Craftsman 11329350 Owner’s Manual

ASSEMBLY, OPERATING INSTRUCTIONS

AND PARTS LIST FOR

CRAFTSMAN 9 INCH RADIAL SAW

MODEL NUMBER 113.29350

The Model Number will be found on a plate attached to your saw,

at the left side of the base. Always mention the Model Number in

all correspondence regarding the CRAFTSMAN RADIAL SAW or when

ordering repair parts.

Carefully read the instructions provided, observe the simple

safety precautions and you will have many hours of satisfactory

use from your new Craftsman tool.

HOW TO ORDER REPAIR PARTS

All parts listed herein may be ordered through SEARS, ROEBUCK AND

CO. or SIMPSONS-SEARS LIMITED. When ordering parts by mail from

the catalog order house which serves the territory in which you live,

selling prices will be furnished on request or parts will be shipped at

prevailing prices and you will be billed accordingly.

1

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

INFORMATION AS SHOWN IN THIS LIST:

1. The PART NUMBER 3. The MODEL NUMBER 113.29350

2. The PART NAME 4. The NAME of item--RADIAL SAW

COAST TO COAST NATION-WIDE

SERVICE FROM SEARS

FOR YOUR CRAFTSMAN RADIAL 5AW

SEARS, ROEBUCK AND CO. and

SIMPSONS-SEARS LIMITED in Canada

back up your investment with quick,

expert mechanical service and genu-

ine CRAFTSMAN replacement parts.

If and when you need repairs or serv-

ice, call on us to protect your invest-

ment in this fine piece of equipment.

SEARS, ROEBUCK AND CO.-U.S.A.

IN CANADA, SIMPSONS-SEARS LIMITED

Printed in U S. A.

Part No. 63152

CRRFT. MR

POWER TOOLSAFETY...AND YOU

3 MINUTES of required reading for the home Crafts-

man.., whether this is your first purchase or you're

an old hand at power tools.

YOU'VE JUST BOUGHT A QUALITY SEARS TOOL.

designed to give you many years of top performance

and trouble-free operation. It's also designed with

1. READ THE INSTRUCTION

MANUAL...

completely, accurately.

Pay special attention to safety pre-

cautions and use of safety features.

2. INSPECTTHE POWERTOOL

THOROUGHLY

Set up the machine according to io-

strucbons. Make certain all parts

are included.

6. USE PROPERELECTRICAL

CONNECTIONS

Make certain proper voltage (I10 of'

220) is used. USE A GROUND WIRE;

AND A SUITABLE PLUG, IF REQUIRED.

Check fusing requirements of the

tool as outlined in the instruction

manual.

5. WEAR SAFETYGLASSES

Safety glasses or eye shields are

recommended for all power tool

operations.

Get in the habit of turning off the

tool when not in use.

Disconnect input cable from power

supply when adjusting toot from one

working position to another.

safety in mind, permitting you to use the tool without

concern so long as certain basic rules are observed.

We'd like to call particular attention to some of the

more important rules to follow for maximum enjoy-

ment of your Sears power tools.

3. FOLLOWOPERATING

INSTRUCTIONSCAREFULLY

They have been developed to in-

sure correct procedure and pre-

vent accidents.

7. DOUBLE-CHECKHOLDING

FIXTURES

Lock all clamps tightly.

Spin parts by hand to check against

misalignment or looseness before

turning on tool.

4. DRESS PROPERLYFOR THE

WORKSHOP

Get rid of loose clothing, roll up

sleeves (or fasten securely), remove

your tie, wear a snug-fitting shol:

apron.

8. KEEP CUTTING TOOLS SHARP

Make certain blades, drills, cutters,

etc., are in top shape. Dull tools

can cause rough cuts, excessive

chipping.., and accidents.

9. DON'T EXCEEDTHE LIMITS

OF THE POWERTOOL

Abusing the power tool by doing

work beyond its capacity reduces

its life and irrcreases the chance of running

injury to the operator. Watch espe-

cially the s_zes of the work and

feed rate.

10. KEEP SPECTATORSAWAY

Curiosity and interest on the part

of the family is fine, but avoid in-

spections when the power tool is

THINK

Carefully plan

2

_il'_., _ _k,_,_" _,_=

I- I

11. SAFETYGUARDS

Accessory safety guards are avail-

able for most tools. Use of these

guards is highly recommended.

Keep protective caps on ends of

exposed, rotating shafts.

each operation

12. AVOIDAWKWARDHAND

POSITIONS

Do not place hands in a position

where a sudden slip could cause

them to move into a cutting tool

Do not force work abnormally into

any cutting tool.

before turning on tool

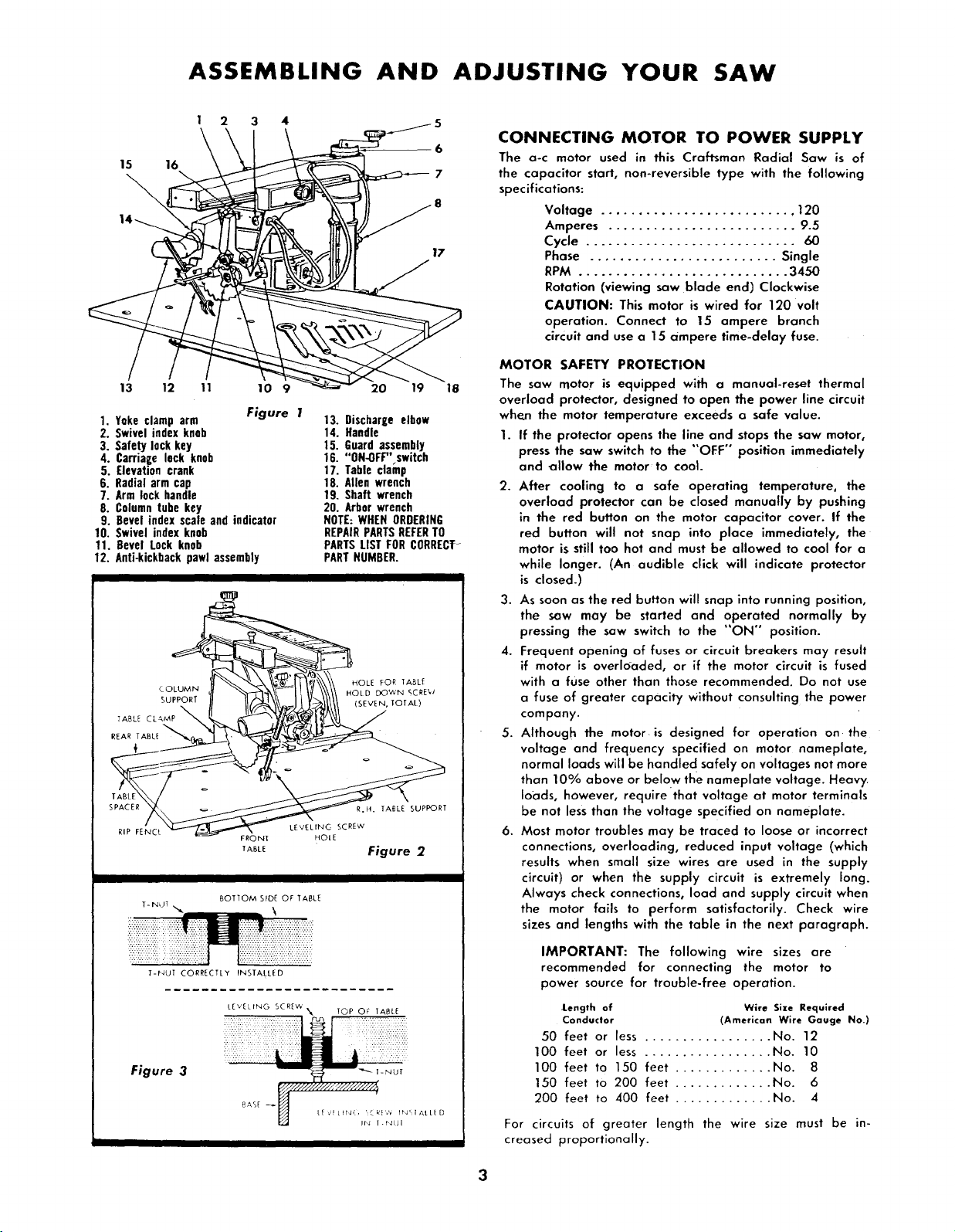

ASSEMBLING AND ADJUSTING YOUR SAW

2 3 4

15 16

13 12 11 10 9 20 19 18

1. Yoke clamp arm

2. Swivel index knob

3. Safety lock key

4. Carriage lock knob

5. Elevation crank

6. Radial arm cap

7. Arm lock handle

8. Columntube key

9. Bevel index scale and indicator

10. Swivel index knob

11. Bevel Lock knob

12. Anti-kickbackpawl assembly

COLUMN

_UPPORT

TABLE CL&MP

REAR TABL_

RIP FENCL

T- NiJT

Figure 1

FRONT

TABLE

BOTTOM SIDE OF TABLE

LEVELING SCREW

13. Discharge elbow

14. Handle

15. Guard assembly

16. "ON-OFF" switch

17. Table clainp

18. Allen wrench

19. Shaft wrench

20. Arbor wrench

NOTE:WHENORDERING

REPAIRPARTSREFERTO

PARTSLIST FORCORRECT-

PARTNUMBER.

HOLE FOR TABLE

)WN gCRE W

(SEVEN, TOTAL)

R.H. TABLE suPPORT

HOtE

Figure 2

6

7

CONNECTING MOTOR TO POWER SUPPLY

The a-c motor used in this Craftsman Radial Saw is of

the capacitor start, non-reversible type with the following

specifications:

Voltage .......................... 120

Amperes ......................... 9.5

17

Cycle ............................ 60

Phase ......................... Single

RPM ............................ 3450

Rotation (viewing saw blade end) Clockwise

CAUTION: This motor is wired for 120 volt

operation. Connect to 15 ampere branch

circuit and use a 15 ampere time-delay fuse.

MOTOR SAFETY PROTECTION

The saw motor is equipped with a manual-reset thermal

overload protector, designed to open the power line circuit

when the motor temperature exceeds a safe value.

1. If the protector opens the line and stops the saw motor,

press the saw switch to the "OFF" position immediately

and _llow the motor to cool.

2. After cooling to a safe operating temperature, the

overload protector can be closed manually by pushing

in the red button on the motor capacitor cover. If the

red button will not snap into place immediately, the

motor is still too hot and must be allowed to cool for a

I

while longer. (An audible click will indicate protector

is closed.)

3. As soon as the red button will snap into running position,

the saw may be started and operated normally by

pressing the saw switch to the "'ON" position.

4. Frequent opening of fuses or circuit breakers may result

if motor is overloaded, or if the motor circuit is fused

with a fuse other than those recommended. Do not use

a fuse of greater capacity Without consulting the power

company.

5. Although the motor is designed for operation on the

voltage and frequency specified on motor nameplate,

normal loads will be handle d safely on voltages not more

than 10% above or below the nameplate voltage. Heavy

loads, however, require that voltage at motor terminals

be not less than the voltage specified on nameplate.

6. Most motor troubles may be traced to loose or incorrect

connections, overloading, reduced input voltage (which

results when small size wires are used in the supply

circuit) or when the supply circuit is extremely long.

Always check connections, load and supply circuit when

the motor fails to perform satisfactorily. Check wire

sizes and lengths with the table in the next paragraph.

T-NUT CORRECTLY INSTALLED

Figure 3

LEVELING SC RE_&

"_ TOP OF TABLE

_*,sr _x///H'_/// ---y/////i,,._,-NUT

L_/_L_N,, :£k_',', I_'IAtL[D

U

IN I.FdUI

IMPORTANT: The following wire sizes are

recommended for connecting the motor to

power source for trouble-free operation.

JLength of Wire Size Required

Conductor (American Wire Gauge No.)

50 feet or less ................. No. 12

100 feet or less ................. No. 10

100 feet to 150 feet ............. No. 8

150 feet to 200 feet ............. No. 6

200 feet to 400 feet ............. No. 4

For circuits of greater length the wire size must be in-

creased proportionally.

3

MOUNTING THE SAW ON A WORK BENCH

The sow shoud be placed on a suitable sturdy work bench,

or Craftsman Power Tool Bench. The base of the saw must

be mounted *lush to a flat surface on the work bench to

prevent distortion of the saw base. The nuts, screws, and

washers which attach the wooden shipping skids to the

saw base may be used to secure the saw base to the work

bench, or tact bench.

ALIGNMENT INSTRUCTIONS

NOTE: The seven basic "steps" that follow are

essential in order to insure correct saw table

alignment.

WARNING: Make sure the power cord is

not plugge d into an electrical outlet when

working on the saw.

STEP ONE--INSTALLATION OF FRONT TABLE

1. Place the large table board upside-down on floor.

Distinguish between the one through-bored (leveling

screw) hole near the center of the board, and the seven

counterbore holes. (See figure 2.) The counterbores are

in the top surface of the board. Drive the T-nut into the

through-hole. (See figure 3.)

2. Place the 1/4-20 "'U" clip nut on the base cross members

to receive the center front tab!e attaching screw.

3. Place the large, front table board on table support

angles.

4. Align the counterbore holes with matching holes in the

support angles. Place a flat washer and a 1/4-20x 1"

pan-head machine screw in each of the six counterbore

holes located above the angles. Use a 1/4-20 x 1-1/4 '_

pan-head machine screw in the counterbore hole at the

center of the table board.

5. Start the leveling screw into the T-nut but do not allow

the point to protrude beyond bottom surface of front

board.

6. Install Iockwashers and nuts on the six screws in the

angles and tighten them finger tight. Start the 1/4-20 x

1-1/4" pan-head screw in the counterbored hole near

the center of front board, leaving it about two turns loose.

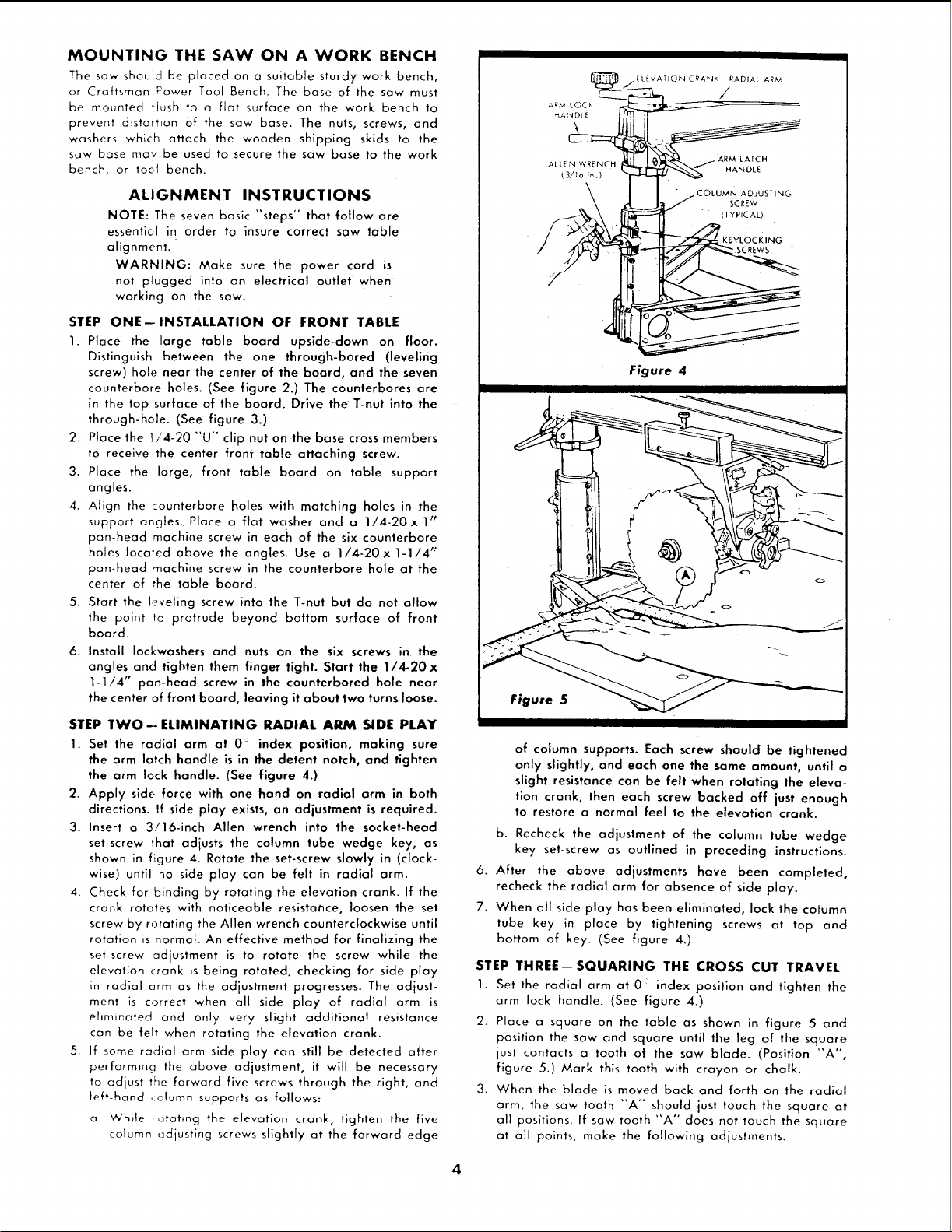

STEP TWO--ELIMINATING RADIAL ARM SIDE PLAY

1. Set the radial arm at 0 J index position, making sure

the arm latch handle is in the detent notch, and tighten

the arm lock handle. (See figure 4.)

2. Apply side force with one hand on radial arm in both

directions. If side play exists, an adjustment is required.

3. Insert a 3/16-inch Allen wrench into the socket-head

set-screw that adjusts the column tube wedge key, as

shown in figure 4. Rotate the set-screw slowly in (clock-

wise) until no side play can be felt in radial arm.

4. Check for binding by rotating the elevation crank. If the

crank rotates with noticeable resistance, loosen the set

screw by rotating the Allen wrench counterclockwise until

rotation is normal. An effective method for finalizing the

set-screw adjustment is to rotate the screw while the

elevation crank is being rotated, checking for side play

in radial arm as the adjustment progresses. The adjust-

ment is correct when all side play of radial arm is

eliminated and only very slight additional resistance

can be felt when rotating the elevation crank.

5. If some radial arm side play can still be detected after

performing the above adjustment, it will be necessary

to adjust the forward five screws through the right, and

left-hand (olumn supports as follows:

a While -otating the elevation crank, tighten the five

column ,_djustlng screws slightly at the forward edge

ALLEN WRENCH

_3,/16 in.)

ARM LATCH

HANDLE

COLUMN ADJUSTING

SCREW

(TYPICAL)

KEYLOCKING

Figure 4

of column supports. Each screw should be tightened

only slightly, and each one the same amount, until a

slight resistance con be felt when rotating the eleva-

tion crank, then each screw backed off just enough

to restore a normal feel to the elevation crank.

b. Recheck the adjustment of the column tube wedge

key set-screw as outlined in preceding instructions.

6. After the above adjustments have been completed,

recheck the radial arm for absence of side play.

7. When all side play has been eliminated, lock the column

tube key in place by tightening screws at top and

bottom of key. (See figure 4.)

STEP THREE--SQUARING THE CROSS CUT TRAVEL

1. Set the radial arm at 0 :' index position and tighten the

arm lock handle. (See figure 4.)

2. Place a square on the table as shown in figure 5 and

position the saw and square until the leg of the square

just contacts a tooth of the saw blade. (Position "A-,

figure 5.) Mark this tooth with crayon or chalk.

3. When the blade is moved back and forth on the radial

arm, the saw tooth "A" should just touch the square at

all positions. If saw tooth "A" does not touch the square

at all points, make the following adjustments.

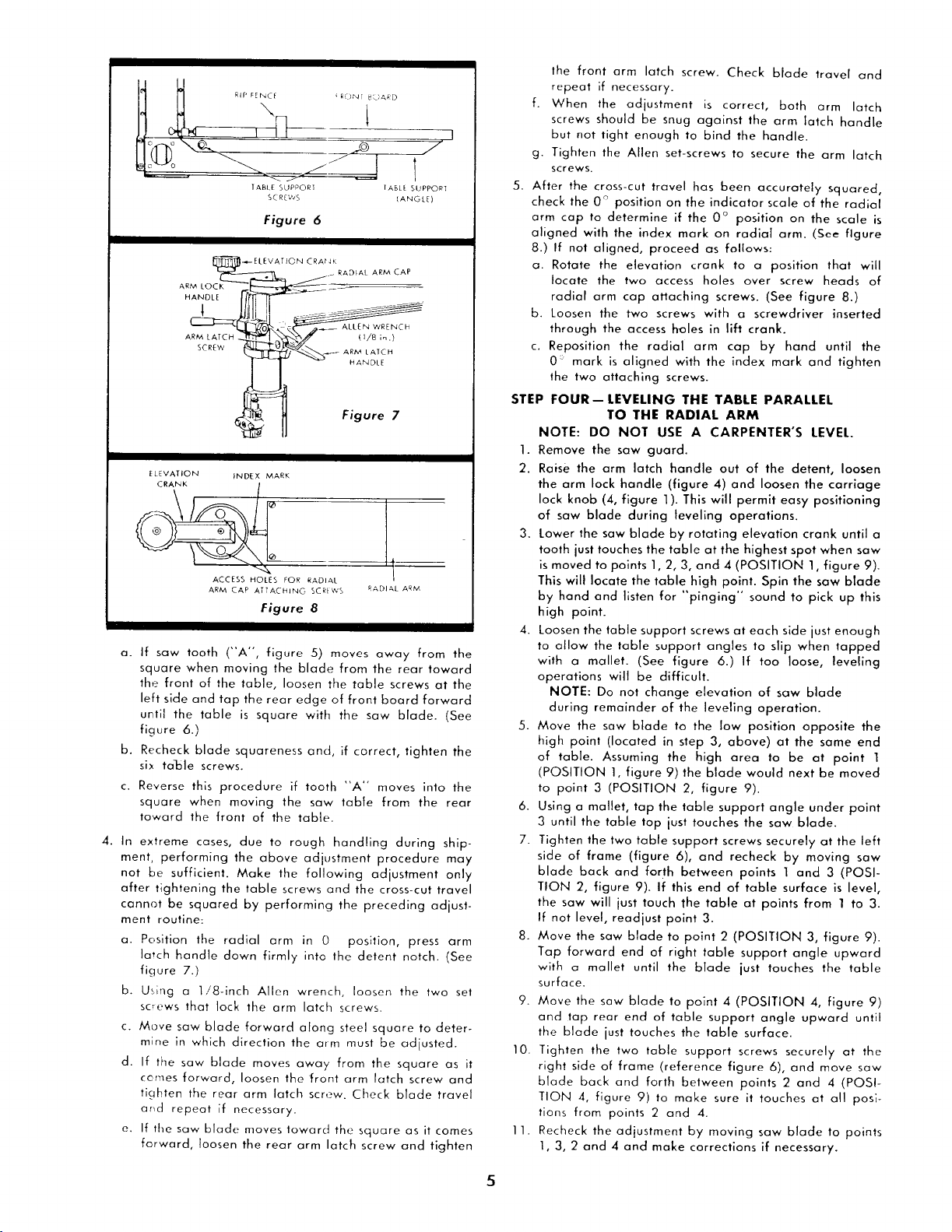

TABLE SUPPORT IABLE SUPPOR_

SCREWS (ANGLE)

Figure 6

ARM LO____

HANDLE

_ELEVATION CRAtdKRADIAL ARM CAP

'c ___ ALLEN WRENCH

_ - Figure 7

ELEVATION INDEX MARK

CRANK 1

o f!: l,_

ACCESS HOLES FOR RADIAL

ARM CAP AT]ACHING SCREWS RADIAL ARM,

Figure 8

a_

If saw tooth ("A", figure 5) moves away from the

square when moving the blade from the rear toward

the front of the table, loosen the table screws at the

left side and tap the rear edge of front board forward

until the table is square with the saw blade. (See

figure 6.)

b.

Recheck blade squareness and, if correct, tighten the

six ta!_le screws.

c.

Reverse this procedure if tooth "A" moves into the

square when moving the saw table from the rear

toward the front of the table.

4. In extreme cases, due to rough handling during ship-

ment, performing the above adjustment procedure may

not be sufficient. Make the fallowing adjustment only

after tightening the table screws and the cross-cut travel

cannot be squared by performing the preceding adjust-

ment routine:

a. Position the radial arm in 0 position, press arm

la_ch handle down firmly into the detent notch. (See

figure 7.)

b.

Using a 1!8-inch Allen wrench, loosen the two set

screws that lock the arm latch screws.

c.

Move saw blade forward along steel square to deter-

mine in which direction the arm must be adjusted.

d.

If the saw blade moves away from the square as it

cemes forward, loosen the front arm latch screw and

tighten the rear arm latch screw. Check blade travel

arid repeat if necessary.

e.

If the saw blade moves toward the square as it comes

forward, loosen the rear arm latch screw and tighten

the front arm latch screw. Check blade travel and

repeat if necessary.

f. When the adjustment is correct, both arm latch

screws should be snug against the arm latch handle

but not tight enough to bind the handle.

g. Tighten the Allen set-screws to secure the arm latch

screws.

5. After the cross-cut travel has been accurately squared,

check the 0 ° position on the indicator scale of the radial

arm cap to determine if the 0 ° position on the scale is

aligned with the index mark on radial arm. (See figure

8.) If not aligned, proceed as follows:

a. Rotate the elevation crank to a position that will

locate the two access holes over screw heads of

radial arm cap attaching screws. (See figure 8.)

b. Loosen the two screws with a screwdriver inserted

through the access holes in lift crank.

c. Reposition the radial arm cap by hand until the

0: mark is aligned with the index mark and tighten

the two attaching screws.

STEP

FOUR--LEVELING THE TABLE PARALLEL

TO THE RADIAL ARM

NOTE: DO NOT USE A CARPENTER'S LEVEL.

1.

Remove the saw guard.

2.

Raise the arm latch handle out of the detent, loosen

the arm lock handle (figure 4) and loosen the carriage

lock knob (4, figure 1). This will permit easy positioning

of saw blade during leveling operations.

3.

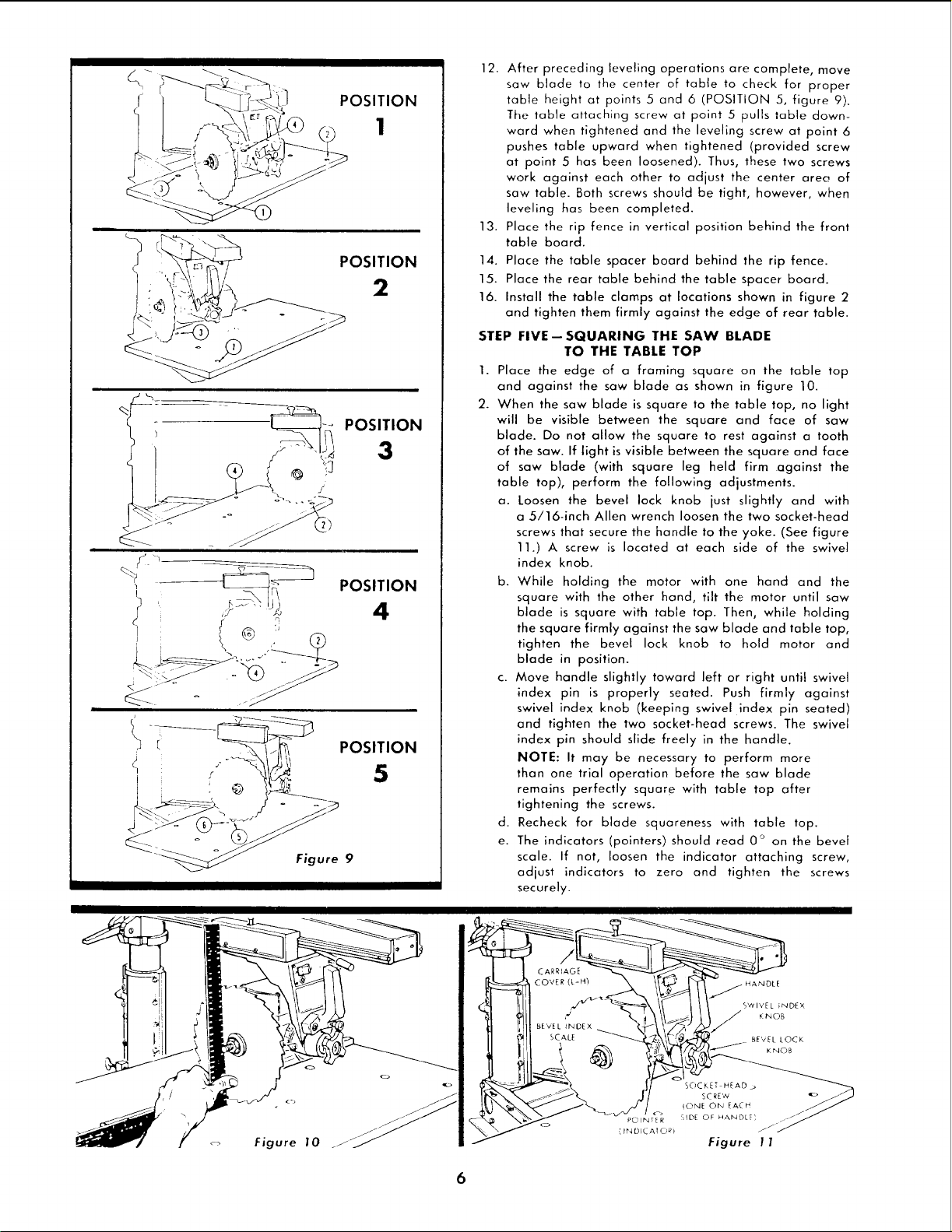

Lower the saw blade by rotating elevation crank until a

tooth just touches the table at the highest spot when saw

is moved to points 1,2, 3, and 4 (POSITION 1, figure 9).

This will locate the table high point. Spin the saw Blade

by hand and listen for "pinging'" sound to pick up this

high paint.

4.

Loosen the table support screws at each side just enough

to allow the table support angles to slip when tapped

with a mallet. (See figure 6.) If too loose, leveling

operations will be difficult.

NOTE: Do not change elevation of saw blade

during remainder of the leveling operation.

5.

Move the saw blade to the low position opposite the

high point (located in step 3, above) at the same end

of table. Assuming the high area to be at point 1

(POSITION 1, figure 9) the Blade would next be moved

to point 3 (POSITION 2, figure 9).

6.

Using a mallet, tap the table support angle under point

3 until the table top just touches the saw blade.

7.

Tighten the two table support screws securely at the left

side of frame (figure 6), and recheck by moving saw

blade back and forth between points 1 and 3 (POSI-

TION 2, figure 9). If this end of table surface is level,

the saw will just touch the table at points from 1 to 3.

If not level, readjust point 3.

8.

Move the saw blade to point 2 (POSITION 3, figure 9).

Tap forward end of right table support angle upward

with a mallet until the blade just touches the table

surface.

9.

Move the saw blade to point 4 (POSITION 4, figure 9)

and tap rear end of table support angle upward until

the blade just touches the table surface.

10.

Tighten the two table support screws securely at the

right side of frame (reference figure 6), and move saw

blade back and forth between points 2 and 4 (POS!-

TION 4, figure 9) to make sure it touches at all posi-

tions from points 2 and 4.

11.

Recheck the adjustment by moving saw blade to points

1, 3, 2 and 4 and make corrections if necessary.

5

/

I

/

-oo

12. After preceding leveling operations are complete, move

saw blade to the center of table to check for proper

POSITION

I

.os,.,o.

POSITION

3

POSITION

4

I

table height at points 5 and 6 (POSITION 5, figure 9).

The table attaching screw at point 5 pulls table down-

ward when tightened and the leveling screw at point 6

pushes table upward when tightened (provided screw

at point 5 has been loosened). Thus, these two screws

work against each other to adjust the center area of

saw table. Both screws should be tight, however, when

leveling has been completed.

13. Place the rip fence in vertical position behind the front

table board.

14. Place the table spacer board behind the rip fence.

15. Place the rear table behind the table spacer board.

16. Install the table clamps at locations shown in figure 2

and tighten them firmly against the edge of rear table.

STEP FIVE--SQUARING THE SAW BLADE

TO THE TABLE TOP

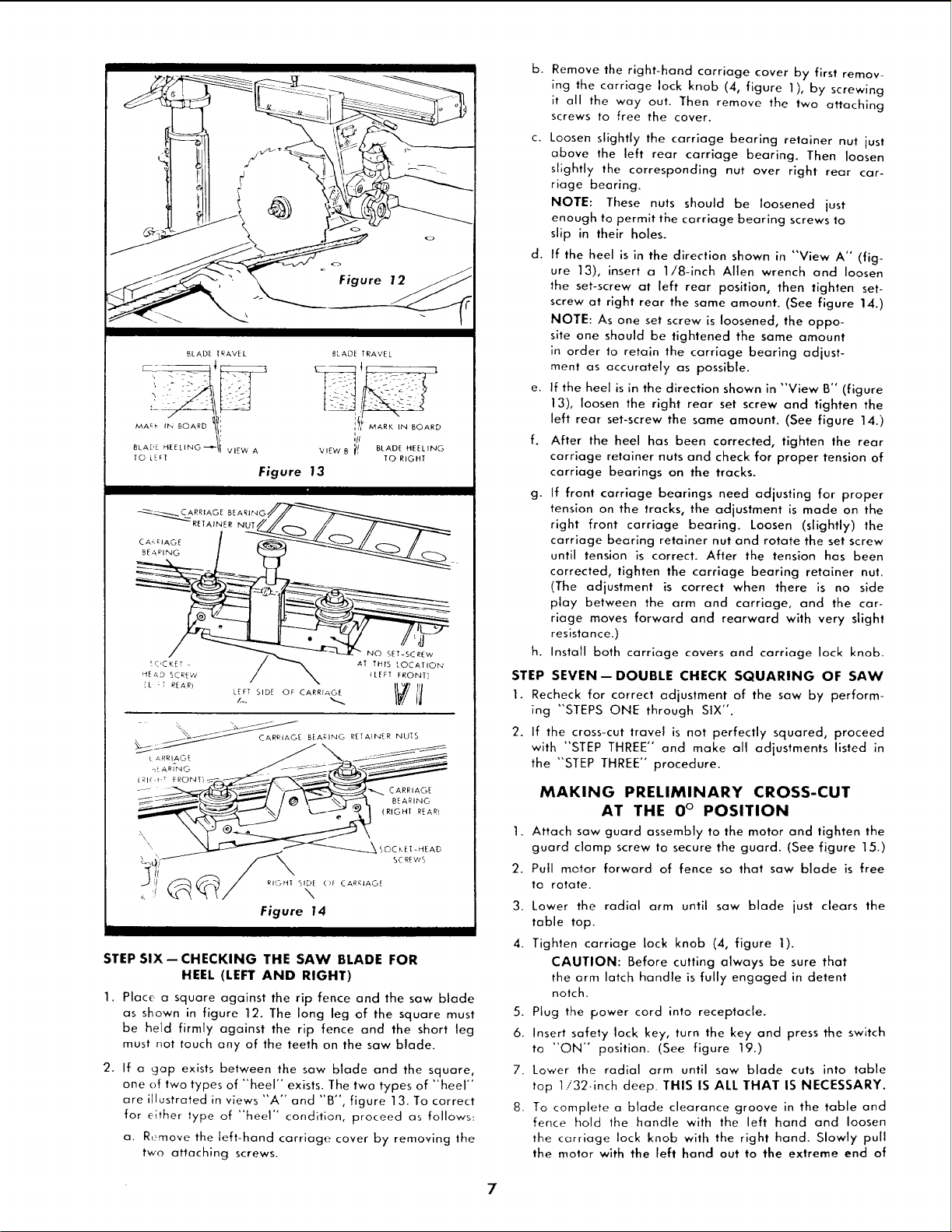

1. Place the edge of a framing square on the table top

and against the saw blade as shown in figure 10.

2. When the saw blade is square to the table top, no light

will be visible between the square and face of saw

blade. Do not allow the square to rest against a tooth

of the saw. If light is visible between the square and face

of saw blade (with square leg held firm against the

table top), perform the following adjustments.

a. Loosen the bevel lock knob just slightly and with

a 5/16-inch Allen wrench loosen the two socket-head

screws that secure the handle to the yake. (See figure

11.) A screw is located at each side of the swivel

index knob.

b. While holding the motor with one hand and the

square with the other hand, tilt the motor until saw

blade is square with table top. Then, while holding

the square firmly against the saw blade and table top,

tighten the bevel lock knob to hold motor and

blade in position.

c. Move handle slightly toward left or right until swivel

index pin is properly seated. Push firmly against

swivel index knob (keeping swivel index pin seated)

and tighten the two socket-head screws. The swivel

index pin should slide freely in the handle.

NOTE: It may be necessary to perform more

than one trial operation before the saw blade

remains perfectly square with table top after

tightening the screws.

d. Recheck for blade squareness with table top.

e. The indicators (pointers) should read 0 ° on the bevel

scale. If not, loosen the indicator attaching screw,

adjust indicators to zero and tighten the screws

securely.

Figure 10

HANDLE

SWIVEL iNDEX

J KNOB

BE'v EL LOCK

KNOB

lONE ON EACH

POIbd_ER SIDE OF HANDLe', .-

SOCKETSCREWHEAD _ j_

Figure 11

6

BLADE TRAVEL

T© L£FT

gLADE TRAVEL

v_EwB t[

i,

BLADE HEELING

TO RIGHT

Figure 13

_CARRIAGE BeArING_

CA _ RETAINER[AGE N U T/_//k"--'_ izizi/

_L v / X ,u.t FRONT)

L[FT/_. SIDE OF CARR,AGE_ 17 II

, __ CARRIAGE BEA_Ir'4G RETAINER NU]S

I_Ql(. f.T FRONT] _ _

,,,, k_'4 _/ \

Figure 14

I

STEP SIX--CHECKING THE SAW BLADE FOR

HEEL (LEFT AND RIGHT)

1. Place a square against the rip fence and the saw blade

as shown in figure 12. The long leg of the square must

be held firmly against the rip fence and the short leg

must not touch any of the teeth on the saw blade.

2. If a gap exists between the saw blade and the square,

one of two types of "heel" exists. The two types of "heel"

are illustrated in views "A" and "B", figure 13. To correct

for either type of "heel" condition, proceed as follows:

a. R,-move the left-hand carriage cover by removing the

two attaching screws.

b.

Remove the right-hand carriage cover by first remov-

ing the carriage lock knob (4, figure 1), by screwing

it all the way out. Then remove the two attaching

screws to free the cover.

c. Loosen slightly the carriage bearing retainer nut just

abave the left rear carriage bearing. Then loosen

slightly the corresponding nut over right rear car-

riage bearing.

NOTE: These nuts shauld be loosened just

enough to permit the carriage bearing screws to

slip in their holes.

d. If the heel is in the direction shown in "View A" (fig-

ure 13), insert a 1/8-inch Allen wrench and loosen

the set-screw at left rear position, then tighten set-

screw at right rear the same amount. (See figure 14.)

NOTE: As one set screw is loosened, the oppo-

site one should be tightened the same amount

in order to retain the carriage bearing adjust-

ment as accurately as possible.

e. If the heel is in the direction shown in "View B" (figure

13), loosen the right rear set screw and tighten the

left rear set-screw the same amount. (See figure 14.)

f. After the heel has been corrected, tighten the rear

carriage retainer nuts and check for proper tension of

carriage bearings on the tracks.

g. If front carriage bearings need adjusting for proper

tension on the tracks, the adjustment is made on the

right front carriage bearing. Loosen (slightly) the

carriage bearing retainer nut and rotate the set screw

until tension is correct. After the tension has been

corrected, tighten the carriage bearing retainer nut.

(The adjustment is correct when there is no side

play between the arm and carriage, and the car-

riage moves forward and rearward with very slight

resistance.)

h. Install both carriage covers and carriage lock knob.

STEP SEVEN--DOUBLE CHECK SQUARING OF SAW

1. Recheck for correct adjustment of the saw by perform-

ing "STEPS ONE through SIX".

2. If the cross-cut travel is not perfectly squared, proceed

with "STEP THREE" and make all adjustments listed in

the "STEP THREE" procedure.

MAKING PRELIMINARY CROSS-CUT

AT THE 0 ° POSITION

1. Attach saw guard assembly to the motor and tighten the

guard clamp screw ta secure the guard. (See figure 15.)

2. Pull motor forward of fence so that saw blade is free

to rotate.

3. Lower the radial arm until saw blade just clears the

table top.

4. Tighten carriage lock knob (4, figure 1).

CAUTION: Before cutting always be sure that

the arm latch handle is fully engaged in detent

notch.

5. Plug the power cord into receptacle.

6. Insert safety lock key, turn the key and press the switch

to "'ON" position. (See figure 19.)

7. Lower the radial arm until saw blade cuts into table

top 1!32-inch deep. THIS IS ALL THAT IS NECESSARY.

8. To complete a blade clearance groove in the table and

fence hold the handle with the left hand and loosen

the carriage lock knob with the right hand. Slowly pull

the motor with the left hand out to the extreme end of

travelandthenpushthemotorbackthroughthefence

totheextremerearposition.Pushtheswitchto"'OFF"

position.

ATTACHING AND DETACHING

THE SAW BLADE

I. Remove the shaft nut and one loose collar.

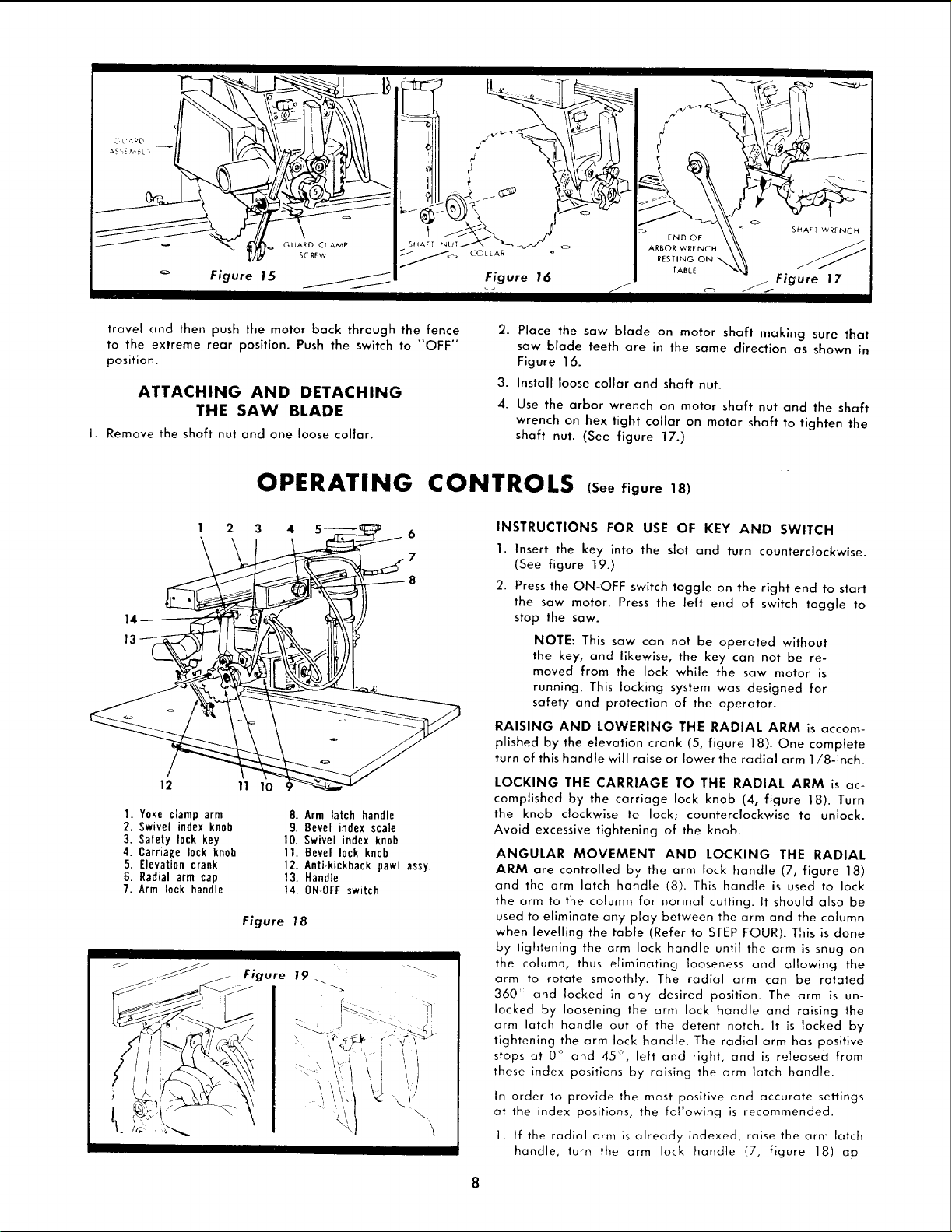

OPERATING CONTROLS (See figure 18)

2. Place the saw blade on motor shaft making sure that

saw blade teeth are in the same direction as shown in

Figure 16.

3. Install loose collar and shaft nut.

4. Use the arbor wrench on motor shaft nut and the shaft

wrench on hex tight collar on motor shaft to tighten the

shaft nut. (See figure 17.)

1 2 3 4 sT___ _6

14----

13--

1. Yoke clamp arm

2. Swivel index knob

3. Safety lock key

4. Carriage lock knob

5. Elevationcrank

6. Radial arm cap

7. Arm lock handle

8. Arm latch handle

9. Bevel index scale

10. Swivel index knob

11. Bevel lock knob

12. Anti-kickback pawl assy.

13. Handle

14. 0N-0FF switch

Figure 18

INSTRUCTIONS FOR USE OF KEY AND SWITCH

1. Insert the key into the slot and turn counterclockwise.

(See figure 19.)

2. Press the ON-OFF switch toggle on the right end to start

the saw motor. Press the left end of switch toggle to

stop the saw.

NOTE: This saw can not be operated without

the key, and likewise, the key can not be re-

moved from the lock while the saw motor is

running. This locking system was designed for

safety and protection of the operator.

RAISING AND LOWERING THE RADIAL ARM is accom-

plished by the elevation crank (5, figure 18). One complete

turn of this handle will raise or Iowerthe radial arm 1/8-inch.

LOCKING THE CARRIAGE TO THE RADIAL ARM is ac-

complished by the carriage lock knob (4, figure 18). Turn

the knob clockwise to lock; counterclockwise to unlock.

Avoid excessive tightening of the knob.

ANGULAR MOVEMENT AND LOCKING THE RADIAL

ARM are controlled by the arm lock handle (7, figure 18)

and the arm latch handle (8). This handle is used to lock

the arm to the column for normal cutting. It should also be

used to eliminate any play between the arm and the column

when levelling the table (Refer to STEP FOUR). This is done

by tightening the arm lock handle until the arm is snug on

the column, thus eliminating looseness and allowing the

arm to rotate smoothly. The radial arm can be rotated

360 and locked ;n any desired position. The arm is un-

locked by loosening the arm lock handle and raising the

arm latch handle out of the detent notch. It is locked by

tightening the arm lock handle. The radial arm has positive

stops at 0 ° and 45 ° , left and right, and is released from

these index positions by raising the arm latch handle.

In order to provide the most positive and accurate se_ings

at the index positions, the fo!/owing is recommended.

1. If the radial arm is already indexed, raise the arm latch

handle, turn the arm lock handle (7, figure 18) ap-

8

Loading...

Loading...