Craftsman 113248340 Owner’s Manual

f

Save This Manual

For Future Reference

ModeJ No.

113.248340

Single Speed Band Saw

with Leg Set

Serial

Number

Model and serial numbers

may be found at the rear of

the base.

You should record both

model and serial number in

a safe place for future use.

FOR YOU

SAFETY

READ ALL

INSTRUCTmONS

CAREFULLY

Sold by SEARS, ROEBUCK AND CO., Hoffman Estates, IL. 60179 U.S.A.

Part No. SP5836

1\

14 iNCH D SAW

• assembly

• operating

, repair parts

Y

Printed in Taiwan

FULL ONE YEAR WARRANTY ON CRAFTSMAN BAND SAW

If within one year from the date of purchase, this Craftsman Band Saw fails due to a defect in material

or workmanship, Sears wi|I repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty applies only while this product is used in the UnitedStates.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

ROEBUCK AND CO.. WA Hoffman Estates, IL 60179

Safety instructions For Band Saw

Safety Signal Words:

DANGER: means if the safety information is not followed

someone will be seriously injured or killed.

WARNING: means if the safety information is not followed

someone could be seriously injured or killed.

CAUTION: means if the safety information is not followed

someone may be injured.

Before Using The Saw:

WARNING: to avoid mistakes that could cause seri- |

ous, permanent injury, do not plug the saw in until

the foliowin_ steps have been completed.

- Completely assemble and align saw (see "Assembly"

and "Alignment" section within).

* Learn the use and function of the ON-OFF switch.

bevel handwheel bevel lock knob. blade guides.

backup bearings, guide bar lock knob and blade guard.

,, Review and understand all safety instructions and

operating procedures in this manua I.

- Review the maintenance methods for this saw.

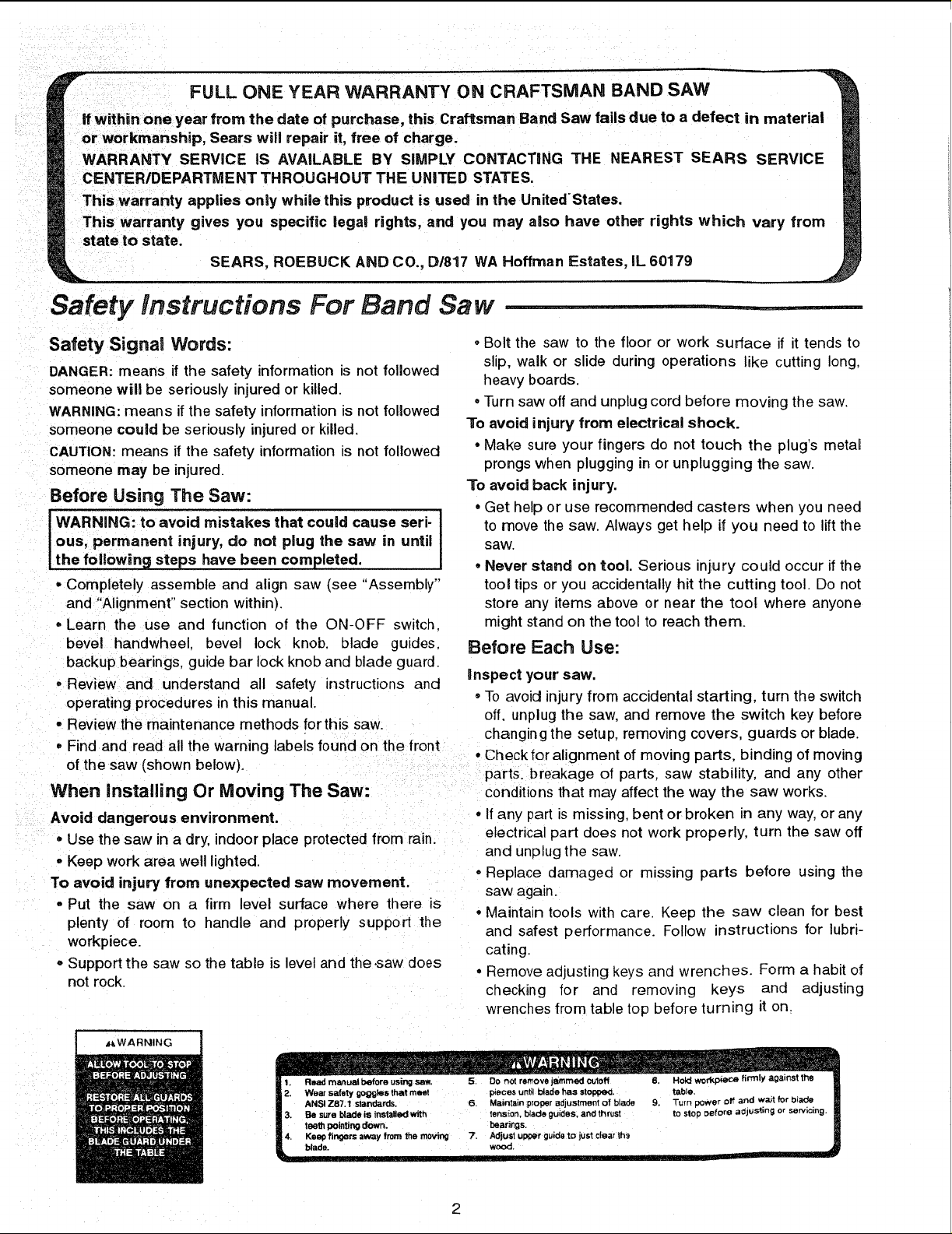

. Find and read all the warning labels found on the front

of the saw (shown below)•

oBolt the saw to the floor or work surface if it tends to

slip, walk or slide during operations like cutting long,

heavy boards.

• Turn saw off and unplug cord before moving the saw.

To avoid injury from electrical shock.

• Make sure your fingers do not touch the plug's metal

prongs when plugging in or unplugging the saw.

To avoid back injury.

• Get help or use recommended casters when you need

to move the saw. Always get help if you need to lift the

[

saw.

• Never stand on tool. Serious injury could occur if the

tool tips or you accidentally hit the cutting tool. Do not

store any items above or near the tool where anyone

might stand on the tool to reach them.

Before Each Use:

inspect your saw.

• To avoid injury from accidental starting, turn the switch

off. unplug the saw, and remove the switch key before

changing the setu p, removing covers, guards or blade.

• Check for alignment of moving parts, binding of moving

parts, breakage of parts, saw stability, and any other

When installing Or Moving The Saw: conditions that may affect the way the saw works.

Avoid dangerous environment. • Ifany part ismissing, bent or broken in any way,or any

oUse the saw in a dry, indoor place protected from rain. electrical part does not work properly, turn the saw off

- Keep work area well lighted, and unplug the saw.

To avoid injury from unexpected saw movem ent.

-Put the saw on a firm level surface where there Is

plenty of room to handle and properly support the

workpiece.

- Support the saw so the table is level and the.saw does

not rock.

• Replace damaged or missing parts before using the

saw again.

• Maintain tools with care Keep the saw clean for best

and safest performance. Follow instructions for lubri-

cating.

• Remove adjusting keys and wrenches. Form a habit of

checking for and removing keys and adjusting

wrenches from table top before turning it on.

I

| _oo_,poi.u.gdo*.. _ _,,_,. -..... |

blade, wood.

To avoid injury from jams, slips or thrown pieces or

broken blades.

Inspect your blade.

,' Choose the right blade size, style and cutting speed for

the material and the type of cutting you plan to do.

,, Use orfly recommended accessories. Consult this

owners manual for recommended accessories. Follow

the instrtJctions that come with the accessories. 7he

use of improper accessories may cause risk of injury to

persons.

• Make sure the blade teeti_ point downward, toward the

table.

,, Make sure the blade guides and thrust bearings are

properly adjusted.

° Make sure the blade te_sion is properly adjusted.

,, Make sure the bevel clamp is tight and no parts have

excessive ptay.

• _[6 avoid accidental Made contact, minimize blade

breakage and provide maximum blade support, always

adjust the upper blade guide and blade guard to just

clear the workpiece.

Inspect your work area.

• Keep work area clean.

° Cluttered areas and benches invite accidents. Floor

must not be slippery from wax or sawdust.

,, fb avoid burns or other fire damage, never use the saw

near flammable liquids, vapors or gases.

PUan your work.

• Use the right tool Don't force tool or attachment to do

a job it was not designed to do.

,, Use this band saw to cut only wood, wood like prod-

ucts and plastics.

CAUTION: To avoid blade breakage, fire or other I

damage to the saw, NEVER use this band saw to

cut metags.

-Know your saw. Read and understand the owner's

manual and labels affixed to the tool. Learn its applica-

tion and limitations as wel! as the specific potential

hazards peculiar to this tool.

° To avoid injury from accidental contact with moving

parts, don't do layout, assembly, or set up work on the

saw while any parts are moving.

° Avoid accidental starting. Make sure switch is "OFF"

before plugging saw into a power outlet.

Plan ahead to protect your eyes, hands, face

and ears.

WEAR YOUR

Dress for safety

Any power saw can throw foreign objects into the ey'es.

This can cause permanent eye damage. Wear safety

goggles (not glasses) that comply with ANSI Z87.1

(shown on package). Everyday eyeg{asses have onty

impact resistance lenses. They are not safety glasses.

Safety goggles are available at Sears retail catatog

stores. Glasses or goggles not in cornpJiance with ANS!

Z87.1 could seriously hurt you when they break.

o Do not wear loose c!othing, gloves, neckties or jewelry

(rings, wrist watches). They can get caught and draw

you into moving parts.

• Wear nonstip footwear.

° Tie back long hair.

° Roll long sleeves above the elbow.

,,Noise levels vary widely. -rb avoid possible hearing

damage, wear ear plugs or muffs when using saw for

hours at a time.

- For dusty operations, wear a dust mask aiong with the

safety goggles.

Inspect your workpiece.

Make sure there are no nails or foreign objects in the

part of the workpiece to be cut.

Use extra caution with large, very small or awkward

workpieces:

" Use extra supports (tables, saw horses, blocks, etc.)

for any workpieces large enough to tip when not held

down to the table top.

oNEVER use another person as a substitute for a table

extension, or as additional support for a workpiece that

is longer or wider than the basic saw table, or to hetp

feed, support or pull the workpiece.

oWhen cutting irregularly shaped workpieces, plan your

work so it will not slip and pinch the blade. A piece of

I

molding for example, must lie flat or be held by a fixture

of jig that wilt not _etit twist, rock or slip while being cut.

° Properly support round material such as dowel rods. or

tubing. They have a tendency to rot_ during a cuL

causing the blade to "bite". To avoid this. atways use a

"V" block or clamp the work to the miter gage.

o Cut only one workpiece at a time.

• Clear everything except the workpiece and related

support devices off the table before turning the saw on.

Plan the way you will hold the workpiece

from start to finish.

• Do not hand hold pieces so small that your fingers win

go under the blade guard. Use jigs or fixtures to hold

the work and keep your hands away from the blade.

° Secure work. Use clamps to hold work when practical.

It's often safer than using your hand. and frees both

hands to operate the too!.

,, Don't overreach, Keep good footing and balance.

Safety instructions for Band Saws (continued) .........

Whenever Sawbiade is Spinning:

quent use of your band saw) cause a careless mis-

take, Always remember that a careless fraction of a

I WARNING: Don't allow familiarity (gained from fre-

second is enough to cause a severe injury.

- Before starting your cut, watch the saw while it runs. If

it makes an unfamiliar noise or vibrates a lot, stop

immediately. Turn the saw off. Unplug the saw. Do not

restart untilfinding and correcting the problem.

. Before removing loose pieces from the table, turn saw

offand wait for all moving parts to stop.

Keep Children Away.

• Keep all visitors a safe distance from the table saw.

• Make sure bystanders are clear of the table saw and

workplece.

Don't Force Tool.

• Letthe blade reach full speed before cutting.

- Itwill do the job better and safer at its designed rate.

- Feed the workpiece into the saw only fast enough to let

the blade cutwithout bogging down or binding.

Before freeing jammed material.

• Turn switch "OFF".

° Unplug the saw.

oWait for all moving parts to stop.

- Remove switch key.

When backing up the workpiece, the blade may bind

in the kerr (cut). This is usually caused by sawdust

clogging up the kerr or because the blade comes out

of the guides, if this happens:

• Turn saw "OFF".

oWait for all moving parts to stop.

° Remove switch key.

° Unplug the saw.

- Remove band saw cover.

- Stick flat blade screwdriver or wedge into the kerf.

oTurn the upper whee4 by hand while backing up the

workpiece.

Before Leaving The Saw.

° Turnthe saw off.

• Wait for all moving parts to stop.

• Unplug the saw.

• Make workshop child-proof.

- Lockthe shop.

- Disconnect master switches.

- Remove the yellow switch key. Store it away from

children and others not qualified to use the tool.

Glossary Of Terms For Woodworking -

Beveling

An angle cutting operation made through the face of the

workpiece.

Compound Cutting

A simultaneous bevel and miter crosscuttingoperation.

Crosscut

A cutting operation made across the width of the work-

piece.

FPM

Feet per minute. Used in reference to surface speed of

blade.

Freehand (as used for band saw)

Performing a cut without the workpiece properly sup-

ported on the work table.

Gum

A sticky, sap based residue from wood products.

Kerr

The material removed bythe blade in a through cut or the

slot produced by the blade in a nonthrough or partial cut.

Leading End

The end of the workpiece which, is pushed into the cut-

tingtool first.

Mitering

An angle cutting operation made across the width of the

workpiece.

Push Stick

A device used to feed the workpiece through the saw dur-

ing narrow ripping type operations and helps keep the

operator's hands well away from the blade.

Resaw

A cutting operation to reduce the thickness of the work-

piece to make thinner pieces.

Resin

A sticky, sap based substance that has dried.

Ripping

A cutting operation along the length of the workpiece.

Sawblade Path

The area of the worktable or workpiece directly in line

with the saw blade.

Set

The distance the tip of the sawblade tooth is bent out-

ward from the face of the blade.

Trailing End

The workpiece end last cut bythe blade.

Workpiece

The item on which the cutting operation is being per-

formed. The surfaces of a workpiece are commonly

referred to as faces, ends, and edges.

Worktable

The surface on whichthe workpiece rests while perform-

ing a cutting or sanding operation.

4

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

The A-C motor used in this saw is non-reversible type, hav-

ing the following specifications:

Rated H.P. ................................................................ 3/4

Maximum Developed H.P...................................... 1-1/2

Voltage .................................................................... 120

Amperes .................................................................... 10

Hertz (Cycles) ........................................................... 60

Phase .................................................................. Single

RPM ...................................................................... 1725

Rotation of Shaft ............................... Counterclockwise

WARNING: To avoid electrical hazards, fire hazards

or damage to the tool, use proper circuit protec-

tion. Your saw is wired at the factory for 120v oper-

ation. Connect to a 120v, 15-amp, branch circuit

and use a 15-amp fuse or circuit breaker.

WARNING: To avoid shock or fire, if power cord is

worn, cut or damaged in any way, have it replaced

immediately.

WARNING: if not properly grounded this power toom

can cause electrical shock-particularly when used

in damp locations close to plumbing. If an electri-

cal shock occurs there is also the potential of a

secondary hazard such as your hands contacting

the sawblade. Not all outlets are properly

grounded, if you are not sure that your outlet is

properly grounded, have it checked by a qualified

electrician.

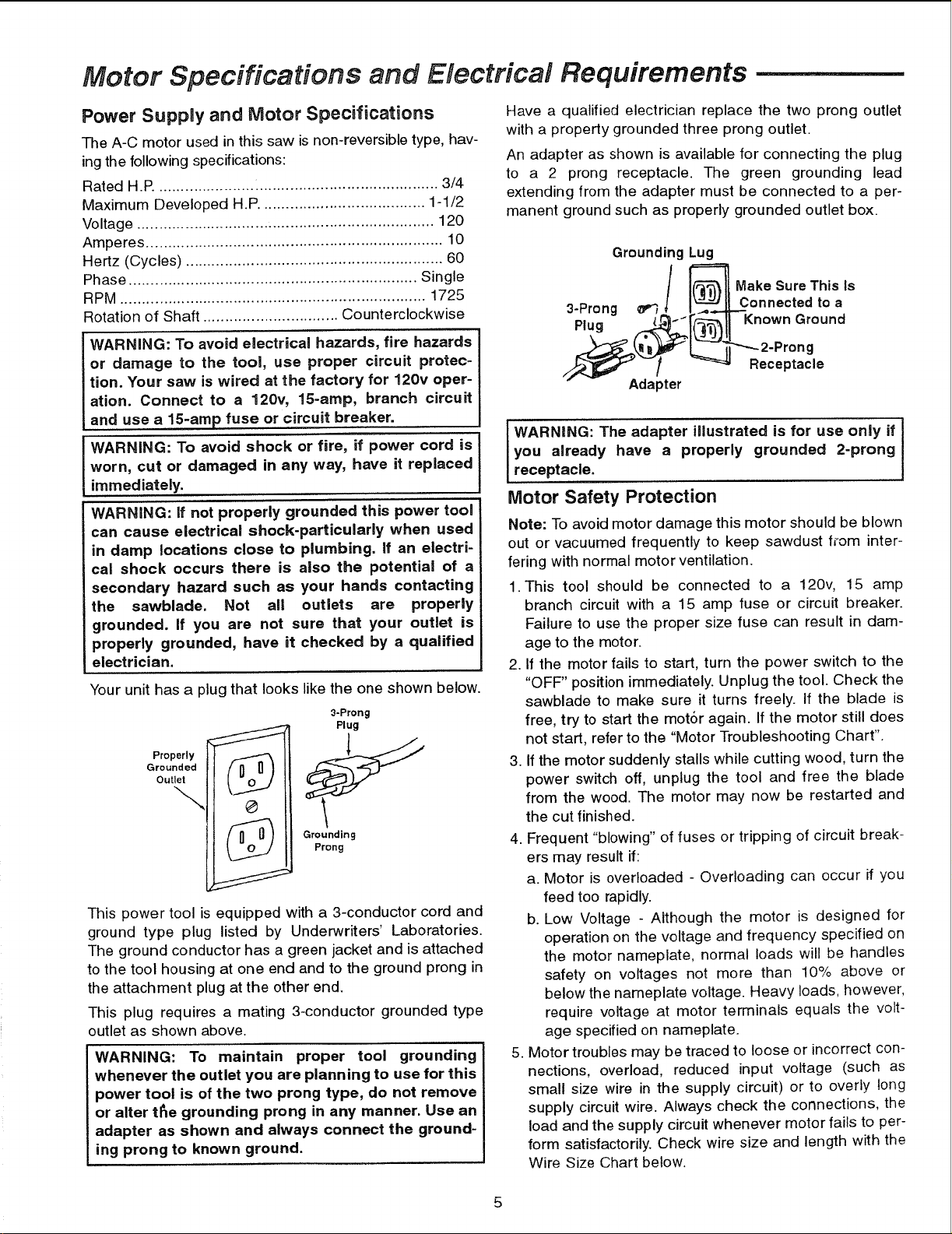

Your unit has a plug that looks like the one shown below.

3-Prong

Plug

Properly

Grounded

Outlet

-,.,,

This power tool is equipped with a 3-conductor cord and

ground type plug listed by Underwriters' Laboratories.

The ground conductor has a green jacket and is attached

to the tool housing at one end and to the ground prong in

the attachment plug at the other end,

This plug requires a mating 3-conductor grounded type

)utlet as shown above.

WARNING: To maintain proper tool grounding

whenever the outlet you are planning to use for this

power tool is of the two prong type, do not remove

or alter ti_e grounding prong in any manner. Use an

adapter as shown and always connect the ground-

ing prong to known ground.

Have a qualified electrician replace the two prong outlet

with a property grounded three prong outlet.

An adapter as shown is available for connecting the plug

to a 2 prong receptacle. The green grounding lead

extending from the adapter must be connected to a per-

manent ground such as properly grounded outlet box.

Grounding Lug

/ _==_MakeSureThisls

3 Pron- _ _ I_-_11 Connected to a

oowo,,o00,

/ _ Receptacle

Adapter

i WARNING: The adapter illustrated is for use only if

you already have a properly grounded 2-prong

receptacle.

Motor Safety Protection

Note: To avoid motor damage this motor should be blown

out or vacuumed frequently to keep sawdust from inter-

fering with normal motor ventilation.

1.This tool should be connected to a 120v, 15 amp

branch circuit with a 15 amp fuse or circuit breaker.

Failure to use the proper size fuse can result in dam-

age to the motor.

2. If the motor fails to start, turn the power switch to the

"OFF" position immediately. Unplug the tool. Check the

sawblade to make sure it turns freely. If the blade is

free, try to start the mot6r again. If the motor still does

not start, refer to the "Motor Troubleshooting Chart".

3. If the motor suddenly stalls while cutting wood, turn the

power switch off, unplug the tool and free the blade

from the wood. The motor may now be restarted and

the cut finished.

4. Frequent "blowing" of fuses or tripping of circuit break-

ers may result if:

a. Motor is overloaded - Overloading can occur if you

feed too rapidly.

b. Low Voltage - Although the motor is designed for

operation on the voltage and frequency specified on

the motor nameplate, normal loads will be handles

safety on voltages not more than 10% above or

below the nameplate voltage. Heavy loads, however,

require voltage at motor terminals equals the volt-

age specified on nameplate.

5. Motor troubles may be traced to loose or incorrect con-

nections, overload, reduced input voltage (such as

small size wire in the supply circuit) or to overly long

supply circuit wire. Always check the connections, the

load and the supply circuit whenever motor fails to per-

form satisfactorily. Check wire size and length with the

Wire Size Chart below.

Motor Specifications and Electrical Requirements (continued)

Wire Sizes

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor bum-out, use the table below to deter-

mine the minimum wire size (A.W.G,) extension cord.

Use only 3-wire extension cords which have 3-prong

grounding type plugs and 3-pole receptacles which

accepts the tools plug,

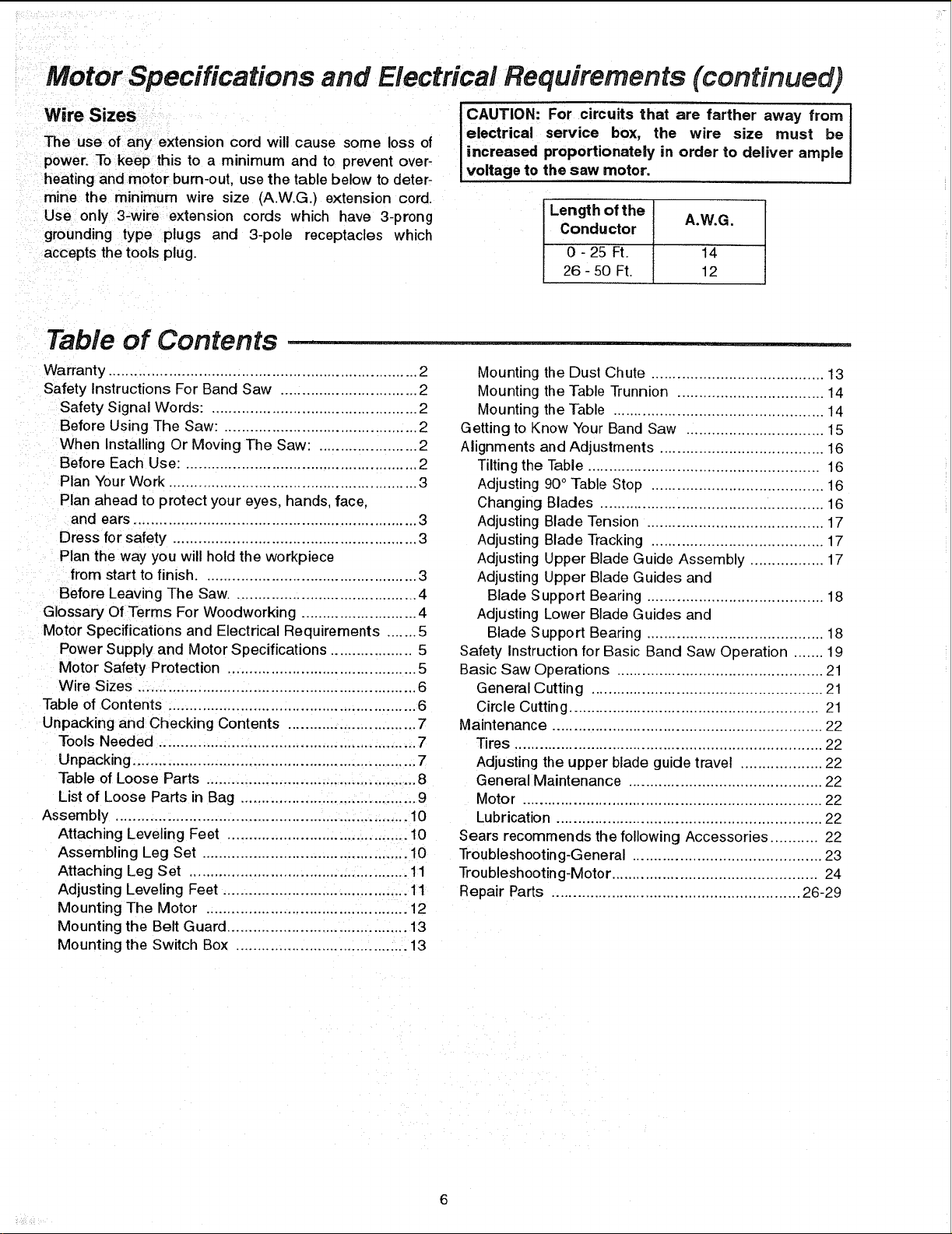

Table of Contents

Warranty ........................................................................ 2

Safety Instructions For Band Saw ................................ 2

Safety Signal Words: ................................................ 2

Before Using The Saw: ............................................. 2

When Installing Or Moving The Saw: ....................... 2

Before Each Use: ...................................................... 2

Plan Your Work .......................................................... 3

Plan ahead to protect your eyes, hands, face.

and ears .................................................................. 3

Dress for safety ......................................................... 3

Plan the way you will hold the workpiece

from start to finish .................................................. 3

Before Leaving The Saw........................................... 4

Glossary Of Terms For Woodworking ........................... 4

Motor Specifications and Electrical Requirements ....... 5

Power Supply and Motor Specifications ................... 5

Motor Safety Protection ............................................ 5

Wire Sizes ................................................................. 6

Table of Contents .......................................................... 6

Unpacking and Checking Contents .............................. 7

Tools Needed ............................................................ 7

Unpacking .................................................................. 7

Table of Loose Parts ................................................. 8

List of Loose Parts in Bag ........................................ 9

Assembly .................................................................... 10

Attaching Leveling Feet .......................................... 10

Assembling Leg Set ................................................ 10

Attaching Leg Set ................................................... 11

Adjusting Leveling Feet ........................................... 11

Mounting The Motor ............................................... 12

Mounting the Belt Guard ......................................... 13

Mounting the Switch Box ........................................ 13

CAUTION: For circuits that are farther away from I

electrical service box, the wire size must be I

increased proportionately in order to deliver ample J

voltage to the saw motor.

Length of the A.W.G.

Conductor

0 -25 Ft. 14

26 - 50 Ft. 12

Mounting the Dust Chute ........................................ 13

Mounting the Table Trunnion .................................. 14

Mounting the Table ................................................. 14

Getting to Know Your Band Saw ................................ 15

Alignments and Adjustments ...................................... 16

Tilting the Table ...................................................... 16

Adjusting 90 ° Table Stop ........................................ 16

Changing Blades .................................................... 16

Adjusting Blade Tension ......................................... 17

Adjusting Blade Tracking ........................................ 17

Adjusting Upper Blade Guide Assembly ................. 17

Adjusting Upper Blade Guides and

Blade Support Bearing ......................................... 18

Adjusting Lower Blade Guides and

Blade Support Bearing ......................................... 18

Safety Instruction for Basic Band Saw Operation ....... 19

Basic Saw Operations ................................................ 2!

General Cutting ...................................................... 21

Circle Cutting .......................................................... 21

Maintenance ............................................................... 22

Tires ........................................................................ 22

Adjusting the upper blade guide travel ................... 22

General Maintenance ............................................. 22

Motor ...................................................................... 22

Lubrication .............................................................. 22

Sears recommends the following Accessories ........... 22

Troubleshooting-General ............................................ 23

Troubleshooting-Motor ................................................ 24

Repair Parts .......................................................... 26-29

Unpacking and Checking Contents

Tools Needed

Tools required for assembly and alignment:

oCombination Square

• 10ram and 14mm combination wrench

Adjustable wrench.

• #1 and #2 Phillips screwdrivers

o Straightedge

Combination Square

lOmm Combination Wrench

14ram Combination Wrench

#1 Phillips Screwdriver

Adjustable Wrench

#2 Phillips Screwdriver

Unpacking

WARNING: To avoid injury from unexpected start-

ing or electrical shock, do not plug the saw in until

all assembly and alignment steps are complete.

The power cord must remain unplugged whenever

you are working on the saw.

Unpacking and Checking Contents

1 Separate all "loose parts" from packaging materials

and check each item with "Table of Loose Parts" to

make sure all items are accounted for, before discard-

ing any packing material.

WARNING: if any parts are missing, do not attempt !

to assemble the band saw, plug in the power cord, I

or turn the switch on until the missing parts are I

obtained and are installed correctly. ]

2. Sometimes small parts get lost in packaging materials.

Do not throw away any packaging until your saw is put

together. If your are missing a part, check packaging

before contacting Sears.

Combination Square Must be True

Straight Edge of

Draw Light Board 314" Thick

Line on Board This Edge Must be

Along this Edge _ _ .Perfectly Straight

Should be no Gap or Overlap when Square

is Flipped Over in Dotted Position

7

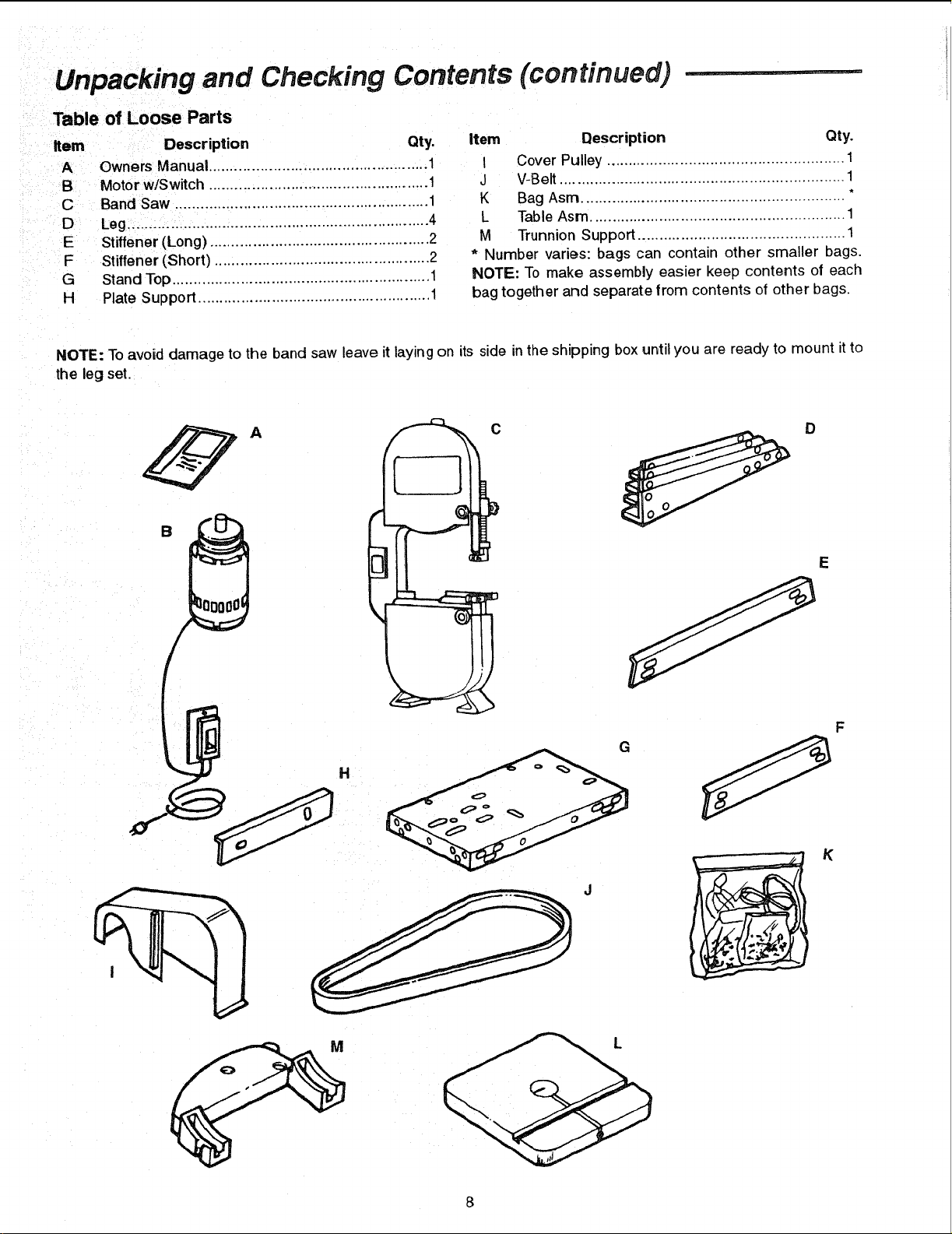

Unpacking and Checking Contents (continued) - -

Table of Loose Parts

Item Description Qty.

A Owners Manual ................................................... 1

B Motor w/Switch ................................................... 1

C Band Saw ........................................................... 1

D Leg...................................................................... 4

E Stiffener (Long) ................................................... 2

F Stiffener (Short) .................................................. 2

G Stand Top ............................................................ 1

H Plate Support ...................................................... 1

NOTE: Toavoid damage to the band saw leave it laying on its side in the shipping box untilyou are ready to mount it to

the leg set.

A C

Item Qescription Qty.

I Cover Pulley ....................................................... 1

J V-Belt .................................................................. 1

K Bag Asm ............................................................. *

L Table Asrn ........................................................... 1

M Trunnion Support ................................................ 1

* Number varies: bags can contain other smaller bags.

NOTE: To make assembly easier keep contents of each

bag together and separate from contents of other bags.

D

E

G

H

j

M

8

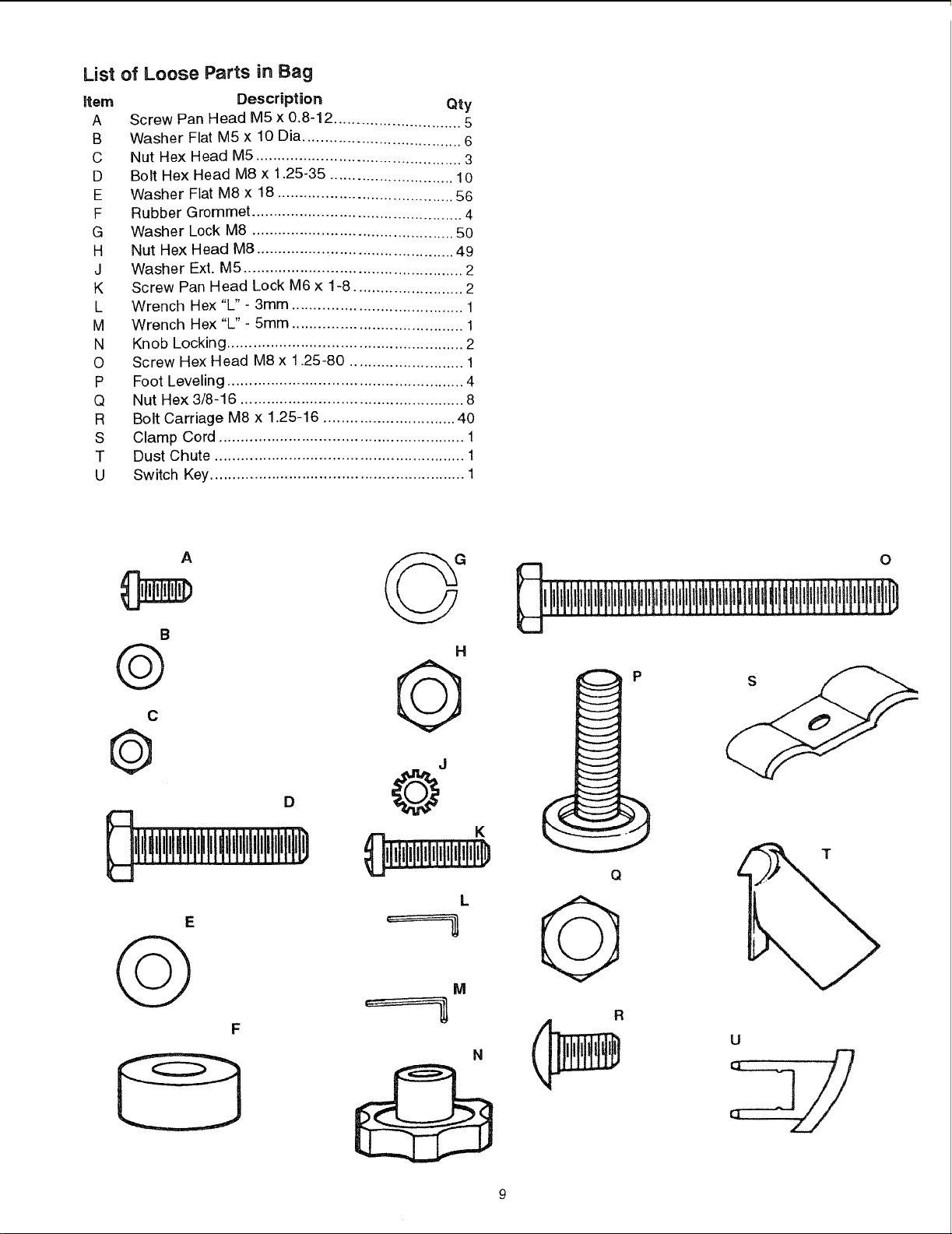

List of Loose Parts in Bag

totem

A

B

C

D

E

F

G

H

J

K

L

M

N

0

P

Q

R

S

T

U

Screw Pan Head M5 x 0.8-12 ............................. 5

Washer Flat M5 x 10 Dia. 6

Nut Hex Head M5 ................ 3

Bolt Hex Head M8 x 1.25-35 ............................ 10

Washer Flat M8 x 18 56

Rubber Grommet ................................................ 4

Washer Lock M8 .............................................. 50

Nut Hex Head M8 ............................................. 49

Washer Ext. M5 .................................................. 2

Screw Pan Head Lock M6 x 1-8 ......................... 2

Wrench Hex "L" - 3mm ....................................... 1

Wrench Hex "L"- 5ram ....................................... 1

Knob Locking ...................................................... 2

Screw Hex Head M8 x 1.25-80 .......................... !

Foot Leveling ...................................................... 4

Nut Hex 3/8-16 ................................................... 8

Bolt Carriage M8 x 1.25-16 .............................. 40

Clamp Cord ........................................................ 1

Dust Chute ......................................................... 1

Switch Key.......................................................... 1

Description Qty

O

Z

L

M

F

N

R

U

Assembly ......

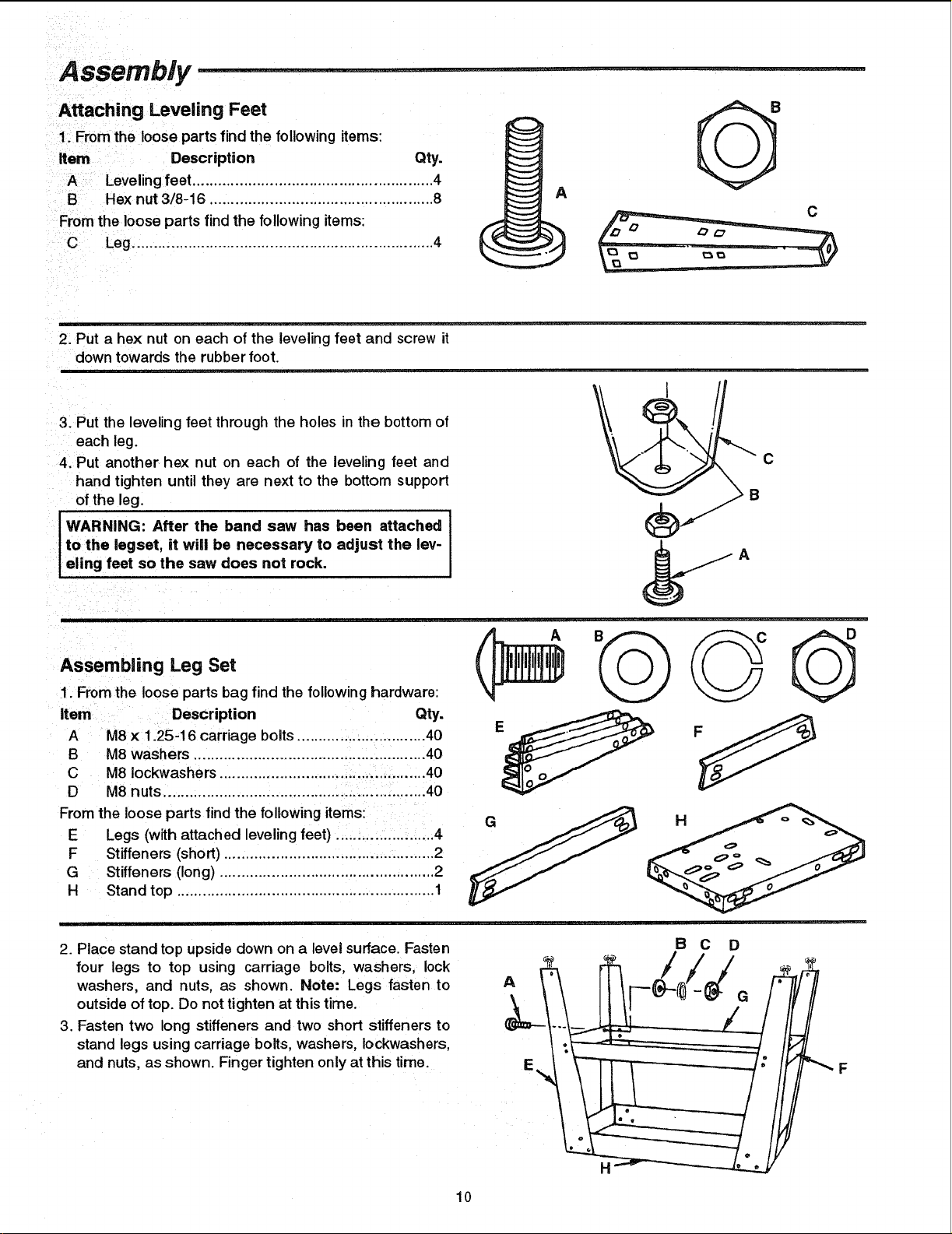

Attaching Leveling Feet

1_From the loose parts find the following items:

Item Description Qty.

A Levelingfeet........................................................ 4

B Hex nut 3/8-16 .................................................... 8

Fromthe loose parts findthe following items:

C Leg...................................................................... 4

2. Put a hex nut on each of the leveling feet and screw it

down towards the rubber foot.

3, Put the leveling feet through the holes in the bottom of

each leg.

4. Put another hex nut on each of the leveling feet and

hand tighten until they are next to the bottom support

of the leg.

WARNING: After the band saw has been attached

to the legset, it will be necessary to adjust the lev-

eling feet so the saw does not rock.

C

B

Assembling Leg Set

1. From the loose parts bag find the following hardware:

Item Description Qty.

A M8x 1.25-16 carriage bolts .............................. 40

B M8 washers ...................................................... 40

C M8 Iockwashers ................................................ 40

D M8 nuts ............................................................. 40

From the loose parts find the following items:

E Legs (with attached leveling feet) ....................... 4

F Stiffeners (short) ................................................. 2

G Stiffeners (long) .................................................. 2

H Stand top ............................................................ 1

2. Place stand top upside down on a level surface. Fasten

four legs to top using carriage bolts, washers, lock

washers, and nuts, as shown. Note: Legs fasten to

outside of top. Do not tighten at this time.

3. Fasten two long stiffeners and two short stiffeners to

stand legs using carriage bolts, washers, Iockwashers.

and nuts, as shown. Fingertighten onlyat this time.

A B

F

G

B C D

A

G

F

10

H

Loading...

Loading...