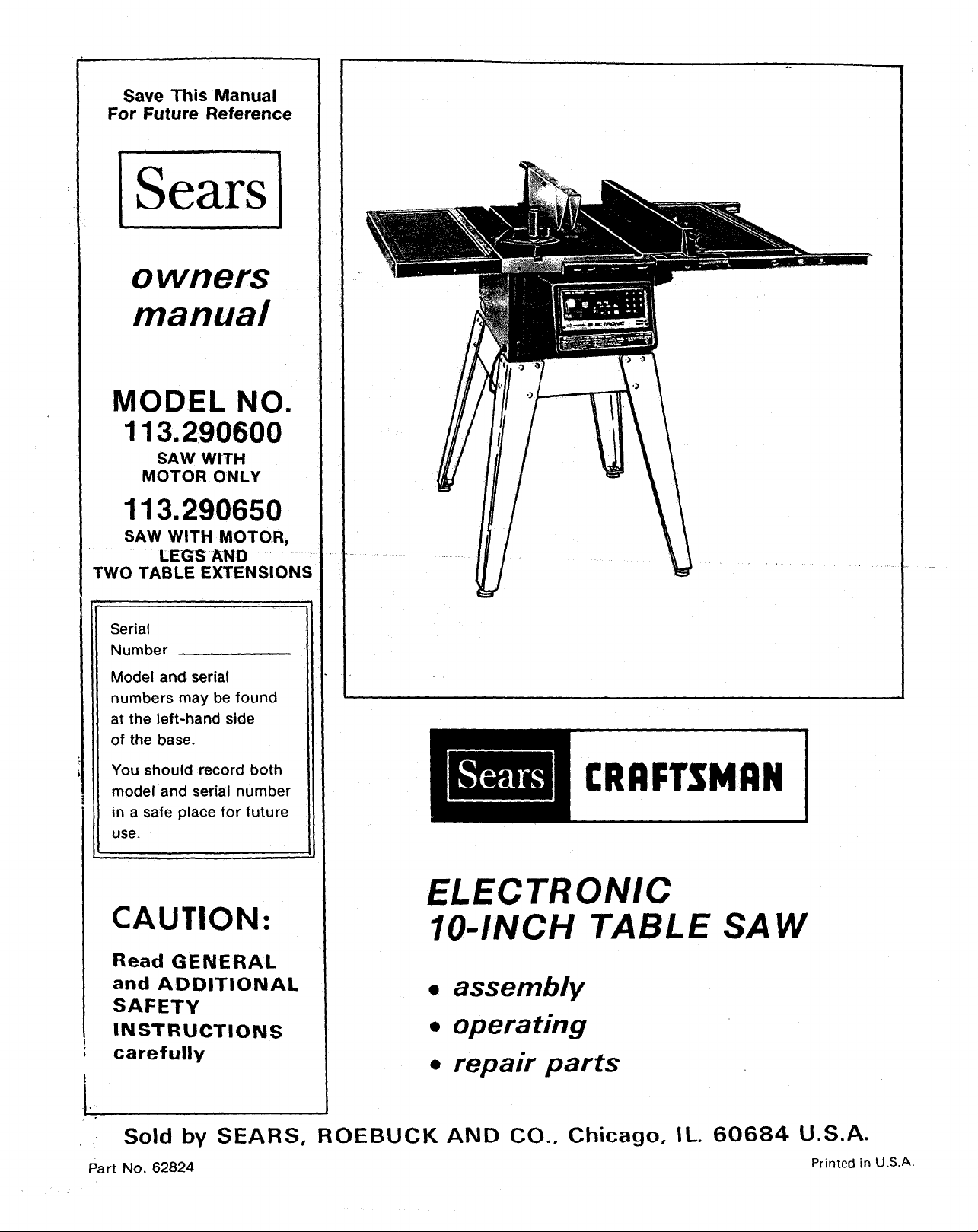

Craftsman 113290650, 113290600 Owner’s Manual

Save This Manual

For Future Reference

owners

manual

MODEL NO.

113.290600

SAW WITH

MOTOR ONLY

113.290650

SAW WITH MOTOR,

LEGS AND

TWO TABLE EXTENSIONS

Serial

Number

Model and serial

numbers may be found

at the left-hand side

of the base.

You should record both

model and serial number

in a safe place for future

use.

CAUTION:

Read GENERAL

and ADDITIONAL

SAFETY

INSTRUCTIONS

!

carefully

CRRFTSMRN

ELECTRONIC

IO-INCH TABLE SAW

• assembly

• operating

• repair parts

• Sold by SEARS, ROEBUCK AND CO., Chicago, IL.

Part No. 62824

60684 U.S.A.

Printed in U.S.A.

FULL ONE YEAR WARRANTY ON CRAFTSMAN TABLE SAW

If within one _year from the date of purchase, this Craftsman Table Saw fails due to a detect in material or

workmanship, Sears will repair It, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty applies only while this product Is used In the United States.

This warranty gives you specific legal rights, and you may also have other fights which vary from state to state.

SEARS, ROEBUCK AND CO., DEPT. 698/731A Sears Tower, Chicago, IL 60684

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual and

labels affixed to the tool. Learn its application

and limi.tations as well as the specific potential

hazards peculiar to this tool.

2. GROUND ALL TOOLS

This tool is equipped with an approved

3-conductor cord and a 3-prong grounding

type plug to fit the proper grounding type

receptacle. The green conductor in the cord is

the grounding wire. Never connect the green

wire to a live terminal.

3. KEEP GUARDS IN PLACE,

in working order, and in proper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents.

Floor must not be slippery due to wax or

sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations

or expose them to rain. Keep work area well

bighted. Provide adequate surrounding work

space.

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from

work area.

8, MAKE WORKSHOP KID-PROOF

with padlocks, master switches, or by

removing starter keys.

9. DON'T FORCE TOOL

It will do the job better and safer at the rate for

which it was designed.

10. USE RIGHT TOOL

Don't force too_ or attachment to do a job it was

not designed for.

11. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wrist watches) to get caught in

moving parts. Nonslip footwear is

recommended. Wear protective hair covering to

contain long hair. Roll long sleeves above the

elbow.

12. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANSI

Z87.1) at all times. Everyday eyeglasses only

have impact resistant lenses, they are NOT

safety glasses. Also, use face or dust mask if

cutting operation is dusty, and ear protectors

(plugs or muffs) during extended periods of

operation.

13. SECURE WORK

Use clamps or a vise to hold work when

practical. It's safer than using your hand, frees

both hands to operate tool.

14. DON'T OVERREACH

Keep proper footing and balance at all times,

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performances. Follow instructions for

lubricating and changing accessories.

16. DISCONNECT TOOLS

before servicing; when changing accessories

such as blades, bits, cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before

plugging in.

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. Follow the instructions that

accompany the accessories. The use of

improper accessories may cause hazards.

19. NEVER STAND ON TOOL

Serious inj ury could occur if the tool is tipped or

if the cutting tool is accidentally contacted.

Do not store materials above or near the tool

such that it is necessary to stand on the tool to

reach the m.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other

part that is damaged should be carefully

checked to ensure that it will operate properly

and perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may effect its operation. A

guard or other part that is damaged should be

properly repaired or replaced.

21. DIRECTION OF FEED

Feed work into a blade or cutter against the

direction of rotation of the blade or cutter only.

22. NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off. Don't leave tool until it comes to

a complete stop.

ADDITIONAL SAFETY INSTRUCTIONS FOR TABLE SA lr3!

WARNING: FOR YOUR OWN SAFETY, DO NOT B. Wear safety goggles that comply with ANSI

OPERATE YOUR SAW UNTIL IT IS COMPLETELY Z87.1, and a face shield or dust mask if

ASSEMBLED AND INSTALLED ACCORDING TO

THE INSTRUCTIONS... AND UNTIL YOU HAVE

READ AND UNDERSTAND THE FOLLOWING:

1. GENERAL SAFETY INSTRUCTIONS FOR

POWER TOOLS... SEE PAGE 2

2. GETTING TO KNOWYOUR SAW... SEE PAGE

22

3. BASIC SAW OPERATION ..... SEE PAGE 27

4. MAINTENANCE ............. : SEE PAGE 41

5, STABILITY OF SAW

If there is any tendency for the saw to tip over or

move during certain cutting operations such as

cutting extremely large heavy panels or long

heavy boards, the saw should be bolted down.

If you attach any kind of table extensions over

24" wide to either end of the saw, make sure you

either bolt the saw to the bench or floor as

appropriate, or support the outer end of the

extension from the bench or floor, as

appropriate.

6. L_)CATION

The saw should be positioned so neither the

operator nor a casual observer isforced to stand

in line with the saw blade.

7. KICKBACKS

A "KICKBACK" occurs during a rip-type

operation when a part or all of the workpiece is

thrown back violently toward the operator.

Keep your face and body to one side of the

sawblade, out of line with a possible "Kickback."

Kickbacks -- and possible injury from them

can usually be avoided by:

A. Maintaining the rip fence parallel to the

sawblade.

B. Keeping the sawblade sharp. Replace or

sharpen antikickback pawls when points

become dull.

C. Keeping sawblade guard, spreader, and

antikickback, pawls in place and operating

properly. The spreader must be in alignment

with the sawblade and the pawls must stop a

kickback once it has started. Check their

action before ripping.

D. NOT ripping work that is twisted or warped or

does not have a straight edge to guide along

the rip fence.

E. NOT releasing work until you have pushed it

all the way past the sawblade.

F. Using a push stick for ripping widths of 2to 6

in., and an auxiliary fence and push block for

ripping widths narrower than 2 in. (See "Basic

Saw Operation Using The Rip Fence"

section.)

G. NOT confining the cut-off piece when

ripping or cross-cutting.

8. PROTECTION: EYES, HANDS, FACE, EARS,

BODY

A. If any part of your saw is missing,

malfunctioning, or has been damaged or

broken such as the motor switch,

electronic' controls, or other operating

control, a safety device or the power cord...

cease operating immediately until the

particular part is properly repaired or

replaced.

3

operation is dusty. Wear ear .plugs or muffs

during extended :peldods of operation

C. Small loose pieces of wood or other objects

that contact the rear of the revolving blade

can be thrown back at_"_he'0_rator at

excessive speed. This can usually be avoided

by keeping the guard and spreader in place

for all thru-sawing operations-(sawing

entirely thru the work) AND by removing all

loose pieces from the table w tb a_!ong Stick of

wood IMMEDIATELY' after they are cut off.

D. Use extra caution when the guard assembly is

removed for resawing_ da,doing, rabbeting, or

molding -- replace the guard as soon as that

operation is completed. '-'--

E. For rip or rip-type cutso the .following endof a

workpiece to which a push stick or push

board s applied mu-st, jbe ° squar_e

(perpendicular to the ferlce) in order that feted

pressure applied to ,the workp_ece.by"the

push stick or block does not cause 'the

workpiece to come away from. thefence, and

possibly cause a kickback.

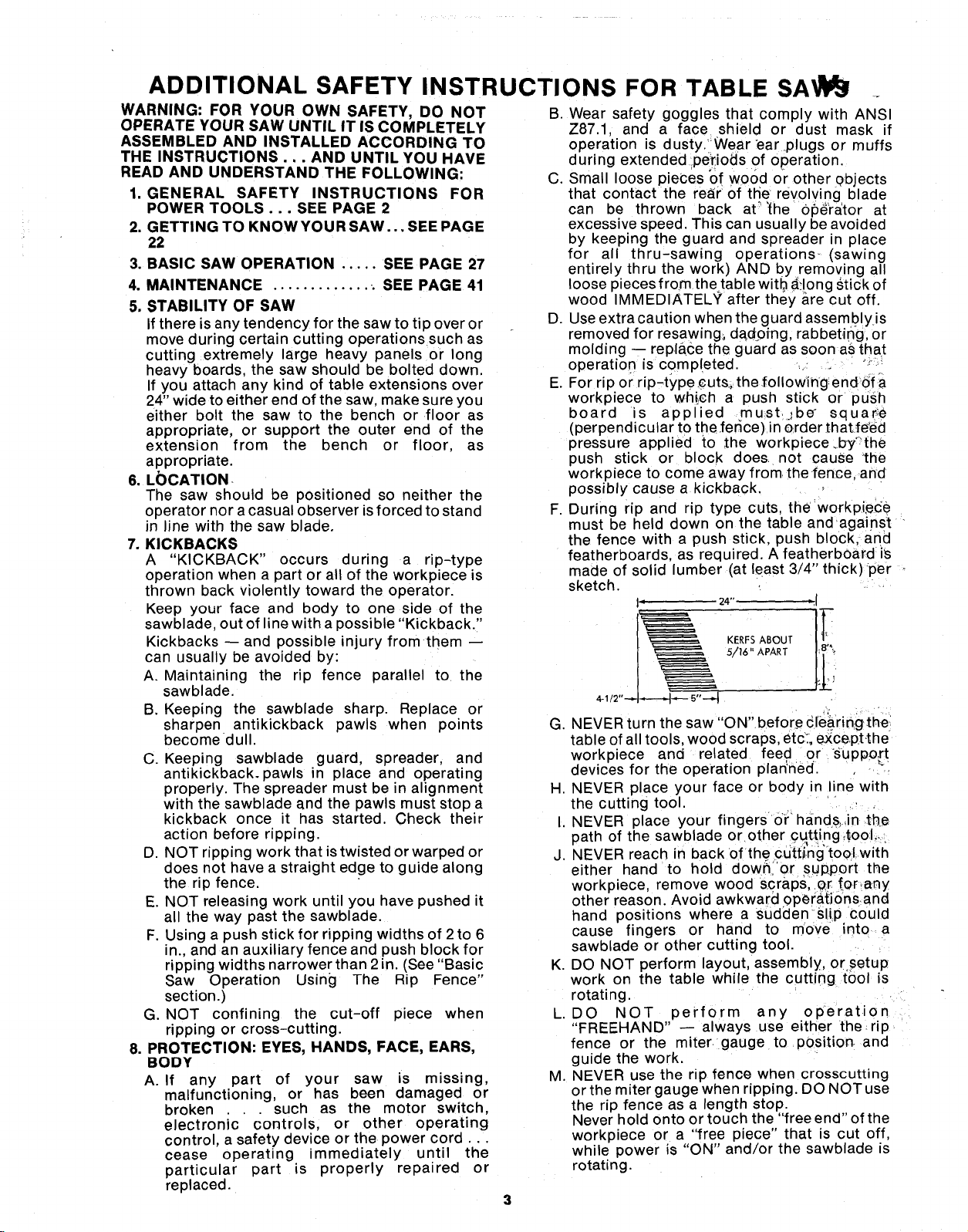

F. During rip and rip type cuts, the workpi.ece

must be held down on the table andagainst

the fence with a push stick, push block, and

featherboards, as required. A featherbOard is

made of solid lumber (at least 3/4" thick) per

sketch.

I" 24" ",1

5/_" APART

G. NEVER turn the saw "ON"before c[e_rin_gthe

table of all tools, wood scraps, etc_.,except,the

workpiece and related feed or Support

devices for the operation plan'*ned.

H. NEVER place your face or body in ine with

the cutting tool.

I. NEVER place your fingers or hand&,in .the

path of the sawblade or other Cqt.ting4oo:L.

J. NEVER reach in back of the cdtti.'ng"tool.with

either hand to hold dowr_i or S!Jp.portthe

workpiece, remove wood scraps,.er for,any

other reason. Avoid awkward 0perat.i0rnsand

hand positions where a Suddenslip could

cause fingers or hand to move into a

sawblade or other cutting tool.

K. DO NOT perform layout, assembly, or setup

work on the table while the cutting tool is

rotating.

L. DO NOT perform any operation

"FREEHAND" -- always use either the rip

fence or the miter gauge to pOsition and

guide the work.

M. NEVER use the rip fence when crosscutting

or the miter gauge when ripping. DO NOT use

the rip fence as a length stop.

Never hold onto or touch the "free end" of the

workpiece or a "free piece" that is cut off,

while power is "ON" and/or the sawblade _s

rotating.

N_$_ "OFF" the saw and disconnect the

_p6wer cord when removing the table insert,

changing the cutting tool, removing or

replacing the blade guard, or making

adjustments.

O. Provide adequate support to the rear and

sides of the saw table for wider or long

workpieces.

P. Plastic and composition (like hardboard)

materials may be cut on your saw. However,

s nce these are usually quite hard and

slippery, the antikickback pawls may not stop

a kickback.

Therefore, be especially attentive to

following proper set-up and cutting

procedures for ripping. Do not stand, or

permit anyone else to stand, in line with a

potential kickback.

Q. If you stall or jam the sawblade in the

workpiece turn saw "OFF" and remove the

workpiece from the sawblade. Check to see if

the sawblade is parallel to the miter gauge

grooves and if the spreader is in proper

alignment with the sawblade. If ripping atthe

time, check to see if the rip fence is parallel

with the sawblade. Readjust as indicated.

R. DO NOT remove smafi pieces of cut-off

material that may become trapped inside the

blade guard while the saw is running. This

could endanger your hands or cause a

kickback. Turn saw "OFF" and wait until

blade stops.

S. Use extra care when ripping wood that has a

twisted grain or is twisted or bowed -- it may

rock on the table and/or pinch the sawblade.

9. KNOW YOUR CUTTING TOOLS

A. Dull, gummy, or improperly sharpened or set

cutting tools can cause material to stick, jam,

stall the saw, or kickback at the operator.

Minimize potential injury by proper cutting

tool and machine maintenance

NEVER ATTEMPT TO FREE A STALLED

SAWBLADE WITHOUT FIRST TURNING

THE SAW OFF.

B Never use grinding wheels abrasive cut-off

wheels, friction wheels (metal slitting blades)

w_re wheels or buffing wheels.

10. USE ONLY ACCESSORIES DESIGNED FOR

THIS SAW

11. Crosscutting operations are worked more

conveniently and with greater safety if an

auxiliary wood facing is attached to the miter

gauge using the holes provided. However, the

facing must not interfere with the proper

functioning of the sawblaae guard.

12. Make sure the top of the arbor or cutting tool

rotates toward you whon _tanding in normal

operating position. Also make sure the cutting

tool, arbor collars and arbor nut are installed

properly. Keep the cutting tool as low as

possible for the operation being performed.

Keep all guards in place whenever possible.

13. Do not use any blade or other cutting tool

marked for an operating speed less than 3450

RPM. Never use a cutting tool larger in diameter

than the diameter for which the saw was

WARNING: DO NOT UNDER ANY CIRCUMSTANCES

ATTEMPT TO SERVICE, REPAIR, DISMANTLE, OR

DISASSEMBLE ANY OF THE ELECTRICAL OR

ELECTRONIC (COMPUTER ETC.) PARTS. REPAIRS ARE TO

BE PERFORMED BY SEARS SERVICE PERSONNEL ONLY.

designed. For greatest safety and efficiency

when ripping, use the maximum diameter blade

for which the saw is designed, since under these

conditions the spreader is nearest the blade.

14. Adjust table inserts flush with the table top.

NEVER operate the saw unless the proper insert

is installed.

15. NEVER feed material into the cutting tool from

the rear of the saw. An accident and serious

injury could result.

16. THINK SAFETY.

Safety is a combination of operator common

sense and alertness at all times when the saw is

being used.

17. NEVER use another person as a substitute for a

table extension, or as additional support for a

workpiece that is longer or wider than the basic

saw table, or to assist in feeding or supporting or

pulling the workpiece.

DO NOT pull the workpiece through the

sawblade - position your body at the nose (in-

feed) side of the guard: start and complete the

cut from that same side. This will require added

table support for long or wide workpieces that

extend beyond the length or width of the saw

table.

18. NOTE AND FOLLOW SAFETY INSTRUC-

TIONS THAT APPEAR ON THE FRONT OF

YOUR SAW.

('_ _ FOR YOUR OWN SAFETY: ...............

1.READANOUNDERSTANDOWNER'S_A_AL s.NEV_ REACHA_OU_OOROVERSAW_-AC_

BEF_e _TING _;_Ne. 7. NeVeR PERFORMANy_ERATION"FReEHANO" _ e_l_ is c_lEe

2. _AR SAFETYGC_ES PElf ANSI ZS_,. 8. USESAWB_OE _ARD F_ "ntnU-S_l_"

3. KESRHANDSOUTOFPATHOFSAWBLAD_9. SHUTO_FMAST_ SWI_CHANOALLOW

4. KNOWHOWTOAV_O"KICKSACKS". SAWBLADETOSTO_eeeOREAO_JSnNG

• use "PUSH STICK" WHEN REOUIRED O_ SERVICINg.

19. WARNING: DO NOT ALLOW FAMILIARITY

(GAINED FROM FREQUENT USE OF YOUR

SAW) TO BECOME COMMONPLACE.

ALWAYS REMEMBER THAT A CARELESS

FRACTION OF A SECOND IS SUFFICIENT TO

INFLICT SEVERE INJURY.

20. WARNING: THE 2-1/2" SAW PULLEYAND THE

2-1/2" MOTOR PULLEY FURNISHED, WILL

RUN THE BLADE AT APPROXIMATELY 3450

RPM WHEN USED WITH A 3450 RPM MOTOR.

NEVER SUBSTITUTE THESE PULLEYS TO

INCREASE THIS SPEED BECAUSE IT COULD

BE DANGEROUS.

NOTE: Do not overtighten arbor nut. Use the arbor

wrench to }ust "snug" it.

WEAR YOUR

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result

in severe eye damage. Always wear safety goggles

complying with ANSI Z87.1 (shown on Package)

before commencing power tool operation. Safety

Goggles are available at Sears retail or catalog.

stores.

4

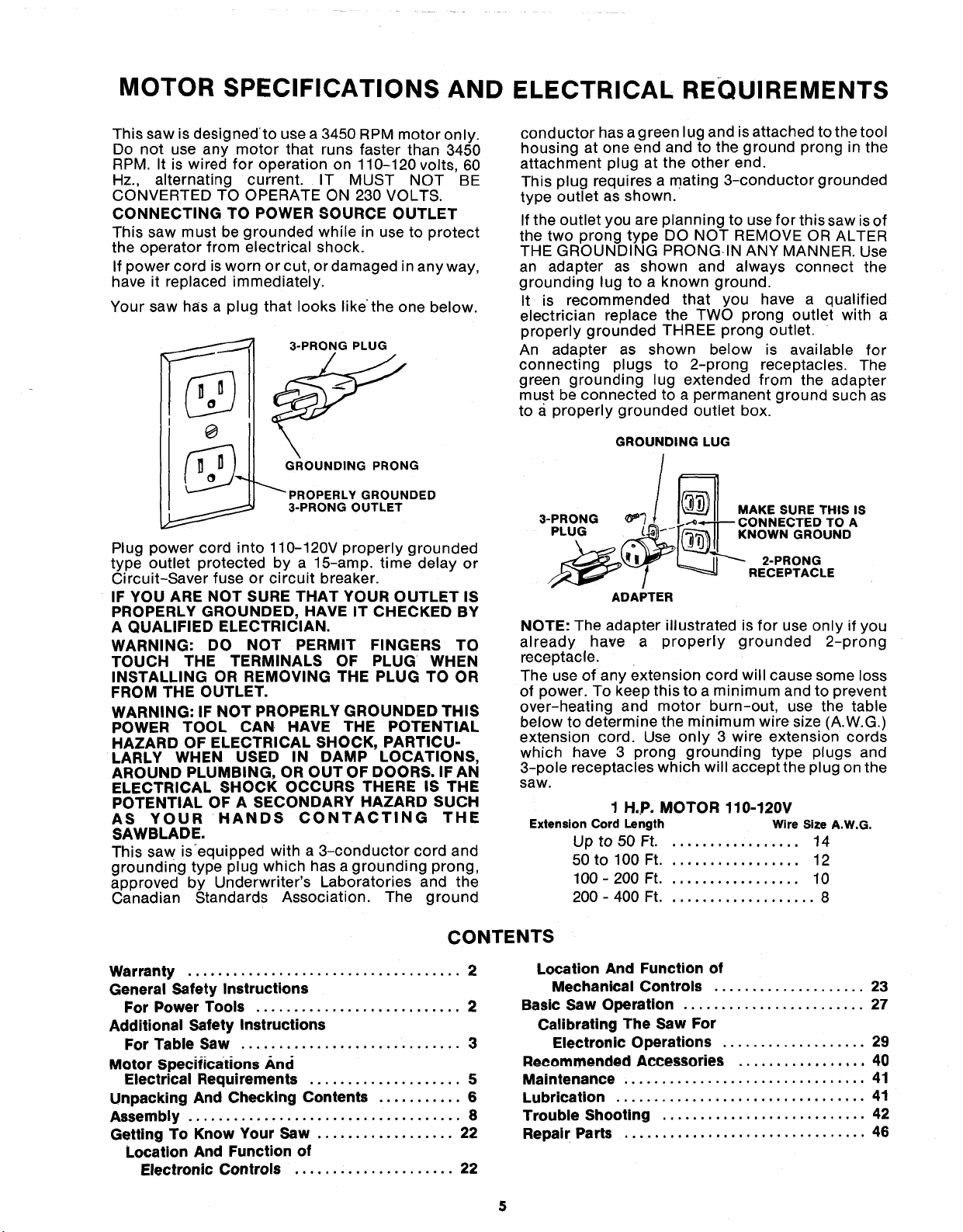

MOTOR SPECIFICATIONS AND ELECTRICAL REQUIREMENTS

This saw isdesigned'to use a 3450 RPM motor only.

Do not use any motor that runs faster than 3450

RPM. It is wired for operation on 110-120volts, 60

Hz., alternating current. IT MUST NOT BE

CONVERTED TO OPERATE ON 230 VOLTS.

CONNECTING TO POWER SOURCE OUTLET

This saw must be grounded while in use to protect

the operator from electrical shock.

If power cord is worn or cut, or damaged in anyway,

have it replaced immediately.

Your saw has a plug that looks likethe one below.

3-PRONG PLUG

....... GROUNDING PRONG

PROPERLY GROUNDED

3-PRONG OUTLET

Plug power cord into 110-120V properly grounded

type outlet protected by a 15-amp. time delay or

Circuit-Saver fuse or circuit breaker.

IF YOU ARE NOT SURE THAT YOUR OUTLET IS

PROPERLY GROUNDED, HAVE IT CHECKED BY

A QUALIFIED ELECTRICIAN.

WARNING: DO NOT PERMIT FINGERS TO

TOUCH THE TERMINALS OF PLUG WHEN

INSTALLING OR REMOVING THE PLUG TO OR

FROM THE OUTLET.

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN HAVE THE POTENTIAL

HAZARD OF ELECTRICAL SHOCK, PARTICU-

LARLY WHEN USED IN DAMP LOCATIONS,

AROUND PLUMBING, OR OUT OF DOORS. IF AN

ELECTRICAL SHOCK OCCURS THERE IS THE

POTENTIAL OF A SECONDARY HAZARD SUCH

AS YOUR HANDS CONTACTING THE

SAWBLADE.

This saw is_equipped with a 3-conductor cord and

grounding type plug which has a grounding prong,

approved by Underwriter's Laboratories and the

Canadian Standards Association. The ground

conductor has a green lug and is attached to the tool

housing at one end and to the ground prong in the

attachment plug at the other end.

This plug requires a mating 3-conductor grounded

type outlet as shown.

If the outlet you are planning to use for this saw is of

the two prong type DO NOT REMOVE OR ALTER

THE GROUNDING PRONG.IN ANY MANNER. Use

an adapter as shown and always connect the

grounding lug to a known ground.

It is recommended that you have a qualified

electrician replace the TWO prong outlet with a

properly grounded THREE prong outlet.

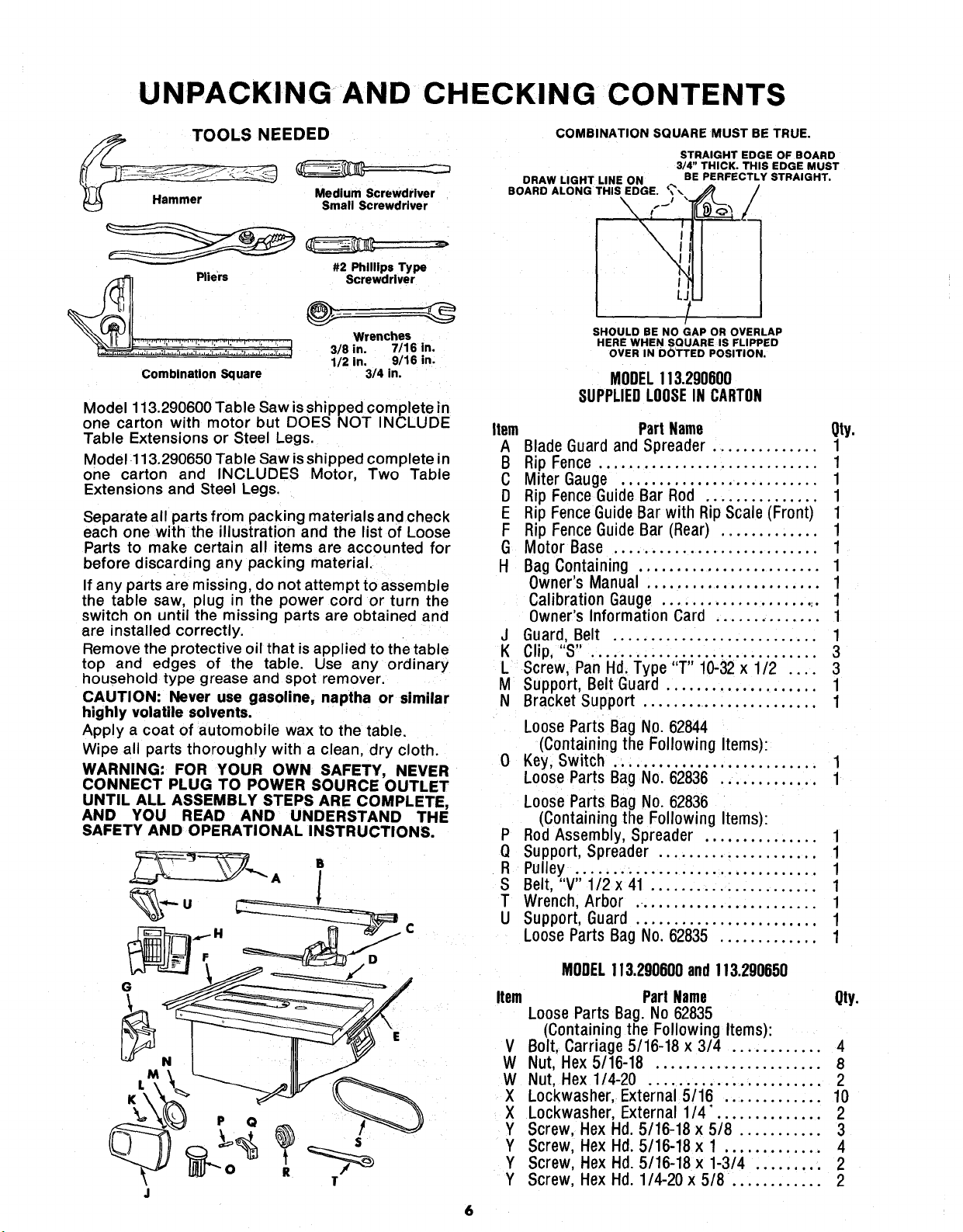

An adapter as shown below is available for

connecting plugs to 2-prong receptacles. The

green grounding lug extended from the adapter

must be connected to a permanent ground such as

to a properly grounded outlet box.

GROUNDING LUG

3-PRONG _'_ .3TED TO A

PLUG KNOWN GROUND

MAKE SURE THIS IS

\

2-PRONG

RECEPTACLE

ADAPTER

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong

receptacle.

The use of any extension cord will cause some loss

of power: To keep this to a minimum and to prevent

over-heating and motor burn-out, use the table

below to determine the minimum wire size (A.W.G.)

extension cord. Use only 3 wire extension cords

which have 3 prong grounding type plugs and

3-pole receptacles which will accept the plug on the

saw.

1 H.P. MOTOR 110-120V

Extension Cord Length Wire Size A.W.G.

Up to 50 Ft.................. 14

50 to 100 Ft.................. 12

100 - 200 Ft.................. 10

200 - 400 Ft.................... 8

CONTENTS

Warranty .................................... 2

General Safety Instructions

For Power Tools ........................... 2

Additional Safety Instructions

For Table Saw ............................. 3

Motor Specifications And

Electrical Requirements .................... 5

Unpacking And Checking Contents ........... 6

Assembly .................................... 8

Getting To Know Your Saw .................. 22

Location And Function of

Electronic Controls ..................... 22

Location And Function of

Mechanical Controls .................... 23

Basic Saw Operation ........................ 27

Calibrating The Saw For

Electronic Operations ................... 29

Recommended Accessories ................. 40

Maintenance ................................ 41

Lubrication ................................. 41

Trouble Shooting ........................... 42

Repair Parts ................................ 46

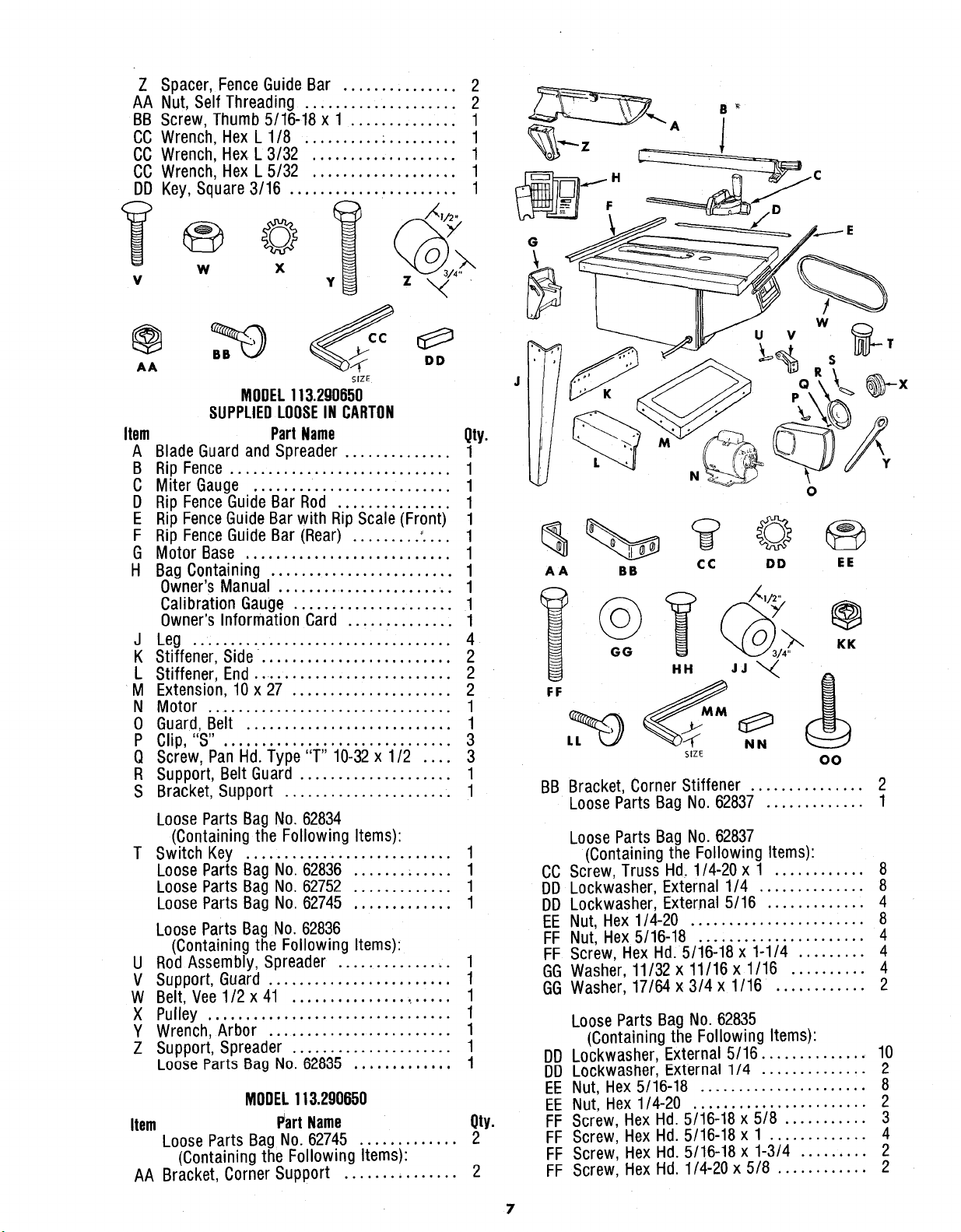

UNPACKING AND CHECKING CONTENTS

TOOLS NEEDED

.. Medium Screwdriver

(_ Hammer Small Screwdriver

#2 Phillips Type

COMBINATION SQUARE MUST BE TRUE.

STRAIGHT EDGE OF BOARD

CRAW LIGHT LINE ON BE PERFECTLY STRAIGHT.

BOARO ALONG THIS EDGE. _'\

3/4" THICK. THIS EDGE MUST

Pliers _'- Screwdriver

Wrenches

1/2 in, 9/16 in.

Combination Square 3/4 in.

@

Model 113.290600 Table Saw is shipped complete in

one carton with motor but DOES NOT INCLUDE

Table Extensions or Steel Legs.

Model 113.290650 Table Saw is shipped complete in

one carton and INCLUDES Motor, Two Table

Extensions and Steel Legs.

Separate all parts from packing materials and check

each one with the illustration and the list of Loose

Parts to make certain all items are accounted for

before discarding any packing material.

If any parts are missing, do not attempt to assemble

the table saw, plug in the power cord or turn the

switch on until the missing parts are obtained and

are installed correctly.

Remove the protective oil that is applied to the table

top and edges of the table. Use any ordinary

household type grease and spot remover.

CAUTION: Never use gasoline, naptha or similar

highly volatile solvents.

Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean, dry cloth.

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET

UNTIL ALL ASSEMBLY STEPS ARE COMPLETE,

AND YOU READ AND UNDERSTAND THE

SAFETY AND OPERATIONAL INSTRUCTIONS.

SHOULD BE NO GAP OR OVERLAP

HERE WHEN SQUARE IS FLIPPED

OVER IN DOTTED POSITION.

MODEL113.290600

SUPPLIEDLOOSEIN CARTON

Item Part Name Qty.

A Blade Guard and Spreader .............. 1

B Rip Fence ............................. 1

C Miter Gauge .......................... 1

D Rip Fence Guide Bar Rod ............... 1

E Rip Fence GuideBar with Rip Scale (Front) 1

F Rip Fence Guide Bar (Rear) ............. 1

G Motor Base ........................... 1

H Bag Containing ........................ 1

Owner's Manual ....................... 1

Calibration Gauge ...................... 1

Owner's Information Card .............. 1

J Guard, Belt ........................... 1

K Clip, "S" . ............................. 3

L Screw, Pan Hd. Type "T" 10-32 x 1/2 .... 3

M Support, Belt Guard .................... 1

N Bracket Support ........................ 1

Loose Parts Bag No. 62844

(Containing the Following Items):

0 Key, Switch ........................... 1

Loose Parts Bag No. 62836 ............. 1

Loose Parts Bag No. 62836

(Containing the Following Items):

P Rod Assembly, Spreader ............... 1

Q Support, Spreader ..................... 1

R Pulley ................................ 1

S Belt, "V" 1/2 x 41 ...................... 1

T Wrench, Arbor ........................ 1

U Support, Guard ........................ 1

Loose Parts Bag No. 62835 ............. 1

P Q

MODEL113.290600and !13.290650

Item PartName Qty.

LooseParts Bag.No 62835

(Containingthe Following Items):

V Bolt,Carriage5/16-18 x 3/4 ............ 4

W Nut, Hex 5/16-18 ...................... 8

W Nut, Hex1/4-20 ....................... 2

X Lockwasher,External5/16 ............. 10

X Lockwasher,External1/4. ............. 2

Y Screw, HexHd 5/16-18 x 5/8 ........... 3

Y Screw, HexHd. 5/16-18 x 1 ............. 4

Y Screw, HexHd. 5/16-18 x 1-3/4 ......... 2

T

Y Screw, HexHd. 1/4-20 x 5/8 ............ 2

Z Spacer, Fence Guide Bar ............... 2

AA Nut, Self Threading .................... 2

BB Screw, Thumb 5/16-18 x 1 .............. 1

CC Wrench, Hex L 1/8 .......... . ......... 1

CC Wrench, Hex L 3/32 ................... 1

CC Wrench, Hex L 5/32 ................... 1

DD Key, Square 3/16 ............ . ......... 1

v

w

X

y_ /_i/2,_:.x/x

z ,,_ ,

@

AA

MODEL113.290650

SUPPLIEDLOOSEIN CARTON

Item Qty.

A Blade Guard and Spreader .............. 1

B Rip Fence ............................. 1

C Miter Gauge .......................... 1

D Rip Fence Guide Bar Rod ............... 1

E Rip Fence Guide Bar with Rip Scale (Front) 1

F Rip Fence Guide Bar (Rear) ......... :... 1

G Motor Base ........................... 1

H Bag Containing ........................ 1

Owner's Manual ........................ 1

Calibration Gauge ..................... 1

Owner's Information Card .............. 1

J Leg .................................. 4

K Stiffener, Side. ........................ 2

L Stiffener, End ........................... 2

M Extension, 10 x 27 ..................... 2

N Motor ................................ 1

0 Guard, Belt ........................... 1

P Clip,"S". ............................. 3

Q Screw, Pan Hd. Type "1" 10-32 x 1/2 .... 3

R Support, Belt Guard .................... 1

S Bracket, Support ...................... 1

Loose Parts Bag No. 62834

(Containing the Following Items):

T Switch Key ........................... 1

Loose Parts Bag No. 62836 ....... . ..... 1

Loose Parts Bag No. 62752 ............. 1

Loose Parts Bag No. 62745 ............. 1

Loose Parts Bag No. 62836

(Containing the Following Items):

U Rod Assembly, Spreader ............... 1

_/ Support, Guard ........................ 1

W Belt, Vee 1/2 x 41 ..................... 1

X Pulley ................................ 1

Y Wrench, Arbor ........................ 1

Z Support, Spreader ..................... 1

Loo_e Parts Bag No. 62835 ............. 1

Item Part Name Qty.

Loose Parts Bag No. 62745 ............. 2

(Containing the Following Items):

AA Bracket, Corner Support ............... 2

Part Name

MODEL113.290650

SIZE

DD

G

AA BB CC DD EE

BB Bracket, Corner Stiffener ............... 2

Loose Parts Bag No. 62837 ............. 1

Loose Parts Bag No. 62837

(Containing the Following Items):

CC Screw, Truss Hd, 1/4-20 x 1 ............ 8

DD Lockwasher, External 1/4 .............. 8

DD Lockwasher, External 5/16 ............. 4

EE Nut, Hex 1/4-20 ....................... 8

FF Nut, Hex 5/16-18 ...................... 4

FF Screw, Hex Hd: 5/16-18 x 1-1/4 ......... 4

GG Washer, 11/32 x 11/16 x 1/16 .......... 4

GG Washer, 17/64 x 3/4 x 1/16 ............ 2

Loose Parts Bag No. 62835

(Containing the Following Items):

DD Lockwasher, External 5/16 ............... 10

DD LOckwasher, External 1/4 .............. 2

EE Nut, Hex 5/16-18 ...................... 8

EE Nut, Hex 1/4-20 ....................... 2

FF Screw, Hex Hd. 5/16-18 x 5/8 ........... 3

FF Screw, Hex Hd. 5/16-18 x 1 ............. 4

FF Screw, Hex Hd. 5/16-18 x 1-3/4 ......... 2

FF Screw, Hex Hd. 1/4-20 x 5/8 ............ 2

7

HH B01t, Carriage 5/16-18 x 3/4 ............ 4

JJ Spacer, Fence Guide Bar ............... 2

KK Nut, Self Threading .................... 2

LL Screw, Thumb 5/16-18 x 1 .............. 1

MM Wrench, Hex "L" 1/8 ................... 1

MM Wrench, Hex "L" 3/32 .................. 1

MM Wrench, Hex "L" 5/32 .................. 1

NN Key, Square 3/16 ...................... 1

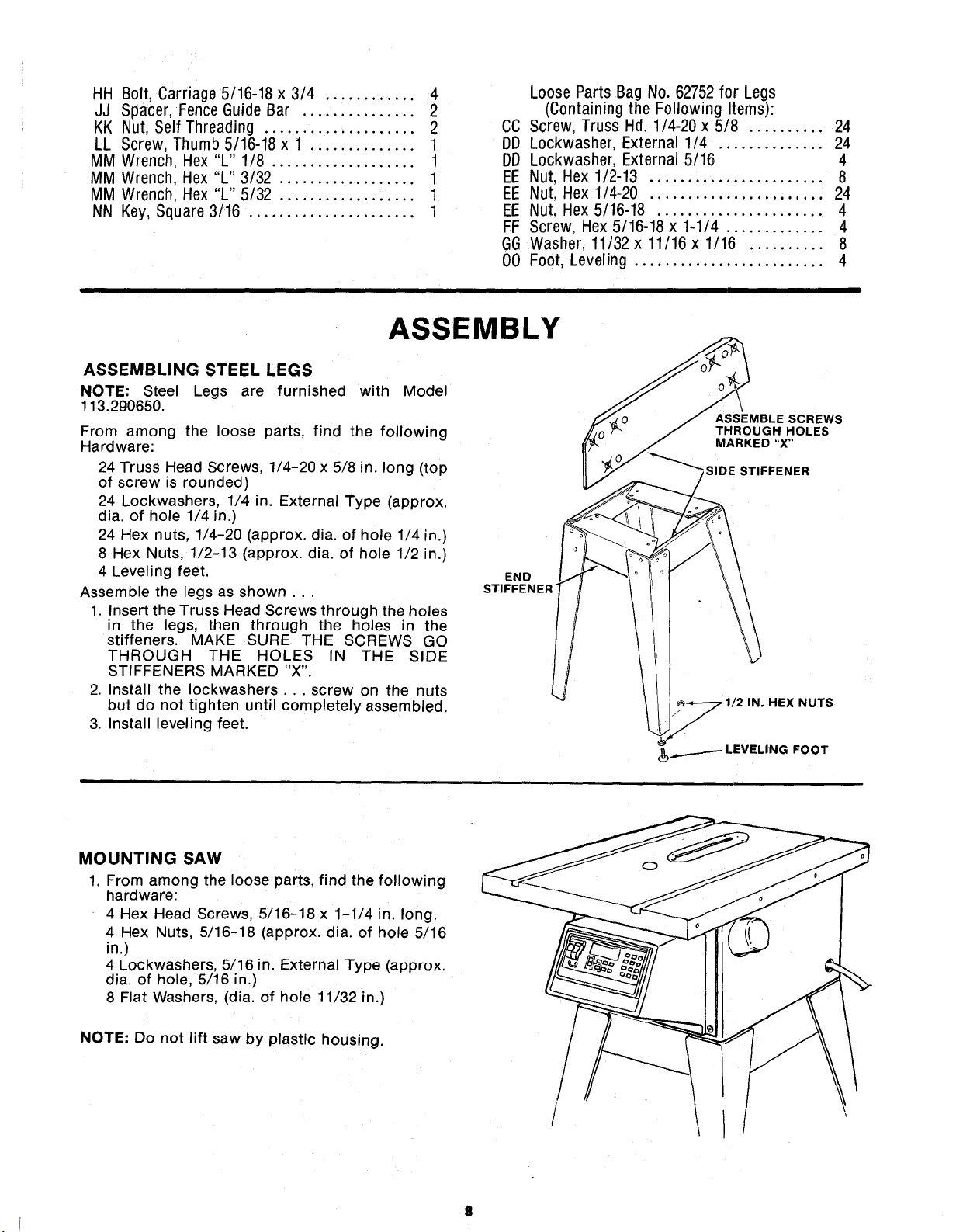

ASSEMBLY

ASSEMBLING STEEL LEGS

NOTE: Steel Legs are furnished with Model

113.290650.

From among the loose parts, find the following

Hardware:

24 Truss Head Screws, 1/4-20 x 5/8 in. long (top

of screw is rounded)

24 Lockwashers, 1/4 in. External Type (approx.

dia. of hole 1/4 in.)

24 Hex nuts, 1/4-20 (approx. dia. of hole 1/4 in.)

8 Hex Nuts, 1/2-13 (approx. dia. of hole 1/2 in.)

4 Leveling feet.

Assemble the legs as shown...

1. Insert the Truss Head Screws through the holes

in the legs, then through the holes in the

stiffeners. MAKE SURE THE SCREWS GO

THROUGH THE HOLES rN THE SIDE

STIFFENERS MARKED "X".

2. Install the Iockwashers... screw on the nuts

but do not tighten until completely assembled.

3. Install leveling feet.

Loose Parts Bag No. 62752 for Legs

(Containing the Following Items):

CC Screw, Truss Hd. 1/4-20 x5/8 .......... 24

DD Lockwasher, External 1/4 .............. 24

DD Lockwasher, External 5/16 4

EE Nut, Hex 1/2-13 ....................... 8

EE Nut, Hex 1/4-20 ....................... 24

EE Nut, Hex 5/16-18 ...................... 4

FF Screw, Hex 5/16-18 x 1-1/4 ............. 4

GG Washer, 11/32 x 11/16 x 1/16 .......... 8

00 Foot, Leveling ......................... 4

ASSEMBLE SCREWS

THROUGH HOLES

MARKED "X"

_SIDE STIFFENER

END

STIFFENER'

/

. 1/2 IN. HEX NUTS

MOUNTING SAW

1. From among the loose parts, find the following

hardware:

4 Hex Head Screws, 5/16-18 x 1-1/4 in, long.

4 Hex Nuts 5/16-18 (approx. dia. of hole 5/16

in.)

4 Lockwashers, 5/16 in. External Type (approx.

dia. of hole, 5/16 in.)

8 Flat Washers, (dia. of hole 11/32 in.)

NOTE: Do not lift saw by plastic housing.

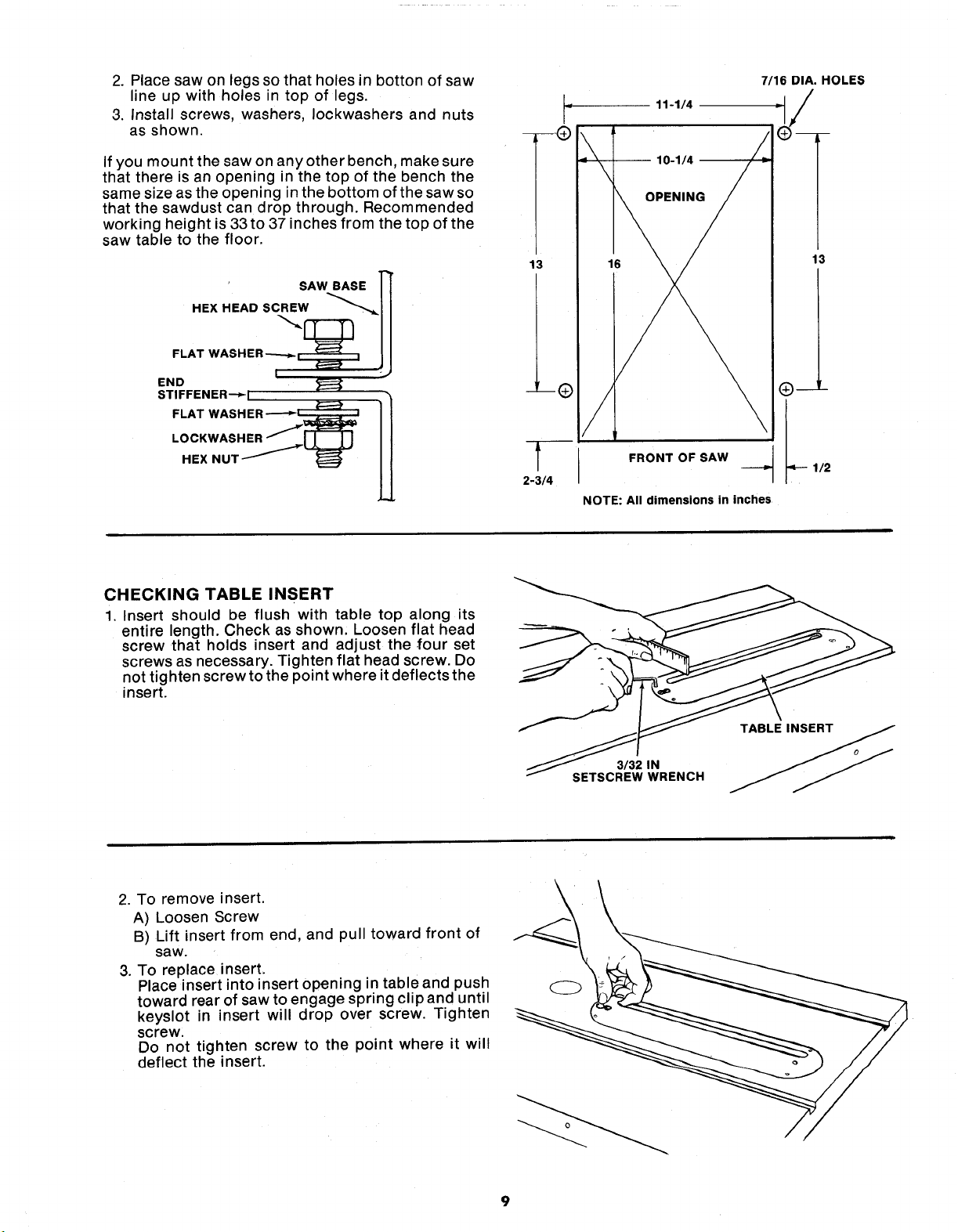

2.Placesawonlegssothatholesin bottonofsaw

lineupwithholesintop of legs.

3.Installscrews,washers,Iockwashersandnuts

asshown.

Ifyoumountthesawonanyotherbench,makesure

thatthereisanopeninginthetopof thebenchthe

samesizeastheopeninginthebottomofthesawso

thatthesawdustcandropthrough.Recommended

workingheightis33to37inchesfromthetopofthe

sawtableto thefloor.

' SAW BASE ]'_

HEXHEAOSCREW i

FLATWASHER7 , ,

END

FLAT WASH ER -'-'-__

LOCKWASHER ....._w_

HEX

STIFFENER--_I i

-- ---_)

13

2-3/4

r

11-1/4

10-1/4 --

16

FRONT OF SAW

NOTE: All dimensions in inches

7/16 DIA. HOLES

13

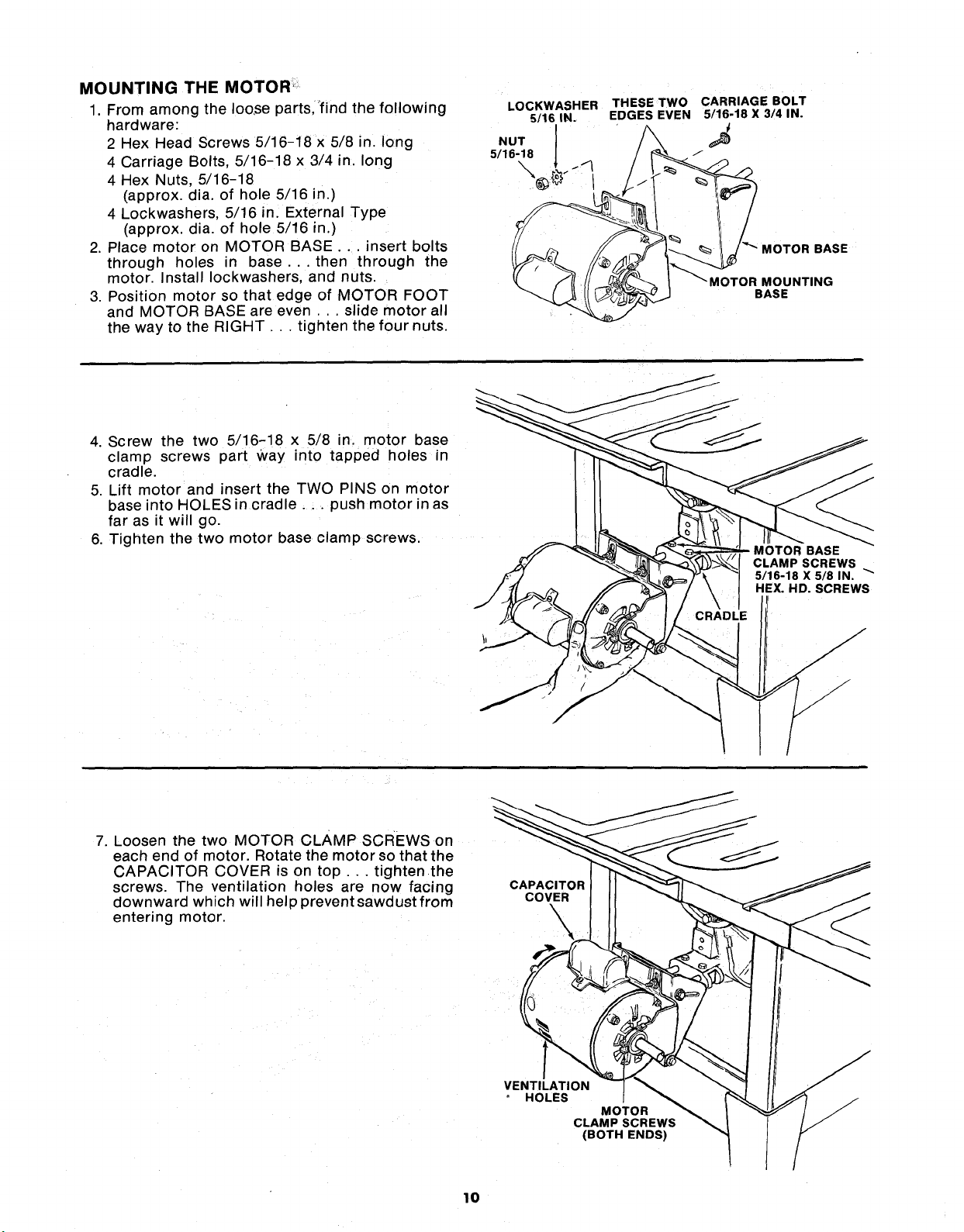

CHECKING TABLE INSERT

1. Insert should be flush with table top along its

entire length. Check as shown, Loosen flat head

screw that holds insert and adjust the four set

screws as necessary. Tighten flat head screw. Do

not tighten screw to the point where it deflects the

insert.

2. To remove insert.

A) Loosen Screw

B) Lift insert from end, and pull toward front of

saw.

3. To replace insert,

Place insert into insert opening in table and push

toward rear of saw to engage spring clipand until

keyslot in insert will drop over screw. Tighten

screw.

Do not tighten screw to the point where it will

deflect the insert.

i SETSCREW WRENCH

3/32 IN

9

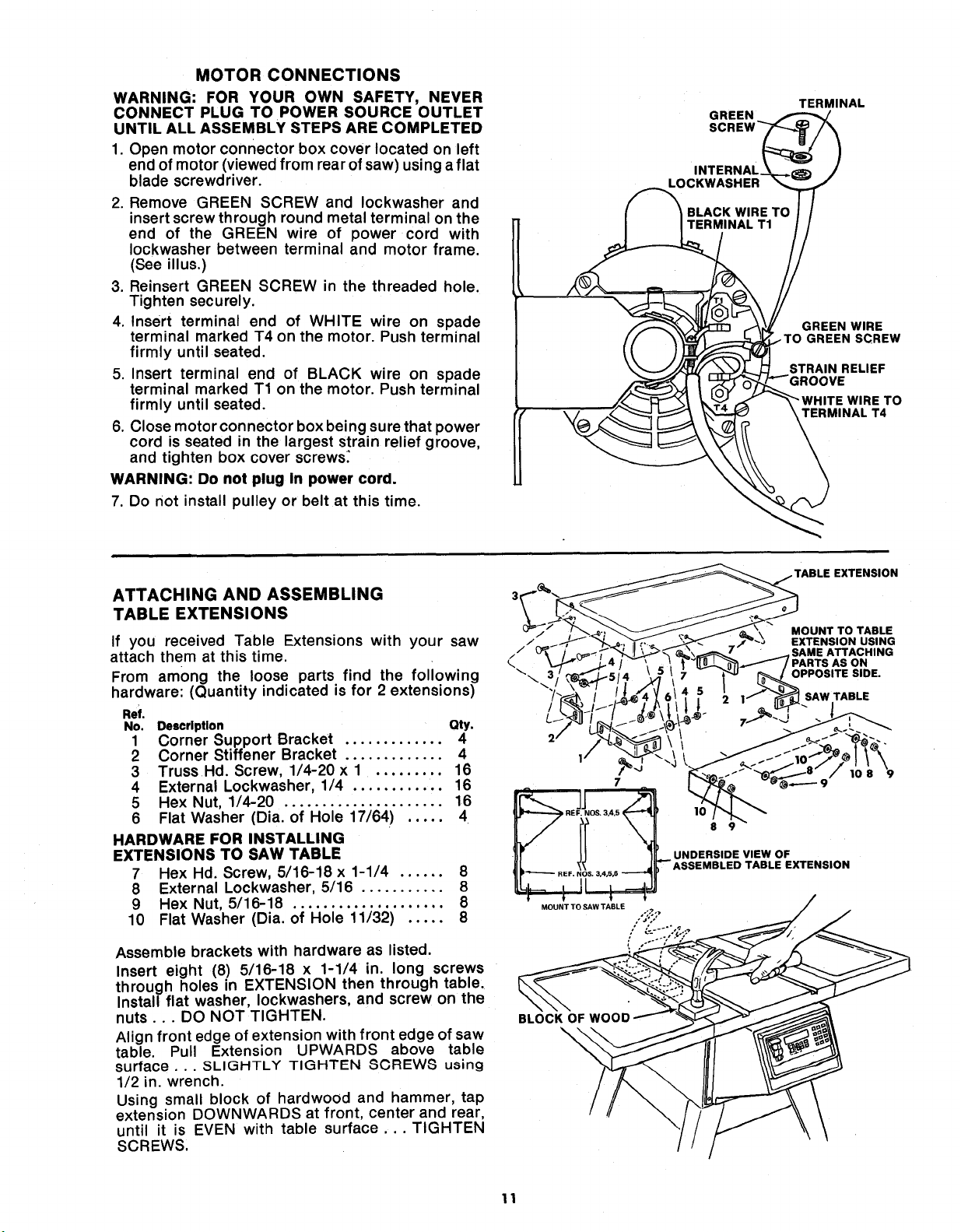

MOUNTING THE MOTOR:

1. From among the Ioo,se parts,"find the following

hardware:

2 Hex Head Screws 5/16-18 x 5/8 in. long

4 Carriage Bolts, 5/16-18 x 3/4 in. long

4 Hex Nuts, 5/16-18

(approx. dia. of hole 5/16 in.)

4 Lockwashers, 5/16 in_ External Type

(approx. dia. of hole 5/16 in.)

2. Place motor on MOTOR BASE .... insert bolts

through holes in base.., then through the

motor. Install Iockwashers, and nuts.

3. Position motor so that edge of MOTOR FOOT

and MOTOR BASE are even ... slide motor all

the way to the RIGHT... tighten the four nuts.

4. Screw the two 5/16-18 x 5/8 in. motor base

clamp screws part Way into tapped holes in

cradle.

5. Lift motor and insert the TWO PINS on motor

base into HOLES in cradle.., push motor in as

far as it will go.

6. Tighten the two motor base clamp screws.

LOCKWASHER THESE TWO CARRIAGE BOLT

6/16 IN. EDGES EVEN 5/16-18 X 3/4 IN.

5/16-18

__ _ MOTOR BASE

MOT% sOUNT'NG

CLAMP SCREWS

5/16-18 X 5/8 IN. "_"

HEX. HD. SCREWS

7. Loosen the two MOTOR CLAMP SCREWS on

each end of motor. Rotate the motor so that the

CAPACITOR COVER is on top.., tightenthe

screws. The ventilation holes are now facing

downward which will help prevent sawdust from

entering motor.

10

CAPACITOR

COVER

\

VENTILATION

HOLES

MOTOR

CLAMP SCREWS

(BOTH ENDS)

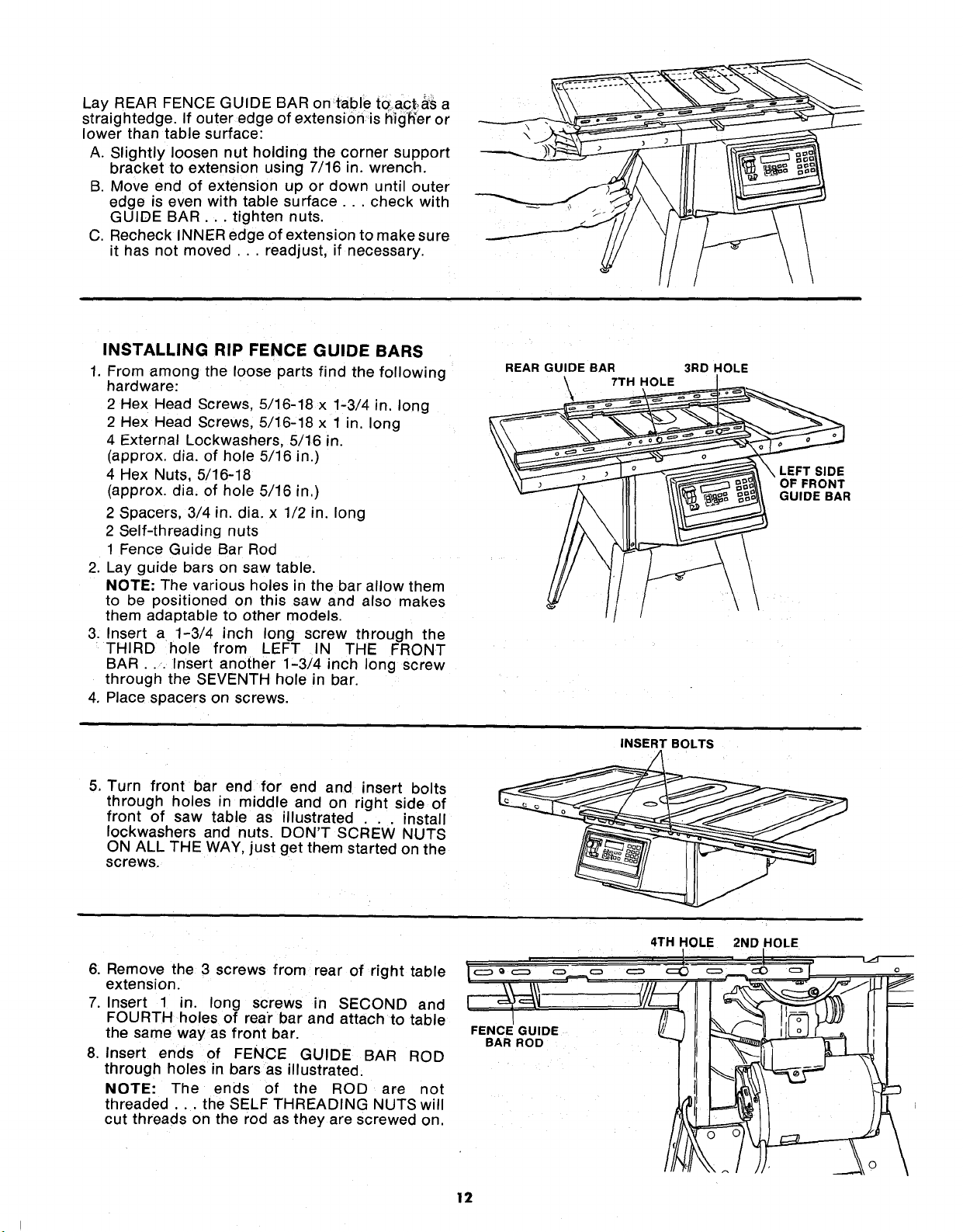

MOTOR CONNECTIONS

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET

UNTIL ALL ASSEMBLY STEPS ARE COMPLETED

1. Open motor connector box cover located on left

end of motor (viewed from rear of saw) using a flat

blade screwdriver.

2. Remove GREEN SCREW and Iockwasher and

insert screw through round metal terminal on the

end of the GREEN wire of power cord with

Iockwasher between terminal and motor frame.

(See illus.)

3. Reinsert GREEN SCREW in the threaded hole.

Tighten securely.

4. Insert terminal end of WHITE wire on spade

terminal marked T4 on the motor. Push terminal

firmly until seated.

5. Insert terminal end of BLACK wire on spade

terminal marked T1 on the motor. Push terminal

firmly until seated.

6. Close motor connector box being sure that power

cord is seated in the largest strain relief groove,

and tighten box cover screws:

WARNING: Do not plug In power cord.

7. Do not install pulley or belt at this time.

L¢

GREEN

INTERNAL

TERMINAL

GREEN WIRE

.TO GREEN SCREW

STRAIN RELIEF

)VE

ITE WIRE TO

TERMINAL T4

ATTACHING AND ASSEMBLING

TABLE EXTENSIONS

If you received Table Extensions with your saw

attach them at this time.

From among the loose parts find the following

hardware: (Quantity indicated is for 2 extensions)

Ref.

No. Description Qty.

1 Corner Support Bracket ............. 4

2 Corner Stiffener Bracket 4

3 Truss Hd. Screw, 1/4-20 x 1 ......... 16

4 External Lockwasher, 1/4 ............ 16

5 Hex Nut, 1/4-20 ..................... 16

6 Flat Washer (Dia. of Hole 17/64) ..... 4

HARDWARE FOR INSTALLING

EXTENSIONS TO SAW TABLE

7 Hex Hd. Screw, 5/16-18 x 1-1/4 ...... 8

8 External Lockwasher, 5/16 ........... 8

9 Hex Nut, 5/16-18 .................... 8

10 Flat Washer (Dia. of Hole 11/32) ..... 8

Assemble brackets with hardware as listed.

Insert eight (8) 5/16-18 x 1-1/4 in. long screws

through holes in EXTENSION then through table.

Install flat washer, Iockwashers, and screw on the

nuts... DO NOT TIGHTEN.

Align front edge of extension with front edge of saw

table. Pull Extension UPWARDS above table

surface... SLIGHTLY TIGHTEN 8CREW8 using

1/2 in. wrench.

Using small block of hardwood and hammer, tap

extension DOWNWARDS at front, center and rear,

until it is EVEN with table surface... TIGHTEN

SCREWS,

BLOCK OF WOO n

\

11

Lay REAR FENCE GUIDE BAR on table to.act.,_S a

straightedge. If outer edge of extension is hig'h'er or

lower than table surface:

A. Slightly loosen nut holding the corner support

bracket to extension using 7/16 in. wrench.

B. Move end of extension up or down until outer

eoge is even with table surface.., check with

GUIDE BAR... tighten nuts.

C. Recheck INNER edge of extension to make sure

it has not moved ... readjust, if necessary.

INSTALLING RIP FENCE GUIDE BARS

1. From among the loose parts find the following

hardware:

2 Hex Head Screws, 5/16-18 x 1-3/4 in. long

2 Hex Head Screws, 5/16-18 x 1 in. long

4 External Lockwashers, 5/16 m.

(approx. dia. of hole 5/16 in.)

4 Hex Nuts, 5/16-18

(approx. dia. of hole 5/16 in.)

2 Spacers, 3/4 in. dia. x 1/2 in. long

2 Self-threading nuts

1 Fence Guide Bar Rod

2. Lay guide bars on saw table.

NOTE: The various holes in the bar allow them

to be positioned on this saw and also makes

them adaptable to other models.

3. Insert a 1-3/4 inch long screw through the

THIRD hole from LEFT IN THE FRONT

BAR... Insert another 1-3/4 inch long screw

through the SEVENTH hole in bar.

4. Place spacers on screws.

REAR GUIDE BAR

3RD HOLE

7TH HOLE

\ LEFT SIDE

OF FRONT

GUIDE BAR

\

\

5, Turn front bar end for end and insert bolts

through holes in middle and on right side of

front of saw table as illustrated . . . install

Iockwashers and nuts. DON'T SCREW NUTS

ON ALL THE WAY, just get them started on the

screws.

6. Remove the 3 screws from rear of right table

extension.

7. Insert 1 in. long screws in SECOND and

FOURTH holes of rear bar and attach to table

the same way as front bar.

8. Insert ends of FENCE GUIDE BAR ROD

through holes in bars as illustrated.

NOTE: The ends of the ROD are not

threaded.., the SELF THREADING NUTS will

cut threads on the rod as they are screwed on.

FENCE GUIDE

BAR ROD

INSERT BOLTS

4TH HOLE

2ND HOLE

12

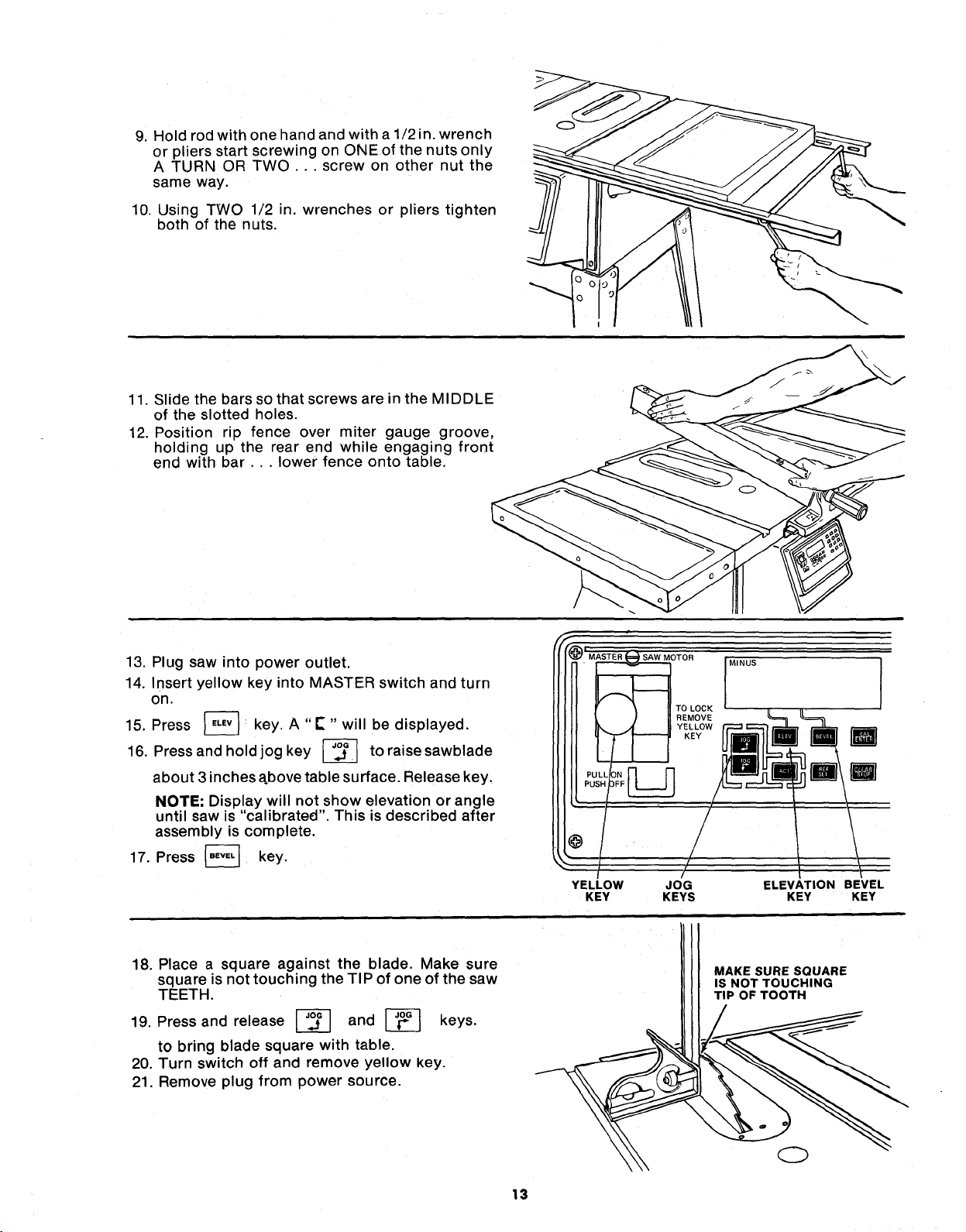

9. Hold rod with one hand and with a 1/2 in. wrench

or pliers start screwing on ONEof the nuts only

A TURN OR TWO ... screw on other nut the

same way.

10. Using TWO 1/2 in. wrenches or pliers tighten

both of the nuts.

11. Slide the bars so that screws are in the MIDDLE

of the slotted holes.

12. Position rip fence over miter gauge groove,

holding up the rear end while engaging front

end with bar.,, lower fence onto table.

13. Plug saw into power outlet.

14. Insert yellow key into MASTER switch and turn

on.

15. Press _ key. A "E" " will be displayed.

16, Press and hold jog key L__ to

raise sawblade

about 3 inches above table surface. Release key,

NOTE; Display will not show elevation or angle

until saw is "calibrated". This is described after

assembly is complete.

17. Press _ key,

18. Place a square against the blade. Make sure

square is not touching the TIP of one of the saw

TEETH.

19. Press and release _ and _ keys.

to bring blade square with table.

20. Turn switch off and remove yellow key.

21. Remove plug from power source.

@

YELLOW

KEY

OTOR

REMOVE

YELLOW

TO LOCK

JOG

KEYS

MINUS

KEY

ELEVATION BEVEL

MAKE SURE SQUARE

IS NOT TOUCHING

TIP OF TOOTH

KEY KEY

13

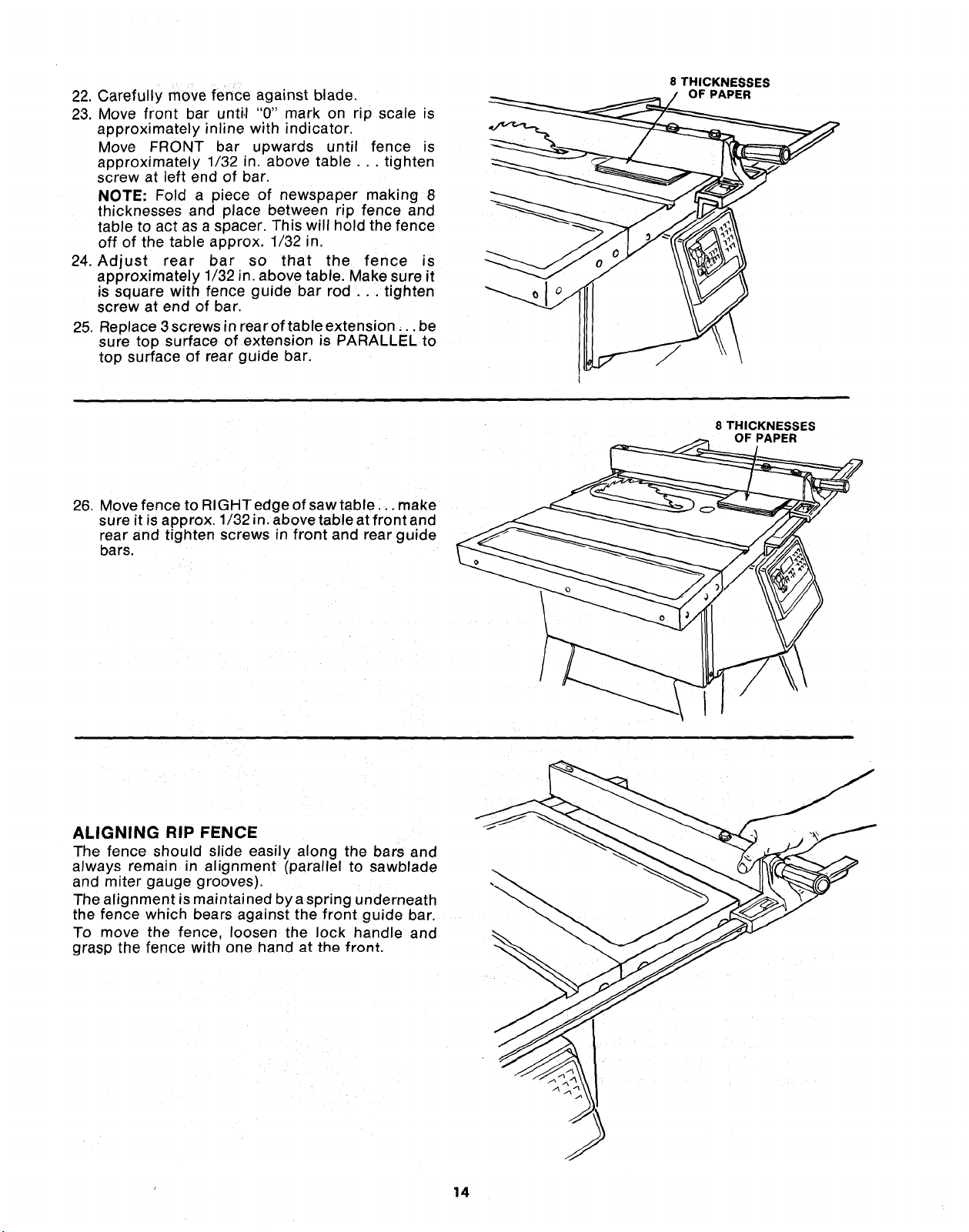

22. Carefully move fence against blade.

23. Move front bar unti,I "0" mark on rip scale is

approximately inline with indicator.

Move FRONT bar upwards until fence is

approximately 1/32 in. above table ... tighten

screw at left end of bar.

NOTE" Fold a piece of newspaper making 8

thicknesses and place between rip fence and

table to act as a spacer. This will hold the fence

off of the table approx. 1/32 n.

24. Adjust rear bar so that the fence is

approximately 1/32 in. above table. Make sure it

is square with fence guide bar rod ... tighten

screw at end of bar.

25. Replace 3 screws in rear of table extension.., be

sure top surface of extension is PARALLEL to

top surface of rear guide bar,

26. Move fence to RIGHTedgeofsawtable .., make

sure it is approx. 1/32 in. above table at front and

rear and tighten screws in front and rearguide

bars.

8 THICKNESSES

OF PAPER

\

\

8 THICKNESSES

ALIGNING RIP FENCE - -_

The fence should slide easily along the bars and

always remain in alignment (parallel to sawblade

and miter gauge grooves).

The alignment is maintained by a spring underneath

the fence which bears against the front guide bar.

To move the fence, loosen the lock handle and

grasp the fence with one hand _t th_ front.

14

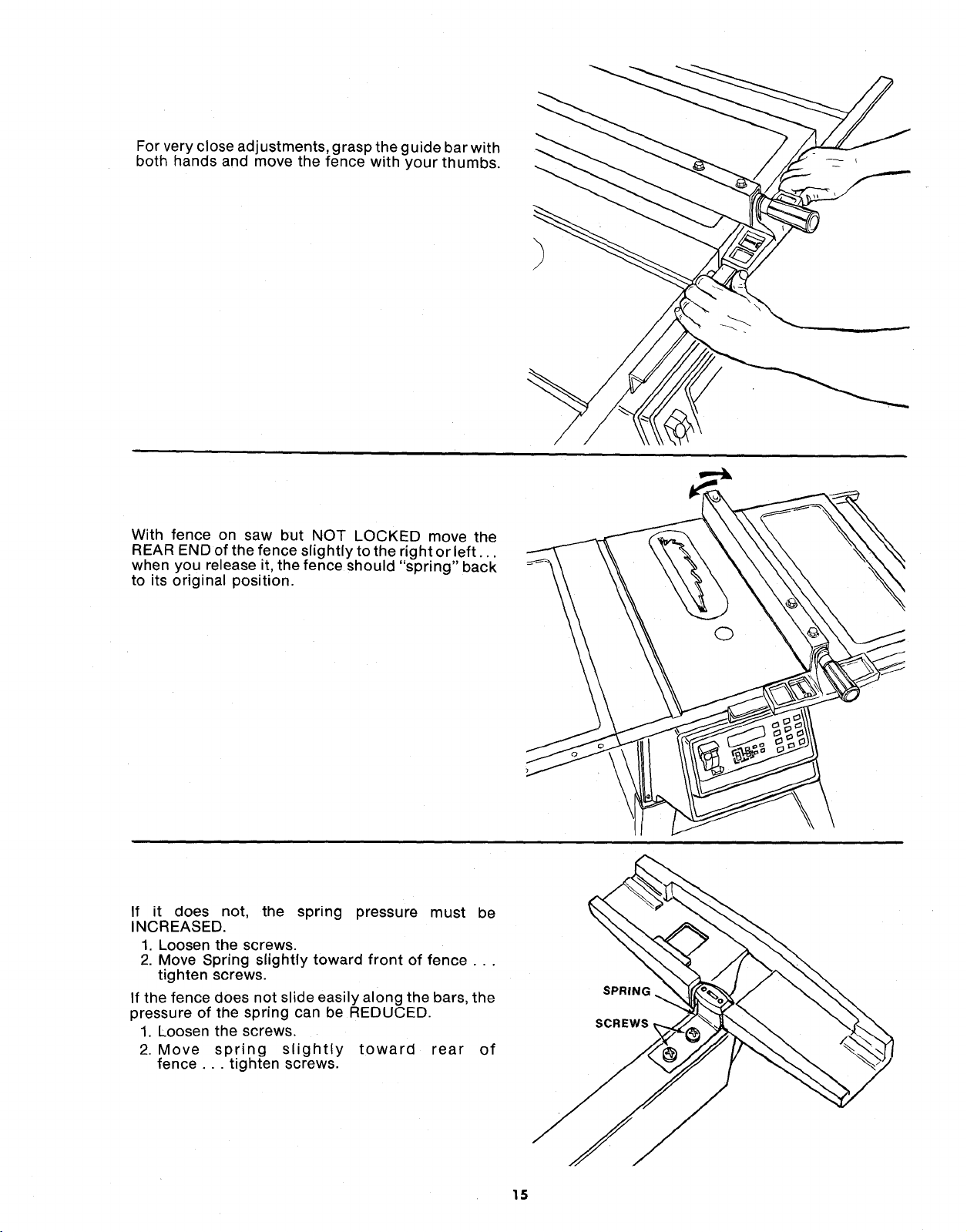

For very close adjustments, grasp the guide bar with

both hands and move the fence with your thumbs.

With fence on saw but NOT LOCKED move the

REAR END of the fence slightly to the right or left...

when you release it, the fence should "spring" back

to its original position.

If it does not, the spring pressure must be

INCREASED.

1. Loosen the screws.

2. Move Spring slightly toward front of fence...

tighten screws.

If the fence does not slide easily along the bars, the

pressure of the spring can be REDUCED.

1. Loosen the screws.

2. Move spring slightly toward rear of

fence ... tighten screws.

SPRING

SCREWS,

15

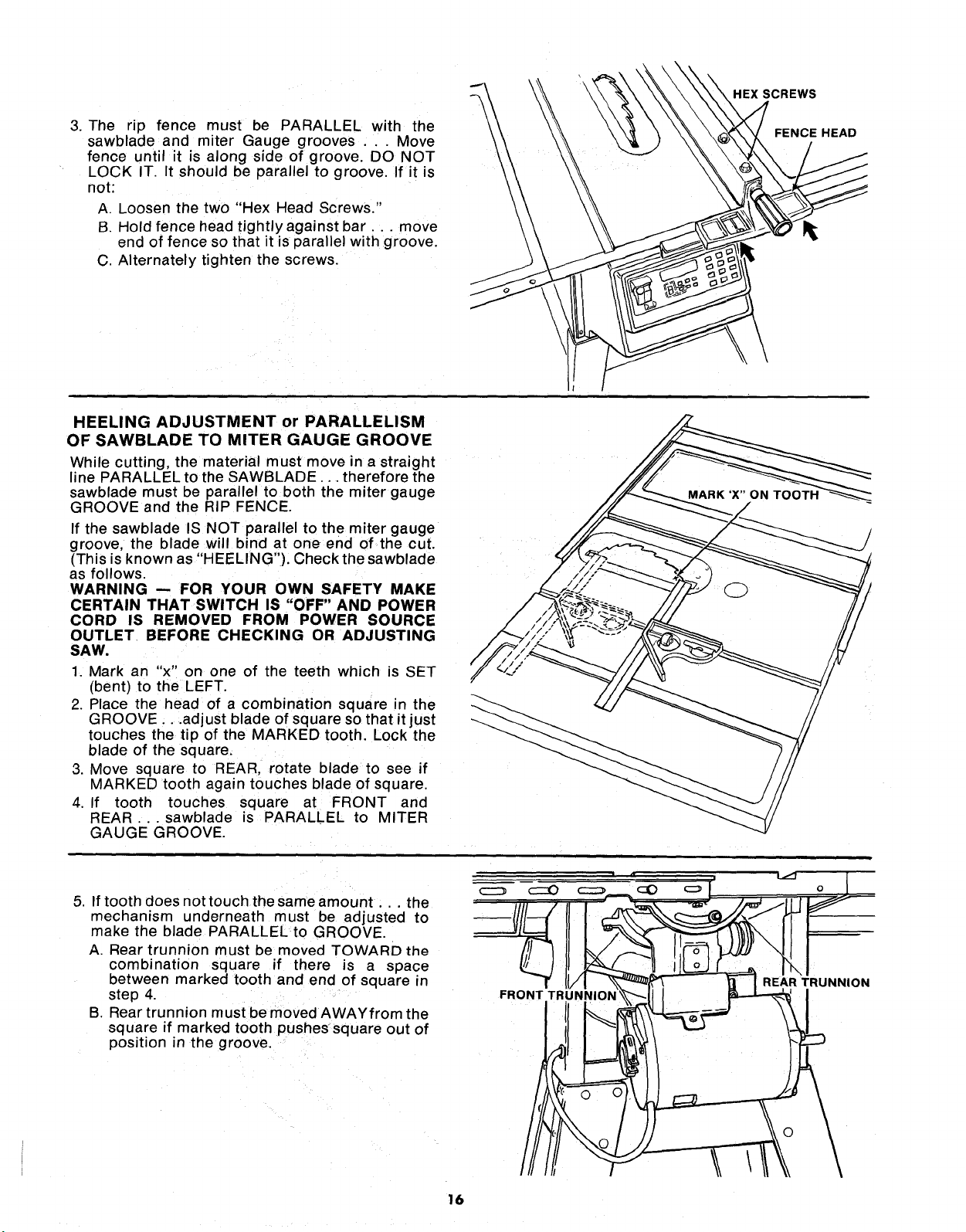

HEXSCREWS

3. The rip fence must be PARALLEL with the

sawblade and miter Gauge grooves ... Move

fence until it is along side of groove. DO NOT

LOCK IT. It should be parallel to groove. If it is

not:

A. Loosen the two "Hex Head Screws."

B. Hold fence head tightly against bar.., move

end of fence so that it is parallel with groove.

C. Alternately tighten the screws.

HEELING ADJUSTMENT or PARALLELISM

OF SAWBLADE TO MITER GAUGE GROOVE

While cutting, the material must move in a straight

line PARALLEL to the SAWBLADE... therefore the

sawblade must be parallel to both the miter gauge

GROOVE and the RIP FENCE.

If the sawblade IS NOT parallel to the miter gauge

groove, the blade will bind at one end of the cut.

(This is known as "HEELING"). Check the sawblade

as follows.

WARNING -- FOR YOUR OWN SAFETY MAKE

CERTAIN THAT SWITCH IS "OFF" AND POWER

CORD IS REMOVED FROM POWER SOURCE

OUTLET BEFORE CHECKING OR ADJUSTING

SAW.

1. Mark an "x" on one of the teeth which is SET

(bent) to the LEFT.

2. Place the head of a combination square in the

GROOVE...adjust blade of square so that it just

touches the tip of the MARKED tooth. Lock the

blade of the square.

3. Move square to REAR, rotate blade to see if

MARKED tooth again touches blade of square.

4. If tooth touches square at FRONT and

REAR ..sawblade is PARALLEL to MITER

GAUGE GROOVE.

FENCE HEAD

5. If tooth does nottouch the same amount.., the

mechanism underneath must be adjusted to

make the blade PARALLEL to GROOVE.

A. Rear trunnion must be moved TOWARD the

combination square if there is a space

between marked tooth and end of square in

step 4.

B. Rear trunnion must be moved AWAYfrom the

square if marked tooth pushessquare out of

position in the groove.

o

REAR TRUNNION

FR(

16

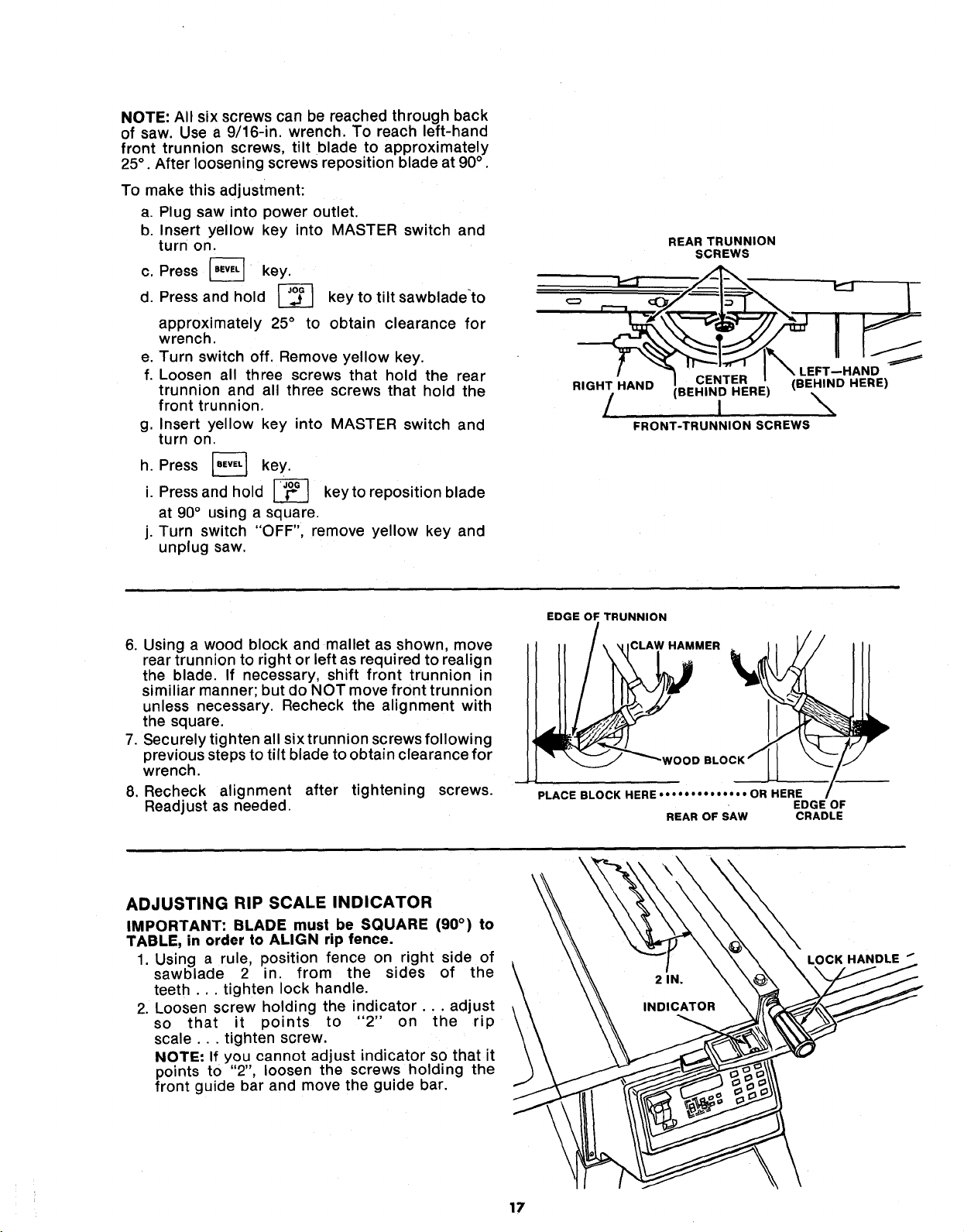

NOTE: All six screws can be reached through back

of saw. Use a 9/16-in. wrench. To reach left-hand

front trunnion screws, tilt blade to approximately

25° . After loosening screws reposition blade at 90° .

To make this adjustment:

a. Plug saw into power outlet.

b. Insert yellow key into MASTER switch and

turn on.

c. Press [-_ key.

d. Press and hold _-_ key to tilt sawbladeto

approximately 25° to obtain clearance for

wrench.

e. Turn switch off. Remove yellow key.

f. Loosen all three screws that hold the rear

trunnion and all three screws that hold the

front trunnion.

g. Insert yellow key into MASTER switch and

turn on.

h. Press [-_ key.

i. Press and hold _ keyto reposition blade

at 90° using a square.

j. Turn switch "OFF", remove yellow key and

unplug saw.

REAR TRUNNION

SCREWS

RIGHT HAND CENTER (BEHIND HERE)

(BEHIND HERE)

! \

FRONT-TRUNNION SCREWS

.EFT--HAND

6. Using a wood block and mallet as shown, move

rear trunnion to right or left as required to realign

the blade. If necessary, shift front trunnion in

similiar manner; but do NOT move front trunnion

unless necessary. Recheck the alignment with

the square.

7. Securely tighten all six trunnion screws following

previous steps to tilt blade to obtain clearance for

wrench.

8. Recheck alignment after tightening screws.

Readjust as needed.

ADJUSTING RIP SCALE INDICATOR

IMPORTANT: BLADE must be SQUARE (90 ° ) to

TABLE, in order to ALIGN rip fence.

1. Using a rule, position fence on right side of

sawblade 2 in. from the sides of the

teeth ... tighten lock handle.

2. Loosen screw holding the indicator.., adjust

so that it points to "2" on the rip

scale.., tighten screw.

NOTE: If you cannot adjust indicator so that it

points to "2", loosen the screws holding the

front guide bar and move the guide bar.

EDGE OF TRUNNION

CLAW HAMMER

PLACE BLOCK HERE .... • • • • • • • •" • OR HERE

REAR OF SAW CRADLE

\

EDGE OF

LOCK HANDLE _

17

Loading...

Loading...