum height possible, or refer to

page 13for ceiling installation.

Header Wall

HeaderWall

"_[_",--2"(5 cm) Track

Highest Point

of Travel

--Door

Sectional door with curved track

Header Wall

',- 8" (20 cm)

Door

Ceiling _ BRACKETMOUNTCEILINGOPTIONALHEADERFOR

Vertical Centerline

of Garage Door

2x4

Structural

Supports

HeaderWall Track

HighestPoint

of Travel

T

One-piece door with horizontaltrack

-leader Wall

8" (20 cm)

Highest

Point

of Travel

Highest

Point

of Travel

12

Hardware

One-piecedoorwithouttrack:

jambhardware

Pivot

One-piece door without track:

pivot hardware

Page 13

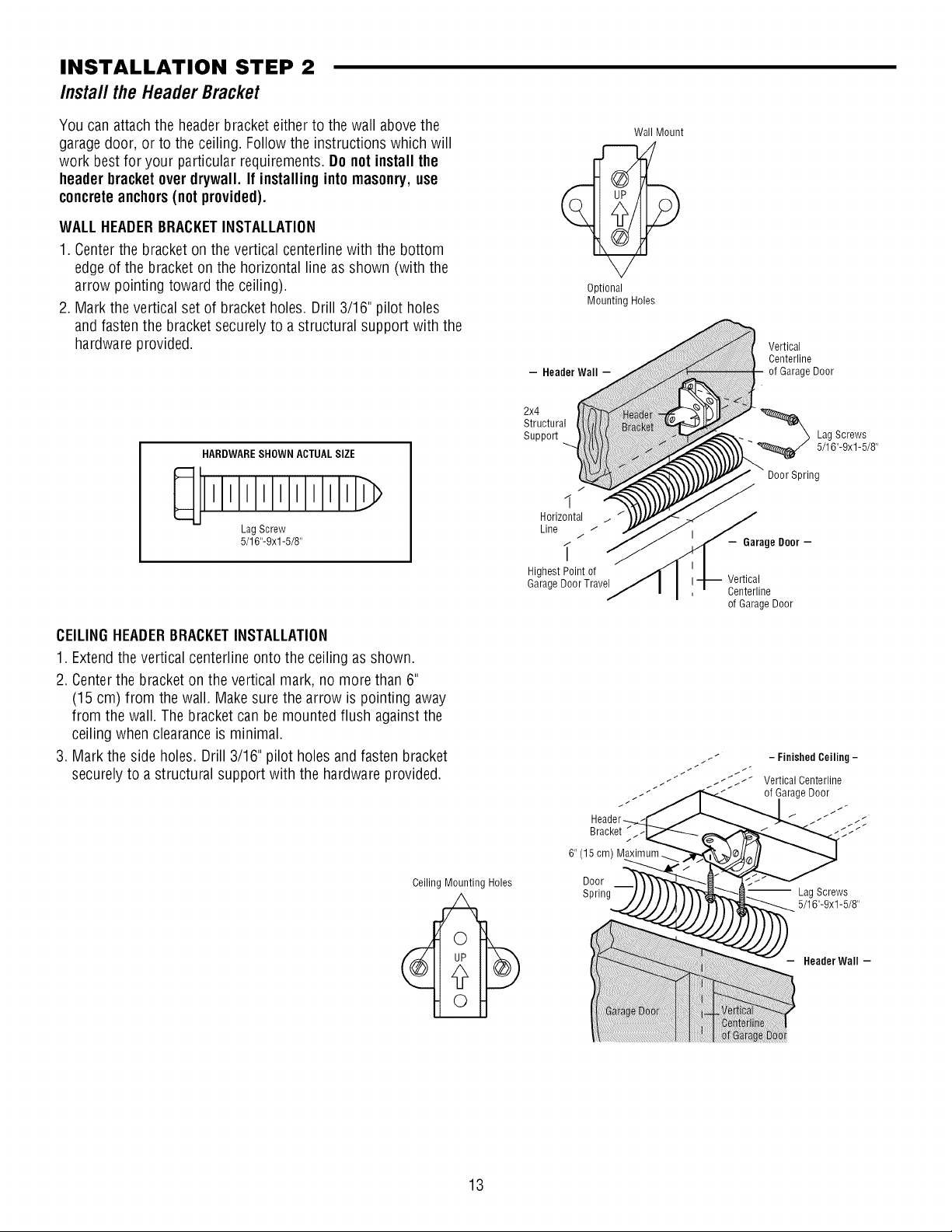

INSTALLATION STEP 2

Install the HeaderBracket

You can attach the headerbracketeither to the wall abovethe

garagedoor, or to the ceiling. Followthe instructions which will

work bestfor your particular requirements. Do notinstall the

headerbracketoverdrywall. If installinginto masonry,use

concreteanchors(notprovided).

WALLHEADERBRACKETINSTALLATION

1. Centerthe bracket on the vertical centerlinewith the bottom

edge of the bracket on the horizontal line asshown (with the

arrow pointing toward the ceiling).

2. Mark the vertical set of bracket holes.Drill 3/16" pilot holes

and fastenthe bracketsecurely to a structural support with the

hardware provided.

HARDWARESHOWN ACTUALSIZE

lllllllllll

LagScrew

5/16"-9xl -5/8"

Optional

Mounting Holes

- Header Wall -

2x4

Structural

SuppoR

7

1

Horizontal

Line

i

HighestPoint of

GarageDoorTravel

Wall Mount

Vertical

Centerline

of GarageDoor

_ Lag Screws

Door Spring

- Garage Door -

Vertical

Centerline

of GarageDoor

5/16"-9xl-5/8"

CEILINGHEADERBRACKETINSTALLATION

1. Extendthe vertical centerline onto the ceiling as shown.

2. Centerthe bracketon the vertical mark, no more than 6"

(15 cm) from the wall. Makesure the arrow is pointing away

from the wall. The bracket can be mounted flush against the

ceiling when clearanceis minimal.

3. Mark the side holes. Drill 3/16" pilot holes and fasten bracket

securelyto a structural support with the hardwareprovided.

Ceiling Mounting Holes

6"(15cm) M a num._.

Door

Spring

-- Lag Screws

5/16"-9xl -5/8"

Header Wall -

13

Page 14

INSTALLATION STEP 3

AttachtheRail to the HeaderBracket

1. Position the openeron the garagefloor below the header

bracket. Usepackingmaterial asa protectivebase.NOTE:If the

door spring is in the wayyou'll needhelp. Havesomeone hold

theopener securely ona temporary support to allow the raftto

clearthe spring.

2. Position the rail bracket againstthe headerbracket.

3. Align the bracket holesand join with a clevis pin 5/16"x1-1/2"

as shown.

4. Inserta ring fastener to secure.

HeaderWall

HeaderBracket

Idler Pulley

__ Garage

Door

Header

Bracket

Mounting

Hole

0

i

\

__ Temporary

Opener Carton or

Support

HARDWARESHOWN ACTUALSIZE

o]

Clevis Pin 5/16"x1-1/2"

14

0

Ring Fastener

Page 15

INSTALLATION STEP 4

PositiontheOpener

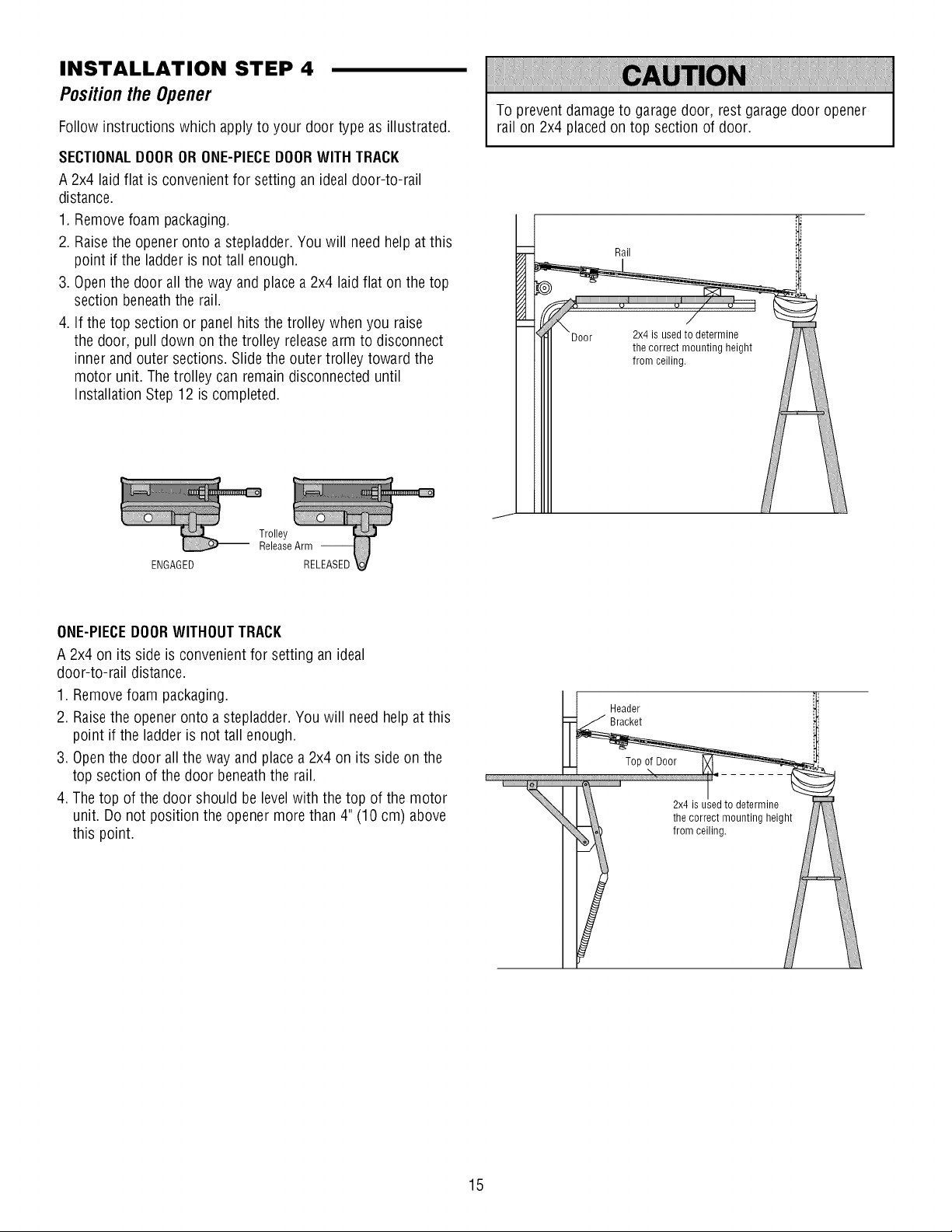

Follow instructions which apply to your door type as illustrated.

SECTIONALDOORORONE-PIECEDOORWITH TRACK

A 2x4 laid flat is convenientfor setting an ideal door-to-rail

distance.

1. Removefoam packaging.

2. Raisethe openeronto a stepladder.You will needhelp at this

point if the ladder is not tall enough.

3. Openthe door allthe way andplace a 2x4 laid flat on the top

section beneaththe rail.

4. If the top section or panel hits the trolley when you raise

the door, pull down on the trolley releasearm to disconnect

inner and outer sections. Slidethe outer trolley toward the

motor unit. Thetrolley can remain disconnecteduntil

Installation Step12 is completed.

To prevent damageto garage door, rest garage door opener

rail on 2x4 placedon top section of door.

Rail

ENGAGED

ONE-PIECEDOORWITHOUTTRACK

A 2x4 on its side is convenient for setting an ideal

door-to-rail distance.

1. Removefoam packaging.

2. Raisethe openeronto a stepladder.You will need help at this

point if the ladder is not tall enough.

3. Openthe door all the way andplace a 2x4 on its side on the

top section of the door beneaththe rail.

4. The top of the door should be levelwith the top of the motor

unit. Do not position the opener morethan 4" (10 cm) above

this point.

Header

Bracket

2x4 is usedto determine

the correct mounting height

from ceiling.

i

15

Page 16

INSTALLATION STEP 5

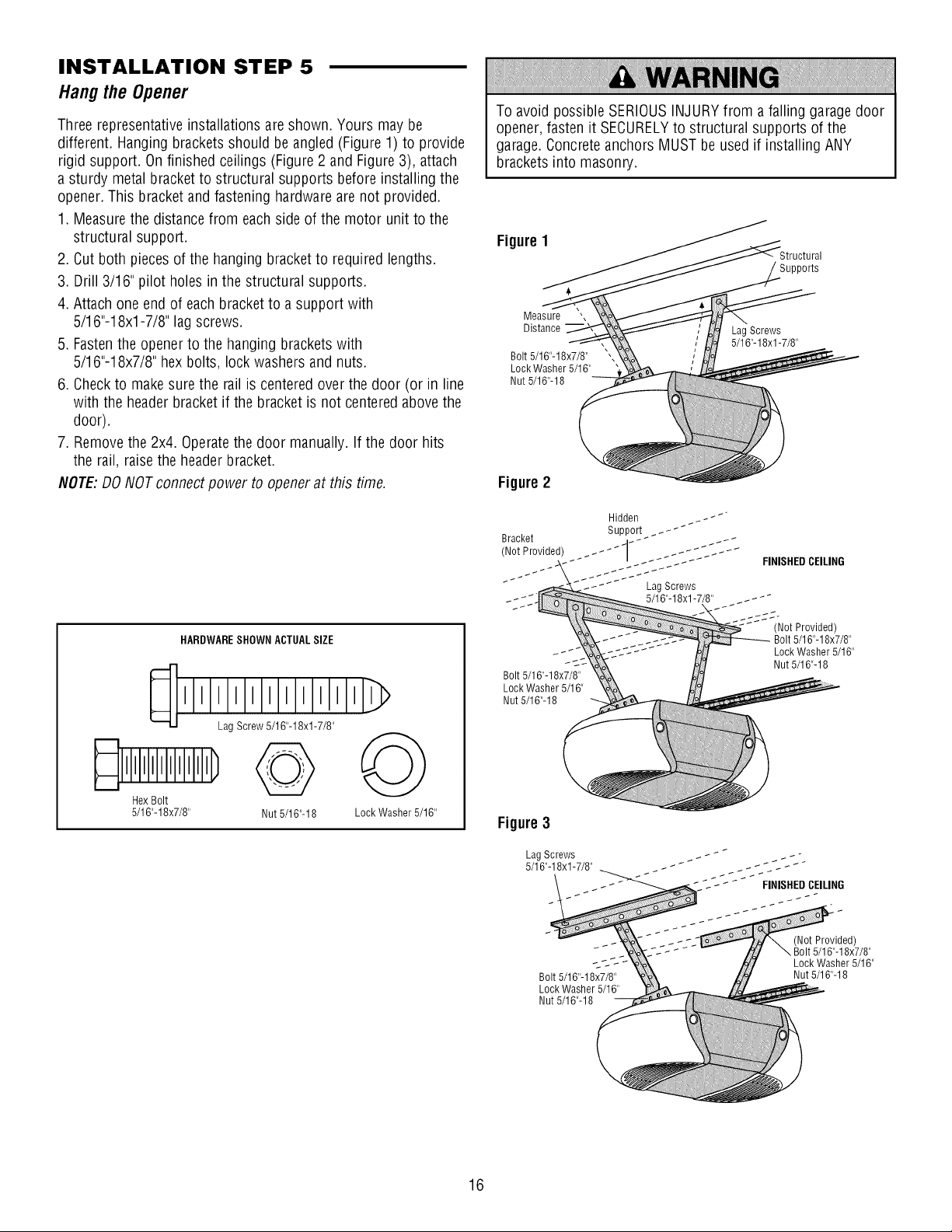

Hangthe Opener

Threerepresentativeinstallations are shown. Yours may be

different. Hangingbrackets should beangled (Figure 1) to provide

rigid support. Onfinished ceilings (Figure2 and Figure3), attach

a sturdy metal bracket to structural supports before installingthe

opener.This bracketand fastening hardwareare not provided.

1. Measurethe distancefrom eachside of the motor unit to the

structural support.

2. Cut both piecesof the hanging bracket to required lengths.

3. Drill 3/16" pilot holes inthe structural supports.

4. Attach oneendof eachbracket to a support with

5/16"-18xl -7/8" lagscrews.

5. Fastenthe opener to the hanging brackets with

5/16"-18x7/8" hex bolts, lock washers and nuts.

6. Checkto make sure the railis centered over the door (or in line

with the headerbracket if the bracket is not centeredabovethe

door).

7. Removethe 2x4. Operatethe door manually. If the door hits

the rail, raisethe headerbracket.

NOTE:DO NOTconnectpower to openerat this time.

To avoid possibleSERIOUSINJURYfrom a falling garagedoor

opener,fasten it SECURELYto structural supports of the

garage.Concrete anchorsMUSTbe usedif installing ANY

brackets into masonry.

Figure1

Supports

Measure ',

Distance

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Lag Screws

5/16"-18xl -7/8"

Figure2

HARDWARESHOWN ACTUALSIZE

>

HexBolt

5/16"-18x7/8" Nut 5/16"-18 LockWasher 5/16"

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Figure3

LagScrews

5/16"-18xl -7/8"

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Lag Screws

5/16"-18xl -7/8" _ _ _ _ _ _-

FINISHEDCEILING

(Not Provided)

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

(Not Provided)

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

16

Page 17

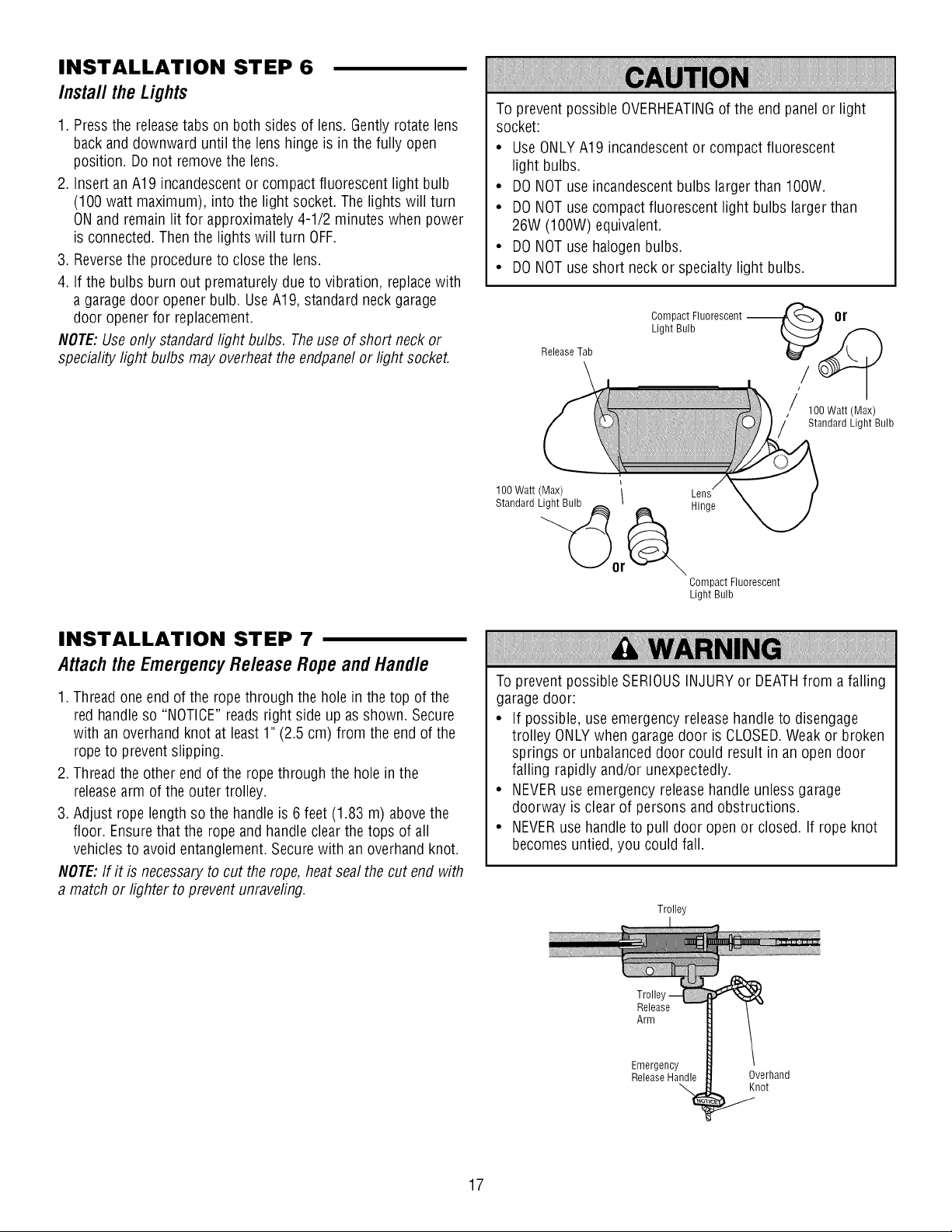

INSTALLATION STEP 6

Install theLights

1. Pressthe releasetabs on both sides of lens. Gentlyrotate lens

back and downward until the lens hinge is in thefully open

position. Do not removethe lens.

2. InsertanA19 incandescentor compact fluorescent light bulb

(100 watt maximum), into the light socket. Thelights will turn

ONand remainlit for approximately 4-1/2 minutes when power

is connected. Then the lights will turn OFF.

3. Reversethe procedureto close the lens.

4. If the bulbs burn out prematurelydue to vibration, replacewith

a garage door openerbulb. UseA19, standard neck garage

door openerfor replacement.

NOTE:Useonly standardlight bulbs. Theuse of short neck or

speciality light bulbs may overheatthe endpanelor light socket.

To prevent possible OVERHEATINGof the end panel or light

socket:

• UseONLYA19 incandescentor compact fluorescent

light bulbs.

• DONOTuse incandescentbulbs larger than 100W.

• DONOTuse compactfluorescent light bulbs larger than

26W (100W) equivalent.

• DONOTuse halogenbulbs.

• DONOTuse short neckor specialty light bulbs.

Compact Fluorescent --

Light Bulb

ReleaseTab

or

100Watt(Max)

Standard Light Bulb

INSTALLATION STEP 7

Attach the Emergency Release Rope and Handle

1. Thread one end of the ropethrough the hole in the top of the

red handleso "NOTICE"readsright side up asshown. Secure

with an overhandknot at least 1" (2.5 cm) from the endof the

ropeto prevent slipping.

2. Thread the other endof the rope through the hole in the

releasearm of the outer trolley.

3. Adjust rope lengthso the handle is 6 feet (1.83 m) abovethe

floor. Ensurethat the rope and handle clear the tops of all

vehiclesto avoid entanglement.Securewith an overhand knot.

NOTE:If it is necessary to cut the rope, heat seal the cut end with

a match or lighter to preventunraveling.

100 Watt (Max) \

Standard Light Bulb _

/

Hinge

Compact Fluorescent

Light Bulb

Toprevent possible SERIOUSINJURYor DEATHfrom a falling

garage door:

• If possible, use emergency releasehandle to disengage

trolley ONLYwhen garagedoor is CLOSED.Weak or broken

springs or unbalanceddoor could result in an open door

falling rapidly and/or unexpectedly.

• NEVERuse emergency release handle unless garage

doorway is clear of persons andobstructions.

• NEVERusehandle to pull door openor closed. If rope knot

becomesuntied, you could fall.

Trolley

17

Trolle

Release

Arm

Emergency

ReleaseHandle

Overhand

Knot

Page 18

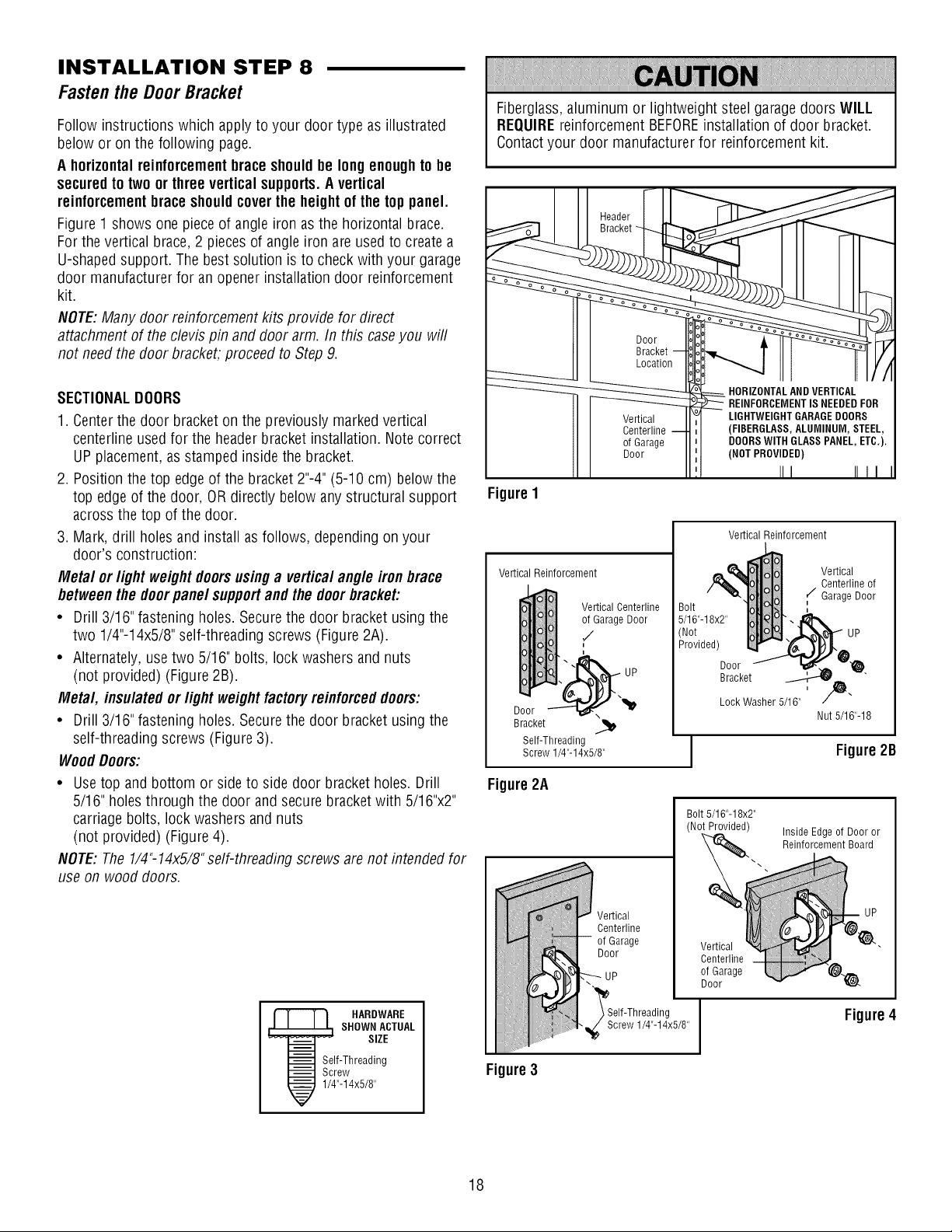

INSTALLATION STEP 8

Fastenthe DoorBracket

Follow instructions which applyto your door type as illustrated

below or on the following page.

A horizontal reinforcementbrace shouldbe longenoughtobe

securedto two or three vertical supports.Avertical

reinforcementbrace shouldcoverthe height of the top panel.

Figure1 shows onepiece of angle iron asthe horizontal brace.

Forthe vertical brace,2 piecesof angle iron are used to createa

U-shapedsupport. The bestsolution is to checkwith your garage

door manufacturerfor an opener installation door reinforcement

kit.

NOTE:Many doorreinforcement kits provide for direct

attachment of the clevis pin and door arm. In this caseyou will

not needthe door bracket, proceed to Step9.

SECTIONALDOORS

1. Centerthe door bracket on the previously markedvertical

centerline usedfor the header bracket installation. Note correct

UPplacement, as stamped insidethe bracket.

2. Position thetop edge of the bracket2"-4" (5-10 cm) below the

top edge of the door, OR directly below anystructural support

acrossthe top of the door.

3. Mark, drill holes andinstall asfollows, depending on your

door's construction:

Metal or light weight doorsusinga vertical angle iron brace

betweenthe doorpanel supportandthe doorbracket:

• Drill 3/16"fastening holes. Securethe door bracket using the

two 1/4"-14x5/8"self-threading screws (Figure2A).

• Alternately, usetwo 5/16" bolts, lock washers andnuts

(not provided) (Figure 2B).

Metal, insulated orlight weight factoryreinforceddoors:

• Drill 3/16"fastening holes. Securethe door bracket using the

self-threading screws (Figure3).

WoodDoors:

• Usetop and bottom or side to side door bracketholes. Drill

5/16" holesthrough the door and secure bracketwith 5/16"x2"

carriagebolts, lock washersand nuts

(not provided) (Figure 4).

NOTE:The1/4"-14x5/8"self-threading screws arenot intended for

use on wood doors.

Fiberglass,aluminum or lightweight steel garagedoors WILL

REQUIREreinforcement BEFOREinstallation of door bracket.

Contactyour door manufacturer for reinforcement kit.

Vertical

Centerline

o1Garage

Door

FigureI

Vertical Reinforcement

Vertical Reinforcement

Vertical Centerline

,,_Garage Door

Door "-'-'-n_'x _1_

Bracket

Self-Threading

Screw 1/4"-14x5/8"

UP

Bolt

5/16"-18x2"

Not

Provided)

Door

Bracket

Lock Washer 5/16"

Vertical

Centerline of

r/Garage Door

Nut 5/16"-18

Figure2B

Figure2A

Bolt5/16"-18x2"

(NotProvided)

Inside Edgeo1Door or

Reinforcement Board

HARDWARE

SHOWN ACTUAL

SIZE

Self-Threading

Screw

1/4"-14x5/8"

Figure3

18

Vertical

Centerline

o1Garage

Door

\

'_Self-Threading

_j_ Screw 1/4"-14x5/8"

Vertical

Centerline

of Garage

Door

Figure4

Page 19

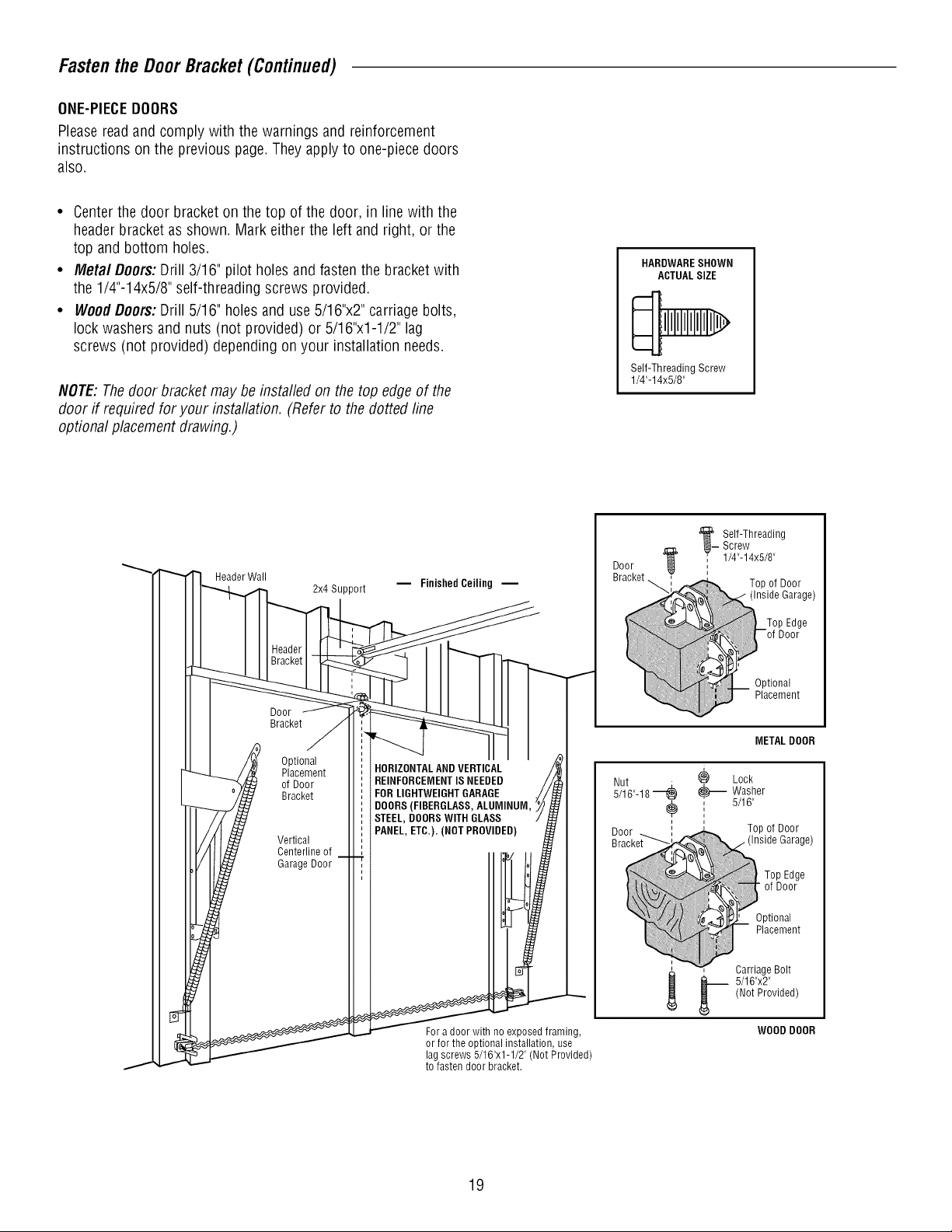

Fasten the Door Bracket (Continued)

ONE-PIECEDOORS

Pleasereadand comply with the warnings and reinforcement

instructions on the previous page.Theyapplyto one-piece doors

also.

• Centerthe door bracketon thetop of the door, in line with the

header bracketas shown. Mark eitherthe left andright, or the

top and bottom holes.

• Metal Doors:Drill 3/16" pilot holes and fasten the bracketwith

the 1/4"-14x5/8" self-threading screws provided.

• WoodDoors:Drill 5/16" holesand use5/16"x2" carriage bolts,

lock washersand nuts (not provided) or 5/16"x1-1/2" lag

screws (not provided) depending on your installation needs.

NOTE:Thedoor bracket maybe installed on the top edgeof the

door if required for your installation. (Referto the dotted line

optional placementdrawing.)

HARDWARESHOWN

ACTUALSIZE

Self-ThreadingScrew

1/4"-14x5/8"

Header Wall

Door

Bracket

Optional

Placement

of Door

Bracket

Vertical

Centerline of

Garage Door

2x4 Support

m Finished Ceiling --

HORIZONTALANDVERTICAL

REINFORCEMENTISNEEDED

FOR LIGHTWEIGHTGARAGE

DOORS(FIBERGLASS,ALUMINUM,

STEEL, DOORSWITH GLASS

PANEL,ETC.). (NOT PROVIDED)

Door

Bracket_

Screw

'__Self-Threading

' 1/4"-14x5/8"

.............._J!!iii!iii}_

_ Washer

, 5/16"

i

_. arriage Bolt

METAL DOOR

Lock

Top of Door

Top Edge

of Door

Optional

Placement

(Not Provided)

5/16"x2"

Garage)

Fora door with no exposed framing,

or for the optional installation, use

lagscrews 5/16"x1-1/2" (Not Provided)

to fasten door bracket.

19

WOOD DOOR

Page 20

INSTALLATION STEP 9

ConnectDoorArm to Trolley

Follow instructions which apply to your door type asillustrated

below and on the following page.

SECTIONALDOORSONLY

Makesure garage door is fully closed. Pullthe emergency release

handleto disconnect the outer trolley from the inner trolley. Slide

the outer trolley back(awayfrom the pulley) about 8" (20 cm) as

shown in Figures1, 2 and 3.

1. Fastenstraight door arm section to outer trolley with the

5/16"x1"clevis pin. Secure the connection with a ring fastener

(Figure1).

2. Fastencurvedsection to the door bracket in the same way,

using the 5/16"x1-1/4"clevis pin.

IMPORTANT:Thegroove on the straight door arm MUSTface

away from the curved door arm (Figure4).

3. Bring arm sections together. Findtwo pairs of holesthat line up

andjoin sections. Select holesas far apart as possible to

increasedoor arm rigidity (Figure2).

Holealignment alternative (Figure3):

• If holes in curved arm are above holesin straight arm,

disconnect straight arm. Cut about 6" (15 cm) from the solid

end. Reconnectto trolley with cut end down as shown.

• Bring arm sections together.

• Findtwo pairs of holesthat line up and join with bolts, lock

washers and nuts.

Pull the emergency releasehandletoward the opener ata 45°

angle so that the trolley releasearm is horizontal. Trolley will

re-engageautomaticallywhen opener is operatedduring the

adjustments.

Figure1

Figure2

Figure3

Trolley Stop

Bolt

Pulley

Zoor

Clevis Pin

5/16"x1-1/4"

Door

Bracket

Ring

Fastener

Bracket

cm) mm.

Curved

Door Arm

, Bolts

5/16"-18x7/8"

Outer

Trolley

Clevis Pin

5/16"xl"

Emergency

StraightDoor

Arm

Handle

HARDWARESHOWN ACTUALSIZE

Nut 5/16"-18 Lock Washer 5/16" Ring Fastener

Clevis Pin Clevis Pin

5/16"x1" (Trolley) 5/16"x1-1/4" (Door Bracket)

on

Hex Bolt

5/16"-18x7/8"

Figure4

2O

(

DoorArm

(Groove

CORRECT

_Bolts

5/16"-18x7/8"

Cut this end

INCORRECT

Page 21

Connect Door Arm to Tro//ey (Continued)

ALL0NE-PIECEDOORS

IMPORTANT."Thegroove on the straight door arm MUSTface

away from the curved door arm (Figure 5).

1. Closethe door. Disconnectthe trolley by pulling the emergency

releasehandle.

2. Fastenthe straight door arm and the curved door arm together

to the longest possible length (with a 2 or 3hole overlap).

3. Attach the straight door arm to the door bracket using the

5/16"x1-1/4" clevis pin. Securewith the ring fastener.

4. Attach the curved door arm to the trolley using the 5/16"x1"

clevis pin. Securewith the ring fastener.

5. Pull the emergencyreleasehandletoward the garagedoor

opener until the trolley release arm is horizontal.

Trolley Stop

Pulley Trolley

Bolt Inner

Figure5

Outer

Trolley

CORRECT

INCORRECT

Ring

Fastener

StraightDoor

Door

Bracket

Arm

i

Curved

Door Arm

Clevis Pin

5/16"x1-1/4"

INSTALLATION STEP 10

Attachthe WarningLabels

1.Attach the entrapment warning labelon the wall nearthe door

control with tacks or staples.

2. Attach the manual release/safetyreversetest label in a visible

location on the inside of the garagedoor.

Bolts

5/16"-18x7/8"

Clevis Pin

5/16"xl"

Emergency

ReleaseHandle

21

Page 22

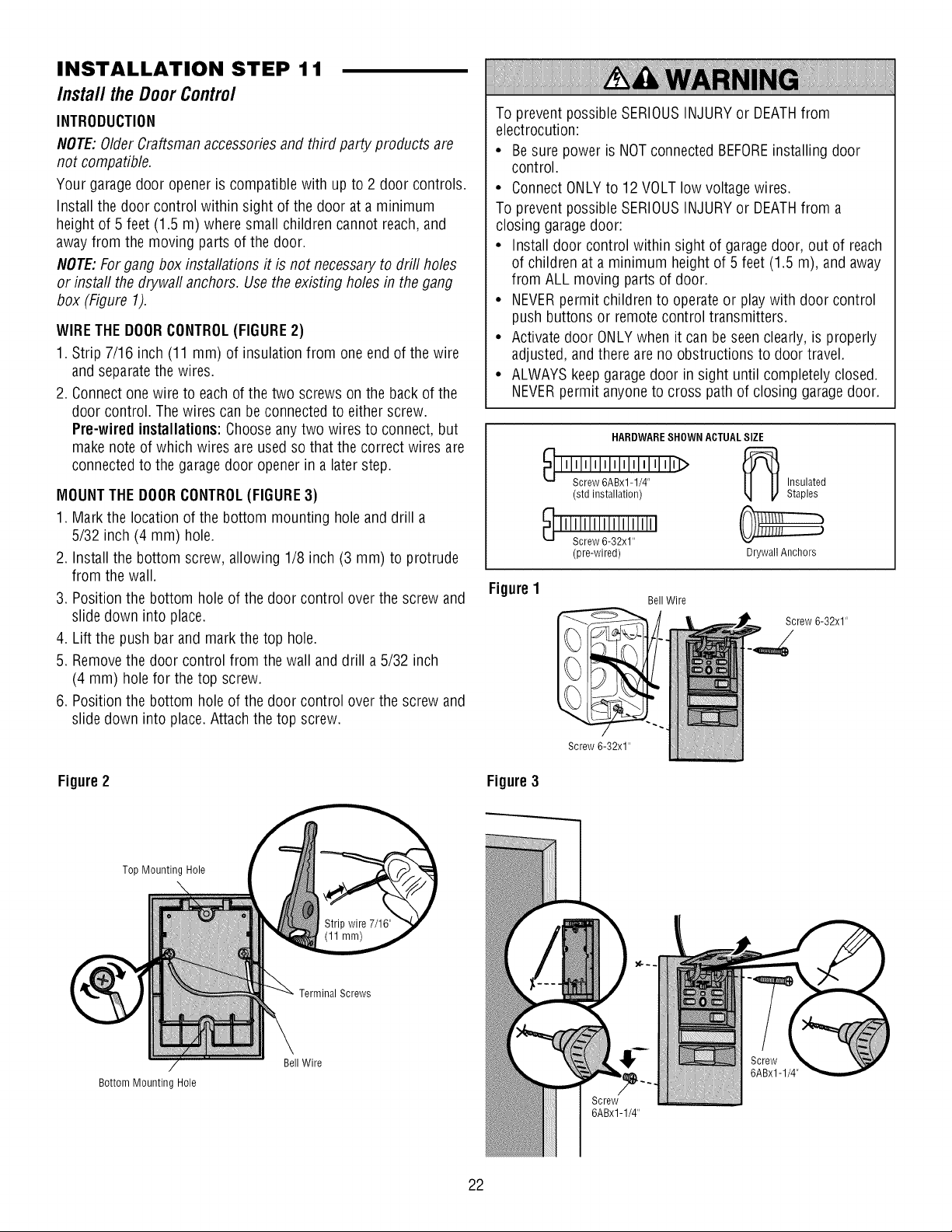

INSTALLATION STEP 11

Install theDoorControl

INTRODUCTION

NOTE:OlderCraftsmanaccessoriesand third party products are

not compatible.

Your garagedoor openeris compatiblewith up to 2 door controls.

Install the door control within sight of the door ata minimum

height of 5 feet (1.5 m) where small children cannot reach,and

away from the moving partsof the door.

NOTE:Forgang box installations it is not necessaryto drill holes

or instafl the drywafl anchors. Usethe existing holes in the gang

box (Figure 1).

WIRETHE DOORCONTROL(FIGURE2)

1. Strip 7/16 inch (11 mm) of insulation from one end of the wire

and separatethe wires.

2. Connect one wire to eachof the two screws on the back of the

door control. Thewires can beconnected to either screw.

Pre-wired installations:Chooseanytwo wires to connect, but

make note of which wires are usedso that the correct wires are

connectedto the garagedoor opener in a laterstep.

MOUNTTHEDOORCONTROL(FIGURE3)

1. Mark the location of the bottom mounting hole and drill a

5/32 inch (4 mm) hole.

2. Installthe bottom screw, allowing 1/8 inch (3 mm) to protrude

from the wall.

3. Position the bottom holeof the door control over the screw and

slide down into place.

4. Lift the push barand markthe top hole.

5. Removethe door control from the wall and drill a 5/32 inch

(4 mm) hole for the top screw.

6. Position the bottom holeof the door control over the screw and

slide down into place. Attach the top screw.

To prevent possible SERIOUSINJURYor DEATHfrom

electrocution:

• Be sure power is NOTconnected BEFOREinstalling door

control.

• ConnectONLYto 12 VOLTlow voltage wires.

To prevent possible SERIOUSINJURYor DEATHfrom a

closing garagedoor:

• Install door control within sight of garage door, out of reach

of children at a minimum height of 5 feet(1.5 m), and away

from ALL moving parts of door.

• NEVERpermit children to operate or playwith door control

push buttons or remotecontrol transmitters.

• Activate door ONLYwhen it can be seenclearly, is properly

adjusted,and there areno obstructions to door travel.

• ALWAYSkeep garage door in sight until completely closed.

NEVERpermit anyoneto cross path of closing garage door.

HARDWARESHOWN ACTUALSIZE

Insulated

Staples

Drywall Anchors

Screw 6-32x1"

Figure1

(std installation)

(pre-wired)

Bell Wire

Screw 6-32x1"

Figure2

Bottom Mounting Hole

Top Mounting Hole

TerminalScrews

Bell Wire

Figure3

6ABx1-1/4"

Screw

6ABx1-1/4"

22

Page 23

Install the Door Contro/ (Continued)

WIRETHE DOORCONTROLTOTHEGARAGEDOOROPENER

(FIGURE4)

Pre-wired installations:When wiring the door control to the

garage door opener makesure you use the same wires that are

connectedto the door control.

1. Runthe white and red/white wire from the door control to the

garagedoor opener. Attachthe wire to the wall and ceiling with

the staples (not applicablefor gang box or pre-wired

installations). Do not piercethe wire with the staple asthis may

cause a short or anopen circuit.

2. Strip 7/16 inch (11 mm) of insulation from the other end of the

wire nearthe garagedoor opener.

3. Connect the wire to the red and white terminals on the garage

door opener.

INSTALLATION STEP 12

Install TheProtectorSystem®

IMPORTANTINFORMATIONABOUTTHESAFETYREVERSING

SENSOR

The safetyreversingsensormustbeconnectedandaligned

correctlybeforethe garagedooropenerwill move in the down

direction.

Thesending sensor (with an amber LED)transmits an invisible

light beamto the receiving sensor (with a green LED). If an

obstruction breaksthe light beam while the door is closing, the

door will stop and reverseto the full open position, and the

garage door opener lights will flash 10times.

NOTE:For energyefficiency thegarage door opener will enter

sleepmode whenthe dooris fully closed. Thesleepmode shuts

the garagedoor opener down until activated. Thesleepmodeis

sequenced with the garagedoor opener light bulb; as the light bulb

turns off the sensor LEDs will turn off and wheneverthegarage

door openerlights turn onthe sensor LEDs will light. Thegarage

door opener will not go into the sleep mode until the garagedoor

opener has completed 5 cyclesuponpower up.

Figure4 DoorControlConnections

Strip wire 7/16" (11 mm)

o release or insert wire, push

in tab with screwdriver tip

Besure power is NOTconnectedto the garagedoor opener

BEFOREinstalling the safety reversing sensor.

To prevent SERIOUSINJURYor DEATHfrom a closing garage

door:

• Correctly connect andalign the safety reversingsensor. This

required safety device MUSTNOTbe disabled.

• Install the safetyreversingsensorso beamis NOHIGHER

than 6" (15 cm) abovegaragefloor.

When installing the safetyreversing sensors checkthe following:

• Sensors are installed insidethe garage,one on either side of

the door.

• Sensors are facing eachother with the lensesaligned and the

receivingsensor lensdoes not receivedirect sunlight.

• Sensors are no more than 6 inches(15 cm) above the floor and

the light beam is unobstructed.

Safety Reversing Sensor

6" (15 cm) max. above floor

Facingthe doorfrom insidethegarage

Invisible Light

Beam Protection

Area

Safety Reversing Sensor

6" (15 cm) max. above floor

23

Page 24

Instal/The ProtectorSystem®(Continued)

INSTALLINGTHE BRACKETS

Besure powerto the opener is disconnected.Installandalign

the brackets so the sensorswill face eachother across the

garagedoor, with the beam no higher than 6" (15 cm) abovethe

floor. Theymay beinstalled in one of three ways, asfollows.

Garage doortrackinstallation (preferred):

• Slip the curved arms overthe rounded edge of each door

track, with the curved arms facingthe door. Snap into place

against the side of the track. It should lie flush, with the lip

hugging the back edgeof the track, asshown in Figure 1.

If your door track will not support the bracket securely, wall

installation is recommended.

Waftinstallation (Figures2 & 3):

• Placethe bracketagainst the wall with curved arms facing the

door. Besure there is enough clearancefor the sensor beam

to be unobstructed.

• If additional depth is needed,an extension bracket (see

Accessories) or wood blocks can be used.

• Use bracketmounting holesas a template to locate and drill

(2) 3/16" diameter pilot holeson the wall at eachside of the

door, no higher than 6" (15 cm) abovethe floor.

• Attach bracketsto wall with lag screws (not provided).

• If using extensionbrackets or wood blocks, adjust right and

left assembliesto the same distance out from the mounting

surface. Make sure all door hardware obstructions are cleared.

Floorinstallation (Figure4):

• Usewood blocks or extension brackets(seeAccessories)to

elevatesensor bracketsso the lenseswill be no higher than

6"(15 cm) above the floor.

• Carefullymeasure and placeright and left assemblies at the

same distanceout from the wall. Besure alldoor hardware

obstructions are cleared.

• Fastento the floor with concrete anchorsas shown.

Figure1

Figure2

Figure3

I --Door

b

-,Track .

DOORTRACKMOUNT (RIGHT SIDE)

Indicator

_J Light

....

WALL MOUNT (RIGHT SIDE)

Fasten Wood Blockto Wallwith

LagScrews (not provided)

Indicator

Light Safety

Reversing

Sensor

crews

-[L --H-_ (notprovided)

Lens -'-'_

WALL MOUNT (RIGHT SIDE)

ii!!_i

ii:iExtension racket

iiiiii:i_ See Accessories

iiiiiiiiiiiiiiiiiiilil:I_n (Providedwith

i!iiii!iJilf-__l__ racket)

CarriageBolt

1/4"-20xl/2"

HARDWARESHOWN ACTUALSIZE

Wing Nut

1/4"-20

Staples

(Providedwith

ExtensionBracket)_" "

Figure4

24

:_i'" _ __ Reversing

FLOORMOUNT(RIGHT SIDE)

i i-- Attachwith

, ConcreteAnchors

_. Sensor

I \ Bracket

Lens Indicator

Light

; (not provided)

Indicator

Light

Reversing

Sensor

Bracket

Page 25

Insta// TheProtectorSystem®(Continued)

MOUNTINGANDWIRING THESAFETYREVERSINGSENSORS

Mounting:

• Slide a 1/4"-20xl/2" carriage bolt headinto the slot on each

sensor. Use wing nuts to fastensensors to brackets, with

lenses pointing toward each other across the door. Besure the

lens is not obstructed by a bracket extension (Figure5).

• Finger tighten the wing nuts.

OptionA -/nsta//ation WithoutPre-Wiring:

• Runthe bellwire from both sensors to the garagedoor opener.

Attachthe wire to the wall and ceiling with the staples

(Figure 6).

OptionB- Pre-Wired /nsta//ation:

If your garagealready has wires installedfor the safety reversing

sensors, follow the instructions below:

• Cut the endof the safety sensor wire, making surethere is

enough wire to reachthe pre-installed wires from the wall

(Figure 7).

• Separatethe safety sensor wires and strip 7/16 inch (11 mm)

of insulation from eachend. Choosetwo of the pre-installed

wires andstrip 7/16 inch (11 mm) of insulation from each end.

Make sure that you choose the same color pre-installedwires

for eachsensor (Figure8).

• Connectthe pre-installed wires to the sensorwires with wire

nuts making surethe colors correspond for eachsensor

(Figure 9).

CONNECTTO GARAGEDOOROPENER:

• Strip 7/16 inch (11 ram) of insulation from eachsetof wires.

Separatewhite and white/black wires sufficiently to connect to

the opener quick-connect terminals. Twist like colored wires

together. Insert wires into quick-connect holes:white to white

and white/black to grey (Figure 10).

Figure5

Figure6

Figure7

Figure9

Wing

Nut

Carriage

Bolt

Figure8

Safety Reversing

Sensor Wires

Pre-lnstalled Wires

Not Provided

Safety

Reversing

Sensor Wires Pre-lnstalled

7/16"

(11mm)

Figure10

BellWire

Finished

m Ceiling

Safety Reversing Sensor

25

) White/Black

Connect Wire to

Quick-Connect

Terminals

1.Strip wire 7/16" (11 mm)

2. Twist like colored wires

together

Safety Reversing 3. To insert or releasewire,

Sensor push in tab with

Invisible Light Beam

Protection Area

screwdriver tip

Red White Grey

Quick-Connect Terminals

Page 26

INSTALLATION STEP 13

ElectricalRequirements

To avoidinstallation difficulties,do notrunthe openerat this

time.

To reduce the risk of electric shock,your garagedoor opener has

a grounding type plug with a third grounding pin. This plug will

only fit into a grounding type outlet. If the plug doesn't fit into the

outlet you have, contact a qualified electrician to install the proper

outlet.

THEREARETWOOPTIONSFORCONNECTINGPOWER:

TYPICALWIRING (OPTIONA)

1. Plug inthe garagedoor openerinto a grounded outlet.

2. DONOTrun garagedoor opener at this time.

PERMANENTWIRING(OPTIONB)

If permanentwiring isrequired byyour local code, refer to the

followingprocedure.To makea permanentconnection through

the 7/8" hole in the top of the motor unit (according to local code):

1. Be sure power is NOTconnectedto the opener, and

disconnect powerto circuit.

2. Removethe garagedoor openercover and set aside.

3. Removethe attachedgreen ground terminal.

4. Cut black and white wires andstrip away 1/2" (1 cm) of

insulation, 3" (7.5 cm) before spadeterminals.

5. Removethe power cord from opener.

6. Install a conduit or flex cableadapterto the 7/8" hole.

7. Run wires through conduit, cut to proper length andstrip

insulation.

8. Attach with wire nuts provided. Attach the ground wire to the

green ground screw.The opener mustbe grounded.

9. Properly secure wire under plastic ties so thatwire does not

come incontact with moving parts.

10.Reinstall the cover.

time.

DONOTrun garagedoor openerat this

To prevent possible SERIOUSINJURYor DEATHfrom

electrocution or fire:

• Besure power is NOTconnectedto the opener, and

disconnect powerto circuit BEFOREremoving cover to

establish permanentwiring connection.

• Garagedoor installation and wiring MUST be in compliance

with ALL local electrical and building codes.

• NEVERuseanextension cord, 2-wire adapter,or change

plug in ANYway to make it fit outlet. Besure the openeris

grounded.

OptionA

RIGHT WRONG

Option B

Black Ground Tab

Wire

PERMANENTWIRING CONNECTION

Ground Wire

Green Ground

Screw

White Wire

Wire Nuts

INSTALLATION STEP 14

Aligningthe SafetyReversingSensors

The doorwill notclose if the sensorshave notbeen installed

and alignedcorrectly.

Whenthe light beamis obstructed or misaligned while the door

is closing, the door will reverse and the garagedoor opener

lights will flash ten times. If the door is alreadyopen, it will not

close.

1. Checkto make sure the LEDsin both sensorsare glowing

steadily. The LEDsin both sensors will glow steadily if they

are aligned and wired correctly.

Thesensors can be aligned by

loosening the wing nuts, aligning

the sensors, and tightening the

wing nuts.

SENDINGSENSOR

26

It the receiving sensor is in

direct sunlight, switch it with

sending sensor so it is on the

RECEIVINGSENSOR

Page 27

A/igning the Safety Reversing Sensors (Continued)

IF THEAMBERLEDONTHESENDINGSENSORIS NOT

GLOWING:

1. Make sure there is power to the garagedoor opener.

2. Make sure the sensor wire is not shorted/broken.

3. Make sure the sensor has beenwired correctly: white wires to

white terminal andwhite/black wires to grey terminal.

ADJUSTMENT

Introduction

Your garagedoor openeris designedwith electronic controls to

make setup and adjustments easy.The adjustments allow you to

program where the door will stop in the open (UP) and close

(DOWN)position. Theelectronic controls sensethe amount of

force requiredto open and close the door. Theforce is adjusted

automatically when you program the travel andcannot be

changed.

NOTE:If anything interferes withthe door's upward travel it will

stop. If anything interferes with the door's downward travel,it will

reverse.

IF THEGREENLEDONTHE RECEIVINGSENSORIS NOT

GLOWING:

1. Make sure the sensor wire is not shorted/broken.

2. Make sure the sensors arealigned.

Without a properly installed safety reversalsystem, persons

(particularly small children) could beSERIOUSLYINJUREDor

KILLEDby a closing garagedoor.

• Incorrect adjustment of garagedoor travel limits will interfere

with proper operationof safety reversalsystem.

• NEVERuseforce adjustments to compensatefor a binding or

sticking garagedoor.

• After ANY adjustments are made,the safety reversal system

MUST betested. Door MUST reverseon contact with

1-1/2" (3.8 cm) high object (or 2x4 laid flat) on floor.

UP (Open)

ONE-PIECEDOORSONLY

When setting the UPtravel for aone-piecedoor ensurethat the

door does not slant backwards when fully open (UP). If the door

is slanted backwardsthis will cause unnecessarybucking and/or

jerking when the door is openingor closing.

To prevent damage to vehicles, be surefully open door

provides adequateclearance.

PROGRAMMINGBUTTONS

The programming buttons are located on the left side panelof the

garage door openerandareused to program the travel.

PROGRAMMING BUTTONS

o o o

UP

j Button

Adjustment

Button

DOWN

Button

27

Page 28

ADJUSTMENT STEP 1

Programthe Travel

1. Pressand hold the

Adjustment Button until the

UPButton beginsto flash

and/or a beep is heard.

Without a properly installed safety reversalsystem, persons

(particularly small children) could be SERIOUSLYINJUREDor

KILLEDby a closing garagedoor.

• Incorrect adjustment of garage door travel limits will interfere

with proper operation of safety reversal system.

• After ANY adjustments are made,the safety reversalsystem

MUST betested. Door MUSTreverseon contact with

1-1/2" (3.8 cm) high object (or 2x4 laid flat) on floor.

2. Pressand hold the UP

Button until the door is in

the desired UPposition.

NOTE:TheUPand DOWN

Buttons can be used to

move the door up and down

as needed.

3. Oncethe door is in the

desired UP position press

and releasethe Adjustment

Button.The garagedoor

opener lights will flash twice

and the DOWNButtonwill

beginto flash.

IMPORTANTNOTE:For

one-piecedoor installations

referto page27.

4. Pressand hold the DOWN

Button until the door is in

the desired DOWNposition.

NOTE:TheUPand DOWN

Buttons can be used to

move the door up and down

as needed.

6. Pressand releasethe UP

Button.When the door

travels to the programmed

UPposition, the DOWN

Button will begin to flash.

7. Pressand releasethe DOWN

Button.The doorwill travel

to the programmed DOWN

position. Programming is

complete.

If the garagedoor opener lights areflashing 5 times during the

stepsfor Programthe Travel,the programming has timed out.

If the garagedoor opener lights areflashing 10 times during

the stepsfor Programthe Travel,the safety reversing sensors

are misaligned or obstructed (refer to page 26). When the

sensorsare aligned and unobstructed, cycle the door through a

complete up and down cycle using the remote control or the UP

and DOWNbuttons. Programming is complete. If you are

unableto operatethe door up and door, repeatthe steps for

Programming the Travel.

5. Oncethe door is in the

desired DOWNposition

press and releasethe

Adjustment Button. The

garagedoor opener lights

will flash twice and the UP

Button will begin to flash.

28

Page 29

ADJUSTMENT STEP 2

Testthe SafetyReversalSystem

TEST

• With the door fully open, place a 1-1/2" (3.8 cm) board (or a

2x4 laid flat) on the floor, centered under the garagedoor.

• Operatethe door in the down direction. The door must reverse

on striking the obstruction.

ADJUST

• If the door stops onthe obstruction, it is not traveling far

enough in the down direction. CompleteAdjustment Step 1.

NOTE:On a sectional door, makesure limit adjustments do not

force the door arm beyond a straight up and down position.

SeeFigure 3, page20.

• Repeatthe test.

• Whenthe door reverseson the 1-1/2" (3.8 cm) board (or 2x4

laid flat), removethe obstruction and runthe openerthrough

3 or 4 complete travel cyclesto test adjustment.

• If the unit continues to fail the Safety ReverseTest, call for a

trained door systems technician.

IMPORTANTSAFETYCHECK:

Testthe Safety ReverseSystemafter:

• Eachadjustment of door arm length, limits, or force controls.

• Any repair to or adjustmentof the garagedoor

(including springs and hardware).

• Any repair to or buckling of the garagefloor.

• Any repair to or adjustmentof the opener.

Without a properly installed safety reversalsystem, persons

(particularly small children) could beSERIOUSLYINJUREDor

KILLEDby a closing garagedoor.

• Safety reversalsystem MUST betested every month.

• After ANY adjustments are made,the safety reversalsystem

MUSTbe tested. Door MUSTreverse on contact with

1-1/2" (3.8 cm) high object (or 2x4 laid flat) on the floor.

E

i

_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_ii_ii_ii!ii_i_ii!i!ii_i_i_ii!iii_i_i_i_i_i_i_ii

ADJUSTMENT STEP 3

TestTheProtectorSysterrP

• Pressthe remote control push button to openthe door.

• Placethe openercarton inthe pathof the door.

• Pressthe remote control push button to close the door. The

door will not move more than an inch (2.5 cm), and the opener

lights will flash.

Thegarage door openerwill not close from a remoteif the

indicator light in either sensor is off (alerting you to the fact that

the sensor is misalignedor obstructed).

If the openerclosesthe doorwhen thesafety reversingsensor

is obstructed(and the sensorsare nomore than 6" (15 cm)

abovethefloor), call fora trained doorsystemstechnician.

1-1/2" (3.8 cm) board

(or a 2x4 laid flat)

Without a properly installed safety reversing sensor, persons

(particularly small children) could beSERIOUSLYINJUREDor

KILLEDby a closing garagedoor.

29

Safety Reversing Sensor Safety Reversing Sensor

Page 30

OPERATION

IMPORTANTSAFETYINSTRUCTIONS

Toreducethe riskof SEVEREINJURYorDEATH:

1. READAND FOLLOWALL WARNINGSAND INSTRUCTIONS.

2. ALWAYSkeep remote controls out of reach of children.

NEVERpermit children to operate or playwith garagedoor

control push buttons or remote controls.

3. ONLYactivategaragedoor when it can beseen clearly, it is

properly adjusted, andthere are no obstructions to door

travel.

4. ALWAYSkeepgarage door in sight until completely closed.

NOONESHOULDCROSSTHEPATHOFTHEMOVING

DOOR.

5. NO ONESHOULDGOUNDERA STOPPED,PARTIALLY

OPENEDDOOR.

6. If possible, use emergencyrelease handleto disengage

trolley ONLYwhen garagedoor is CLOSED.Weakor broken

springs or unbalanceddoor could result in an open door

falling rapidly and/or unexpectedly,causing SEVEREINJURY

or DEATH.

7. NEVERuse emergencyreleasehandleunlessgarage

doorway is clear of persons and obstructions.

8. NEVERuse handleto pull garagedoor open or closed. If

rope knotbecomes untied, you could fall.

Features

9. After ANY adjustments are made,the safety reversal

system MUST be tested.

10. Safety reversalsystem MUST betested everymonth.

Garagedoor MUSTreverseon contact with 1-1/2" high

(3.8 cm) object (or a2x4 laid flat) on the floor.

11. ALWAYSKEEPGARAGEDOORPROPERLYBALANCED

(see page3). An improperly balanceddoor may NOT

reversewhen required and could result in SEVEREINJURY

or DEATH.

12. ALL repairsto cables,spring assembliesand other

hardware, ALL of which are under EXTREMEtension,

MUSTbe madeby a trained door systems technician.

13. ALWAYSdisconnect electric power to garagedoor opener

BEFOREmakingANY repairsor removing covers.

14. This operator system is equippedwith an unattended

operation feature. The door could move unexpectedly. NO

ONESHOULDCROSSTHE PATHOFTHEMOVINGDOOR.

15. DONOTenablethe Timer-to-Close functionality if operating

either one-piece or swinging garagedoors. To beenabled

ONLYwhen operating a sectionaldoor.

16SAVETHESEINSTRUCTIONS.

Your garagedoor openeris equippedwith features to provide you

with greater control over your garagedoor operation.

TIMER-TO-CLOSE

TheTimer-to-Close feature automatically closesthe door after a

specifiedtime period that can beadjusted using the door control.

Prior to the door closing therewill be an audible and visual alert.

ASSURELINKTM

AssureLinkTM technology uses a 900MHz signal to provide

two-way communication betweenthe garage door opener and

AssureLinkTM accessories.Your garagedoor opener is compatible

with up to 8 AssureLinkTM accessories.

REMOTECONTROLSANDDOORCONTROLS

Your garagedoor openeris compatiblewith up to 2 door controls.

Your garagedoor openerhas alreadybeen programmed at the

factory to operatewith your remote control, which changes with

eachuse, randomly accessing over 100 billion new codes.The

garagedoor opener is compatible with up to 8 remotecontrols

and 1keylessentry.

THEPROTECTORSYSTEM®(SAFETYREVERSINGSENSORS)

When properly connectedand aligned, the safety reversing

sensors will detect an obstruction in the pathof the infrared

beam. If an obstruction breaks the infrared beamwhile the door is

closing, the door will stop andreverseto full open position, and

the opener lights will flash 10 times. If the door is fully open, and

the safety reversingsensors arenot installed, or are misaligned,

the door will not close from a remote control. However,you can

close the door if you hold the button on the door control or

keyless entry until the door is fully closed. Thesafety reversing

sensors do no effect the opening cycle.

ENERGYCONSERVATION

For energy efficiency the garagedoor opener will enter sleep

mode when the door is fully closed. The sleep mode shuts the

garage door opener down until activated. Thesleep mode is

sequencedwith the garage door opener light bulb; as the light

bulb turns off the sensor LEDswill turn off andwhenever the

garage door opener lights turn onthe sensor LEDswill light.

Thegarage door openerwill not go into the sleep mode until the

garage door opener hascompleted 5 cycles upon power up.

LIGHTS

Thegarage door opener light bulbs will turn on when the opener

is initially plugged in; power is restored after interruption, or

when the garagedoor opener is activated.Thelights will turn off

automatically after 4-1/2 minutes. An incandescentA19 light bulb

(100 watt maximum) or for maximum energy efficiencya 26W

(100W equivalent) compact fluorescent light (CFL)bulb may

be used.

Thegarage door opener is equippedwith an addedfeature;the

lights will turn on when someoneenters through the open garage

door andthe safety reversing sensor infrared beamis broken.

For addedcontrol over the light bulbs onyour garage door

opener,see the Door Controlsection.

3O

Page 31

Features(Continued)

USINGYOURGARAGEDOOROPENER

Thegarage door opener can beactivatedthrough a wall-mounted

door control, remote control, wireless keylessentryor

AssureLinkTM accessory.

When the door is closed andthe garagedoor opener is activated

the door will open. If the door sensesan obstruction or is

interrupted while opening the door will stop. Whenthe door is in

any position other than closedandthe garage door opener is

activated the door will close. If the garage door opener sensesan

obstruction while closing, the door will reverse.If the obstruction

Door Contro/

USINGTHEDOORCONTROL

Push Bar

1 Minute

TTC LED

5 Minute

TTC LED

10 Minute

TTC LED

Push Bar

Press the push bar to open or closethe door.

Light Button

Press the LIGHT button to turn the garagedoor openerlights on

or off. Whenthe lights areturned on they will stay on until the

LIGHTbutton is pressedagain, or until the garagedoor opener is

activated. Oncethe garagedoor opener is activatedthe lights will

turn off after the specified periodof time (the factory setting is

4-1/2 minutes). The LIGHTbutton will not control the lights when

the door is in motion. The duration of the light timing can be

adjusted using the door control.

HOLDButtonfor the

Timer-To-Close(TTC)

LIGHT

Button

Motion

Sensor

interrupts the sensor beam the garagedoor opener lights will

blink 10 times. However,you can close the door if you hold the

button on the door control or keylessentry until the door is fully

closed.The safety reversingsensors do no effectthe opening

cycle.

Thesafety reversing sensor must be connected and aligned

correctly before the garagedoor opener will move in the down

direction.

The followingfeaturesare accessibleby lifting thepush bar on

the Motion-DetectingControlPanel:

LEARNA DEVICE

Any compatible remote controls, wireless keylessentry, or

AssureLinkTM accessoriescan be programmedto the garagedoor

opener by pressing the Learn button onthe Motion-Detecting

Control Panel.

Lock

The LOCKfeatureis designedto prevent activation of the garage

door openerfrom remote controls while still allowing activation

from the door control and keyless entry. Thisfeature is useful for

addedpeaceof mind when the home is empty (i.e.vacation).

Tlmer-to-C/ose(TTC)

DONOTenableTTCif operating a one-piece door. TTC is to be

used ONLYwith sectional doors.

Factorydefault is set to off. TTCcan besetto automatically close

your garage door from the fully open position after a specified

period of time (1, 5, 10 minute intervals).The garagedoor opener

will beepand the lights will flash beforeclosing the door. If the

door encountersan obstruction while closing, the garagedoor

openerwill make a second attempt to closethe door. If the

obstruction has not beencleared after the second attempt, the

garagedoor openerwill reverseopen, stop andWILL NOTclose

until the obstruction hasbeen cleared.TTCWILL NOTwork if the

safety reversing sensors are misaligned. Thisfeatureis NOT

intendedto be the primary method of closing the door. Akeyless

entryshouldbe installedinthe eventof anaccidentallock out

when usingthisfeature.

AUTOMATICLIGHT

Motion Sensor

Factory default is set to on. This featurewill automatically turn on

the garagedoor opener lightswhen motion is sensed.The lights

will come on for the set periodof time, then shut off.

The lightswill turn on when someoneenters through the open

garage door and the safety reversing sensor infrared beam is

broken.

If usingthe garagedoor openerlight as a work light disablethe

Automatic Light Feature,otherwise the light will turn off

automatically if you are beyondthe rangeof the sensor.

31

Page 32

Motion-DetectingControlPanelSetup

Motion

Sensor

Switch

LEARNButton _

LOCKButton

1 Minute

TTC LED

5 Minute

TTC LED

10 Minute J

TTC LED

TIME TO CLOSE

TIMER-TO-CLOSE(TTC)

NOTE:DONOTenable TTCif operating a one-piece door. TTCis

to be used ONLYwith sectional doors.

Activate:

Pressand holdthe ONbutton until one of the TTCLEDslight up.

Then press the ONbutton again to cyclethrough the time interval

options (the corresponding TTCLEDwill light for eachtime

interval). The garagedoor openerlight bulbs will blink as

confirmation.

Deactivate:

Pressand holdthe OFFbutton until all TTCLEDsturn off anda

beepis heardfrom the motor unit.

Command LED

NOTE: If the command LED is

continuously blinking, the Lock feature

needs to be deactivated.

ON

J Button

OFF

I

0

Button

HOLD OPEN

Button

LIGHT Button

-_. Motion

Sensor

LIGHT

TOchangetheamount oftime the garagedooropenerlights

will stayon:

Press and hold the LOCKbutton until the garage door opener

lights flash.* The time interval is indicated by the numberof

flashes.

1 1Y_Minutes

2 2 Y_Minutes

3 3 Y_Minutes

4 4 Y_Minutes

To cycle through the time intervals repeatthe step above.

Temporarily hold dooropen(suspendTTC):

Pressand releasethe HOLDOPENbutton. Pressthe HOLDOPEN

button againto resumenormal TTCoperation.

LOCK

Activate:

Press and hold the LOCKbutton for 2 seconds.The command

LEDwill flash as long asthe lock feature is activatedand your

handheld remote control will not operateyour door at this time.

Deactivate:

Press and hold the LOCKbutton again for 2 seconds.The

command LEDwill stop flashing and normal operation will

resume.

LIGHTFEATURE

Deactivate:

Press and hold the LIGHTbutton until the garagedoor opener

lights turn on, then off again.*

Activate:

Start with the garagedoor opener lights on. Press and hold the

LIGHTbutton until the garagedoor openerlights turn off, then on

again.*

MOTIONSENSOR

Activate/Deactivate:

Slide the motion sensor switch ONor OFF.

* Approximately 10 seconds

32

Page 33

Programming

Your garagedoor openerhas beenprogrammedat the factory to operatewith your remote control. The remote control can be

programmed using the door control or the garagedoor opener. To program additional remotecontrols refer to the instructions provided

with the additional remote controls.

PROGRAMA REMOTEUSINGTHELEARNBUTTON TO ADD, REPROGRAIVl,ORCHANGEA REMOTECONTROL/

KEYLESSENTRYPIN USINGTHEMOTION-DETECTING

CONTROLPANEL

1. Pressand releasethe Learnbutton on

the garage door opener.The Learn

indicator light will glow steadily for 30

seconds.

2. Within 30 seconds, press and hold the