Craftsman 12458833 Owner’s Manual

Operator’s Manual

10″

CONTRACTOR TABLE SAW

Model No.

124.58833

Safety

Unpacking

CAUTION:

Read and follow all Safety

Rules and Operating

Instructions before First Use of

this Product. Keep this Manual

with Tool.

Sears Brands Management Corp., Homan Estates, IL 60179 U.S.A

www.craftsman.com

Assembly

Operation

Maintenance

Parts List

Español

TABLE OF CONTENTS

Warranty .........................................................................................2

Safety Rules.................................................................................2-5

Unpacking.......................................................................................5

Assembly....................................................................................6-13

Installation................................................................................13-14

Operation.................................................................................14-20

Maintenance.................................................................................20

Troubleshooting............................................................................21

Parts Illustrations, Lists and Notes...........................................22-30

Español.........................................................................................31

WARRANTY

CRAFTSMAN LIMITED WARRANTY

FOR ONE YEAR from the date of sale this product is warranted

against defects in material or workmanship.

WITH PROOF OF SALE a defective product will receive free

repair. If the product cannot be repaired it will be replaced free of

charge.

For warranty coverage details to obtain free repair, visit the web

page: www.craftsman.com/warranty

This warranty does not cover the blade, which is an expendable

part that can wear out from normal use within the warranty period.

This warranty applies for only 90 days from the date of sale if this

product is ever used while providing commercial services or if

rented to another person.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Sears Brands Management Corporation, Homan Estates, IL

60179

For Questions/Comments or Technical Assistance-Please call

Customer Service; 1-(877) 866-8392 (M-F 8:30AM-5PM EST.)

SAFETY RULES

WARNING:

precautions before operating tool.

PROPOSITION 65 WARNING

WARNING:

products can expose you to wood dust, a substance known to the

State of California to cause cancer. Avoid inhaling wood dust or

use a dust mask or other safeguards for personal protection. For

more information go to

Your risk from these exposures vary, depending on how often you

do this type of work. To reduce your exposure to dust: work in a

well ventilated area and work with approved safety equipment.

Always wear OSHA/NIOSH approved, properly tting face mask or

respirator when using such tools.

CAUTION:

dened in this manual — even if you are familiar with use of

this or similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury.

BE PREPARED FOR THE JOB

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear face mask or dust mask if operation is dusty.

For your own safety, read all of the instructions and

Drilling, sawing, sanding or machining wood

www.P65Warnings.ca.gov/wood.

Always follow proper operating procedures as

2

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant lenses.

They are

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications

that cause drowsiness.

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite

accidents.

• Do not use power tools in dangerous environments. Do not

use power tools in damp or wet locations. Do not expose

power tools to rain.

• Work area should be properly lighted.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

• Keep power cords from coming in contact with sharp

objects, oil, grease and hot surfaces.

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specic maintaining and adjusting

procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before switching machine on.

• Keep all parts in working order. Check to determine that

the guard or other parts will operate properly and perform

their intended function.

• Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condition

that may aect a tool’s operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs.

(Use parts list provided to order replacement parts.)

• Maintain proper adjustment of rip fence and blade guard.

• Never adjust saw while running. Disconnect power to avoid

accidental start-up.

• Have damaged or worn power cords replaced immediately.

• Keep blade sharp for ecient and safest operation.

KNOW HOW TO USE THE TOOL

• Use right tool for the job. Do not force tool or attachment to

do a job for which it was not designed.

• Disconnect tool when changing blade.

• Avoid accidental start-up. Make sure that the tool is in the

“o” position before plugging in, turning on safety

disconnect or activating breakers.

• Do not force tool. It will work most eciently at the rate for

which it was designed.

• Keep hands away from blade and moving parts and cutting

surfaces.

• Never leave tool running unattended. Turn the power o

and do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is

tipped or if blade is unintentionally contacted.

• Know your tool. Learn the tool’s operation, application and

specic limitations.

NOT

safety glasses.

• Handle workpiece correctly. Press rmly against table.

Protect hands from possible injury.

• Turn machine o if it jams. Blade jams when it digs too

deeply into workpiece. (Motor force keeps it stuck in the

work.)

• Feed work into the blade only as recommended in

“Operation.”

WARNING:

until it is completely assembled and installed according to

instructions.

STABILITY OF SAW

If there is any tendency for the saw to tip over or move during

certain cutting operations, such as cutting extremely heavy

panels or long heavy boards, the saw should be bolted down.

If you attach any kind of extensions over 24" wide to either

end of the saw, make sure you either bolt the saw to the oor,

as appropriate, or support the outer end of the extension

from the bench or oor, as appropriate.

LOCATION

The saw should be positioned so neither the operator nor a

casual observer is forced to stand in line with the saw blade.

KICKBACKS

A kickback occurs during a rip-type operation when a part or

all of workpiece is thrown back violently toward operator.

Keep your face and body to one side of the saw blade, out of

line with a possible kickback.

Kickbacks and possible injury from them can usually be

avoided by:

• Maintaining rip fence parallel to saw blade.

• Keeping saw blade sharp. Replace or sharpen anti-

kickback pawls when points become dull.

• Keeping saw blade guard, spreader, and anti-kickback

pawls in place and operating properly. The spreader must

be in alignment with the saw blade and the pawls must

stop a kickback once it has started. Check their action

before ripping.

• Not ripping work that is twisted or warped or does not

have a straight edge to guide along the rip fence.

• Not releasing work until you have pushed it all the way

past the saw blade.

• Using a push stick for ripping widths less than 6 inches.

• Not conning the cuto piece when ripping or crosscutting.

PROTECTION: EYES, HANDS, FACE, BODY, EARS

• If any part of your saw is missing, malfunctioning, or has

been damaged or broken (such as the motor switch,

electronic controls, other operating control, a safety device

or power cord), cease operating immediately until the

particular part is properly repaired or replaced.

• Wear safety goggles that comply with United States ANSI

Z87.1 and a face shield or dust mask if operation is dusty.

Wear ear plugs or mus during extended periods of

operation.

• Small loose pieces of wood or other objects that contact

the rear of the revolving blade can be thrown back at the

operator at excessive speed. This can usually be avoided

by keeping the guard and spreader in place for all

thru-sawing operations (sawing entirely thru work) and

by removing all loose pieces from the table with a long stick

of wood immediately after they are cut o.

For your own safety, do not operate your saw

• Use extra caution when the guard assembly is removed for

resawing, dadoing, or rabbeting—replace guard as soon

as that operation is completed.

• Never turn the saw ON before clearing the table of all

tools, wood scraps, etc., except the workpiece and related

feed or support devices for the operation planned.

• Never place your face or body in line with the cutting tool.

• Never place your ngers or hands in path of saw blade or

other cutting tool.

• For rip or rip-type cuts, the following end of a workpiece to

which a push stick or push board is applied must be

square (perpendicular to the fence) in order that feed

pressure applied to the workpiece by the push stick or

block does not cause the workpiece to come away from

the fence, and possibly cause a kickback.

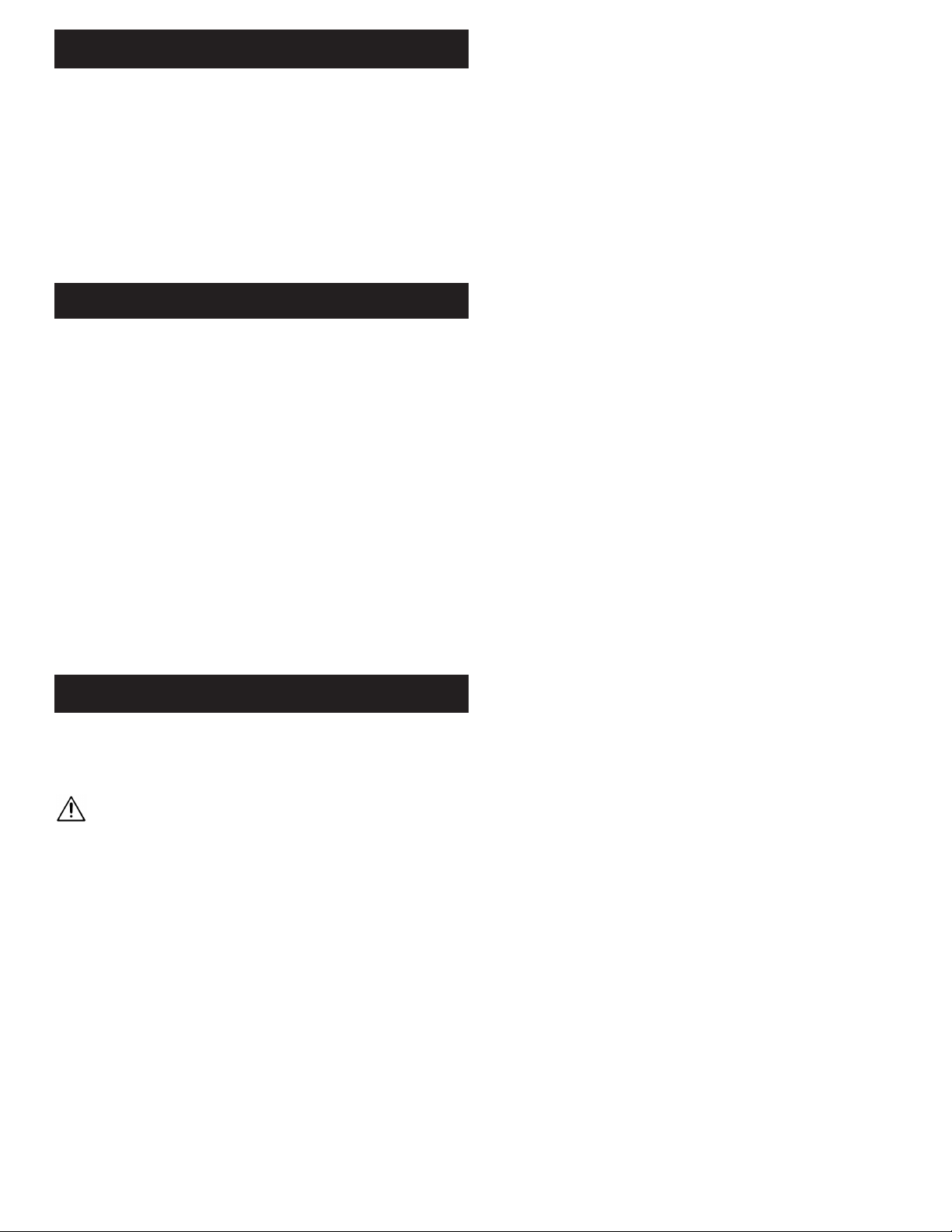

• During rip and rip-type cuts, workpiece must be held down

on table and against fence with a push stick, push block,

or featherboards, as applicable (see Figures 1a and 1b,

page 4).

The push stick and push block examples shown on page

4 are useful for keeping hands and ngers away from saw

blade during ripping, rabbeting and dadoing. Apply downward pressure and push workpiece through the cut and past

the blades. Several other congurations may be suitable for

safe operation.

Featherboards are used to keep the work in contact with the

rip fence or table during the cutting operation. Use of featherboards can help to prevent kickbacks and binding. Feather-

boards should be used for all “non thru-sawing” operations.

• Never reach in back of the cutting tool with either hand to

hold down or support the workpiece, remove wood scraps,

or for any other reason. Avoid awkward operations and

hand positions where a sudden slip could cause ngers or

hand to move into a saw blade or other cutting tool.

• Do not perform layout, assembly, or setup work on the

table while the cutting tool is rotating.

• Do not perform any operation freehand—always use either

rip fence or miter gauge to position and guide the work.

• Never use the rip fence when cross-cutting or the miter

gauge when ripping. Do not use rip fence as a length stop.

Never hold onto or touch free-end of workpiece or a free-

piece that is cut o, while power is ON and/or saw blade is

rotating.

• Shut the saw OFF and disconnect power source when

removing the table insert, changing the cutting tool,

removing or replacing the blade guard, or making adjust

ments.

• Provide adequate support to the rear and sides of the saw

table for wide or long workpieces.

• Plastic and composition materials (like hardboard) may be

cut on your saw. However, since these are usually quite

hard and slippery, the anti-kickback pawls may not stop a

kickback. Therefore, be especially attentive to following

proper setup and cutting procedures for ripping. Do not

stand, or permit anyone else to stand, in line with a poten-

tial kickback.

• If you stall or jam the saw blade in the workpiece, turn saw

OFF and remove the workpiece from the saw blade.

Check to see if the saw blade is parallel to the miter

gauge grooves and if the spreader is in proper alignment

with the saw blade. If ripping at the time, check to see if

the rip fence is parallel with the saw blade. Readjust as

required.

3

• Do not remove small pieces of cuto material that may

become trapped inside the blade guard while the saw is

running. This could endanger your hands or cause kick

back. Turn saw OFF and wait until blade stops.

• Use extra care when ripping wood with twisted grain or

wood that is twisted or bowed—it may rock on table and

pinch saw blade.

• Never use grinding wheels, abrasive cuto wheels, friction

wheels (metal slitting blades), wire wheels or bung

wheels.

KNOW YOUR CUTTING TOOLS

• Dull, gummy, improperly sharpened or set cutting tools can

cause material to stick, jam, stall saw, or kickback at

operator. Minimize potential injury by proper care and

machine maintenance.

WARNING:

without rst turning saw OFF.

Never attempt to free a stalled saw blade

USE ONLY ACCESSORIES DESIGNED FOR SAW

• Crosscutting operations are worked more conveniently and

with greater safety if an auxiliary wood facing is attached

to miter gauge using holes provided. However, facing must

not interfere with proper functioning of saw blade guard.

• Make sure the top of the arbor or cutting tool rotates

toward you when standing in normal operating position.

Also make sure the cutting tool, blade ange and arbor

nut are installed properly. Keep the cutting tool as low as

possible for the operation being performed. Keep all

guards in place whenever possible.

• Do not use any blade or other cutting tool marked for

operating speed less than 4000 RPM. Never use a cutting

tool larger in diameter than diameter for which saw was

designed. For greatest safety and eciency when ripping,

use maximum diameter blade for which saw is designed,

since under these conditions spreader is nearest the

blade.

4

• Adjust table inserts ush with table top. Never operate saw

unless proper insert is installed.

• Never feed material into the cutting tool from the rear of

the saw. An accident and serious injury could result.

Hardware Bag #1 (For extension table assembly)

M10X25 Socket head bolt (6)

10mm Lock washer (6)

10mm Flat washer (6)

THINK SAFETY

Safety is a combination of operator common sense and alertness at all times when the saw is being used.

Never use another person as a substitute for a table extension, or as additional support for a workpiece that is longer or

wider than basic saw table, or to assist in feeding, supporting

or pulling the workpiece.

Do not pull the workpiece through the saw blade—position

your body at the infeed side of the guard; start and complete

the cut from that same side. This will require added table

support for long or wide workpieces that extend beyond the

length or width of the saw table.

CAUTION:

of your saw.

Follow safety instructions that appear on the front

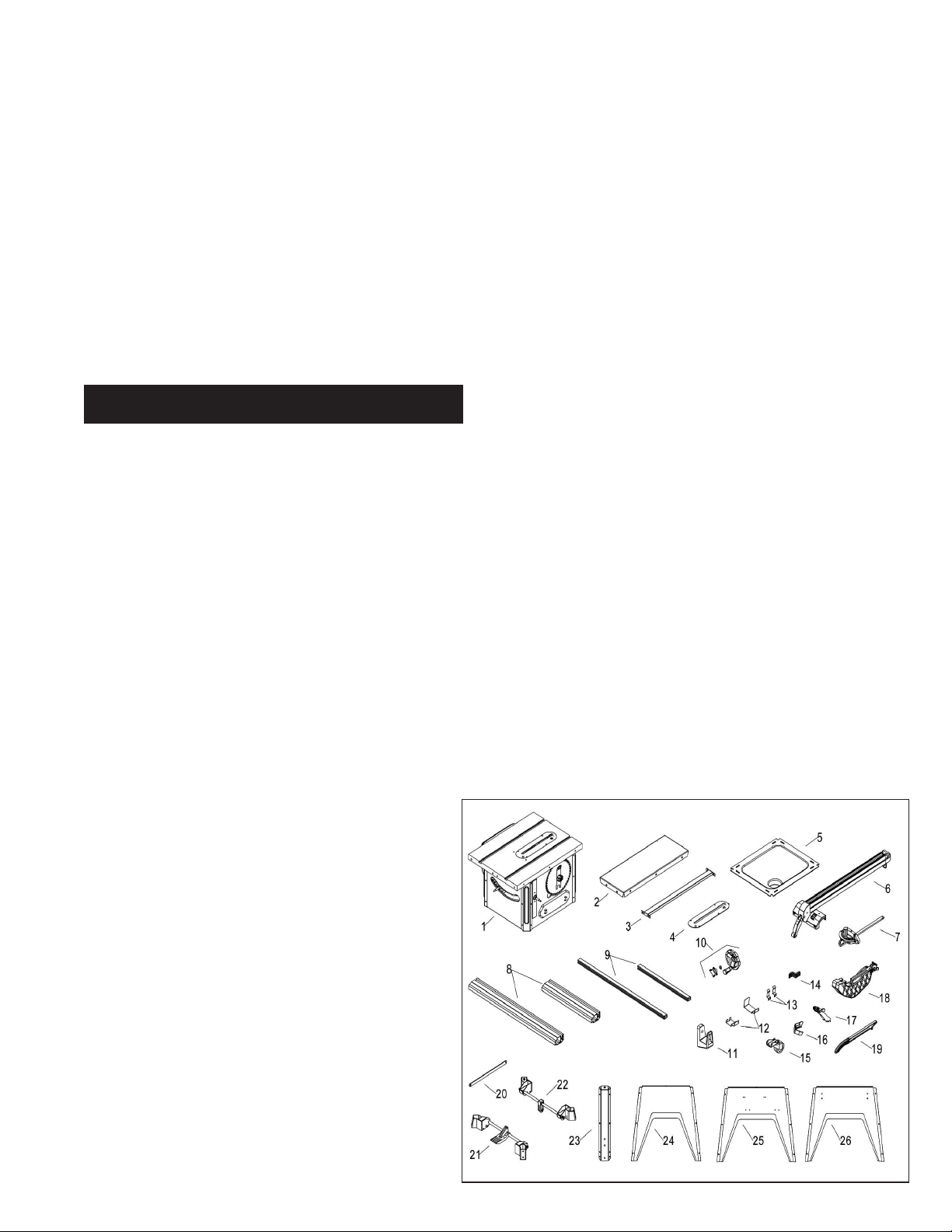

UNPACKING

Refer to Figure 2.

• Open shipping box. Remove all parts, except saw body,

from both styrofoam packing bases and set parts and top

base safely aside. Remove the dust chute from the saw

cabinet.

• Use utility knife to cut down the four corners of the shipping

box, allowing cardboard sides to lay on oor and fully

exposing the styrofoam packing base.

• Cut away enough styrofoam from motor cover side of

packing base so that, with the aid of an assistant, you can

slide the saw body from the base onto cardboard. Saw

table will remain on cardboard until instructed in Assembly

section to turn saw body upright onto leg base.

CAUTION:

Use this manual to order replacement parts.

Check for shipping damage or missing parts. If any parts are

damaged or missing, call 1-888-331-4569 for replacement.

The table saw body comes assembled as one unit. Additional

parts which need to be fastened to the saw should be located

and accounted for before assembling:

1. Table saw

2. Extension table (2)

3. Brace

4. Table insert

5. Dust chute

6. Rip fence assembly

7. Miter gauge assembly

8. Front rail (2)

9. Rear rail (2)

10. Handwheel with knob (2)

11. Rip fence storage hooks (2)

12. Blade guard storage hooks (2)

13. Push stick storage hooks (2)

14. Line cord wrap hooks (2)

15. Caster (4)

16. Foot (4)

17. Anti-kickback pawl assembly

18. Blade guard assembly

19. Push stick

20. Link plate

21. Front caster support assembly

22. Rear caster support assembly

23. Corner support (4)

24. Base panel “A” (2)

25. Base panel “B”

26. Base panel “C”

Do not attempt assembly if parts are missing.

Hardware Bag #2 (For guide rail and brace assembly)

M8X30 Hex head bolt (16)

M8X16 Hex head bolt (4)

8mm Lock washer (20)

8mm Flat washer (20)

M8 Hex nut (16)

M8 Acorn hex nut (4)

Hardware Bag #3 (For switch assembly)

M6X16 Hex head bolt (2)

6mm Flat washer (2)

6mm Lock washer (2)

M6 Hex nut (2)

Hardware Bag #4

M10X25 Socket head bolt (4)

10mm Lock washer (4)

10mm Flat washer (4)

(For assembling stand to main machine)

-----------------------------------------------------M8X16 Socket pan head screw (8)

(For assembling caster supports to corner support)

------------------------------------------------------------------M6X12 Socket pan head screw (24)

(For assembling corner support to base panel)

-------------------------------------------------------------M6X20 Socket pan head screw (4)

6mm Flat washer (4)

M6 Hex nut (4)

(For assembling fence storage hooks and line cord hooks)

----------------------------------------------------------------------------M4X8 Pan head screw (8)

(For assembling push stick storage and blade guard storage

hooks)

4mm Flat washer (8)

Hardware Bag #5

10/13mm Open end wrench

4mm Hex wrench 6mm Hex wrench

5mm Hex wrench 8mm Hex wrench

Figure 2 - Unpacking

5

ASSEMBLY

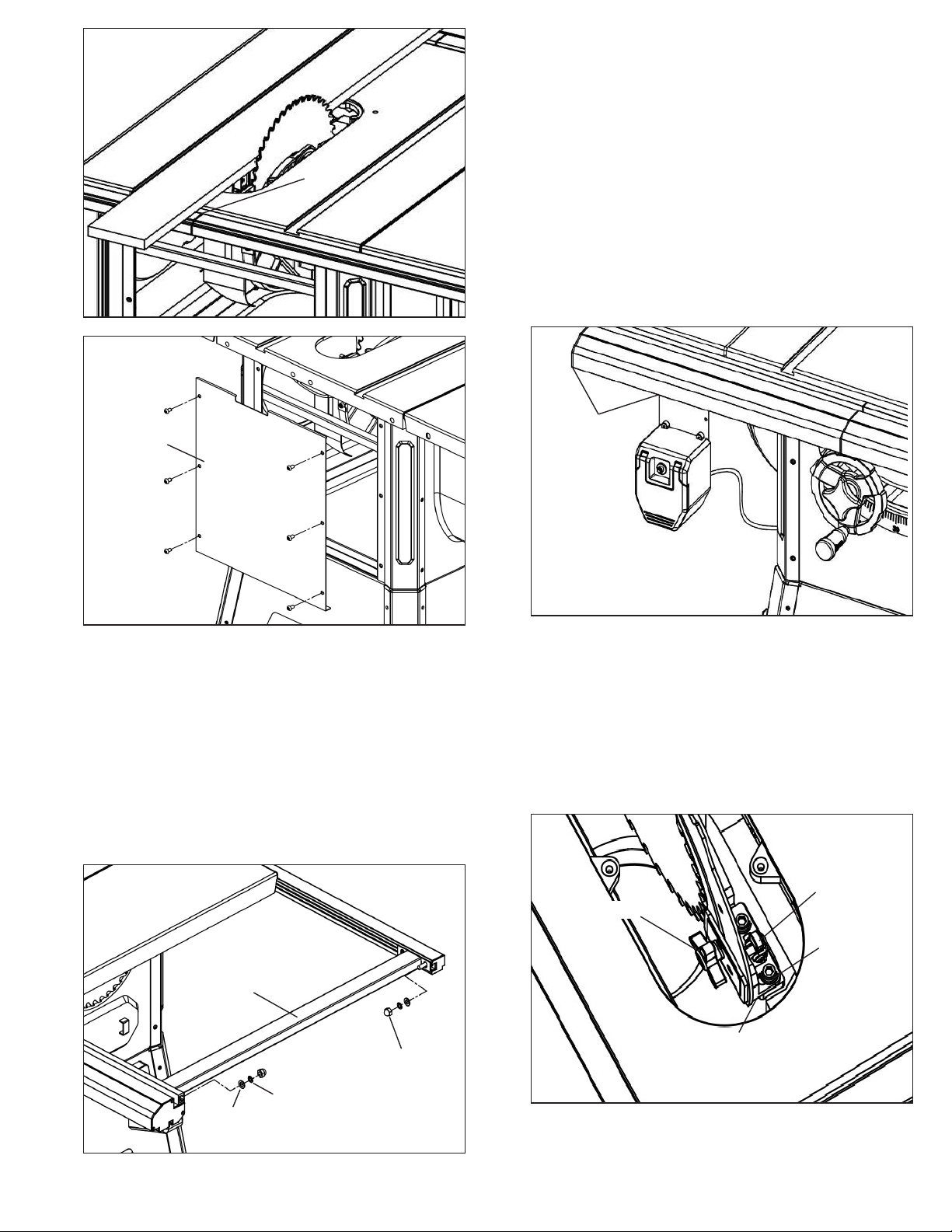

ASSEMBLE MOBILE BASE PANELS

Refer to Figure 5.

CAUTION:

Do not attempt assembly if parts are missing.

Use this manual to order replacement parts. Be certain all

parts are clean and free of shipping preservative. Also, completely remove all parts of packing. Saw cabinet should be

assembled directly on the oor.

SAW INSTALLATION

Positioning the saw on a level surface will improve stability

and accuracy and prevent warpage and failure of cast components and welds.

WARNING:

Make certain that the saw is disconnected from

the power source.

INSTALL HANDWHEELS

Refer to Figure 3.

• Remove saw cabinet and place upside down on cardboard

box or cardboard on oor.

• Place one of the handwheels onto the blade raise/lower

shaft located on the front of the cabinet. Align the groove

in the back of the handwheel with the pin.

• Thread the washer and locking knob onto the threaded end

of the shaft. Do not overtighten or handwheel will not turn.

• Repeat the steps above to assemble the remaining hand

wheel and locking knob onto the blade tilt shaft located on

the side of the cabinet.

Tools Required:

Hardware Required:

4mm Hex Wrench.

Twenty-four M6 x 12 socket pan head

screws (Hardware bag #4).

• Attach a corner support to each front panel edge with three

M6 x 12 socket pan head screws.

NOTE:

Place the panel edges INSIDE the corner support

surfaces.

NOTE:

Front panel and rear panel are both stamped ‘A’.

Front panel has warning label.

• Repeat above step for the rear panel.

Figure 5

Panel B (left)

M6 x 12 Socket

Pan Head

Screws (x24)

Panel A (rear)

Figure 3

Handwheel

Flat Washer

Locking Knob

Cardboard

REMOVE PACKING MATERIAL

Refer to Figure 4.

• Use the blade height handwheel to lower the motor.

• Remove the packing material from behind the motor.

• Return motor to the raised position.

Figure 4

Panel C (right)

Panel A (front)

• Turn all panels upside down to perform base assembly.

• Attach one corner of left panel (stamped ‘B’) to front panel

A.

• Attach the other corner of left panel B to rear panel A.

• Repeat above two steps for attachment of right panel

(stamped ‘C’).

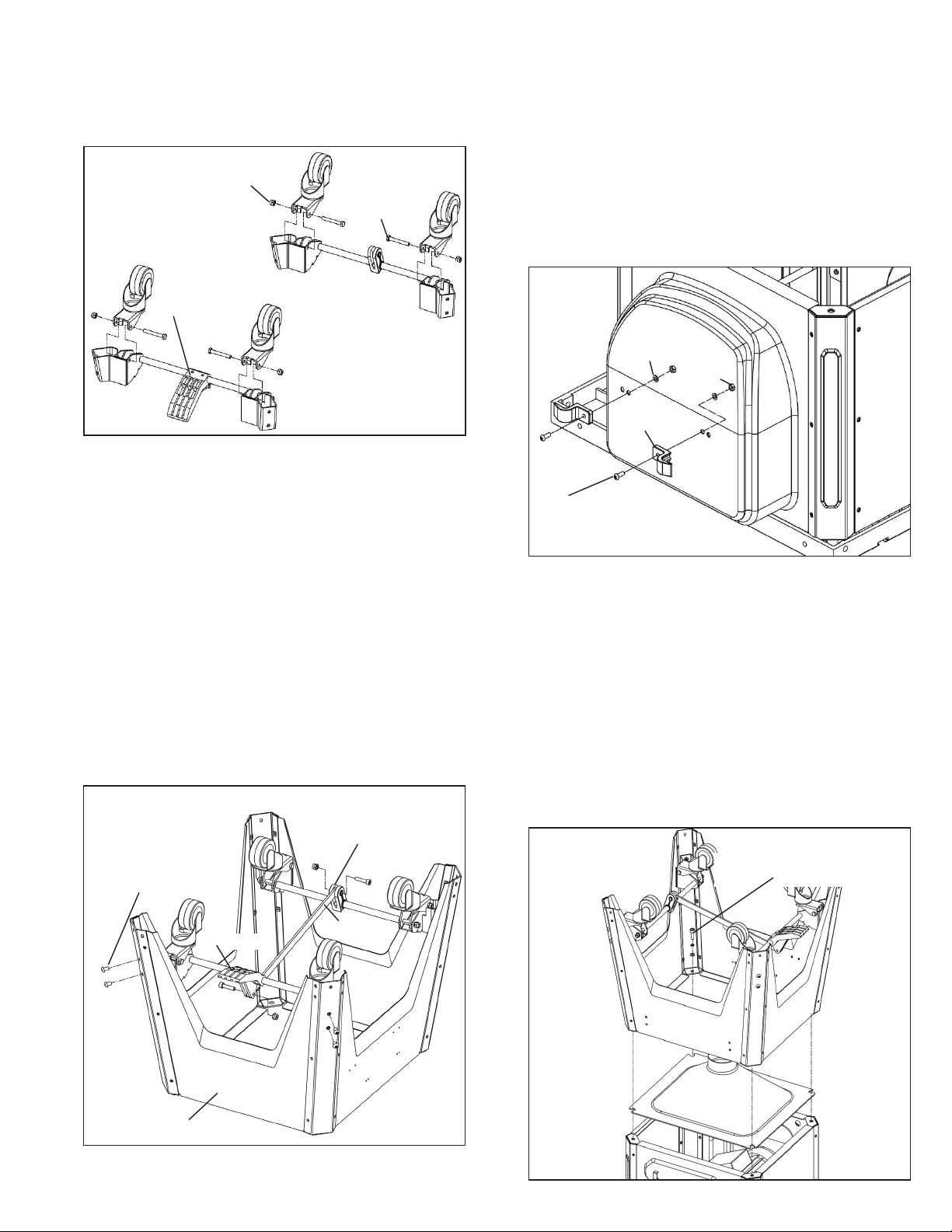

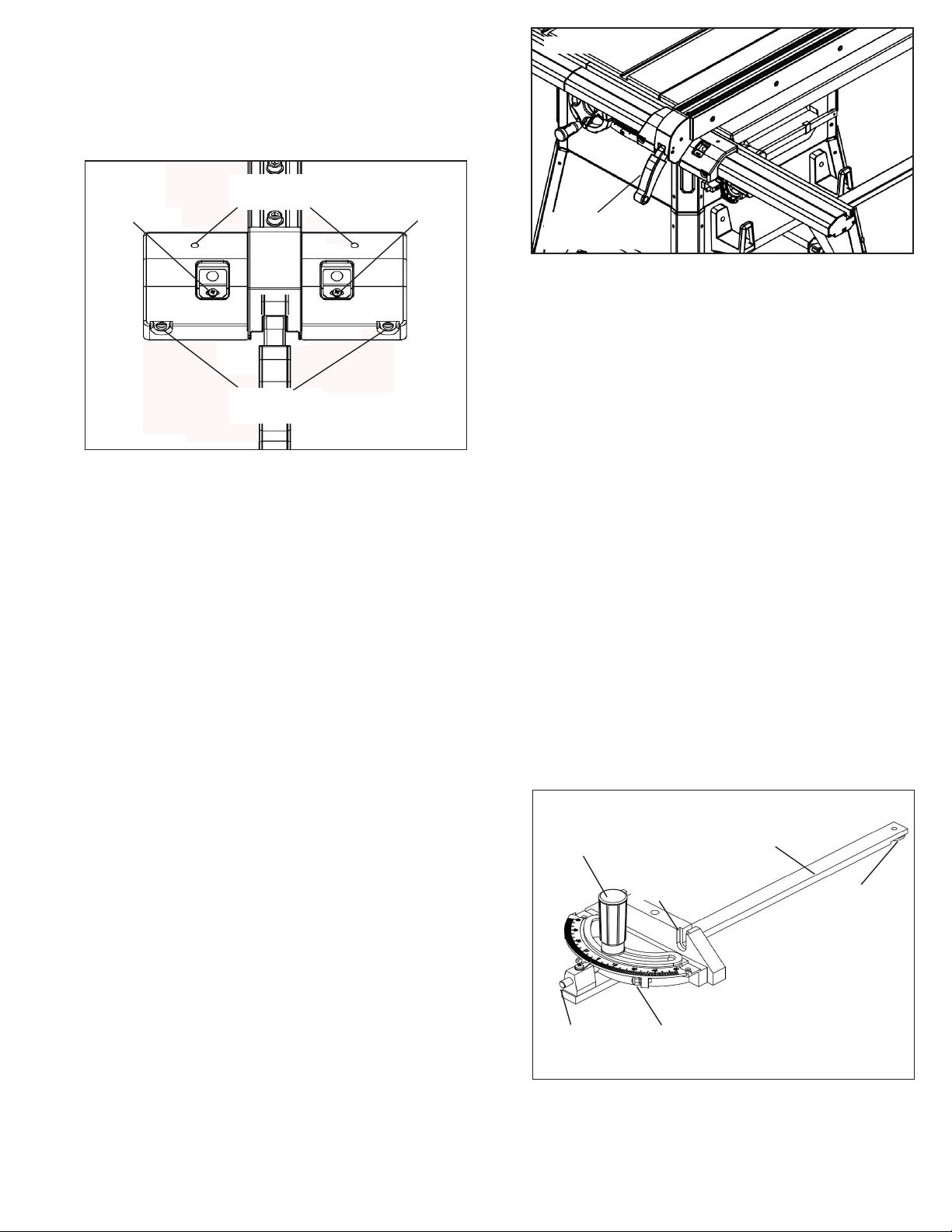

ASSEMBLE CASTER SETS

Refer to Figures 6 & 7.

Tools Required:

One 6mm Hex wrench and one 13mm

Open End or Adjustable Wrenches.

• Remove casters (4), link plate and caster supports (2) from

carton.

Figure 6

Casters

Packing Material

Caster Support (rear)

Link Plate

Caster Support (front)

6

• Loosen and remove the pre-installed bolts and hex nuts

from the brackets (see Figure 7).

• Rotate foot pedal bar so that foot pedal is pointing down

towards the oor.

• Place casters onto the brackets and secure in position with

bolts and hex nuts provided.

Figure 7

Hex Nut

Bolt

Foot Pedal

ATTACH CASTER SETS TO BASE

Refer to Figure 8.

ATTACH CORD WRAP HOOKS

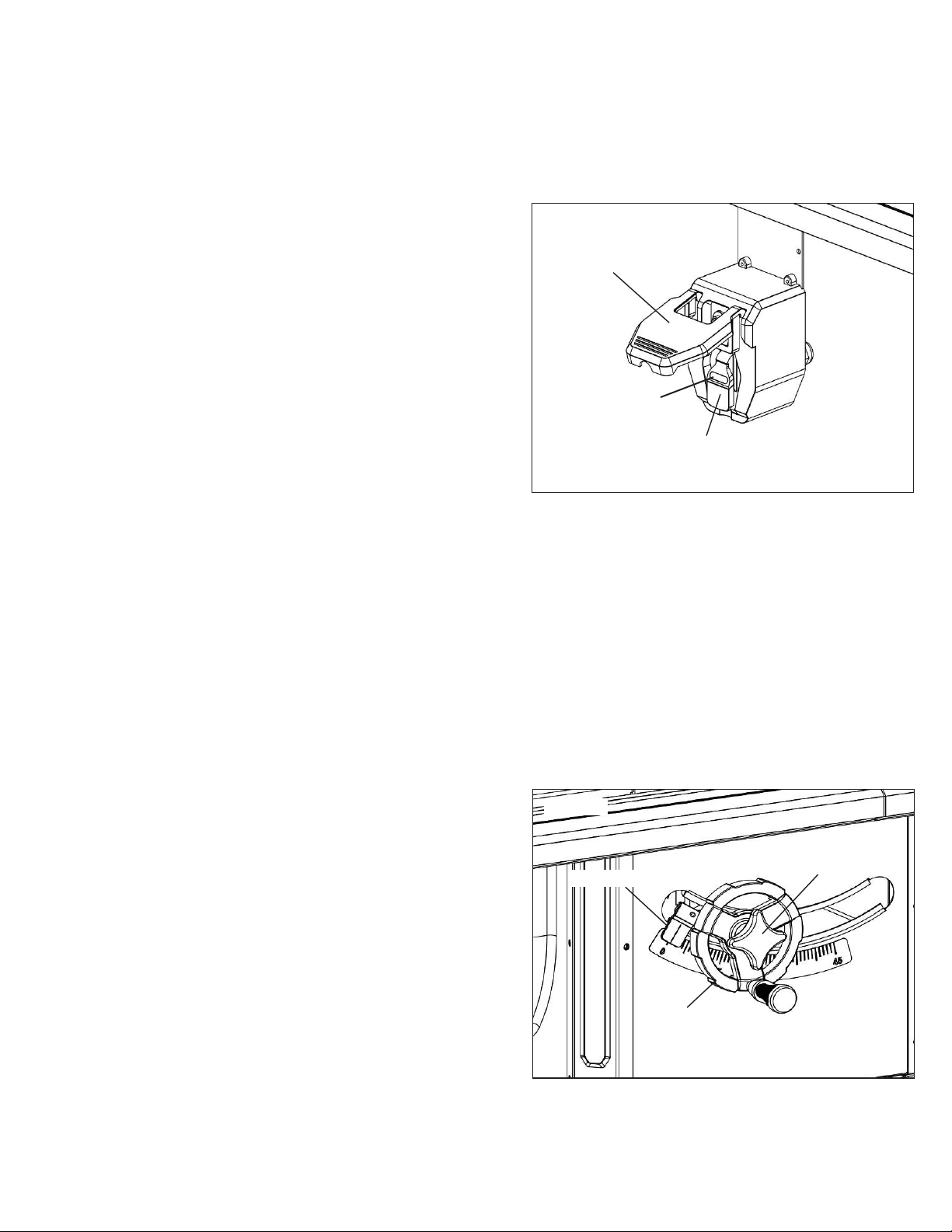

Refer to Figure 9.

Tools Required:

Hex wrench 4mm and 10mm open end

wrench.

Hardware Required:

Two M6 x 20 socket pan head screws,

two M6 at washers and two M6 hex nuts (Hardware bag

#4).

• Place cord wrap hook into position on motor housing.

• Insert washer onto bolt. Insert bolt through hole and thread

nut onto bolt end on inside of housing.

• Repeat for other hook.

Figure 9

Flat Washer

M6

Hex Nut

M6

Cord Wrap

Hook

Tools Required:

Hex wrench 5mm, Hex wrench 6mm and

13mm Open end wrench.

Hardware Required:

Eight M8 x 16 socket pan head screws

(Hardware bag #4).

• Attach the foot pedal caster set to the two front corner

supports using four M8 x 16 socket pan head screws.

• Attach the link block caster set to the two rear corner

supports.

• Remove the socket head bolt and hex nut from the foot

pedal, insert the link plate into the slot of foot pedal and

secure in place with the socket bolt and hex nut.

• Remove the socket head bolt and hex nut from the link

block of rear caster set, insert the link plate into the slot of

link block and secure in place with the socket bolt and hex

nut.

Figure 8

Link Block

M8 x 16 Socket

Pan Head Screws

(8)

Link Plate

Foot Pedal

M6 x16 Socket

Pan Head

Screw

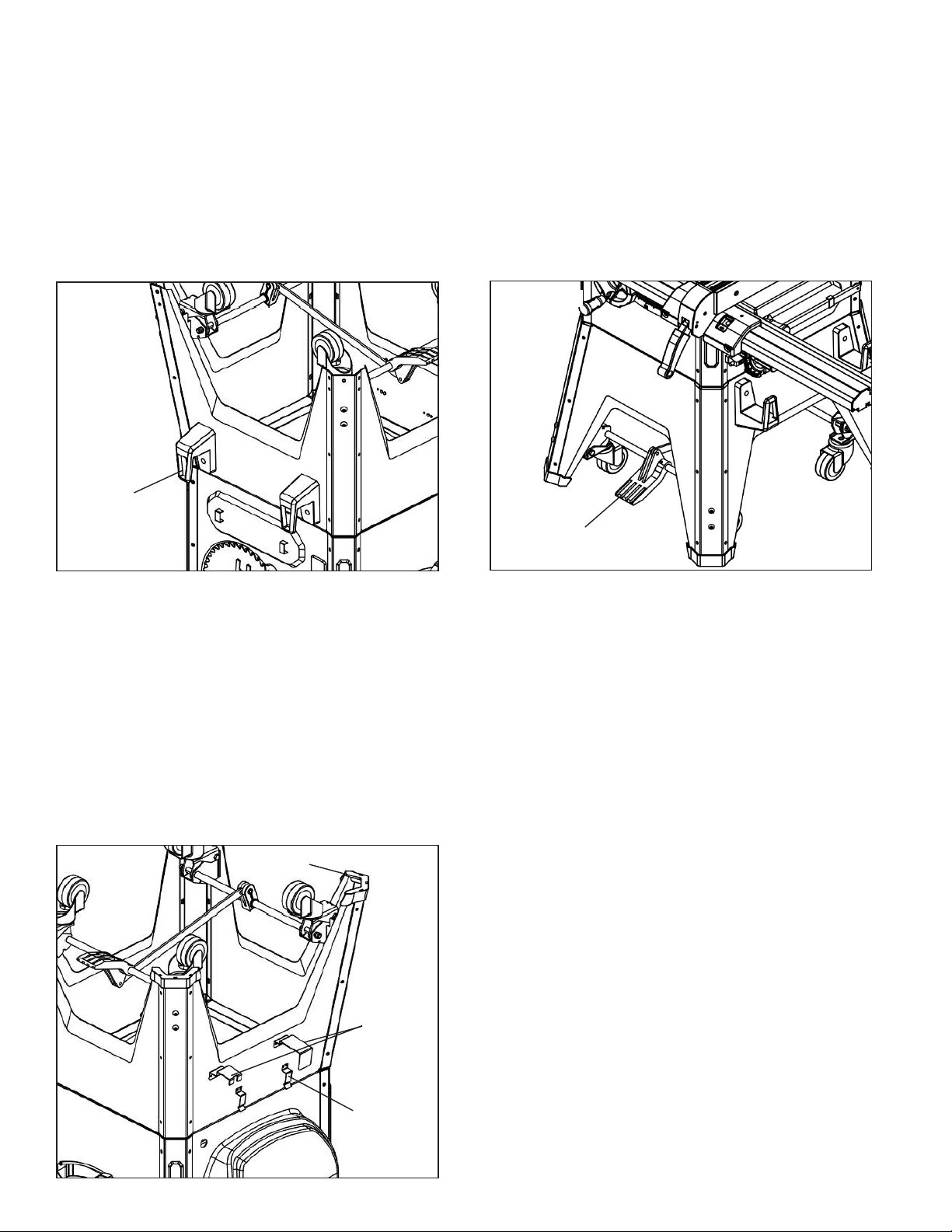

ATTACH BASE TO CABINET

Refer to Figure 10.

Tools Required:

Hardware Required:

8mm Hex Wrench.

Four M10 x 25 socket head bolts, four

M10 lock washers and four M10 at washers (Hardware bag

#4).

• Place dust chute over the cabinet as shown. Make sure

the holes in the corners are aligned with the slots in the

dust chute.

• Place the base assembly over the dust chute and secure

the base assembly to the cabinet using the at washers,

lock washers and bolts.

• Secure all fasteners in the base assembly fully tight.

Figure 10

Bolt/Lock Washer/Flat

Washer (x4)

Panel A (front)

Dust Chute

7

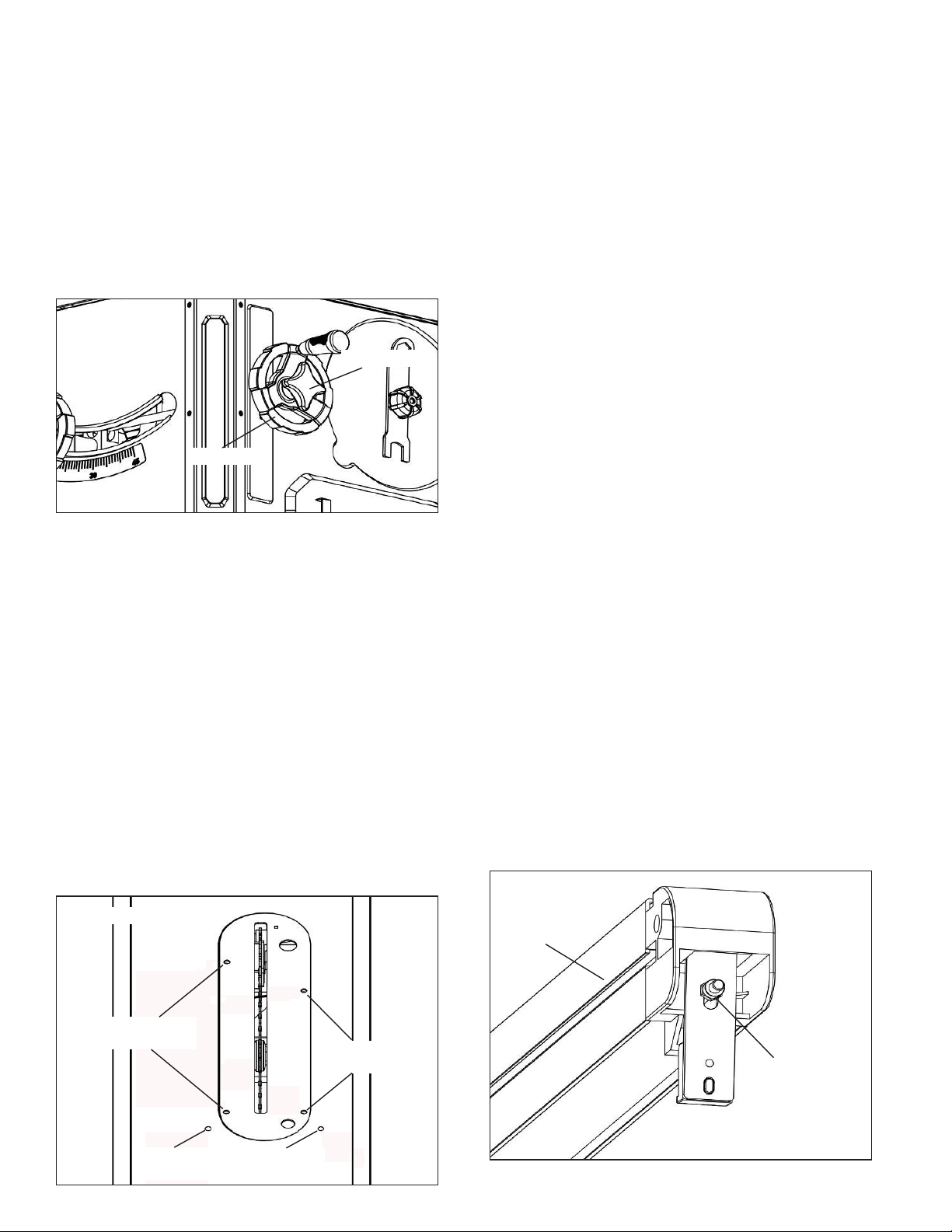

ATTACH RIP FENCE STORAGE BRACKETS

Refer to Figure 11.

Tools Required:

4mm Hex wrench and 10mm Open end

wrench.

Hardware Required:

Two M6 x 16 socket pan head screws,

two 6mm at washers and two 6mm hex nuts (Hardware bag

#4).

• Place rip fence bracket into position against right side panel

of cabinet.

• Insert washer onto bolt. Insert bolt through hole and thread

nut onto bolt end on inside of panel.

• Repeat for other bracket.

• Press the four molded plastic feet onto the base legs.

• With the aid of an assistant turn the saw upright. First, turn

the saw onto the back side. Then raise saw upright onto the

base feet.

WARNING:

To avoid injury,

Do Not

attempt to turn saw

upright by yourself.

TEST CASTER MECHANISM

Refer to Figure 12-2.

Press down on the foot pedal to raise the saw up onto the

casters. Move the saw back and forth on the casters to

ensure that the mechanism is properly working. Press the

foot pedal again to lower the saw onto the oor into a

stationary position.

Figure 11

Rip Fence Storage

Bracket (x2)

BLADE GUARD, PUSH STICK

STORAGE BRACKETS, RUBBER FEET

Refer to Figure 12-1.

Tools Required:

Hardware Required:

Phillips screwdriver.

Eight M4 x 8 pan head screws, eight

4mm at washers (Hardware bag #4).

• Install the push stick storage brackets to the left side panel

of the base using four M3 x 10 screws, four M3 lock

washers and four M3 at washers.

• Install the blade guard storage brackets to the left side

panel of the base using four M3 x 10 screws, four M3 lock

washers and four M3 at washers.

NOTE:

Attach the slotted bracket to the front side of the saw.

Figure 12-1

Rubber Feet

Blade Guard

Storage

Brackets

Push Stick

Storage

Bracket (x2)

Figure 12-2

Foot Pedal

ATTACH EXTENSION TABLES

Refer to Figure 13.

IMPORTANT:

Table is coated with a protectant. To ensure

proper t and operation, remove coating. Coating is easily

removed with mild solvents, such as mineral spirits, and a

soft cloth. Avoid getting solution on paint or any of the rubber

or plastic parts. Solvents may deteriorate these nishes. Use

soap and water on paint, plastic or rubber components. After

cleaning, cover all exposed surfaces with a light coating of

oil. Paste wax is recommended for table top.

WARNING:

Never use highly volatile solvents. Non amma-

ble solvents are recommended to avoid possible re hazard.

Tools Required:

included).

.

Hardware Required:

8mm Hex Wrench and Straight Edge (not

Six M10 x 25 socket head bolts, six

10mm lock washers and six 10mm at washers (Hardware

bag #1).

• Assemble extension table to the table using socket head

bolts, lock washers and at washers.

• Wipe surface clean.

• Hand tighten only. Do not tighten completely until tables

are level. Use a straightedge to level tables.

• Repeat above procedure for the other extension table.

• Use a straight edge to check level and atness between

main and extension tables between main and extension

tables along their entire length.

• After tables are adjusted level and at, secure the exten-

sion tables by tightening the bolts completely.

8

Straight Edge

Figure 13

BLADE INSTALLATION

Refer to Figures 14 and 15.

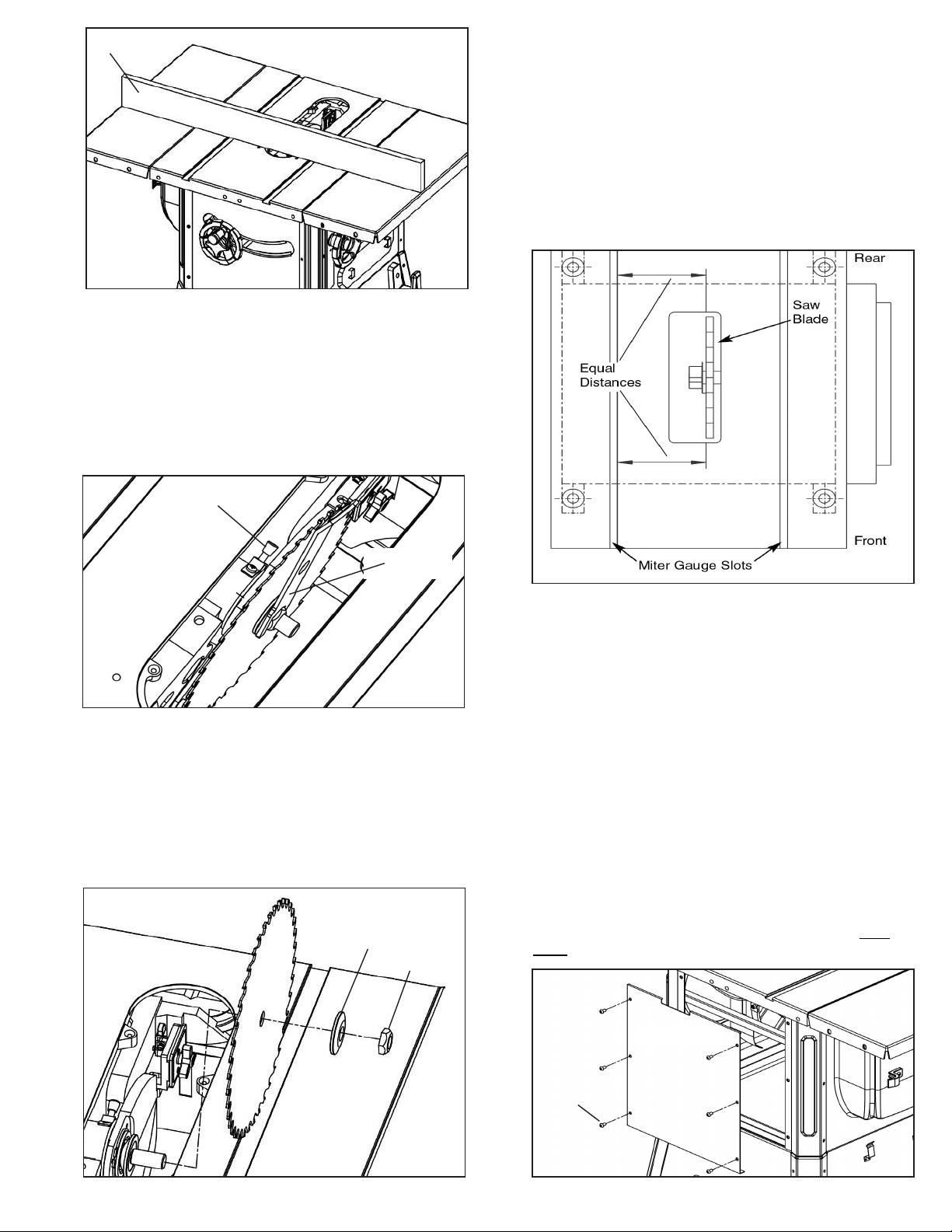

CHECK TABLE ALIGNMENT

Refer to Figures 16, 17 and 18. Pages 9 and 10.

• Saws are shipped from the factory with the table adjusted

so the miter gauge slots are parallel to the saw blade.

However, in order to obtain the best results from the saw, it

is suggested this adjustment be checked before operating.

• A simple method of checking alignment is as follows: Bolt

or clamp a dowel rod or similar object to miter gauge (a

combination square can be substituted). Pick out a tooth

on front of blade and set the dowel to it so it is just touching.

Move same tooth to back of blade.

Tools Required:

24mm Open end Wrench.

• Loosen knob on right side of cabinet.

• Remove blade and wrench. Replace knob.

• Ensure the blade assembly is raised all the way up.

• Depress arbor lock and use wrench to loosen ange nut.

Remove ange and nut from arbor.

Depress Arbor Lock

24MM

Wrench

Figure 14

BLADE INSTALLATION Cont.

Refer to Figures 14 and 15.

• Place blade on arbor. Make sure arrow on blade and teeth

point towards front of saw.

• Replace ange and nut on arbor. Depress the arbor lock

and rotate arbor by hand until arbor locks in place. Keep

arbor lock depressed and use 8mm Hex Wrench to fully

tighten blade onto arbor.

Figure 15

Flange

Nut

Figure 16

• Gauge this tooth with the dowel rod. If the tooth is in the

same position, relative to the miter gauge slot, the table is

parallel with the blade. In short, the miter gauge slots must

be parallel with the blade. This means that when measuring

distance between blade and miter gauge slot at the

front and rear of the blade, the distances will be equal

(see Figure 16).

NOTE:

Be sure to measure the distance or make the test

on the same tooth of the saw blade in both front and rear

positions.

CHECK TABLE ALIGNMENT Cont.

Refer to Figures 16, 17 and 18. Pages 9 and 10.

• If an adjustment is necessary, proceed as follows: Loosen

and remove the six socket pan head screws and the rear

panel (see Figure 17). Loosen the four hex head bolts on

the trunnion (see Figure 18) and shift trunnions until a

position is found where the saw blade is parallel to the

miter guage slots.

NOTE:

Saw blade should also be centered within its table

insert opening.

Figure 17

Rear Panel

Pan Head

Screw (x6)

9

Figure 18

Trunnion Bolts (x4)

• Tighten the four trunnion hex head bolts and lock washers

securely.

This procedure will set the table and blade in parallel

position and prevent the trunnion from shifting.

NOTE:

If you perform this adjustment, leave the back panel

o to perform rear rail assembly as described in the next

section.

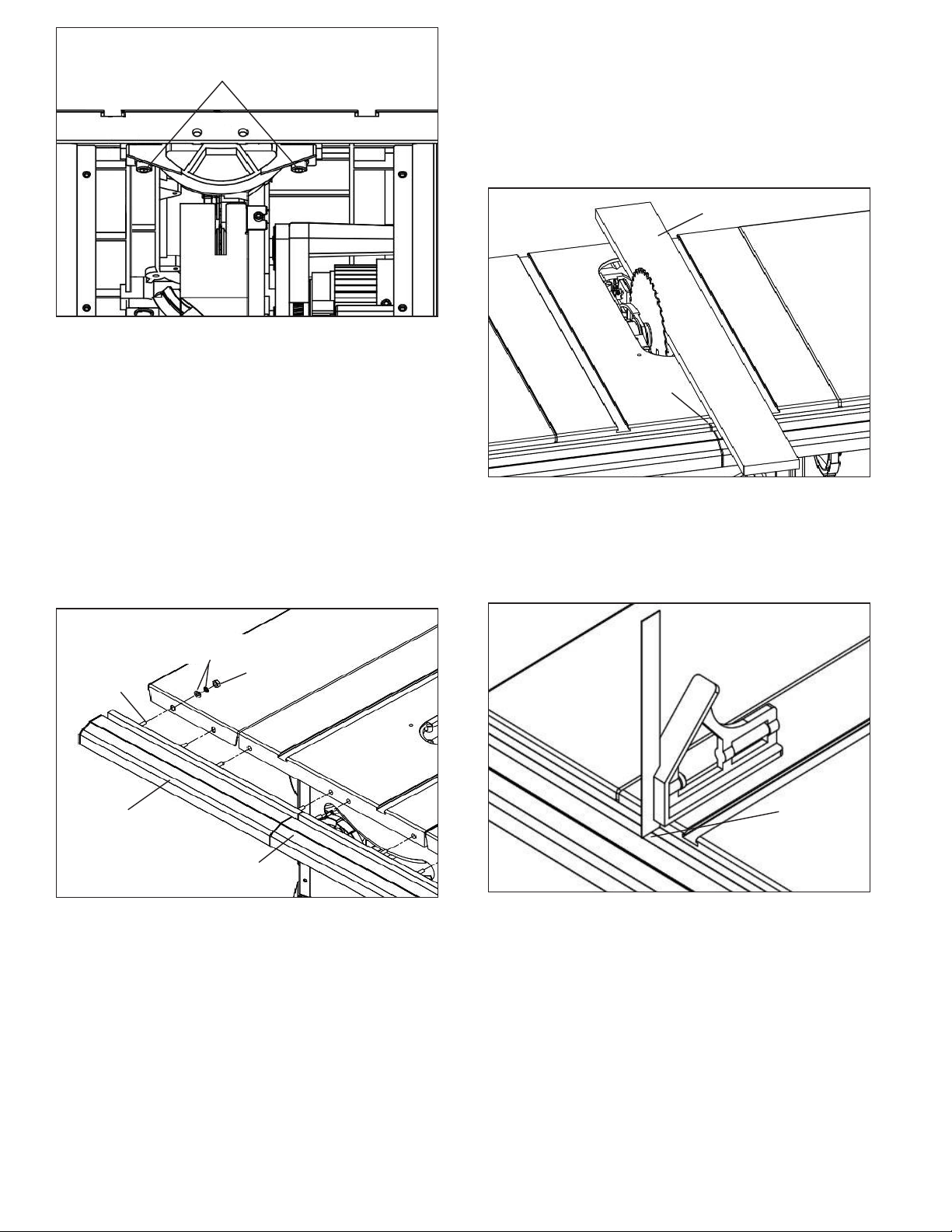

RAIL ASSEMBLY

Refer to Figures on Pages 10 and 11.

Tools Required:

Hardware Required:

13mm Open end Wrench

Sixteen M8 x 30 hex head bolts,

sixteen 8mm lock washers, sixteen 8mm at washers and

sixteen M8 hex nuts. (Hardware bag #2).

NOTE:

Hand tighten all hardware during rail assembly. Do

not completely tighten hardware until all rails are mounted.

NOTE:

You may have to shift right rail as far right as it will go

to attach left rail.

• Position rails so that rails are butted together and the joint

between rails is aligned with right side of the blade. You

may need a mallet to lightly tap rails together. Make sure

rails are completely butted together at the joint.

Figure 20 Straight Edge

Rail

Joint

• Use a straight edge to align right edge of rail joint to blade.

Fully tighten right rail.

• Use a level to check level and atness between right and

left rail. When level, fully tighten left rail.

• Before proceeding, ensure all hardware is tightly secured.

Figure 19

M8 Flat & Lock

M8 x 30 Hex

Head Bolts

Short Rail

(Left)

Washers

M8 Hex

Head Nut

Long Rail

(Right)

RAIL ASSEMBLY Cont.

Refer to Figures on Pages 10 and 11.

NOTE:

For this procedure the longer rail is installed to the

right; the shorter rail is installed to the left.

• Assemble the left front rail to the right front rail. Slide the

protruding pins from the left rail into the pin slots of the right

rail.

• Insert four M8 x 30 hex head bolts into the T-slot of the right

front guide rail.

• Insert four M8 x 30 hex head bolts into the T-slot of the left

front guide rail.

• Attach the assembled front rail to the table casting and to

the right and left table extensions using at washers, lock

washers and hex nuts.

Figure 21

Check Gap

Along Rail

• To allow for attachment of rear rails, loosen and remove the

six socket pan head screws and back panel. Figure 23,

page 11.

• Install and level the rear rails in the same manner as the

front rails. Use a straight edge to align the left edge of rail

joint to the blade. Figure 22, page 11.

• Before proceeding, ensure all hardware is tightly secured.

• Replace back panel of the cabinet. Figure 23, page 11.

10

Figure 22

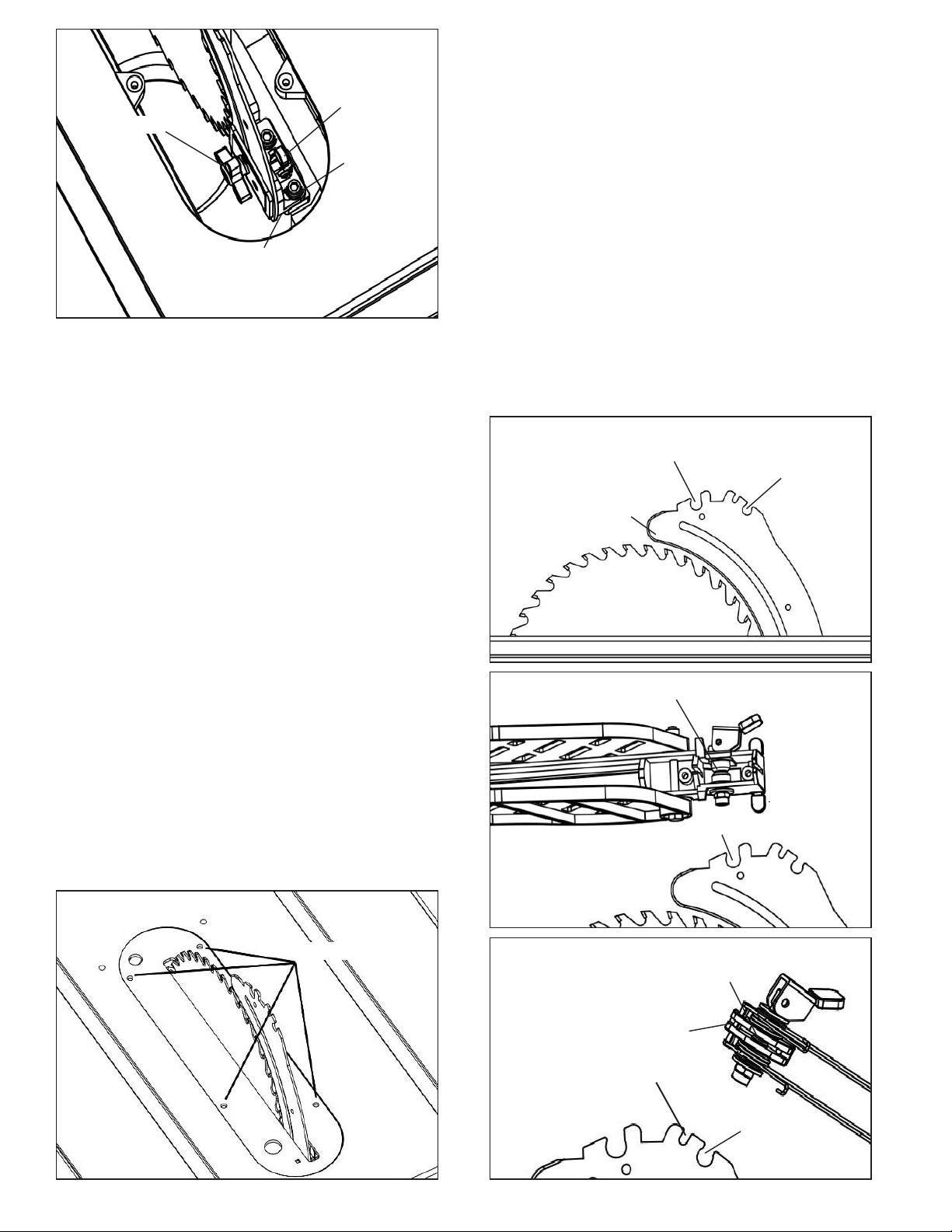

ATTACH SWITCH ASSEMBLY

Refer to Figure 25.

Figure 23

Replace

Rear Panel

Straight Edge

Rail

Joint

Tools Required:

Hardware Required:

at washers, two M6 lock washers and two M6 hex nuts.

(Hardware bag #3).

• From the top of the switch bracket, insert two bolts

through bracket holes.

• Loosely attach at washer, lock washer and nut to bolts.

• Insert bolt heads into T-slot on bottom of left front rail.

• Slide switch assembly 6″ to 8″ from left end of rail as

shown in Figure 25.

• Fully tighten at washers, lock washers and hex nuts to

secure switch assembly in place.

6″ to 8″ from

Left End of Rail

10mm Open end Wrench.

Two M6 x 16 hex head bolts, two M6

RAIL BRACE INSTALLATION

Refer to Figure 24.

Tools Required:

Hardware Required:

four 8mm lock washers, four 8mm at washers and four M8

acorn nuts. (Hardware bag #2).

• Insert four M8 x 16 hex bolts through holes in bracket at

each end of brace.

• Attach brace to the far right end of the rails by sliding hex

bolts into the rail T-slots. Secure bolts in position with 8mm

at washers, 8mm lock washers and 8mm acorn nuts.

Figure 24

13mm Open end Wrench

Four M8 x 16 hex head bolts,

Brace

8mm

Lock Washer

8mm

Flat Washer

8mm

Acorn Nut

Figure 25

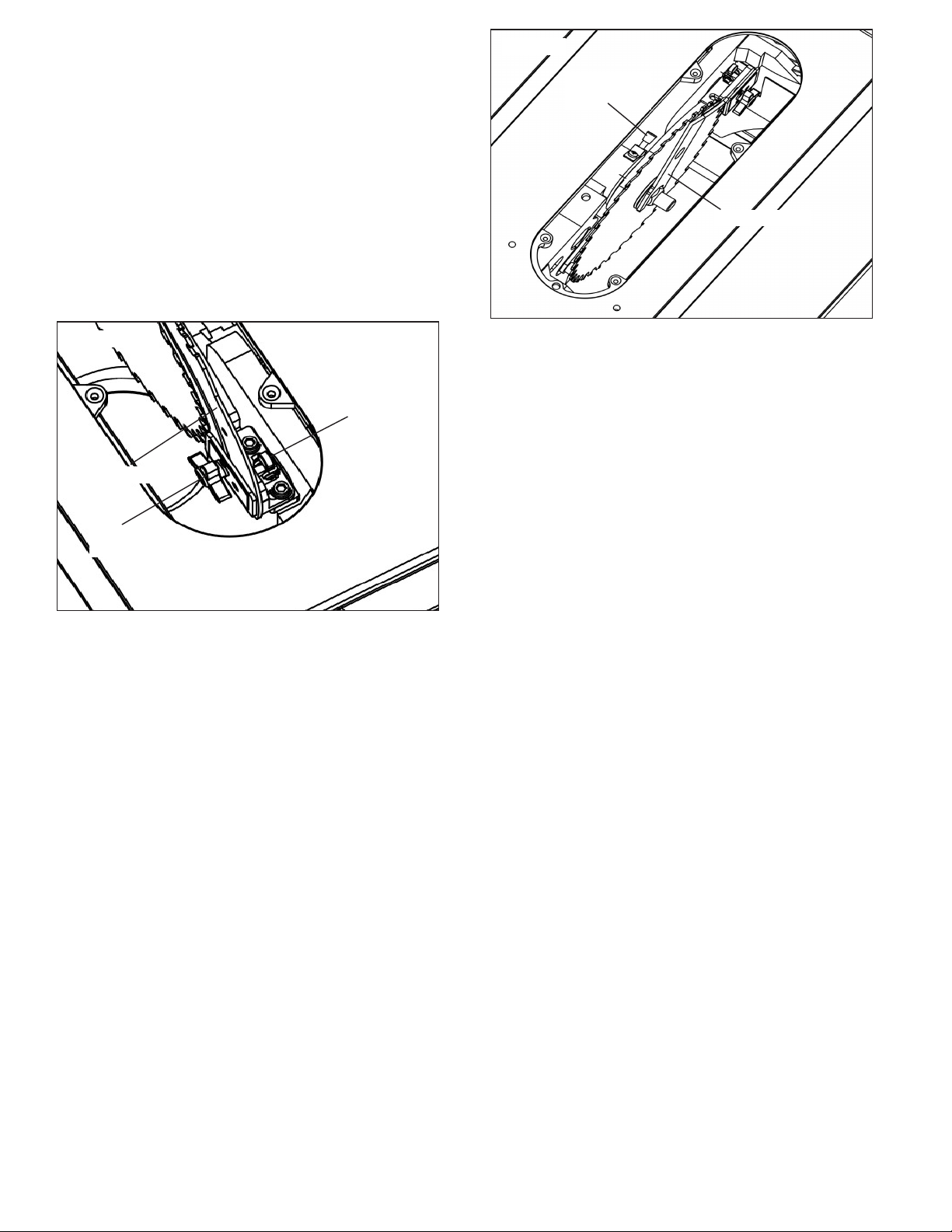

RIVING KNIFE POSITION AND ADJUSTMENT

Refer to Figure 26.

• The riving knife is pre-installed on the saw. Raise the blade

completely to access the riving knife.

• Loosen the locking knob and raise the riving knife to its

highest position. Riving knife has three holes for three posi-

tions. The highest position is for all thru cuts. The middle

position is for rabbets and other non-thru cuts, (with guard

and pawls removed). The lowest position is for dado cuts.

Figure 26

Locking Pin

Locking Knob

Socket Head

Cap Screw

Riving Knife

Bracket

RIVING KNIFE POSITION AND ADJUSTMENTS

CONTINUED ON PAGE 12

11

Figure 26

Locking Pin

Locking Knob

Socket Head

Cap Screw

Riving Knife

Bracket

• Make sure locking pin is aligned with riving knife hole and

secure in position by tightening locking knob.

• Riving knife must be in line with blade. Make sure riving

knife sits at against mounting bracket and lock plate.

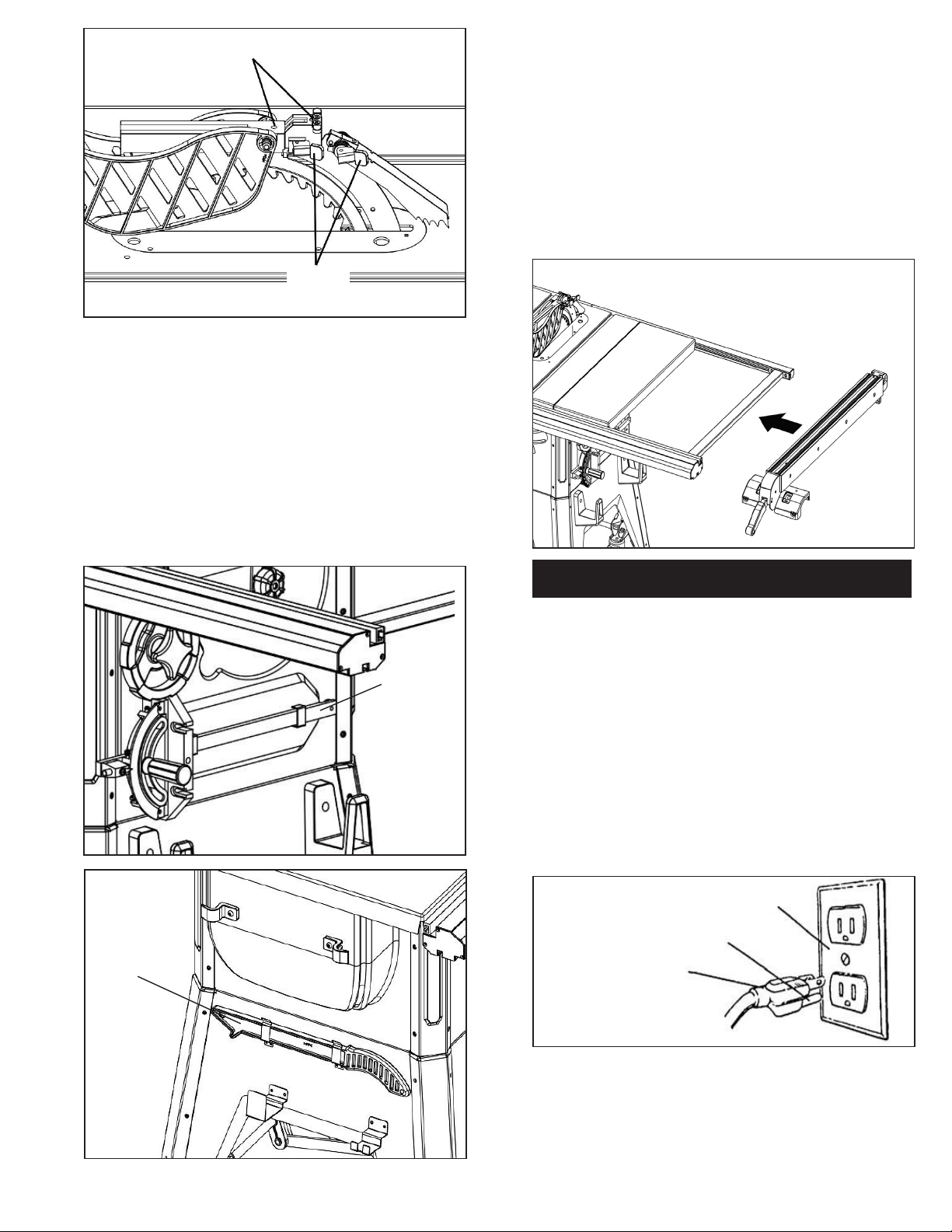

ATTACH BLADE GUARD AND ANTI-KICKBACK

PAWLS

Refer to Figures 28-31, pages 12 and 13.

• Place the slot of blade guard body over the riving knife.

Slot of bushing is placed in the notch indicated in Figures

28 and 29.

• The bushings have a beveled edge and must be located in

the center of the notch to lock properly.

• Position guard completely down on riving knife and press

latch to lock in position.

• Blade guard body should be parallel to the table. If not,

adjust the 2mm set screws as necessary.

• Place anti-kickback pawl set onto riving knife at notches

indicated. The spring pin is placed in the front notch and

bolt is placed in the rear notch.

• Press pawl set completely down and press latch to secure

in position.

NOTE:

The teeth of anti-kickback pawls should touch table

surface. Use set screws to adjust if needed.

RIVING KNIFE TO BLADE ADJUSTMENT

Refer to Figure 26.

• Riving knife to blade clearance: the gap between the riving

knife and the saw blade should be an even distance

across the entire radius.

• The riving knife should also be in line with the saw blade. If

adjustment is necessary:

1. Locate the riving knife bracket.

2. Loosen the two socket head cap screws slightly enough

to move the bracket, bringing the riving knife in line with

the saw blade. Make sure the gap between the blade

and knife is even and from 1⁄4″ to 5⁄16″ in distance.

3. Once the riving knife is aligned with the blade, tighten

the socket head cap screws.

INSTALL TABLE INSERT

Refer to Figure 27.

• Make sure that the riving knife is raised to its highest

position.

• Place table insert into throat of table.

• Insert is held in position by magnet in table.

• To adjust insert level with table, adjust leveling screws up

or down.

Figure 28

Figure 29

Blade Guard Position

Pawl Set Position

Riving Knife

Bushing

Notch

Figure 27

Leveling Screws

Figure 30

Bolt

Pin

Insert Pin Here

Insert Bolt

Here

12

Figure 31

Set Screws

INSTALL RIP FENCE

Refer to Figure 34.

• Position rip fence assembly at end of saw. Be certain

locking lever is in UP unlocked position.

• Place rip fence assembly onto rails, positioning clamp over

rear rail and then placing rip fence onto front guide rail.

• Rip fence should now ride freely on rip fence rails. Once

rip fence is completely installed, it should be parallel with

the miter gauge and perpendicular to the table. If not, refer

to “Rip Fence Adjustment” found on pages 16 and 17 in the

Operation section of this manual.

Latches

NOTE:

The tension of the latch operation for both the Blade

Guard and Pawl Set is pre-set at the factorty. Adjustment (if

needed) can be done by loosening or tightening the 10mm

nylon locking nut on the opposite side of each latch.

INSTALL MITER GAUGE AND PUSH STICK

Refer to Figures 32 and 33.

• The miter gauge comes preassembled. Unpack the miter

gauge and clean thoroughly. Insert into storage slots on

right side of cabinet.

• Insert the push stick into brackets on left side of base.

Miter Gauge

Figure 32

Figure 34

INSTALLATION

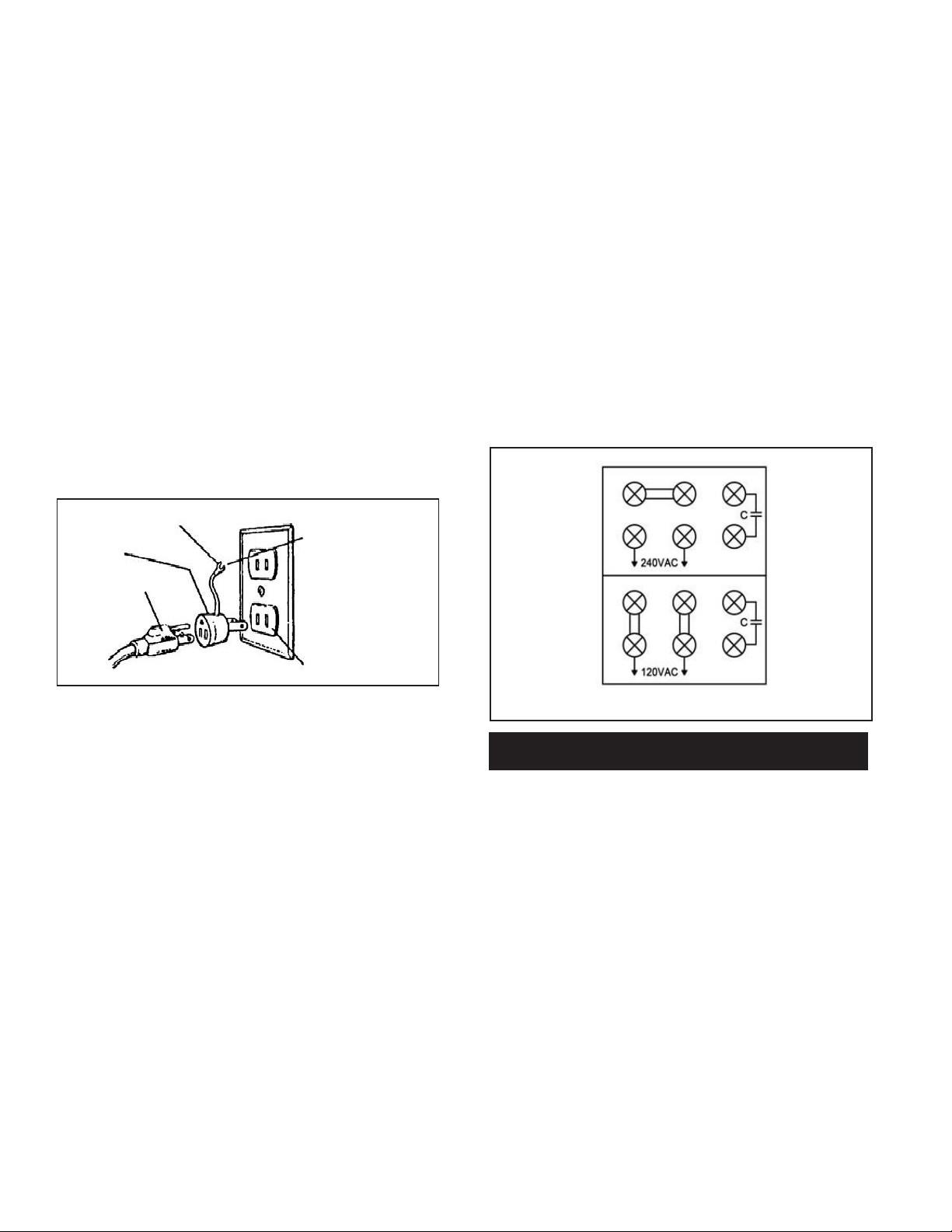

GROUNDING INSTRUCTIONS

WARNING:

conductor can result in the risk of electrical shock. Equipment should be grounded while in use to protect operator

from electrical shock.

• Check with a qualied electrician if grounding instructions

are not understood or if in doubt as to whether the tool is

properly grounded.

• This tool is equipped with an approved 3-conductor cord

rated at 300V and a 3-prong grounding type plug

(see Figure 35) for your protection against shock hazards.

• Grounding plug should be plugged directly into a properly

installed and grounded 3- prong grounding-type receptacle,

as shown (Figure 35).

Improper connection of equipment grounding

Figure 33

Push Stick

Properly Grounded Outlet

Grounding Prong

3-Prong Plug

Figure 35

CONTINUED ON PAGE 14

13

• Do not remove or alter grounding prong in any manner. In

the event of a malfunction or breakdown, grounding

provides a path of least resistance for electrical shock.

WARNING:

plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is properly

installed and grounded in accordance with all local codes

and ordinances. Do not modify plug provided. If it will not t

in outlet, have proper outlet installed by a qualied

electrician.

• Inspect tool cords periodically and if damaged, have them

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

grounding wire. If repair or replacement of the electric cord

or plug is necessary, do not connect the green (or green

and yellow) wire to a live terminal.

• Where a 2-prong wall receptacle is encountered, it must be

replaced with a properly grounded 3-prong receptacle

installed in accordance with National Electric Code and

local codes and ordinances.

WARNING:

electrician.

A temporary 3-prong to 2-prong grounding adapter (see

Figure 36) is available for connecting plugs to a two pole

outlet if it is properly grounded.

Do not permit ngers to touch the terminals of

This work should be performed by a qualied

Extension Cord Length (120V Operation)

Wire Size A.W.G.

Up to 25 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Up to 50 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

NOTE:

recommended.

ELECTRICAL CONNECTIONS

WARNING:

power source before inspecting any wiring.

The saw is prewired for use on a 120 volt, 60Hz power

supply.

The power lines are inserted directly onto the switch. The

green ground line must remain securely fastened to the

frame to properly protect against electrical shock.

240 VOLT OPERATION

• To use the saw with a 240V, single-phase power supply,

have a qualied electrician attach a 240 volt, 15A 3-prong

(NEMA 6-15P) plug onto saw line cord and install the proper

connectors and receptacles to power supply.

• See wiring diagram (Figure 37) for wiring instructions.

Using extension cords over 50 ft. long is not

Make sure unit is o and disconnected from

Figure 37

Grounding Lug

Adapter

3-Prong Plug

• Do not use a 3-prong to 2-prong grounding adapter unless

permitted by local and national codes and ordinances.

• (A 3-prong to 2-prong grounding adapter is not permitted

in Canada.) Where permitted, the rigid green tab or terminal

on the side of the adapter must be securely connected

to a permanent electrical ground such as a properly

grounded water pipe, a properly grounded outlet box or a

properly grounded wire system.

• Many cover plate screws, water pipes and outlet boxes are

not properly grounded. To ensure proper ground, grounding

means must be tested by a qualied electrician.

EXTENSION CORDS

• The use of any extension cord will cause some drop in

voltage and loss of power.

• Wires of the extension cord must be of sucient size to

carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G.)

extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool

plug.

• If the extension cord is worn, cut, or damaged in any way,

replace it immediately.

Figure 36

Make Sure

This Is

Connected

To A Known

Ground

2-Prong Receptacle

Wiring Schematic

OPERATION

DESCRIPTION

The Craftsman 10″ Model Number 58833 contractor saw

oers precise cutting performance for all woods up to 3-1⁄8″

thick. The saw is designed for the professional user and is

ruggedly constructed for continuous service. The 10″ Saw is

recommended for use with a 10″ blade.

The saw features an extra large cast iron table. Saw body

has on board storage for push stick, miter gauge, rip fence

and saw blades. Saw is equipped with a riving knife and a

clear acrylic blade guard with anti-kickback feature. Cabinet

is constructed of heavy gauge welded steel, totally enclosed

and is ported for a 4″ vacuum hose.

Rip Fence Assembly features a heavy-duty precision rip

fence that is designed for simple and one-hand

maneuverability.

Front rail is calibrated in inches and millimeters with a

magnied window for close tolerances.

14

SPECIFICATIONS

Capacity with 10″ Blade:

Depth of cut at 90°..........................................................3-1/8″

Maximum tilt angle of arbor (left)........................................45°

Depth of cut at 45°........................................................2-3/16″

Max. cut right of blade with rip fence.............................29-1/2″

Max. cut left of blade with rip fence..............................14-1/2″

Saw Dimensions:

Table height..................................................................37-3/8″

Cabinet depth...............................................................21-3/4″

Cabinet width......................................................................19″

Table area ...........................................................27″ x 20-1/8″

Front of table to blade ..................................................11-3/8″

Rip Fence Dimensions:

Rip fence .....................................................................31-5/8″

Rip fence rails (front and rear) .................................... 56-1/2″

Blade capacity maximum ...................................................10″

Blade arbor .......................................................................5/8″

Dado blade capacity maximum .........................................3/4″

Saw Construction:

Cabinet ..................................... Totally Enclosed Steel Panel

Table ........................................................................ Cast Iron

Rip fence ................. Aluminum Tube with HDPE Guide Plate

Drive system.................................................................. V-belt

Exhaust port ....................................................................... 4″

Miter gauge ............... Cast Aluminum withT-slot Roller Guide

Blade guard ......................... Acrylic with Anti-kickback Pawls

Switch ......................... Locking Paddle Switch with Overload

Arbor RPM................................................ 3450 RPM approx.

Motor:................. 1-3/4 HP, 3450 RPM, 120V/15A, 240V/7.5A

Single-Phase, Capacitor Start/Run

Gross weight .............................................................. 308 lbs

STARTING AND STOPPING THE SAW

Refer to gure 38.

WARNING:

place. Be sure blade is not in contact with workpiece when

motor is started. Start motor and allow saw to come to full

speed.

WARNING:

nameplate and power source are the same.

• The ON/OFF switch is located under the front rail of the

table saw at the left side.

• To turn saw on, stand to either side of the blade—never

inline with it. Raise large red OFF paddle and pull up ON/

OFF switch. Always allow saw blade to come up to full

speed before cutting.

• Do not turn motor switch ON and OFF rapidly. This action

overheats the motor and may cause saw blade to loosen.

• Never leave saw unattended while the power is on.

• To turn the table saw o, press the large red OFF paddle.

Never leave saw unattended until the blade has come to a

complete stop.

The saw can be locked from unauthorized use by locking

the switch. To lock the switch:

• Turn the switch to OFF position and disconnect saw from

power source.

• Pull the key out. The switch cannot be turned on with the

key removed.

Never operate saw without blade guards in

Make sure the electrical characteristics of motor

NOTE:

Should the key be removed from the switch at the ON

position, the switch can be turned o but cannot be turned on

again.

• To replace key, slide key into the slot on switch until it

snaps.

WARNING:

below table surface. If blade is tilted, return it to vertical

position. Turn o safety disconnect or circuit breaker when

saw is not in use.

Figure 38

Large Red O Paddle

BLADE HEIGHT ADJUSTMENT

Refer to gure 39.

• Blade height is controlled by handwheel on the front of the

saw.

• To adjust height, loosen locking hand knob. Rotate knob

counterclockwise approximately three turns. Turn hand

wheel to desired blade height.

CAUTION:

the surface of the material to be cut. However, if hollow

ground blades are used, raise blade to its maximum height

to allow for greater blade clearance.

• Lock blade height into position. Lock handwheel by tighten-

ing locking knob clockwise. Tighten only until snug.

IMPORTANT:

pressure is necessary to lock handwheel securely.

Figure 39

For your own safety, lower blade or cutting tool

Switch Key

Switch

For safety, blade should be raised only 1/8″above

Do not over tighten. Only a small amount of

Lock Knob

Angle Indicator

Handwheel

BLADE HEIGHT ADJUSTMENT

CONTINUED ON PAGE 16

15

BLADE TILT ADJUSTMENT

Refer to Figures 39 and 40.

• The saw blade can be set at any angle between 90° and

45°. Blade tilt is controlled by the handwheel (Fig. 40) on

the right side of the saw. The indicator (Fig. 39, pg. 15) on

front of saw shows the tilt angle of the blade.

• To adjust tilt, loosen locking hand knob. Rotate knob coun-

terclockwise at least three turns. Turn handwheel to desired

blade angle. Lock blade angle into position.

• Lock handwheel by tightening locking hand knob clockwise.

Tighten only until snug.

• The saw is equipped with positive stops at 90° and 45°.

These positive stops allow operator to position saw blade

at 90° and 45° quickly and accurately.

Figure 40

Lock Knob

Handwheel

90° STOP ADJUSTMENT

Refer to Figures 39 thru 41.

• Raise saw blade above table as far as possible. Set blade

at 90° to table by turning the tilting handwheel. Place a

square on table and check to see if blade is perpendicular

to the table. When checking put square ush against saw

blade. Do not put square on teeth of saw blade.

• If the blade will not tilt to 90°, turn (counterclockwise) the

set screw at the left front of the table insert until the blade

can be positioned to 90°.

• Once the blade has been tilted to 90° (conrm this using

your square), tighten the bevel handwheel lock knob,

located on the side of the cabinet. This will keep the blade

from tilting further.

• Turn the set screw (clockwise) until it comes in contact

with the positive stop.

• Check tilt indicator pointer. If necessary, adjust pointer so it

points to 0° mark on scale. To adjust pointer, remove

handwheel and loosen screw on pointer. Be sure to tighten

screw securely after adjustment is completed.

Figure 41

45° STOP ADJUSTMENT

Refer to Figures 39 thru 41.

• Tilt the saw blade to 45°. Using a combination square,

check to see if blade is 45° to the table.

• If the blade will not tilt to 45°, turn (counterclockwise) the

set screw located at the right of the table insert, until the

blade can be positioned to 45°.

• With the blade at 45°, tighten the bevel handwheel lock

knob to keep the blade from further tilting.

• Turn the set screw clockwise until it comes in contact with

the positive stop.

TABLE INSERT ADJUSTMENT

Refer to Figure 41.

• The table insert must always be level with the saw table.

• Place a straight edge across the front and rear of the table

insert. Check that the insert is perfectly level with the saw

table.

• To level the table insert, turn one or more adjusting set

screws as needed and recheck.

• The table insert is equipped with two nger holes for easy

removal.

RIP FENCE ADJUSTMENT

The saw’s rip fence is precision manufactured, incorporating

ne adjustments for accurate cuts. The saw is built to allow

the operator to accurately adjust the rip fence without problems in a matter of seconds.

LEVELING THE FENCE TO THE TABLE

• Lift the lock handle to unlock the fence.

• Observe the space between the fence bottom and the

table. The space should be equal along the entire length

of the fence.

• If the space is not equal, the rails need to be adjusted so

that rails are at the same vertical position with respect to

the table. See Rail Assembly, pages 10-11.

SETTING FENCE CLAMPING PRESSURE

Refer to Figure 42.

The rip fence has been adjusted at the factory to lock

securely when the lock handle is pushed down. To adjust:

• Unlock fence and remove it from the rails.

• Adjust the hex nut until the fence is held securely when

the lock handle is pushed down.

Figure 42

Fence Body

Table Insert

Leveling Screws

90° Stop

Adjustment

45° Stop

Adjustment

Table Insert

Leveling Screws

Hex Nut

16

SETTING FENCE PERPENDICULAR AND PARALLEL

Refer to Figure 43.

PERPENDICULAR ADJUSTMENT

• Position fence anywhere on table and lock it down.

• Place a square on the table next to the fence and check to

see that the fence is at 90° to the table.

Figure 44

Figure 43

Curser Screw

PARALLEL ADJUSTMENT

• Position fence so that fence edge is aligned with slot edge.

• Slot and fence edge should be parallel.

• If an adjustment is necessary, unlock the fence and turn

either of the two adjusting screws.

• Lock fence in position and recheck. Continue this proce-

dure until fence is square to the table.

CURSOR ADJUSTMENT

Refer to Figure 43.

• Raise the saw blade above the table.

• Position the fence several inches to the right of the saw

blade.

• Lock the fence down and measure the exact distance

between the saw blade and the inside of the fence.

• Loosen the screw on the right lens and slide it left or right

until the cursor (red line) equals the measurement obtained

in the previous step.

• Retighten the screws and make a test cut. Measure the

cut piece to verify that the cursor is correctly set.

• Ax the rip fence several inches to the left of the saw blade

and perform the procedure described above for the left

lens.

NOTE:

This adjustment should be checked whenever a new

blade is installed.

Perpendicular

Adjustment

Curser Screw

Parallel

Adjustment

Fence Locking

Lever

MITER GAUGE ADJUSTMENT

Refer to Figure 45.

• Miter gauge supplied with saw is equipped with individually

adjustable index stops at 0° and 45°, right and left, and

can be manually adjusted up to 60° right and left.

Adjustment to index stops can be made by loosening the

desired locking nut and tightening or loosening three adjust ing screws. Be sure to tighten locking nut after adjustment

is made.

• Face of the miter gauge has two holes for the purpose of

attaching an auxiliary fence.

• Miter gauge is accurately constructed for precision work

and is guided through the T-slot with a roller guide

mounted at front of guide bar. Roller guide adds to miter

gauge’s stability and prevents the guide bar from leaving

the T-slot.

• To operate the miter gauge, simply loosen locking handle

and move the miter gauge body to the desired angle. The

miter gauge will stop at 0° and 45°, both right and left. To

position miter gauge body past these points, simply pull out

gauge stop.

• Position the miter gauge body at desired angle and tighten

the locking handle.

• Ensure the workpiece is straight and tight against miter

gauge body so that the workpiece does not rock or rotate.

Always use both hands when operating the miter gauge.

• The miter gauge is used for cross-cutting, compound miter

cutting, miter cutting, rabbeting, bevel cutting and dadoing.

Figure 45

Locking Handle

Miter Gauge

Body

Guide Bar

Roller Guide

RIP FENCE OPERATION

Refer to Figure 44.

• Unlock the fence by lifting the locking lever. Using the

scale for placement, position the rip fence. Lock the rip

fence into position by placing the locking lever in the down

position.

• The rip fence is used for the following operations: ripping,

bevel ripping, ploughing, resawing, rabbeting and dadoing.

17

Gauge Stop

Index Stop Adjusting

Screw & Lock Nut (x3)

INSTALLING AND REMOVING THE RIVING KNIFE

Refer to Figure 46. Additional instructions on page 12.

Install:

• Line up the riving knife in the proper direction to the

mounting bracket.

• Push the riving knife all the way down into the mounting

bracket. Make sure the lock pin is locked in the hole of the

riving knife. (The lock hole is on the button side of the

riving knife).

• If the riving knife is not locked properly, hold the locking

knob and pull the lock pin out; then re-insert the pin

securely in the hole of the riving knife. While raising or

lowering the knife, pin will snap in the hole of the knife when

located at one of the three positions.

• Tighten the locking knob.

Figure 47

Arbor Lock

Pin

Blade Wrench

Figure 46

Lock Pin

Riving Knife

Locking

Knob

Remove:

• Loosen the locking knob.

• Hold the knob and pull the locking pin out.

• Remove the riving knife out of the mounting bracket.

NOTE:

Make sure blade is at the highest position before

adding or removing the riving knife.

CHANGING THE SAW BLADE

Refer to Figure 47.

WARNING:

power cord from its power source when changing the saw

blade.

WARNING:

stamped onto the riving knife. You must select a blade with a

kerf width larger than the thickness of the riving knife.

Thinner blades may cause the workpiece to bind during cutting.

WARNING:

holes, rated at or higher than 3800 R.P.M.

• Remove blade guard assembly and pawl assembly.

• Remove the table insert.

• Unlock the raise/lower handwheel lock and raise saw

blade to maximum height.

• Depress the arbor lock pin (see Figure 47) and slowly

rotate blade toward you until pin engages into arbor. Hold

arbor in locked position.

Turn the power switch “OFF” and unplug the

When replacing blades, check the thickness

USE ONLY 10″ diameter blades with 5⁄8″ arbor

• Place supplied open-end wrench on the arbor nut. Turn

wrench counterclockwise to loosen nut. Remove arbor nut,

blade ange and saw blade.

• Place new blade on arbor. Make sure saw blade teeth

point down at the front side of saw table. Place ange and

nut on arbor and securely snug blade in position.

• Replace table insert.

• Replace blade guard assembly and pawl assembly.

TYPES OF SAWING OPERATIONS

WARNING:

following safety precautions.

• Never make any cut freehand (without using miter gauge

or rip fence). Blade can bind in the cut and cause a kick

back.

• Always lock miter gauge or rip fence securely when in use.

• Remove rip fence from the table when miter gauge is in

use.

• Remove miter gauge from table when rip fence is in use.

• Make sure blade guard is installed for all “through sawing”

operations. Through sawing operations are those opera-

tions in which the saw blade cuts completely through the

thickness of the wood. Replace guard immediately after

completion of resawing, rabbeting and dadoing.

Frequently check action of anti-kickback pawls by passing

the workpiece alongside the spreader while saw is o. Pull

the workpiece toward you. If the pawls do not dig into the

workpiece and hold it, the pawls must be sharpened. (See

Maintenance section, page 20.)

• Have blade extend approximately 1/8″ above top of work

piece. Additional blade exposure increases hazard

potential.

• Do not stand directly in front of blade in case of a kickback.

Stand to either side of the blade.

• Keep your hands clear of the blade and out of the path of

the blade.

• If the blade stalls or stops while cutting, turn switch OFF

and safety disconnect OFF before attempting to free the

blade.

• Do not reach over or behind the blade to pull the workpiece

through the cut, to support long or heavy workpieces,

to remove small cut-o pieces of material or for

any other reason.

For your own safety, always observe the

18

Loading...

Loading...