Craftsman 113201480 Owner’s Manual

Save This Manual

For Future Reference

MODEL NO.

113.201480

Serial

Number

Model and serial

number may be found

at the rear

of the cabinet.

You should record both

model and serial number

in a safe place for

future use.

CAUTION:

Read

SAFETY

INSTRUCTIONS

carefully

• •i•: i•i::¸:_:::: : ; :• :; :

50-295 AMP

DUAL RANGE

VARIABLE CONTROL

ACARC

e assembly

® operating

Sold by SEARS,

Part No. 61421

® repair parts

ROEBUCK AND CO., Chicago, IL

60684 U.S.A.

Printed ;inU.S.A_

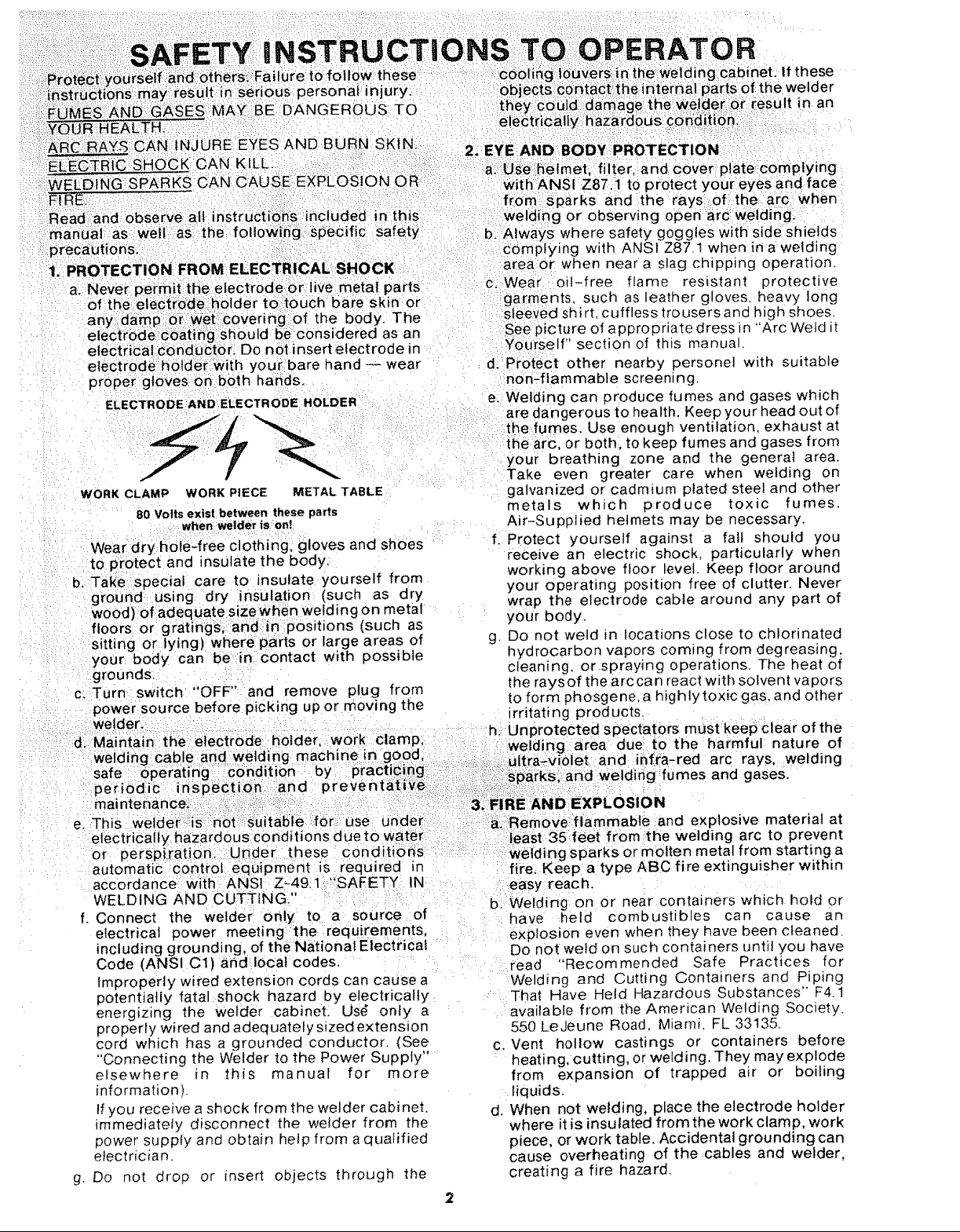

a:. Never permit the electrode or live metal parts

of:the eiectrodeholder t0_t0uch bare sk nor

any: damp:o_ W_eti::covering of the body. The

electrede:cbating slioutd be considered as an

electrical conducltor_ Do n0t insert electrode in

electrode hotde_iWith your bare hand -- wear

pr0pergloVes on both hands.

ELECTRODE AND ELECTRODE HOLDER

WORK CLAMP WORK PIECE METAL TABLE

80 Volts exist between these parts

when welder ison!

Weardry hole_free clothing, gloves and shoes

to protect and insulate the body:

b. Take special care to insulate yourself from

ground using dry insulation (such as dry

wood) of adequate sizewhen welding on metal

floors or gratings, and in:Positions (such as

sitting or lying) where parts or fargo areas of

your body can be in contact with possible

grounds:

c: Turn switch "OFF", and remove plug from

power source before picking up or moving the

welder.

:d. Maintain the electrode: holder, work clamp,

welding cable arid welding machine in good; :i i:

safe Operating i €onditior_ :by : Practii_i_g:!!i: :i:::':

per io d!ic in S pect ion ::=and p r e ve n tat ive i!,:_i,:__!.il

area or when near a slag chipping operation.

c, Wear oil-free flame resistant protective

garments, such as leather gloves heavy long

sleeved shirt, cuffless trousers and high shoes.

See picture of appropriate dress in "Arc Weld it

YOurself" section of this manual.

d. Protect other nearby persone] with suitable

nOn-flammable screening.

e. Welding can produce fumes and gases which

are dangerous to health. Keep your head out of

the fumes. Use enough ventilation, exhaust at

the arc, or both, to keep fumes and gases from

your breathing zone aod the general area.

Take even greater care when welding on

galvanized or cadmium plated steel and other

metals which produce toxic fumes.

Air-Supplied helmets may be necessary.

f. Protect yourself against a fall should you

recewe an electric shock, particularly when

working above floor level. Keep floor around

your operating position free of clutter. Never

wrap the electrode cable around any part of

your body.

g. Do not weld in locations close to chlorinated

hydrocarbon vapors coming from degreasing.

cleaning, orspraying operations. The heat of

the rays of the arc can react with solvent vapors

to form phosgene, a highlytoxic gas. and other

irritating products.

h. nprotected spectators must keepclear of the

area due to the harmful nature of

et and infra-red arc rays, welding

and weldirig fumes and gases.

e. This Welder':_iis ':not;}:::i_uitable i:iori:_:use

electrically hazardous conditions due to

or persph;atiom Under these c0ndil

automatic control equipment iS required in

accordance: with ANSI Z-49.1:.";SAFETY IN

WELDING AND CUTTING_"

f. Connect the welder on!y to a source of

electrical power meeting the requirements,

including grounding, of the National Electrical

Code (ANSI C1) and local codes,

Improperly wired extension cords can cause a

potentially fatal shock hazard by electrically

energizing the Welder cabinet. Us_ only a

properly wired and adequately sized extension

cord which has a grounded conductor. (See

"Connecting the WeJder to the Power Supply ....

elsewhere in this manual for more

information).

If you receive a shock from the welder cabinet.

immediately disconnect the welder from the

power supply and obtain help from a qualified

electrician.

g. Do not drop or insert objects through the

a::Remove:flammable and explosive material at

ieast 35 feet from the welding arc to prevent

welding sparks or molten metal from starting a

fire. Keep a type ABC fire extinguisher within

.easy reach.

b. Welding on or near containers which hold or

have held combustibles can cause an

explosion even when they have been cleaned.

Do not weld on such containers until you have

read "Recommended Safe Practices for

Welding and Cutting Containers and Piping

That Have Heid Hazardous Substances" F4.1

available from the American Welding Society.

550 LeJeune Road, Miami. FL 33135.

c. Vent hollow castings or containers before

heating, cutting, or welding. They may explode

from expansion of trapped air or boiling

liquids.

d. When not welding, place the electrode holder

where it is insulated from the work clamp, work

piece, or work table. Accidental grounding can

cause overheating of the cables and welder,

creating a fire hazard.

e.Neverconnecttheworkcableorclamptoany

objectbuttheworkpieceormeta_worktable.

Connectingto otherobjectssuchasbuilding

ground can cause stray currents to flow,

resultinginoverheatingorfire.

4. PREVENTATIVE MAINTENANCE

a. Never apply power to the welder with any part

of the ,cabinet" removed. Position on-off

switch in "off" position and disconnect welder

from the power supply before doing

maintenance work inside the machine.

Removal of the welder cabinet should be done

onty by a qualified service technician.

b. Before connecting the welder power cord to

the receptacle, check the following:

1. Inspect the power cord and welding cables

for cuts or burns and make sure blades and

ground pin on the plug are straight.

2. Inspect "ON-OFF" switch leverfor cracks or

broken parts.

3, Inspect electrode holder jaw insulators for

cracks or broken parts.

c. Never weld anything on or to the welder

cabinet, as a burn through may cause

transformer failure.

d. If any part of your welder is malfunctioning or

has been damaged or broken, such as switch,

cables, helmet, electrode holder, cease

operation immediately and disconnect welder

from the power source and turn switch "OFF"

until the particular part is properly repaired or

replaced.

5. ADDITIONAL SAFETY INFORMATION

a. For additional safety information, purchase

copies of "Practice for Occupational and

Educational Eye and Face Protection" (ANSI

Z87.1), "Safety in Welding and Cutting" (ANSI

Z49.1), and "Fire Prevention in Use of Cutting

.... , and ,Welding Processes" (ANSIiNFPA No.

518) from the American National Standards

Institute, 1430 Broadway, New York, New

York, 10018. Purchase copiesof"OSHA Safety

and Health Standard" 29 CFR 1910 from the

U.S. Government Printing Office, Washington,

D.C. 20402.

SPECiFICATiONS

INPUT

Volts AC.. ............................ ..... 230

Hertz (Cycles) .;..... ...................... 60

Rated Input Amps .......................... 60

Delay Action Type Circuit Breaker or Fuse 60Amp

Short Circuit Amps ....................... 100

Power Cord Length ................ wire direct

OUTPUT

AC Low Range Amps .................. 50-185

AC High Range Amps .................. 65-295

DC Range Amps ............................ *

Arc Voltage ................................ 30

AC Open Circuit Volts (max) ............... 80

DC Open Circuit Volts (Max) ................ *

Kilo-Volt-Amps .......................... 16,8

Kilo-Watts ............................... 11.0

Power Factor % ............................ 65

Duty Cycle % .......................... 20-100

GENERAL

Electrode Capacity ................... 1/16-1/4

Low Hydrogen ...................... 1/16-3/16

Stainless Steel ...................... 1/16-3/16

Aluminum .................................. *

Electrode Cable Length ................... 12'

Work Cable Length ....................... 10'

Dimensions .................... 15" x 12" x 21"

" Does not apply to this welder

READ AND OBSERVE THE INSTRUCTIONS

APPEARING ON THE WARNING INFORMA-

TION FOUND ON THE CABINET,

ELECTRODE HOLDER AND ON THE INSIDE

OF THE WELDING HELMET.

TURNING WELDE R ON, CHECK THE ELECTRODE HOLDER TO

t .,_ WARNING ELECTR,CSHOCKCA.BEFATAL!BeFOa_I

BE SURE THAT THERE ARE NO PROTRUDING SCRE W HEADS

_1_ AND THAT ALL INSULATION iS SECURE _ _ :" '_

WARNING! ARC WELDING CAN BE iN3URIOUS TO OPERATOi_ AND PERSONS

_N THE WORK AREA -- CONSULT OWNERS MANUAL BEFORE OPERATING

To get the most from your welder we suggest you read the manual carefully--

even if you're an accomplished welder, and keep it available to serve as a

handy reference, or in the event that repair parts would be required.

FULL ONE YEAR WARRANTY ON CRAFTSMAN ELECTRIC WELDER

if thisCraftsman Etectric Welder fails to perform properly, dueto adefect inmateriaJor workmanship,within oneyear

from thedate of purchase, Sears will repair it free of charge. This warranty applies only whilethis product isinuseinthe

United States.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE WELDERTO THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may have other rights wtiich vary from state to state_

SEARS, ROEBUCK AND CO., Dept, 698/731Ai Sears Tower, Chicago, IL 60684

i

1

LENS (_

SHADE NO.

OPERATING!I_INSTR_CTI ONS

Operating ContrOls ................. 6

0 ........................ 7

Warranty _ : ii !:.! :i _.:_i:::.:... :.:;_:.:. _.i _. !., _i 3

Getting tO ::'.. :,:_:i. :. 4

Unpacking and C_cki"gGontents :;: .!;;...... 4

T ................. 8

ARC ..... 1-1

WELDING ROD SPECIFICATIONS ......... 2-1

REPAIR PARTS ............................ 2-6

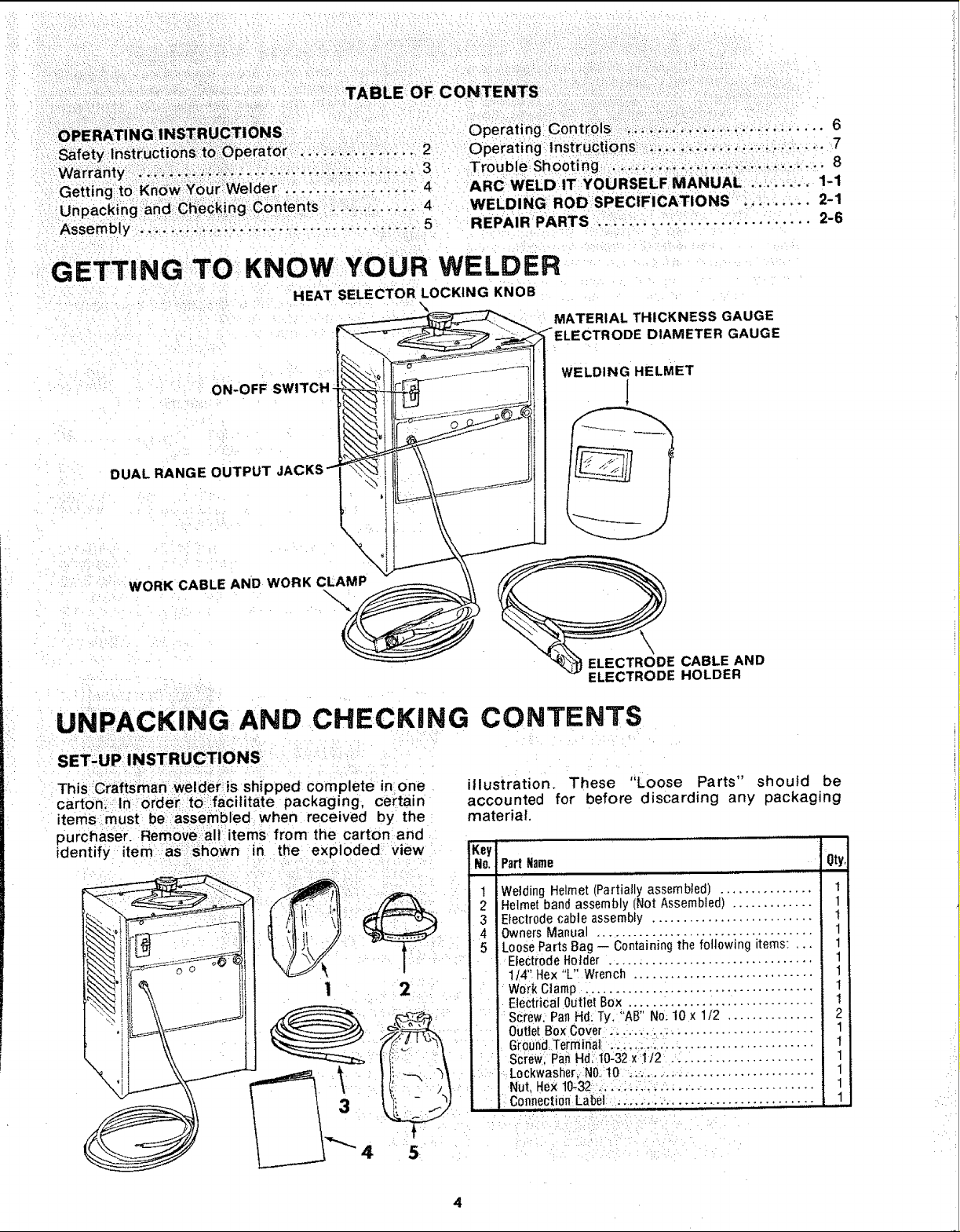

GETTING TO: KNOW YOUR WELDER

HEAT SELECTOR LOCKING KNOB

MATERIAL THICKNESS GAUGE

_ELECTRODE DIAMETER GAUGE

ON-OFF SWITCH

DUAL RANGE OUTPUT _"

WORK CABLE AND WORK CLAMP

-%

\

\

\

WELDING HELMET

ELECTRODE CABLE AND

ELECTRODE HOLDER

UNPACKING AND CHECKING CONTENTS

SET-UP INSTRUCTIONS _

This Craftsmanwelder:is shipped complete in one

carton_ 'In order to:facilitate packaging; ce_'tain

items must be assembled when received by the

purchaser. Remove:all items from the carton and

identify item as _shown in the exploded view

_:__ _i 1 WeidingHetmet(Partia,lyassembted) ...............

--__ ii 1 "_ 2 E,ectrodeHoJder ..............................

illustration. These "Loose Parts" should be

accounted for before discarding any packaging

material.

Key

No. PartName ' Oty

2 Helmet band assembly (NotAssembled) .............

3 Electrode cable assembly ..........................

4 OwnersManual ...................................

5 LooseParts Bag -- Containing the following items: ,..

1/4" Hex"L" Wrench .............................

WorkClamp .:....................................

Screw. Pan Hd: Ty, "AB" No. 10 x 1/2 ..............

i OutletBoxCover. ...... ..: ....................... '

• G_oundTerminal ...... ; .-:...........................

i ] Screw PahHdi10-32 x'_t2 .. .... , ................

J Nut, Hex10:32 ..... ::..:_..: .... ..................

, ConnectionLabel ;... :.. .........

!

1

1

t

1

1

1

1

I

I

2

t

t

1

1

1

1

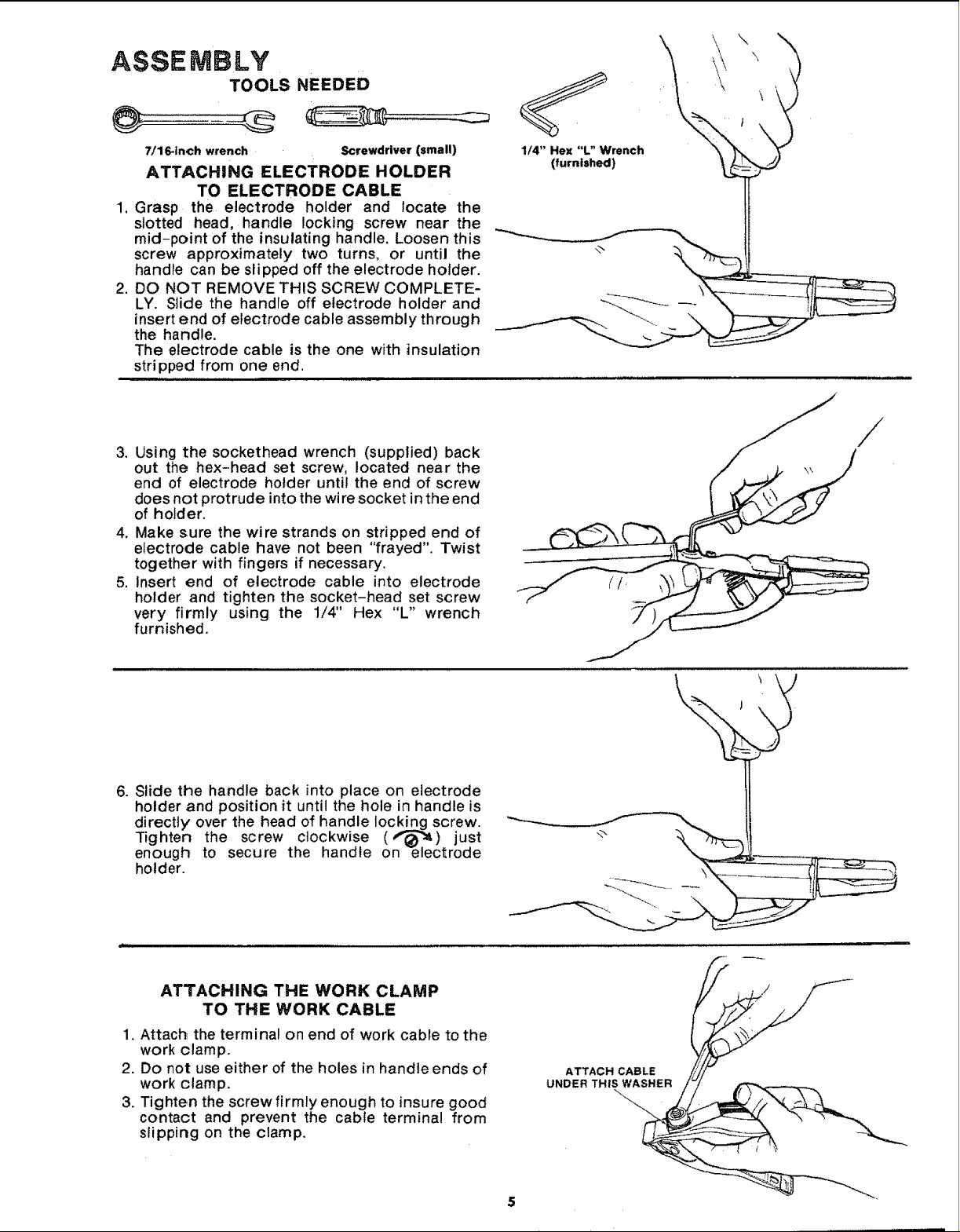

ASSEMBLY

TOOLS NEEDED

@

7/16-inch wrench Screwdriver (small)

ATTACHING ELECTRODE HOLDER

TO ELECTRODE CABLE

,

Grasp the electrode holder and locate the

slotted head, handle locking screw near the

mid-point of the insulating handle. Loosen this

screw approximately two turns, or until the

handle can be slipped off the electrode holder.

,

DO NOT REMOVE THIS SCREW COMPLETE-

LY. Slide the handle off electrode holder and

insert end of electrode cable assembly through

the handle.

The electrode cable is the one with insulation

stripped from one end.

3. Using the sockethead wrench (supplied) back

out the hex-head set screw, located near the

end of electrode holder until the end of screw

does not protrude into the wire socket inthe end

of holder.

4. Make sure the wire strands on stripped end of

electrode cable have not been "frayed". Twist

together with fingers if necessary.

5. Insert end of electrode cable into electrode

holder and tighten the socket-head set screw

very firmly using the 1/4" Hex "L" wrench

furnished.

1/4" Hex "L" Wrench

(furnished)

6. Slide the handle back into place on electrode

holder and position it until the hole in handle is

directly' over the head of handle Iock__nngscrew.

Tighten the screw clockwise (,"_.) just

enough to secure the handle on e_ectrode

holder.

ATTACHING THE WORK CLAMP

TO THE WORK CABLE

1. Attach the terminal on end of work cable to the

work clamp.

2. Do not use either of the holes in handle ends of

work clamp.

3. Tighten the screw firmly enough to insure good

contact and prevent the cable terminal from

slipping on the clamp.

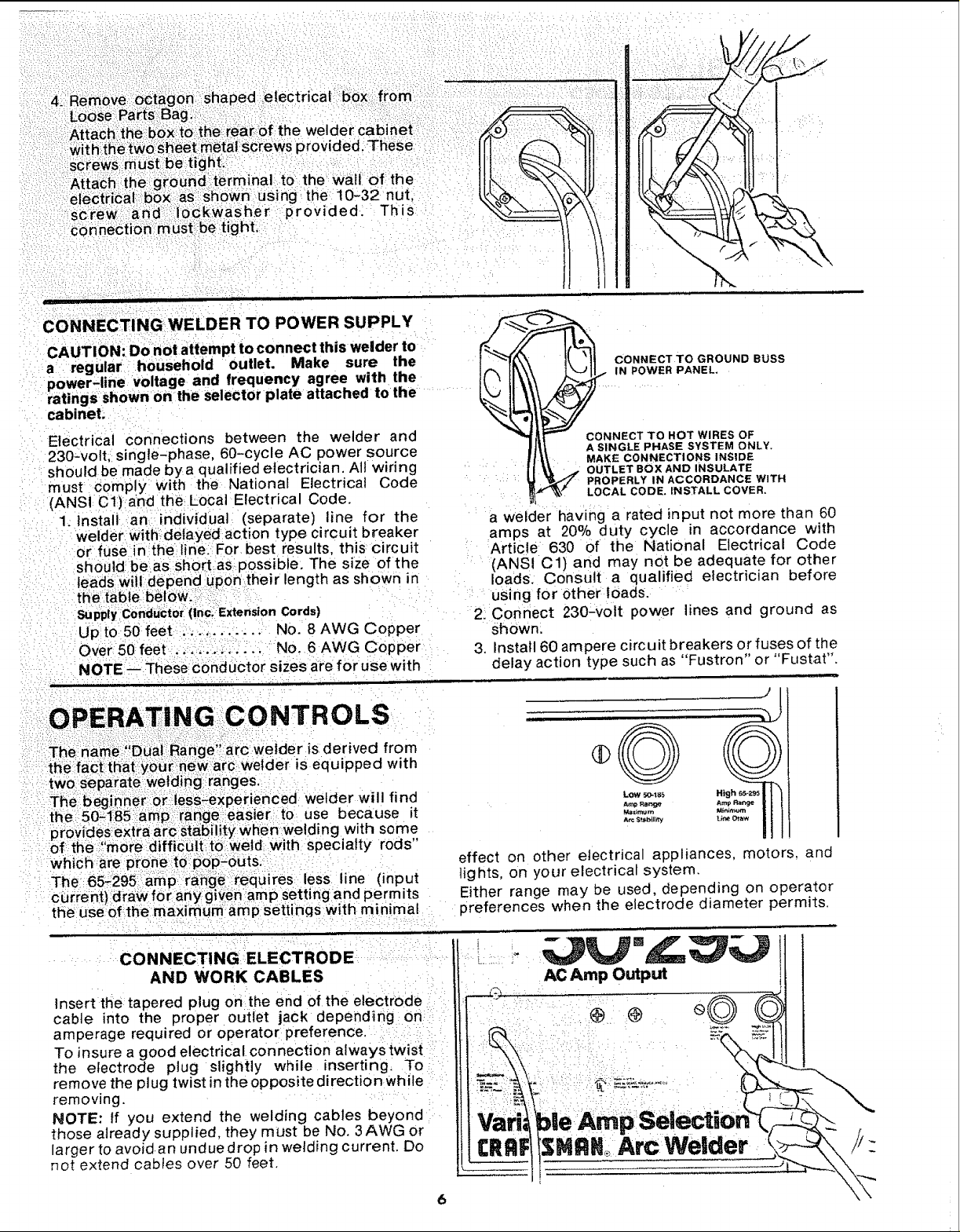

CONNECTING WELDER TO POWER SUPPLY

CAUTION: Do not attempt to connect this welder to

a regular household outlet. Make sure the

power-line voltage and frequency agree with the

ratings shown on the selector plate attached tothe

cabinet_

Electrical connections between the welder and

230-volt, single-phase, 60-cycle AC power source

should be made by a qualified electrician. All wiring

must comply With the National Electrical Code

(ANSI Ct)a'nd theLocal Electrical Code.

1. Install an individual (separate)line for the

welder With;delayed action type circuit breaker

or fuse in the line:: For best results, this circuit

should: boas shortas possible. The size of the

leads:will depend Upon:their length as shown in

the: table belOW_:i:::_

Suppty C0nduCtor (i.c. Exteriston Cords)

Up to 50 feet ._- ........ No. 8 AWG Copper

Over 50:feet .._ .......... No. 6 AWG Copper

NOTE .-These conductor sizes are for use with

i ............ ,.,, , , . , ,

CONNECT TO GROUND BUSS

IN POWER PANEL,

CONNECT TO HOT WIRES OF

A SINGLE PHASE SYSTEM ONLY.

OUTLET BOX AND INSULATE

_ _ MAKE CONNECTIONS INSIDE

PROPERLY IN ACCORDANCE WITH

LOCAL CODE. INSTALL. COVER,

a welder having a rated input not more than 60

amps at 20% dutY cycle in accordance with

Article 630 of the National Electrical Code

(ANSI C1) and may not be adequate for other

loads. Consult a qualified electrician before

using for other loads.

2_

Connect 230-vott power lines and ground as

shown.

3.

Install 60 am pete circuit breakers or fuses of the

delay action type such as "Fustron" or "Fustat".

H

L ,

CON NECTING ELECTRODE

AND WORK CABLES

Insert the tapered plug on the end of the electrode

cable into the proper outlet jack depending on

amperage required or operator preference.

To insure a good electrical connection always twist

the electrode plug slightly while inserting. To

remove the Dlug twist in theoppositedirection while

removing.

NOTE: If you extend the welding cables beyond

those already supplied, they must be No. 3 AWG or

larger to avoidan unduedrop in welding current. Do

not extend cables over 50 feet.

LOW r_O-18,_

Am_ Rar_ge

M=xLmum

Arc $_I_#_v

effect on other electrical appliances, motors, and

lights, on your electrical system.

Either range may be used, depending on operator

preferences when the electrode diameter permits.

L

AC Amp Output

leArnp se

$MRN Arc Welder

__J

6

Connectthework clamp to the piece to be welded,

(to complete the electrical circuit) or to the welding

table itself provided it is metallic or wilt conduct

electricity!

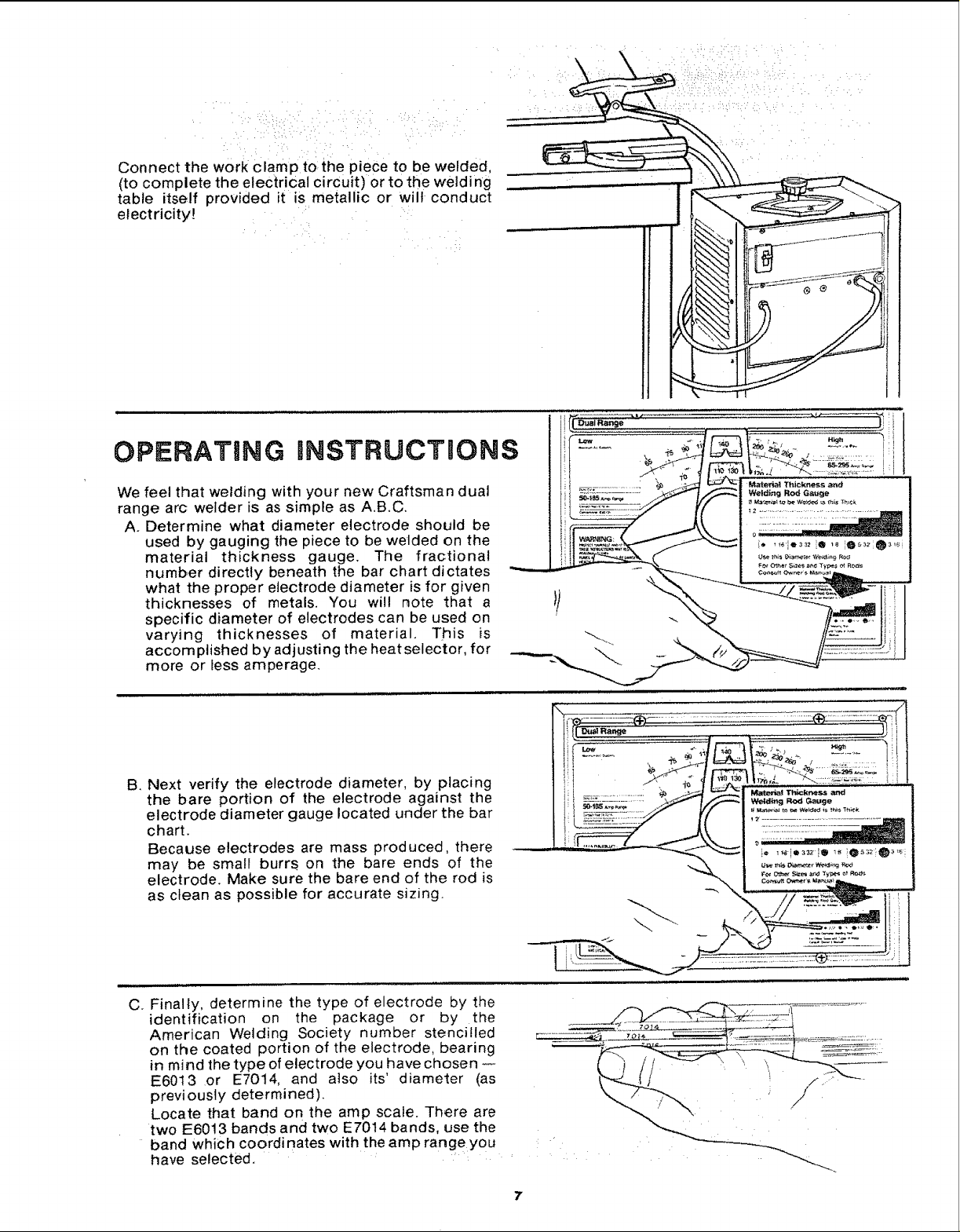

OPERATING INSTRUCTIONS

We feel that welding with your new Craftsman dual

range arc welder is as simple as A.B.C.

A. Determine what diameter electrode should be

used by gauging the piece to be welded on the

material thickness gauge. The fractional

number directly beneath the bar chart dictates

what the proper electrode diameter is for given

thicknesses of metals. You will note that a

specific diameter of electrodes can be used on

varying thicknesses of material. This is

accomplished by adjusting the heat selector, for

more or less amperage.

B. Next verify the electrode diameter, by placing

the bare portion of the electrode against the

electrode diameter gauge located under the bar

chart.

Because electrodes are mass produced, there

may be small burrs on the bare ends of the

electrode. Make sure the bare end of the rod is

as clean as possible for accurate sizing.

C. Finally, determine the type of electrode by the

identification on the package or by the

American Welding Society number stencilled

on the coated portion of the electrode, bearing

in mind the type of electrode you have chosen

E6013 or E7014, and also its' diameter (as

previously determined).

Locate that band on the amp scale. There are

two E6013 bands and two E7014 bands, use the

band which coordinates with the amp rangeyou

have selected.

7

weld.

Because metals vary {n their make up and the

technique of each operat0r is different, you may

find it necessary to: increase: or decrease the

amperage output accord!ngly.

CAUTION: Donol loosen and move amp se|ector

while welding..

The duty cycle scales bracketing the amperage

sca':les are provided for your convenience and

protection of your new weGder. Duty cycle is the

performance level of the welder based on a 10

minute time span. For example welding for 6

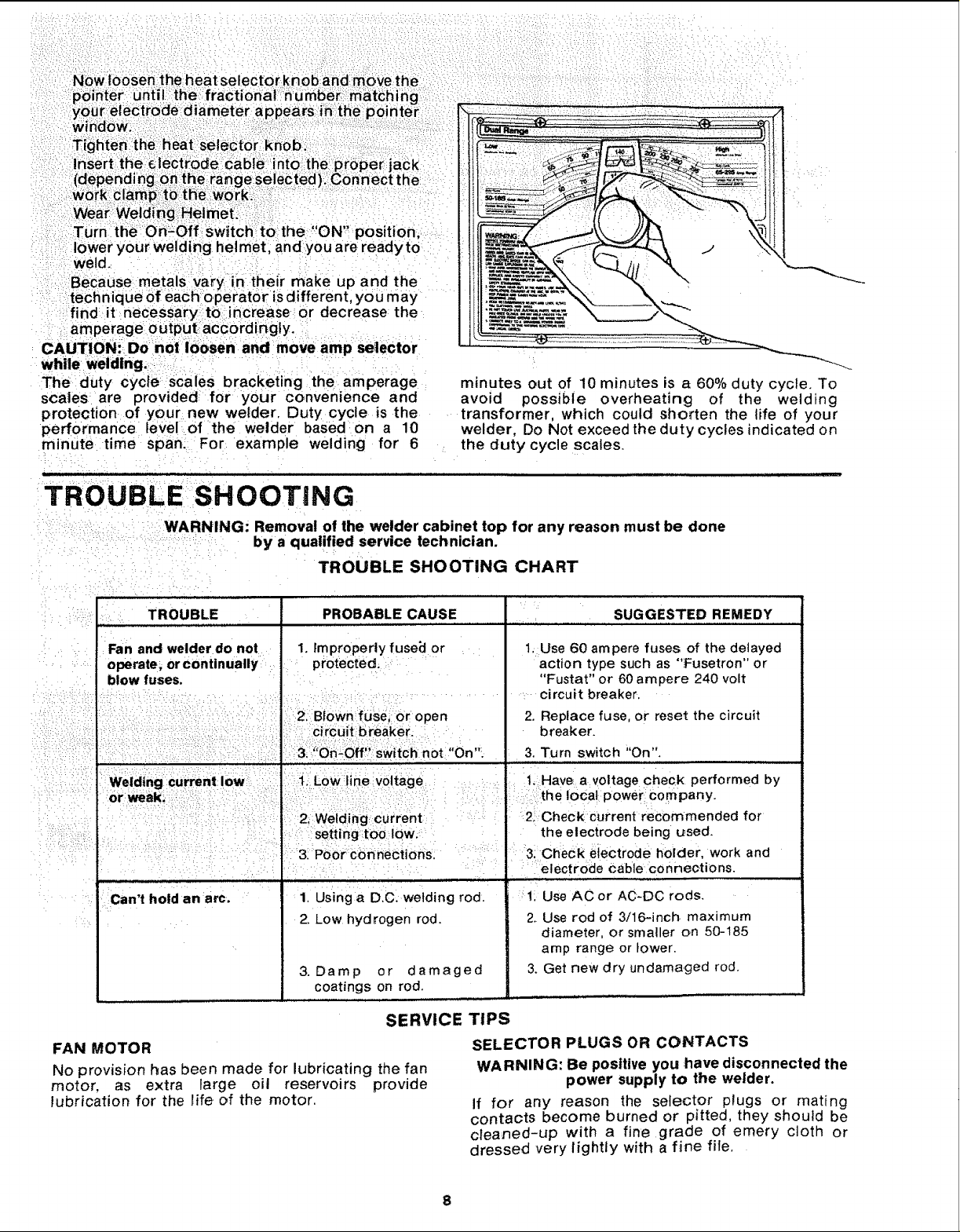

TROUBLE SHOOTING

minutes out of 10 minutes is a 60% duty cycle. To

avoid possible overheating of the welding

transformer, which could shorten the life of your

welder, Do Not exceed the duty cycles indicated on

the duty cycle scales.

WARNING: Removal of the welder cabinet top for any reason must be done

TROUBLE , SUGGESTED REMEDY

Fan and welder do not 1. Improperly fuse_l or 1. Use 60 ampere fuses of the delayed

operate; orcontinually : protected, action type such as "Fusetron" or

blow fuses. ' : "Fustat" or 60 ampere 240 volt

i; Welding current low: !i:i i'::':_ilLow ine voi'tage , "t. Have a voltage 'c'heck performed by

or:weak; : ! ; :/ : :the local powerl Company.

.... : I: Welding current I 2! Check current recommended for

: : : ! : setting:too Iowl I the electrode being used.

...... :- : : iI 3 P0or:c0nnect ons I 3: Check eiectrode holder work and

Can't hold an arc.

by a q ualified service technician.

TROUBLE SHOOTING CHART

PROBABLE CAUSE

I ................ circuit breaker.

i 2, Blown:fuse,; or open 2. Replace fuse, or reset the circuit

Circuitbreaker. breaker.

.3,?"OPi:-0ff":switch not "On". 3. Turn switch _'On".

; I : ..... .... : electrode Cable Connections.

1. Using a D.C. welding rod.

2. Low hydrogen rod.

3. Damp or damaged

coatings on rod.

i 1: Use ACor AC-DC rods.

2. Use rod of 3/16-inch maximum

diameter, or smaller on 50-185

amp range or lower.

3. Get new dry undamaged rod.

SERVICE TIPS

FAN MOTOR

No provision has been made for lubricating the fan

motor, as extra large oil reservoirs provide

lubrication for the life of the motor.

SELECTOR PLUGS OR CONTACTS

WARNING: Be positive you :have disconnected the

power supply to the welder.

If for any reason the selector plugs or mating

contacts become burned or pitted, they should be

cleaned-up with a fine grade of emery cloth or

dressed very lightly with a fine fife.

8

fl

%_

A COMPREH ENSIVE

GUIDE FOR YOUR

NEW CRAFTSMAN

ARC WELDER AND

WHAT iT W=ILL DO

CONTAt NS:

INFORMATION ABOUT

o VARIOUS TYPES OF RODS

o USEFUL ACCESSORIES

e TIPS ON CUTTING, WELDING

AND BRAZING

,,J

Form No. SP574+5 t.1

_i_?/:-: ¸ _:!. ......

TABLE OF _cONTENTs

_iii_!i.i___

Page

Your WelderandWhatit Will Do ............. 1-3

Howthe CraftSmanCOntactRod SimplifiesWelding 1-3

WhatHappensWhenYou Weld? .. .......... 1-3

RoadeefareWeiding .:i._._,.!..:,....i.,.... 1-4

LearnBy Doing ........................... 1-5

PositionWelding ......................... 1-11

Cast4ronWelding....; .... ...... . 1-14

.a,dSu ,,=jn.Wor,,C. .gEd,-IIZ 1-15

TheTwin CarbonArc Torch ............... 1-16

CuttingandOtherMiscellaneousOperations ... 1-17

Read this Manual carefully for additional welding information.

1.2

. _ ••• H• •••• H•¸

SEARS, ROEBUCK AND COMPANY

AND S|MPSONS-SEARS LIMITED

YOUR WELDER and what H wil/ do . .

Your CRAFTSMAN ArcWelderisa sturdilyconstructedandthoroughlytestedmachineengineeredto

give many years of efficient trouble-freeservice. It is listed by Underwriters' Laboratories,

incorporated,whichmeansthat it passesal! requirementsof safety, fire hazardand temperaturerise

limitsasspecifiedin their Standardfor Transfer-TypeArc-WeldingEquipment.

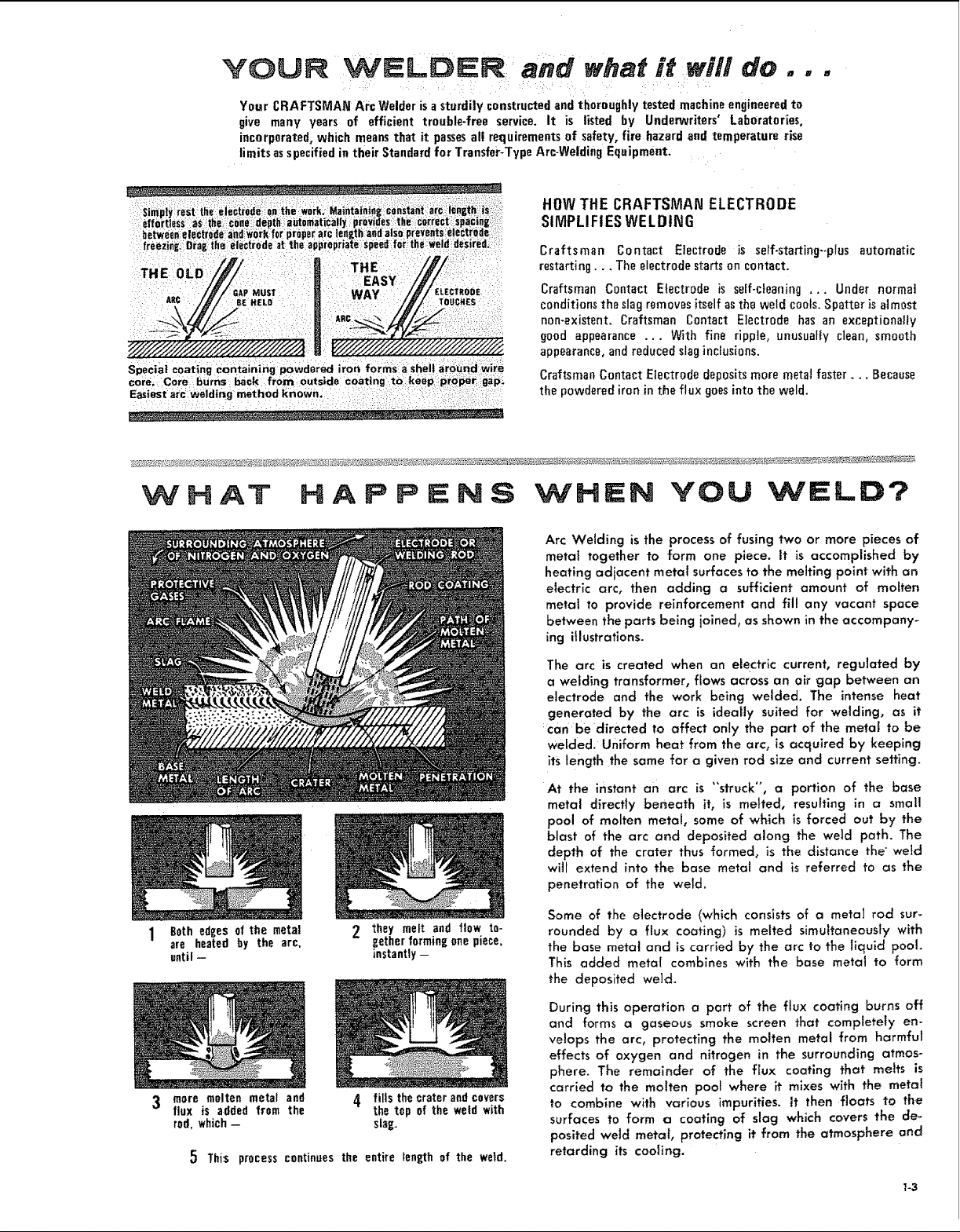

S reply rest the electrode :an the iwork, Maintaining consta_nt:arcilength::is _

effortless as the cOne_:depth aOtomatiCaly pt+oydes the correct! spacin[i

betweenelectr#de:a:ndlw0rkfor properarc length andals0 p{ev _ht_,e ei_trede

freezinj Drag the electrode at the appropriate speed f0r the Weld:desired_:

E

,ec/_'/_# MUSe' WAY /Ji''LoEC_OOe

HOWTHE CRAFTSMAN ELECTRODE

SIMPLIFIES WELDING

Craftsman Contact Electrode is se/f-starting--p{usautomatic

restarting... The electrode startson contact.

Craftsman Contact Electrode is self-cleaning... Under normal

conditionstheslagremovesitselfastheweld cools.Spatter is almost

non-exiszent. Craftsman Contact Electrode has an exceptionally

good appearance... With fine ripple, unusuafiyclean, smooth

appearance,andreducedslaginclusions.

Special coating containing powdered iron forms a shell around wire

Core, Core burns back from outside coating to keep proper: go:p;

Easiest arc_welding method known.

CraftsmanContact Electrodedepositsmoremetal faster... Because

the powderedironin the flux goesintothe weld.

W H AT H A P P N S WHEN YOU WELD?

Arc Welding isthe processof fusing two or more pieces of

metal together to form one piece. It is accomplished by

heating adjacent metal surfaces to the melting point with an

electric arc, then adding a sufficient amount of molten

metat to provide reinforcement and fill any vacant space

between the parts being ioined, asshown in the accompany-

ing itlustrations.

The arc is created when an electric current, regulated by

a welding transformer, flows across an air gap between an

electrode and the work being welded. The intense heat

generated by the arc is ideally suited for welding, as it

:can be directed to affect only the part of the metal to be

welded, uniform heat from the arc, is acquired by keeping

its length the same for a given rod size and current setting.

1 Bath edges of the metal

are heated by the arc,

until --

mare molten metal and

flux is added from the

rod, which-

5 This process continues the entire length of the weld.

2 _hey melt and flow to-

gether forming onepiece,

instantly -

4 fills thecrater andcovers

the top of the weld with

sing.

At the instant an arc is "struck", a portion of the base

metal directly beneath it, is melted, resulting in a small

pool of molten metal, some of which is forced out by the

blast of the arc a_d deposited along the weld path. The

depth of the crater thus formed, is the distance the" weld

will extend into the base metal and is referred to as the

penetration of the weld.

Some of the electrode (which consists of a metal rod sur-

rounded by a flux coating) is melted simuhaneousty with

the base metal and is carried by the arc to the liquid pool

This added mete! combines with the base metal to form

the deposited we}.d.

During this operation a part of the flux coating burns off

and forms a gaseous smoke screen that completely en-

ve!ops the arc, protecting the molten metal from harmful

effects of oxygen and nitrogen in the surrounding atmos-

phere. The remainder of the flux coating that melts is

carried to the molten pool where it mixes with th_ metal

to combine with various impurities. It then floats to the

surfaces to form a coating Of slag which covers the de-

posited weld metc_{,protecting it from the atmosphere and

retarding its coollng.

Loading...

Loading...