Craftsman 113244512 Owner’s Manual

SAVE THIS MANUAL

FOR FUTURE

REFERENCE

_ARS

owners

manual

MODEL NO.

113.244512

Serial

Number

Model and serial

number may be found

at the right-hand side

of the frame.

You should record both

model and serial

number in a safe place

for future use.

CAUTION:

Read GENERAL and

ADDITIONAL SAFETY

INSTRUCTIONS

carefully

IO-INCH DIRECT DRIVE

BAND SA W

,, assembly

• operating

, repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. 69188

FULL ONE YEAR WARRANTY ON CRAFTSMAN BAND SAW

If within one year from the date of purchase, this Craftsman Band Saw fails due to a defect in

material or workmanship, Sears will repair it, free of charge.

,WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS USED IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state,

SEARS, ROEBUCK AND CO.. 698/731A, Sears Tower, Chicago. IL 60684

general safety instructions for power tools

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual and

labels affixed to the toot. Learn its application

and limitations as well as'the specific potential

hazards peculiar to this toot,

2. GROUND ALL TOOLS

This tool is equipped with an approved 3-

conductor cord and a 3+prong grounding type

plug to fit the proper grounding type receptacle

The green conductor in the cord is the grouna.

ing wire. Never connect the green wIre to a hve

terminal.

3. KEEP GUARDS IN PLACE

-- in working order, and n proper adjustment

and alignment.

_4_ REMOV=E ADJUSTING KEYS AND WRENCHES

Form a habit of checking to see that keys ane

adjusting wrenches are removed from tool

before turning ;t on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents.

Floor must not be slippery due to wax or saw.

dust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations

or expose them to rain. Keep work area well

lighted. Provide adequate surrounding work

space.

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from

work area.

8. MAKE WORKSHOP CHILD-PROOF

-- with padlocks, master switches, or by re-

moving starter keys.

9. DON'T FORCE TQOL

It will do the job better and safer at the rate for

which it was designed.

10. USE RIGHT TOOL

Don't force tool or attachment to do a job it was

not designed for.

11. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or

_jewelry (rings, wristwatches) to get caught in

moving parts. NONSLIP footwear _s recom-

mended, Wear protective hair covering to con-

tain long hair, Roll long sleeves above the

elbow.

12. USE SAFETY GOGGLES (Head Protection)

Wear safety goggles (must comply with ANSI

Z87.1) at all times. Everyday eyeglasses only

have impact resistant lenses, they are NOT

safety glasses. Also, use face or dust mask if

cutting operation is dusty, and ear protectors

(plugs or muffs) during extended periods of

operation.

13. SECURE WORK

Use clamps or a v+se to hold work when practi-

cal. It's safer than using your hand, frees both

hands to operate tool.

14. DON'T OVERREACH

KeeD proper footing and balance at all times.

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

16. DISCONNECT TOOLS

before servicing; when changing accessories

such as blades, bits. cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is m "OFF" position before

pluggtng in.

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. Follow the instructions that

accompany the accessories. The use of im-

proper accessories may cause hazards.

19. NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped

or if the cutting tool is accidentally contacted.

Do not store materials above or near the tool

such that it is necessary to stand on the tool to

reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other

part that is damaged should be carefully check-

ed to ensure that it will operate properly and

perform its intended function. Check for align-

ment of moving parts, binding of moving parts.

breakage of parts, mounting, and any other con-

ditions that may affect its operation. A guard or

other part that _s damaged should be properly

repaired or replaced.

21. DIRECTION OF FEED

Feed work into a blade or cutter against the

direction of rotation of the blade or cutter only.

22. NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Don't leave tool until it comes

to a complete stop.

additi

Safety is a combination of operator common

sgnse and alertness at all times when the band

saw is being used.

WARNING: FOR YOUR OWN SAFETY, DO NOT

ATTEMPT TO OPERATE YOUR BAND SAW

UNTIL iT IS COMPLETELY ASSEMBLED AND

INSTALLED ACCORDING TO THE INSTRUC-

TIONS... AND UNTIL YOU READ AND UNDER-

STAND THE FOLLOWING:

1. General Safety instructions for Power Tools 2

2. Getting To Know Your Band Saw ............ 13

3. Basic Band Saw Operation ................. 15

4. Maintenance .............................. 16

°

Stability of Machine.

Your band saw must be bolted securely to a

work bench. In addition, if there is any tend-

ency for the band saw to tip over or move

during certain operations such as cutting

long heavy boards, bolt your workbench to

the floor.

,

Location

This band saw is intended for indoor use

only.

,

Protection: Eyes, Hands, Face, Ears, Body

a. Always wear safety goggles that comply

with ANSI Z87.1. Wear a face shield if oper-

ation is dusty. Wear ear plugs or muffs

during extended periods of operation. Do

not wear gloves, jewelry or watches, Roll

long sleeves above the elbow.

b. Do not cut pieces of material too small to

hold securely by hand.

c. Avoid awkward hand positions where a

sudden slip could cause a hand to move

into the blade.

d. Never turn your band saw "ON" before

clearing the table of all Objects (tools,

scraps of wood, etc.) except for the work-

piece and related feed or support devices

for the operation planned.

e. Make sure the blade runs downward to-

ward the table. Always adjust tracking

wheel correctly so that the blade does not

run off the wheels.

f. Always adjust blade tension correctly.

onal safety

instructions for

PAGE

n

ALWAYS adjust the upper blade guide and

g,

blade guard to just clear the workpiece to

protect the operator, to keep blade break-

age to a minimum, and to provide maxi-

mum support for blade.

h.

When cutting a large piece of material,

provide additional support at table height.

i.

Hold the work firmly against the table.

Do not feed the material too fast while cut-

j.

ting. Only feed the material fast enough so

that the blade will cut. Keep fingers away

from the blade.

k. Use caution when cutting off material

which is irregular in cross section which

could pinch the blade before the cut is

completed. A piece of molding for example

must lay flat on the table and not be per-

mitted to rock while being cut.

I. Use caution when cutting off round materi-

al such as dowel rods, or tubing. They have

a tendency to roll while being cut causing

the blade to "bite". Always clamp round

material to a miter gauge, or provide

equivalent support.

m. When backing up the workpiece, the blade

may bind in the kerf (cut)... this is usually

caused by sawdust clogging up the kerf or

because the blade comes out of the

guides. If this happens:

1. Turn off the band saw.., remove plug

from power source outlet...remove

cover from band saw. Insert a screw-

driver or wedge in the kerf.., rotate the

wheels by hand while backing up the

workpiece.

Never leave the band saw work area with

n.

the power on, before the machine has

come to a complete stop, or without re-

moving and storing the switch key.

o.

Never operate band saw with cover remov-

ed.

p.

Do not perform layout, assembly, or setup

work on the table while the blade is moving.

Turn saw "off" and remove plug from pow-

q.

er supply outlet before installing or remov-

ing an accessory.

r.

Use only RECOMMENDED ACCESSORIES

listed on page 16.

saw

additional safety instructions for

band saw

Should any part of this band saw be missing,

bend, or fail in any way, or any electrical

component fail to perform properly, shut off

power switch and remove plug from power

supply outlet. Replace damaged, missing,

and!or failed parts before resuming opera-

tion.

WARNING: DO NOT ALLOW FAMILIARITY GAINED FROM FREQUENT USE OF YOUR BAND SAW TO

BECOME COMMONPLACE. ALWAYS REMEMBER THAT A CARELESS FRACTION OF A SECOND IS

SUFFICIENT TO INFLICT SEVERE INJURY.

WEAR YOUR

9. Think Safety.

Safety is a combination of operator common

sense and alertness whenever the band saw

is in operation.

10. This band saw is designed to cut wood and

wood like products only.

The operation of any power tool can result in

foreign objects being thrown into the eyes,

which can result in severe eye damage. Always

wear safety goggles complying with ANSI Z87.1

(shown or] Package) before beginning power tool

operation. Safety Goggles are available at Sears

retail or catalog stores.

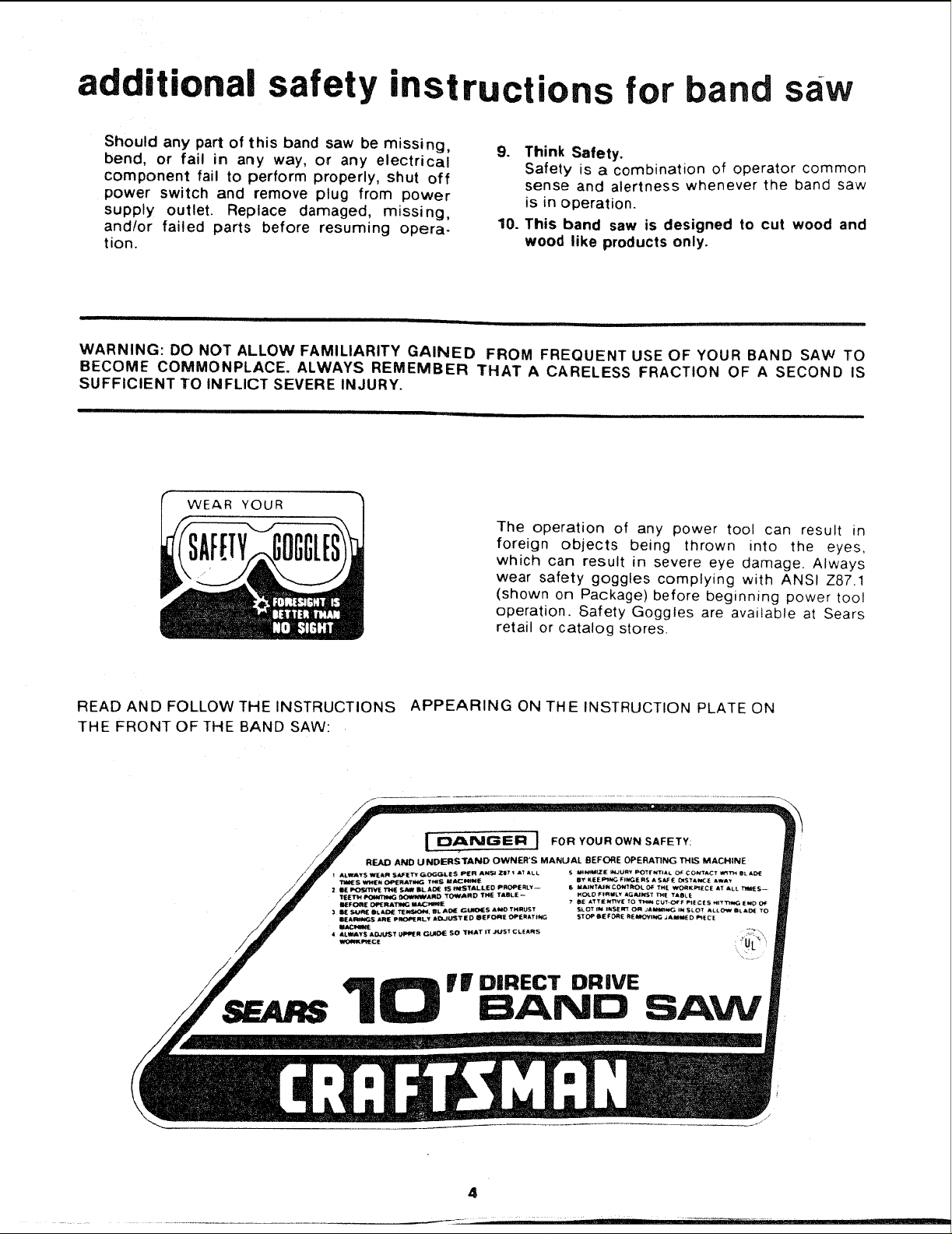

READ AND FOLLOW THE INSTRUCTIONS APPEARING ON THE INSTRUCTION PLATE ON

THE FRONT OF THE BAND SAW:

f | DIRECT DRIVE

BA D SAW

4

motor specifications

II

requirements

electrical

This machine is designed to use, and is equip-

ped with, a 1725 RPM motor. It is wired for opera-

tion on 110-120 volts, 60 Hz., alternating current.

(TOOL MUST NOT BE CONVERTED TO OPER-

ATE ON 230 VOLT).

For replacement motor refer to parts list in this

manual.

CONNECTING TO POWER SUPPLY OUTLET

This machine must be grounded while in use to

protect the operator from electric shock.

Plug power cord into a 110-120V properly ground-

ed type outlet protected by a 15-amp. fuse or cir-

cuit breaker.

If you are not sure that your outlet is properly

grounded, have it checked by a qualified electri-

cian.

WARNING: DO NOT PERMIT FINGERS TO

TOUCH THE TERMINALS OF PLUGS WHEN

INSTALLING OR REMOVING THE PLUG TO OR

FROM THE OUTLET.

WARNING: IF NOT PROPERLY GROUNDED

THIS POWER TOOL CAN CAUSE AN ELECTRI-

CAL SHOCK PARTICULARLY WHEN USED IN

DAMP LOCATIONS CLOSE TO PLUMBING. IF

AN ELECTRICAL SHOCK OCCURS THERE IS

THE POTENTIAL OF A SECONDARY HAZARD

SUCH AS YOUR HANDS CONTACTING THE

SAW BLADE.

If power cord is worn or cut, or damaged in any

way, have it replaced immediately.

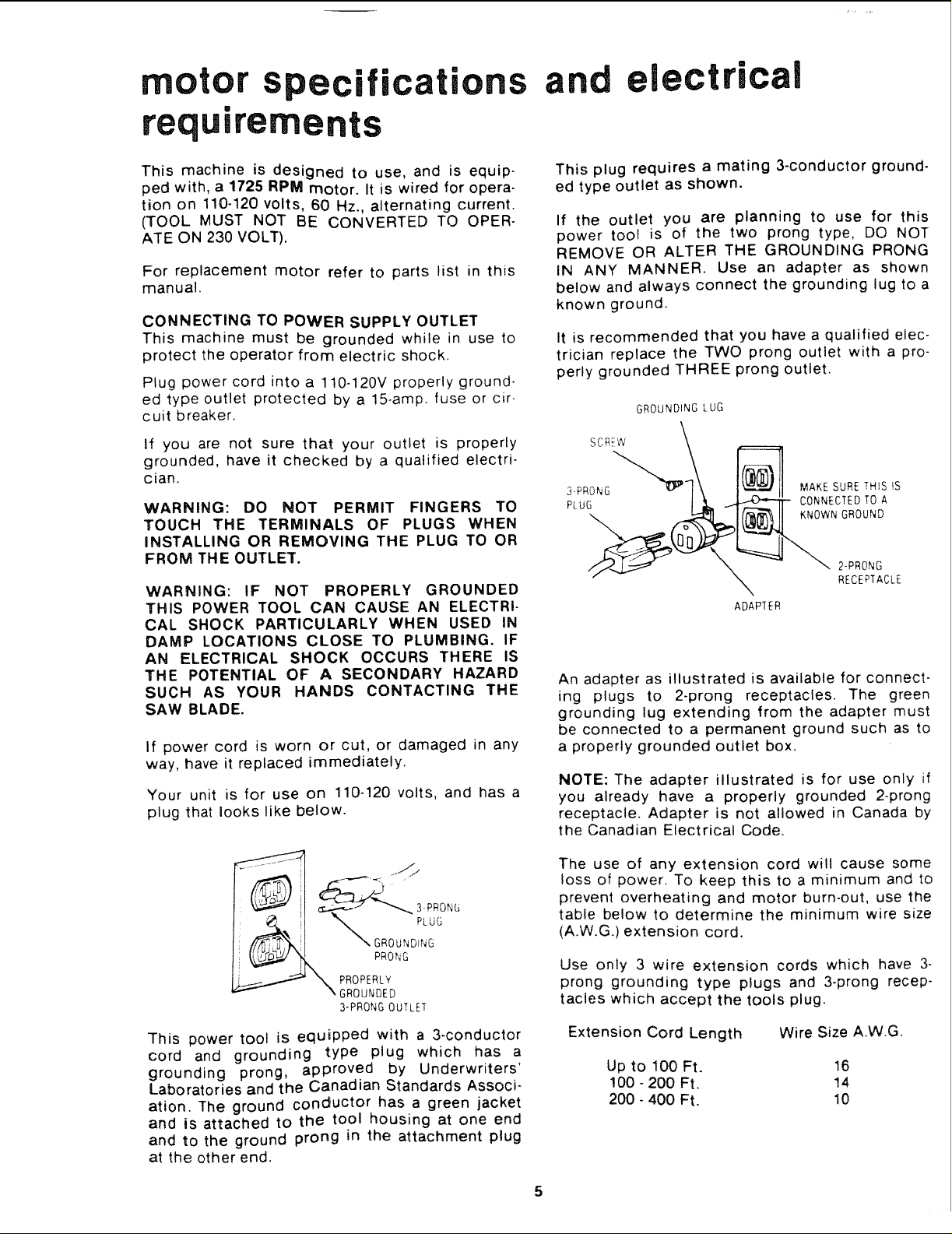

Your unit is for use on 110-120 volts, and has a

plug that looks like below.

This plug requires a mating 3-conductor ground-

ed type outlet as shown.

If the outlet you are planning to use for this

power tool is of the two prong type, DO NOT

REMOVE OR ALTER THE GROUNDING PRONG

IN ANY MANNER. Use an adapter as shown

below and always connect the grounding lug to a

known ground.

It is recommended that you have a qualified elec-

trician replace the TWO prong outlet with a pro-

perly grounded THREE prong outlet.

GROUNDING LUG

SCREW

3.PRONG_'_I_q\ _ MAKE SURE TH,S iS

ADAP]ER

An adapter as illustrated is available for connect-

ing plugs to 2-prong receptacles. The green

grounding lug extending from the adapter must

be connected to a permanent ground such as to

a properly grounded outlet box,

NOTE: The adapter illustrated is for use only if

you already have a properly grounded 2-prong

receptacle. Adapter is not allowed in Canada by

the Canadian Electrical Code.

GROUNDING

PRONG

_ PROPERLY

GROUNDED

3-PRONG OUTLET

This power tool is equipped with a 3-conductor

cord and grounding type plug which has a

grounding prong, approved by Underwriters'

Laboratories and the Canadian Standards Associ-

ation. The ground conductor has a green jacket

and is attached to the tool housing at one end

and to the ground prong in the attachment plug

at the other end.

The use of any extension cord wil! cause some

loss of power. To keep this to a minimum and to

prevent overheating and motor burn-out, use the

table below to determine the minimum wire size

(A.W.G.) extension cord.

Use only 3 wire extension cords which have 3-

prong grounding type plugs and 3-prong recep-

tacles which accept the tools plug.

Extension Cord Length Wire Size A.W.G.

Up to 100 Ft. 16

100 - 200 Ft. 14

200 - 400 Ft. 10

5

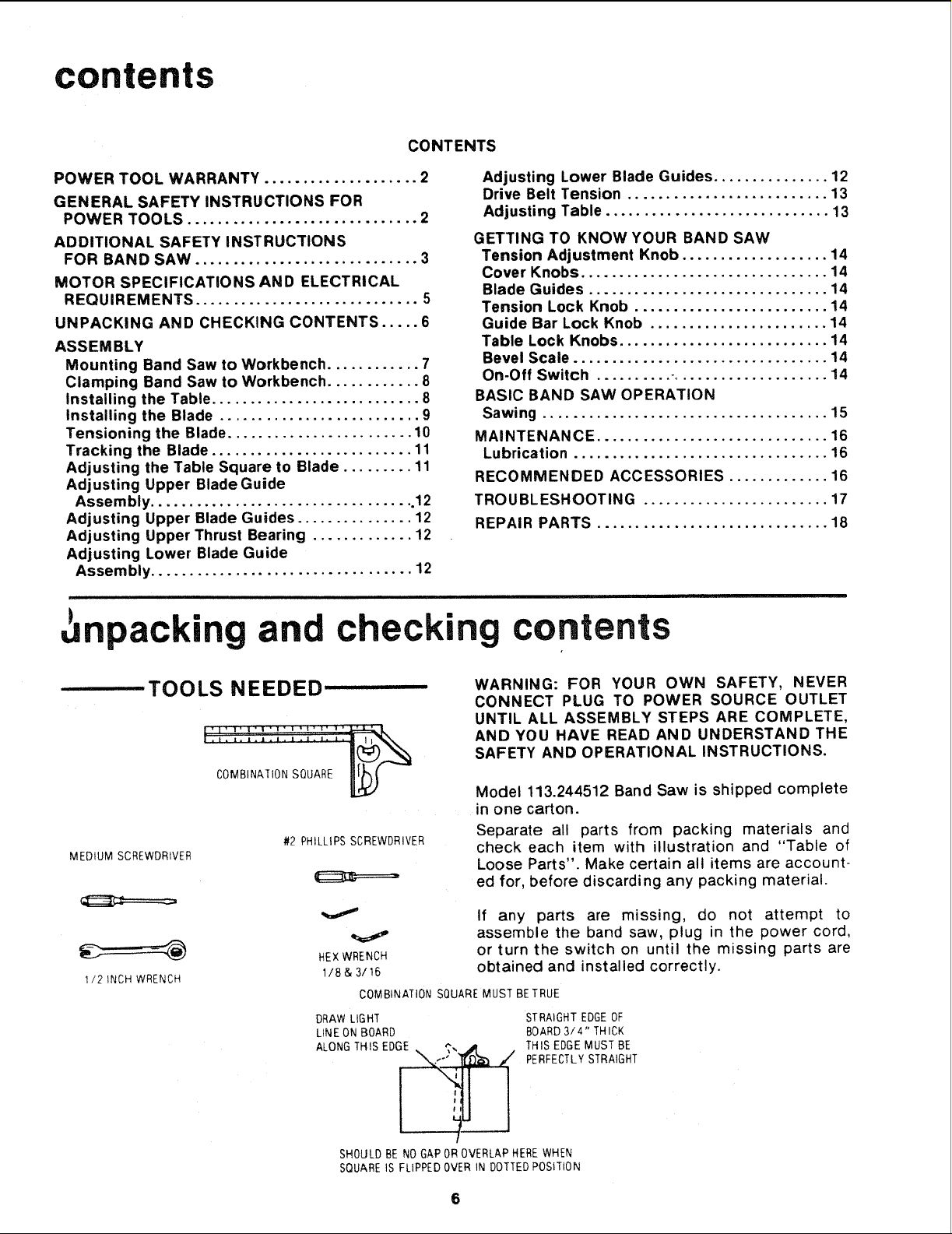

contents

CONTENTS

POWER TOOL WARRANTY .................... 2

GENERAL SAFETY INSTRUCTIONS FOR

POWER TOOLS .............................. 2

ADDITIONAL SAFETY INSTRUCTIONS

FOR BAND SAW ............................. 3

MOTOR SPECIFICATIONS AN D ELECTRICAL

REQUIREMENTS ............................. 5

UNPACKING AND CHECKING CONTENTS ..... 6

ASSEMBLY

Mounting Band Saw to Workbench ............ 7

Clamping Band Saw to Workbench ............ 8

Installing the Table ........................... 8

Installing the Blade .......................... 9

Tensioning the Blade ........................ 10

Tracking the Blade .......................... 11

Adjusting the Table Square to Blade ......... 11

Adjusting Upper Blade Guide

Assembly .................................. .12

Adjusting Upper Blade Guides ............... 12

Adjusting Upper Thrust Bearing ............. 12

Adjusting Lower Blade Guide

Assembly .................................. 12

Adjusting Lower Blade Guides ............... 12

Drive Belt Tension .......................... 13

Adjusting Table ............................. 13

GETTING TO KNOW YOUR BAND SAW

Tension Adjustment Knob ................... 14

Cover Knobs ................................ 14

Blade Guides ............................... 14

Tension Lock Knob ......................... 14

Guide Bar Lock Knob ....................... 14

Table Lock Knobs ........................... 14

Bevel Scale ................................. 14

On-Off Switch .......... -.................... 14

BASIC BAND SAW OPERATION

Sawing ..................................... 15

MAINTENANCE .............................. 16

Lubrication ................................. 16

RECOMMENDED ACCESSORIES ............. 16

TROUBLESHOOTING ........................ 17

REPAIR PARTS .............................. 18

i

, npacking and checking contents

TOOLS NEEDED

MEDIUM SCREWDRIVER

1/2 INCH WRENCH

, I, t, _,1 , 11 1 , I','li I = i(,_'_. _

COMBtNA-fION SQUARE

#2 PHILLIPS SCREWDRIVER

HEX WRENCH

118& 3/16

COMBINATIONSQUAREMUST BETRUE

DRAW LIGHT

LINE ON BOARD

ALONG THIS EDGE _.._. _ /

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET

UNTIL ALL ASSEMBLY STEPS ARE COMPLETE,

AND YOU HAVE READ AND UNDERSTAND THE

SAFETY AND OPERATIONAL INSTRUCTIONS.

Model 113.244512 Band Saw is shipped complete

in one carton.

Separate all parts from packing materials and

check each item with illustration and "Table of

Loose Parts". Make certain all items are account-

ed for, before discarding any packing material.

If any parts are missing, do not attempt to

assemble the band saw, plug in the power cord,

or turn the switch on until the missing parts are

obtained and installed correctly.

STRAIGHTEDGEOF

BOARD3/4" THICK

THIS EDGEMUSTBE

PERFECTLYSTRAIGHT

l'i l

SHOULDBE NO GAPOROVERLAPHEREWHEN

SQUARE IS FLIPPED OVER tN DOTTED POSITION

6

Loading...

Loading...