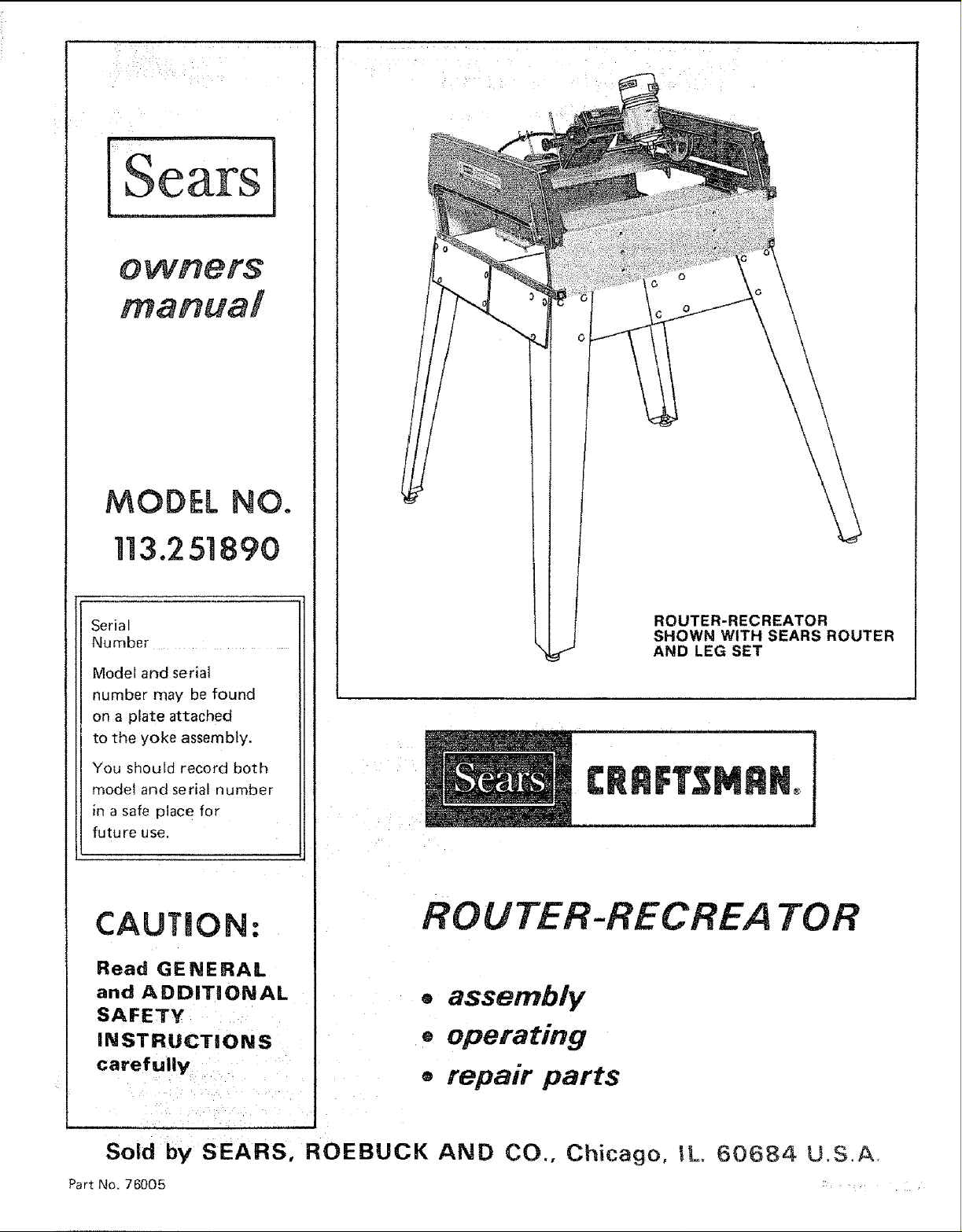

Craftsman 113251890 Owner’s Manual

Serial

Number ............

Model and serial

number may be found

on a pfate attached

to the yoke assembly.

You should record both

model and serial number

in a safe place for

future use.

ROUTER-RECREATOR

SHOWN WITH SEARS ROUTER

AND LEG SET

CAUTmON:

Read GENERAL

and ADDITIONAL

SAFETY ....

iNSTRUCTIONS

carefully

Sold_by SEARS, ROEBUCK

Part No. 76005

ROUTER-RECREA TOR

® assembly

® operating

o repair parts

AND CO., Chicago, 1L. 60684 U.S.A.

This warranty g Yes you specif c egal rights, and you may also have other rights which vary

from State to state; _

SEARSI ROEBUCK AND CO., DEPT. 69B/731A Sears ToWer. Chicago, IL 60684

Before =operating the Recreator read and understand your Router and Router Recreator

owner's manuals and affixed warnings.

The General Safety Instructions which follow apply to your Router and Router Recreator

co mbinaUon as a "power tool."

genera!l safety instructions for power tools

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual and 12.

labels affixed to the tool Learn its application

and limitations as well as the specific potential

hazards peculiar to this tool.

2. GROUND ALL TOOLS UNLESS

DOUBLE INSULATED 13.

If tool is equipped with an approved

3-conductor cord and a 3--prong grounding

type pug to fit the proper grounding type

receptacle. The green conductor in the cord is

the grounding wire. Never: connect the green 14.

wire to a live terminal

3, KEEP GUARDS iN PLACE

and in working order.

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to seethat keys and 16.

adjusting wrenches are removed f,rom tool

before tui'ning it on. : i :- :

5; KEEP WORK AREA CLEAN : 17.

Cluttef;ed areas and benches nv te accidents.

Ftoor must not be slippery dueto wax: or

sawdust. --18.

6, AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet location.

Keep work area well lit. Provide adequate

surrounding work space.

7. KEEP CHILDREN AWAY 19.

AH visitors should be kept a safe distance from

work area,

8. MAKE WORKSHOP KID-PROOF

-- with padlocks, master switches, or by

removing starter keys.

9. DON'T FORCE TOOL

It wit! do the job better and safer at the rate for

which it was designed.

10. USE RIGHT TOOL

Don't force tool or attachment to doa job it was

not designed for.

WEAR PROPER APPAREL

No loose clothing, g oves, neckties or jewelry to

get :caught in moving, parts. Rubber-soled damaged should

footwear is recOmn_ended fop best footing replaced.

USE SAFETY GOGGLES

Safety goggles must comply with ANSI

Z87.1-t968, Also use face or dust mask if

cutting operation is dusty. Everyday

eyeglasses only have =mpact resistant lenses,

they are not safety glasses.

SECURE WORK

Use clamps or a vise to hold work when

practical, it's safe r than using your hand, frees

both hands to operate toot.

DON'T OVERREACH

Keep proper footing and balance at all ttmes.

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for

lubrication and changing accessories.

DISCONNECT TOOLS

before servicing; when changing accessories

Such as blades, bits, cutters, _tc.

AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF position before

plugging in.

USERECOMMENDEDACCESSORIES

Consult the owner's manual for recommended

accessories. Follow the instructions that

accompany the accessories. The use of

tmprope_" accessories may cause hazards.

NEVER STAND ON TOOL

Serious injury could occur if the toot is tipped

or if the cutting tool is accidentally contacted.

Do not store materials above or near the tool

such that it is necessary to stand on the tool to

reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other

part that is damaged should be carefully

checked to ensure that it will operate properly

and perform its intended function,

Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting,

and any other conditions that may affect its

operation. A guard or other part that as

be properly repaired or

additional safety instructions for router-recreator

1. ALWAYS USE EYE PROTECTION.

The operation of any cutting tool can result in

foreign objects being thrown into the eyes,

which can result in severe eye damage. Always

wear safety goggles complying with ANSI

Z87.! before commencing cutting tool

operation. We recommend Wide Vision Safety

Mask for use over goggles.., available at Sears

retail or catalog stores.

2. DON'T FORCE TOOL

The Recreator was designed for smooth

operation, therefore, parts should never be

forced to operate.

Note and follow the instructions found on the

WARNING label which appears on the yoke

assembly.

FOR YOUR OWN SAFETY

1. READ AND UNDERSTAND OWNER'S MANUAL OF

ROUTER RECREATOR AND ROUTER BEFORE

OPERATING MACHINE.

2. WEAR SAFETY GOGGLES AND EAR PROTECTION.

3. DO NOT WEAR GLOVES, NECKTIE, OR LOOSE

CLOTHING. TIE BACK LONG HAIR.

4. EXCEPT FOR SPINDLE WORK NEVER USE A

SMALLER DIA. STYLUS TiP THAN THE CUTTER.

5. BE POSITIVE YOU DO NOT RUN CUTTER INTO

C-CLAMPS.

3. KEEP HANDS CLEAR OF BITS

AND WORKING AREA.

4_ KEEP ROUTER RECREATOR AND

ROUTER CLEAN

After every use, clean saw dust off the

Recreator and Router,

NOTE: Motors used onwood-working tools are

particularly susceptible to the accumulation of

sawdust and wood chips and shouid be blown

out or "vacuumed" frequently to prevent

interference with normal motor ventilation.

WARNING

WEAR YOUR

CONTENTS

General Safety Instructions ................ 2

Additional Safety Instructions ............. 3

Introduction .. : ........................ 4

Unpacking and Checking Contents .......... 4

Getting to Know Your Router-Recreator ..... 4

Assembly .............................. 5

Base Assembly ....................... 5

Yoke Assembly ....................... 7

Cable Assemblies ...................... 8

Instaliing the Router ................... 9

Installation of the Counterweight ......... 1!

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result

in severe eye damage. Always wear safety goggles

complying with ANSI Z87,1 (shown on Package)

before commencing power tool operation. Safety

Goggles are available at Sears retail or catalog

stores.

Installing the Pulley Guards ............. 12

Mounting Your Router-Recreator to a Stand. !2

Alignment ............................. !3

Operation ............................. 15

Genera! Operating Hints ................ 15

Three Dimensional Carving .............. 16

Sign Making .........................

Decorative Edging ..................... 22

Spindle Decorating ................... 23

Recommended Accessories ............... 25

Repair Parts ...........................

2O

26

ntroduchon

Thank :you for- the purchase of your, Router and more enjoyable operatiOn later,

Recreator we think 0neof the most exciting and "tart b " '- :' - " "; " "

- _ ,:_,_ ,_ __L__ ..,:_:n._i" ":"r_ _ y cnect_ ng anQ accoun[ ng mr all the loose

creaEivetuon_ w G,,)llle.alU g H yed =. --arts If an -art " ; " ";" "

: .... .... . : p . yp s are missing cnecK me car_on once

In order tofaclitate;handlingand.minimiZe any more, then contact your local Sears Retail or

damage that might occur during shipment your new Catalog outlet for replacement.

Recreator s packaged un-assembled We know Th

youreanxloustoseewnatyournew_oolwtl oo u an-" th...... ............ '-

.... n: w areful readn the u upar_numDeroTmemlssmgpar_wi Devery

a Tew minutes spe t no , c y g het-fu n .............

fo low ng instructions, wi 1 result in less frustration p s_€;ur_ng _ne replacemem part.

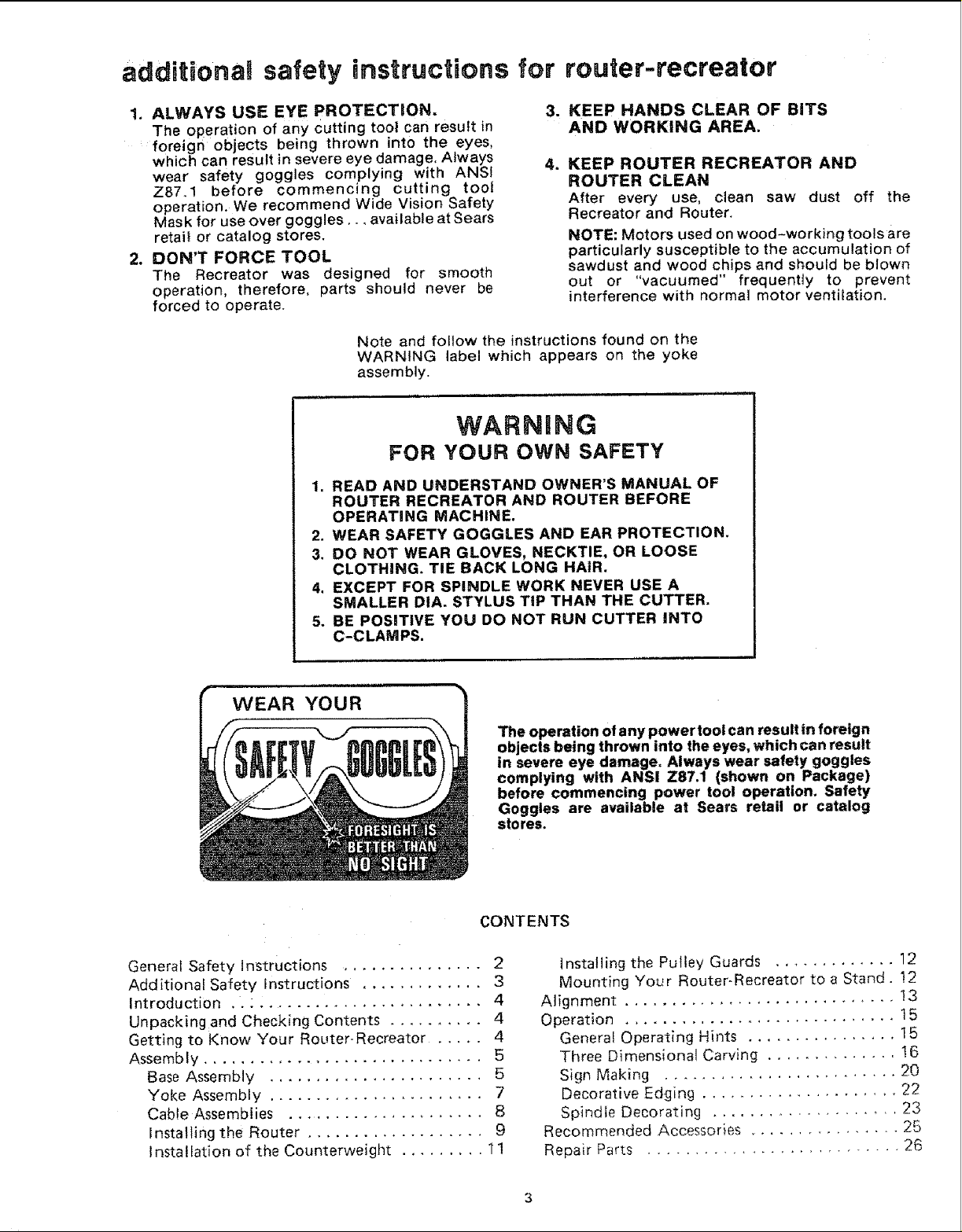

unpacking and checking contents

• . . T . .... : " "t J- b t e model number or your Recreator (113 251890)

ITEM DESCRIPTION

A Corner Brackets ........................ 2 A 8 C

B Track Brackets ......................... 2 h A , _ |

C Pulley Cover Guards ................... 2 1_ t Y /7 _ _ *

E She f Boards .......................... 4 ii/i_iii._j _2 P.c -- _,_'_"_ % X

G 1/16 ' styIUSRR_d ............... ........ 11 Sii___

J Yoke Assembly .. ........ : .............. _ i _ r=_ I i _ t

K Shaft .................. ; ............... 1 N' _ V _K J _\ _

L Pulleys (5") ............................ 21 L K H \G F

M Counterweight Shaft .. ........ ..........

N Counterweight ......................... 1

P Shaft Lock Brackets .................... 2

Q Loose Parts Bags ....................... 2

Bag. No, 76008 contains the following:

Cable ................................... 2

Spindle Center Screw .................... 2

Stylus Mount ........................... 1

Large Knob ........................... 1

Small Knob ...; ........................ 1

3/4" Stylus Collar ...................... 1

Stylus Grip .... ......................... I

Bag NO. 76018 contains the _otlowing:

Screw. Pan, Hd. t/4-20 x1-1/,_..... ..... : 20

Screw Pan Hd t/4-20 x 1/2 ........... 18

Nut, Hex 1/4-20 . . ......... ....... _ 32

Wing Nut. 1/4-20 ....................... 2

QTY.

_, D E

ITEM DESCRIPTION QTY.

Collar .................................. 2

Screw, Soc. Set 1/4-20 x 1/4 ............. 4

Nut. Hex 8-32 .......................... 2

Washer 3/16 x 3/8 x 1/32 ............... 2

Screw, Seres Pan Hd, 10-32 x 3/4 ...... 2

Lockwasher_ External 1/4 .............. 2

Screw, Soc. Set 5/16-18 x 5/16 .......... 1

Screw. Hex Hd 3/8-16 × 1-1/2 .......... 2

Washer. 3/8 x 7/8 x 5/64 ................ 2

Nut. Hex Jam 3/8-16 .................... 6

Wrench. Hex "L" t/8 .................... 1

Wrench, Hex "L" 5/32 .................. 1

Screw, Rd. Hd. 1/4-20 x 2-1/2 ........... 1

Screw, Pan lid 10-32 x 1/2 .............. 3

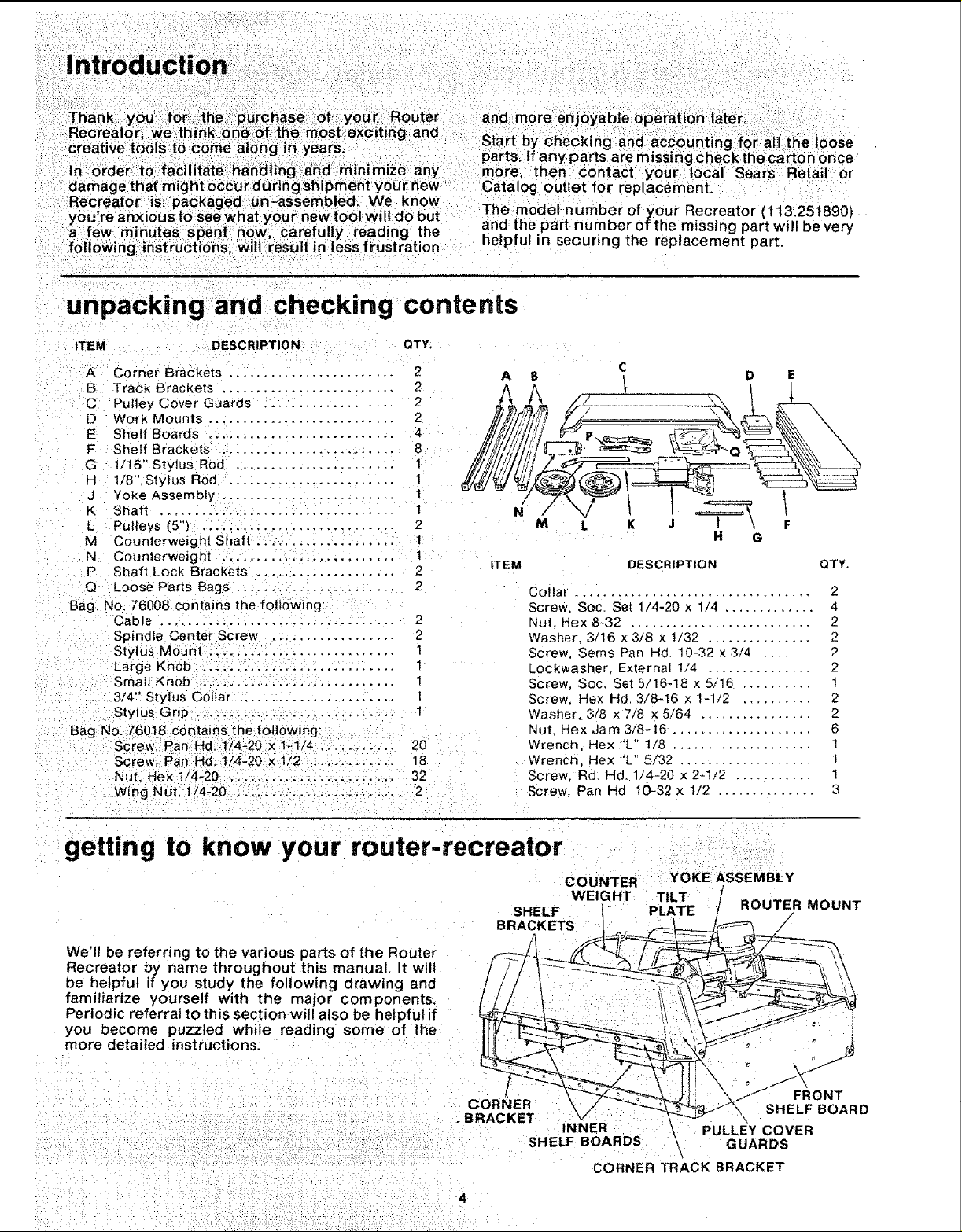

getting to know your router-recreator

We'll be referring to the various parts of the Router

Recreator by name throughout this manual• It will

be helpful if you study the following drawing and

familiarize yourself with the major components,

Periodic referral to this section will also be helpful if

you become puzzled while reading some of the

more detailed instructions.

. BRACKET INNER PULLEY COVER

i

" 4

" : -: SHELF BOARDS _ GUARDS

COUNTER YOKE ASSEMBLY

WEIGHT TILT

l FRONT

CORNER SHELF BOARD

CORNER TRACK BRACKET

PLATE ROUTER MOUNT

/

assembly

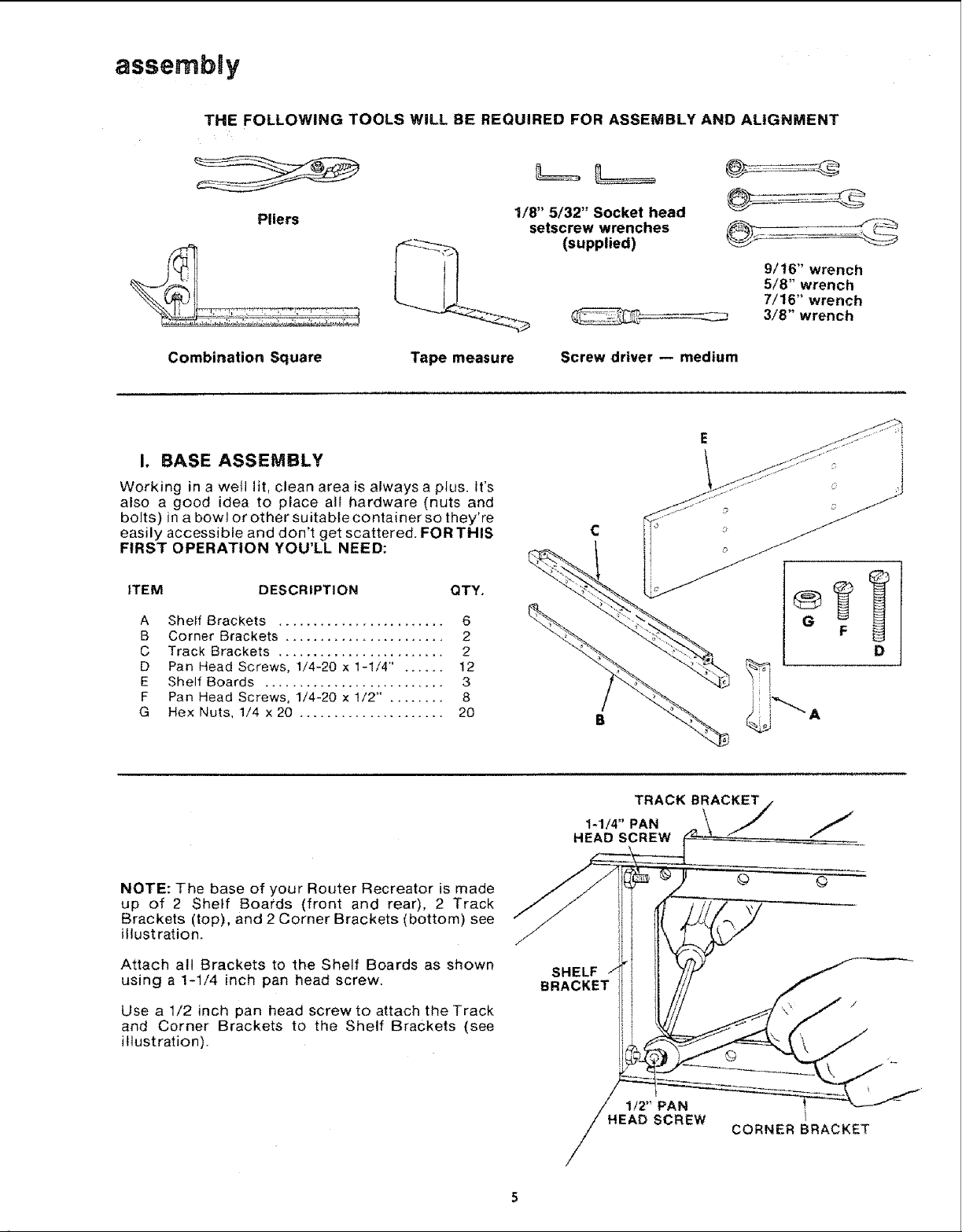

THE FOLLOWING TOOLS WiLL BE REQUIRED FOR ASSEMBLY AND ALIGNMENT

Pliers

Combination Square

Tape measure Screw driver -- medium

I. BASE ASSEMBLY

Working in a welt lit, clean area is always a plus. It's

also a good idea to place all hardware (nuts and

bolts) in a bowl or other suitable container so they're

easily accessible and don't get scattered. FOR THIS

FIRST OPERATION YOU'LL NEED:

ITEM DESCRIPTION QTY.

A Shelf Brackets ........................ 6

B Corner Brackets ....................... 2

C Track Brackets ........................ 2

D Pan Head Screws, 1/4-20 x 1-1/4" . ..... 12

E Shelf Boards .......................... 3

F Pan Head Screws, 1/4-20 x 1/2" . ....... 8

G Hex Nuts, 1/4 x 20 ..................... 20

1/8" 5/32" Socket head

setscrew wrenches

(supplied)

C

9/16" wrench

5/8" wrench

7/16" wrench

3/8" wrench

D

NOTE: The base of your Router Recreator is made

up of 2 Shelf Boards (front and rear), 2 Track

Brackets (top), and 2 Corner Brackets (bottom) see

illustration.

Attach all Brackets to the Shelf Boards as shown

using a 1-1/4 inch pan head screw.

Use a 1/2 inch pan head screw to attach the Track

and Corner Brackets to the Shelf Brackets (see

illustration).

TRACK BRACKET

1-1/4"PAN j

HEAD SCREW

SHELF

BRACKET

H1/2 ' PAN 1

EAD SCREW CORNER BRACKET

© ©

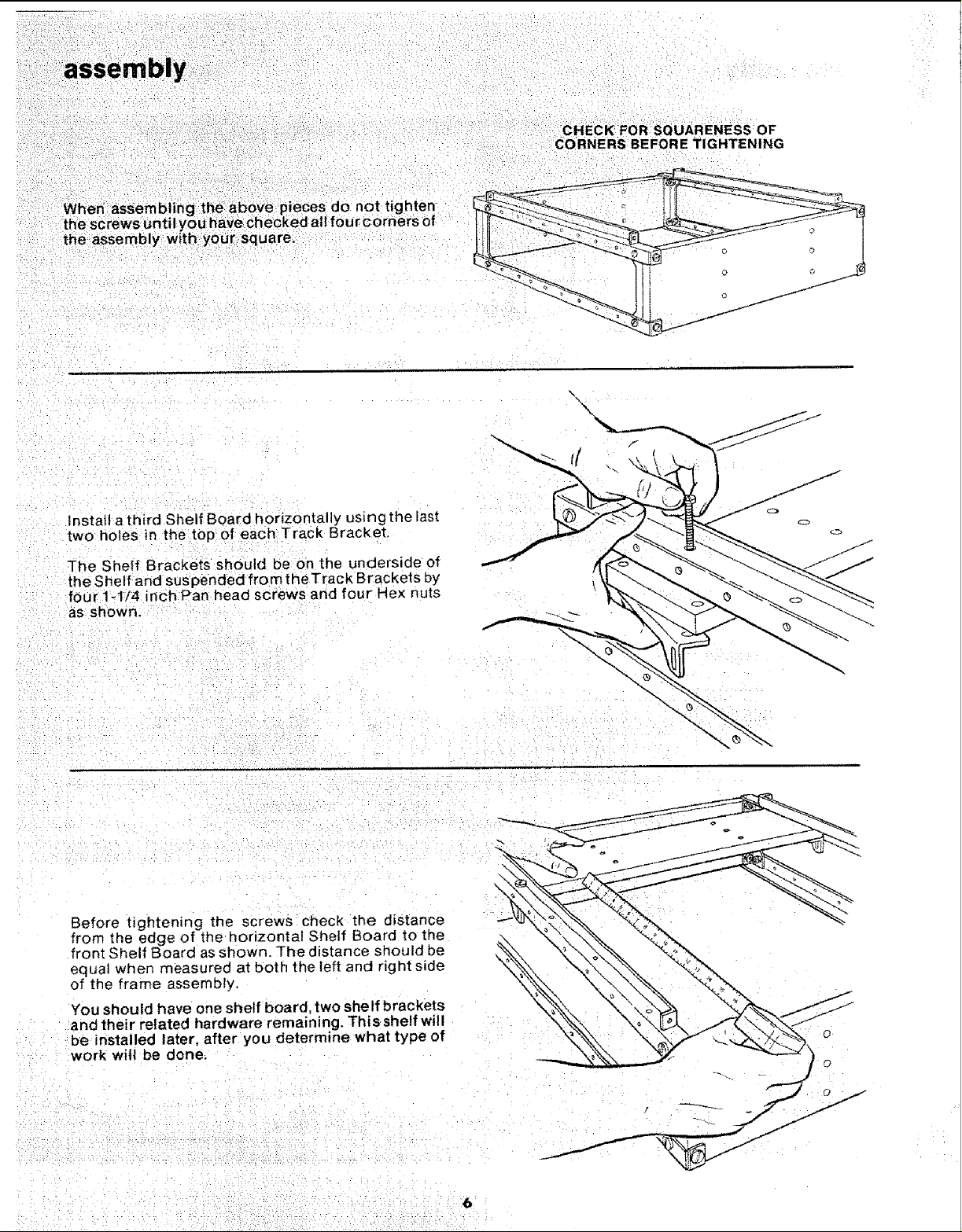

: CORNERS BEFORE TIGHTENING

When assembling the above pieces do not tighten

the screws until you have checked all four cornerS of

the assembly with your square.

Instafl a third Shelf Board horizontally us_ngthe last

two holes in the:top of each Track Bracket,

The Shelf Brackets should be on the underside of

the Shelf and sus pended from the Track Brackets by

four 1-1/4 inch Pan head screws and four Hex nuts

as shown.

CHECK FOR SQUARENESS OF

\

Before tightening the screws check the distance

from the edge of the horizontal She{f Board to the

front Shelf Board as shown. The distance shouEd be

equal when measured at both the left and rig ht side

of the frame assembly,

You should have one shelf board, two she If brac kets

and their related hardware remaining. Thisshelf will

be installed later, after you determine what type of

work will be done.

6 ¸

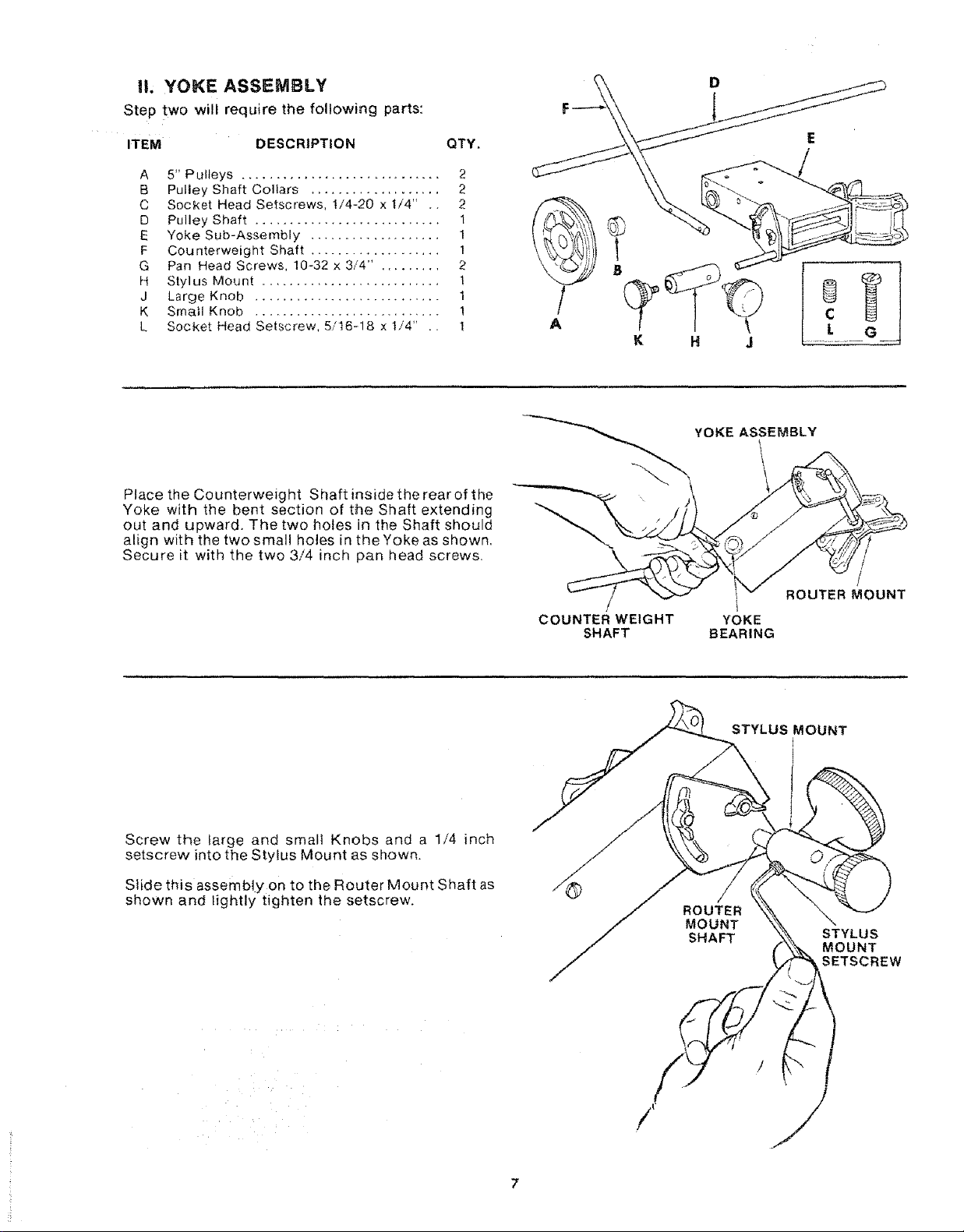

l!. YOKE ASSEMBLY

Step two will require the following parts:

ITEM DESCRJPT|ON QTY,

A 5" Pulleys ............................. 2

B Pulley Shaft Collars ................... 2

C Socket Head Setscrews, I/4-20 x t/4" .. 2

D Pulley Shaft ........................... 1

E Yoke Sub-Assembly ................... 1

F Counterweight Shaft ................... 1

G Pan Head Screws, 10-32 x 3/4" . ........ 2

H Stylus Mount .......................... 1

J Large Knob ........................... 1

K Small Knob ........................... !

L Socket Head Setscrew, 5/16-18 x t/4" .. 1

Place the Counterweight Shaft inside the rear of the

Yoke with the bent section of the Shaft extending

out and upward. The two holes in the Shaft should

align with the two small holes in the Yoke as shown.

Secure it with the two 3/4 inch pan head screws,

D

YOKE ASSEMBLY

/

Screw the large and small Knobs and a 1/4 inch

setscrew into the Stylus Mount as shown.

Slide this assembly on to the Router Mount Shaft as

shown and lightly tighten the setscrew.

COUNTER WEIGHT

SHAFT

ROUTER MOUNT

YOKE

BEARING

STYLUS MOUNT

STYLUS

MOUNT

SETSCREW

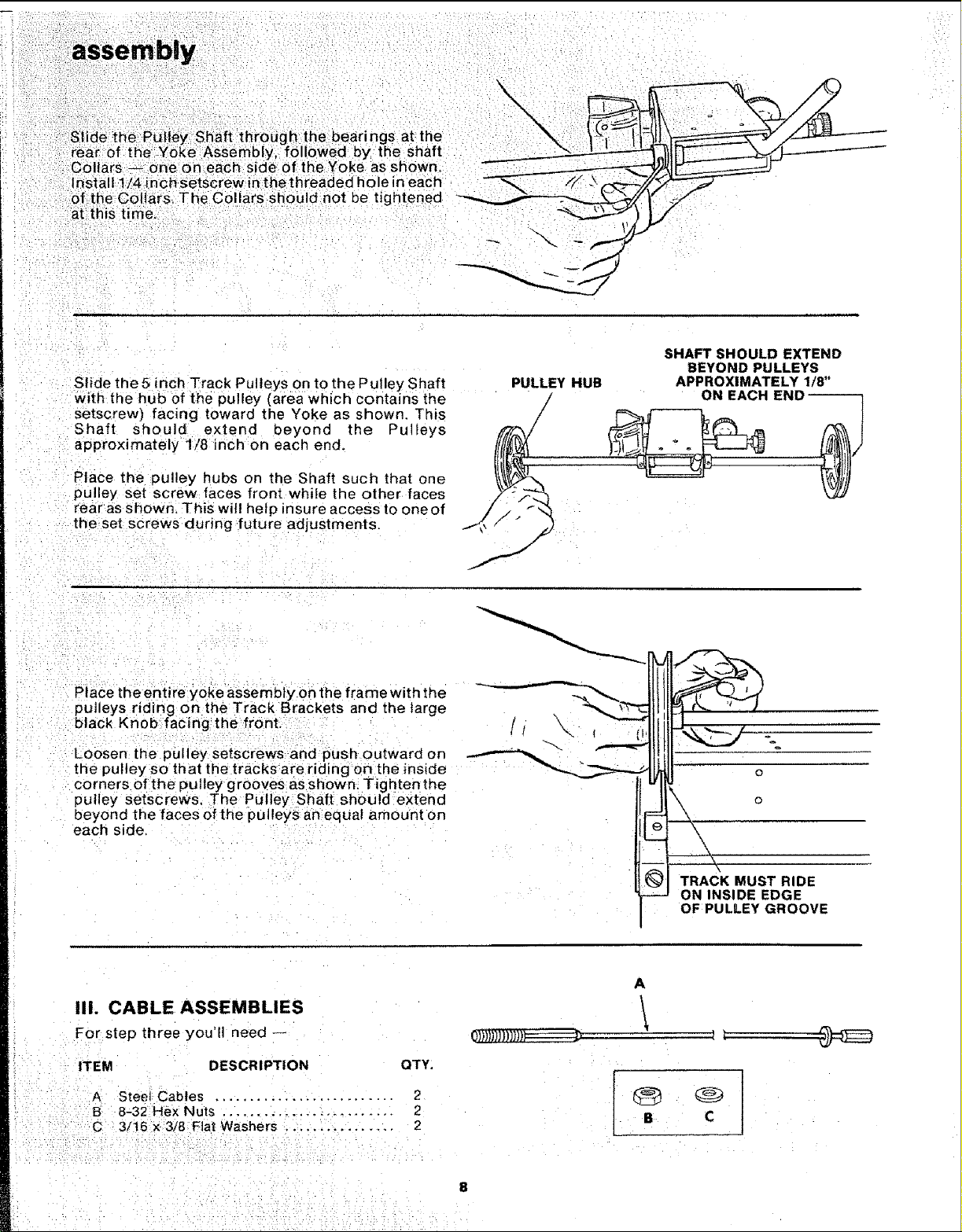

de the Pulley shaft through the bearings at the

.rear of the Y0ke Assembly followed by the shaft

Collars _ one or1 each side of the Yoke as shown,

install 1/4 inchsetsCrew in thethreaded h01e in each

of the Collars. The Collars should not be

at this time.

Slide the 5 inch Track Pulleys o n to the Pulley Shaft

with the hub of the pulley (area which contains the

setscrew) facing toward the Yoke as shown. This

Shaft shoulc_ extend beyond the Pulleys

approximately 1/8 inch on each end.

Place the pulley hubs on the Shaft such that one

pulley set screw faces front while the other faces

rear as Shown. This wil! help insure access to one of

the set screws during future adjustments.

PULLEY HUB

/

/

SHAFT SHOULD EXTEND

BEYOND PULLEYS

APPROXIMATELY 1/8"

ON EACH END

PlaCe the entire yoke assembly on the frame with the

pulleys riding on the Track Brackets and the large

black Knob facing the front.

Loosen the pulley setscrews and push outward on

the pulley so that the tracks are riding on the inside

corners of the pulley grooves as shown. Tighten the

pulley setscrews. The Pulley Shaft should extend

beyond the faces of the pulleysan equal amount on

each side,

Iii. CABLE ASSEMBLIES

For step three you'll need --

ITEM DESCRIPTION QTY:

A Steel Cables .......................... 2

B 8-32 Hex Nuts ..................... 2

C 3/t6 X 3/8 Flat Washers ............... 2

TRACK MUST RIDE

ON INSIDE EDGE

OF PULLEY GROOVE

A

0))))))l)))})})--

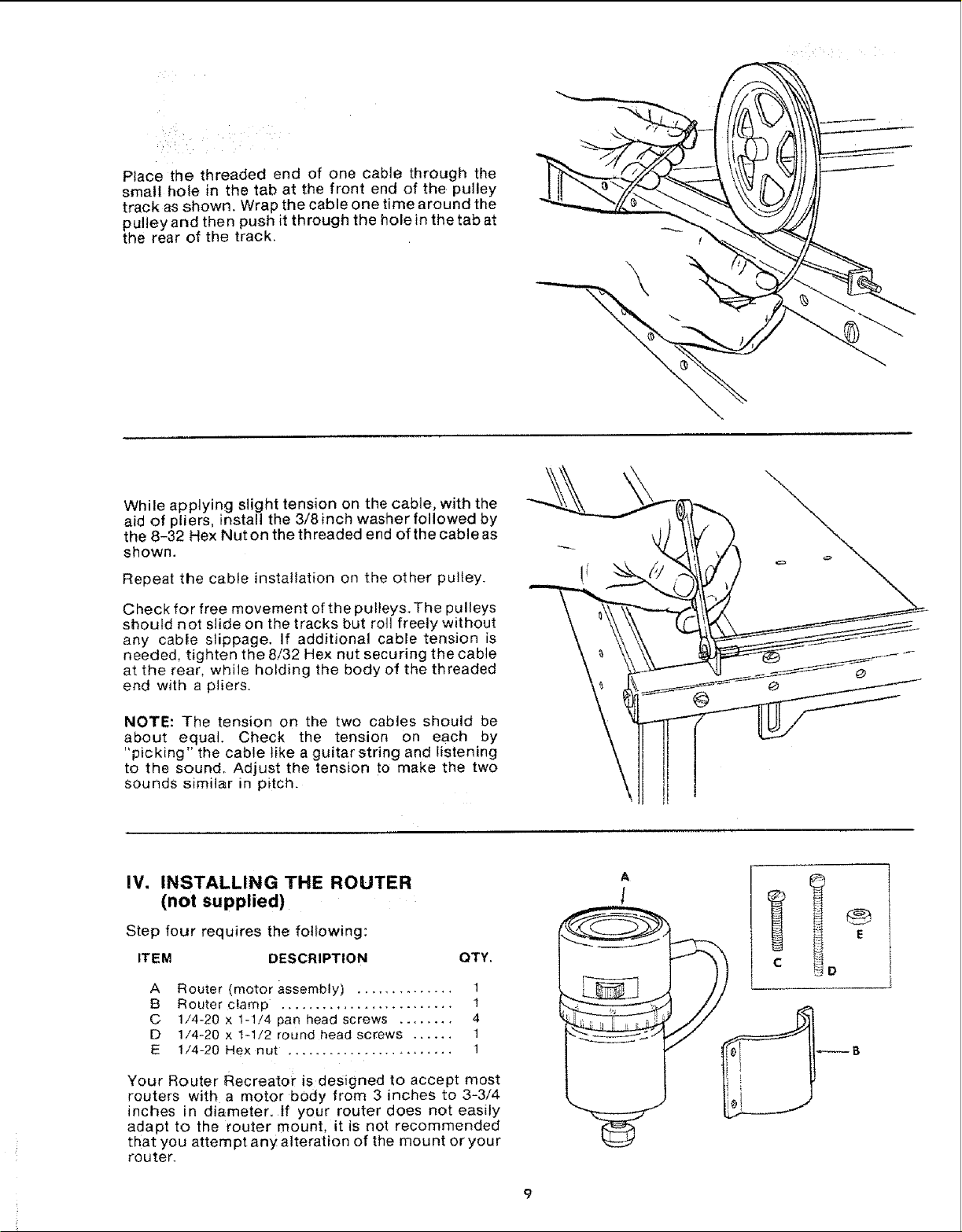

Place the threaded end of one cable through the

small hole in the tab at the front end of the pulley

track as shown. Wrap the cable one time around the

pulley and then push it through the hole in the tab at

the rear of the track.

While applying slight tension on the cable, with the

aid of pliers, install the 3/8 inch washer followed by

the 8-32 Hex Nut on the threaded end of the cable as

shown.

Repeat the cable installation on the other pulley.

Check for free movement of the pulleys. The pulleys

should not sJide on the tracks but roll freely without

any cable slippage. If additional cable tension is

needed, tighten the 8/32 Hex nut securing the cable

at the rear, while holding the body of the threaded

end with a pliers.

NOTE: The tension on the two cables should be

about equal. Check the tension on each by

"picking" the cable like a guitar string and listening

to the sound. Adjust the tension to make the two

sounds similar in pitch.

iV. INSTALLING THE ROUTER

(not supplied)

Step four requires the following:

ITEM DESCRIPTION

A Router (motor assembly) .............. 1

B Router clamp , ........................ 1

C 1/4-20 x 1-1/4 pan head screws ........ 4

D 1/4-20 x t-1/2 round head screws ...... 1

E 1/4-20 Hex nut . ....................... 1

Your Router Recreator is designed to accept most

routers with a motor body from 3 inches to 3-3/4

inches in diameter. If your router does not easily

adapt to the router mount, it is not recommended

that you attempt any alteration of the mount or your

router.

QTY.

E

Loading...

Loading...