Craftsman 113244510 Owner’s Manual

SAVE TH_S MANUAL

FOR FUTURE

REFERENCE

Serial

Number

Model and serial

number may be found

at the right-hand side

of the frame.

You should record both

model and serial

number in a safe place

for future use.

CAUTION:

Read GENERAL and

ADDiTiONAL SAFETY

iNSTRUCTiONS

carefully

IO.INCH

SA

* assembly

. operating

o repair parts

ECT

IVE

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. 69182

FULL ONE YEAR WARRANTY ON CRAFTSI'_AN BAND SAW

H within one year from the date of purchase, this Craftsman Bared Saw fails due to a defect in

material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE

CENTERtDEPARTMENT THROUGHOUT THE UNITED STATES.

THiS WARRANTY APPLIES ONLY WHILE THIS PRODUCT iS USED IN THE UNITED STATES.

This warranty gives you specific legat rights, and you may also have other rights which vary from

state _o stale,

SEARS, ROEBUCK AND CO_ 698J731A, Sears Tower, Chicago, }L 60684

enera! safety instructions for power

t_ KNOW YOUR POWER TOOL

iabe_s affixed _n _he _ool Lear_ {ts ar)p_mauon

and lm],,tahons as w!}_l as 1he ::,[ec_fm ootent:ai

f'tazards pecui_af 1o tf_s too

2, GROUND ALL TOOLS

Th_'_ tOOt ___ equip'0@d ',,%qth ;_r'_ cg_DrOW:_d 3

COndUCtO_ COrd and a 3-pronq gtounom_g Wpe

pit_q to h! the proper _roundmg type rece[)tacte

The qT@et_ G_.)ndi.Jctor +n tr_e cord is the _rour++o

mq wire Never connec_ the gr_+_:,_ wire to a !lye

terminal

3. KEEP GUARDS IN PLACE

and ah(jnmen_

4. REMOVE ADJUSTING KEYS AND WRENCHES

[:Orm _ b,abH Of checkmq _ F_x? lrw]! _'v'< _ncI

adjus_ln_ wrencl_es _rx._ ren]ove(_ _orn tool

5, KEEP WORK AREA CLEAN

Chdtered areas and ben,;hen mw_e a<c_dents

F_oot must no1 be siippery due _O wax o_ saw

dUSl

6. AVOID DANGEROUS ENVIRONMENT

Drm_ u,_e t_ower tools m damp or we_ locaIions

or expose them to ram Keep work area welt

_Hjhted Provide adequate surrounding work

SDaCe

7. KEEP CHILDREN AWAY

At_ vtsdors Should I)@ kel.)t a safe dmtance horn

work area

8. MAKE WORKSHOP CHILD-PROOF

-- w_{h p(.adiocks, r]'laster S',gqtCheS. or bv r@

mowng sfader keys

9. DON'T FORCE TOOL

It w_!I do the job better arid safer at the fate for

wh<:h it was des_gnecL

10. USE RIGHT TOOL

Don't force toot of attachment to do a job _t was

not designed for.

tl, WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckhes or

jewelry _rings, wristwatches) to get caught in

moving parts NONSLIP footwear is recom.

mended. Wear protective hair covering to con-

tain !ong hair. Rot! long sleeves above the

eibow.

12. USE SAFETY GOGGLES (Head Prolection)

Wear safety goggles (must comply with ANSi

2

Z87.1) at a{! times. Everyday eyegiasses only

have ir_pact resistant lenses, they are NOT

saf_,,y 9_asses. Also. use face of dust mask _f

cul!m{:_ operation _s dusty, and ear protectors

WHUGS Or TT1Uf{S) dUi'ir_g extended periods of

opera_ ran.

13. SECURE WORK

Use cla,,r_ps or a v_se to ho!d work when practD

(;a_ It's .safer tf_ar_ us_r_f! your hand, frees both

hands tO operate tooi_

t4. DON'T OVERREACH

K.eep proper foot,rig and baiance at all times.

15. MAINTAIN TOOTS WITH CARE

Keeb tools sharp and clean for best and safest

Derforn_ance. Foitow instructions for !ubricating

and chang_ ng accessories

16. DISCONNECT TOOLS

bef<_re servicing; when changing accessories

such as blades, bits,cutters, etc.

17. AVOID ACCIDENTAL STARTING

_ake sure switch is in "OFF" posdion before

plugging in.

18. USE RECOMMENDED ACCESSORIES

(.}onsull the owner's manual for recommended

accessories Follow the instructions that

accompany the accessories. The use of im-

proper accessories may cause hazards.

19. NEVER STAND ON TOOL

Serious iniury could occur if the toot is f_pped

or if the cutting too_ is accider, taily contacted.

Do not store materials above or near the toot

such that it is necessary to stand on the tool to

reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool. a guard or other

part that is darnaged shouid be carefuily check-

ed to ensure that _t wdi operate properly and

peHorrn its intended function. Check for aligr>

rnent of rr'_oving parts, binding of moving parts_

breakage of parts, r'nount_ng, and any other con-

ditions that may affect its operation. A guard or

other part that is damaged should be properly

repaired or replaced.

21. DIRECTION OF FEED

Feed work into a blade or cutter against the

direction of rotation of the blade or cutter only.

22. NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Don't lea,_e tooi until it comes

to a complete stop.

tooJs

additional safety instructiens for band saw

Safety is a combination of operator common

sense and alertness at aii times when the band

saw is being used.

WARNING: FOR YOUR OWN SAFETY, DO NOT

ATTEMPT TO OPERATE YOUR BAND SAW

UNTIL _T IS COMPLETELY ASSEMBLED AND

INSTALLED ACCORDING TO THE iNSTRUC-

TiONS... AND UNTIL YOU READ AND UNDER-

STAND THE FOLLOWING:

PAGE

1. General Safety Instructions for Power Too_s 2

2, Getting To Know Your Band Saw ........... 13

3, Basic Band Saw Operation ................. !5

4o Maintenance .............................. 16

.

Stability of Machine.

Your band saw must be bolted securely to a

work ben, cir. In addition, if there is any tend-

ency for the band saw to tip over or move

during certain operations such as cutting

_ong heavy boards, bolt your workbench to

the floor.

6_

Location

This band saw is intended for indoor use

only.

7.

Protection: Eyes, Hands, Face, Ears, Body

a. Aiways wear safety goggles that comply

with ANSI Z87.1. Wear a face shield if oper-

ation is dusty. Wear ear plugs or muffs

during extended periods of operation. Do

not wear gloves, jewelry or watches. Roll

long sleeves above the elbow.

b. Do not cut pieces of material too small to

hold securely by hand.

c. Avoid awkward hand positions where a

sudden slip could cause a hand to move

into the blade.

d. Never turn your band saw "ON" before

clearing the table of all Objects (tools.

scraps of wood, etc.) except for the work-

piece and related feed or support devices

for the operation planned.

e. Make sure the blade runs downward to-

ward the table, Always adjust tracking

wheel correctly so that the blade does not

run off the wheels.

f. Always adjust blade tension correctly.

g ALWAYS adjust the upper blade guide and

blade g_;ard to just clear the workpiece to

protect the operator, to keep blade break-

age to a minimum, and to provide maxi-

mum support for blade.

h. When cutting a large piece of material,

provide additional support at table height.

i. Hoid the work firmly against the tabie.

j. Do not feed the material too fast while cut-

ting. Oniy feed the material fast enough so

that the blade will cut. Keep fingers away

from the blade.

k. Use caution when cutting off material

which is irregular in cross section which

could pinch the blade before the cut is

completed. A piece of molding for example

must lay flat on the table and not be per-

mitted to rock while being cut.

]. Use caution when cutting off round materi-

al such as dowet rods. or tubing, They have

a tendency to roll while being cut causing

the blade to "bite". Always clamp round

material to a miter gauge, or provide

equivalent support.

m. When backing up the workpiece, the blade

may bind in ttle kerf (cut) ... this is usually

caused by sawdust clogging up the kerr or

because the blade comes out of the

guides. If this happens:

1. Turn off the band saw. .. remove plug

from power source outtet...remove

cover from band saw. insert a screw-

driver or wedge in the kerf ... rotate the

wheels by hand while backing up the

workpiece.

n. Never leave the band saw work area with

the power on, before the machine has

come to a complete stop. or without re-

moving and storing the switch key.

o. Never operate band saw with cover remov-

ed.

p. Do not perform layout, assembly, or setup

work on the table while the biade is T,-noving.

q. Turn saw "off" and remove plug from pow-

er supply outlet before installing or remov-

ing an accessory.

r. Use only RECOMMENDED ACCESSORIES

listed on page 16.

3

additional safety instructions for band saw

.

Should any part of this band saw be m_ssing,

bend. or fail in any way, or any electrical

component fai! to perform properly, shut off

power switch and remove plug from power

supply outlet. Replace damaged, missing,

and/or failed parts before resuming opera-

tion.

_ J _ __ _ ..............

WARNING: DO NOT ALLOW FAMILIARITY GAINED FRO_ FREQUENT USE OF YOUR BAND SAW TO

BECOME COMMONPLACE. ALWAYS REMEMBER THAT A CARELESS FRACTUON OF A SECOND IS

SUFFICIENT TO INFLICT SEVERE INJURY.

9. Think Safety.

Safety is a combination of operator common

sense and alertness whenever the band saw

is in operation.

10. This band saw is designed to cut wood and

woed like products only.

I 1

The operation of any power tool can result in

foreign objects being thrown into the eyes,

which can result in severe eye damage. Always

wear safety goggles complying with ANSI Z87.1

(shown on Package) before beginning power tool

operation. Safety Goggles are available at Sears

retail or catalog stores.

READ AND FOLLOW THE INSTRUCTIONS APPEARING ON THEJNSTRUCTION PLATE ON

THE FRONT OF THE BAND SAW:

! D,O_I_JGER '1 FOR YOUR OWN SAFETY:

READ AND UNDERSTAND OWNER'S MANUAL BEFORE OPERATING THIS MACHINE:

1, ALWAYS WEAR SAFETY GOGGLES PER ANSI 7.87.1 AT ALL S, MINIMIZE INJURY POTENTIAL OF CONTACT WITH BLADE

TIMER WHEN OPERATING THIS MACHINE. BY KEEPING FINGERS A SAFE DISTANCE AWA'L

2. BE POSAT1VE THE SAW BLADE iS NSTALLEO PROPERLY-- 6, MAINTAIN CONTROL OF THE WORKPIECE AT ALL TIMES--

TEETH POeRTING DOWNWARD TOWARD THE TABLE-- HOLD FIRMLY AGAINST THE TABLE.

BEFORE OPERATING MACHINE. 7. BE ATTENTIVE TO THIN CUT-OFF PIECES HITTING END OF

3. ME SURE BLADE TENSION, BLADE GUIDES AND THRUST SLOT IN iNSERT, OR JAMMING IN SLOT. ALLOW BLADE TO

BEARINGS ARE PROPERLY ADJUSTED BEFORE OPERATING STOP BEFORE REMOVING JAMMED PIECE.

MACHINE

4. ALWAYS ADJUST UPPER GUIDE SO THAT IT JUST CLEARS _.._ _,÷._

WORKPIECE

f| DIRECT DRIVE

EJANI:3 SAW

motor speci ications

requirements

and electrical

This machine is designed to use, and is equip-

ped with, a 1725 RPM motor. It is wired for opera-

tion on 110-120 volts, 60 Hz., alternating current.

(TOOL MUST NOT BE CONVERTED TO OPER-

ATE ON 230 VOLT).

For replacement motor refer to parts list in this

manual.

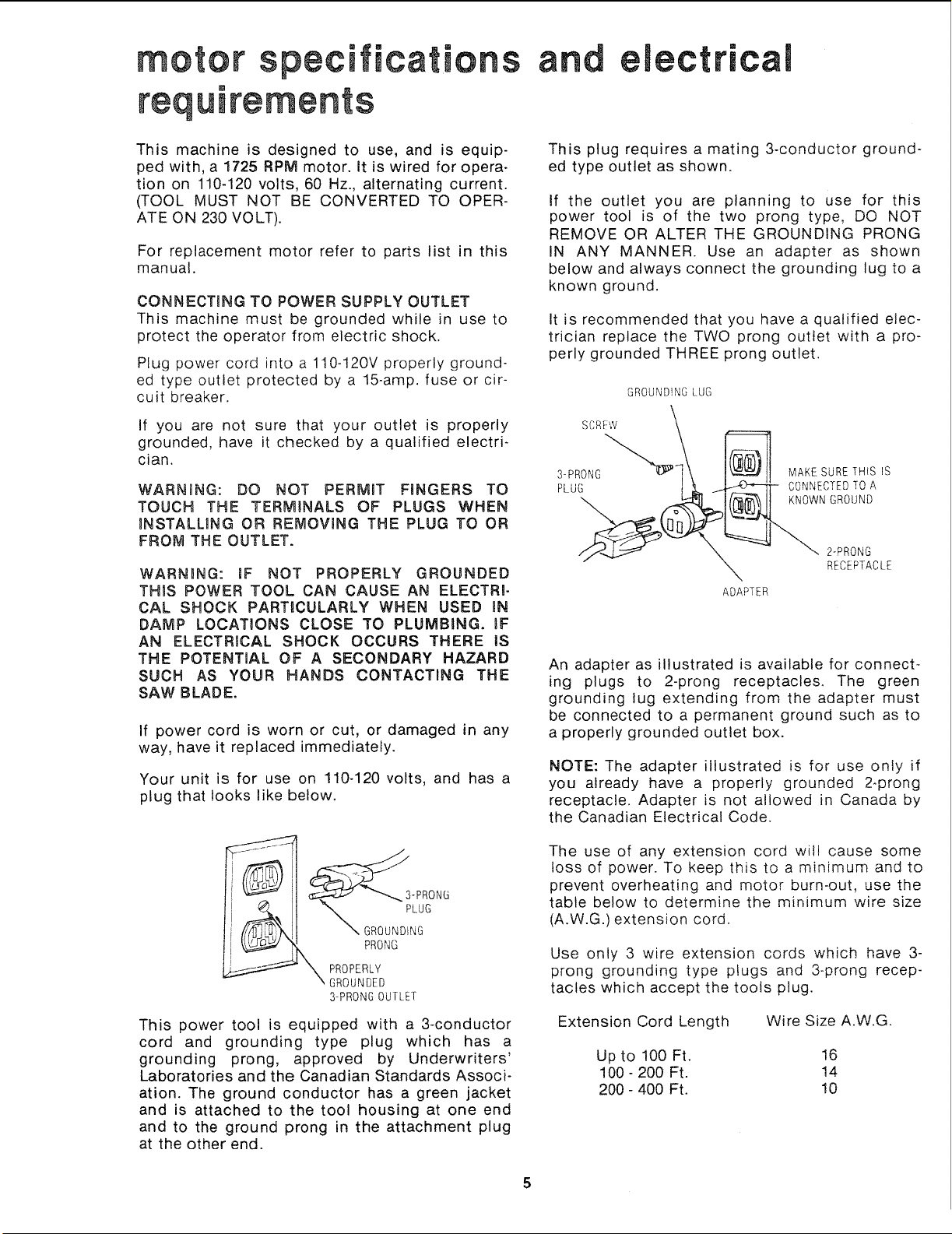

CONNECTING TO POWER SUPPLY OUTLET

This machine must be grounded while in use to

protect the operator from electric shock.

Plug power cord into a 110-120V properly ground-

ed type outlet protected by a 15-amp. fuse or cir-

cuit breaker.

If you are not sure that your outlet is properly

grounded, have it checked by a qualified electri-

cian.

WARNING: DO NOT PERMIT FINGERS TO

TOUCH THE TERMINALS OF PLUGS WHEN

iNSTALLING OR REMOVING THE PLUG TO OR

FROM THE OUTLET.

WARNING: IF NOT PROPERLY GROUNDED

THiS POWER TOOL CAN CAUSE AN ELECTRI-

CAL SHOCK PARTICULARLY WHEN USED IN

DAMP LOCATIONS CLOSE TO PLUMBING. BF

AN ELECTRICAL SHOCK OCCURS THERE IS

THE POTENTIAL OF A SECONDARY HAZARD

SUCH AS YOUR HANDS CONTACTING THE

SAW BLADE.

If power cord is worn or cut, or damaged in any

way, have it replaced immediately.

Your unit is for use on 110-120 volts, and has a

plug that looks like below.

This plug requires a mating 3-conductor ground-

ed type outlet as shown.

If the outlet you are planning to use for this

power tool is of the two prong type, DO NOT

REMOVE OR ALTER THE GROUNDING PRONG

IN ANY MANNER. Use an adapter as shown

below and always connect the grounding lug to a

known ground.

It is recommended that you have a qualified elec-

trician replace the TWO prong outlet with a pro-

perly grounded THREE prong outlet.

GROUND!NG LUG

SCR_:W \

-- _ RECEPTACLE

ADAPTER

An adapter as illustrated is available for connect-

ing plugs to 2-prong receptacles. The green

grounding lug extending from the adapter must

be connected to a permanent ground such as to

a properly grounded outlet box.

NOTE: The adapter illustrated is for use only if

you already have a properly grounded 2-prong

receptacle. Adapter is not allowed in Canada by

the Canadian Electrical Code.

3-PRONG

PLUG

GROUNDING

i

\

This power tool is equipped with a 3-conductor

cord and grounding type plug which has a

grounding prong, approved by Underwriters'

Laboratories and the Canadian Standards Associ-

ation. The ground conductor has a green jacket

and is attached to the tool housing at one end

and to the ground prong in the attachment plug

at the other end.

PR0i'4G

PROPERLY

GROUNDED

3-PRONGOUTLET

The use of any extension cord will cause some

loss of power. To keep this to a minimum and to

prevent overheating and motor burn-out, use the

table below to determine the minimum wire size

(A.W.G.) extension cord.

Use only 3 wire extension cords which have 3-

prong grounding type plugs and 3-prong recep-

tacles which accept the tools plug.

Extension Cord Length Wire Size A.W.G.

Up to 100 Ft. 16

100 - 200 Ft. 14

200 - 400 Ft. 10

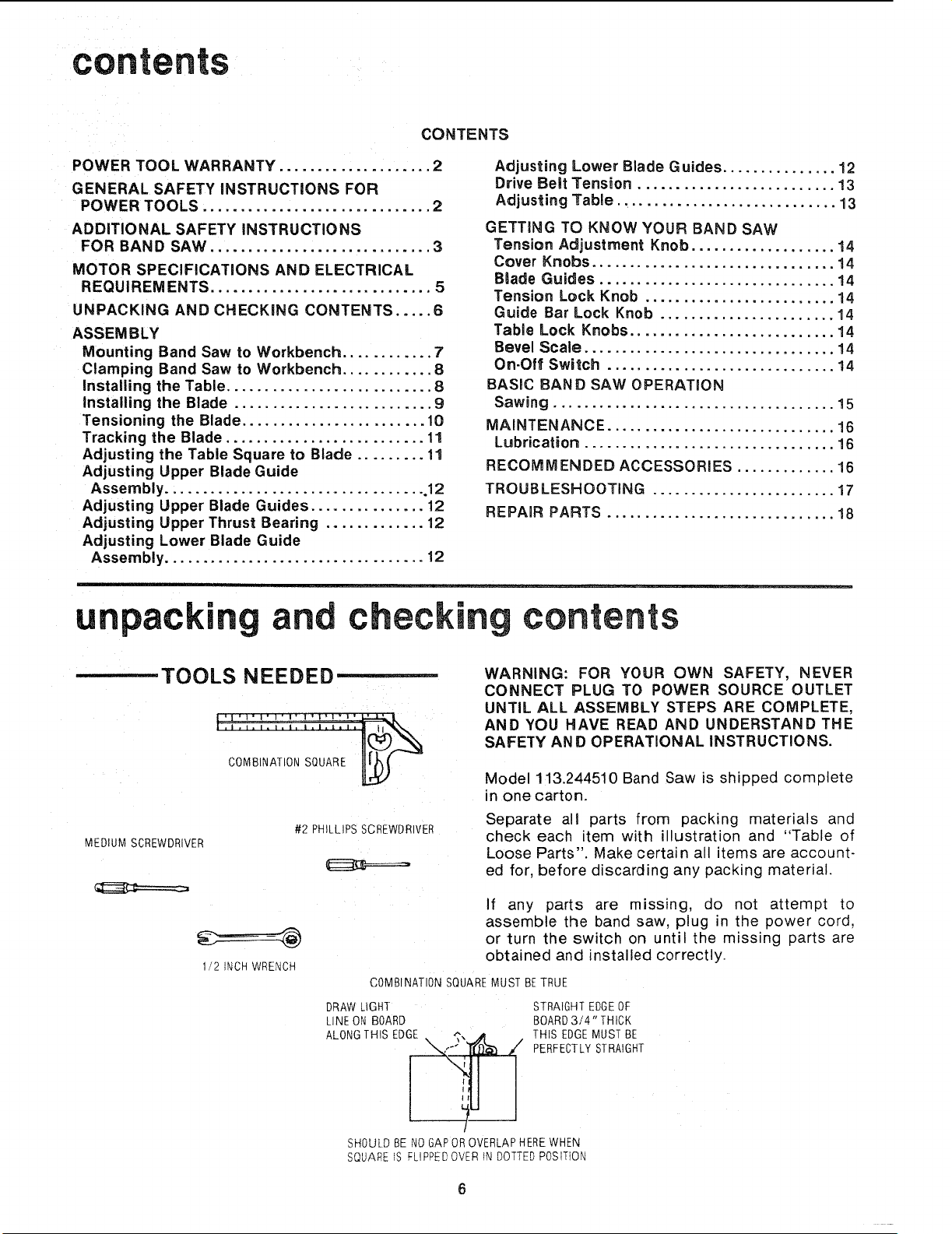

contents

CONTENTS

POWER TOOL WARRANTY .................... 2

GENERAL SAFETY iNSTRUCTIONS FOR

POWER TOOLS .............................. 2

ADDITIONAL SAFETY INSTRUCTIONS

FOR BAN D SAW ............................. 3

MOTOR SPECIFICATIONS AND ELECTRICAL

REQUIREMENTS ............................. 5

UNPACKING AND CHECKING CONTENTS ..... 6

ASSEMBLY

Mounting Band Saw to Workbench ............ 7

Clamping Band Saw to Workbench ............ 8

Installing the Table ........................... 8

Installing the Blade .......................... 9

Tensioning the Blade ........................ 10

Tracking the Blade .......................... 11

Adjusting the Table Square to Blade ......... 11

Adjusting Upper Blade Guide

Assembly .................................. .12

Adjusting Upper Blade Guides ............... 12

Adjusting Upper Thrust Bearing ............. 12

Adjusting Lower Blade Guide

Assembly .................................. 12

Adjusting Lower Blade Guides ............... 12

Drive Belt Tension .......................... 13

Adjusting Table .............................. 13

GETTING TO KNOW YOUR BAND SAW

Tension Adjustment Knob ................... 14

Cover Knobs ................................ 14

Blade Guides ............................... 14

Tension Lock Knob ......................... 14

Guide Bar Lock Knob ....................... 14

Table Lock Knobs ........................... 14

Bevel Scale ................................. 14

On-Off Switch .............................. 14

BASIC BAND SAW OPERATION

Sawing ..................................... 15

MAINTENANCE .............................. 16

Lubrication ................................. 16

RECOMMENDED ACCESSORIES ............. 16

TROUBLESHOOTING ........................ 17

REPAIR PARTS .............................. 18

unpackin and checking contents

TOOLS NEEDED

I _] ' • I" I' I" I' l_l_ I '

,I , I, I. I1 I, I1 IILi li

COMBINATION SQUARE

MEDIUM SCREWDRIVER

1/2 NCH WRENCH

#2 PHILLIPSSCREWDRIVER

COMBINATIONSQUAREMUST BETRUE

DRAWLIGHT

LINEON BOARD

ALONG[HiS EDGE _,

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET

UNTIL ALL ASSEMBLY STEPS ARE COMPLETE,

AND YOU HAVE READ AND UNDERSTAND THE

SAFETY AN D OPERATIONAL INSTRUCTIONS.

Model 113.244510 Band Saw is shipped complete

in one carton.

Separate all parts from packing materials and

check each item with illustration and "Table of

Loose Parts". Make certain all items are account-

ed for, before discarding any packing material.

If any parts are missing, do not attempt to

assemble the band saw, plug in the power cord,

or turn the switch on until the missing parts are

obtained and installed correctly.

STRAIGHTEDGEOF

BOARD3/4" THICK

THIS EDGEMUSTBE

PERFECTLYSTRAIGHT

SHOULDBE NOGAPOROVERLAPHEREWHEN

SQUAREiS FLIPPEDOVERINDOTTEDPOSITION

Loading...

Loading...