f ManuQi._, _

Save This

For Future Reference

owners

MODEL NO.

115o244500

10-1NCH BAND SAW

Serial

Number

Model and serial numbers

may be found on the back

of the saw.

You should record both

model and serial number in

a safe place for future use,

FOR YOU

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY

® assembly

o operating

® repair paffs

J

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.SoA.

Part No, SP5492 printed in Taiwan

FULL ONE YEAR WARRANTY ON CRAFTSMAN BAND SAW

If within one year from the date of purchase, this Craftsman Band Saw fails due to a defect in

materia! or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERV-

iCE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty applies only while this product is used in the United States.

This warranty gives you specific legal dghts, and you may also have other rights which vary

from state to state.

SEARS, ROEBUCK AND CO., Dept. 698/731 A, Sears Tower, Chicago, IL 60684

Safety instructions for Band Saw

Safety _s a combinatfon of common sense, staying

alert and knowing how your band saw WORKS.Read

this manual to understand this saw.

BEFORE USING THE SAW:

serious, permanent iniury, do not plug the saw

I ARNING: To avoid mistakes that could cause I

in until the following steps are completed.

• Assembly ana alignment ISee pages 7-12).

WARNING

i, i

WHEN INSTALLING OR MOVING THE SAW.

AVOID DANGEROUS ENVIRONMENT. Use the saw

in a dry, indoor place protected from rain, Keep work

area well lighted.

To avoid injury from unexpected saw movement:

* Put the saw on a firm level surface where there is

plenty of room for handling and properly support-

ing the workpiece.

- Support the saw so the table is level and the saw

does not rock.

o Bolt the saw to the support surface if it tends to

slip, Watk, or slide during operations like cutting

tong, heavy beards.

- Turn saw off and unplug cord before moving the

saw,

To avoid injury or death from electrical shock:

* GROUND THE SAW. This saw has an approved

3-conductor cord and a 3-prong grounding type

plug. Use only 3-wire, grounded outlets rated

!20 volts, 15 amperes (amps). The green con-

ductor in the cord is the grounding wire. To avoid

electrocution, NEVER connect the green

wire to a live terminal.

Learn the use and function of the ON-OFF

switch, table lock knob. blade guides, backup

bearings, upper slide lOCKknoo. blade guard,

tension catch, and tracking screw. (See pages

13 & 14")

Review and understand al of the safety instruc-

tion and ooerating proceaures n this manual.

Review the maintenance methods for this saw.

(See page 187

Read the following WARNING labels found on the

front of the saw:

DANGER

o Make sure your fingers do not touch the plug's

metal prongs when plugging or unplugging the

saw'.

NEVER STAND ON TOOL, Serious injury could

occur if the tool tips or you accidentally hit the cutting

tool. Do not store anything above or near the tool

where anyone might stand on the tool to reach them.

BEFORE EACH USE:

Inspect your saw.

DISCONNECT THE SAW. To avoid injury from acci-

dental starting, unplug the saw, turn the switch off

and remove the switch key before changing the

setup, opening covers, removing guards, or blade.

CHECK FOR DAMAGED PARTS. Check for:

• alignment of moving parts,

• binding of moving parts,

• broken parts,

• stable mounting, and

• any other conditions that may affect the way the

saw works,

If any part is missing, bent, or broken in any way, or

any electrical part doesn't work properly, turn the saw

off and unplug the saw. REPLACE damaged, miss-

ing, or failed parts before using the saw again.

MAINTAIN TOOLS WITH CARE. Keep the saw clean

for best and safest performance. Follow instructions

for lubricating.

REMOVE ADJUSTING KEYS AND WRENCHES

from tool before turning it on.

Dress for safety.

WEAR YOUR _'_

I

To avoid injury from jams, slips or thrown pieces:

• Choose the right size and style blade for the

material and the type of cutting you plan to do.

. USE ONLY RECOMMENDED ACCESSORIES.

(See page 18). Consult this owner's manual for

recommended accessories. Follow the instruc-

tions that come with the accessories. The use of

improper accessories may cause risk of injury to

persons.

= Make sure the blade teeth point downward,

toward the table.

o Make sure the blade guides and thrust bearings

are properly adjusted.

, Make sure the blade tension is properly adjusted.

• Make sure the table lock knob is tight and no

parts have excessive play.

, To avoid accidental blade contact, minimize

blade breakage and provide maximum blade

support, always adjust the upper blade guide and

blade guard to just clear the workpiece.

, KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents. Floor must not be

slippery.

To avoid burns or other fire damage, never use the

saw near flammable liquids, vapors or gases.

PJan ahead to protect your eyes,

hands, face, ears.

KNOW YOUR SAW. Read and understand the

owner's manual and labels affixed to the tool. Learn

its application and limitations as wel! as the specific

potential hazards peculiar to this tool.

To avoid injury from accidental contact with moving

parts, don't do layout, assembly, or setup work on the

saw while any parts are moving.

AVOID ACCIDENTAL STARTING. Make sure switch

is "OFF" before plugging saw into a power outlet.

Plan your work.

. USE THE RIGHT TOOL. Don't force tool or

attachment to do a job it was not designed to do.

, Use this band saw to cut only wood, wood like

products, and plastics.

Any power saw can throw foreign objects into the

eyes. This can cause permanent eye damage. Wear

safety goggles (not glasses) that comply with ANSI

Z87.1 (shown on package). Everyday eyegiasses

have only impact resistant lenses. They are not safe

ty glasses. Safety goggles are available at Sears

retail catalog steres. Glasses or goggles not in com-

pliance with ANSI Z87.1 could seriously hurt you

when they break.

• Do not wear loose clothing, gloves, neckties or

jewelry (rings, wrist watches). They can get

caught and draw you into moving parts.

, Wear nonslip footwear.

• Tie back long hair.

o Roli long sleeves above the elbow.

• Noise levels vary widely. To avoid possibTe hear-

ing damage, wear ear plugs or muffs when using

your saw for hours at a time.

o For dusty operations, wear a dust mask along

with the safety goggles.

inspect your workpiece.

Make sure there are no nails or foreign objects in the

part of the workpiece to be cut.

Use extra caution with large, very small or awk-

ward workpieces:

, Use extra supports (tables, saw horses, blocks,

etc.) for any workpieces large enough to tip when

not held down to the table top.

• NEVER use another person as a substitute for a

tab!e extension, or as additional support for a

workpiece that is longer or wider then the basic

saw table, or to help feed, support or pull the

workpiece.

o When cutting irregularly shaped workpieces, plan

your work so it will not pinch the blade. A piece

of molding for example, must iay flat or be held

by a fixture or jig that wilt not iet it twist, rock or

slip while being cut.

•Properiy support round material such as dowel

rods, or tubing. They have a tendency to roll dur*

ing a cut, causing the blade to "bite". To avoid

this, always use a 'W' block or clamp the work to

the miter gage.

Cut only one workpiece at a time.

- Clear everything except the workpiece and relat-

ed support devices off the table before turning

the saw on.

P_an the way you will hold tt_e wo_kpiece from

start to fin{sh,

DO no_ hand _o!d o_ece_; so sma_ ma_ your fingers

writ gO u:}der ttse b_ade cJar(_ [_se Hgs or ti×tures to

hold the work add _,_._eoveu,' har_ds awsJ ;rein ttte

blade

Avoid awkward :.,Derat_oqs ann tsand oo5;[_or}s where

a g_JOdefi s_p COL£d cause hngers or r}af_d 1o move

_n_othe Made

DON'T OVERREACH t',eeD qo_ foot,n? asd balance

WHENEVER SAW IS RUNN|NG.

WARNING: Dent let familiarity (gamed from

l'requent use of your band sawJ cause a

second is enough to cause a severe _njury.

L careJess mistake. A careaess fraction of a

Before sta_r_g ,,cx,,rcal watch it1<-:._.;awwn,le/f r_J;_Sit i

makes an u_afis_i_ar n@se or vibrates a lot stop _rTl[l_e

Oaleiy Turn the saw off Unplug tl_e saw Do r_ot restart

untd hnding and correcting the problem.

KEEP CHILDREN AWAiY Keep all ws_tom a :,are @s

tance from the saw. Make sure bystandem _e elea_ of

the saw and workpiece

DON% FORCE TOOL. !t wiU do the job better and safer

at its designed rale Feed the wo_kpiece _nfo the saw

blade only fast enough to let it cur w_thout bog@rig

down or b_nding.

Before free_,ng any iammed materiah

- rum _w_tch 'OFF'L

• Remove sw_tch key

- {Jnp_ug the saw.

- Wa_t for aH moving parts to stop.

When backing up lhe workpiece, the blade may

bind in the kerr (cut). This is usually caused by

sawdust clogging up the kerr or because the

b_ade comes out of the guides, ff this happens:

]-urn switc} 'OFF"

Remove switch key.

Un_!uq saw.

W_;_H_or aU mowng parts .to stop

Or_en eand saw cover

Sbck flat biade screwdriver or wedge into the

kerr

- hm_ me t;pper whee, by hand while backing up

_t-_ wor_ pete

Before removing toose pieces from the table, turn

saw off and wait for all moving paris to stop.

BEFORE LEAVING THE SAW:

W,:_Hfor aHr-t:ovin(; parts to stoo

Make workshop cr_ild proo_. Lock the shop.

Dmcor'nect m>_ste_ switc._es Remove the yellow

sw,tch key. Sto_e _ta_,vay from chi:drer_ a,_d others not

quatiSed to t,'se ti_e re,hi

g ossary of terms for woodworking

Beveling

An angle cutting ope_atim_ through the _ace of the

board.

Crosscu_

A cutting operation made across the width of the

workpiece

Compound Cutting

A simultaneous bevet and miter cutting operation.

FPM

Feet per minute. Used in reference to surface speed

of blade.

Freehand (as used for band saw)

Performing a cut without the workpiece properly sup.,

ported on the work table.

Gum

A sticky., sapbased residue from wood products

Kerr

The ma_eriai removed by the blade in a tl_rough cut or

the SlOt produced by the btade in a nor_-through or

partJa_ cut

Lead_ng Er._d

The end of the workpiece whici_ is pushed into the

cutting tooi first

_teri_g

An angte cutting operation rnade across the width of

the workpiece.

Push Slick

A device used to teed the workpiece tSrou_h the saw

during hallow _ppi_q:_ type op_ratior_s so the opera-

tor's hands a;e kept wO]} away from t!e biade.

Resaw

A culling operatior_ to red_ce the th ckness of the

workpiece to make th r_ner pieces

Resin

A sticky, sap.based subslance that has dried.

Ripping

A cutting op_wation along the ier',gth, of the workpiece.

Sawbiade Path

The area of the worktabie or workpiece d rectly in !ine

with the saw biade

Set

[he distance ti_e tip of the saw biade tooth is bent

outward from the face of the b_ade

Tracking

Adlusting the upper wheel so t_e bandsaw blade runs

in the center of ti_e whee!s.

Trai_ng End

1he workpiece end iast cut by the saw blade.

Workpieee

The item on which the cuSing operation is being per-

formed. The surfaces of a workpiece are commonly

referred to as faces, ends, and edges.

Worktable

The surface on which the workpieee rests while per-

forming a cutting operation.

re@tot specifications and e ectrica 8quirem÷nts

This machine is designed to use, and is equipped with,

a 1725 RP_ motor, tt is wired for operation on 120

volts, 60 Hz., alternating current. (TOOL MUST NOT

BE CONVERTED TO OPERATE ON 230 VOLT).

For replacement motor refer to parts list in this manual.

CONNECTING TO POWER SUPPLY OUTLET

This machine must be grounded while in use to protect

the opera,or from electric shock.

Plug power cord into a !20V properly grounded type

outlet protected by a 15-amp. fuse or circuit breaker.

if you are not sure that your outlet is properly grounded,

have it checked by a qualified eiect_rician.

terminals of p_ugs when insta_ing or removing

( WARNING: Do not permit fhgers to ta_Jch the

the p_ug to or from the out_et.

WARNING: _fnot propeF[y grounded this power

tool can cause an e_ectrica_ shock, particu{ar_y

when used in damp locations close to plumbing,

ff an electriea_ shock occurs there is the potentia_

of a secondary hazard such as your hands con-

tacting the saw blade.

S

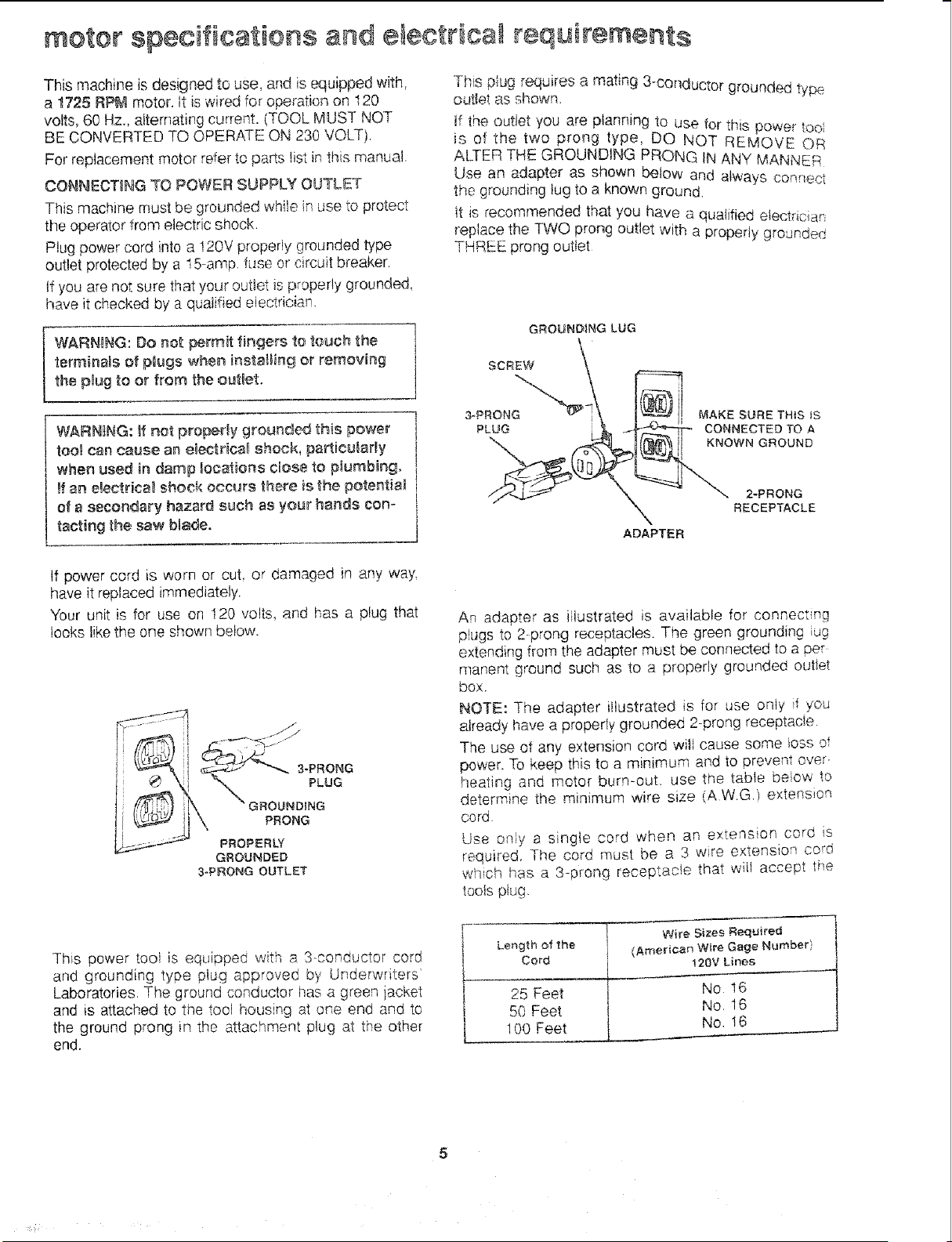

his Dug requires a mating 3-conductor ground6_ typ_

out{or as shown.

If the outlet you are planning to use for this power tool

is of the two prong type, DO NOT REMOVE OR

ALTER THE GROUNDING PRONG tn ANY MANNER

Use an adapter as shown below and always connect

the grounding lug to a known ground.

tt is recommended that you have a qualified electrician

replace the TWO prong outlet with a property grounded

THREE prong outiet

GROUNDING LUG

\

SCREW \

iI

, ... i% .C oo,o

2-PRONG

/'//_ X "\ RECEPTACLE

"k

ADAPTER

if power cord is worn or cut, or damaged in any way,

have it replaced immediately.

Your unit is for use on I20 volts, and has a plug that

looks likethe one shown below.

i _ _-tt//

t \! "-,,\ ...... PLUG

ti\ P oNe

_LT__._.:::_/ PROPERLY

This power tooi is equipped with a 3 conductor cord

and grounding type plug approved by Underwriters'

Laboratories. The ground conductor has a green jacket

and is attached to the tool housing at one end and to

the ground prong in the attachment plug at the other

end.

GROUNDED

3-PRONG OUTLET

An adapter as iilustrated is available for connecSng

p!ugs to 2-prong receptacles. The green grounding iu9

extending from the adapter must be connected to a pe_

manent ground such as to a properly grounded outlet

bOX.

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacie.

The use of any extension cord will cause some ioss of

power. To keep this to a m_nimum and to prevent over

heating and motor burn-out, use the table beiow to

determine the minimum wire size (A W.G.) extension

cord.

Use only a single cord when an extension cord is

required. The cord must be a 3 w_re ex_ensio_ cord

which has a 3-prong receptacle that will accept the

tools p!ug.

Wire Sizes Required

Length of the (AmeriCan Wire Gage Number)

Cord I 12or Lines

25 Feet No !6

50 Feet No. 16

100 Feet No. !6

contents

POWER TOOLWARRANTY.................. 12

SAFETY iNSTRUCTiONS FOR BAND SAW, .......... 2

GLOSSARY OF TERMS FOR WOODWORKING .....4

MOTOR SPECIFICAT ON..> AND ELECTRICAL

REQUIREMENTS .............................................. 5

UNPACKING AND CHECKING CON_rENTS ......... ;,6

ASSEMBLY

Mounting Band Saw to Workbench ...................... 7

lnstalI _g the Tabie ............................... 8

Installing !he Blade ...................................... 9

_ens!o,n_ng ,t_e Btade ............................ i 0

Trackir_g the B_ade

'" ', ................................. 11

BASIC BAND SAW OPERATION ....................... 16

MAINTENANCE ..................................................... 19

RECOMMENDED ACCESSORIES ....................... 19

TROUBL ESHOOTING ........................................ 20

REPAIR PARTS .................................................... 21

unpacking and checking contents

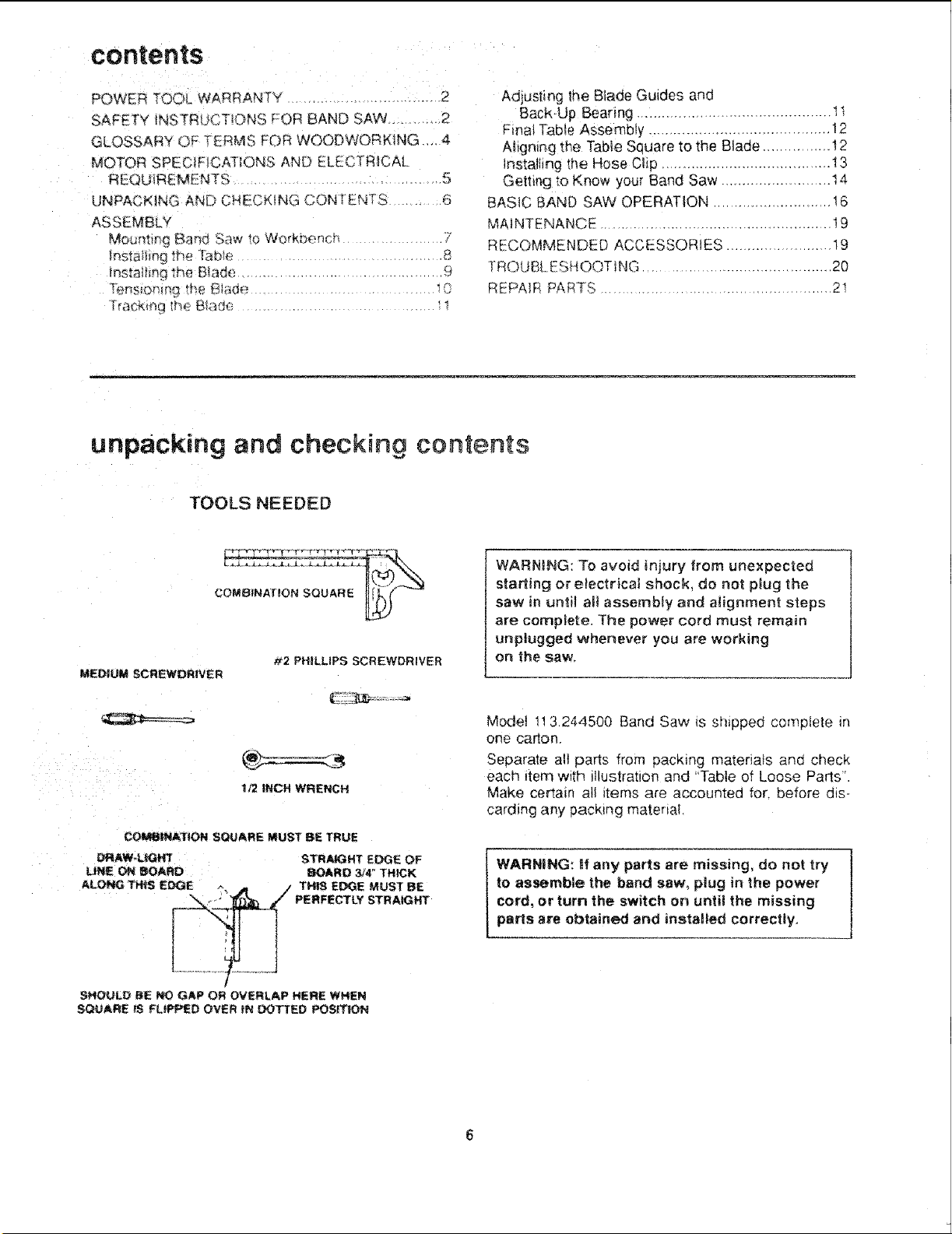

TOOLS NEEDED

Adiusting the Blade Guides and

Back.Up Bearing .............................................. 11

Final Tabie Assembly ........................................... 12

Aligning the Tab!e Square to the Blade .............. 12

Instaliing the Hose Clip ...................................... 13

Getting to Know your Band Saw ......................... 14

oo.B.,.o,so .R tithe--

#2 PHILLtPS SCREWDRIVER

MEDIUM SCREWDRIVER

COMB|N&TtONSQUAREMUST BE TRUE

_AW+Lt_HT STRAIGHTEDGEOF

LINE ON_ARD BOARD 314"THICK

SH4_JLD BE NO GAP OR OVERLAP HERE WHEN

_UARE tS FLtPPED OVER tN DOTTED POSi<T1ON

WARNING: To avoid injury from unexpected

staring or electrical shock, do not plug the

saw in unlil all assemMy and alignment steps

are complete. The power cord must remain

unplugged whenever you are working

on the saw,

Model 113.244500 Band Saw is shipped complete in

one carton.

Separate all parts from packing materials and check

each item with illustration and "Table of Loose Parts".

Make certain atl items are accounted for. before dis-

carding any packing material,

WARNING: if any parts are missing, do not try

to assemble the band saw, plug in the power

cord, or turn the switch on until the missing

parts are obtained and installed correctly.

....% j

assembly

--w

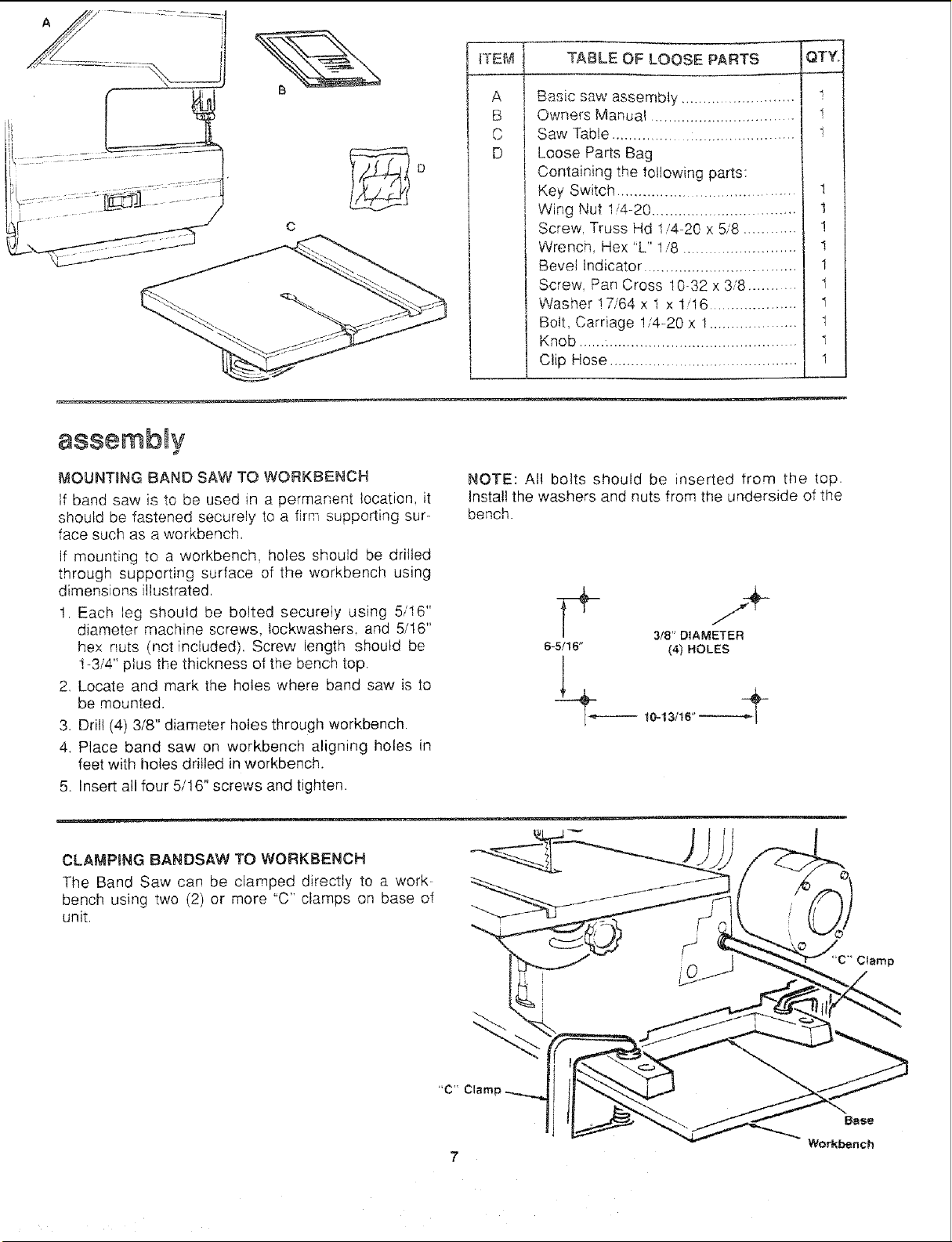

_TEf_

A

B

C

D

TABLE OF LOOSE PARTS

Basic saw assembly ..........................

Owners Manual .................................

Saw Table ................. :......................

Loose Parts Bag

Containing the following parts:

Key Switch .......................................

Wing Nut IJ4-20 .................................

C

Screw, Truss Hd I/4-20 x 5/8 ............

Wrench, Hex "L" 1/8 ........................

Bevei Indicator ..................................

Screw Pan Cross 1032 x 3/8 ...........

Washer !7/64 x 1 x 1/16 ....................

Bolt, Carriage 1/4-20 x 1....................

Knob ......: .........................................

Clip Hose .......................................

11

MOUNTING BAND SAW TO WORKBENCH

If band saw is to be used in a permanent location, it

should be fastened securely to a firm supporting sur-

face such as a workbench.

If mounting to a workbench, holes should be drilled

through supporting surface of the workbench using

dimensions illustrated,

1. Each leg should be bolted secureiy using 5/t6"

diameter machine screws, tockwashers, and 5/16"

hex nuts (not included). Screw length should be

1-3/4" plus the thickness of the bench top.

2, Locate and mark the holes where band saw is to

be mounted.

3. Drill (4) 3/8" diameter holes through workbench.

4. Place band saw on workbench aligning holes in

feet with holes driiled in workbench.

5. Insert all four 5/16" screws and tighten.

CLAMPING BANDSAW TO WORKBENCH

The Band Saw can be clamped directly to a work-

bench using two (2) or more 'C" clamps on base of

unit.

NOTE: All bolts should be inserted from the top.

Install the washers and nuts from the underside of the

bench.

"_ 3/8" DtAMETEJ_R+

6-5/16" (4) HOLES

'_'------- 16-13/16"

Base

Workbench

7

assembly

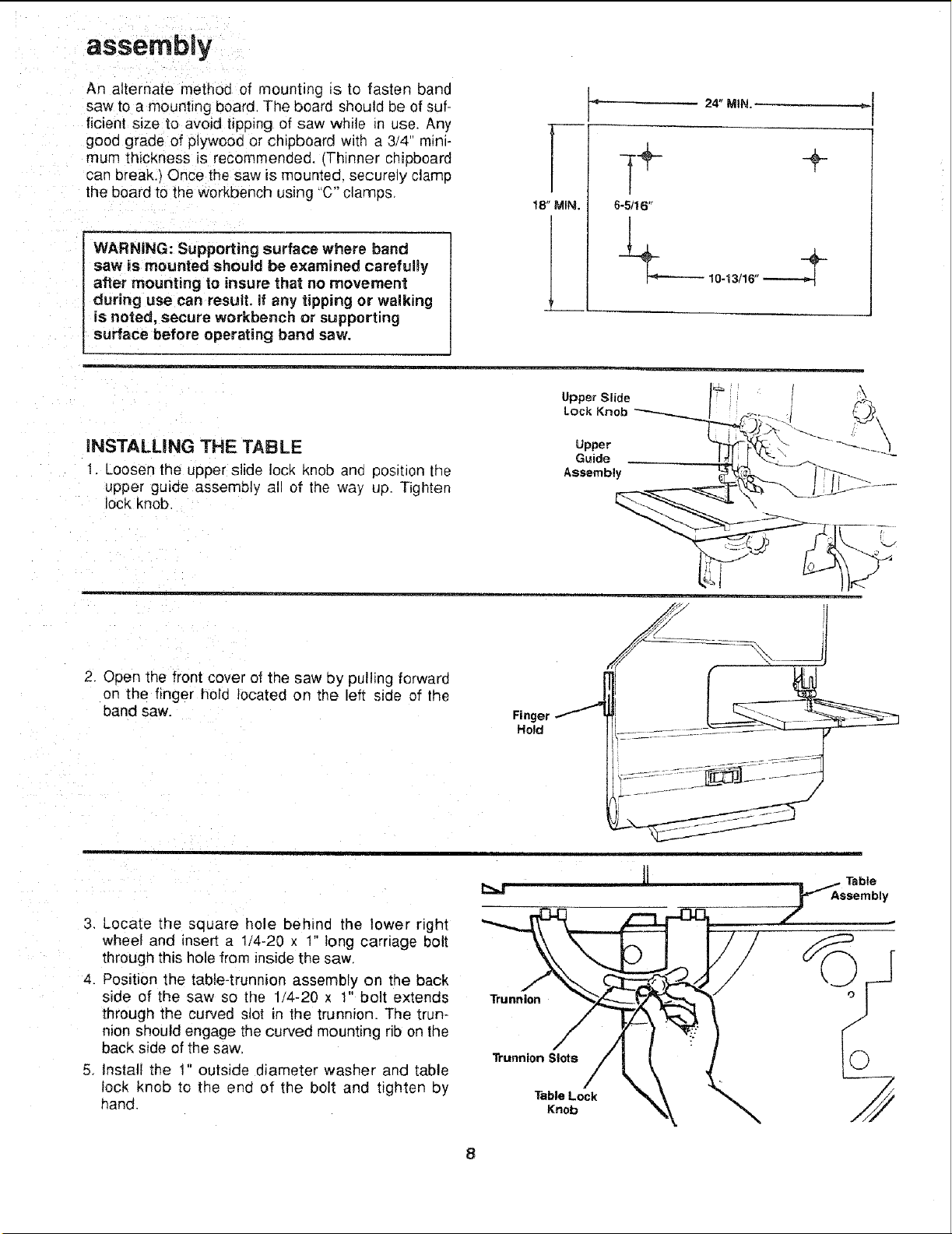

An alternate method of mounting s to fasten band

saw to a mounting board. The board should be of suf-

ficient size to avoid tipping of saw while _nuse. Any

good grade of plywooe or chipboard with a 3/4" m_n_-

mum thickness is recommended. (Thinner chipboard

can break._ Once the saw is mounted, securely clamp

the board to the workbench using "C" clamps

WARNING: Supporting surface where band

saw is mounted should be examined carefully

after mounting to insure that no movement

during use can result, if any tipping or walking

is noted, secure workbench or supporting

surface before operating band saw.

- - ........ ---4

Upper Slide

Lock Knob

iNSTALLiNG THE TABLE

1. Loosen the upper slide lock knob ano position the

upper guide assembly al of the way uo, Tighten

lock knob.

Assembly

-< 24" MIN.

6-5/16"

_ 10-13/16"

Upper

Guide

2. Ouen the front cover of the saw oy pulling forward

on the finger hold located on the left side of the

band saw.

3. Locate the square hole behind the lower right

wheel and insert a 1/4-20 x 1" tong carriage bolt

through this hole frorr inside the saw.

4. Position the table-trunnion assembly on the back

side of the saw so the 1/4-20 x 1" bolt extends

through the curved slot in the trunnion. The trun-

nion should engage the curved mounting rib on the

back side of the saw,

5. Install the 1" outside diameter washer and table

lock knob to the end of the bolt and tighten by

hand.

l

Finger /

Hold

ibte

Assembly

Trunnion

_unnion S|=s

Table Lock

Knob

8

Loading...

Loading...