Page 1

CAUTION..

Read SAFETY

RULES and

|NSTRUCTION$

carefulJy

MODEL NO.

1!3.207910

i _ / • •: _•_ i: ¸ • i

225 AMP

A. C. ARC WELDER

assembly ® eperating ®repair parts

SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A. and SIMPSONS-SEARS UMITED, Toronto

Part No. 61222 P_inte_l _n u,S. ,.

Page 2

SAFETY INSTRUCTmONS TO OPERATOR

g. Do not weld in locations close to chlorinated

hydrocarbon vapors coming from degreasing,

cleaning, or spraying operations, The heat of the rays

of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating

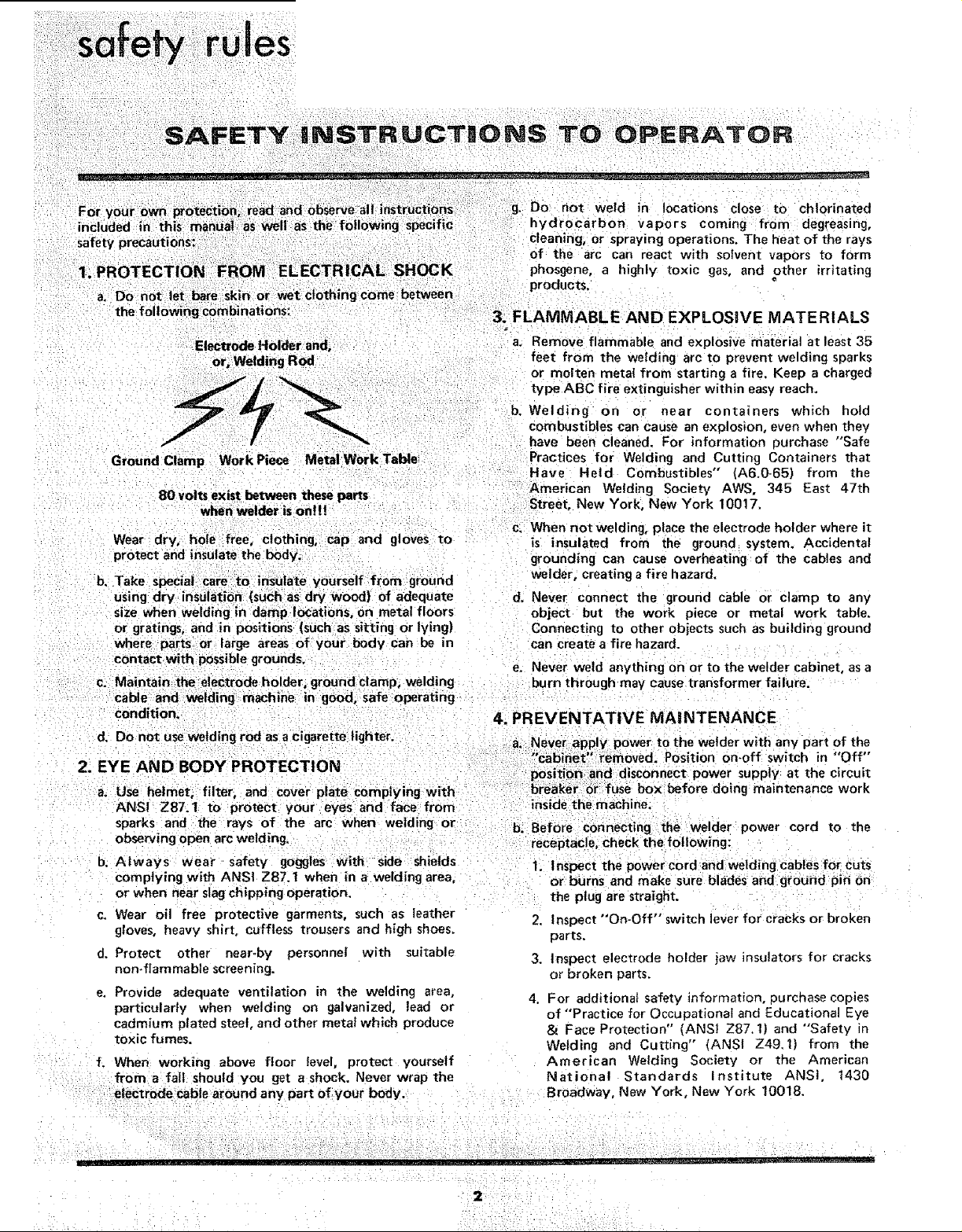

a. Do not let bare skin or wet clothing come between

the fo lowing combinations:

Ground Clamp Work Piece Metal Work Table

80 volts exist between these parts

when welder is on!!!

Wear dry, hole free, clothing, cap and gloves to is insulated from the ground system. Accidental

protect and insulate the body. grounding can cause overheating of the cables and

b. Take special care to insulate yourself from ground welder, creating a fire hazard.

using dry insulation (such as dry Wood) of adequate d. Never connect the ground cable or clamp to any

size when welding in damp locations, on metal floors object but the work piece or metal work table,

or gratings, and in positions (such as sitting or lying) Con,necting to other ob|ects such as building ground

where parts or large areas of your body can be in can create a fire hazard,

contact with possible grounds.

c. Maintain the electrode holder, ground clamp, welding burn through may cause transformer failure.

cable and welding machine in good, safe operating

condition. 4. PREVENTATIVE MAINTENANCE

d. Do not use welding rod as acigarette lighter.

2. EYE AND BODY PROTECTION

a. Use helmet, filter, and cover plate complying with

ANSi Z87.1 to protect your eyes and face from

sparks and the rays of the arc when welding or b.

observing open arc welding,

b, Always wear safety goggles with side shields

complying-with ANSI Z87,1 when in a welding area,

or when near slag chipping operation.

c, Wear oil free protective garments, such as leather

gloves, heavy shirt, cuffless trousers and high shoes,

d. Protect other near_by personnel with suitable

non-flammable screening,

e, Provide adequate ventilation in the welding area,

particularly when welding on galvanized, lead or

cadmium plated steel, and other metal which produce

toxic fumes.

f. When working above floor level, protect yourself

from a fail should you get a shock, Never wrap the

electrode cable around any part of your body.

products.

3. FLAMMABLE AND EXPLOSIVE MATERIALS

Remove flammable and explosive material at least 35

feet from the welding arc to prevent welding sparks

or molten metal from starting a fire, Keep a charged

type ABC fire extinguisher within easy reach.

Welding on or near containers which hold

combustibles can cause an explosion, even when they

have been cleaned. For information purchase "Safe

Practices for Welding and Cutting Containers that

Have Held Combustibles" (A6.G65) from the

American Welding SocieW AWS, 345 East 47th

Street, New York, New York 10017,

c. When not welding, place the electrode holder where it

e. Never weld anything on or to the welder cabinet, as a

Never apply power to the welder with any part of the

•;Cabinet!" l"emoved, Position on-off= switch in "Off

position and disconnect power supply at the circuit

breaker or fuse box before doing maintenance work

inside the machine.

Before connecting the we der power cord to the

receptacle, check the following:

I, Inspect the power cord and welding cables for Cuts

or burns and make sure blades and ground pin On

the plug are straight.

2, Inspect "'On-Off" switch lever for cracks or broken

parts.

3. Inspec_ electrode holder jaw insulators for cracks

or broken parts.

4. For additional safety information, purchase copies

of "Practice for Occupational and Educational Eye

& Face Protection" (ANSI Z87. I1 and "Safety in

Welding and Cutting" (ANSI Z49,1) from the

American Welding Society or the American

National Standards Institute ANSI, 1430

Broadway, New York, New York 10018.

2

Page 3

o

i

TOOLS NEEDED

Screwdriver [medium)

3!8-inch wrench 7/!6*inch wrench

UNPACKING AND CHECKING CONTENTS

This Craftsman welder is shipped complete in one carton.

In order to facilitate packaging, certain items have been

removed at the factory, and must be assembled when

received by the purchaser. Remove all items from the loose

parts bag and identify them by referring to figure I. These

"'Loose" parts are listed below and should be accounted for

before discarding any packing material. (See figure 1.)

! 2

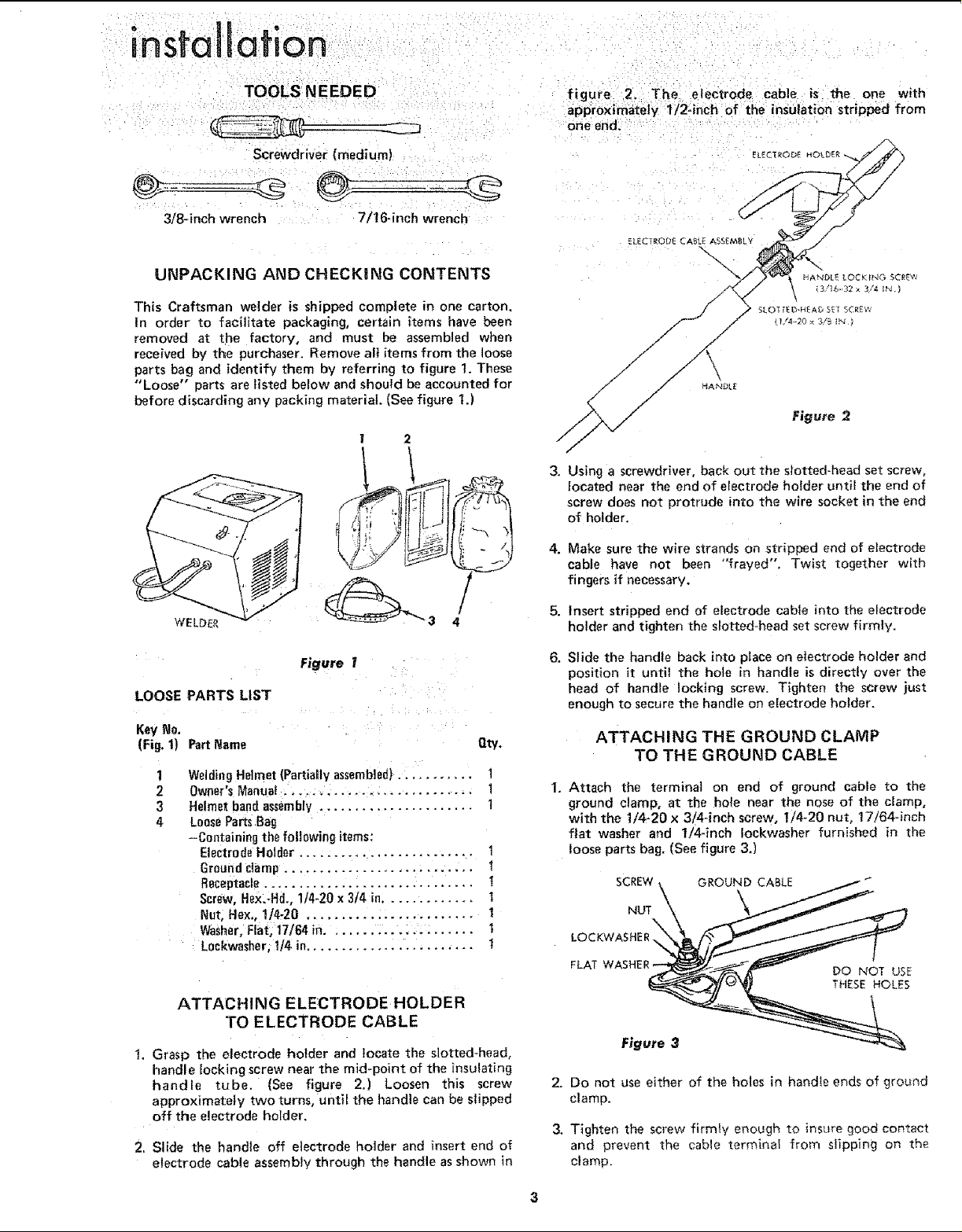

figure 2. The electrode cable is the one with

approx mately 1/2-inch of the insulation stripped from

One end.

3.

Using a screwdriver, back out the stetted-head set screw,

_ocated near the end of electrode holder until the end of

screw does not protrude into the wire socket in the end

of holder.

/

4

Figure t

LOOSE PARTS LIST

Key No.

(Fig, !) Part I_ame

1

Welding Helmet {Partially assembled)., i ........ 1

2

Owner's Manual: ...... , ...... ............... I

3

Helmet band assembly ...................... 1

4

Loose Parts Bag

-Containing the following items:

Electrode H01der ... : : .................... 1

Ground c_amp. .................. . ... .... 1

Receptacle ............. _....... .. ....... t

Screw, Hex.-Hd., 1/4-20 x 3/4 in............. t

Nut, Hex,, 1/4-26 ........................ t

Washer, Rat, 17/64 in ....... :... _/.: ...... I

L0ckwasher, t/4 in........................ I

ATTACHING ELECTRODE HOLDER

TO ELECTRODE CABLE

1. Grasp the electrode holder and locate the slotted-head,

handle iocking screw near the mid-point of the insulating

handle tube. (See figure 2.) Loosen this screw

approximate|,/two turns, until the handle can be slipped

off the electrode holder.

2. Slide the handle off electrode holder and insert end of

electrode cable assembly through the handle as shown in

Sty.

4.

Make sure the wire strands on stripped end of electrode

cable have not been "fra,/ed', Twist together with

fingers if necessary.

.

Insert stripped end of electrode cable into the electrode

holder and tighten the slotted-head set screw firmly,

6.

Slide the handle back into place on electrode holder and

position it until the hote in handle is directly over the

head of handle locking screw. Tighten the screw just

enough to secure the handle on electrode holder.

ATTACHING THE GROUND CLAMP

TO THE GROUND CABLE

Attach the terminal on end of ground cable to the

ground clamp, at the hole near the nose of the clamp,

with the 1/4-20 x 3/4-inch screw, !/4-20 nut, 17/64-inch

flat washer and 1!4-inch lockwasher furnished in the

loose parts bag. (See figure 3.)

SCREW

NUT \_,

Figure 3

2. Do not use either of the holes in hand!e ends of ground

clamp.

3. Tighten the screw firml,/ enough to insure good contact

and prevent the cable termina! from s!ipping on the

clamp.

GROUND CABLE

DO NOT USE

THESE HOLES

Page 4

current settings, slight rotation of the knob will cause it

to "snap" into a detent and line up with a number on

the scale=

from One Scale

rotate it until the

the short end with the lower scale.

the long end

Electrical connections between the welder and 230-volt,

single-phase,60-Cycle a-cpower source should be made by a

qualified electrician, A!l wiring must comply with the local

electrical code.

NOTE: Make sure the welder islocated at least i

12-inches from a walt. or other obstruction (at

both sides) in order to provide an unobstructed

flow of air for adequate cooling.

I. It is recommended that an individual (separate) line be

installed for thewelderwith a fuse block in the line. For

best results, this circuit should be as short as possible.

For power leads use armored cable or non-metallic

sheathed cable, in accordance with the local electrical

code. The size of the leads wilt depend upon their length

as shown in the table below,

Q

Power Lead Length - Power Lead Size

Upto 30 feet ....................... No.8 AWG

30to 50 feet ......................... No. 6 AWG

Over 50 feet .......................... No. 4 AWG

CAUTION: Do not attempt to connect this welder to a

regular household outlet. WELDER OPERATION

Install 50 ampere fuses, of the delayed.action type such 1. Before actually performing any welding operations,

as "Fustat" or "Fusetron", in the fuse block or a 50 make:sure the following safety suggestions are observed.

amp, 240 volt circuit breaker, a. Wear the helmet for protection Of face and eyes.

Connect the two p0wer leeds (see table above for size) : NEVER WELD WITHOUT WEARING

and a ground lead (No, 10 AWG, 0r larger)to the

terminals in receptacle as shown in figure 4 : OF THE FACE.

230 VOLT POW_I_ L! NES

• : : : against the "sun-burning" effect Of the welding arc.

WARN NG

THE HELMET IN CORRECT POSITION IN FRONT

b. It is advisable to wear heavy gloves, with cuffs long

enough to protect any exposed portion of the arms

Figure 5

( D "113 : : €_ On certain welding jobs it may be desirable to wear

C-_._-.-OROUND ; additional protective Clothing such as a safety apron,

Figure 4 SLOTCONFIGURATIONFOP, 2. Refer to the following table and select a welding rod

50 AMPERE,250VOLT RECEPTACLE having a diameter corresponding to the current selected

4. Check the "ON-OFF" switch on cabinet to make sure it

is "OFF" [figure 3] and connect the plug on welder cord

to the receptacle.

EXPLANATION OF CONTROLS

1. Pointer Positions --

Twelve welding heats (ampere settings) are made with a

single control knob. [See figure 5.) When the long end of

the knob, which serves as a pointer, is pointed to the

ampere scale, the end, wilt line up with the upper row of

figures which is labeled the "'HI" scale. When rotated

180 degrees, the short end of the knob will line up with

the lower row of figures labeled the "LO" scale.

Z Selecting the Desired "'Heat" --

A detent inside the welder holds the desired ampere 4. Connect the ground cable to the piece tobe welded with

selection securely. To change the ampere selection, push the ground clamp. Make sure the contact area is clean in

down on the knob. rotate to the new position; :_ order to insure a good electrical connection.

release it, A!ways make sure the mechanism ,snaPs"into 5. Place the "ON-OFF" switch in the "ON" position. The

a detent when the knob is released. If downward force fan inside the welder should be.running and the welder is

on the knob iS released when the pointer is between two ready for operation.

safety leggings and/or safety spats.

for the particular welding job to be performed. For each

welding current there is a corresponding diameter

welding rod that will provide best results. These are

recommended settings for Craftsman "mild steel" rods.

ROD SIZE 13/32 ] t/8 l 5132 I 3/16

Mild Steel .......... 40-75 75-145 100-160 145-225

Machinable Cast iron ... 40-75 75-115 100-t45 130-180

Hard Surfacing ....... 60-90 t00-130 130-145 160-225

Contact Rod ........ 60-115 130-160 !80-225

3. Insert the bare end of welding rod selected into the

electrode holder on end of electrode cable,

HEAT SETTING

4

Page 5

trouble shooting

REMOVAL OF POI NTER

FOR DmSASSEMBLY OF CABINET

I, If for any reason the cabinet top (Key No. 1) has to be

removed, set the pointer to the 225 amp setting.

2. Remove screw securing pointer to shaft (see Fig. 6).

3. Pull pointer straight up to remove.

4. Remove screws {Key Nos. 9 and 10 } and lift cabinet top

off.

5. If the moveable contact {Key No, 11) requires

replacement, be sure that it is positioned on the 225

amp setting before reassembly of the cabinet top.

6. After reptacina the cabinet top place a t/8" or 3/32"

diameter welding rod (or something similar) into the

threaded hole in the top of the shaft. Note the direction

the rod has to be moved sideways in order to bring the

shaft to the center of the hole in the cabinet. Do not

remove rod.

7, Place the free end of the rod through the hole in the

pointer and slide the pointer down the rod untN it rests

on the water lip around the hole in the cabinet.

8. Rotate the point_,,r on the rod so that the "HI" end of

the pointer is set to the 225 amp setting.

9. Now move the rod sideways as in paragraph 6 until the

i.......

I Figure 6

hub of the pointer slips through the hole in the cabinet

and rests on top of the shaft.

!0. While keeping the hub of the pointer centered in the

hole in the cabinet, slightly rotate the knob back and

forth until you feel the hex hole in the bottom of the

pointer engage the hex shaft; then gently push straight

down, Release the knob and remove the rod, The

pointer should now be indexed at the 225 amp setting,

11. Install the screw through the pointer into the hex shaft,

WARNING: Make sure the branch circuit main disconnect switch or circuit fuses are

removed (or welder plug and cord removed from its receptacle) before removing the

welder cabinet or lid. Placing the "ON-OFF" switch on the welder in the "OFF" position

does not remove voltage from the power leadsinside the welder - BE SAFE AND BE

ALIVE, OPEN THE BRANCH CIRCUIT.

TROUBLE

Fan does not run, but

welder operates,

Fan and welder do not

operate, or c0ntinualiy

blow fuses.

..... ,,, ,

Welding current low or

weak.

TROUBLE SHOOTING CHART

PROBABLE CAUSE

1: Tight fan motor shaft,

2, Loose or broken motor

leads_

1iImproperlyfU ed

protected.

2. Short-clrcuited coil.

3, Shorted leads.

4. Blown fuse, or open

circuit breaker,

5°

Open or loose leads,

6.

"ON-OFF" switch not

closed.

: I.

Low line voltage.

2.

Welding current setting

too low.

3.

Poor connections.

Welding cable too

I 4,

tong, or too small,

REMEDY

I. Replace motor.

2. Remove cabinet top and repair leads.

_, , ,,

I. Use 50 ampere fuses of the delayed action type such

as "Fusetron" or ,Fustat"; or a 50 ampere 240 volt

circuit breaker,

2. Rem0ve the top and look for charred, burned or

blackened coils, Replace the transformer and switch

assembly.

3, Remove the top and separate leads that touch each other.

4. Replace fuse, or reset the circuit breaker.

5. Remove cabinet top and repair.

6. Turn switch "ON", If switch fails to toggle "ON",

replace it,

I. Have a voltage check performed by the !ocal

power company.

2. Check current recommended for the electrode

being used,

3. Check electrode holder, ground and electrode cable

connections.

4. Shorten length, or increase size of cable.

Can't hold an arc.

1,

Using a D.C, welding 1, Use AC or AC-DC rods,

rod.

2.

Low hydrogen rod.

2, Use rods of 1!Sqnch maximum diameter, or smaller

on t30 amperes, or less,

Page 6

parts

• i ¸ // •

CRAFTSMAN A_ ARC WELDER

': _MODEI_NUMBER 1!3.207910

51

9

eANY ATTEMPT TO REPAIR THIS 16_

TRANSFORMER MAY CREATE A HAZARD

UNLESS REPAIR IS DONE BY A

QUALIFIED SERVICE TECHNICIAN.

REPAIR SERVICE IS

NEARESTSEARSSTORE.

41

47\

10

\

\[ \\ <26

37

]

Page 7

PARTS LIST FOR CRAFTSMAN A-C ARC WELDER

MODEL NUMBER 113.207910

WHEN ORDERING REPAIR PARTS. ALWAYS GIVE THE FOLLOWING INFORMATION AS SHOWN ON THIS LIST:

1. THE PART NUMBER 3. THE MODEL NUMBER 113.207910

2. THE PART DESCRIPTION 4. THE CODE NUMBER

5. THE NAME OF ITEM ARC WELDER

Always order by Part Number - not by Key Number

Key Part

No. No.

61224

9426307

3

61225

4

61226

5

61227

6

61119

7

448035

60012

9426106

10

273229

11

61228

12

61229

13

115109

9422329

14

15 61223

16 134556

17 116120

18 60141

19 61251

20 61107

2t 61143

22 30307

23 436695

24 116118

Description

Cabinet, Top

*Screw, Type BA, No, 8 x t/2,

Pan Hd. Slotted

i Plate, Selector

Pointer

Screw, Nylon

Handle

*Screw, Mach., No. 10-32 x 1/2,

Pan Hd. Slotted

Nut, Hex Lock

*Screw, Type BA, No. t0 x 1/2,

Pan Hd. Slotted

*Screw, Hex ind. Washer Hd.,

1/4-20 x 1/2

Contact, Movable

Guide

Lockwasher, External 1/4

*Screw, Hex.lnd. Washer Hd.

I/4-20 x 3/4

eTransformer Asm., Switch

*Nut, Hex., 5/16-18 x 9/16 x 7/32

*Lockwasher, 5/16

*Washer,Plain, 11/32 x 7/8 x 1/t6

Bracket, Support

Receptacle

Plug and Cord

Connector, Cable

*Screw,MachO,No. 8-32 x !/2,

Pan Hd. Slotted

* Lockwasher, N o. 8

Key Part

No, No,

25 115998

26 193255

27 30254

28 110969

29 60237

30 126218

31 9415477

32 51439

33 9414920

34 138167

35 115120

36 61017

37 30284

38 61230

39 61161

40 61231

41 37005

42 138166

43 60136

44 61234

45 61233

46 60033

47 61235

48 61236

49 9422149

51 37952

61222

Description

_Nut,Hex,No,8-32 x 11/32 x !/8

*Screw, Mach.No, 6-32 × 3/t6,

Pan Hd, Slotted

Switch

*Washer,Plain, I/2 x 1-1/4 x 3/32

*Bolt, Carriage, 5/16-18 x 1

*Bolt,Carriage,5/16-18 x 3/4

*Screw, Mach., 1/4-20 x 3/4,

lnd.Hex Hd.

Clamp, Ground

*Washer, t7/64 x 5/8 x 1/!6

Lockwasher 1/4

*Nut, Hex.,1/4-20 x 7/16 x 3/!6

Relief, Cable Strain

Holder, Electrode

Cabinet, Bottom

Motor

Bracket, Fan

Blade° Fan (w/Set Screw)

Lockwasher, int.Tooth No. B

*Washer,Plain 13/64 x 5/8 x t/32

Cable Asm.,Ground

Cable Assembly,Electrode

*Screw,Maeh.,5/16-18 x 3/4 Hex.Hd.

Spring

Shaft, Asm.

Washer,Plain, 15/32 x 3/4 x 1/16

-i-Helmet Assembly, Welding

{Partially Assembled)

Owners Manual (Not Illustrated)

* Standard Hardware Item. May be Purchased Locally.

t Stock Item. May be secured through the Hardware Departments of most Sears or Simpsens-Sears Retail

Stores or Catalog Order Houses.

o Any attempt to repair this transformer may create a hazard unless repair isdone by a qualified service

technician, Repair service is available at your nearest Sears Store.

Craftsman power tools (or welders) are unconditionally

guaranteed for one year to give complete satisfaction or the tool

will be repaired free of charge,

This guarantee service is available through any of our stores, or

service centers throughout the United States or Canada.

SEARS, ROEBUCK AND CO • SIMPSONS-SEARS LIMITED

Page 8

How to ORDER Repair Parts

l Sears

o_er$

manual

The Model Number will be found on the selector plate attached

to the top of the welder cabinet. Always mention the Model

Number when requesting service or repair parts for your ARC

WELDER.

All parts listed herein may be ordered through SEARS,

ROEBUCK AND CO. or SIMPSONS-SEARS LIMITED. When

ordering parts by mail, selling prices will be furnished on

request or parts will be shipped at prevailing prices and you wil!

be billed accordingly.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION AS SHOWN IN THIS LIST.

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER 113.207910

4. The CODE NUMBER

5. The NAME of ITEM - ARC WELDER

Sears

SER VICE

is at

YOUR

SERVICE

wherever YOU

live or move

in the U.S.A.

SEARS, ROEBUCK AN D CO:; :ChiCago, IL 60684 U.S.A; and SIMPSONS-SEARS LIMITED, Toronto

Your Sears merchandise takes on added value when you

discover that Sears has over 2,000 Service Units through out the

country. Each is staffed by Sears-trained, professional

technicians using Sears approved parts and methods.

Part No. 61222

Form No. SP3775-3

Printed in U.S.A. 5/74

Loading...

Loading...