Craftsman 113201372 Owner’s Manual

MODEL N_ °

113.201372 _

Serial

Number

Model and serial

number may be found

at the rear

of the cabinet.

You should record both

model and serial number

in a safe place for

future use,

CAUTION:

Read

230 AMP

DUAL RANGE

ARC WELDER

SAFETY

UNSTRUCTIONS

carefully

® assembly

e operating

® repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

Part No. 61337 Printed in U SA

SAFETY gNSTRUCTIONS TO OPERATOR

For your own protection, read and observe all instructions

included in this manual as well as the following specific

safety precautions:

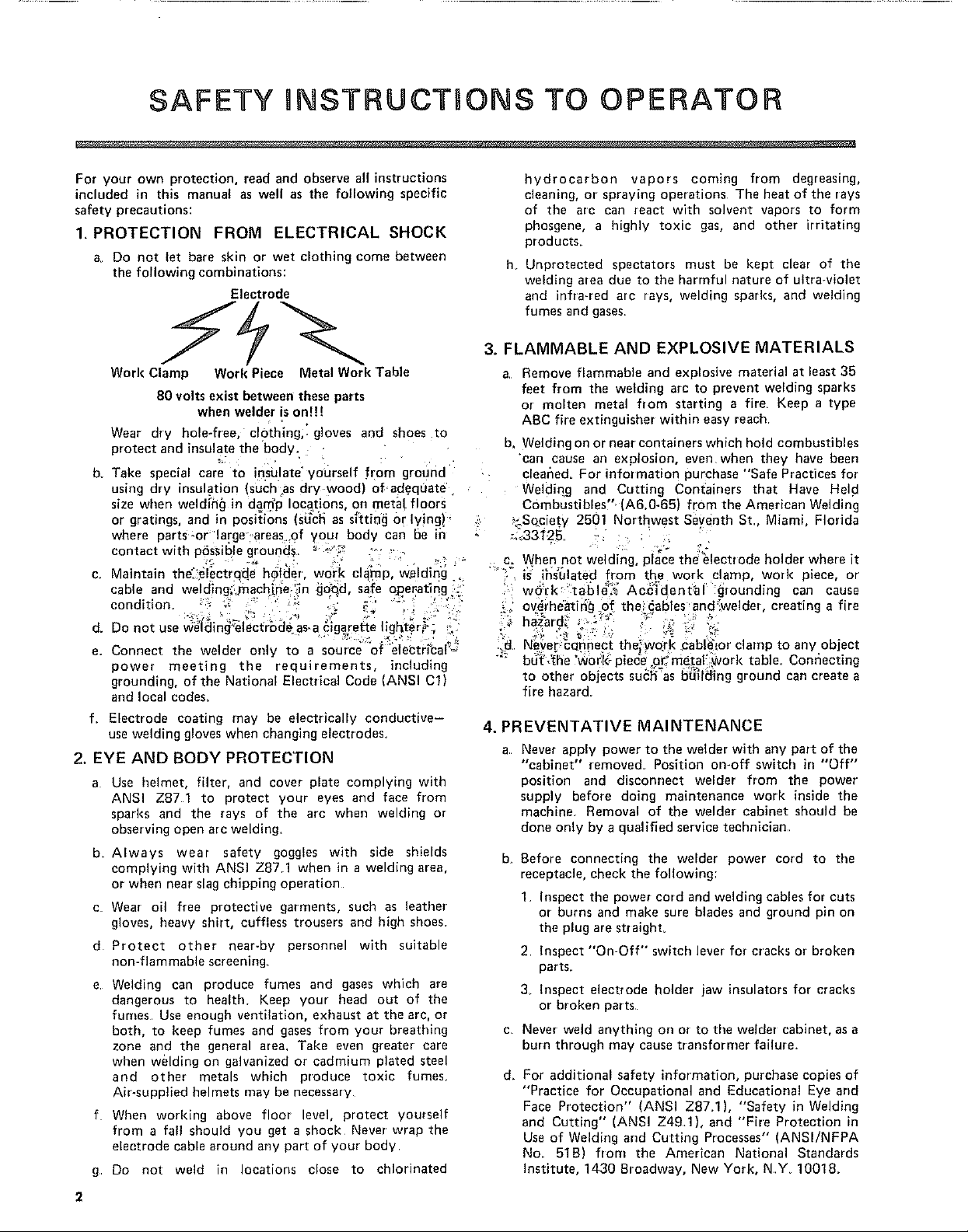

1, PROTECTION FROM ELECTRICAL SHOCK

a_ Do not let bare skin or wet clothing come between

the following combinations:

Electrode

Work Clamp

Work Piece Metal Work 'Table

80 volts exist between these parts

when welder is onH!

Wear dry hole-free, clothing,_ gloves and shoes to

protect and insulate the body.

b. Take special care to insulate" yourself from ground

using dry insulation (suchas dry wood) of-ad.equate

size when welding] in dam'p locations on metal floors

or grat ngs, and m poslt_ons (such as s=ttmgor lying ! "

where parts-or"large"areas of your body can be ir

contact with phssible ground_. ; ".;_ ro "_

C. Maintain the_.#l_ctr_de h_tder work clamp, w_ldin'g

cable and welding_:rnach_ne'._n_Qd, safe operating._

condition, : _ _; " " ,:' -' • "

Do not use weldm_ electrode as-aclaarette hg_ter, . -

e. Connect the welder only to a source of electncal'.-

power meeting the requirements, irrcluding

grounding, of the National Electrical Code (ANSI Cl)

and local codes.

f. Electrode coating may be electrically conductive-

use welding gloves when changing electrodes.

2. EYE AND BODY PROTECTION

a. Use helmet, filter, and cover plate complying with

ANSI Z87 1 to protect your eyes and face from

sparks and the rays of the arc when welding or

observing open arc welding,

b Always wear safety goggles with side shields

complying with ANSI Z871 when in a welding area,

or when near slag chipping operation

c. Wear oil free protective garments, such as leather

gloves, heavy shirt, cuffless trousers and high shoes.

d Protect other near-by personnel with suitable

non-flammable screening_

e

Welding can produce fumes and gases which are

dangerous to health, Keep your head out of the

fumes, Use enough ventilation, exhaust at the arc, or

both, to keep fumes and gases from your breathing

zone and the general area, Take even greater care

when welding on galvanized or cadmium plated steel

and other metals which produce toxic fumes

Ab-supplied helmets may be necessary

f When working above floor level, protect yourself

from a fall should you get a shock Never wrap the

electrode cable around arty part of your body

g Do not weld in locations close to chlorinated

2

hydrocarbon vapors coming from degreasing,

cleaning, or spraying operations The heat of the rays

of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating

products

h Unprotected spectators must be kept clear of the

welding area due to the harmful nature of ultra÷violet

and infra-red arc rays, welding sparks, and welding

fumes and gases

3. FLAMMABLE AND EXPLOSIVE MATERIALS

a Remove flammable and explosive material at least 35

feet from the welding arc to prevent welding sparks

or molten metal from starting a fire Keep a type

ABC fire extinguisher within easy reach.

b, Welding on or near containers which hold combustibles

can cause ar_explosion, even when they have been

cleaned= For information purchase "Safe Practices for

Welding one Cutting Containers that Have Hel d

Combustibles" (A6.0-65_ from the American Welding

:.Society 2501 Northwest Seventh St Miami, Florida

c. When not welding, place the electrode holder where it

"" i_ ihs'61ated from the work clamp, work piece, or'

wc_rk 'table_._ Ac_'idental grounding can cause

,_ overheating of the_ables'and_welder, creating a fire

haz_rd_ _ ::_" _ "

iild Never-c_nnect the_work cablelor clamp to any obJect

b_ _'he 'worl<:p e_e o_ me.to_ork tab e Conr]ecting

to other objects such as bu_l_mg ground can create a

fire hazard.

4. PREVENTATIVE MAINTENANCE

a. Never apply power to the welder with any part of the

"cabinet" removed_ Position on-off switch in "Off"

position and disconnect welder from the power

supply before doing maintenance work inside the

machine. Removal of the welder cabinet should be

done only by a qualified service technician,

b.

Before connecting the welder power cord to the

receptacle, check the following:

1 Inspect the power cord and welding cables for cuts

or burns and make sure blades and ground pin on

the plug are straighL

2 Inspect "On-Off" switch lever for cracks or broken

parts.

3 Inspect electrode holder jaw insulators for cracks

or broken parts.

c.

Never weld anything on or to the welder cabinet, as a

burn through may cause transformer failure.

d_

For additional safety information, purchase copies of

"Practice for Occupational and Educational Eye and

Face Protection" (ANSI Z87.1), "Safety in Welding

and Cutting" (ANSI Z49.1), and "Fire Protection in

Use of Welding and Cutting Processes" (ANSI/NFPA

No. 518) from the American National Standards

institute, 1430 Sroadway, New York, N.Y 10018_

READANDOBSERVETHEINSTRUCTIONSAPPEARINGONTHEWARNINGLABELSFOUNDONTHEINSIDEOF

THEWELDINGHELMET,ANDONTHESELECTORPLATE,CABINETANDELECTRODEHOLDER.

_MERIEAN N,_ 71ON,_L ST,INI,),_RDS hV_TITUTE

WARNII_G: prolel:I VotJt_ell _t_d {_thefs _e;l(I ;_f_{I

F UJ%_ES AND GASES c;lll he (i,ln{J_ fal_s tn ymJl he_hh

ARC RAYS call inlllle eyel and hum stroll ELECTRIC

SHOCK cml kill

• Be,_d and understand _l_e incm_Hanh_fef _ =nslnJ_io_t_

• Keep your head aut of _1_ h_nles

• U_a enmJ_h Vel_il_iOl_, _xha_Jst al Ihe ;_,c, ot boUI

• Wear cot _ecl eye, _ar _nd body ltlo_ectlon

• Do I_O_ _ouch llve elec_ rical I)aFt_

• See American National Si,_nIt,_f(I Z49.1 S_lety in

WARNING ELeCTR,C SHOCK CAN BE FATALt BEFORE

TURNING WELDER ON CHECK THE ELECTRODE HOLDER TO

BE SURE THAT THERE ARE NO PROTRUDING SCREW HEADS

AND THAT ALL INSULATION IS SECURE _ _ll!! 2

PttEC,_UTION_RY I Af]EL

unders14_mt lh_ I_bel

and yo_Jt amployef's _alely pr acllce_

lo kee I) _ume_ and _ase_ from 7o_f I_re;_lhi_ I z_)m_

and the {Jene[al area

Wl!h_hlg mid Cliilin=j ¸' i)_JIilillle(I I}7 lhe Ait/eficalt

Wohthlg Sociel¥ 2501 N W 71h SI,, _,tbm_ Florida

33125; OSIIA Saf_W _1_{IHe_hh SI,_ndatds 29 CFR

1910, availal)_J_ hont U S Dep_tmenl o_ Labor

Washinglon , DC 20210

DO NOT R E_,_OV E THIS LABEL

CllRI0_

USe _lJ 101 IE,_ _n0 _y_ pi01egi0n

a_ins$ =nj_io_ rays Itom _c _ding

_nd culling US_ propel shade li!I_

plale _P¢_.I {ssi_IO _12 plo[_ction

(Iil_ pble b_ck_up plale• s_p_lale

salely spectacles) shou+d be worn

wheII U_l_ 0 this device It_cl fe-

sislanl plal_ ale DOT un_le.lkable

elted ¢_ s_la_h_d _Je_ t_u_ VISI_I

al_{_ 5_liO_$1 le_uc8 pI01eGIJ0r_--

{epia_eintricately

Inspecl {(equ_Ily an_ immedi31_ly

I_p_u_ _om ot d_m_ged p_tls

t,it4_ ir_ t¢=¢.¢_ =f JJ.I.L zr/1

DO NOT REMOVE "fills [/_3,E L

LENS

SHADENO

FULL ONE YEAR WARRANTY ON CRAFTSMAN ELECTRIC WELDER

If this Craftsman Electric Welder fails to perform properly, due to a defect in material or workmanship,

within one year from the date of purchase, Sears will repair it free of charge,

WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE WELDER TO THE NEAREST

SEARS STORE OR SERVICE CENTER THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state,

SEARS, ROEBUCK AND CO. Sears Tower_ BSC 41-3, Chicago, IL 60684

WARNING - FOR YOUR SAFET'_

R_GAR_ING B0 VOLT POTENTIAL

SHOC;{ AT ELECT}IOD_

REGARDING POTENTIAL SHOCK ON CABINET

COW,FORMING TO 1H_ _ATIONAL _L_CTnlCAL COD_

REGAROING £yE INJURY

REGARDING FIRE

LI_ O_AW _*nC eT_muY't

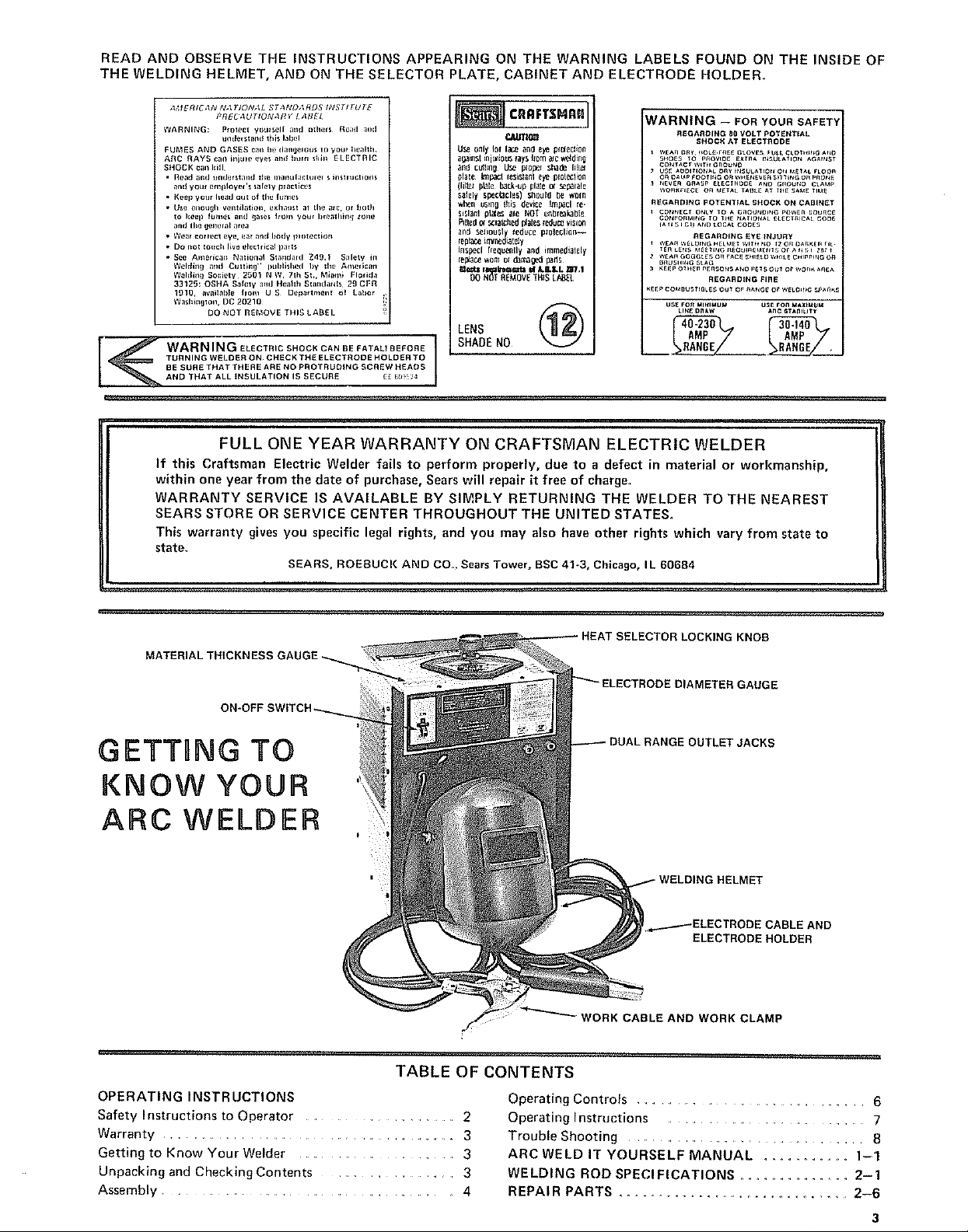

MATERIAL THICKNESS GAUGE.

ON-OFF SWITCH.-.

GETTING TO

KNOW YOUR

ARC WELDER

TABLE OF CONTENTS

OPERATING INSTRUCTIONS

Safety I nstructions to Operator .............................. 2

Warranty ............................................ 3

Getting to Know Your Welder ............................. 3

Unpacking and Checking Contents .......................... 3

Assembly ................................... 4

LOCKING KNOB

'IAMETER GAUGE

DUTLETJACKS

HELMET

AND

ELECTRODE HOLDER

WORK CABLE AND WORK CLAMP

Operating Controls ................................ 6

Operating Instructions ........................... 7

Trouble Shooting ............................... 8

ARC WELD IT YOURSELF MANUAL .............. 1-1

WELDING ROD SPECIFICATIONS ............... 2-1

REPAIR PARTS ..................................... 2-6

SPECIFICATIONS

Input Volts (AC): ........... 230

Hertz (Cycles): ................ 60

Output Amperage: ........ 30 to 140

40 to 230

Rated Input Amps: ............... 50

Short Circuit Input Amps: ......... 66

Fuse or Circuit

Breaker Required: ......... 50 Amps

Arc Voltage: ............... 25

KVA: .................... 108

KW: ........................... 7 1

Max Open Circuit

Output Volts .......... 80

Power Factor ........... 66%

Duty Cycle: ........ 20 to 100%

Electrode Capacity: 1/16" to 3/16"

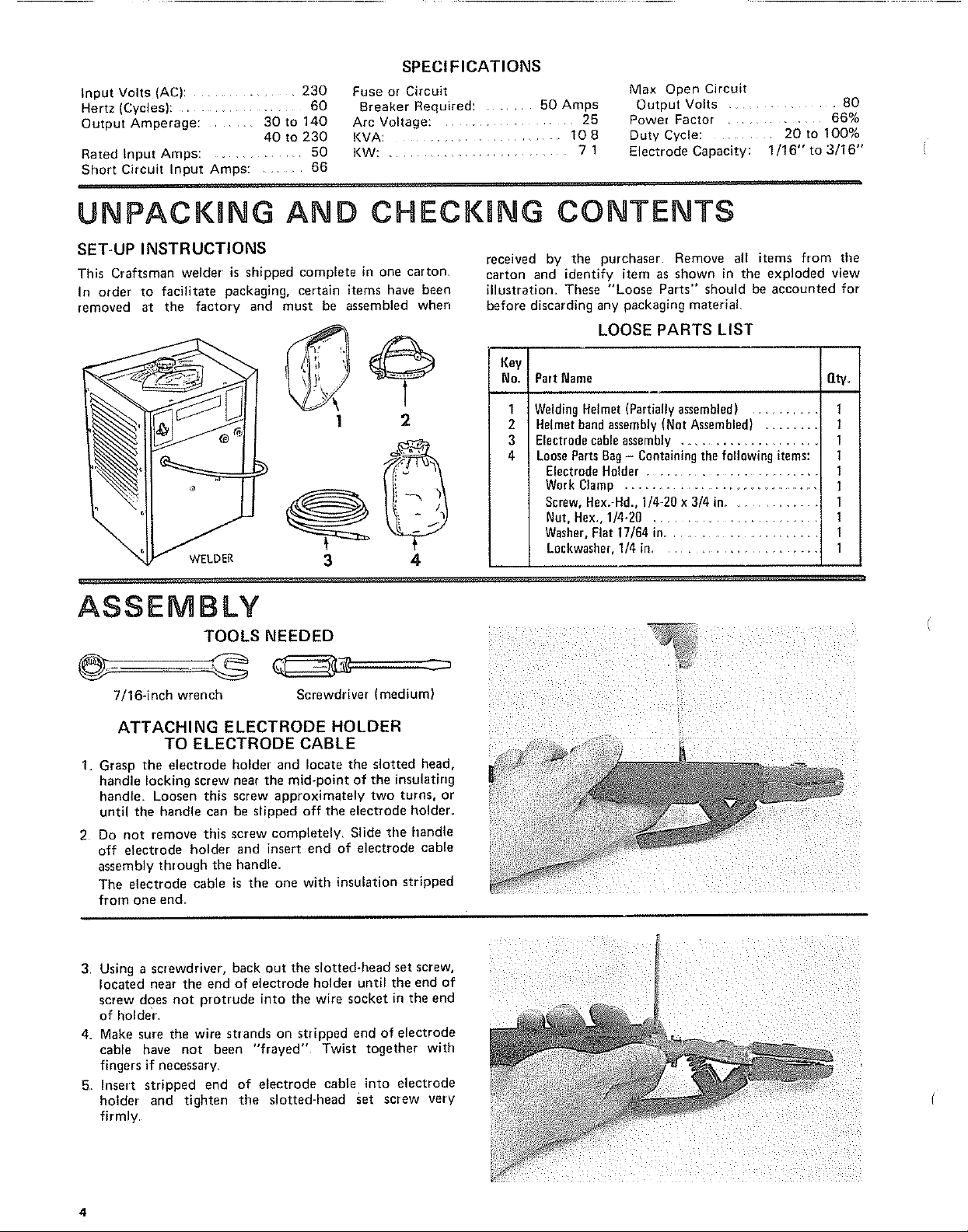

UNPACKING AND CHECKUNG CONTENTS

SET-UP INSTRUCTIONS

This Craftsman welder is shipped complete in one carton

In order to facilitate packaging, certain items have been

removed at the factory and must be assembled when

3 4

ASSEMBLY

TOOLS NEEDED

received by the purchaser Remove all items from the

carton and identify item as shown in the exploded view

illustration These "Loose Parts" should be accounted for

before discarding any packaging material.

LOOSE PARTS LIST

Key

No. Part Name

1 WeldingHelmet(Partially assembled) ..........

2 Helmet bandassembly(Not Assembled) ........

3 Electrodecableassembly .........................

4 LoosePartsBag- Containing the following items:

Electrode Holder .....................................

Work Clamp ........................................... 1

Screw,Hex.-Hd.,1/4-20 x 3/4 in............... 1

Nut, Hex., 1/4-20 ........................... 1

Washer,Flat 17/64 in............................... 1

Loci{washer,1/4 in 1

O.ty.

i

t

1

1

I

1

,,lOinchwrenchScrewdriver(medium)

ATTACHING ELECTRODE HOLDER ............. ....

TO ELECTRODE CABLE

I. Grasp the electrode holder and locate the slotted head,

handle locking screw near the mid-point of the insulating

handle Loosen this screw approximately two turns, or

until the handle can be slipped off the electrode bolder..

2 Do not remove this screw completely. Slide tile handle

off electrode holder and insert end of electrode cable

assembly through the handle.

The electrode cable is the one with insulation stripped

from one end

3 Using a screwdriver, back out the slotted-head set screw,

located near the end of electrode holder until the end of

screw does not protrude into the wire socket in the end

of holder

4. Make sure the wire strands on stripped end of electrode

cable have not been "frayed" Twist together with

fingers if necessary.

5 Insert stripped end of electrode cable into electrode

holder and tighten the slotted-head set screw very

firmly

4

6 Slide the handle back into place on electrode holder and

position it until the hole in handle is directly over the

head of handle locking screw Tighten the screw

clockwise @ just enough to secure the Inandle on

electrode holder

_i_i ii _' _ i

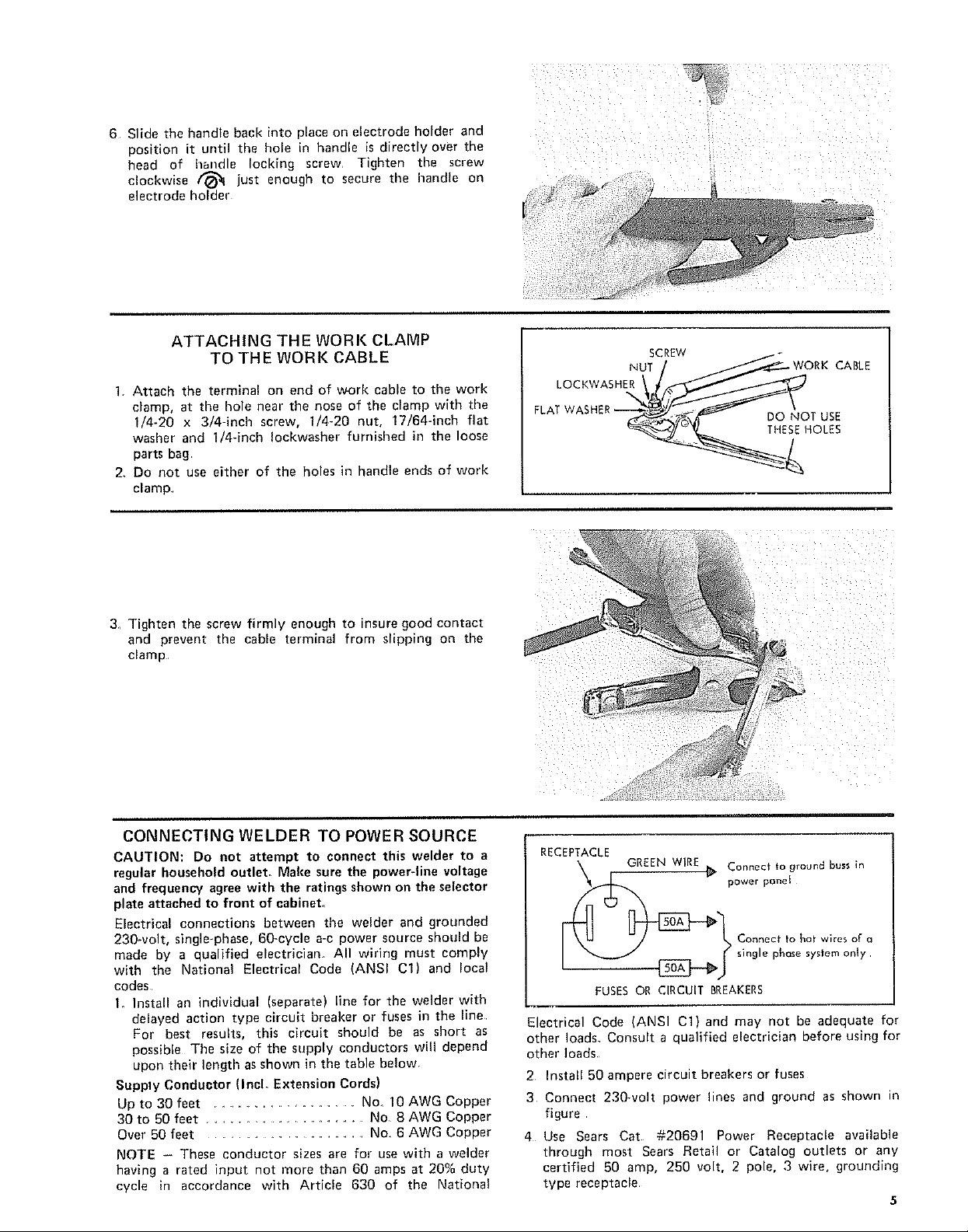

ATTACHING THE WORK CLAMP

TO THE WORK CABLE

1. Attach the terminal on end of work cable to the work

clamp, at the hole near the nose of the clamp with the

1/4-20 x 3/4-inch screw, 1/4-20 nut, 17/64-inch flat

washer and I/4-inch Iockwasher furnished in the loose

parts bag

2_ Do not use either of the holes in handle ends of work

clamp

3_ Tighten the screw firmly enough to insure good contact

and prevent the cable terminal from slipping on the

clamp

SCREW

LOCKWASHNUTE_ HWORKCABLE

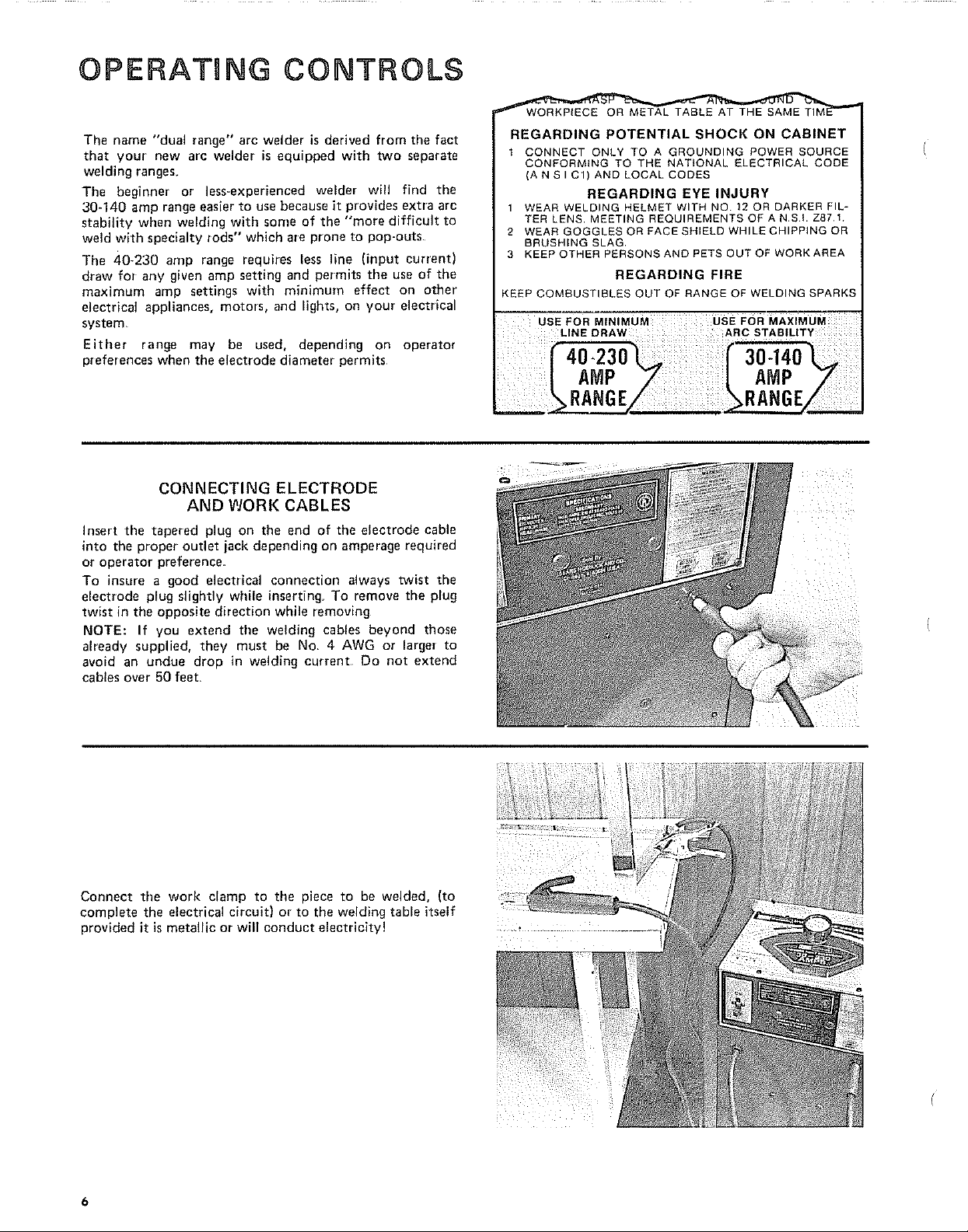

CONNECTING WELDER TO POWER SOURCE

CAUTION: Do not attempt to connect this welder to a

regular household outlet. Make sure the power-line voltage

and frequency agree with the ratings shown on the selector

plate attached to front of eabinet.

Electrical connections between the welder and grounded

230-volt, single-phase, 60-cycle a-c power source should be

made by a qualified electrician. All wiring must comply

with the National Electrical Code (ANSI C1) and local

codes

1. Install an individual (separate) line for the welder with

delayed action type circuit breaker or fuses in the line

For best results, this circuit should be as short as

possible The size of the supply conductors will depend

upon their length as shown in the table below

Supply Conductor (Incl. Extension Cords)

Up to 30 feet ............................ No_ 10 AWG Copper

30 to 50 feet ............................. No 8 AWG Copper

Over 50 feet ................................... No 6 AWG Copper

NOTE - These conductor sizes are for use with a welder

having a rated input not more than 60 amps at 20% duty

cycle in accordance with Article 630 of the National

RECEPTACLE

k GREENWIRE_. Connectto ground bussin

Connect to hot wires o[ Q

powerponet

single phase system only

FUSES OR CIRCUIT BREAKERS

Electrical Code (ANSI C1) and may not be adequate for

other loads Consult a qualified electrician before using for

other loads

2 Install 50 ampere circuit breakers or fuses

3 Connect 230wolt power lines and ground as shown in

figure

4 Use Sears Cat #20691 Power Receptacle available

through most Sears Retail or Catalog outlets or any

certified 50 amp, 250 volt, 2 pole, 3 wire, grounding

type receptacle.

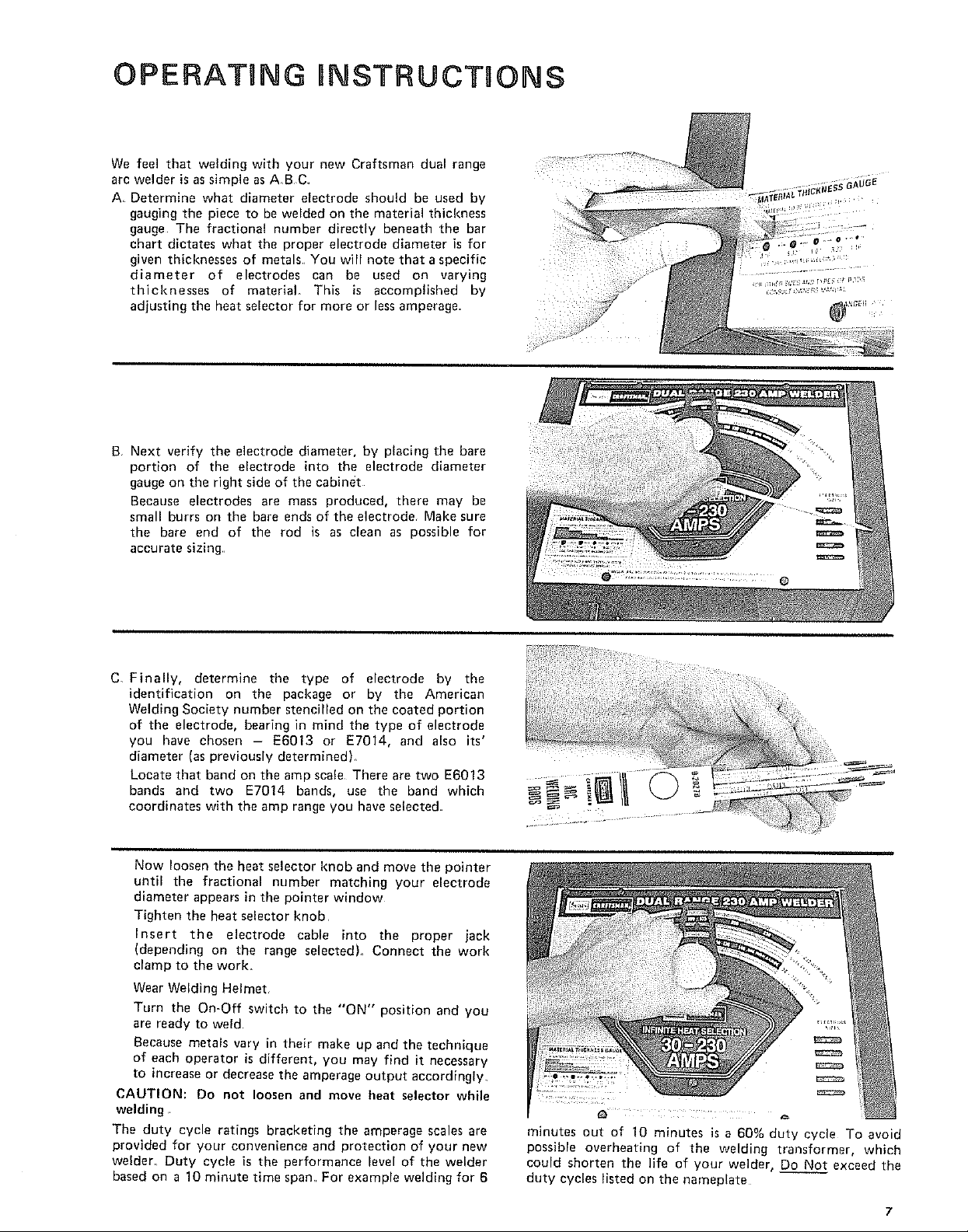

OPERATnNG CONTROLS

The name "dual range" arc welder is derived from the fact

that your new arc welder is equipped with two separate

welding ranges,

The beginner or less-experienced welder will find the

30-140 amp range easier to use because it provides extra arc

stability when welding with some of the "more difficult to

weld with specialty rods" which are prone to pop-outs

The 40-230 amp range requires less line (input current)

draw for any given amp setting and permits the use of the

maximum amp settings with minimum effect on other'

electrical appliances, motors, and lights, on your electrical

system,

Either range may be used, depending on operator

preferences when the electrode diameter permits

CONNECTING ELECTRODE

AND WORK CABLES

insert the tapered plug on the end of the electrode cable

into the proper outlet jack depending on amperage required

or operator preference.

To insure a good electrical connection always twist the

electrode plug slightly while inserting_ To remove the plug

twist in the opposite direction while removing

NOTE: If you extend the welding cables beyond those

already supplied, they must be No= 4 AWG or larger to

avoid an undue drop in welding current Do not extend

cables over 50 feet,

_TAL TABLE AT THE SAME TIM

REGARDING POTENTIAL SHOCK ON CABINET

1 CONNECT ONLY TO A GROUNDING POWER SOURCE

CONFORMING TO THE NATIONAL ELECTRICAL CODE

(A N S I C1) AND LOCAL CODES

1 WEAR WELDING HELMET WITH NO 12 OR DARKER FIL-

TER LENS MEETING REQUIREMENTS OF A NSI. Z87,1.

2 WEAR GOGGLES OR FACE SHIELD WHILE CHIPPING OR

BRUSHING SLAG.

3 KEEP OTHER PERSONS AND PETS OUT OF WORK AREA

KEEP COMBUSTIBLES OUT OF RANGE OF WELDING SPARKS

uSE FOR MINIMUM UsE FOR MAXIMUM

REGARDING EYE INJURY

REGARDING FIRE

LINE DRAW ARC STABILITY

AMP AMP Z

RANGE/

Connect the work clamp to the piece to be welded, (to

complete the electrical circuit) or to the welding table itself

provided it is metallic or will conduct electricity!

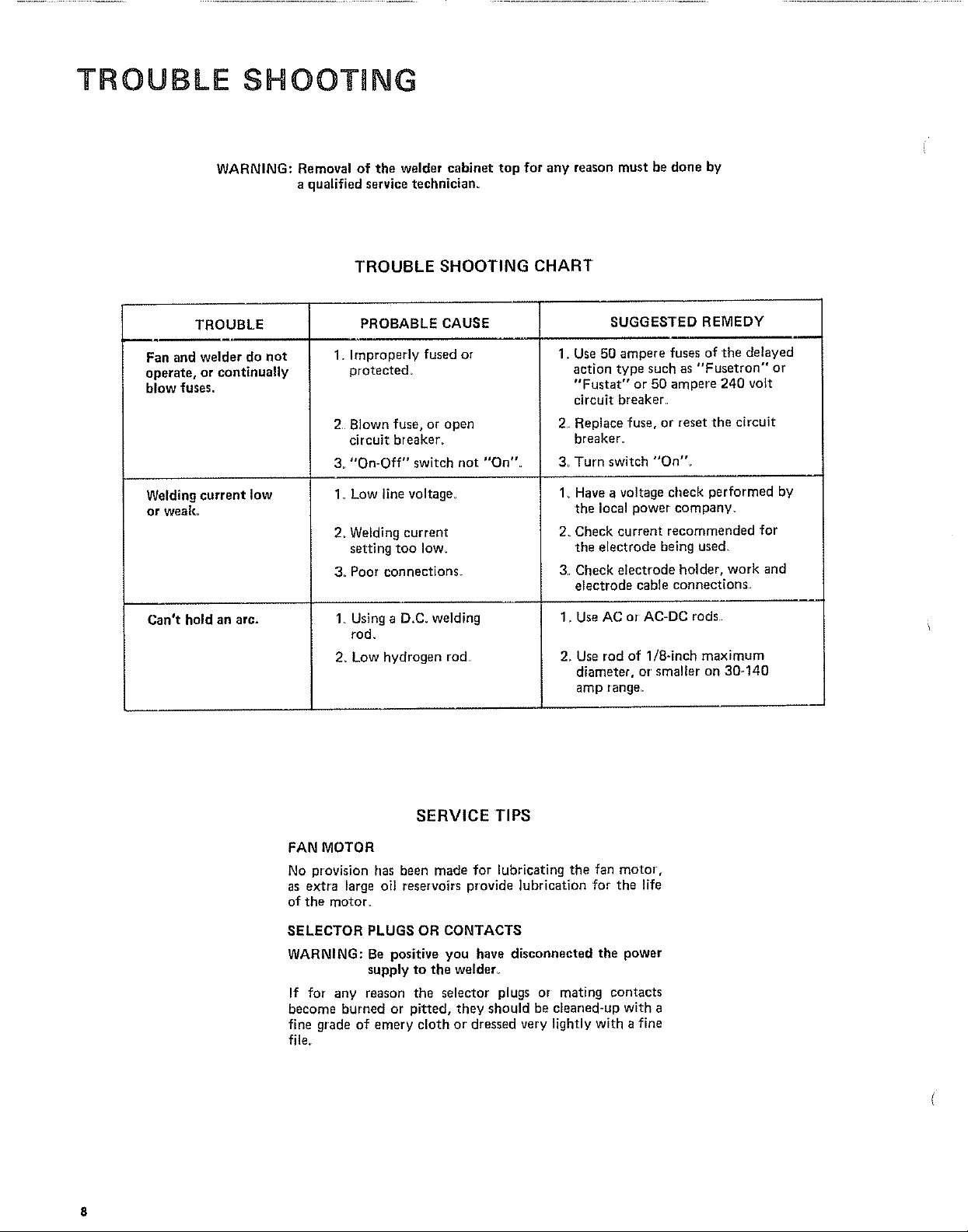

OPERATING RNSTRUCTIONS

We feel that welding with your new Craftsman dual range

arc welder is assimple asA B C

A Determine what diameter electrode should be used by

gauging the piece to be welded on the material thickness

gauge The fractional number directly beneath the bar

chart dictates what the proper electrode diameter is for

given thicknesses of metals You will note that a specific

diameter of electrodes can be used on varying

thicknesses of material. This is accomplished by

adjusting the heat selector for more or less amperage•

B Next verify the electrode diameter, by placing the bare

portion of the electrode into the electrode diameter

gauge on the right side of the cabinet

Because electrodes are mass produced, there may be

small burrs on the bare ends of the electrode Make sure

the bare end of the rod is as clean as possible for

accurate sizing,

C, Finally, determine the type of electrode by the

identification on the package or by the American

Welding Society number stencilled on the coated portion

of the electrode, bearing in mind the type of electrode

you have chosen - E6013 or E7014, and also its'

diameter (as previously determined)_

Locate that band on the amp scale There are two E6013

bands and two E7014 bands, use the band which

coordinates with the amp range you have selected•

Now loosen the heat selector knob and move the pointer

until the fractional number matching your electrode

diameter appears in the pointer window

Tighten the heat selector knob

Insert the electrode cable into the proper jack

(depending on the range selected), Connect the work

clamp to the work.

Wear Welding Helmet,

Turn the On-Off switch to the "ON" position and you

are ready to weld

Because metals vary in their make up and the technique

of each operator is different, you may find it necessary

to increase or decrease the amperage output accordingly,

CAUTION: Do not loosen and move heat selector while

welding

The duty cycle ratings bracketing the amperage scales are

provided for your convenience and protection of your new

welder_ Duty cycle is the performance level of the welder

based on a 10 minute time span. For example welding for 6

minutes out of 10 minutes is a 60% duty cycle To avoid

possible overheating of the welding transformer, which

could shorten the life of your welder, Do Not exceed the

duty cycles listed on the nameplate

7

TROUBLE SHOOTING

WARNING: Removal of the welder cabinet top for any reason must be done by

a qualified service technician.

TROUBLE SHOOTING CHART

TROUBLE SUGGESTED REMEDY

Fan and welder do not

operate, or continually

blow fuses.

Welding current low

or weak,

Can't hold an arc.

PROBABLE CAUSE

1. Improperly fused or

protected_

2 Blown fuse, or open

circuit breaker_

3_"On-Off" switch not "On".

1. Low line voltage,

2_ Welding current

setting too Iow_

3, Poor connections.

1 Using a D.C. welding

rod.

2. Low hydrogen rod

1. Use 50 ampere fuses of the delayed

action type such as "'Fusetron" or

"Fustat" or 50 ampere 240 volt

circuit breaker.

2 Replace fuse, or reset the circuit

breaker.

3 Turn switch "On".

1_ Have a voltage check performed by

the local power company_

2. Check current recommended for

the electrode being used.

3, Check electrode holder, work and

electrode cable connections

1_Use AC or AC-DC rods

2, Use rod of 1/8-inch maximum

dian'leter, or' smaller on 30-140

amp range.

SERVICE TIPS

FAN MOTOR

No provision has been made for lubricating the fan motor,

as extra large oil reservoirs provide lubrication for the life

of the motor.

SELECTOR PLUGS OR CONTACTS

WARNING: Be positive you have disconnected the power

supply to the welder_

If for any reason the selector plugs or mating contacts

become burned or pitted, tiley should be cleaned-up with a

fine grade of emery cloth or dressed very lightly with a fine

file,

f

A COMPREHENSIVE

GUIDE FOR YOUR

NEW CRAFTSMAN

ARC WELDER AND

WHAT iT W_LL DO

CONTAINS:

INFORMATION ABOUT

o VARIOUS TYPES OF RODS

o USEFUL ACCESSORIES

TIPS ON CUTTING, WELDING

AND BRAZING

,,,J

Form No SP574-4 1-]

IJELD gT Y©U SELF

TABLE OF CONTENTS

Your WelderandWhat It Will Oo ............. 1-3

How the CraftsmanContactRodSimplifiesWelding 1-3

WhatHappensWhenYou Weld? .............. 1-3

ReadBeforaWelding ....................... 14

LearnBy Doing .......................... 1-5

PositionWelding ......................... 1-11

Cast-IronWelding ........................ 1-14

HardSurfacingWornCuttingEdges .......... 1-15

TheTwin CarbonArc Torch ............... 1-16

CuttingandOther MiscellaneousOperations ..o 1-17

Inert-GasMetal-ArcWelding ................ 1-19

Page

Read this Manual carefully for additional welding information.

1o2

SEARS, ROEBUCK AND COMPANY

AND SIMPSONS-SEARS LIMITED

YOUR WELDER and what it will do =°.

Your CRAFTSMAN Arc Welderisasturdilyconstructedendthoroughlytestedmachineengineeredto

give many years of efficient trouble-free service. It is listed by Underwriters' Laboratories,

incorporated,which meansthat it passesall requirementsof safety,fire hazardand temperaturerise

limitsasspecifiedin theirStandardfor Transfer-TypeArc-WeldingEquipment,

HOW THE CRAFTSMAN ELECTRODE

SIMPLIFIES WELDING

Craftsman Contact Electrode is self-starting-plus automatic

restarting , The electrodestartson contacL

Craftsman Contact Electrode is serf-cleaning..... Under normal

conditionstheslagremovesitselfasthe weld cools,Spatter is almost

nen-existenL Craftsman Contact Electrode has an exceptionally

good appearance _ With fine ripple, unusually clean, smooth

appearance,andreduced slaginclusions

CraftsmanContact Electrode depositsmore metalfaster . Because

the powderediron in the flux goesintotile weld_

1 Beth edges of the metal

are heated by the arc,

until--

2 they melt and flow to

gether formingone piece,

instantly--

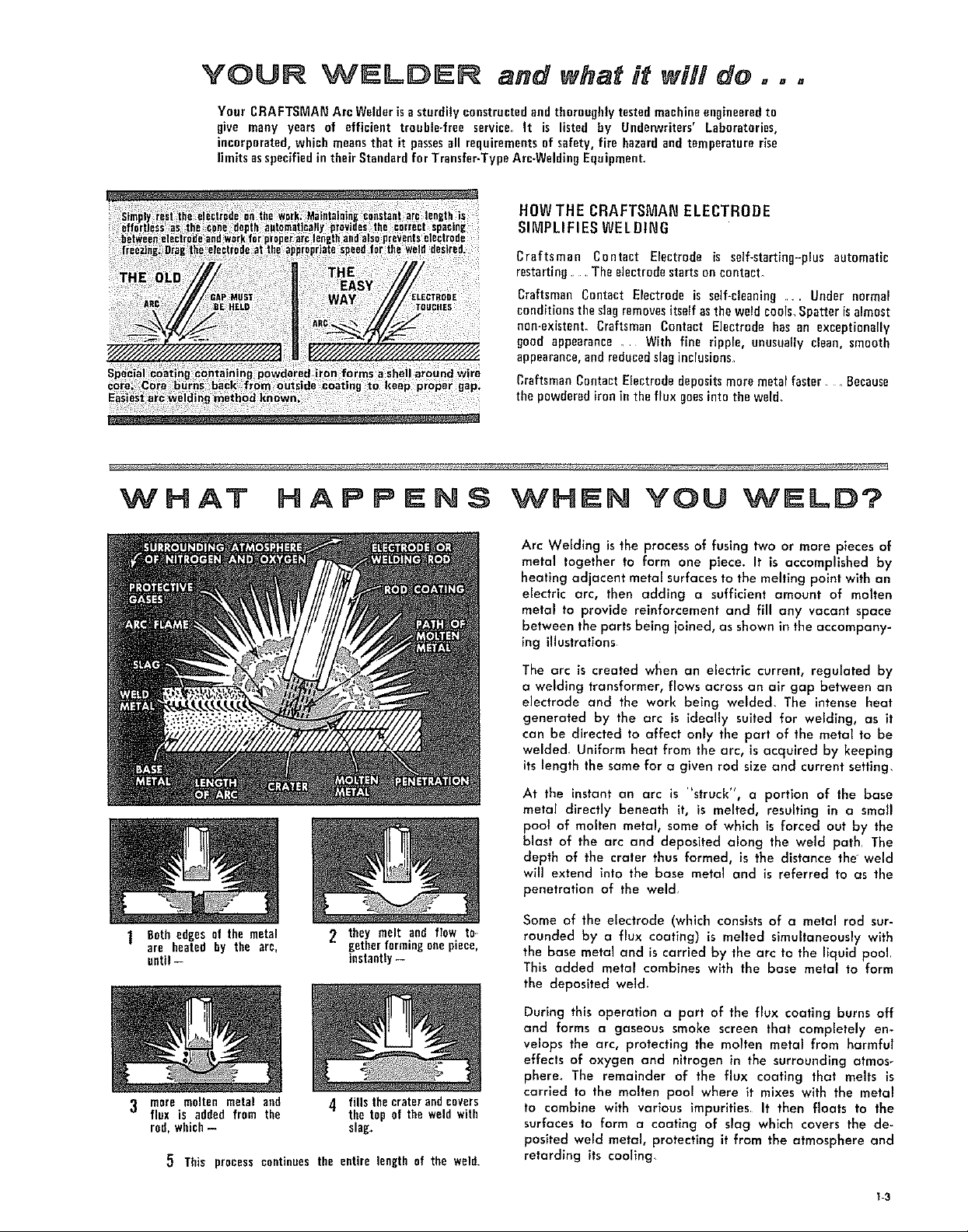

Arc Welding is the process of fusing two or more pieces of

metal together to form one piece. It is accomplished by

heating adjacent metal surfaces to the melting point with an

electric arc, then adding a sufficient amount of molten

metal to provide reinforcement and fill any vacant space

between the parts being joined, as shown in the accompany-

ing illustrations

The arc is created when an electric current, regulated by

a welding transformer, flows across an air gap between an

electrode and the work being welded, The intense heat

generated by the arc is ideally suited for welding, as it

can be directed to affect only the part of the metal to be

welded, Uniform heat from the arc, is acquired by keeping

its length the same for a given rod size and current setting,

At the instant an arc is "struck", a portion of the base

metal directly beneath it, is melted, resulting in a small

pool of molten metal, some of which is forced out by the

blast of the arc and deposited along the weld path, The

depth of the crater thus formed, is the distance the weld

will extend into the base metal and is referred to as the

penetration of the weld

Some of the electrode (which consists of o metal rod sur-

rounded by a flux coating) is melted simultaneously with

the base metal and is carried by the arc to the liquid pool

This added metal combines with the base metal to form

the deposited weld,

3 mere molten metal and

flux is added from the

rod, which-

5 This process continues the entire length of the weld

4 fills the crater andcovers

the top of the weld with

slag,

During th_s operation a part of the flux coating burns off

and forms a gaseous smoke screen that completely en-

velops the arc, protecting the molten metal from harmful

effects of oxygen and nitrogen in the surrounding atmos-

phere, The remainder of the flux coating that melts is

carried to the molten pool where it mixes with the metal

to combine with various impurities It then floats to the

surfaces to form a coating of slag which covers the de-

posited weld metal, protecting it from the atmosphere and

retarding its cooilng

I-3

Loading...

Loading...