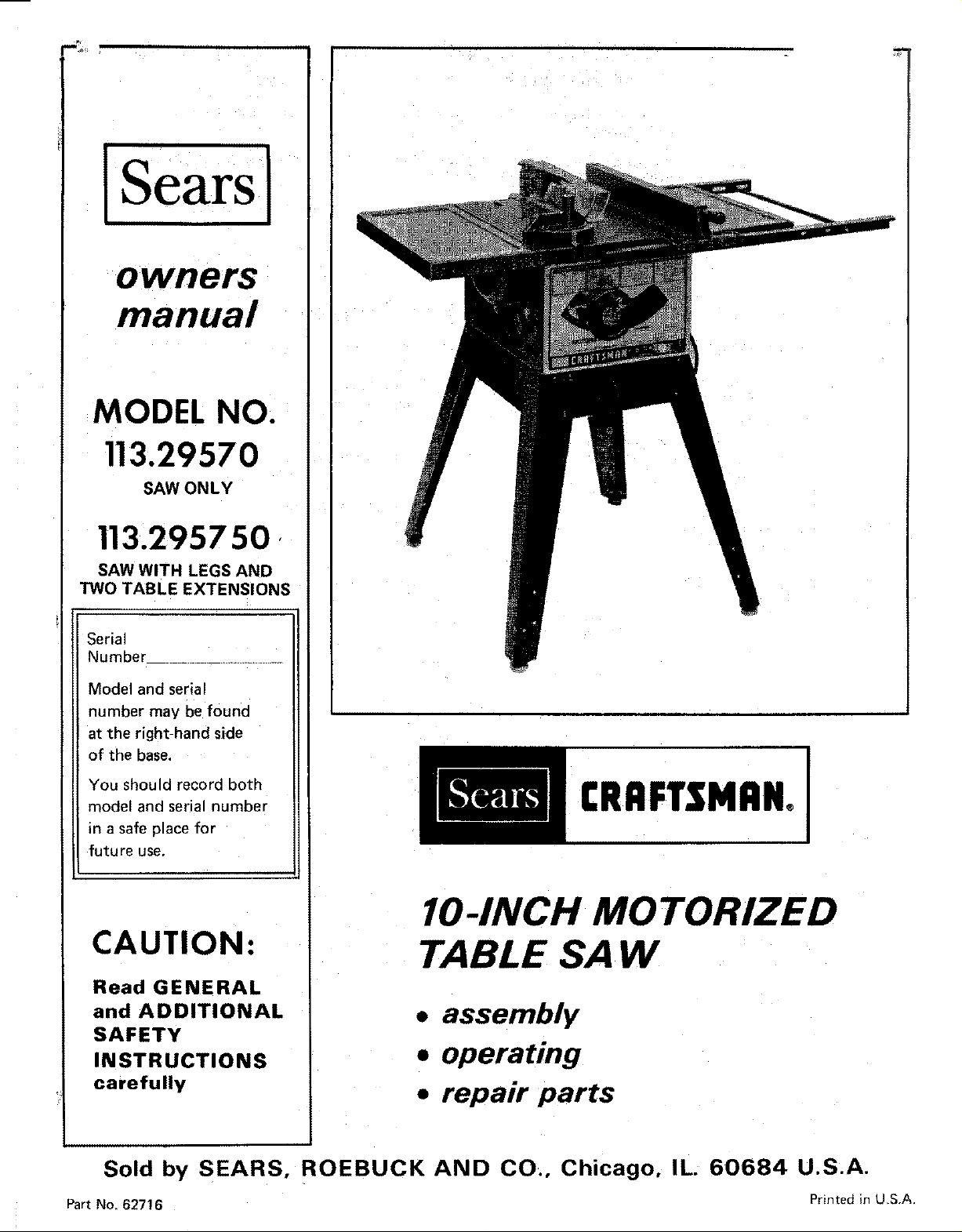

Craftsman 113295750, 11329570 Owner’s Manual

ISears]

owners

manual

MODEL NO.

113.29570

SAW ONLY

113.295750

SAW WITH LEGS AND

TWO TABLE EXTENSIONS

Serial

Number .......

Model and serial

number may be found

at the right-hand side

of the base.

You should record both

model and serial number

in a safe place for

future use,

CAUTION:

Read GENERAL

and ADDITIONAL

SAF ETY

INSTRUCTIONS

carefully

CRAFTSMAN°

IO-INCH MOTORIZED

TABLE SAW

• assembly

• operating

• repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

Part No. 62716 Printed in U_S.A.

FULL ONE YEAR WARRANTY ON CRAFTSMAN TABLE SAWS

If within one year from the date of purchase, this Craftsman Table Saw fails due to a defect in material or

workmanship, Sears will repair it. free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE

OR SERVICE CENTER THROUGHOUT THE UNITED STATES,

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state,

SEARS. ROEBUCK AND CO.. Sears Tower. BSC 41-3. Chicago, ]L 60664

general safety instructions for power tools

1. KNOW YOUR POWER TOOL

Read the owner's manual carefull,_. Learn ts

aoDlication and limitations as well as the specific

potenttal hazards peculiar to this tool

2. GROUND ALL TOOLS

Th ; tool s equipped with an approved 3*conductor

coro and a 3*prong grounding tvoe plug Io fit the 14.

Drouer grounamg [yDe receptacle. The green conauctot

'n me cord _s the grounding w_re. Never connect the

green wire to a live terminal 15.

3. KEEP GUARDS IN PLACE

n working order, and n proper

alignment.

adjustment and

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on,

5. KEEP WORK AREA CLEAN

Cluttered areas and benches mvite accidents. Floor

must not be slippery clue to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet {ocations or

expose them to rain. Keep work area well lighted, the

Provide adequate surrounding work space, accessories. The use of improper accessories may

7. KEEP CHILDREN AWAY i9 NEVER STAND ON TOOL

AII visitors should be kept a safe distance f_om Work _ ....

area. benous Injury eou d occur if the to01 is tipped or if the

8. MAKE WORKSHOP KID-PROOF Do not store materials above or near the tool such that

- with padlocks, master switches, or by removing

starter keys.

9. DON'T FORCE TOOL ....

It will do the job better and safer at the rate for which

it was designed.

10. USE RIGHT TOOL

Don't force tool or attachment to do a job it was not

designed for.

11. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches) to get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair. Roll long sleeves

above the elbow

12. USE SAFETY GOGGLES (Head ProtectiOn)

Wear Safety goggles (must comply with ANSI Z87.1)

at all times. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses. Also, use

face or dust meal( if cutting operation isdusty; and ear

protectors (plugs or muffs] during extended periods of

operation.

13.

SECURE WORK

Use clamos or a vise to hold work when practical, t's

safer than using your hand. frees both hands to operate

tool

DON'T OVERREACH

Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE

Keen tools sharp and clean for oest and safest

performance. Follow instructions for lubricating and

changing accessories

16. DISCONNECT TOOLS

before serv=cmg; when changing accessoHes such as

blades, bits. cutters etc

17. AVOID ACCIDENTAL STARTING

Make sure switch is 'n OFF poston before plugging

in.

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. Follow the instructions that accompany

Cause hazards.

cutting tool is accidentally contacted.

it is necessary to stand on the tool to reach them.

20, CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that

is damaged should be carefully checked to ensure that it

witl operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may .affect its operation. A guard or

other part that is damaged should be properly repaired

or replaced.

21. DIRECTION OF FEED .....

Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

22, NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off. Don't leave tool until it comes to a

complete stop.

ADDITIONAL SAFETY INSTRUCTIONS

FOR TABLE SAWS

WARNING: FOR YOUR OWN SAFETY, DO NOT

OPERATE YOUR SAW UNTIL IT IS COMPLETELY

ASSEMBLED AND INSTALLED ACCORDING TO THE

INSTRUCTIONS ... AND UNTIL YOU HAVE READ

AND UNDERSTOOD THE FOLLOWING.

1 GENERAL SAFETY INSTRUCTIONS FOR POWER

TOOLS... SEE PAGE 2

2. GETTING TO KNOW YOUR SAW... SEE PAGE 15

3, BASIC SAW OPERATION... SEE PAG E 17

4, ADJUSTMENTS... SEE PAGE 23

5. MAINTENANCE... SEE PAGE 26

6. STABILITY OF SAW

If there _sany tendency for the saw to tio over or move

during certain cutting operations such as cutting

extremely large heavy panels or long heavy boards, the

sawshould be bolted down.

If you attach any kind of table extensions over 24"

wide to either end of the saw, make sure you either

bolt the saw to the bench or floor as appropriate, or

support the outer end of the extension from the bench

or floor, as appropriate.

LOCATION

The saw should be aositioned so neither the ooerator

nor a casual observer is forced to stand in hne with the

saw blade.

8. KICKBACKS

Kickbacks can cause serious injury: A "KICKBACK'"

occurs when a part of the workplece binds between the

sawblade and the rip fence or other fixed object, rises

from the table, and is thrown toward the operator,

<eeD your face and body to one side of the sawblade,

out of line with a possible "Kickback.'"

Kickbacks - and possible injury from them can

usually be avoided by:

A, Maintaining the rip fence paragel to the sawblade.

B. Keeping the sawblade sharp. Replacing antikickback

pawls when points become dull.

C. Keeping sawblade guard, spreader, and antikickback

pawls in place and operating properly. The spreader

must be in alignment with the sawblade and the

pawls must stop a kickback once it has started.

Check their action before ripping.

D. NOT ripping work that is twisted or warped or does

not have a straight edge to guide along the rip fence,

E. NOT releasing work untiI you have pushed it all the

way past the sawbiade.

F. Using a "PUSH STtCK" (See Page 16) for ripping

widths of 2 to B in., and an auxiliary fence and push

block for ripping widths narrower than 2 in. (See

"Basic Saw Operation UsJngTbe Rip Fence" section.)

G. NOT confining the cut-off piece when ripping or

crosscutting,

H. When ripping apply the feed force to the section of

the workpiece between the saw blade and the rip

fence.

9. PROTECTION: EYES, HANDS, FACE, EARS, BODY

A. If any part of your saw is malfunctioning, has been

damaged or broken.., such as the motor switch, or

orher operating contlol, a safety d_vice or the

power cord ,., cease operating immediately until

the particular part is properly repaired or replaced.

B. Wear safety goggles that comply with ANSI Z87.1,

and a face shield if operation is dusty. Wear ear

plugs or muffs during extended periods of

operation.

C. Small loose pieces of wood or other objects that

contact the rear of the revolving blade can be

thrown back at the operator at excessive speed. This

can usually be avoided by keeping the guard and

spreader n glace for all "THRU-SAWING"

operations (sawing entirely thru the work) AND by

remowng all loose pieces from the table with a long

stick of wood IMMEDIATELY after they are cut

off.

D=

Use extra caution when the guard assembly is

removed for resawmg, dadoing, rabbeting, or

molding -- replace the guard as soon as that

operation is completed,

E.

NEVER turn the saw "ON" before clearing the

table of all tools, wooa scraos, etc,, except the

workpiece and related feed or support devices _for

the operation planned.

F.

NEVER place your face or body in line with the

cutting tool.

G.

NEVER place vour fingers or hands in the path of

the sawblade or other cutting tool.

H.

NEVER reach in back of the cutting tool with

either hand to hold down or support the workplace,

remove wood scraos, or for any other reason. Avoid

awkward operations and hand positions where a

sudden slip could cause fingers or hand to move

into a sawolade or other cutting tool.

I. DO NOT perform any operation "FREEHAND'"

alwa_,,s use either the np fence or the miter gauge to

oosition and guide the work.

J, NEVER use the rip fence when crosscutting or the

miter gauge when ripping. DO NOT Jse the rip

fence asa length stop.

Never hold onto or touch the "free end" of the

workpiece or a "'free piece*' that is cut off, while

power is "ON" and/or the sawblade is rotating.

K. Shut "OFF" the saw and disconnect the power cord

when removing the table insert, changing the

cutting tool, removing or replacing the blade guard,

or making adjustments.

L. Provide adequate support to the rear and sides of

the saw table for wider or long workpieces.

M. Plastic and composition (like hardboard) materials

may be cut on your saw. However, since these are

usually quite hard and slippery, the antikickback

pawls may not stop a kickback.

Therefore, be especially attentive to following

proper set-up and cutting procedures for ripping.

Do not stand, or permit anyone else to stand, in line

with a potential kickback.

N. DO NOT perform layout, assembly, or setup work

on the table while the cutting tool is rotating.

O. If you stall or jam the sawblade in the workpiece,

turn saw "OFF", remove the workpiece from the

sawblade, and check to see if the sawblade is

parallel to the miter gauge grooves and if the

spreader is in proper alignment with the sawblade.

If ripping at the time, check to see if the rip fence is

parallel with the sawblade. Readjust as indicated.

10. KNOW YOUR CUTTING TOOLS

A Dul!, gummy, or improperly sharpened or" set cutting

tOOIS can cause material to stick, jam, stall the saw,

or kickback at the operator.

Minimize potential injury by proper cutting tool

and machine maintenance.

NEVER ATTEMPT TO FREE A STALLED

SAWBLADE WITHOUT FIRST TURNING THE

SAW OFF.

B. Never use grinding wheels, abrasive cut-off wheels,

friction wheels (metal slitting blades) wire wheels or

buffing wheels,

11. USE ONLY ACCESSORIES DESIGNED FOR THIS

SAW.

12, Crosscutting operations are more conveniently worked

and with greater safety f an auxiliary wood facing is

attached to the miter gauge using the holes provided.

However. the facing must not interfere with the proper

functioning of the sawbtade guard.

13. Make sure the top of the arbor or cutting tool rotates

toward you when standing ir normal operating

aosition. Also make sure the cutting tool, arbor collars

and arbor nut are installed properly. Keep the cutting

tool as Fow as possible for the operation being

performed. Keep all guards in place whenever possible.

14. Do not use any blade or other cutting tool marked for

an operating speed less than 3450 RPM. Never use a

cutting tool larger in diameter than the diameter for

which the saw was designed. For greatest safety and

efficiency when ripping, use the maximum diameter

blade for which the saw is designed, since under these

conditions the spreader is nearest the blade,

15. Adjust table inserts flush with the table top. NEVER

Operate the saw unless the _roper insert is installed.

WEAR YOUR

16. Never feed material into the cutting tool from the rear

of the saw. An accident and seriousinjury could result.

17. THINK SAFETY.

Safety is a combination of operator common senseand

alertness at all times when the saw is being used,

18. NOTE AND FOLLOW SAFETY INSTRUCTIONS

THAT APPEAR ON THE FRONT OF YOUR SAW,

DANGER

FOR YOUR OWN SAFETY

READ AND UNDERSTAND OWNER'S MANUAL

BEFORE OPERATING MACHINE:

1. WEAR SAFETY GOGGLES

2. USE SAW-BLADE GUARD FOR "THRU-SAWING"

3. KEEP HANDS OUT OF PATH OF SAWBLADE

4. USE A "PUSH-STICK" WHEN REQUIRED

5. KNOW HOW TO AVOID "'KICKBACKS'"

6. DO NOT PERFORM OPERATI ONS "FREEHAND"

7. NEVER REACH AROUND OR OVER SAW BLADE

19.

WARNING: DO NOT ALLOW FAMILIARITY

(GAINED FROM FREQUENT USE OF YOUR SAW)

TO BECOME COMMONPLACE. - ALWAYS

REMEMBER THAT A CARELESS FRACTION OF A

SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY.

The operation of any power tool can result in foreign

objects being, thrown into the eyes, which can result m

severe eye damage. Always wear safety goggles complying

with ANSI Z87.1 (shown on Package) before commencing

power tool operation. Safety Goggles are available at Sears

retail or catalog stores.

MOTOR SPECIFICATIONS AND

ELECTRICAL REQUIREMENTS

MOTOR SPECI FICATIONS

The AC motor used in this saw is a capacitor start,

non-reversible type, with the following specifications:

Voltage ................................. 120

Amperes ................................. 12

Hertz .................................. 60

Phase ............................... Single

RPM ................................. 3450

Rotation (viewec[ from

Sawblade end) .............. Counterclockwise

MOTOR SAFETY PROTECTION

The saw motor is equipped with a manual-reset thermal

overload protector, designed to open the power line circuit

when the motor temperature exCeeds a safe value.

NOTE: The starting relay is a GRAVITY SENSITIVE

TYPE. NEVER TURN THE POWER ON WHILE THE SAW

IS UPSIDE DOWN AS THiS WILL DAMAGE THE

MOTOR

1, If the protector opens the line and stops the saw motor,

move the saw switch lever to the "OFF" position

immediately and allow the motor to cool.

2. After cooling to a safe operating temperature, the

overload protector can be closed manually by pushing

in the red RESET button on the front of the saw. If the

red I_utton Will not snag into place immediately, the

motor is still too hot and must be allowed to coo! for a

while longer.

3. As soon as the red button wi snap into running

position, the saw may be started and operated normally

by moving the saw switch lever to the "ON" position.

4. Frertuent opening of fuses or circuit breakers may result

if motor is overloaded, or if the motor circuit is fused

with a fuse other than those recommended, Do not use

a fuse of greater capacity without consulting the power

company,

5 Although the motor is designed for operation on the

voltage and frequency specified on motor nameplate,

normal loads will be handled safely on voltages not

more than 10% above or below the maneplate voltage.

Heavy loads, however, require that voltage at motor

terminals by no_ less than the voltage specified oll

nameplate.

6. Most motor troubles may be tracec to loose or

incorrect connections, overloading, reduced input

voltage (which results when small size wires are used i=_

the supply circuit} or when the supply circuit is

extremely long. Always check connection, load and

supply circuit when the motor fails [o aertorrn

satisfactorily. Check wire sizes and lengths with table at

end of this section.

CONNECTING TO POWER SOURCE OUTLET

This saw must be grounded while in use to protect the

operator from electrical shock.

If power cord is worn or cut, or damaged in anv way,

have it replaced immediately.

4

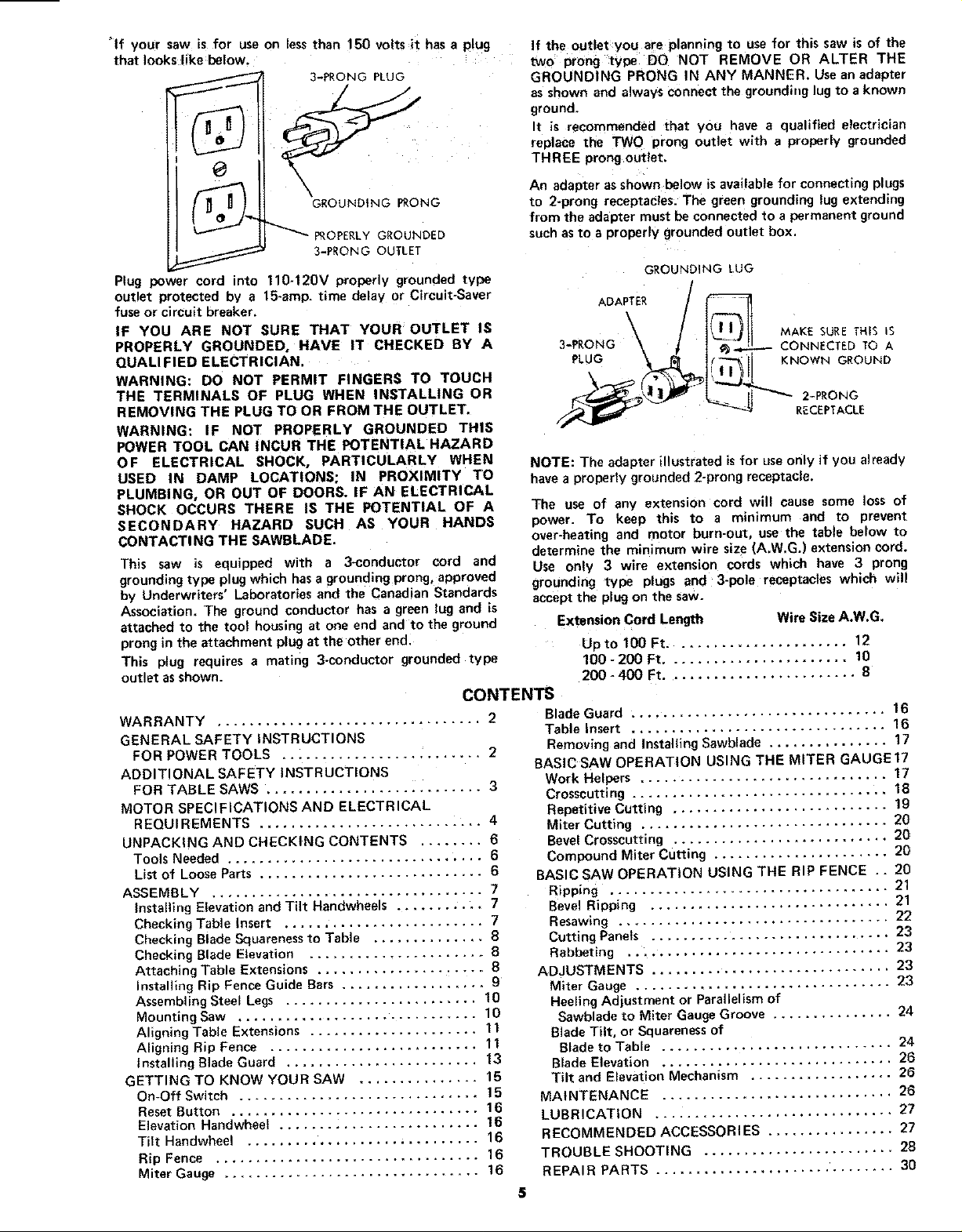

"If yoursawis for useon lessthan 150 volts it has a plug

that looks like below.

3-PRONG PLUG

\

GROUNDING PRONG

PROPERLY GROUNDED

3-PRONG OUTLET

Plug power cord into 110-120V properly grounded type

outlet protected by a 1S-amp. time delay or Circuit-Saver

fuse or circuit breaker.

IF YOU ARE NOT SURE THAT YOUR OUTLET IS

PROPERLY GROUNDED, HAVE IT CHECKED BY A

QUALI FlED ELECTRICIAN.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUG WHEN INSTALLING OR

REMOVING THE PLUG TO OR FROM THE OUTLET,

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK, PARTICULARLY WHEN

USED IN DAMP LOCATIONS: IN PROXIMITY TO

PLUMBING, OR OUT OF DOORS. IF AN ELECTRICAL

SHOCK OCCURS THERE IS THE POTENTIAL OF A

SECONDARY HAZARD SUCH AS YOUR HANDS

CONTACTING THE SAWBLADE.

This saw is equipped with a 3_conductor cord and

grounding type plug which has agrounding prong, approved

by Underwriters' Laboratories and the Canadian Standards

Association, The ground conductor has a green lug and is

attached to the toot housing at one end and to the ground

prong in the attachment plug at the other end.

This plug requires a mating 3-conductor grounded type

outlet asshown.

CONTENTS

WARRANTY ................................. 2

GENERAL SAFETY INSTRUCTIONS

FOR POWER TOOLS ................. _....... 2

ADDITIONAL SAFETY INSTRUCTIONS

FOR TABLE SAWS ........................... 3

MOTOR SPECIFiCATiONS AND ELECTRICAL

REQUIREMENTS ............................ 4

UNPACKING AND CHECKING CONTENTS ........ 6

Tools Needed ................................ 6

List of Loose Parts ............................ 6

ASSEMBLY .................................. 7

Installing Elevation and Tilt Handwheels ........... 7

Checking Table Insert ......................... 7

Checking Blade Squareness to Table .............. 8

Checking Blade Elevation ...................... 8

Attaching Table Extensions ..................... 8

Installing Rip Fence Guide Bars .................. g

Assembling Steel Legs ........................ 10

Mounting Saw .............................. 10

Aligning Table Extensions ..................... 11

Aligning Rip Fence .......................... If

Installing Blade Guard ........................ 13

GETTING TO KNOW YOUR SAW ............... 15

On-OffSwltah .............................. 15

Reset Button ............................... 16

Elevation Handwheel ......................... 16

Tilt Handwheel ............................. 16

Rip Fence ................................. 16

Miter Gauge ................................ 16

If the outlet you are planning to use for this saw is of the

two prong type DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER. Use an adapter

as shown and always connect the groundi.g lug to a known

ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE 10rongoutlet.

An adapter asshown below is available for conne_ing plugs

to 2-prong receptacles, The green grounding lug extending

from the adapter must be connected to a permanent ground

such asto a properly grounded outlet box.

GROUNDING LUG

ADAPTER

\

MAKE SURE THiS iS

3-PRONG CONNECTED TO A

PLUG KNOWN GROUND

2-PRONG

RECEPTACLE

NOTE: The adapter illustrated {sfor use only if you already

have a properly grounded 2-prong receptacle.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent

over-heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.) extension cord.

Use only 3 wire extension cords which have 3 prong

grounding type plugs and 3-pole receptacles which w_ll

accept the plug on the saw.

Extension Cord Length Wire Size A,W.G.

Upto 100 Ft ...................... 12

100 - 200 Ft ....................... 10

200 - 400 Ft ......................... 8

Blade Guard ................................ 16

Table Insert ................................ 16

Removingand InstallingSawblade ............... 17

BASIC SAW OPERATION USING THE MITER GAUGE 17

Work Helpers ............................... 17

Crosscutting ................................ 18

Repetitive Cutting ........................... lg

Miter Cutting ............................... 20

Bevel Crosscutting ........................... 20

Compound Miter Cutting ...................... 2(]

BASIC SAW OPERATION USING THE RIP FENCE .. 20

Ripping ................................... 21

Bevel Ripping .............................. 21

Rasaw_ng .................................. 22

Cutting Panels .............................. 23

Rabbeting ................................. 23

ADJUSTMENTS .............................. 23

Miter Gauge ................................ 23

Heeling Adjustment or Parallelism of

Sawblade to Miter Gauge Groove ............... 24

Blade Tilt, or Squareness of

Blade to Table ............................. 2,$

Blade Elevation ............................. 26

Tilt and Elevation Mechanism .................. 26

MAINTENANCE ............................. 26

LUBRICATION .............................. 2'7

RECOMMENDED ACCESSORIES ................ 27

TROUBLE SHOOTING ........................ 2,g

REPAIR PARTS .............................. 30

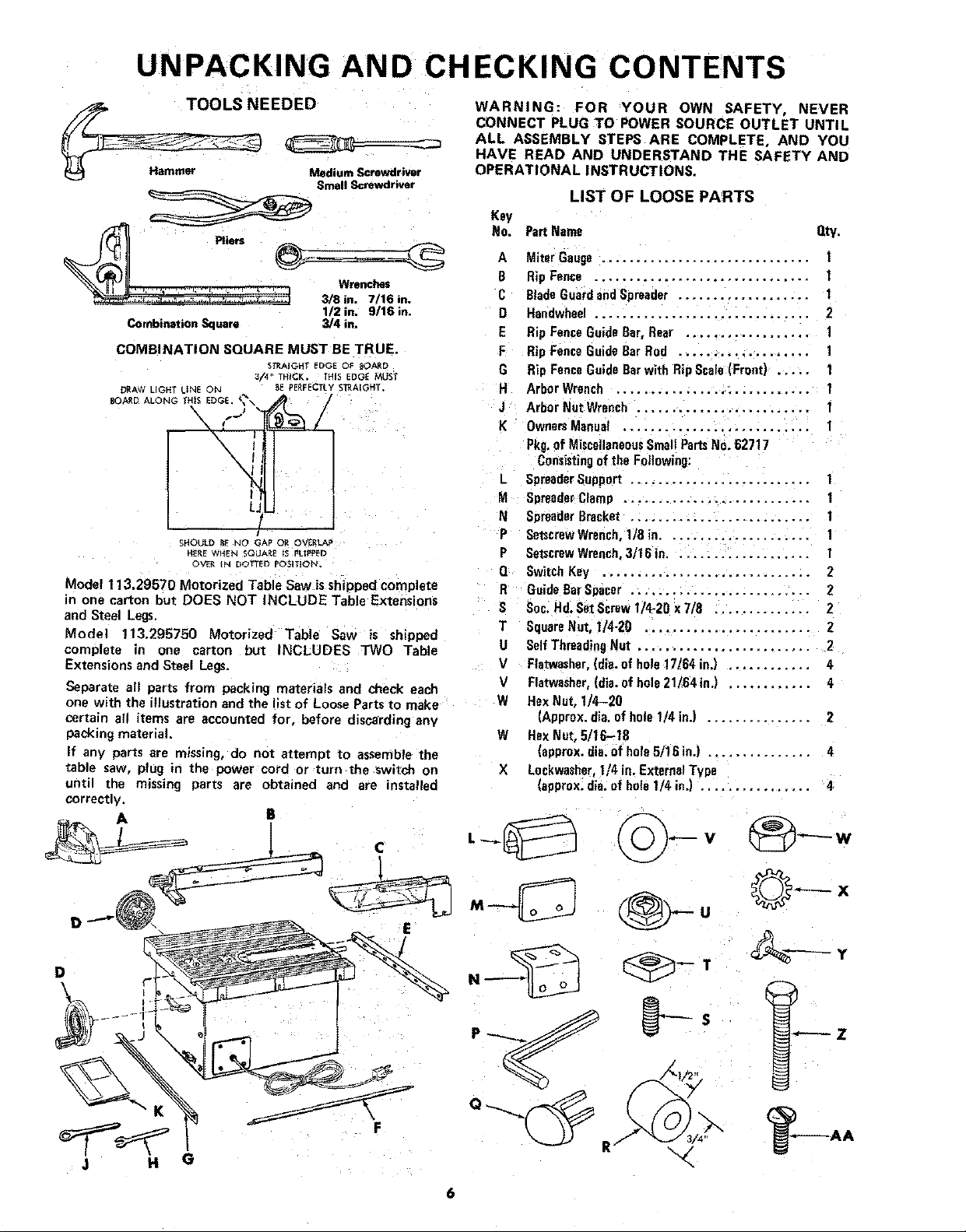

UNPACKING AND CHECKING CONTENTS

z//_ TOOLS NEEDED

Hammer Medium Screwdriver

Combination Square 3/4 in.

COMBINATION SQUARE MUST BE TRUE.

S_AIGHT EDGE OF _,)ARD

DRAW LIGHT LiNE ON BE PERFECTLY STRAIGHT.

ROARD ALONG I'HIS EDGE* ¢_\

3/4 THICK. THIS EDG_ MUST

Small Sorewdriver

112in. 9116in.

\,

LJ

SHOULD BE NO 3AP OF OVERLAp

4ERE WHEN SQUARE {S FLII=PED

OVER {N DOTTED POSITION.

Model t 13.29570 Motorized Table Sew isshipped complete

in one carton but DOES NOT INCLUDE Table Extensions

and Steel Legs.

Model 113.295750 Motorized Table Saw is shipped

complete in one carton but INCLUDES TWO Table

Extensions and Steel Legs.

Separate all parts from packing materials and check each

one with the illustration and the list of Loose Parts to make

certain all items are accounted for, before discarding any

packing material,

If any parts are mtssing, do not attempt to assemble the

table saw, plug in the power cord or turn the switch on

until the missing parts are obtained and are installed

correctly.

A B

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET UNTIL

ALL ASSEMBLY STEPS ARE COMPLETE, AND YOU

HAVE READ AND UNDERSTAND THE SAFETY AND

OPERATIONAL INSTRUCTIONS.

LIST OF LOOSE PARTS

Key

No. PartName Qty,

A MiterGauge ..............................1

B Rip Fence ............................... 1

C BladeGuardand Spreader ................... 1

D Handwheel............................... 2

E Rip FenceGuideBar, Rear .................. 1

F Rip FenceGuideBarRod ................... 1

G Rip FenceGuideBar with RipScale(Freut) ..... 1

H ArborWrench ............................ 1

J Arbor Nut Wrench ......................... 1

K OwnersMenuat .......................... 1

Pkg.of MiscellaneousSmall PartsNo. 627!7

Consistingofthe Following:

L SpreaderSupport .......................... 1

M SpreaderClamp ........................... 1

N SpreaderBracket ......................... 1

P SetscrewWrench,l/Sin ..................... 1

P SetscrewWrench,3/16 in.................... 1

Q Switch Key ..............................2

R GuideBar Spacer .......................... 2

S Soc, Hd.Set ScrewI/4-20 x 7/8 .............. 2

T SquareNut, 1/4-20 ........................ 2

U SelfThreadingNut ........................ 2

V Flatwasher,(die,of hole 17/64 in.) ............ 4

V Flatwasher,(dia. ofhole 21/64 in.) ............ 4

W HexNut, 1/4-20

{Approx.dia. of hole 1/4 in.) ............... 2

W HexNut, 5/16-18

(approx.die. of hole5/16 in.) ............... 4

X Lockwasher,1/4 in. ExternalType

{approx.die,of hole1/4 in,] ............... 4

°

j H G

6

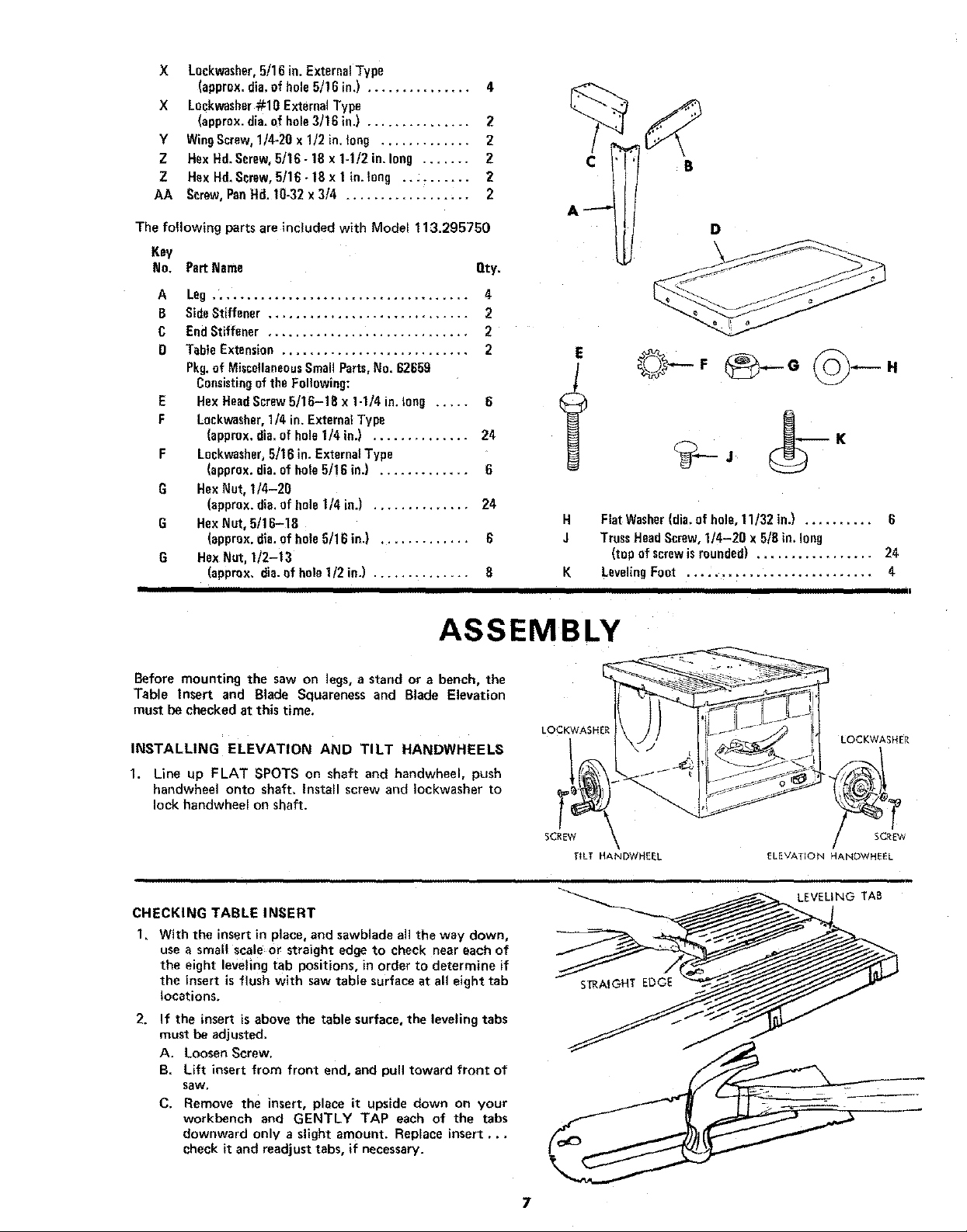

X Lockwasher,5/16 in. ExternalType

(approx.dia. of hole5/16 in.) ............... 4

X Luckwashar-#10 ExternalType

(approx.die. of hole3/18 in.) ............... 2

Y WingScrew,1/4-20 x 1/2 {n.long ............. 2

Z Rex Hd.Screw, 5/16 - 18 x 1-1/2 im long ....... 2

Z Hex Hd,Screw,5/16 -f8 x 1 in. tong .......... 2

AA Screw,Pro1Hd. 10-32 x3/4 .................. 2

B

The following parts are included with Model 113.295750

Key

No. PartName Qty.

A Leg . .................................... 4

B SideStiffener ............................. 2

C EndStiffener ............................. 2

I1 Table Extension ........................... 2

Pkg.of Misce!laneousSmallParts,No. 62659

Consistingof the Following:

E Hex HeadScrew5/16--18 x 1-1/4 in.long ..... 6

F Lockwashsr,1/4 in. ExternalType

(appmx.dia,of hole1/4 in.) .............. 24

F Leckwasher,5/16 in. ExternalType

(approx.dia. of hole5/16 in.) ............. 6

G HexNut, 1/4-20

(approx.dia. of hole1/4 in.) .............. 24

G HexNut, 5/16-]8

(approx.die. of hole5/16 in.) ............. S

G Hex Nut, 1/2-13

(approx, die. af hole1/2 in.) .............. 8

III

ASSEMBLY

D

H FlatWasher(dia, of hole, 11/32 in.) .......... 6

J TrussHeadScrew,1/4-20 x 5/8 in. long

(top of screwis rounded) ................. 24

K LevelingFoot ..... . ..................... 4

Before mounting the saw on legs, a stand or a bench, the

Table Insert and Blade Squareness and Blade Elevation

must be checked at this time,

INSTALLING ELEVATION AND TILT HANDWHEELS

1. Line up FLAT SPOTS on shaft and handwheel, push

handwhee] onto shaft, Install screw and Iockwasber to

lock handwheel on shaft.

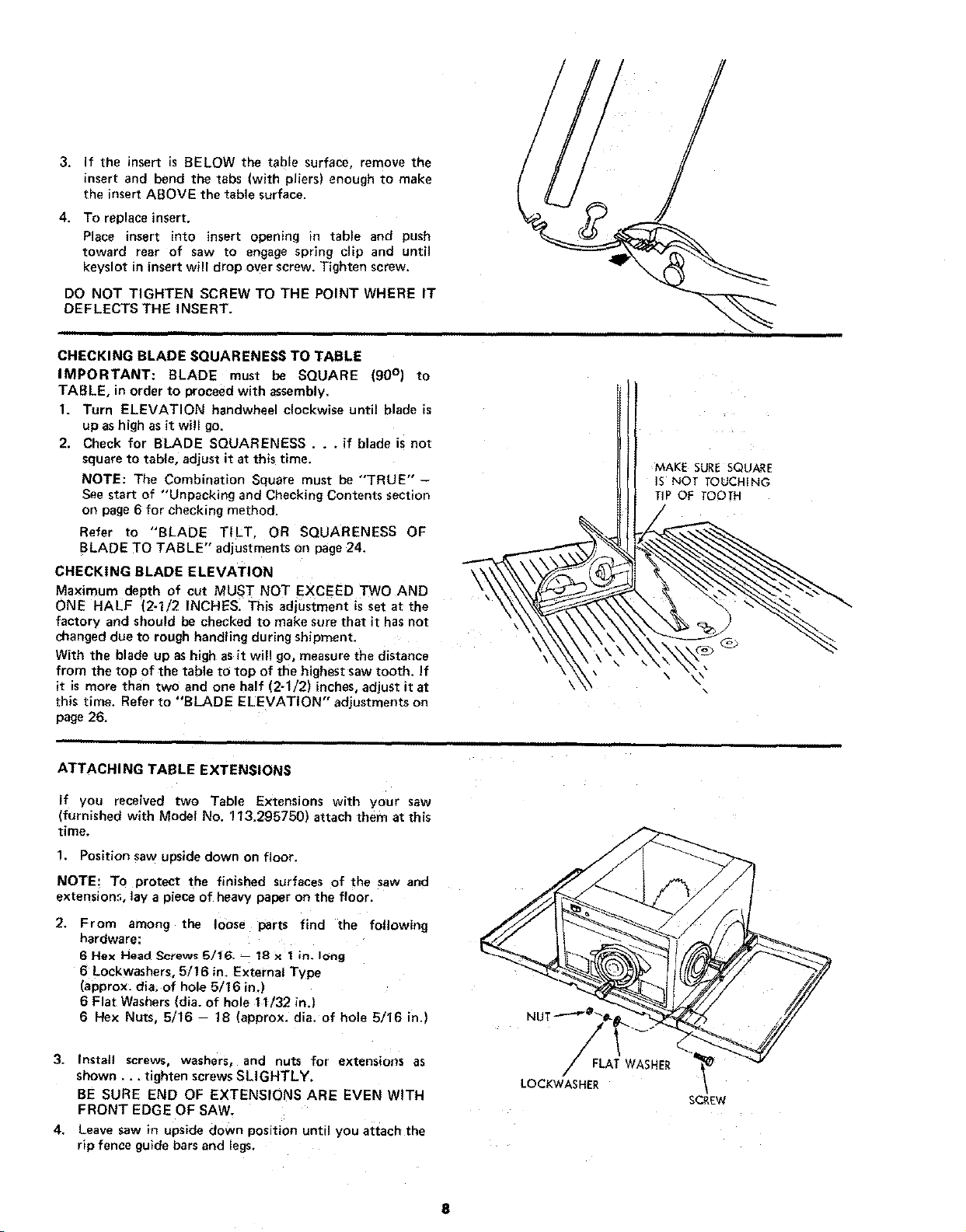

CHECKING TABLEINSERT

I, With the insert in place, and sawblade all the way down,

use a small scale or straight edge to check near each of

the eight leveling tab positions, in order to determine if

the insert is flush with saw table surface at all eight tab

locations.

2. If the insert is above the table surface, the leveling tabs

must be adjusted.

A. Loosen Screw.

B. Lift insert from front end, and pull toward front of

sew,

C. Remove the insert, place it upside down on your

workbench end GENTLY TAP each of the tabs

downward only a slight amount. Replace insert...

check it and readjust tabs, if necessary.

LOCKWASHER

T

SCREW

TILT HANDWHEEL

LOCKWASHER

SCREW

ELEVATION HANDWHEEL

LEVELING TAB

7

3. If the insert is BELOW the table surface, remove the

insert and bend the tabs (with pliers) enough to make

the insert ABOVE the table surface.

4. To replace insert.

Place insert into insert opening in table and push

toward rear of saw to engage spring clip and until

keyslot in insert wi!l drop over screw. Tighten screw.

DO NOT TIGHTEN SCREW TO THE POINT WHERE IT

DEFLECTS THE INSERT.

CHECKING BLADE SQUARENESS TO TABLE

IMPORTANT: BLADE must be SQUARE (90°) to

TABLE, in order to proceed with assembly.

1. Turn ELEVATION handwheel clockwise until blade is

up ashigh as it will go.

2. Check for BLADE SQUARENESS . . . if blade is not

square to table, adjust it at this time.

NOTE: The Combination Square must be "TRUE"-

See start of "Unpacking and Checking Contents section

on page 6 for checking method.

Refer to "BLADE TILT, OR SQUARENESS OF

BLADE TO TABLE" adjustments on page24.

CHECKING BLADE ELEVATION

Maximum depth of cut MUST NOT EXCEED TWO AND

ONE HALE (2-1/2 INCHES. This adjustment iS set at the

factory and should be checked to make sure that it has not

changed due to rough handling during shipment.

With the blade up as high asit will go, measure the distance

from the top of the table to top of the highest saw tooth. If

it is more than two and one half (2=1/2) inches, adjust it at

this time. Refer to "BLADE ELEVATION" adjustments on

page 26.

MAKE SURE SQUARE

IS NOT TOUCHING

TiP OF TOOTH

\

i f iii

ATTACHING TABLE EXTENSIONS

If you received two Table Extensions with your saw

(furnished with Model No. 113.295750) attach them at this

time.

1. Position saw upside down on floor.

NOTE; To protect the finished surfaces of the saw and

extensions, lay a piece of heavy paper on the floor.

2,

From among the loose parts find the following

hardware:

6 Hex Head ,_crew_6/16. -- 18 × 1 in. long

6 Lockwashers, 5/16 in. External Type

(approx: die; of hole 5/16 in,)

6 Flat Washers (dia. of hole 11/32 in.)

6 Hex Nuts, 5/16 - 18 (approx. die. of hole 5/16 in.)

3. Install screws, wasbars_ and nuts for extensions as

shown.., tighten screws SLIGHTLY.

BE SURE END OF EXTENSIONS ARE EVEN WITH

FRONT EDGE OF SAW.

4. Leave saw in upside down position until you attach the

rip fence guide bars and legs.

FLAT WASHER

LOCKWASHER

SCREW

$

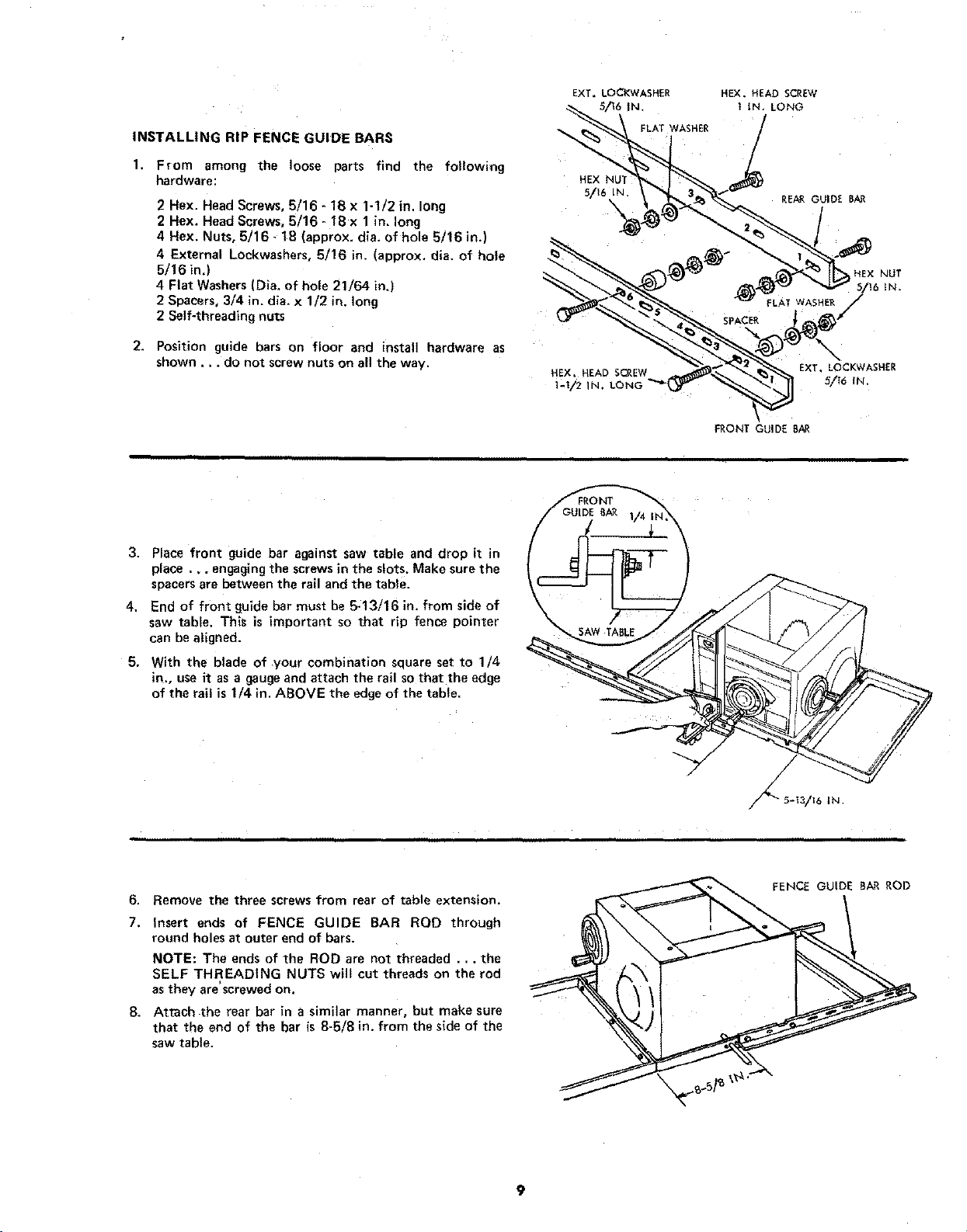

INSTALLING RIP FENCE GUIDE BARS

1. From among the loose _rts find the following

hardware:

2 Flex. Head Screws. 5/16 - 18 x 1-I/2 in. long

2 Flex. Head Screws, 5/16 - 18 x 1 in, long

4 Hex, Nuts, 5/16- 18 (approx. dia. of hole 5/16 in.)

4 External Lockwasbers, 5/16 in. (approx. dia. of hole

5/16 in,)

4 Flat Washers(Dia. of hole 21/64 in,)

2 Spacers, 3/4 in. dia, x 1/2 in. Ionf!

2 Self-threading nuts

2. Position guide bars on floor and instal hardware as

shown.., do not screw nuts on all the way,

EXT. LOCKWASHER HEX. HEAD SCREW

5/16 IN. I IN. LONG

FLAT WAS½ER /

HEX NU

5/16

FRONT GUIDE BAR

3. Place front guide bar against saw table and drop it in

place ... engaging the screws in the slot s. Make sure the

spacers are between the rail and the table.

4. End of front guide bar must be 5:13/16 in. from side of

saw table. Thi_ is important so that rip fence pointer

can be aligned.

6. With the blade of your combination square set to 1/4

in., use it as a gauge and attach the rail so that the edge

of the rail is 1/4 in. ABOVE the edge of the table.

6, Remove the three screws from rear of table extension,

7, Insert ends of FENCE GUIDE BAR ROD through

round holes at outer end of bars.

NOTE: The ends of the ROD are not threaded ... the

SELF THREADING NUTS will cut threads on the rod

as they are'screwed on.

8. Attach the rear bar in a similar manner, but make sure

that the end of the bar is 8-5/8 in. from the side of the

saw table.

/

5-13/16 IN.

FENCE GUIDE BAR ROD

9

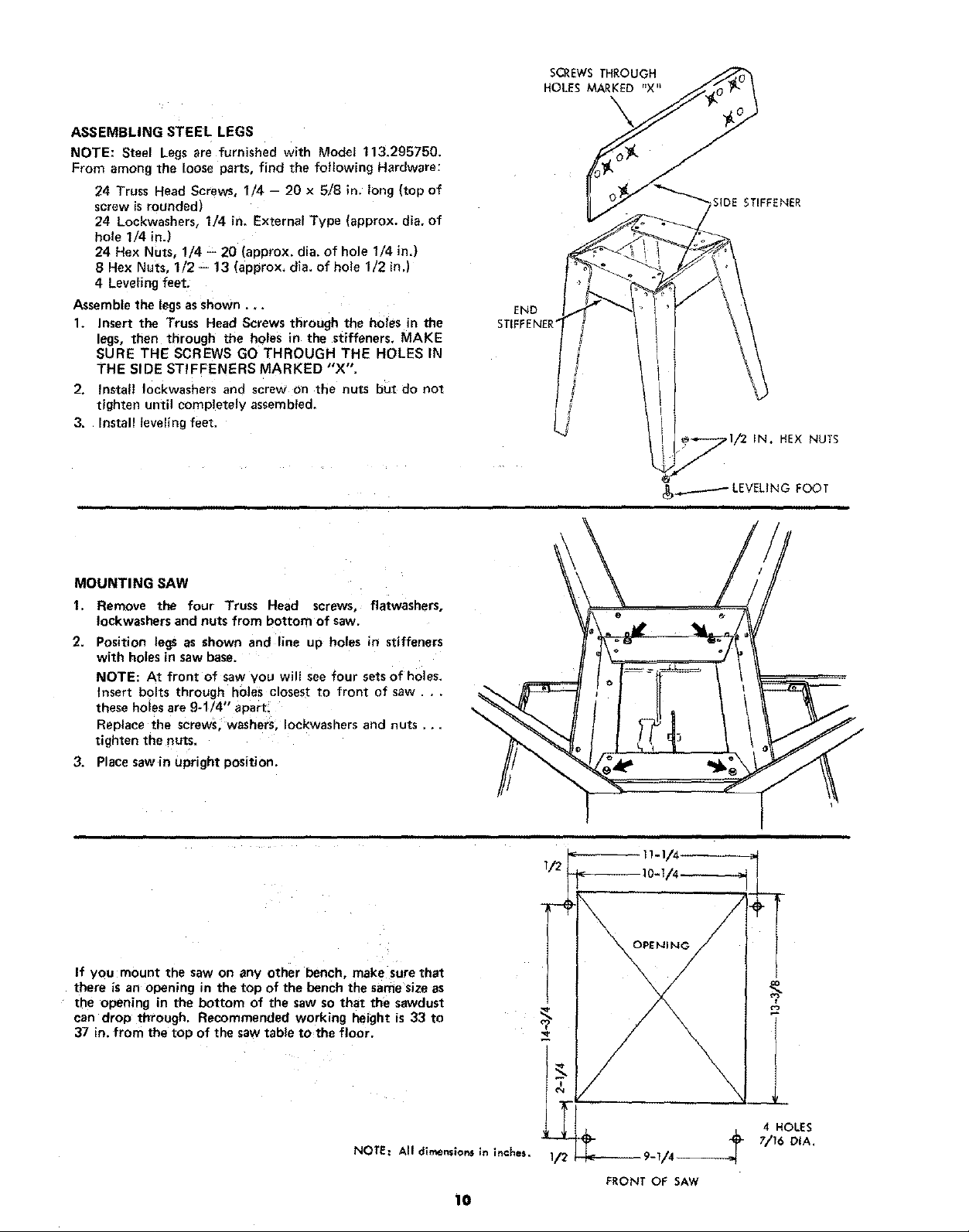

ASSEMBLING STEEL LEGS

NOTE: Steel Legs are furnished with Model 113.295750,

From among the loose parts, find the following Hardware:

24 Truss Head Screws, 1/4 - 20 x 5/8 in. long (top of

screw is rounded)

24 Lockwashers, 1/4 in. External Type (approx. dia. of

hole 1/4 in.)

24 Hex Nuts, 1/4 - 20 (approx, dia. of hole 1/4 in.}

8 Hex Nuts, 1/2 -- 13 (approx. dia. of hole 1/2 in.)

4 Leveling feet,

Assemble the legs asshown...

1. Insert the Truss Head Screws through the holes in the

legs, then through the holes in the stiffeners, MAKE

SURE THE SCREWS GO THROUGH THE HOLES IN

THE SIDE STIFFENERS MARKED "X".

2. Install Iockwashers and screw on the nuts but do not

tighten until completely assembled.

3. Install leveling feet.

SCREWS THROUGH

HOLES MARKED "X"

SIDE STIFFENER

END

STIFFENER _

_:_.,._..----- LEVELING FOOT

MOUNTING SAW

I, Remove the four Truss Head screws, flatwashers,

Iockwashers and nuts from bottom of saw.

2. Position legs as shown and line up holes in stiffeners

with holes in saw base.

NOTE: At front of saw you will see four ,_etsof holes.

Insert bolts through holes closest to front of saw.

these holes are 9-1/4'" apart.

Replace the screws, washers, Iockwashers and nuts...

tighten the nuts.

3. Place saw m upright position.

i ,,,,,

If you mount the saw on any other bench, make sure that

there is an opening in the top of the bench the same size as

the opening in the bottom of the saw so that the sawdust

can drop through. Recommended working height is 33 to

37 in. from the top of the saw table tothe floor.

T

,i,i

)/2

NOTE: All dimensions in inches,

i0

/

4 HOLES

;;'/16 OIA.

FRONT OF SAW

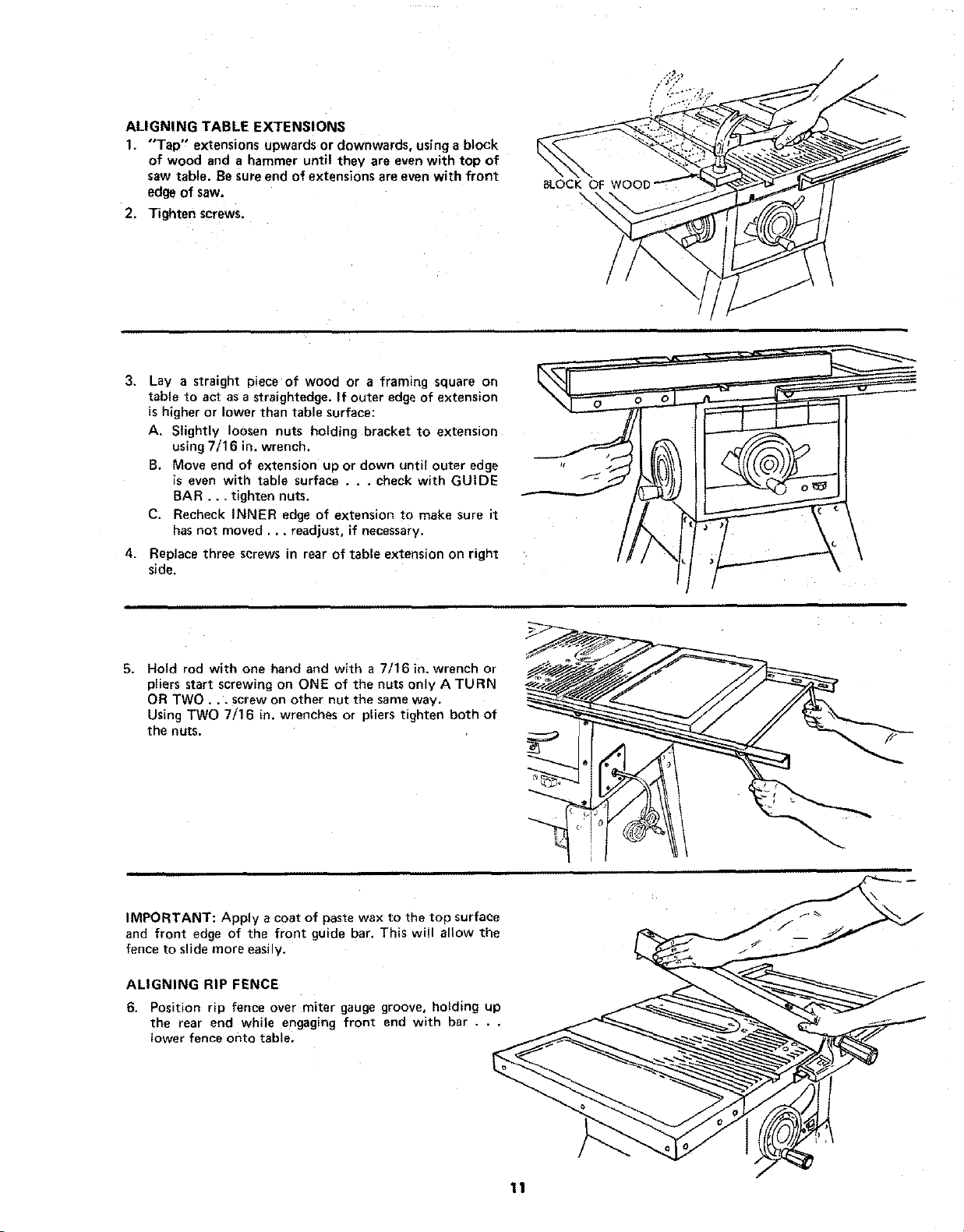

ALIGNING TABLE EXTENSIONS

1. "TAD" extensions upwards or downwards, using a block

of wood and a hammer until they are even with top of

saw table. Be sureend of extensions are even with front

edge of saw,

2. Tighten screws.

3. Lay a straight piece of wood or a framing square on

table to act as a straightedge. If outer edge of extension

is higher or lower than table surface:

A, Slightly loosen nuts holding bracket to extension

using 7/16 in. wrench.

B. Move end of extension up or down until outer edge

is even with table surface . . . check with GUIDE

BAR,.. tighten nuts.

C. Recheck INNER edge of extension to make sure it

has not moved . .. readjust, if necessary.

4. Replace three screws in rear of table extension on right

side.

BLOCK OF WOQD

5. Hold rod with one hand and with a 7/16 in. wrench or

pliers start screwing on ONE of the nuts only A TURN

OR TWO... screw on other nut the same way.

Using TWO 7/16 in. wrenches or pliers tighten both of

the nuts.

IMPORTANT: Apply a coat of paste wax to the top surface

and front edge of the front guide bar. This will allow the

fence to slide more easily.

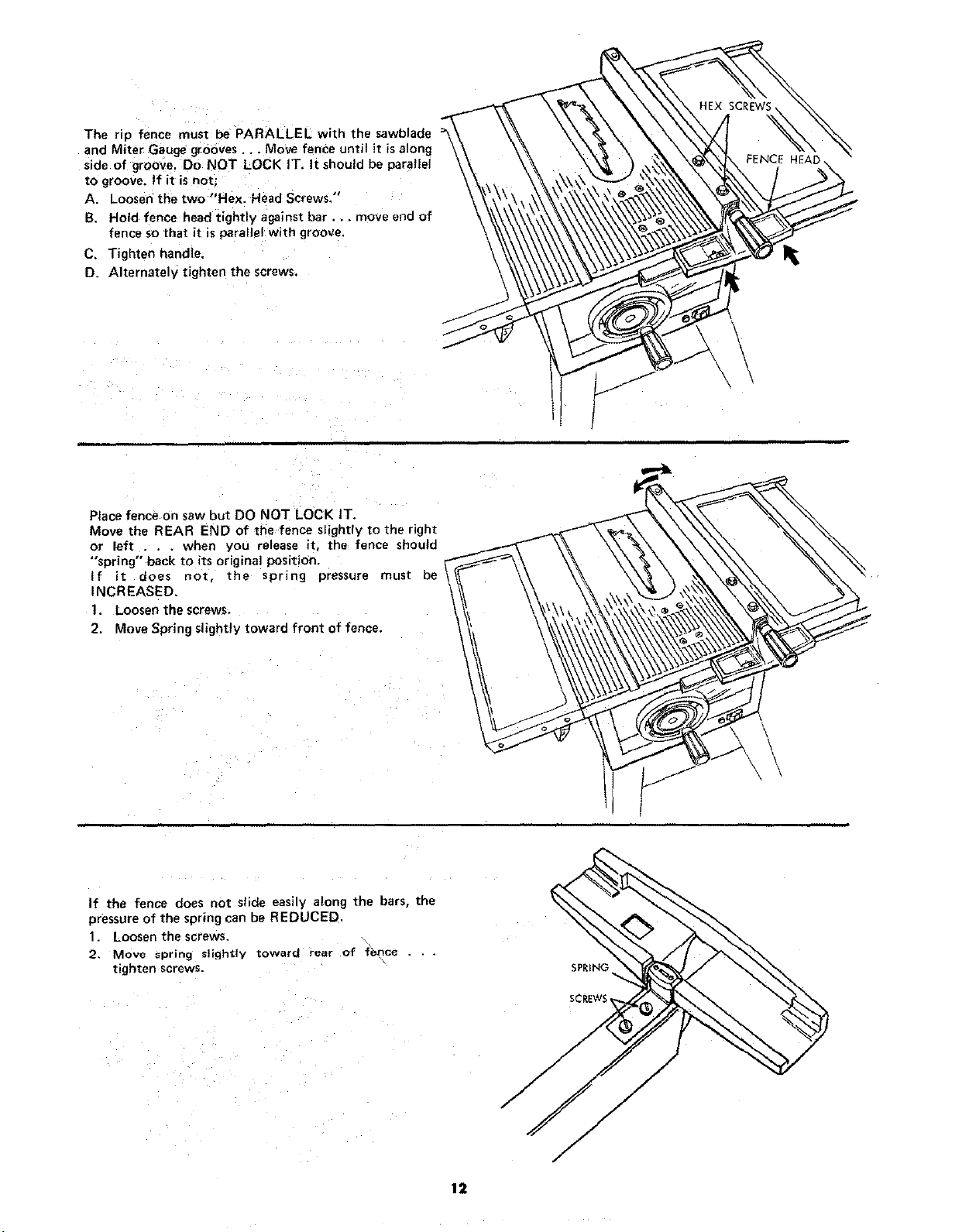

ALIGNING RIP FENCE

6. Position rip fence over miter gauge groove, holding up

the rear end while engaging front end with bar . . .

lower fence onto table,

11

The rip fence must be PARALLEL with the sawblade

and Miter Gauge grooves... Move fence until it is along

side of groove. Do NOT LOCK IT. It should be I_arallel

to groove. If it is not;

A. Loosen the two "Hex. Head Screws."

B. Hold fenCe head tightly against bar . .. move end of

fence so that it is parallel with groove.

C. Tighten handle.

D. Alternately tighten the screws,

Place fence on saw but DO NOT LOCK IT.

Move the REAR END of the fence slightly to the right

or left . . . when you release it, the fence should

"spring" back to its original position.

If it does not, the spring pressure must be

INCREASED.

1. Loosen the screws,

2. Move Spring slightly toward front of fence.

If the fence does not slide easily along the bars, the

pressure of the spring can be REDUCe,

1. Loosen the screws.

2. Move spring slightly toward r_ar of (t_ncc . . .

tighten screws.

12

Loading...

Loading...