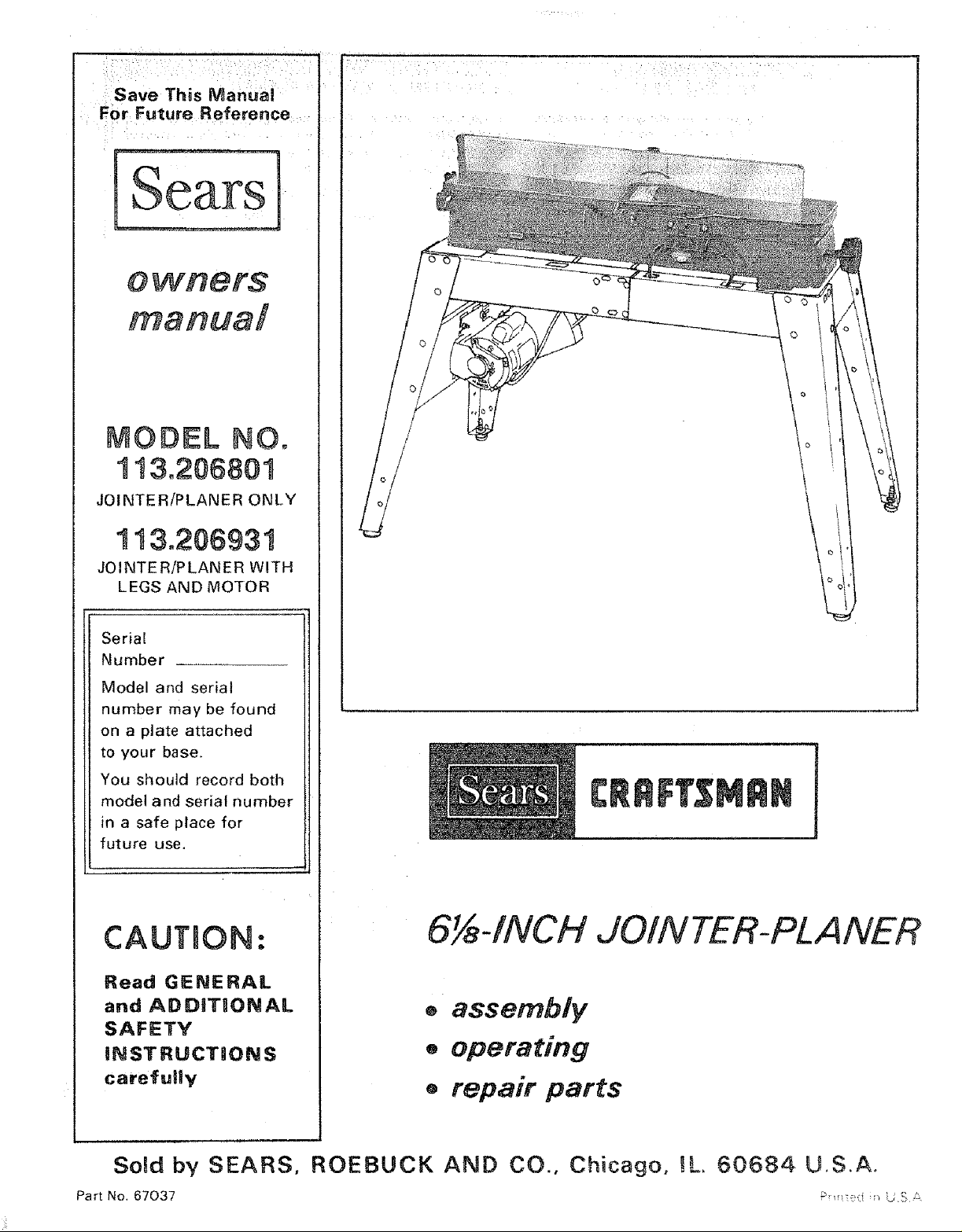

Craftsman 113206931, 113206801 Owner’s Manual

Save This Manual

For Future Reference

MODEL NO.

113,206801

JOINTER/PLANER ONLY

113.206931

JOINTER/PLANER WITH

LEGS AND MOTOR

Serial

Number

Model and serial

number may be found

on a plate attached

to your base.

You should record both

model and serial number

in a safe place for

future use.

CAUTION:

Read GENERAL

and ADDITBONAL

SAFETY

aNSTRUCTIONS

carefully

6 -INCH JO/N TER-PLANER

• assembly

o operating

• repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

Part No. 67037 #,_._._ _bS._

general safety instructions For power fools

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual and labels operation.

affixed to the tool. Learn its application and

limitations as well as the specific potential hazards

peculiar to this tool.

2. GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor

cord and a 3. arong grounding type plug to fit the

3roper grounding tv_ae receptacle. The green conductor

r_ the cord is the grounding w_re. Never connect the

green wire to a I,ve terminal.

3. KEEP GUARDS IN PLACE

_r_ working order, and _n proper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form hab, t of checking to see that keys and adjusting

wrenches are removed from tool before turning lr on

5. KEEP WORK AREA CLEAN

Cluttered areas and benches inwte accidents. Floor

must not be sl operv due to wax o_ sawdust.

-6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools n damp or wet locations or

expose them to rain. Keep work area well ghted, the accessories. The use of _mproDer accessories may

Provide adequate surrounding work space, cause hazards.

7. KEEP CHILDREN AWAY

AIr visitors should be kept a safe distance from work

_rea,

8. MAKE WOR KSHOP KID-PROOF

wtth padlocks, master switches or by removing

starter keys.

9. DON'T FORCE TOOL

It w_!t do the job better and safer at the rate for which

tt was designed.

10. USE RIGHT TOOL

Don't force tool or attachment to do a ]ob tt was not

designed for.

11, WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches) to get caught in moving parts.

Nonstip footwear is recommended. Wear protective

hair covering to contain long hair. Roll tong sleeves

above the elbow.

12. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANS Z87.1 ) at

all times. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses. Also, use

face or dust mask if cutting operation is dusty, and ear

protectors (plugs or muffs) dt_Hng extended periods of

13.

SECURE WORK

Use clam3s or a vise to hold work when practical. It's

safer than using your hand, frees both hands to operate

tool.

DON'T OVERREACH

14.

Keep proper footing and balance at all times,

15.

MAINTAIN TOOLS WITH CARE

<eep toots shart) and clean for Pest and safest

performance. Fo[tow instructions for l[_bricating and

chang_ rig accessories.

16. DISCONNECT TOOLS

before servicing; when changing accessories such as

blades, bits, cutters, etc.

!7. AVOI D ACCI DENTAL STARTING

Make sure switch Is tn "OFF" position before ptuggmg

in,

18. USE RECOMMENDED ACCESSORI ES

Consult the owner's manual for recommended

accessories. Foltow the instructiOnS that accompany

19. NEVER STAND ON TOOL

Serious injury could occur if the tool is t_pped or if the

cutPng [ool _saccidentally contacted.

Do not _.[ore materials above or near the tool such that

_t _s_)ecessary to stand on the too to reach them,

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that

_s damageo should be carefully checked to ensure that _t

will operate properly and perform its intended function.

Check for alignmem of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may ,affect _ts operation. A guard or

other part that is damaged should be 3roperly repa_reo

or replaced.

21. DIRECTION OF FEED

Feed work into a blade or cutter against the dtrection

of rotation of the blade or cutter on y

22. NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off Don't leave tool untd _t comes to a

complete stop.

Safetyis a combination of operator common sense and

alertness at all times when the Jointer*Planer is being used.

WARNING: FOR YOUR OWN SAFETY, DO NOT AT-

TEMPT TO OPERATE YOUR JOINTER-PLANER UNTIL

IT IS COMPLETELY ASSEMBLED AND INSTALLED

ACCORDING TO THE INSTRUCTIONS .., AND UNTIL

YOU HAVE READ AND UNDERSTOOD THE FOLLOW-

ING.

PAGE

1. GENERAL SAFETY INSTRUCTIONS FOR POWER

TOOLS .................................. 2

2. GETTING TO KNOW YOUR JOINTER-PLANER 12

3. BASIC MACHINE OPERATION ............... t8

4. USE OF HOLD-DOWN/PUSH BLOCKS ......... 19

5. MAINTENANCE ........................... 21

6. STABILITY OF MACHINE

if there is any tendency for the Jointer-Planer to tip

over or move during certain operations such as when

planing or jointing long heavy boards, the Jointer-

Planer (stand) should be bofted to the floor.

7. LOCATION

The Jointer-Planer should be positioned so neither the

operator nor a casual observer is forced to stand in line

with the wood while it is being planed.

This machine is intended for indoor use only. Provide

adequate lighting.

8. KICKBACKS

Kickbacks can cause serious injury. A kickback occurs

when the operator looses control of the workpiece

causing it to be kicked back toward him.

Kickbacks - and possible injury from them can usually be

avoided by:

a. Hotdingthe workpiece firmly against tables and fence.

b. Not taking too deep a cut at one time. A deep cut

requires more effort to feed the wood while pianing

and can cause the wood to kickback. A cut between

1/32 and 1/16 of an inch deep will produce the best

results.

c. Not jointing, planing, or beveling pieces of wood

smaller than recommended. (See section in this man-

ual, "BasicJointer-Planer Operations.") Smaller pieces

of wood can tip over on th[ tabtes0 or into the cutter

head and can be kicked back toward you.

9. PROTECTION: EYES, HANDS, FACE, EARS, BODY

If any part of yOur jointer is malfunctioning, has been

damaged or broken . . . such as the motor switch, or

other operating control, a safety device or the power

cord . . . cease operating immediately unlit the

particular part is properly repaired or replaced.

b. Wear safety goggles that comply with ANSI Z87,1

and a face shield if operation is dusty. Wear ear plugs

or muffs during extended periods of operation.

C.

Do not plane, ioint, or bevel wood shorter than !2

in. Smaller pieces of wood can tip over on the

tables, or into the cutterhead and be kicked back to-

ward you,

Always use the hold down/push block when }ointing

or beveling wood narrower than 3 in. but never ioint

or bevel wood narrower than 3/4 in,, or less than 1/4

inch thick.

e. Always use the hold down/push blocks when planing

wood thinner than 3 in, but never plane wood thinne_

than 1/2 in. under any circumstances.

f. Avoid awkward hand positions, where a sudden slip

could cause a hand to move into the cutters.

Never turn your Jointer-Ptaner "ON" before clearing

the table(s) of all objects (tools, scraps of wood, etc,)

except for the workpiece and related feed or support

devices for the operation planned.

h,

Make sure the cutterhead revolves in the right direc-

tion, (toward the infeed table).

i.

KEEP CUTTER GUARD 1N PLACE AND OPERAT-

ING PROPERLY AT ALL TIMES. Regularly check

the tension of the cutter guard spring to assure

satisfactory operation. (See Getting To Know Your

Jointer-Ptaner section.)

Always feed the wood completely through the cutter

head and past the cutter guard so that the guard re-

turns to the rest position against the fence. When

using only one hold down/push block to feed the

wood, do not place your other hand on the Jointer-

Planer.

t0. Warped wood should be surface planed on the concave

side for best results.

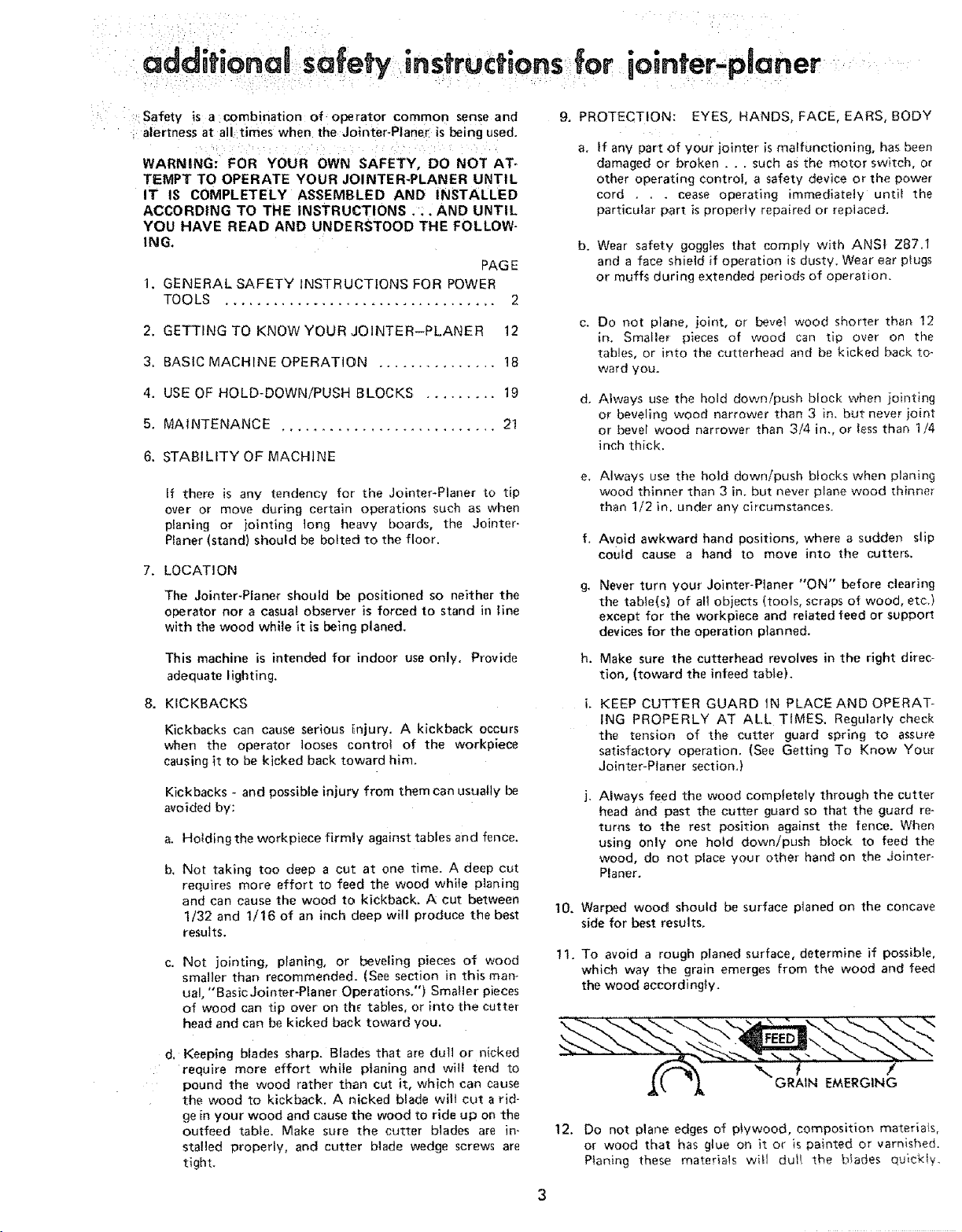

tl. To avoid a rough planed surface, determine if possible,

which way the grain emerges from the wood and feed

the wood accordingly.

d, Keeping blades sharp. Blades that are dull or nicked

require more effort while planing and wilt tend to

pound the wood rather than cut it, which can cause

the wood to kickback. A nicked blade will cut a rid-

ge in your wood and cause the wood to ride up on the

outfeed table. Make sure the cutter blades are in-

stalled properly, and cutter blade wedge screws are

tight.

!2. Do not plane edges of plywood, composition materials,

or wood that has glue on it or is painted or varnished.

Planing these materials will dut_ the b_ades qu;ckl%

addifionaR safety instruchons for mo nter..planer

!3, TO be sure you will make a depth of cut as panned, WHEN USED WITH A 3450 RPM MOTOR NEVER

always lower the infeed tab e S ightty beYOnd the SUBSTITUTE OTHER PULLEYS TO NCREASE THIS

depth Wanted, then raise the table to the desiredd_,pth. SPEED BECAUSE IT COULD BE DANGEROUS.

• PROM FREQUENT USE OF YOUR JOINTER-PLANER)

TO BECOME COMMONPLACE. ALWAYS REMEMBER

15; Never leave the Jointer-P aner work area w th the power

On, before the Jointer-Planer has come to a complete

stop, or without removing and storing the switch key.

16. Never operate the Jointer-Planer with protective cover

on the unused shaft end of the motor removed.

17, Do not attempt to perform an abnormal or little-used

operation without study and the use of adequate hold

down/push blocks, jigs, fixtures, stops, etc.

lB. DO NOT perform tayou_, assembly, or setup work on

the tab|e while the cutting tool is rotating.

WARNING: THE 2" JOINTER-PLANER PULLEY AND

THE 2-1/2" MOTOR PULLEY FURNISHED WILL RUN

THE CUTTER HEAD AT APPROXIMATELY 4300 RPM

THAT A CARELESS FRACTION OF A SECOND IS

SUFFICIENT TO INFLICT SEVERE INJURY,

t9. Read and follow the instructions appearing on the

danger label on the cutter guard.

DANGER - FOR YOUR OWN SAFETY

READ AND UNDERSTAND OWNER*S

MANUAL BEFORE OPERATING MACHINE

1 WEAR SAFETY GOGGLES PER ANSI Z87 1 AT ALL TIMES

2 NEVER PERFORM A JOINT1NG OR PLANING OPERATION W_TH CUTTER

HEAD OR DRIVE GLIARD REMOVED

3 NEVER MAKE A JOtNTING OFt PLANING CUT DEEPER THAN _/g INCH

4 ALWAYS USE HOLD DOWN/PUSH SLOCKS EOR JOINTtNG MATERIAL

NARROWER THAN 3 INCHES OR PLANING MATER_AL THINNER THAN 3

INCRES.

WEAR YOUR

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result n

severe eye damage. Always wear safety goggles complying

with ANSI Z87.1 (shown on Package) before commencing

power too! operation. Safety Goggles are available at Sears

retail or catalog stores.

cortfents

POWER TOOL GUARANTEE ............... 2

GENERAL SAFETY INSTRUCTIONS FOR

POWER TOOLS ............................ 2

ADDITIONAL SAFETY INSTRUCTIONS FOR

JOINTER-PLANER .......................... 3

MOTOR SPECIFICATIONS AND ELECTRICAL

REQUIREMENTS ........................... 5

Connecting to Power Source Outlet ........ 5

Check Motor Rotation .................... 5

UNPACKING AND CHECKING CONTENTS .... 6

ASSEMBLY ................................ 7

Assembling Steel Legs ................... 7

Mounting Jointer-Planer On Recommended

Craftsman Stand ......................... 8

Checking Cutterblade Screws .............. 8

Installing Sliding Guard ................. 9

Mounting Switch .......................... 9

Mounting Recommended Craftsman Motor

and Belt Guards ....... ; ..................

-Check Mot0r Rotation .:_:..: ......... ;.... 10 : REPAIR PARTS ............................. 27

Jointer-PUlley Beff G uardlnstaliation :: :.. i I

GETTING TO KNOW YOUR JOINTER-PLANER 12

Depth of Cut HandwheeJ .................. 12

Fence Locks and Stops ................... 12

Fence Tilt Scale .......................... 13

Cutter Guard .......................... 14

Infeed Table .......................... 14

On-Off Switch ........................... 16

BASIC JOtNTER-PLANER O PERATION ....... 18

Feeding the Workpiece ................... 18

Using the Hold Down/Push Blocks ........ 19

Beveling ................................. 20

MAINTENANCE ............................ 21

Replacing Cutter Blades .................. 21

Installing Cutter Guard Spr=ng ............. 23

Sharpening Cutter Blades ................. 24

GENERAL MAINTENANCE .................. 25

LUBRICATION .............................. 25

TROUBLE SHOOTING ...................... 26

RECOMMENDED ACCESSORIES ............ 26

motor specifications and emedrkaR requkernents :

This machine is designed to use a 3450 RPM motor only.

Do not use any motor that runs faster than 3450 RPM.

It is wired for operation on 110-120 volts, 60 Hz.,a/ter-

nating current. IT MUST NOT BE CONVERTED TO

OPERATE ON 230 VOI.TS, EVEN THOUGH SOME OF

THE RECOMMENDED MOTORS ARE DUAL VOLTAGE.

THESE CRAFTSMAN MOTORS HAVE BEEN

FOUND TO BE ACCEPTABLE FOR USE ON

THIS TOOL.

H P RP_a VOLTS CATALOG NO.

1/2 3450 110q20 1216

1/2 3450 110-120 1218

3/4 3450 110-120 12t9

3/4 3450 110-120 1226

CAUTION: Do not use blower or washing machine motors

or any motor with an automatic reset overload protector

as their use may be hazardous.

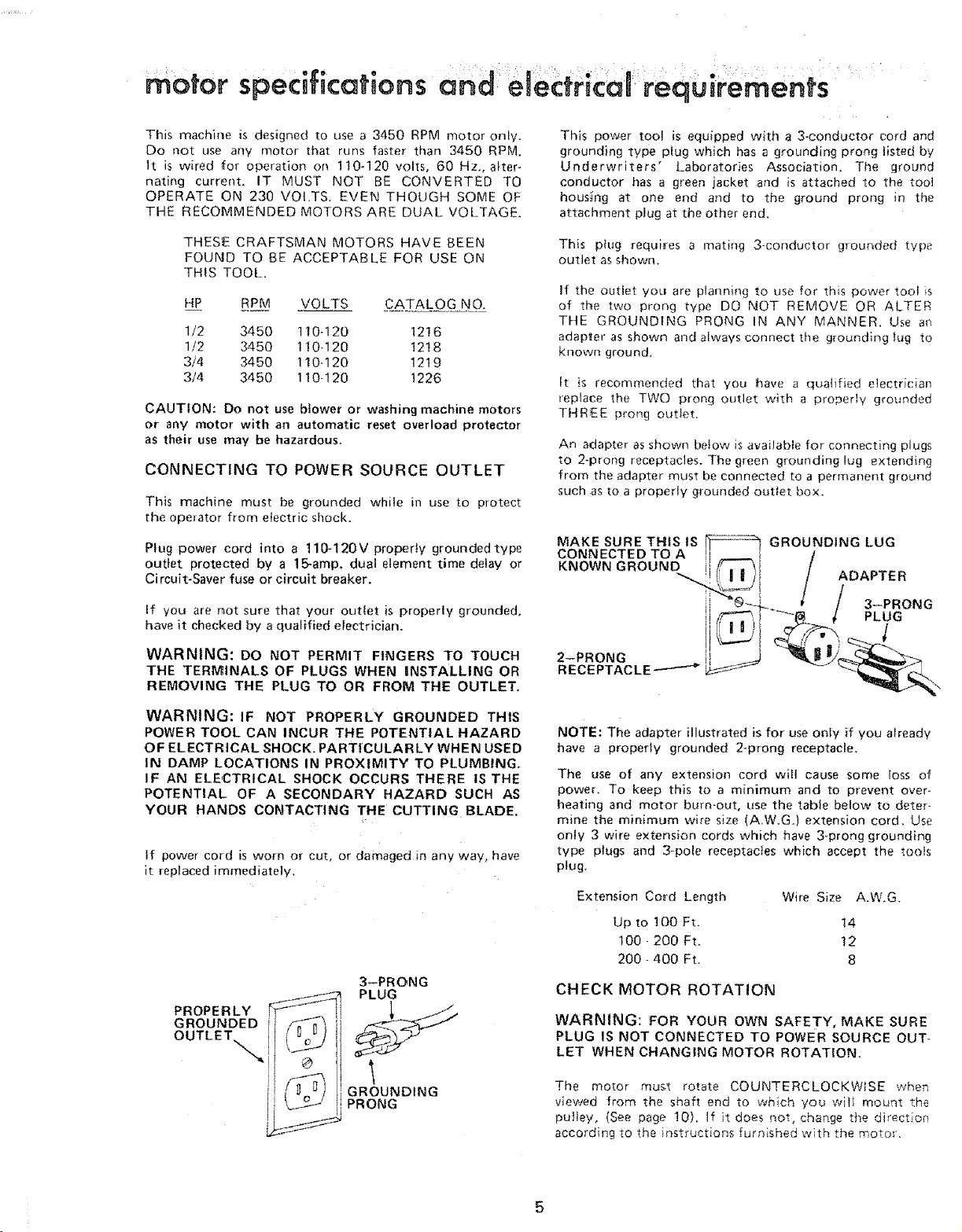

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded while in use to protect

the operator from etectric shock.

Plug power cord into a 110_120V properly grounded type

outlet protected by a 15-amp, dual element time delay or

Circuit-Saver fuse or circuit breaker.

If you are not sure that your outlet is properly grounded,

have it checked by a qualified electrician.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUGS WHEN INSTALLING OR

REMOVING THE PLUG TO OR FROM THE OUTLET.

This power too! is equipped with a 3-conductor cord and

grounding type plug wMch has a grounding prong listed by

Underwriters" Laboratories Association, The ground

conductor has a green jacket and is attached to the tool

housing at one end and to the ground prong in the

attachment plug at the other end.

This piug requires a mating 3-conductor grounded type

outlet as shown.

If the outlet you are planning to use for this power too_ is

of the two prong type DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown and always connect the grounding lug to

known ground,

It is recommended that you _nave a quafified electrician

replace the TWO prong outlet with a properhi grounded

THREE prong outlet,

An adapter as shown below is available for connecting plugs

to 2-prong receptacles. The green grounding lug extending

from the adapter must be connected to a perrnanent ground

such as to a properly grounded outtet box.

MAKE SURE THIS IS _-'_"'-_

CONNECTED TO A i

KNOWN GROUND

H

i

Li

GROUNDING LUG

ADAPTER

3-PRONG

PLUG

J

2--PRONG

RECEPTACLE

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK. PARTICULARLY WHEN USED

IN DAMP LOCATIONS IN PROXIMITY TO PLUMBING.

IF AN ELECTRICAL SHOCK OCCURS THERE IS THE

POTENTIAL OF A SECONDARY HAZARD SUCH AS

YOUR HANDS CONTACTING THE CUTTING BLADE,

If power cord is worn or cut, or damaged in any way, have

it replaced immediately.

3-PRONG

PLUG

PROPERLY

GROUNDED

OUTLET_._

GROUNDING

PRONG

NOTE: The adapter illustrated is for use onIy if you already

have a properly grounded 2-p:rong receptacle.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to deter-

mine the minimum wire size (A,W.G.) extension cord. Use

only 3 wire extension cords which have 3-prong grounding

type plugs and 3opole receptacles which accept the too&

plug,

Extension Cord Length Wire Size A.W.G.

Up to 100 Ft. 14

100 - 200 Ft. 12

200- 400 Ft. 8

CHECK MOTOR ROTATION

WARNING: FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONNECTED TO POWER SOURCE OUT*

LET WHEN CHANGING MOTOR ROTATION.

The motor must rotate COUNTERCLOCKWISE when

viewed from the shaft end to which you wilI mount the

pulley, (See page 10}, If it does not, change the direction

according to the instructions furnished with the motor,

UI

and checking contents

1 7/]6_i Wrench Medium Screwdriver

1121 Wro="

3/41Wre.ch

" " 3/8' Wrench

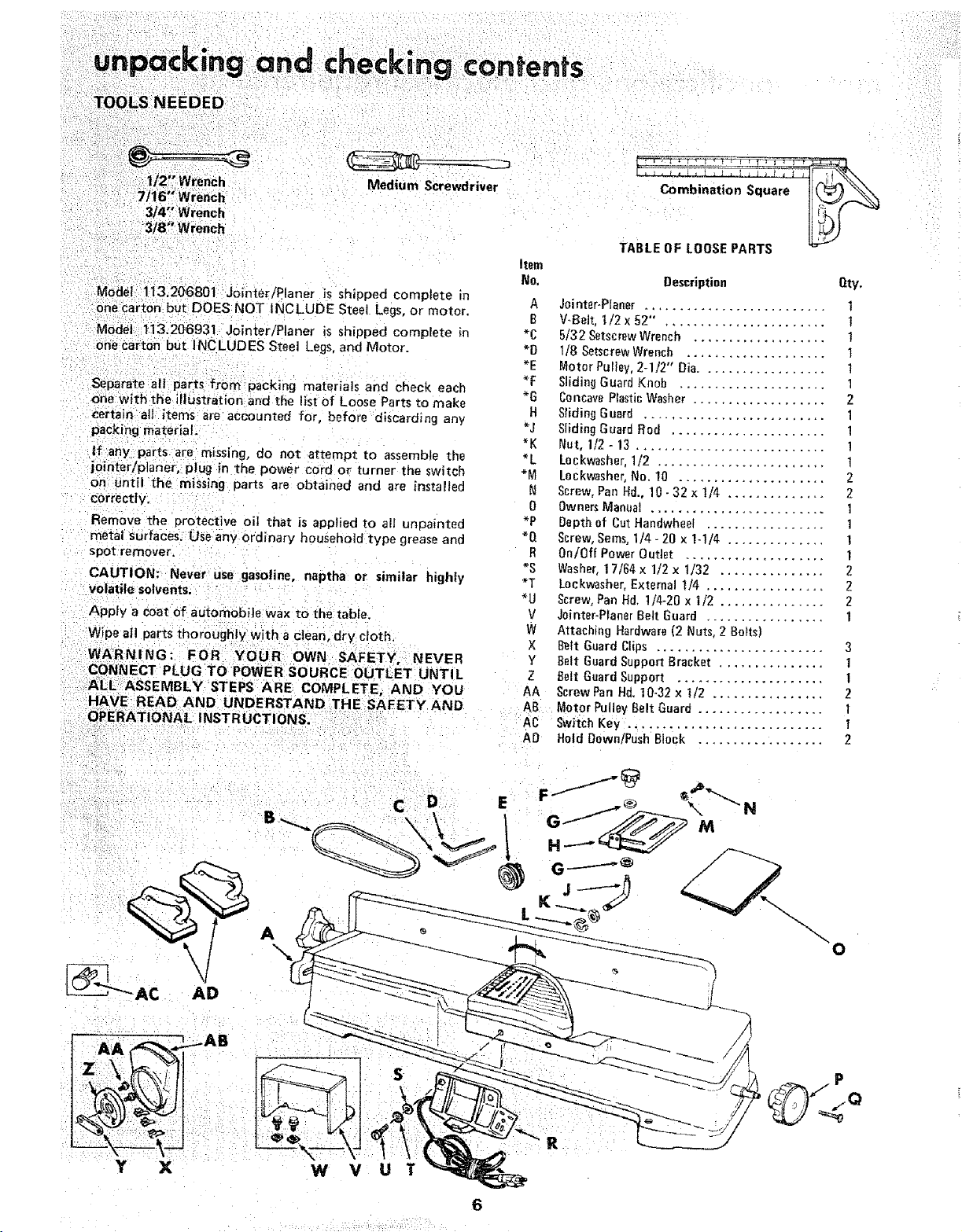

Model 113 206801 Jointer/P aner is shipped complete n

one carton but DOES NOT INCLUDE Steel Legs,or motor.

Model: 113,206931 JointerlPlaner is shipped complete in

one carton but INCLUDES Steei Legs, and Motor.

Separate all parts from packing materials and check each

one with the itlUstrat{on and the list of Loose Parts to make

certain all items are accounted for, before discarding any

packing material:

tf any parts are missing, do not attempt to assemble the

jointer/planer; plug n the Dower cord or turner the switch

on until the missing parts are obtained and are installed

correctly.

Remove the protective oi that is applied to all unpainted

metal surfaces. Use any ordinary household type grease and

spot remover.

CAUTION: Never use gasoline, naptha or similar highly

volatile solvents.

Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean, dry c oth.

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET UNTIL

ALL ASSEMBLY STEPS ARE COMPLETE, AND YOU

HAVE READ AND UNDERSTAND THE SAFETY AND

OPERAT aNAL INSTRUCTIONS.

i •

Combination Square

TABLE OF LOOSE PARTS

Item

No. Description Qty,

A Jainter-Plaeer .......................... 1

B V-Belt, I/2x 52" . ...................... t

*C 5/32 Setscrew Wrench ................... t

*D 1/8 Setscrew Wrench .................... I

*E Motor Pulley, 2-1/2" Dia.................. 1

*F Sliding Guard Knob ..................... 1

"13 Concave Plastic Washer ................... 2

H Sliding Guard .......................... 1

*J Sliding Guard Rod ...................... !

*K Nut, 1/2 - 13 ........................... !

*L Lockwasher, 1/2 ........................ 1

*M Lockwasher, No. 10 ..................... 2

N Screw, Pan Hd,, 10 - 32 x t/4 .............. 2

0 Owners Manual ......................... 1

*P Depth of Cut Handwheel ................. 1

*Q Screw, Seres, I/4- 20 x 1-1/4 .............. 1

R 0n/0ff Power OutJet .................... 1

*S Washe_, 17/64 × 1/2 x 1/32 ............... 2

*T Lockwesher, E×ternaJ 1/4 ................. 2

*U Screw, Pan Hd. 1/4-213 x 1/2 ............... 2

V Jointer-Planer Belt Guard ................. 1

W Attaching Hardware (2 Nuts, 2 Botts)

X _lt Guard Clips ........................ 3

Y Belt Guard Support Bracket ............... 1

Z Belt Guard Support ..................... 1

AA Screw Pan Hd. 10-32 x ti2 ................ 2

AB Motor Pulley Belt Guard .................. 1

AC Switch Key ............................ 1

AD Held Dawn/Push Black .................. 2

AD

AA (,€_._._A B

Y x

A

\

W V U T

unpacking and

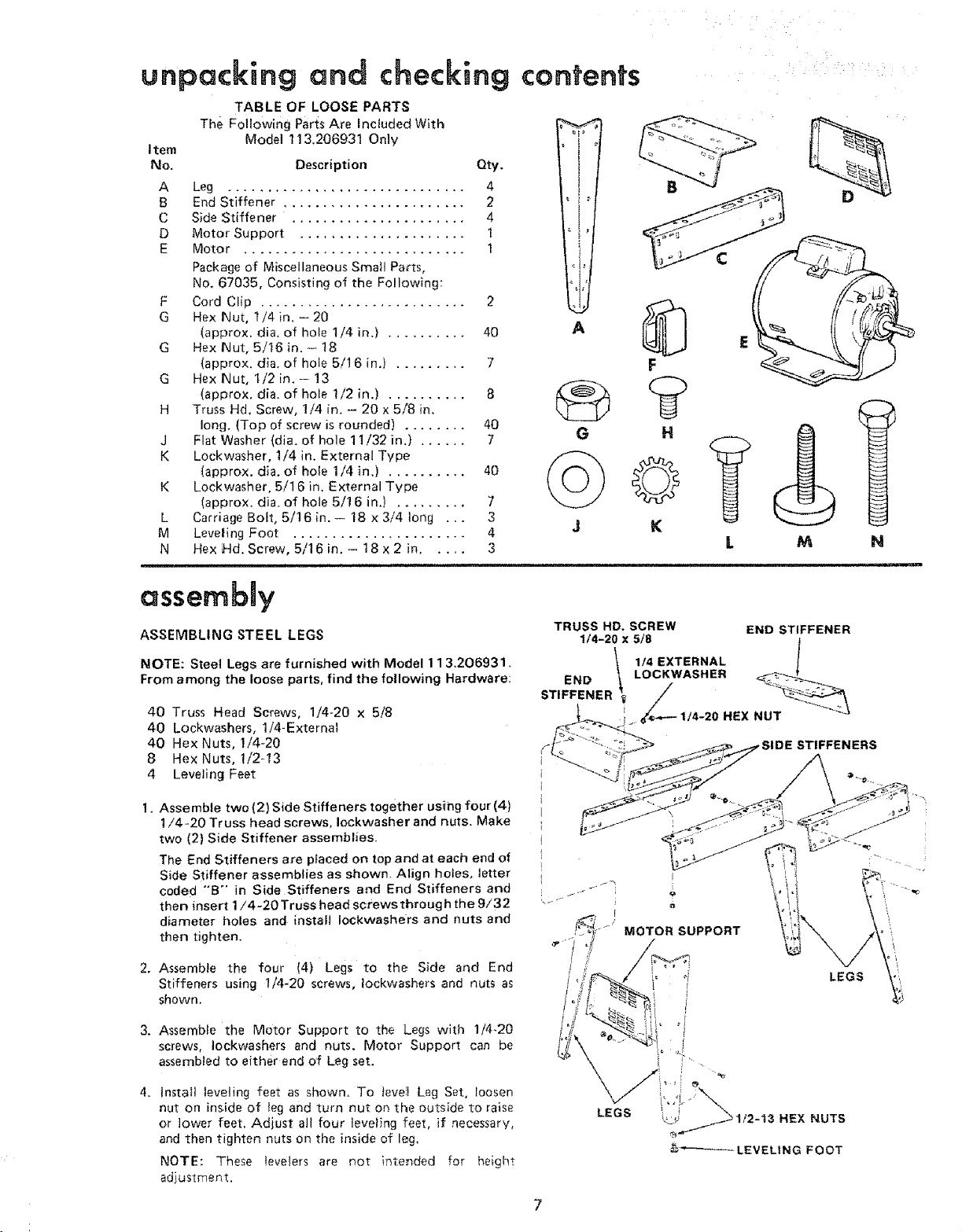

TABLE OF LOOSE PARTS

The Following Parts Are included With

Item

No,

A

Leg .............................. 4

End Stiffener ....................... 2

8

C

Side Stiffener ...................... 4

D

Motor Support ..................... 1

E

Motor ............................ 1

Package of Miscellaneous Small Parts,

No. 67035, Consisting of the Following:

F

Cord Clip .......................... 2

G

Hex Nut, 1/4 in. - 20

G

Hex Nut, 5/I6 in. - 18

G

Hex Nut, 1/2 in. - 13

H

Truss Hd, Screw, !/4 in. - 20 x 5/'8 in.

J

Flat Washer (dia, of hole 11/32 in.) ...... 7

K

Lockwasher, 1/4 in. External Type

K

Lockwasher, 5/1 6 in. External Type

L

Carriage Boh, 5/16 in. - 18 x 3/4 long ... 3

M

Leveling Foot ...................... 4

N

Hex Hd. Screw, 5/16 in. - 18 x 2 in ..... 3

Model 113.206931 Only

Description Qty.

(approx. die, of hole 1/4 in.) .......... 40

(approx. alia. of hole 5/1 6 in.) ......... 7

(approx. die. of hole 1/2 in.) .......... 8

long. (Top of screw is rounded) ........ 40

(approx. dia. of hole 1/4 in.) .......... 40

(approx. die. of hole 5/16 in,) ......... 7

= JL _ , LLUH,H,

checking contents

A

J K

C

F

L M

N

assembly

ASSEMBLING STEEL LEGS

NOTE: Steel Legs are furnished with Model 11 3.206931.

From among the loose parts, find the following Hardware:

40 Truss Head Screws, 1/4-20 x 5/8

40 Lockwashers, 1/4-External

40 Hex Nuts, 1/4-20

8 Hex Nuts, 1/2q3

4 Leveling Feet

1. Assemble two (2) Side Stiffeners together using four (4)

1/4-20 Truss head screws, Iockwasher and nuts. Make

two (2) Side Stiffener assemblies.

The End Stiffeners are placed on top and at each end of

Side Stiffener assemb)ies as shown. Align holes, letter

coded "'B'" in Side Stiffeners and End Stiffeners and

then insert 1/4-20 Truss head screws through the 9/32

diameter holes and install Iockwashers and nuts and

then tighten.

2. Assemble the four (4) Legs to the Side and End

Stiffeners using 1/4-20 screws, Iockwashers and nuts as

shown,

3. Assemble the Motor Support to the Legs with 1/4,20

screws, ]ockwashers and nuts. Motor Support can be

assembled to either end of Leg set.

TRUSS HD. SCREW END STIFFENER

1/4-2i X 51//84EXTERNAL 1

END \ LOCKWASHER _

STIFFENER !_ _//_ 1/4_20 HEX NUT _"

IDE STIFFENERS

4. Install leveling feet as shown. To )eve,] Leg Set, loosen

nut on inside of leg and turn nut on the outside to raise

or lower feet. Adjust all four leveling feet, if necessary,

and then tighten nuts on the inside of leg.

NOTE: These levelers are not intended for height

adius_ment,

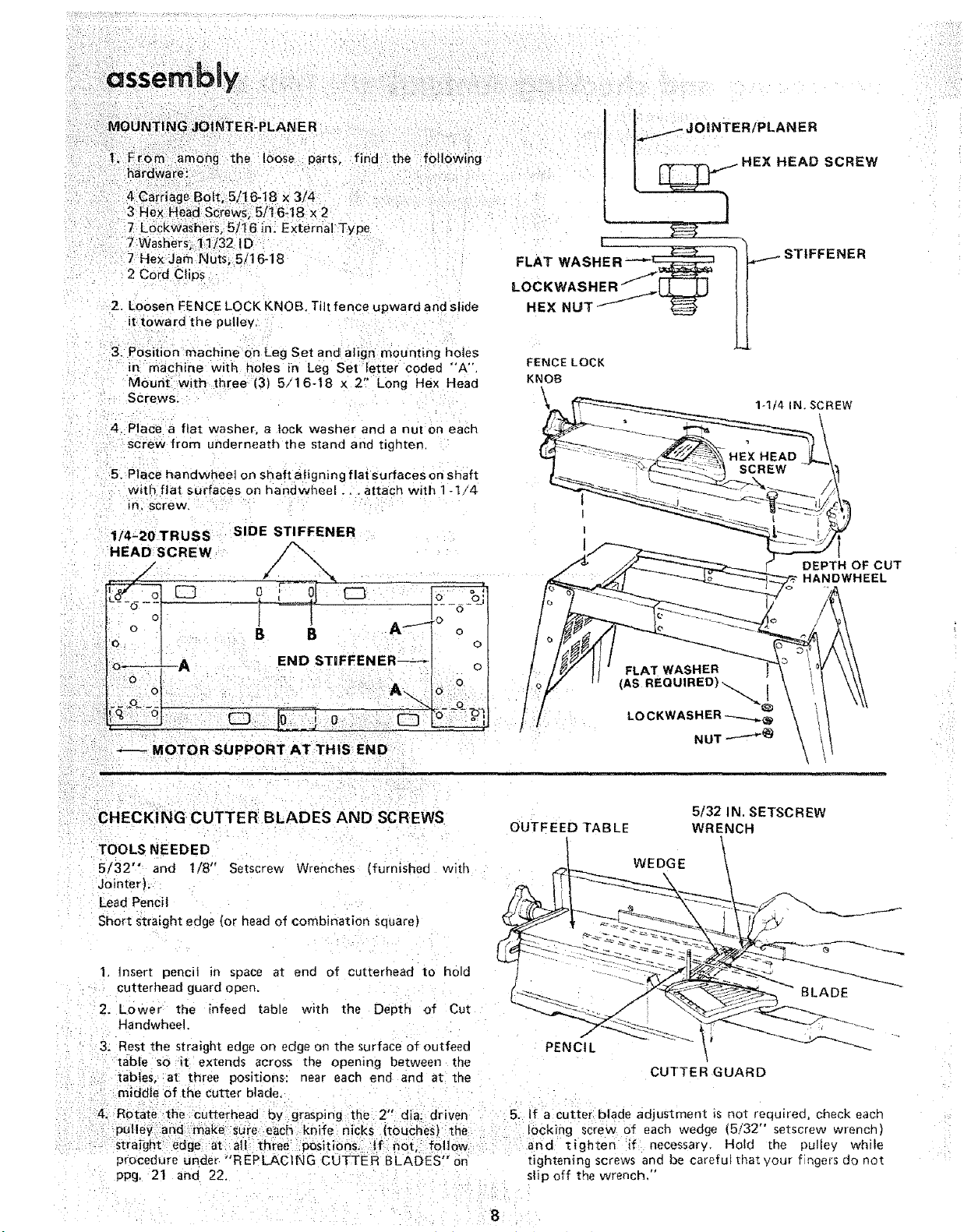

parts, find the following

18 x 3/4

x2

7 Washers; 11/32 ID

7 Hex Jam NUts, 5/16-18

2 Cord Clips

2. Loosen FENCE LOCK KNOB. Tilt fence upward and slide

J_toward the pulley.

_ JO|NTERfPLANER

_HEX HEAD SCREW

FLATWASHER--- ST|FFENER

LOCK WAS H E R .-""_::]

HEXNUT

3. Position machine on Leg Set and align mounting holes

m machine with holes in Leg Set letter coded "'A".

Mount with three (3) 5/16-t8 x 2" Long Hex Head

Screws.

4. Place a flat washer, a lock washer and a nut on each

screw from underneath the stand and tighten.

5. Place handwhee] on shaft aligning flat surfaces on shaft

with flat surfaces on handwheel _.. attach with 1-1/4

In. screw,

114-20 TRUSS SIDE STIFFENER

HEAD SCREW

/

o B B o

o ! / ...._o o

°_A END STIFFENER o

0 _ _ 0

o : : _ A o

-,_ -Q. 7_---_- ...... _o_.D-

-- MOTOR SUPPORT AT THIS END

FENCE LOCK

KNOB

1-1t4 IN. SCREW

I

I

I

I

DEPTH OF CUT

_DWHEEL

CHECKING-CUTTER: BLADES AND SCREWS

TOOLS NEEDED

5/32" and t/8" Setscrew Wrenches (furnished with

Jointer).

Lead Pencil

Short straight edge (or head of combination square)

1. tnsert pencil in space at end of cutterhead to hold

cutterhead guard open.

2. Lower the infeed table with the Depth of Cut

Handwheel.

3. Rest the straight edge on edge on the surface of outfeed

table so it extends across the opening between the

tables, at three positions: near each end and at the

middle of the cutter blade.

4. Rotate the cutterhead by grasping the 2" alia. driven

pulley and make sure each knife nicks (touches) the

straight edge at a ! three post on:s tf not f0 ow

p ocedure unde REPLAC NG CUTTER BLADES on

ppg. 21 and 22.

OUTFEED TABLE

WEDGE

PENCI L

5. If a cutter blade adjustment _s not required, check each

locking screw of each wedge 15/32" setscrew wrench)

and tighten if necessary, Hold the pulley while

tightening screws and be careful that your f'ngers do not

slip off the wrench,"

WRENCH

BLADE

CUTTER GUARD

5/32 IN. SETSCREW

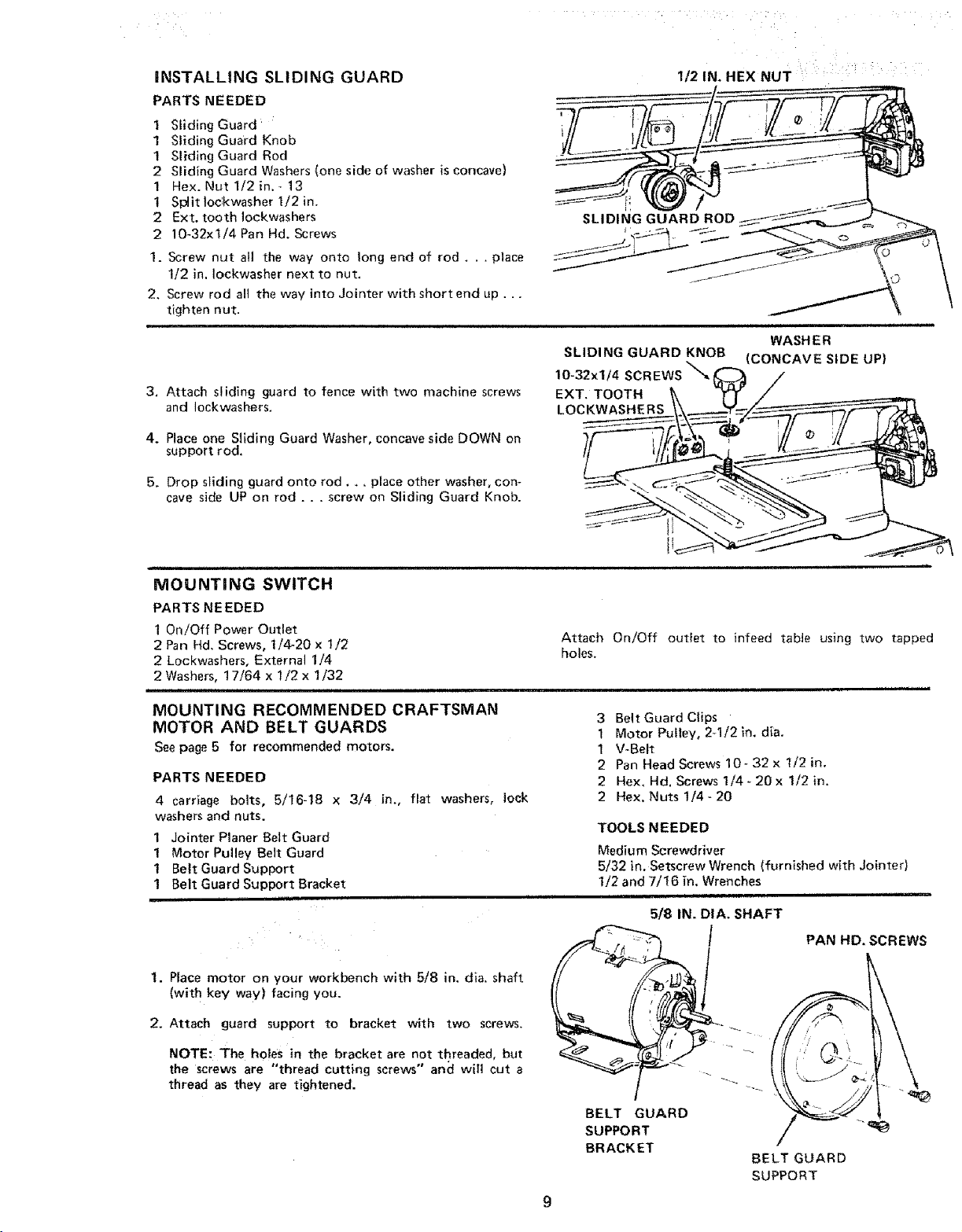

iNSTALLING SLIDING GUARD

PARTS NEEDED

I Sliding Guard _

1 Sliding Guard Knob

1 Sliding Guard Rod

2 Sliding Guard Washers (one side of washer is concave)

1 Hex. Nut 1/2 in. _ 13

t Spait toc'kwasher I/2 in.

2 Ext, tooth tockwashers

2 10-32xl/4 Pan Hd. Screws

1. Screw nut all the way onto long end of rod . . . place

1/2 in. Iockwasher next to nut.

2. Screw rod alt the way into Jointer with short end up...

tighten nut.

3, Attach sliding guard to fence with two machine screws

and Iockwashers.

4. Place one Sliding Guard Washer, concave side DOWN on

support rod,

5, Drop sliding guard onto rod.., place other washer, con-

cave side UP on rod . . . screw on Sliding Guard Knob.

1/2 IN. HEX NUT

SLI DIt'_'GGUARD

SLIDING GUARD KNOB

10-32xl/4 SCREWS'_

EXT. TOOTH

LOCKWASHERS

i :

ii ii lul ii i ill i,u,nu, u,,,,

WASH E R

(CONCAVE SIDE UP)

MOUNTING SWITCH

PARTSNEEDED

1 On!Off Power Outlet

2 Pan Hd. Screws, 1/4-20 x t/2

2 Lockwashers, External 1/4

2 Washers, 17/64 x 1/2 x 1/32

MOUNTING RECOMMENDED CRAFTSMAN

MOTOR AND BELT GUARDS

Seepage5 for recommendedmotors.

PARTS NEEDED

4 carriage bolts, 5/16-t8 x 3/4 in., flat washers, lock

washers and nuts.

1 Jointer Planer Belt Guard

1 Motor Pulley Belt Guard

I Belt Guard Support

! Belt Guard Support Bracket

i ii i,,pl

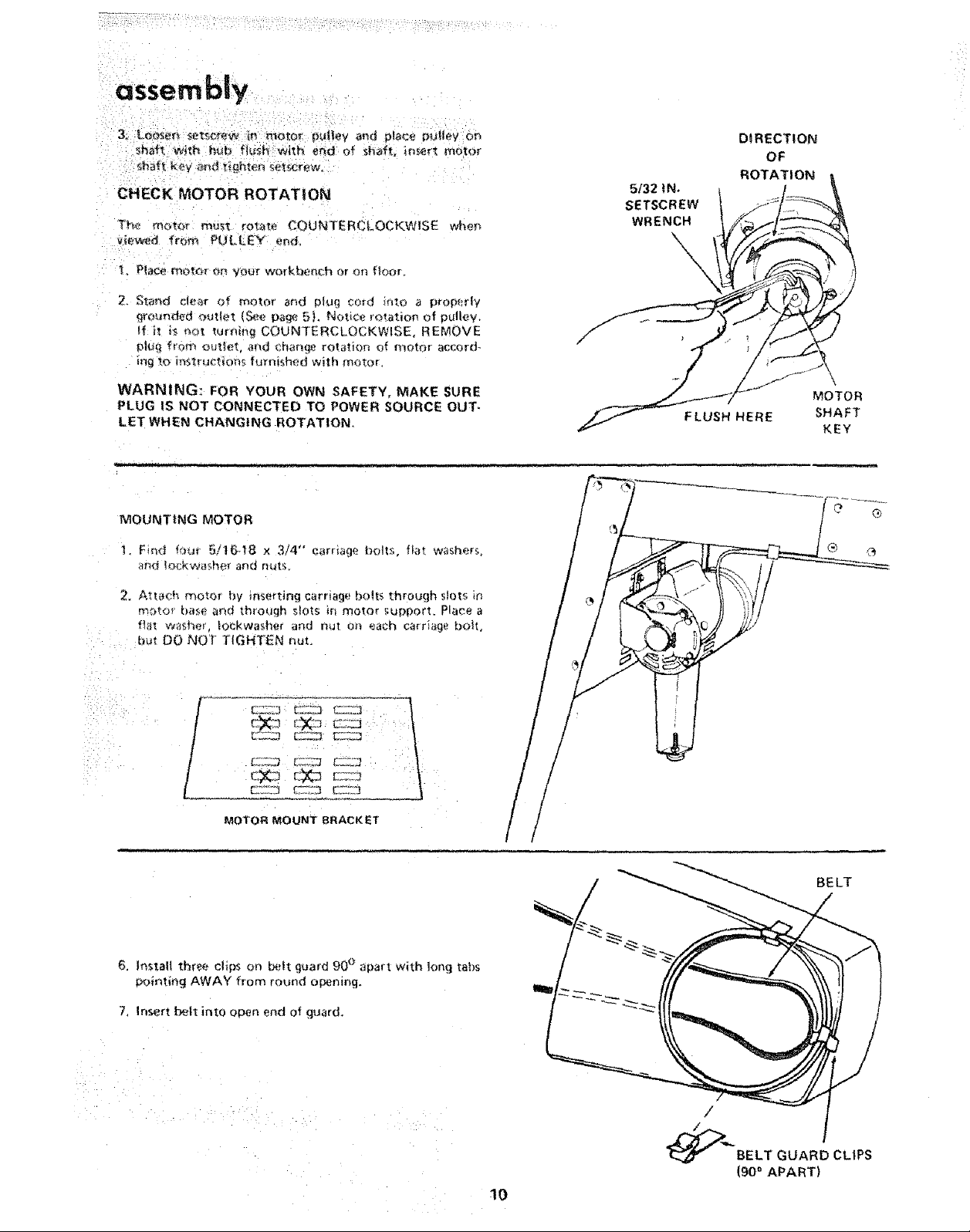

t. Place motor on your workbench with 6/8 in. dia. shaft

(with key way) facing you.

2. Attach guard support to bracket with two screws.

Attach On/Off outlet to infeed table using two tapped

holes.

3 Belt Guard Clips

1 Motor Pulley, 2q/2 in. dia.

1 V-Belt

2 Pan Head Screws 10- 32 x I/2 in,

2 Hex, Hd. Screws 1/4 - 20 x t/2 in,

2 Hex. Nuts t/4- 20

TOOLS NEEDED

Medium Screwdriver

5/32 in, Setscrew Wrench (furnished with Jointer)

t/2 and 7/t6 in. Wrenches

5/8 IN. DIA. SHAFT

PAN HD. SCREWS

NOTE: The holes in the bracket are not threaded, but

the screws are "thread cutting screws" and will cut a

thread as they are tightened.

BELT GUARD

SUPPORT

BRACKET

BELT GUARD

SUPPORT

osse

:::shaft _th h_bl fi_,_ with of Sh_t_ ioser'_ rn6tOr

mbb

CHECK MOTOR ROTATION

T_,_ m_ m_,_ rotate COUNTERC{.OCKWiSE whe_

Wewed fr_ PL_LL£Y end_

1L Piaee motor or_ your workbench or on floor.

2. Stared clear of motor and plug cord into a properly

9rounded outlet (See pa_¢ 5). f_}otice r_tation of pulley,

If it is not tutoring COUNTERCLOCKWISE, REMOVE

plug from out_et, and chancre rotation of motor accord-

ing to instructions furnished with motor.

i

DIRECTION

OF

ROTATION

5t32 IN.

SETSCREW

WRENCH

WARNING: FOR YOUR OWN SAFETY, MAKE SLIRE

PLUG IS NOT CONNECTED TO POWER SOURCE OUT.

LET WHEN CHANG!NG ROTATION.

"_" --:--:- ; ; __ ,.............. J__JLU'L_I_I'E..L ' =!.... &CIJ_UU['L'....

MOUNTING MOTOR

i, Find fo_t 5116-t8 x 3/4" carriage bolts, flat washers,

and lockw_sher and nuts_

2_ Attach r'_otor by iriserting carriage bolts through slots in

motor' base and thro_Jgh slOtS in motor supporL Place a

f}al washer, lo_.kwasher and nut on each carriage bolt,

: , b_t DO NOT TIGHTf_N nut.

">/:

i i__

/

MOTOR MOUNT BRACKt_T

ECZ2"3

MOTOR

FLUSH HERE

SHAFT

KEY

®

J

6. Install three clips on belt guard 90 ° apart with long tabs

pointing AWAY from round opening.

7, Insert belt into open end of guard.

/•

BELT

/

1_..,_-"" BE LT O UAR D C LIPS

(90 _ APART)

10

Loading...

Loading...