Craftsman 113198251, 113198211 Owner’s Manual

I SaveThisManual

ForFutureReference

I

10" ELECTRONIC

RADIAL SAW WITH

23" CABINET AND

1 DOOR

10" ELECTRONIC

RADIAL SAW WITH

LEG SET

Serial

Number

Model and serial numbers

may be found at the rear of

the base

You should record both

model and serial number in

a safe place for future use,

113°198211_\

113o19825t

10-.INCH ELECTRONUC

RADIAL SAW

CAUTION:

® Assembly

READ ALL

INSTRUCTIONS

CAREFULLY

Sold by SEARS, ROEBUCK AND CO., Chicago, JL. 60684 U.S.A.

Part No, SP5102 Printed in U,S,A

® Operating

® Repair parts

FULLONEYEARWARRANTYONCRAFTSMANRADIALSAW

!t within one year from the date of purchase, this Craftsman Radial Saw fails due to a defect in material or

workmanship, Sears wilt repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES,

This warranty applies only while this product is used in the United States.=

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO, DEPT. 698/73tA Sears Tower, Chicago, IL 60684

i1,1 ,,i,1,1111 i, ,,

Table of Contents

,i ,i,, i .... , ii III II

Section Title Page Numbers

Safety Information ......................................................... 3-6

Putting Your Saw Iogether. .............................................. 7-18

Location and Function of Controls ..................................... t9-22

Alignment of Blade ..................................................... 23-38

Digital Display .................................. ........................... 39-44

Electrica! Connections ......................................... 45-46

Crosscutting ............................................................... 47-53

Ripping .................................................................... 54-62

Cutting Accessories ................................................... 63-66

Recommended Accessories .................................................. 67

Glossary ..................................................................... 68

Helpful Hints .......................................................... 69-71

Maintaining Your Saw ................................................ 72-77

"[rouble Shooting ..................................................... 78-83

Parts Lists ............................................................. 84-99

2

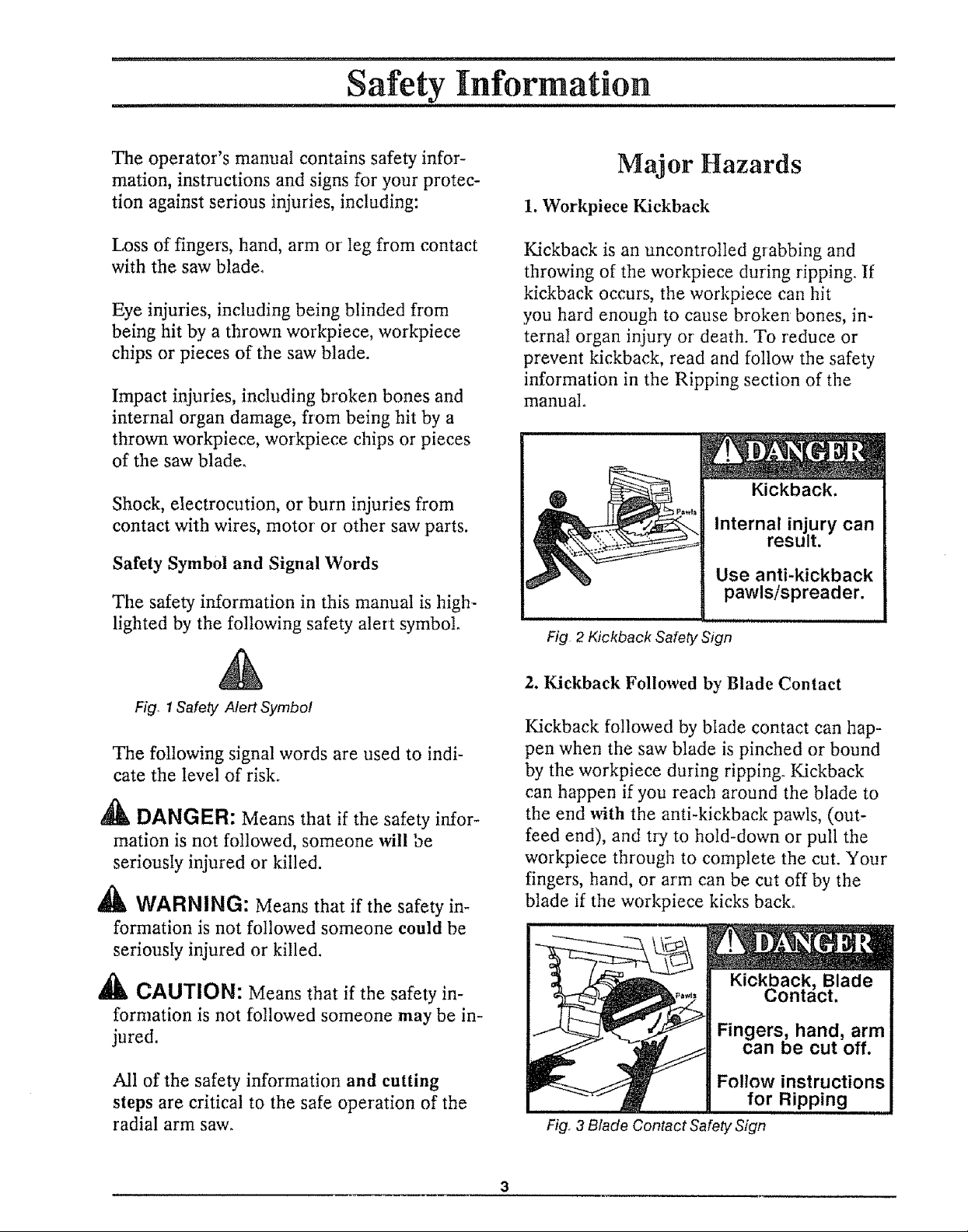

Safety Information ......................

The operator's manual contains safety infor-

mation, instructions and signs for your protec-

tion against serious injuries, including:

I_x)ssof fingers, hand, arm or leg from contact

with the saw blade.

Eye injuries, including being blinded from

being hit by a thrown workpiece, workpiece

chips or pieces of the saw blade.

Impact injuries, including broken bones and

internal organ damage, from being hit by a

thrown workpiece, workpiece chips or pieces

of the saw blade.

Shock, electrocution, or burn injuries from

contact with wires, motor or other saw parts.

Safety Symbol and Signal Words

The safety information in this manual is high-

lighted by the following safety alert symbol.

Major Hazards

1. Workpiece Kickback

Kickback is an uncontrolled grabbing and

throwing of the workpiece during ripping. If

kickback occurs, the workpiece can hit

you hard enough to cause broken bones, in-

ternal organ injury or death. To reduce or

prevent kickback, read and follow the safety

information in the Ripping section of the

manual.

Fig 2 Kickback Safety Sign

&

Fig_ 1Safety Alert Symbol

The following signal words are used to indi-

cate the level of risk.

,_k DANGER: Means that if the safety infor-

mation is not followed, someone will be

seriously injured or killed.

WARNING: Means that if the safety in-

formation is not followed someone could be

seriously injured or killed.

,_k CAUTION: Means that if the safety in-

formation is not followed someone may be in-

jured.

All of the safety information and cutting

steps are critical to the safe operation of the

radial arm saw.

2. Kickback Followed by Blade Contact

Kickback followed by blade contact can hap-

pen when the saw blade is pinched or bound

by the workpiece during ripping. Kickback

can happen if you reach around the blade to

the end with the anti-kickback pawls, (out-

feed end), and try to hold-down or pull the

workpiece through to complete the cut. Your

fingers, hand, or arm can be cut off by the

blade if the workpiece kicks back.

Kickback, Blade

Contact.

Fingers, hand, arm

can be cut off.

Follow instructions

for Ripping

Fig. 3 Blade Contact Safety Sign

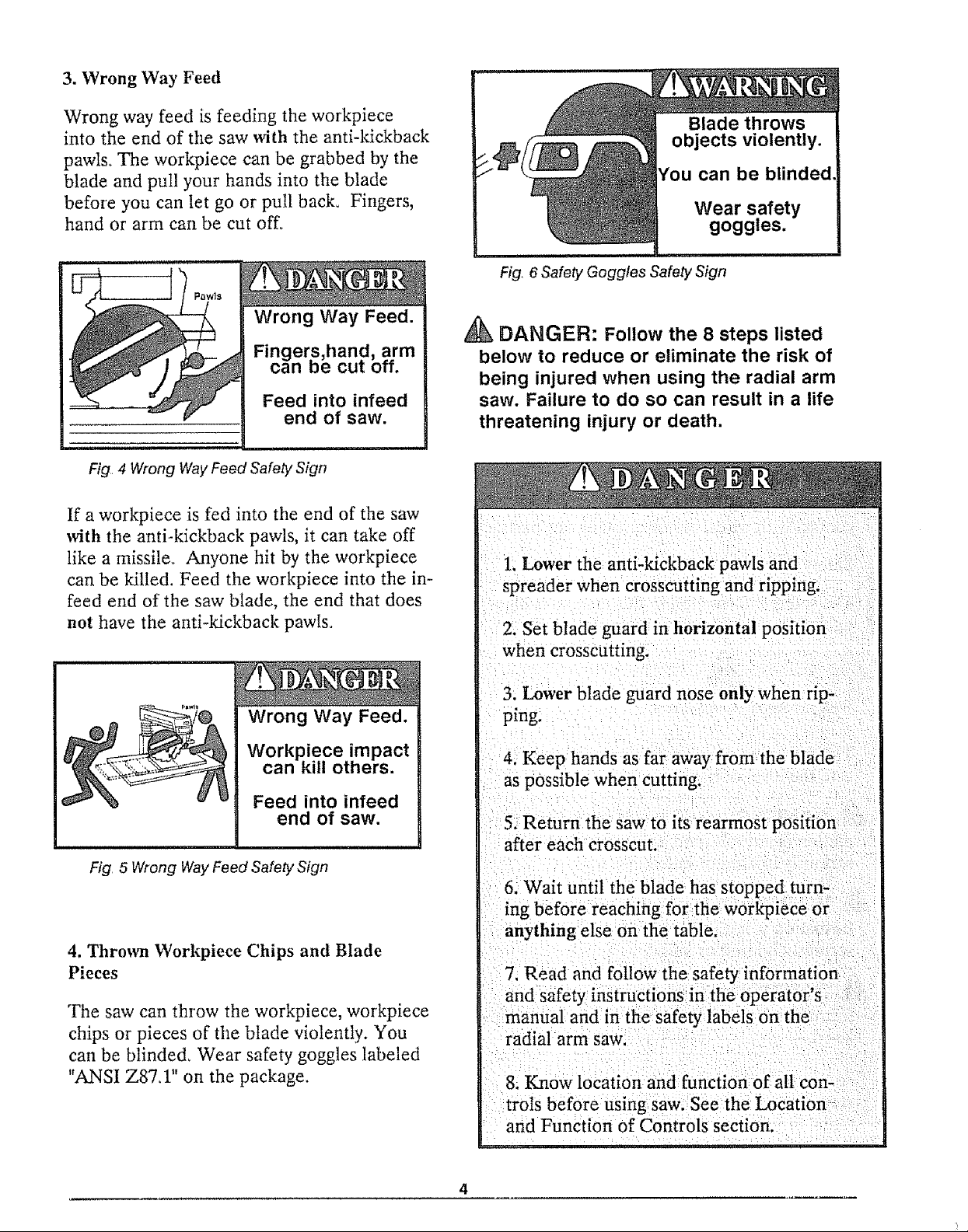

3. Wrong Way Feed

Wrong way feed is feeding the workpiece

into the end of the saw with the anti-kickback

pawls_ The worl_iece can be grabbed by the

blade and pull your hands into the blade

before you can let go or pull back. Fingers,

hand or arm carl be cut off°

Fig 4 Wrong Way Feed Safely Sign

If a workpiece is fed into the end of the saw

with the anti-kickback pawls, it can take off

like a missile. Anyone hit by the workpiece

can be killed. Feed the workpiece into the in-

feed end of the saw blade, the end that does

not have the anti-kickback pawls°

Fig, 6 Safety Goggles Safety Sign

DANGER: Follow the 8 steps listed

below to reduce or eliminate the risk of

being injured when using the radial arm

saw. Failure to do so can result in a life

threatening injury or death.

1. Lower the anti-kickback pawls and

spreader when crosscutting and ripping.

2. Set blade guard in horizontal position

when crosscutting.

Wrong Way Feed.

Workpiece impact

can kill others.

Feed into infeed

end of saw.

Fig 5 Wrong Way Feed Safely Sign

4. Thrown Workpiece Chips and Blade

Pieces

The saw can throw the workpiece, workpiece

chips or pieces of the blade violently. You

can be blinded_ Wear safety goggles labeled

"ANSI Z87A" on the package.

3. Lower blade guard nose only when rip-

ping.

4. Keep hands as far away from the blade

as possible when cutting.

5. Return the saw to its rearmost position

after each crosscut.

6, Wait until the blade has stopped turn-

[ng before reaching:for the workpiece or

anything else on the table.

7, Read and follow the: safety information

and safety instructions in the operator's

manual and in the safety labels on the

radia! arm saw,

8. Know location and function of a[1 con-

trols before using saw. See the Location

and Function of Controls section.

Personal Safety

Saw Safety

L Wear safety goggles labeled "ANSI Z87A"

on the package. Do not wear regular glasses,

they are not safety glasses.

2. Wear snug fitting clothes, short sleeve

shirts and nonslip footwear. Cover up or tie

long hair. Do not wear loose, baggy clothes,

gleves, neckties, rings, watches or any other

,jewelry.

3. Wear a dust mask, with your safety gog-

gles, if cutting operation is dusty.

4. Wear hearing protectors, ear plugs or

muffs, if you use the saw daily°

5. Keep good footing and balance. Don't over-

reach.

Work Area Safety

1. Keep children, pets and visitors out of the

work area.

2. Make the work area child proof. Remove

the yellow key from the red switch and place

it out of reach and sight. Lock work area.

!. Keep guards and anti-kickback pawls in

place and in working order.

2. Check for broken or damaged parts before

using saw. A damaged guard or other saw

part should be checked for alignment, bind-

ing, breakage and correct mounting to make

sure they are working properly. Repair or

replace damaged guards or other saw parts.

3. Unplug saw before doing maintenance,

making adjustments, and changing blades and

accessories.

4_Use clamps or vice to hold workpiece

when practical° It's safer than using your

hands and frees them to operate the saw.

5. Do not force the saw, saw blade or acces-

sories to do jobs they are not designed to do.

6. Make sure the yellow key is removed and

the red switch is in the off position before

plugging in the power cord.

7. Cut only wood, woodlike or plastic

materials. Do not cut metal materials.

3. Keep floors dry and free from sawdust, wax

or other slippery materials.

4. Keep work area clean, uncluttered and

well lighted_

5. Use the saw in a dry area. Do not use in

wet or damp area. Do not use outside.

6. Clear the table of all objects (adjusting

wrenches, tools, scraps of wood etc.) except

the workpiece to be cut, fixtures or clamps

before turning the saw on.

7. Do not do layout, assembly or setup work

on the table while the blade is turning.

8. Store items away from the saw. Do not

climb on the saw to reach items. Do not

stand on the table; the saw can tip oven

8. Secure the saw to floor, wall, bench or

table if it slides, tips or walks during use°

9. Feed the workpiece against the direction

of rotation of the blade when ripping.

!0. Turn the saw off before leaving work

area. Do not leave the saw until the blade

has stopped.

1t. Lock the rip and miter locks before

moving the saw from one location to another°

12. Turn the saw off and remove yellow key if

the blade jams° Do not try to free a jammed

workpiece with the saw on.

13. Turn the saw off if it vibrates excessively

or makes an unfamiliar noise. Correct any

problems before restarting saw.

14. Rip workpieces that are longer than the

diameter of the blade being used. Do not rip

a workpiece that is shorter than the diameter

of the blade being used.

15. Cut only one workpiece at a timer Do

not cut stacked workpieces or lay them edge

to edge for cutting,

Workpiece Support Safety

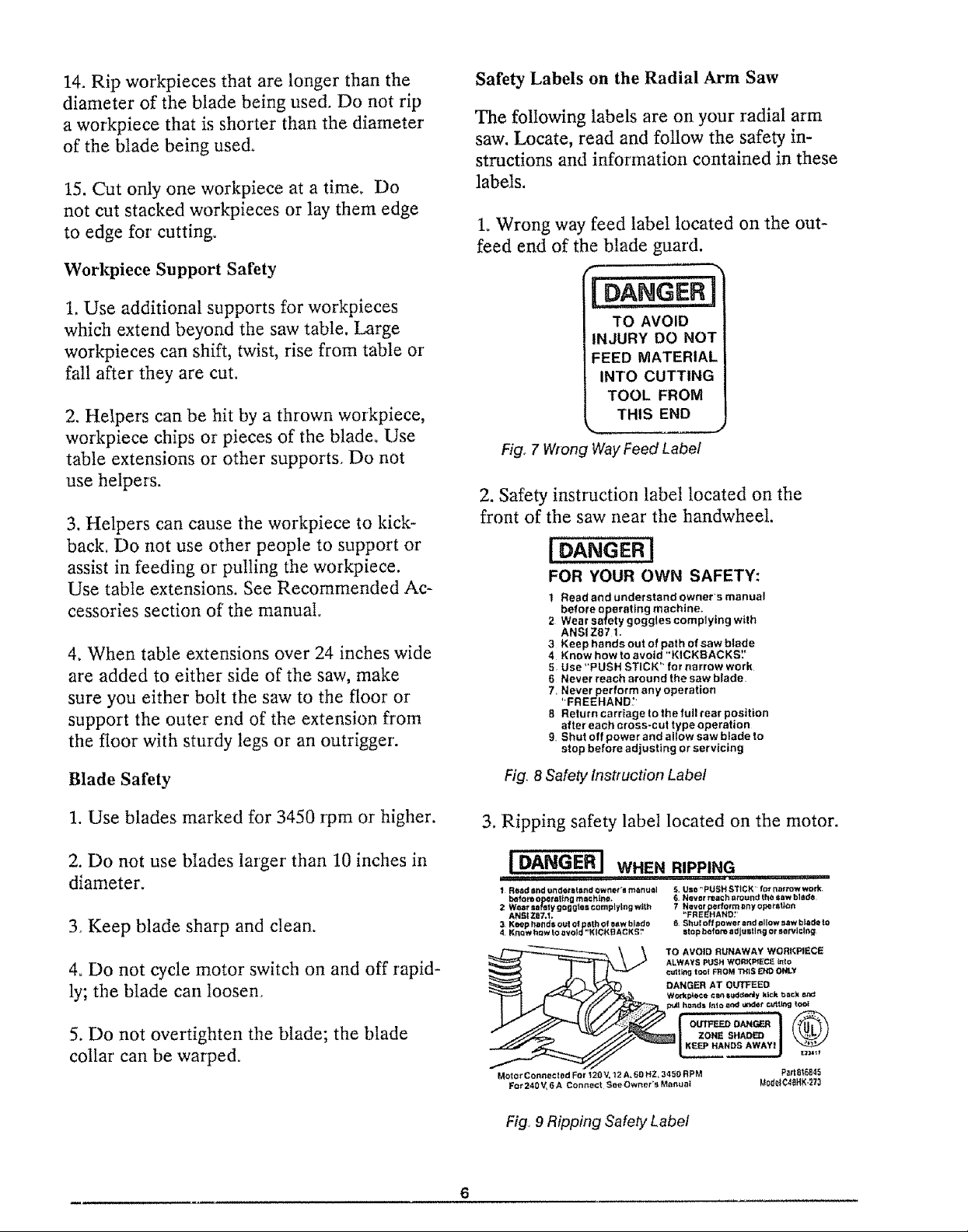

Safety Labels on the Radial Arm Saw

The following labels are on your radial arm

saw. Locate, read and follow the safety in-

structions and information contained in these

labels.

1. Wrong way feed label located on the out-

feed end of the blade guard.

1. Use additional supports for workpieces

which extend beyond the saw table. Large

workpieces can shift, twist, rise from table or

fall after they are cut.

2. Helpers can be hit by a thrown workpiece,

workpiece chips or pieces of the blade. Use

table extensions or other supports. Do not

use helpers.

3. Helpers can cause the workpiece to kick-

back_ Do not use other people to support or

assist in feeding or pulling the workpiece.

Use table extensions. See Recommended Ac-

cessories section of the manual°

4. When table extensions over 24 inches wide

are added to either side of the saw, make

sure you either bolt the saw to the floor or

support the outer end of the extension from

the floor with sturdy legs or an outrigger.

TO AVOID

INJURY DO NOT

FEED MATERIAL

INTO CUTTING

TOOL FROM

THIS END

Fig, 7 Wrong Way Feed Label

2. Safety instruction label located on the

front of the saw near tile handwheel.

IDAN ERI

FOR YOUR OWN SAFETY:

t Readandunderstandowner'smanua!

before operating machine.

2 Wear safety goggles complying with

ANSI Z87 t,

3 Keep hands out el pat h of saw blade

4 Know how to avoid "KICKBACKS','

5 Use "PUSH STICK '_ for narrow work

6 Never reach around the saw blade

7, Never perform any operation

"FREEHAND?

8 Returncarriagetothefutlrearposttion

after each cross-cut type operation

9, Shut off power and allow saw blade to

stop before adjusting or servicing

Blade Safety

1. Use blades marked for 3450 rpm or higher.

2. Do not use blades larger than 10 inches in

diameter.

3J Keep blade sharp and clean.

4_Do not cycle motor switch on and off rapid-

ly; the blade can loosen.

5. Do not overtighten the blade; the blade

collar can be warped°

Fig. 8 Safety Instruction Label

3. Ripping safety label located on the motor.

[ DANGER I WHENRIPPING

1 Rea=dBndunflot_l_ndownst'_rn_nu_l 5. Uso"PUSH_TICK' for naf_wwork,

before o_ toting mnchtna. _ N_ver reor:h around the sow bl0{]e

2 ANslW_t=Qfaty goggtos complyingwtt_zaT.1. 7 Nev_t,,FRE_p_/_NO/,ffotm_rt y opott_lto_t

31K_phallde_oulo(p_thofeawhlt_ds 8 ShuloffpowerandallowP.awb)Qdato

Krlow haw Io avoid "N tCN1EIA C I(=-;',' IStop before ad|u_llng or _tvlcllt,_

TO AVOID RUNAWAY WORKPIECE

, i, ,,,,11

,'_,%'L%"oW%';_ o%

DANGER AT OUTFEED

WO_p_CO Cart I_dd_y kick t_=¢X

MoIo_ Connected For 120 V, 12 A, 60 HZ, 3450 RPM P_'I 8t6815

For 240V_ 6 A Cont_ect See Owner's Manual MsdelCt_HK,273

Fig° 9 Ripping Safety Label

: Putting Your Saw Together .....................................

Your radial arm saw is easy to put together,

however it will take time. Ask a friend to

help, and follow these assembly instructions°

It is important for your safety, and for the

quality of your cuts, that the saw be put

together with care.

This manual was written for two different

models of the radia! arm saw: model

113, 198211 with cabinet and door, and model

t 13.198251 with leg set.

The following assembly sections should be

followed for both models:

Unpacking / Set up

Information

Attaching Handwheel

Mounting Motor

Mounting Saw

Attaching Trim Ledge and Trim Caps

Mounting Table Locks

Mounting the Front Table

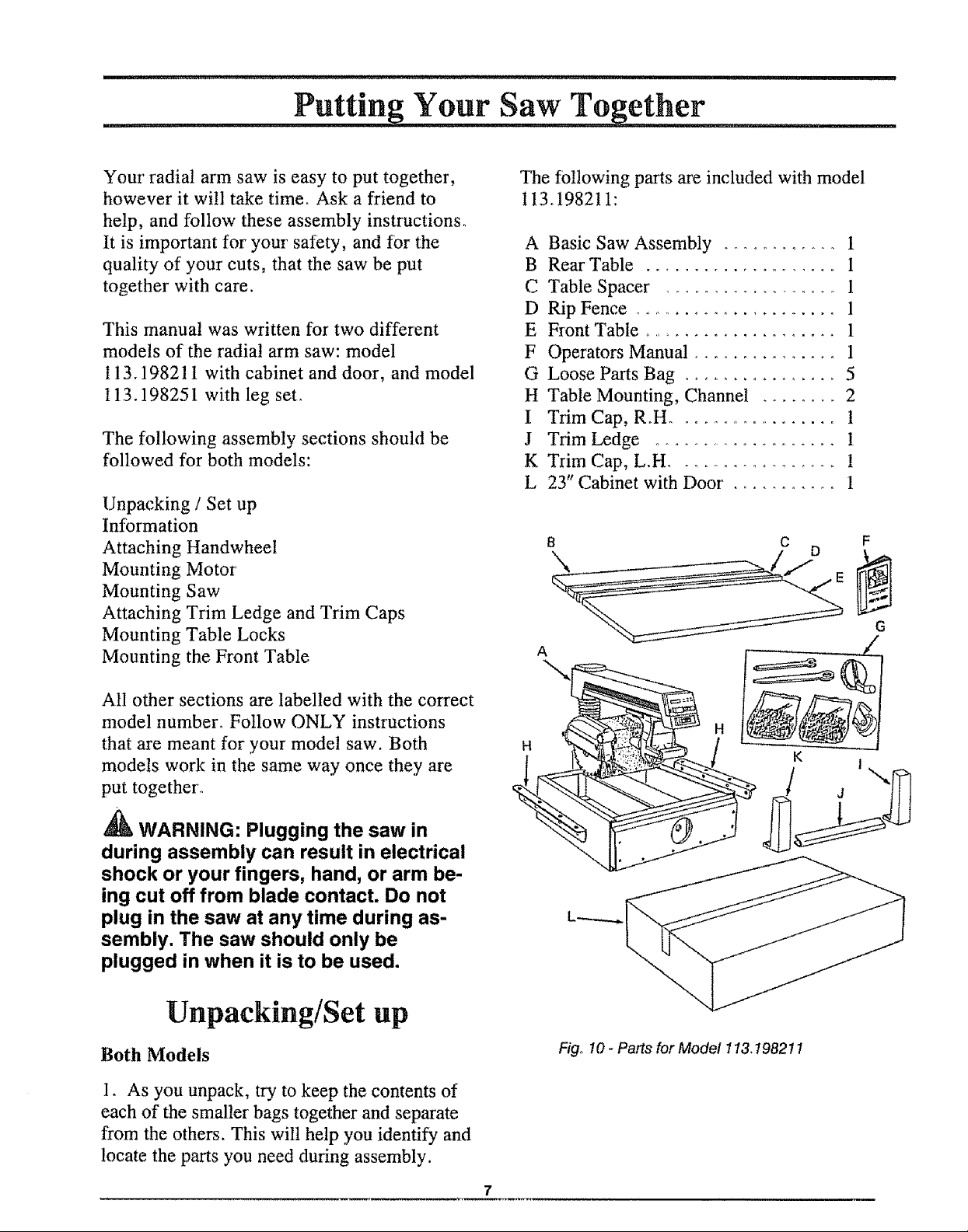

The following parts are included with model

I13_198211:

A Basic Saw Assembly ............ 1

B Rear Table .................... 1

C Table Spacer .................. 1

D Rip Fence ...................... 1

E Front Table ..................... 1

F Operators Manual ............... 1

G Loose Parts Bag ................ 5

H Table Mounting, Channel ........ 2

I Trim Cap, R.H ................... 1

J Trim Ledge .................... 1

K Trim Cap, L.H ................. 1

L 23" Cabinet with Door ........... 1

C F

G

A

\

All other sections are labelled with the correct

model number_ Follow ONLY instructions

that are meant for your model saw. Both

models work in the same way once they are

put together°

_ WARNING: Plugging the saw in

during assembly can result in electrical

shock or your fingers, hand, or arm be-

ing cut off from blade contact. Do not

plug in the saw at any time during as-

sembly. The saw should only be

plugged in when it is to be used.

Unpacking/Set up

Both Models

1. As you unpack, try to keep the contents of

each of the smaller bags together and separate

from the others. This will help you identify and

locate the parts you need during assembly.

H

Fig, 10 - Parts for Model !13,t98211

K

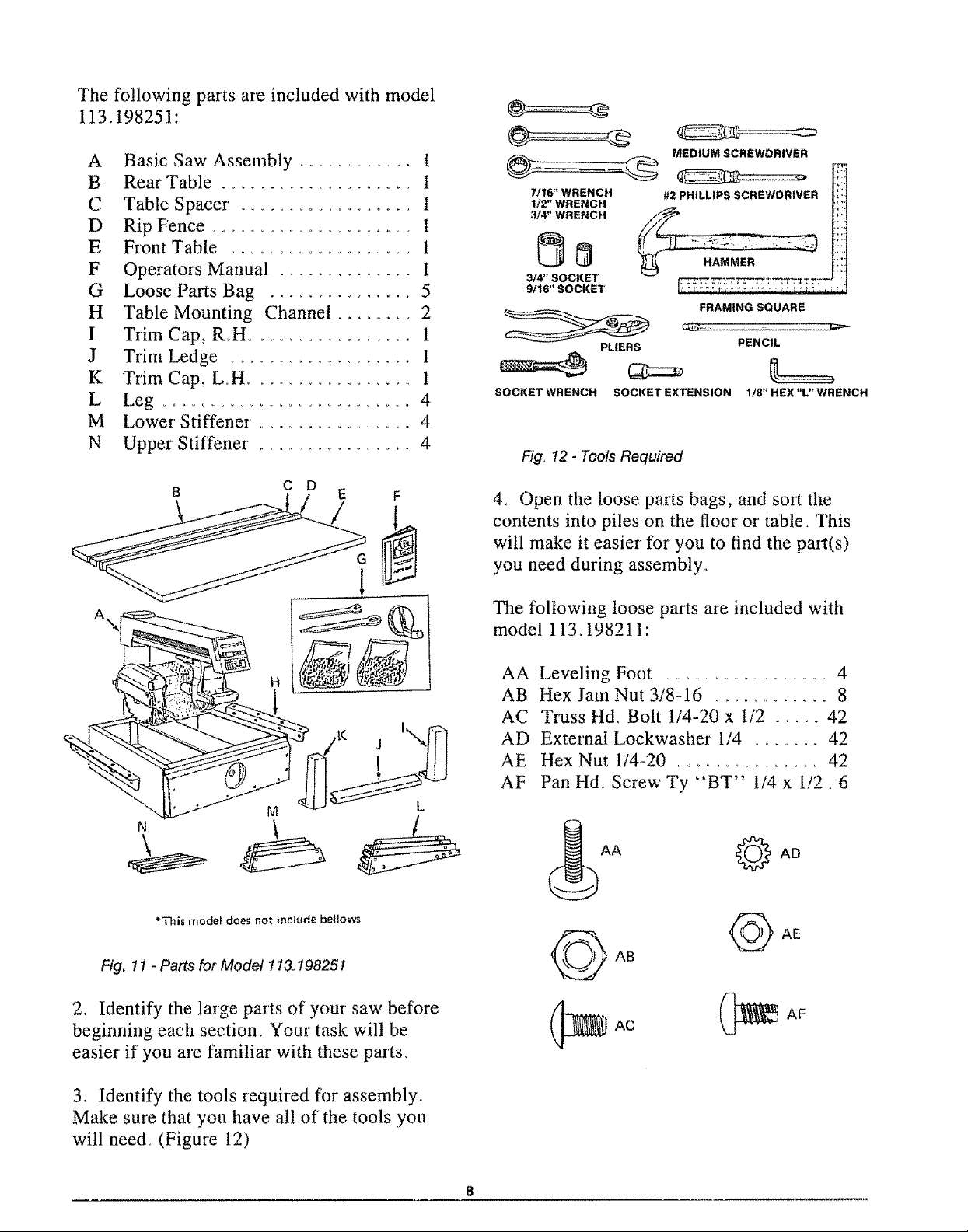

The following parts are included with model

113.198251:

A Basic Saw Assembly ............ !

B Rear Table .................... 1

C Table Spacer .................. t

D Rip Fence ........................ I

E Front Table ................................ 1

F Operators Manual ............... i

G Loose Parts Bag ............... 5

H Table Mounting Channel ........ 2

I Trim Cap, Roll ................. 1

J Trim Ledge .................... 1

K Trim Cap, Loll .................. 1

L Leg ...................................... 4

M Lower Stiffener ,................... 4

N UpperStiffener . .................. 4

B C D E F

MEDIUM SCREWDRIVER

7/16" WRENCH

112" WRENCH

3/4" WRENCH

314" SOCKET

9/16" SOCKET

PLIERS PENCIL

SOCKET WRENCH SOCKET EXTENSION 118" HEX "L" WRENCH

Fig° 12 - Tools Required

#2 PHILLIPS SCREWDRIVER

_T"? t;" g _ "t?t:'? t_

FRAMING SQUARE

4. Open the loose parts bags, and sort the

contents into piles on the floor or table. This

will make it easier for' you to find the part(s)

you need during assembly_

M

*This model does not include bellow_

Fig,_11 - Parts for Model 113.198251

2. Identify the large parts of your saw before

beginning each sectiom Your task will be

easier if you are familiar with these parts.

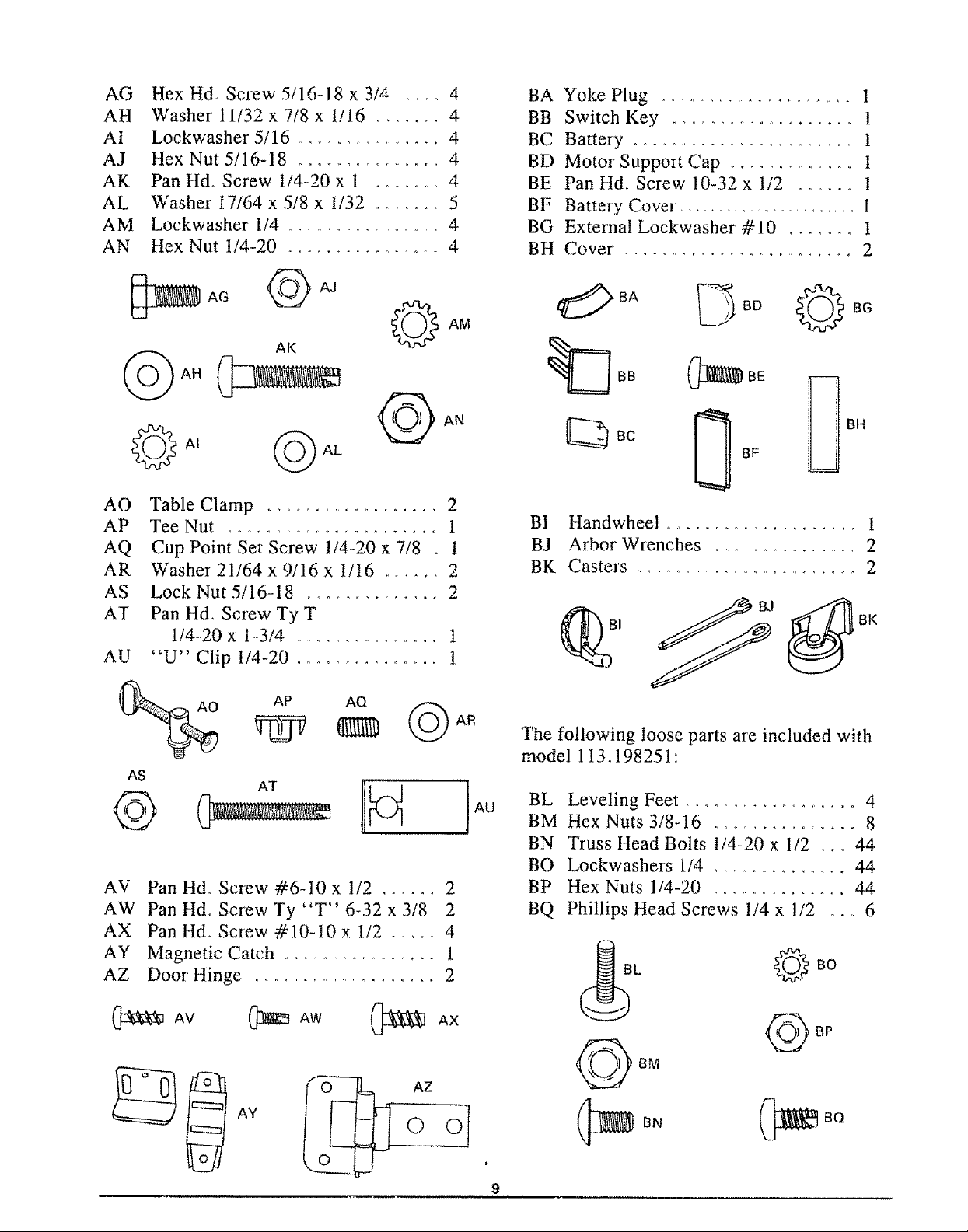

The following loose parts are included with

model 113.198211 :

AA Leveling Foot ....................... 4

AB Hex Jam Nut 3/8-16 .............. 8

AC Truss Hd, Bolt 1/4-20 x 1/2 ..... 42

AD External Lockwasher 1/4 ....... 42

AE Hex Nut 1/4-20 ....................... 42

AF Pan Hd. Screw Ty "BT" 1/4 x 1/2 • 6

AA _ AD

AF

3. Identify the tools required for assembly.

Make sure that you have all of the tools you

will need° (Figure 12)

AG Hex Hd_ Screw 5/16-18 x 3/4 .... 4

AH Washer 11/32 x 7/8 x t/I6 ....... 4

AI Lockwasher 5/16 ....................... 4

AJ Hex Nut 5/16-18 ..................... 4

AK Pan Hd. Screw i/4-20 x 1 ........... 4

AL Washer I7/64 x 5/8 x 1/32 ....... 5

AM Lockwasher I/4 ................. 4

AN Hex Nut I/4-20 ................ 4

BA Yoke Plug ........................ 1

BB Switch Key ........................ t

BC Battery ............................ t

BD Motor Support Cap .................. t

BE Pan Hd. Screw 10-32 x 1/2 .......... I

BF Battery Cover, ....................... 1

BG External Lockwasher #10 ........ t

BH Cover. ............................. 2

_AG @ AJ

AK

_At _ AL

AO Table Clamp ...................... 2

AP Tee Nut ................................ 1

AQ Cup Point Set Screw 1/4-20 x 7/8 . 1

AR Washer 21/64 x 9/16 x !/t6 ...... 2

AS Lock Nut 5/16-18 ................. 2

AT Pan Hd. ScrewTyT

1/4-20 x I-3/4 ................... 1

AU "U" Clip 1/4-20 ................ t

AP AQ

AS

_BA _ BD 0 BG

Be

BF

BI Handwheel ........................ 1

BJ Arbor Wrenches .................. 2

BK Casters ............................. 2

BJ

BK

AR

The following loose parts are included with

model 1 I3.198251"

©

AV Pan Hd. Screw #6-I0 x 1/2 ...... 2

AW Pan Hdo Screw Ty "T" 6-32 x 3/8 2

AX Pan Hd. Screw #10-t0 x t/2 ..... 4

AY Magnetic Catch ....................... 1

AZ Door Hinge ....................... 2

_AV (_AW _AX

AT

AY

AU

BL Leveling Feet ......................... 4

BM Hex Nuts 3/8-16 ................. 8

BN Truss Head Bolts 1/4-20 x I/2 ,.. 44

BO Lockwashers 1/4 ................. 44

BP Hex Nuts 1/4-20 .............. 44

BQ Phillips Head Screws t/4 x !/2 .... 6

L

©

BM

BN

BQ

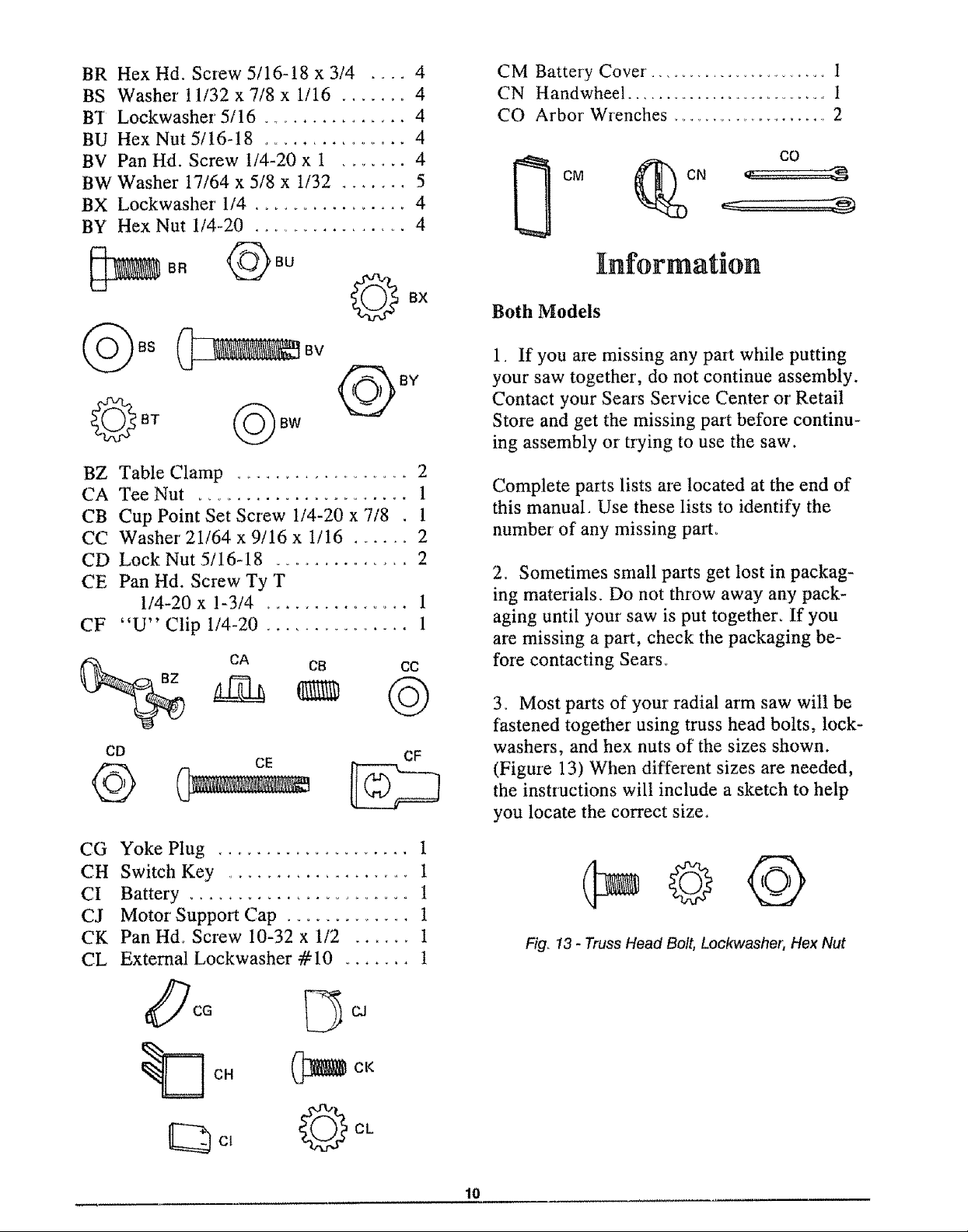

BR Hex Hd. Screw 5/16-18 x 3/4 .... 4

BS Washer 11/32 x 7/8 x 1/16 ....... 4

B'I Lockwasher 5/16 ................ 4

BU Hex Nut 5/16-18 ................ 4

BV Pan Hd. Screw t/4-20 x 1 ....... 4

BW Washer 17/64 x 5/8 x 1/32 ....... 5

BX Lockwasher 1/4 ................ 4

BY Hex Nut 1/4-20 ................ 4

CM Battery Cover _............................ 1

CN Handwheel ............................. 1

CO Arbor' Wrenches ......................... 2

CO

CM (_DCN

BR

BZ Table Clamp ...................... 2

CA Tee Nut ....................... 1

CB Cup Point Set Screw 1/4-20 x 7/8 . 1

CC Washer' 21/64 x 9/16 x t/16 ...... 2

CD Lock Nut 5/16-18 ................. 2

CE Pan Hd. Screw Ty T

1/4-20 x !-3/4 ............... 1

CF "U" Clip I/4-20 ................ 1

CD CE CF

BU

BV

BY

CA CB C@

Information

Both Models

1. If you are missing any part while putting

your saw together, do not continue assembly.

Contact your Sears Service Center or Retail

Store and get the missing part before continu-

ing assembly or trying to use the saw.

Complete parts lists are located at the end of

this manual, Use these lists to identify the

number of any missing part_

2. Sometimes small parts get lost in packag-

ing materials. Do not throw away any pack-

aging until your saw is put together. If you

are missing a part, check the packaging be-

fore contacting Sears°

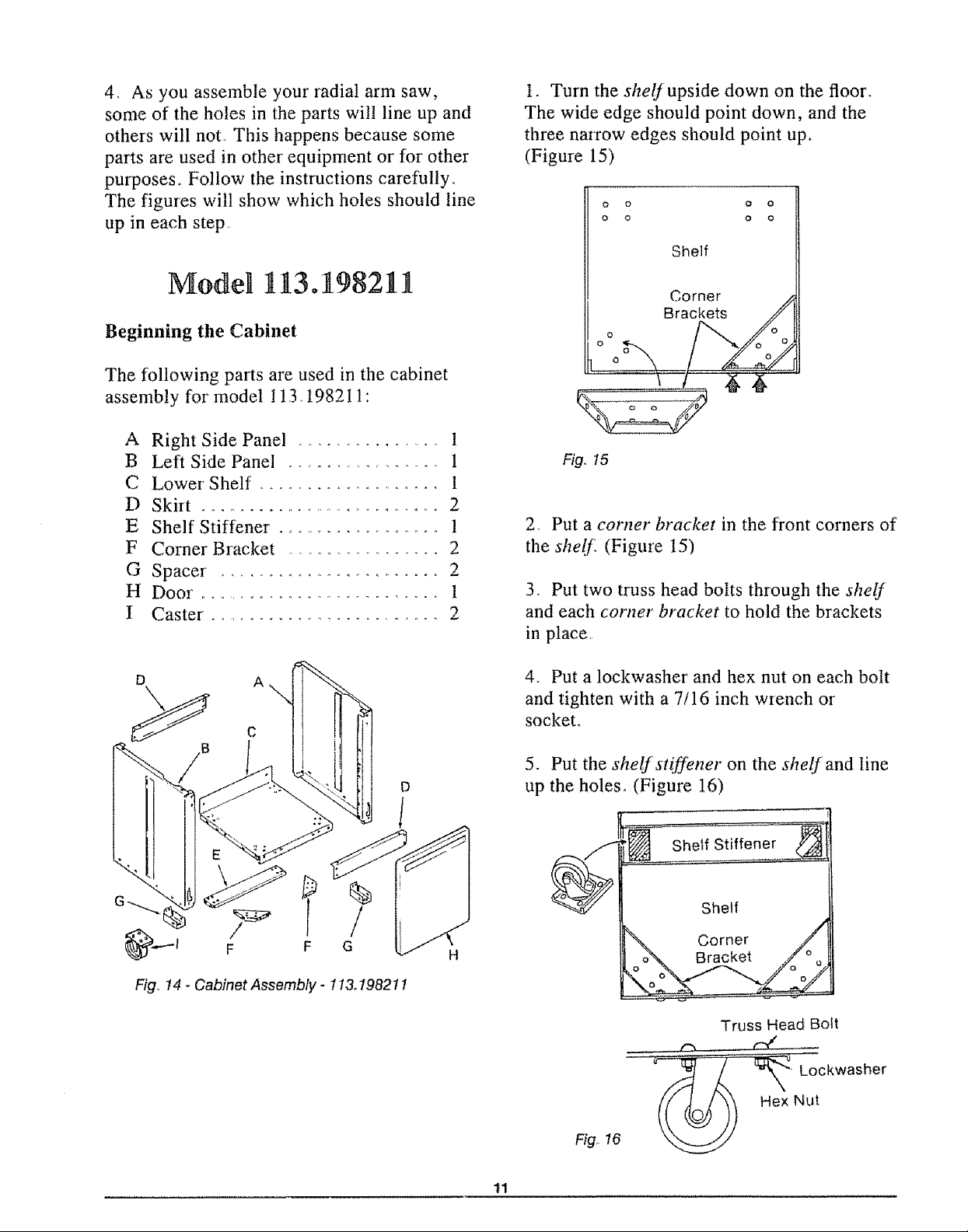

3. Most parts of your radial arm saw will be

fastened together using truss head bolts, lock-

washers, and hex nuts of the sizes shown.

(Figure 13) When different sizes are needed,

the instructions will include a sketch to help

you locate the correct size,

CG Yoke Plug

CH Switch Key

CI

Battery ....................... !

CJ

Motor' Support Cap ............. 1

Pan Hd. Screw 10-32 x 1/2 ...... 1

CK

CL

External Lockwasher #10 ....... 1

OCG _ CJ

O c,

Fig_ 13 - Truss Head Belt, Lockwashet; Hex Nut

10

4, As you assemble your radial arm saw,

some of the holes in the parts will line up and

others will not, This happens because some

parts are used in other equipment or for other

purposes_ Follow the instructions carefully,,

The figures will show which holes should line

up in each step,

t, Turn the shelJ upside down on the floor°

The wide edge should point down, and the

three narrow edges should point up.

(Figure 15)

0 o 0 0

0 0 0 0

Shelf

Model 11t3.19821.1

Beginning the Cabinet

The following parts are used in the cabinet

assembly for model t 13_ 198211:

A Right Side Panel .................. 1

B Left Side Panel .................... 1

C Lower Shelf ....................... 1

D Skirt ................................... 2

E Shelf Stiffener ..................... 1

F Corner Bracket ................... 2

G Spacer ....................... 2

H Door° ............................... 1

I Caster ............................. 2

Corner /j

Brackets f

0 0 0 O0_

Fig. 15

2. Put a corner bracket in the front corners of

the shelf (Figure 15)

,3. Put two truss head bolts through the shelf

and each corner bracket to hold the brackets

in place,

4o Put a lockwasher and hex nut on each bolt

and tighten with a 7/16 inch wrench or

socket,

F G

Fig, 14 - Cabinet Assembly - 113.198211

5. Put the she!jstiffener on the shelf and line

D

up the holes. (Figure 16)

Truss Head Bolt

(m

Lockwasher

Hex Nut

Fig° 16

11

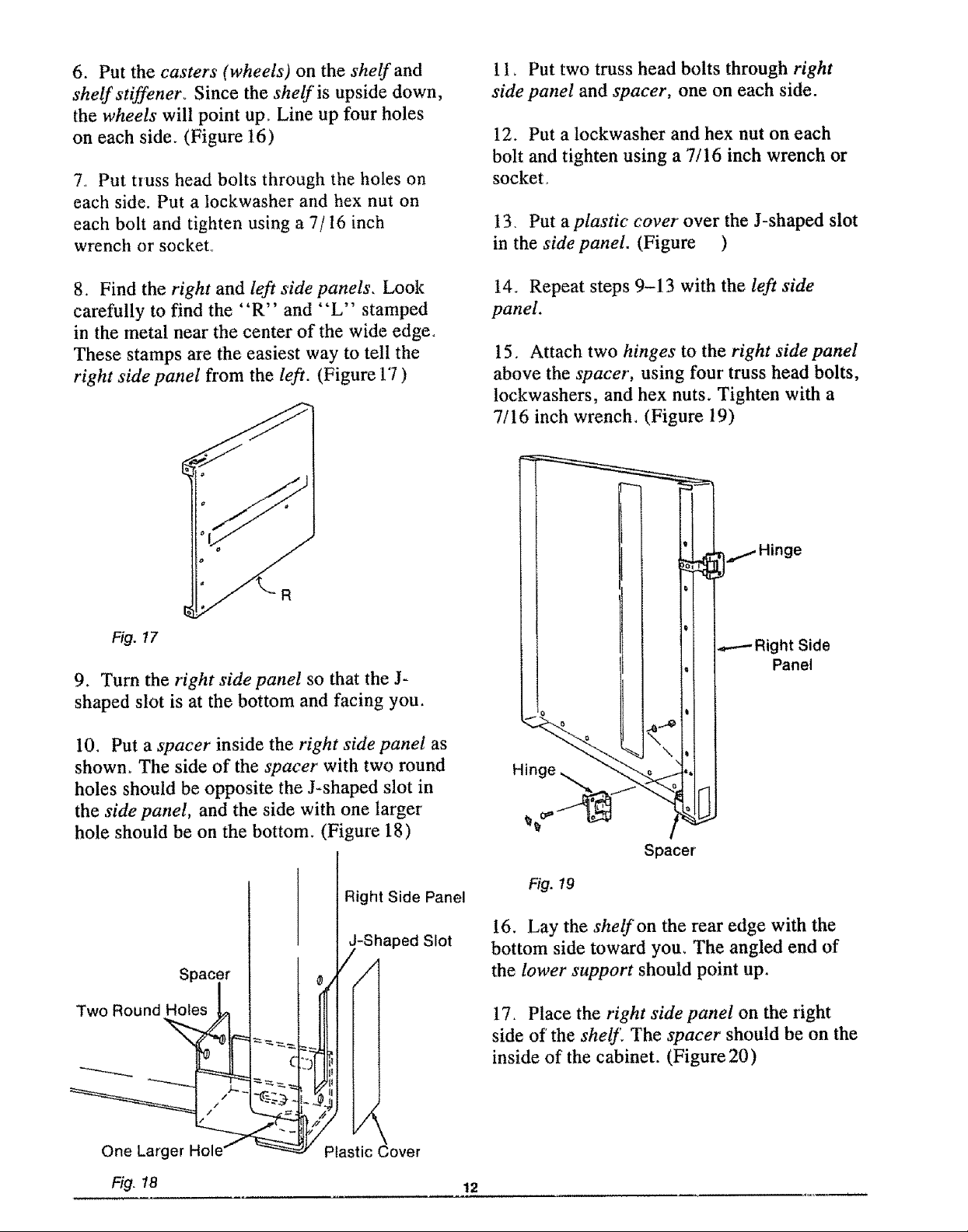

6. Put the casters (wheels) on the shelf and

shelfstiffenero Since the shelf is upside down,

the wheels will point up oLine up four holes

on each side. (Figme 16)

% Put truss head bolts through the holes on

each side. Put a lockwasher and hex nut on

each bolt and tighten using a 7/16 inch

wrench or socket°

1t_ Put two truss head bolts through right

side panel and spacer, one on each side.

12. Put a lockwasher and hex nut on each

bolt and tighten using a 7/16 inch wrench or

socket.

13. Put a plastic cover over the J-shaped slot

in the side panel. (Figure )

8. Find the right and left side panels, Look

carefully to find the "R" and "L" stamped

in the metal near the center of the wide edge.

These stamps are the easiest way to tell the

right side panel from the left. (Figure 1'7)

R

Fi9.17

9. Turn the right side panel so that the J-

shaped slot is at the bottom and facing you.

t4. Repeat steps 9-13 with the left side

panel.

15. Attach two hinges to the right side panel

above the spacer, using four truss head bolts,

lockwashers, and hex nuts. Tighten with a

7/16 inch wrench_ (Figure 19)

10. Put a spacer inside the right side panel as

shown_ The side of the spacer with two round

holes should be opposite the J-shaped slot in

the side panel, and the side with one larger

hole should be on the bottom. (Figure 18)

Right Side Panel

, -Shaped Slot

/

Spacer

One Larger Hole

Fig.la

Plastic Cover

%

Spacer

Fig. 19

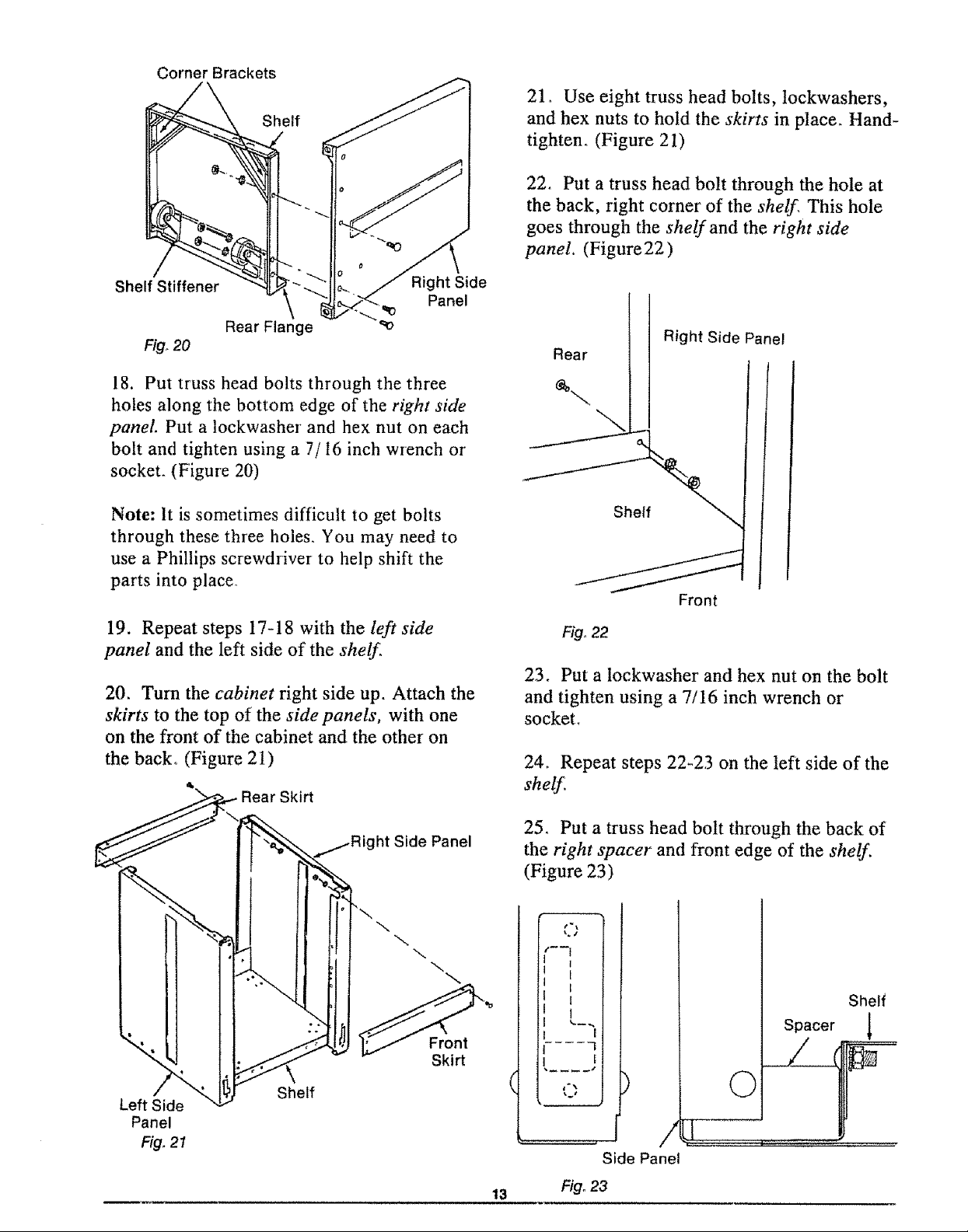

!6. Lay the shelf on the rear edge with the

bottom side toward you_ The angled end of

the lower support should point up.

17. Place the right side panel on the right

side of the shelf. The spacer should be on the

inside of the cabinet. (Figure 20)

12

Corner Brackets

Shelf

21, Use eight truss head bolts, lockwashers,

and hex nuts to hold the skirts in place. Hand-

tighten. (Figure 21)

22, Put a truss head bolt through the hole at

the back, right corner of the shelf, This hole

goes through the shelf and the right side

panel. (Figure22)

Shelf Stiffener

Rear Flange

Fig_20

18, Put truss head bolts through the three

holes along the bottom edge of the right side

panel Put a lockwasher and hex nut on each

bolt and tighten using a 7/16 inch wrench or

socket. (Figure 20)

Note: It is sometimes difficult to get bolts

through these three holes. You may need to

use a Phillips screwdriver to help shift the

parts into place.

_" Right Side

Panel

19. Repeat steps 17-18 with the left side

panel and the left side of the shelf.

20. Turn the cabinet right side up. Attach the

skirts to the top of the side panels, with one

on the front of the cabinet and the other on

the back. (Figure 21)

Skirt

Rear

I Right Side Panel

I

I

Shelf

Front

Fig, 22

23. Put a lockwasher and hex nut on the bolt

and tighten using a 7/16 inch wrench or

socket.

24° Repeat steps 22-23 on the left side of the

shelf,

Left Side

Panel

Fig. 21

Shelf

Side Panel

\

\

\

Skirt

25. Put a truss head bolt through the back of

the right spacer and front edge of the shelf.

(Figure 23)

I

I

I

t

I

.... 2

Spacer !

©

Side Panel

13

Fig. 23

Shelf

26 Put a lockwasher and hex nut on the bolt

and tighten using a 7/16 inch wrench or

socket.

35. Adjust the lower' nut with the 9/16 inch

wrench until the leveling foot is at the desired

height°

27° Repeat steps 25-26 with the left spacer_

28_ Move the cabinet to the location where

you will use your saw.

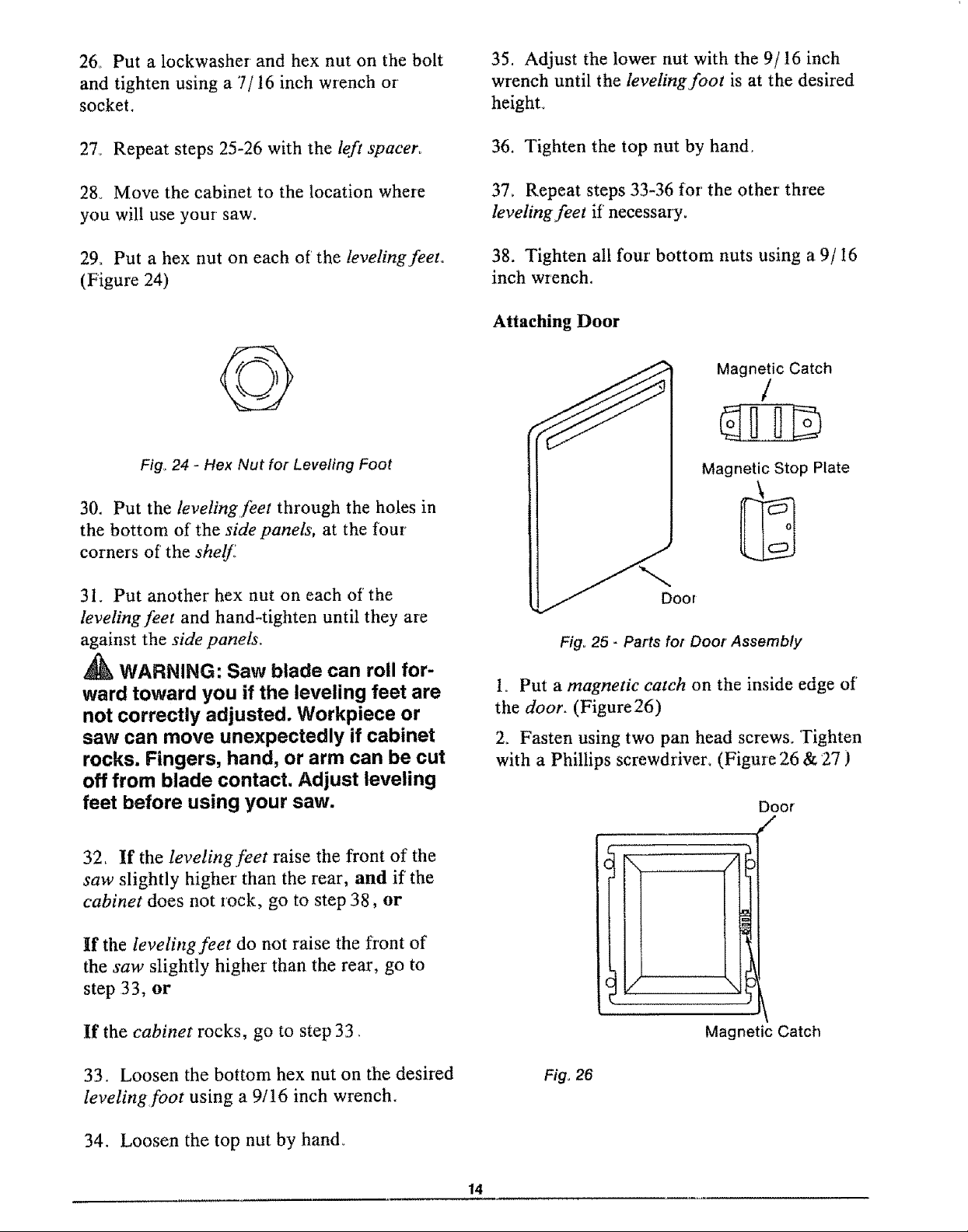

29° Put a hex nut on each of the levelingfeeto

(Figure 24)

Fig° 24 - Hex Nut for Leveling Foot

30. Put the leveling feet through the holes in

the bottom of the side panels, at the four

corner's of the shelf

31. Put another hex nut on each of the

leveling feet and hand-tighten until they are

against the side panels_

WARNING: Saw blade can roll for-

ward toward you if the leveling feet are

not correctly adjusted. Workpiece or

saw can move unexpectedly if cabinet

rocks. Fingers, hand, or arm can be cut

off from blade contact. Adjust leveling

feet before using your saw.

36. Tighten the top nut by hand,

37_ Repeat steps 33-36 for the other' three

leveling feet if necessary.

38. Tighten all four bottom nuts using a 9/16

inch wrench.

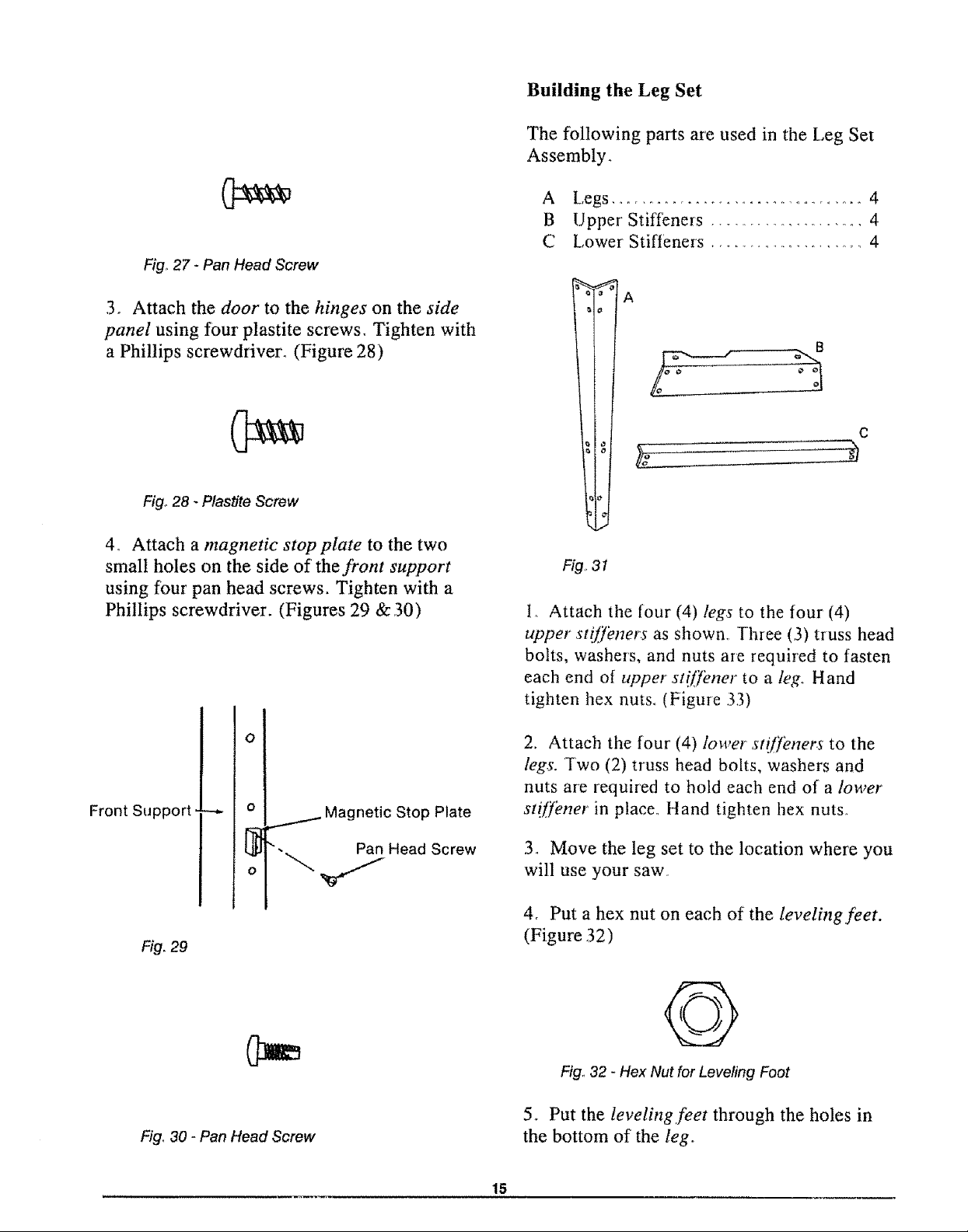

Attaching Door

Magnetic Catch

/

Magnetic Stop Plate

Fig, 25 - Parts for Door Assembly

Io Put a magnet& catch on the inside edge of'

the door. (Figure26)

2_ Fasten using two pan head screws. Tighten

with a Phillips screwdriver_ (Figure 26 & 27 )

Door

,,,-

32, If the leveling feet raise the front of tile

saw slightly higher than the rear, and if the

cabinet does not rock, go to step 38, or

If the leveling feet do not raise the front of

the saw slightly higher than the rear, go to

step 33, or

If the cabinet rocks, go to step 33,

33. Loosen the bottom hex nut on the desired

leveling foot using a 9/16 inch wrench.

34. Loosen the top nut by hand_

Magnetic Catch

Fig, 26

14

Fig° 27 - Pan Head Screw

3. Attach the door to the hinges on the side

panel using four plastite screws, Tighten with

a Phillips screwdriver. (Figure 28)

Fig_28 - Plastite Screw

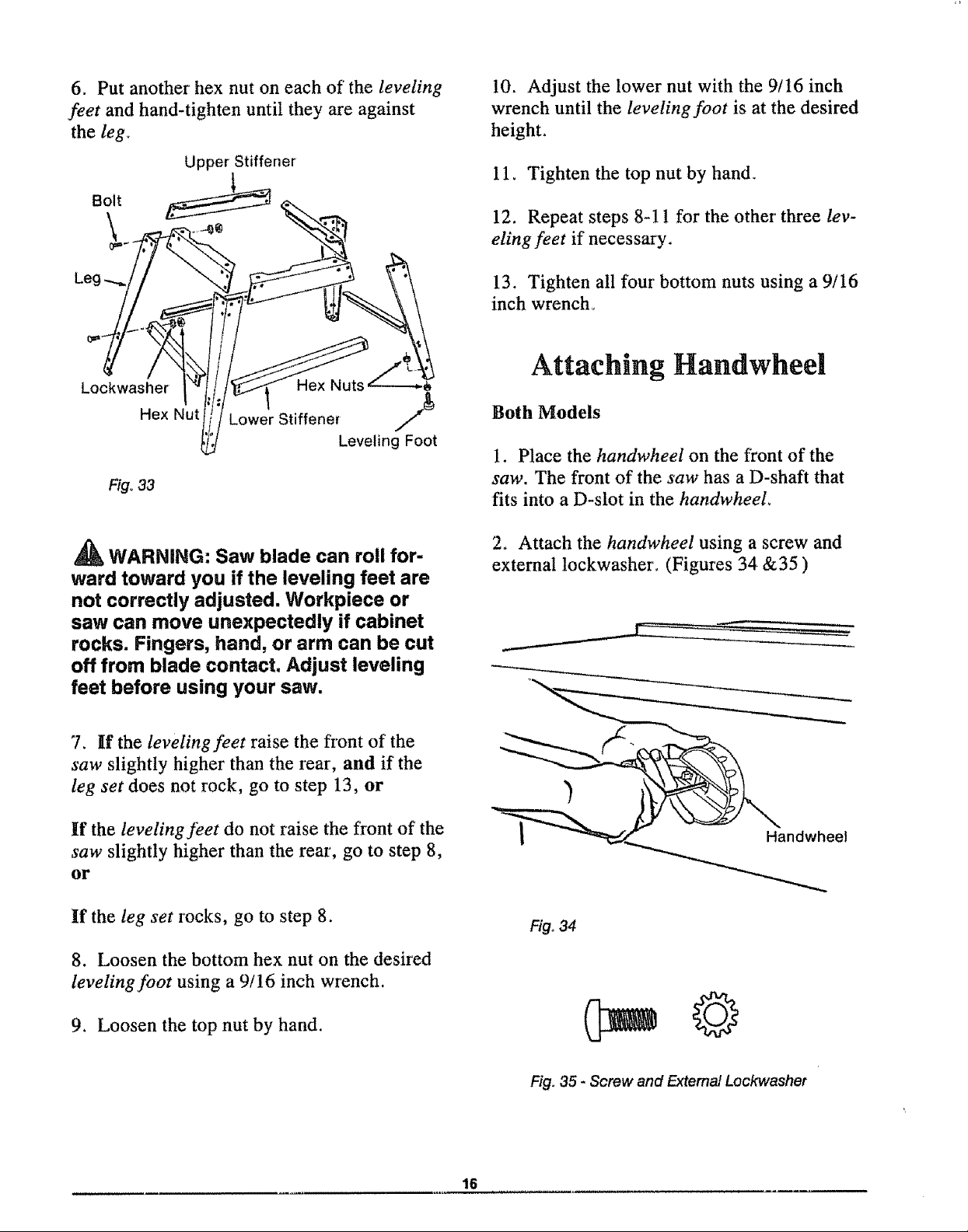

Building the Leg Set

The following parts are used in the Leg Set

Assembly.

A Legs .................................... 4

B Upper Stiffeners ....................... 4

C Lower Stiffeners ....................... 4

rA

B

C

4, Attach a magnetic stop plate to the two

small holes on the side of the front support

using four pan head screws. Tighten with a

Phillips screwdriver. (Figures 29 & 30)

o

Front Support

Fig. 29

0

/ Magnetic Stop Plate

tS{

_. Pan Head Screw

LII

o

Fig31

i. Attach the four (4) legs to the four (4)

upper st!ffeners as shown, Three (3) truss head

bolts, washers, and nuts are required to fasten

each end of upper stiffener to a leg. Hand

tighten hex nuts. (Figure 33)

2. Attach the four (4) lower st!ffeners to the

legs. Two (2) truss head bolts, washers and

nuts are required to hold each end of a lower

st

6. Put another' hex nut on each of the leveling

feet and hand-tighten until they are against

the leg_

10. Adjust the lower nut with the 9/16 inch

wrench until the leveling foot is at the desired

height.

Upper Stiffener

Bolt

Leg

Lockwasher Hex Nuts

Hex Nut Lower Stiffener /_

Leveling Foot

F/go33

WARNING: Saw blade can roll for-

ward toward you if the leveling feet are

not correctly adjusted. Workpiece or

saw can move unexpectedly if cabinet

rocks. Fingers, hand, or arm can be cut

off from blade contact. Adjust leveling

feet before using your saw.

11. Tighten the top nut by hand.

12. Repeat steps 8-1 t for the other' three lev-

eling feet if necessary.

13. Tighten all four bottom nuts using a 9/16

inch wrench°

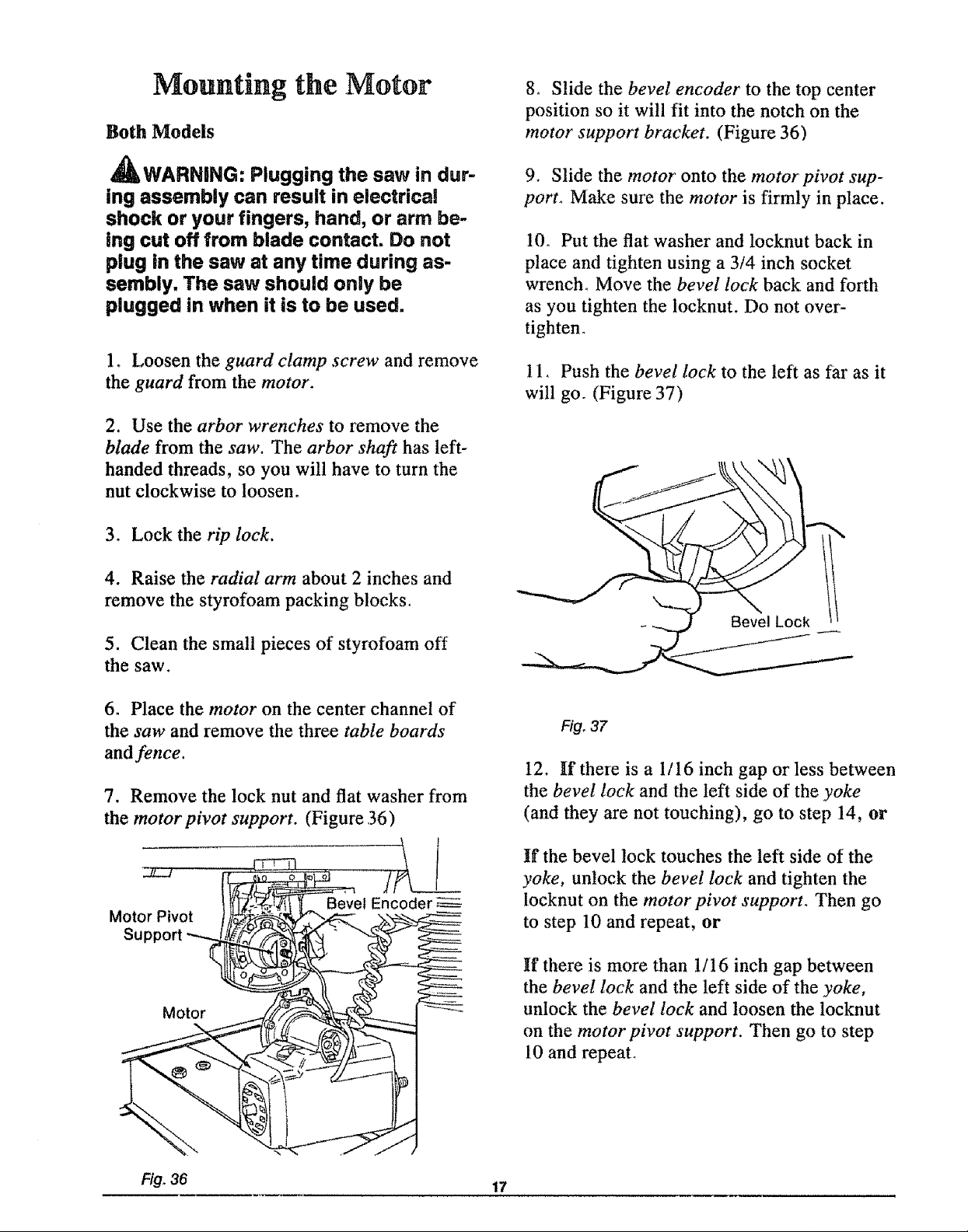

Attaching Handwheel

Both Models

1. Place the handwheel on the front of the

saw. The front of the saw has a D-shaft that

fits into a D-slot in the handwheeL

2. Attach the handwheel using a screw and

extemat lockwasher. (Figures 34 &35 )

7. If the leveling feet raise the front of the

saw slightly higher than the rear, and if the

leg set does not rock, go to step 13, or

If the leveling feet do not raise the front of the

saw slightly higher than the rear, go to step 8,

OF

if the leg set rocks, go to step 8.

8. Loosen the bottom hex nut on the desired

leveling foot using a 9/16 inch wrench.

9. Loosen the top nut by hand.

Handwheel

Fig. 34

Fig. 35 - Screw and Extemal Lockwashet

16

Mounting the Motor

Both Models

8o Slide the bevel encoder to the top center

position so it will fit into the notch on the

motor support bracket. (Figure 36)

_WARNING: Plugging the saw in dur-

ing assembly can result in electrical

shock or your fingers, hand, or arm be-

ing cut off from blade contact. Do not

plug in the saw at any time during as-

sembly. The saw should only be

plugged in when it is to be used.

1. Loosen the guard clamp screw and remove

the guard from the motor.

2. Use the arbor wrenches to remove the

blade from the saw. The arbor shaft has left-

handed threads, so you will have to turn the

nut clockwise to loosen.

3. Lock the rip lock.

4. Raise the radial arm about 2 inches and

remove the styrofoam packing blocks.

9. Slide the motor onto the motorpivot sup-

port_ Make sure the motor is firmly in place.

10. Put the flat washer and locknut back in

place and tighten using a 3/4 inch socket

wrench° Move the bevel lock back and forth

as you tighten the locknut. Do not over-

tighten°

11. Push the bevel lock to the left as far as it

will go. (Figure 37)

5. Clean the small pieces of styrofoam off

the saw.

6. Place the motor on the center channel of

the saw and remove the three table boards

and fence.

7. Remove the lock nut and flat washer from

the motorpivot support. (Figure 36)

Bevel Encoder

Motor Pivot

Support _

Motor

Fig, 37

12. If there is a 1/16 inch gap or less between

the bevel lock and the left side of the yoke

(and they are not touching), go to step 14, or

If the bevel lock touches the left side of the

yoke, unlock the bevel lock and tighten the

locknut on the motor pivot support. Then go

to step 10 and repeat, or

If there is more than t/16 inch gap between

the bevel lock and the left side of the yoke,

unlock the bevel lock and loosen the locknut

on the motor pivot support. Then go to step

10 and repeal

Fig. 36 17

13o Repeat steps 10-11 until the bevel lock

wilt not touch the left side of the ,yoke, and

the gap is not more than 1/16 inch_

14. Lock the bevel lock.

Attaching Trim Ledge and

Trim Caps

Both Models

15. Snap the yokeplug into place. The yoke

plug is in the loose parts bag

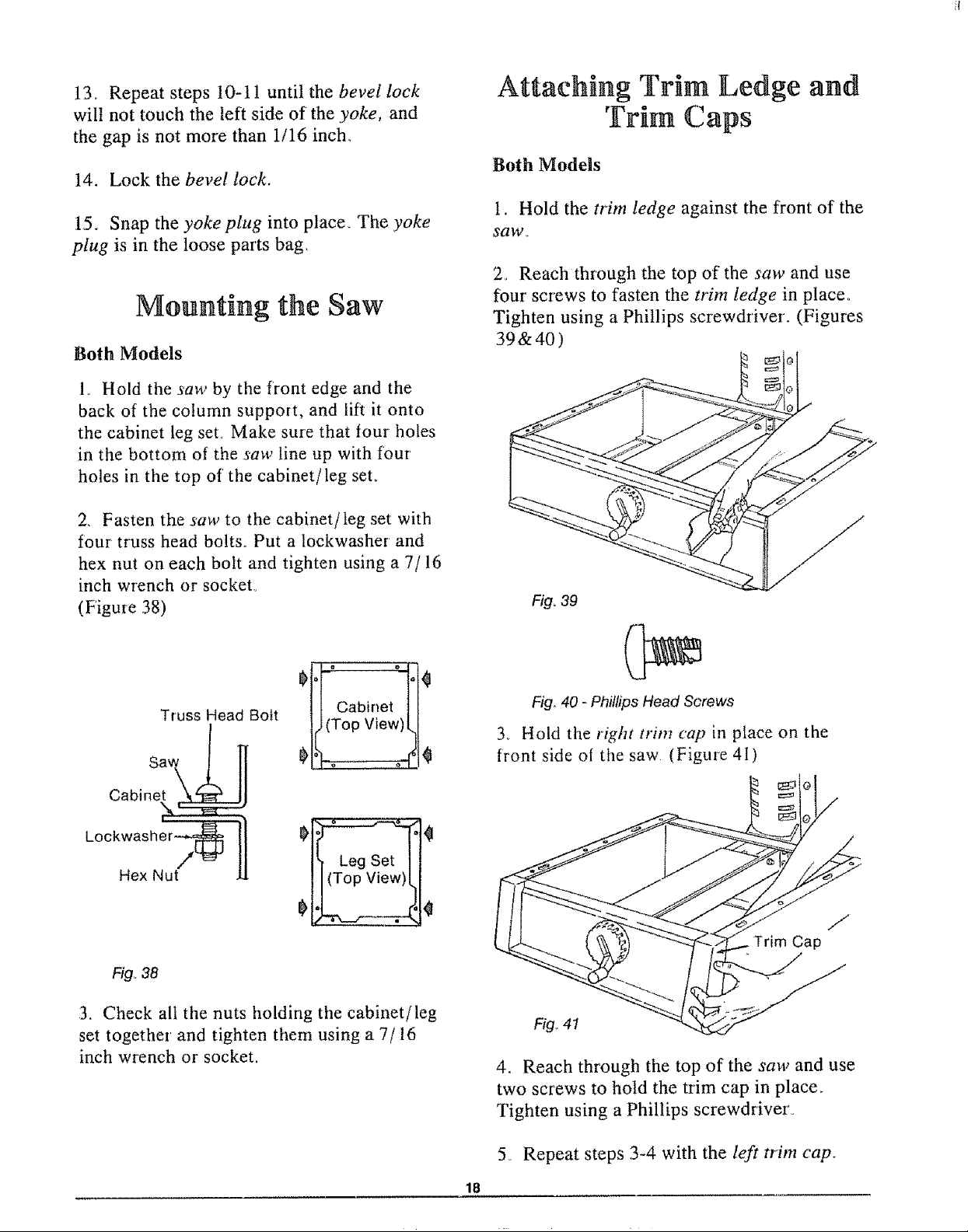

Mounting the Saw

Both Models

1 Hold the saw by the front edge and the

back of the column support, and lift it onto

the cabinet leg seL Make sure that four holes

in the bottom of the saw line up with four

holes in the top of the cabinet/leg seL

2. Fasten the saw to the cabinet/leg set with

four truss head bolts_ Put a lockwasher and

hex nut on each bolt and tighten using a 7/16

inch wrench or socket°

(Figuie 38)

1. Hold the trim ledge against the front of the

saw.

2.. Reach through the top of the saw and use

four screws to fasten the trim ledge in place.

Tighten using a Phillips screwdriver. (Figures

39&40)

Fig, 39

01°Foto[0

Truss Head Bolt

Cabinet

Loci

Hex Nut

Fig. 38

3. Check all the nuts holding the cabinet/leg

set together and tighten them using a 7/16

inch wrench or socket.

11Cabinet I /

Fig_40 - Phillips Head Screws

3. Hold the right trim cap in place on the

front side of the saw (Figure 41)

J

Trim Cap

Fig,.41

4. Reach through the top of the saw and use

two screws to hold the trim cap in place,

Tighten using a Phillips screwdriver_

5_ Repeat steps 3-4 with the left trim cap.

18

,i,

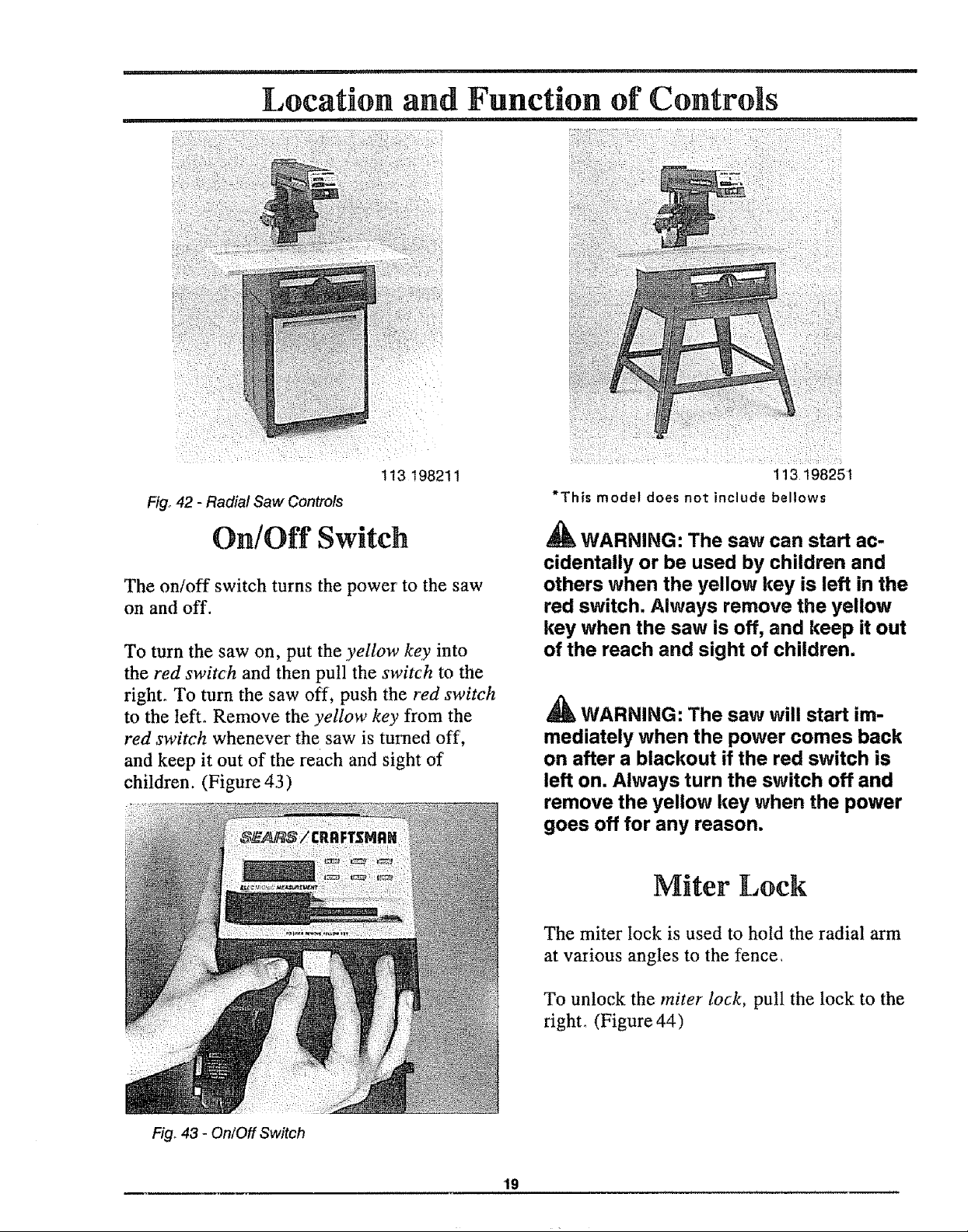

Location and Function of Controls

Fig_42 - Radial Saw Controls

I,II,l,ll,,

113 198211

On/Off Switch

The on/off switch turns the power to the saw

on and off.

To turn the saw on, put the yellow key into

the red switch and then pull the switch to the

right. To turn the saw off, push the red switch

to the lefL Remove the yellow key from the

red switch whenever the saw is turned off,

and keep it out of the reach and sight of

children. (Figure 43)

WARNING: The saw can start ac-

cidentally or be used by children and

others when the yellow key is left in the

red switch. Always remove the yellow

key when the saw is off, and keep it out

of the reach and sight of children.

_, WARNING: The saw will start im-

mediately when the power comes back

on after a blackout if the red switch is

left on. Always turn the switch off and

remove the yellow key when the power

goes off for any reason.

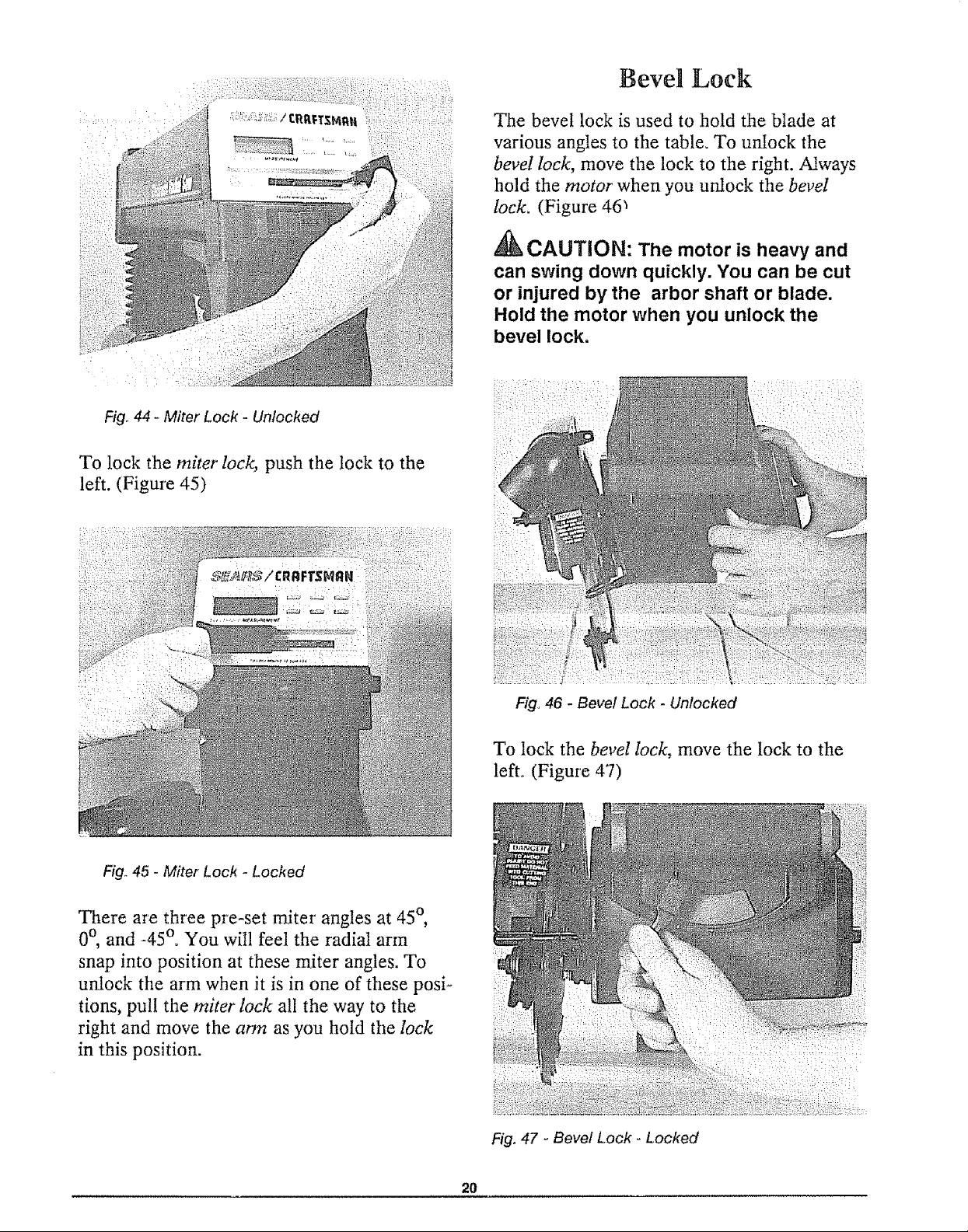

Miter Lock

The miter lock is used to hold the radial arm

at various angles to the fence,

Fig. 43 - On/Off Switch

To unlock the miter lock, pull the lock to the

right, (Figure 44)

19

Fig,,44 - Miter Lock - Unlocked

To lock the miter lock, push the lock to the

left. (Figure 45)

Bevel Lock

The bevel lock is used to hold the blade at

various angles to the table. To unlock the

bevel lock, move the lock to the right. Always

hold the motor when you unlock the bevel

lock. (Figure 46_

,_k CAUTION: The motor is heavy and

can swing clown quickly. You can be cut

or injured by the arbor shaft or blade.

Hold the motor when you unlock the

bevel lock.

Fig.,45 - Miter Lock - Locked

There are three pre-set miter angles at 45°,

0°, and -45°° You will feel the radial arm

snap into position at these miter angles. To

unlock the arm when it is in one of these posi-

tions, pull the miter lock all the way to the

right and move the arm as you hold the lock

in this position.

Fig° 46 - Bevel Lock - Unlocked

To lock the bevel lock, move the lock to the

left. (Figure 47)

Fig. 47 - Bevel Lock - Locked

20

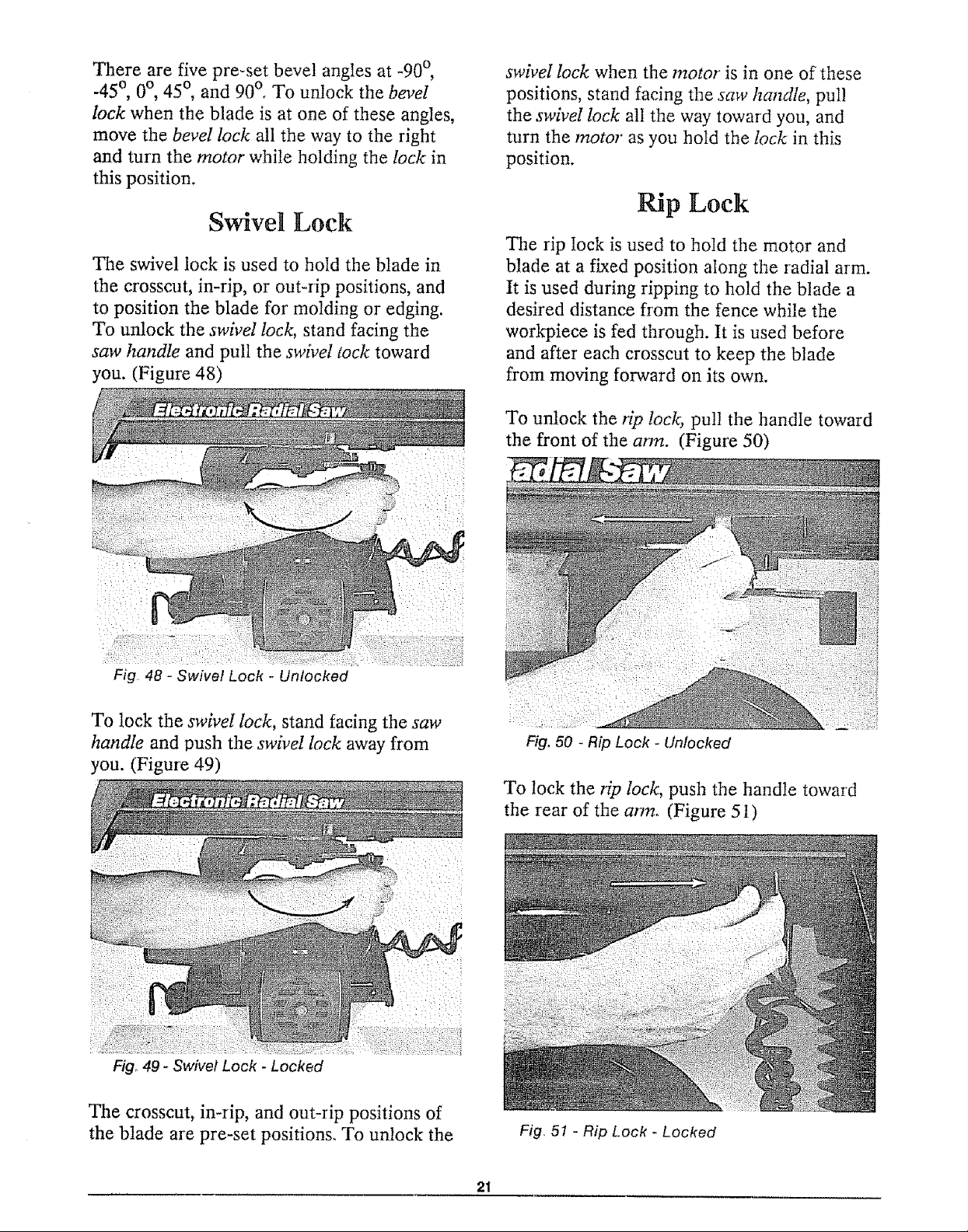

There are five pre-set bevel angles at -90°,

-45°, 0°, 45°, and 90°. To unlock the bevel

lock when the blade is at one of these angles,

move the bevel lock all the way to the right

and turn the motor while holding the lock in

this position.

Swivel Lock

The swivel lock is used to hold the blade in

the crosscut, in-rip, or out-rip positions, and

to position the blade for molding or edging.

To unlock the swivel lock, stand facing the

saw handle and pull the swivel lock toward

you. (Figure 48)

swivel lock when the motor is in one of these

positions, stand facing the saw handle, puI!

the swivel lock all the way toward you, and

turn the motor as you hold the lock in this

position.

Rip Lock

The rip lock is used to hoId the motor and

blade at a fixed position along the radial arm.

It is used during ripping to hold the blade a

desired distance from the fence while the

workpiece is fed through. It is used before

and after each crosscut to keep the blade

from moving forward on its own.

To unlock the tip lock, pull the handle toward

the front of the ann. (Figure 50)

Fig 48 - Swivel Lock - Unlocked

To lock the swivel lock, stand facing the saw

handle and push the swivel lock away from

you. (Figure 49)

Fig° 49 - Swivel Lock - Locked

The crosscut, in-rip, and out-rip positions of

the blade are pre-set positions. To unlock the

Fig, 50 - Rip Lock - Unlocked

To lock the rip lock, push the handte toward

the rear of the arm. (Figure 5 I)

Fig, 51 - Rip Lock - Locked

21

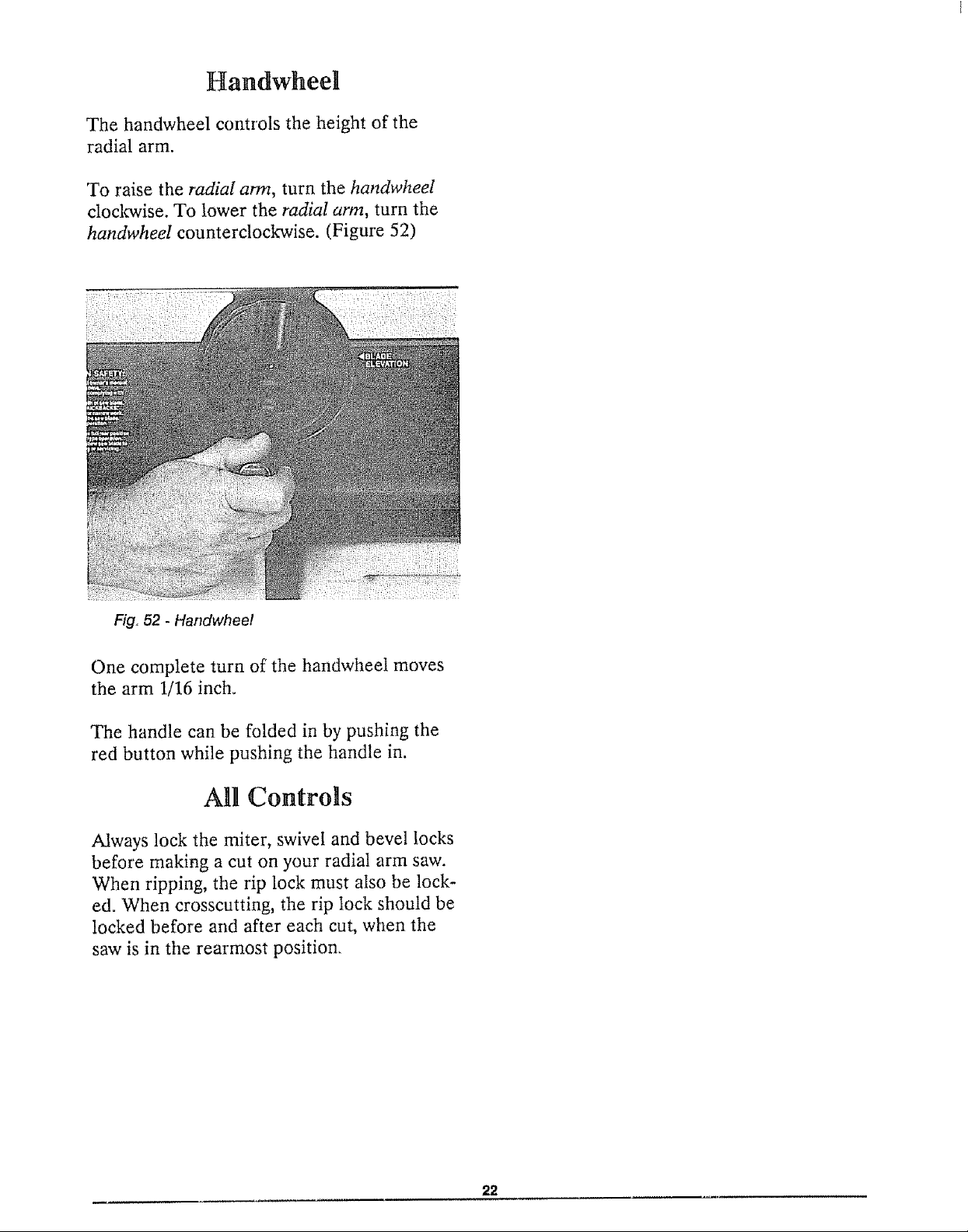

Handwheel

The handwheel controls the height of the

radial arm.

To raise the radial arm, turn the handwheel

clocle, vise. To lower the radial arm, turn the

handwheeI counterclockwise. (Figure 52)

Fig. 52 - Handwheel

One complete turn of the handwheel moves

the arm 1/16 inch.

The handle can be folded in by pushing the

red button while pushing the handle in.

All Controls

Always lock the miter, swivel and bevel locks

before making a cut on your radial arm saw.

When ripping, the rip lock must also be lock-

ed. When crosscutting, the rip Iock should be

locked before and after each cut, when the

saw is in the rearmost position.

22

The blade of your radial arm saw must be

aligned properly for two reasons: to make

cuts accurate, and to prevent binding of the

blade and workpiece which can cause jams or

thrown workpieces.

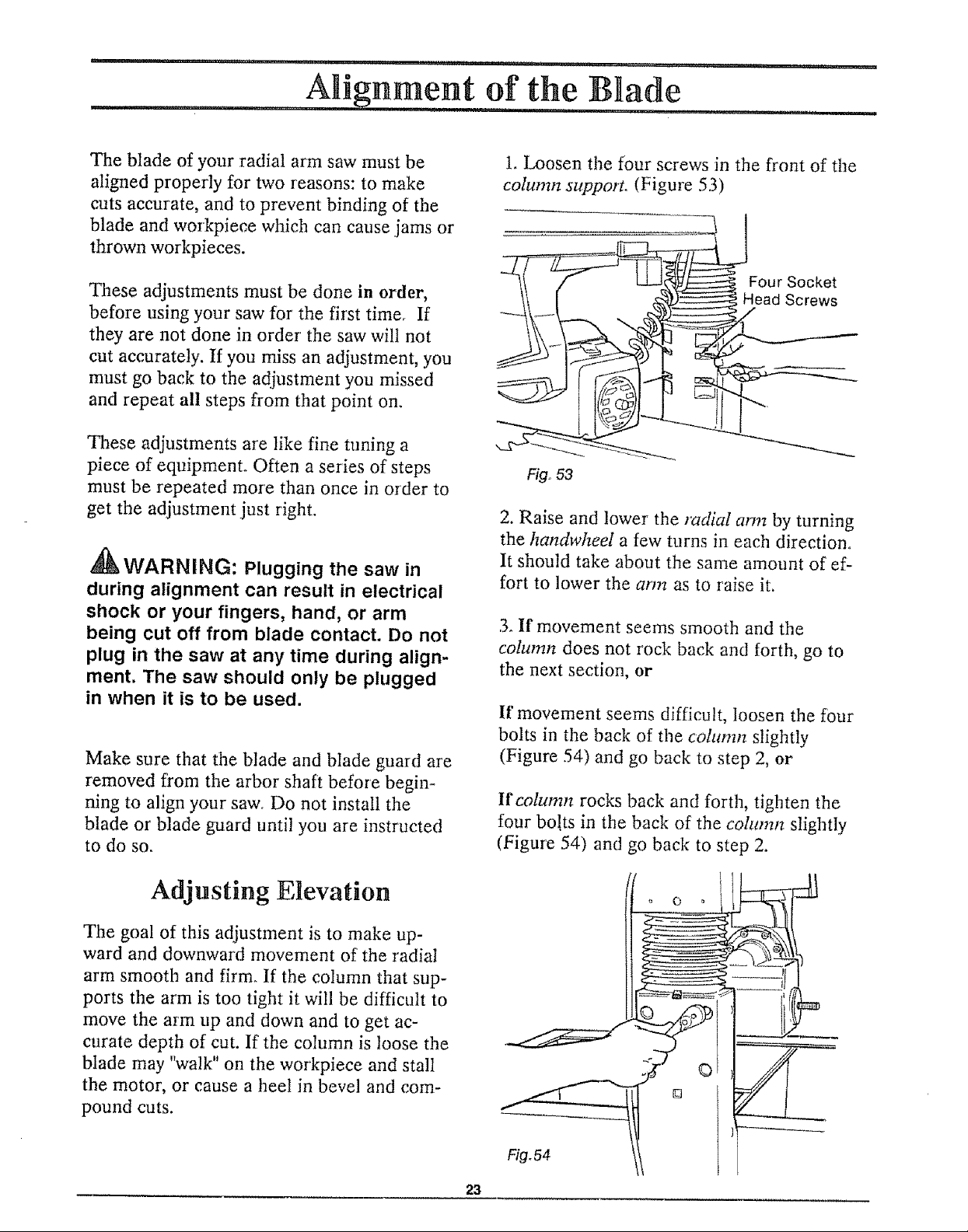

1. Loosen the four screws in the front of the

cohmm support. (Figure 53)

These adjustments must be done in order,

before using your saw for the first time. If

they are not done in order' the saw will not

cut accurately. If you miss an adjustment, you

must go back to the adjustment you missed

and repeat all steps from that point on.

These adjustments are like fine tuning a

piece of equipment. Often a series of steps

must be repeated more than once in order to

get the adjustment just right.

gk _

_WARNINL_: Plugging the saw in

during alignment can result in electrical

shock or your fingers, hand, or arm

being cut off from blade contact. Do not

plug in the saw at any time during align-

ment. The saw should only be plugged

in when it is to be used.

Make sure that the blade and blade guard are

removed from the arbor shaft before begin-

ning to align your saw. Do not install the

blade or blade guard until you are instructed

to do so.

Four Socket

Head Screws

Fig,,53

2. Raise and lower the radial arm by turning

the handwheeI a few turns in each direction.

It should take about the same amount of ef-

fort to lower the arm as to raise it.

3oIf movement seems smooth and the

column does not rock back and forth, go to

the next section, or

If movement seems difficult, loosen the four

bolts in the back of the cohmm slightly

(Figure 54) and go back to step 2, or

If column rocks back and forth, tighten the

four bolts in the back of the cohtmn slightly

(Figure 54) and go back to step 2.

Adjusting Elevation

The goal of this adjustment is to make up-

ward and downward movement of the radial

arm smooth and firm. If the column that sup-

ports the arm is too tight it will be difficult to

move the arm up and down and to get ac-

curate depth of cut. If the column is loose the

blade may "walk" on the workpiece and stall

the motor, or cause a heel in bevel and com-

pound cuts.

ooot

23

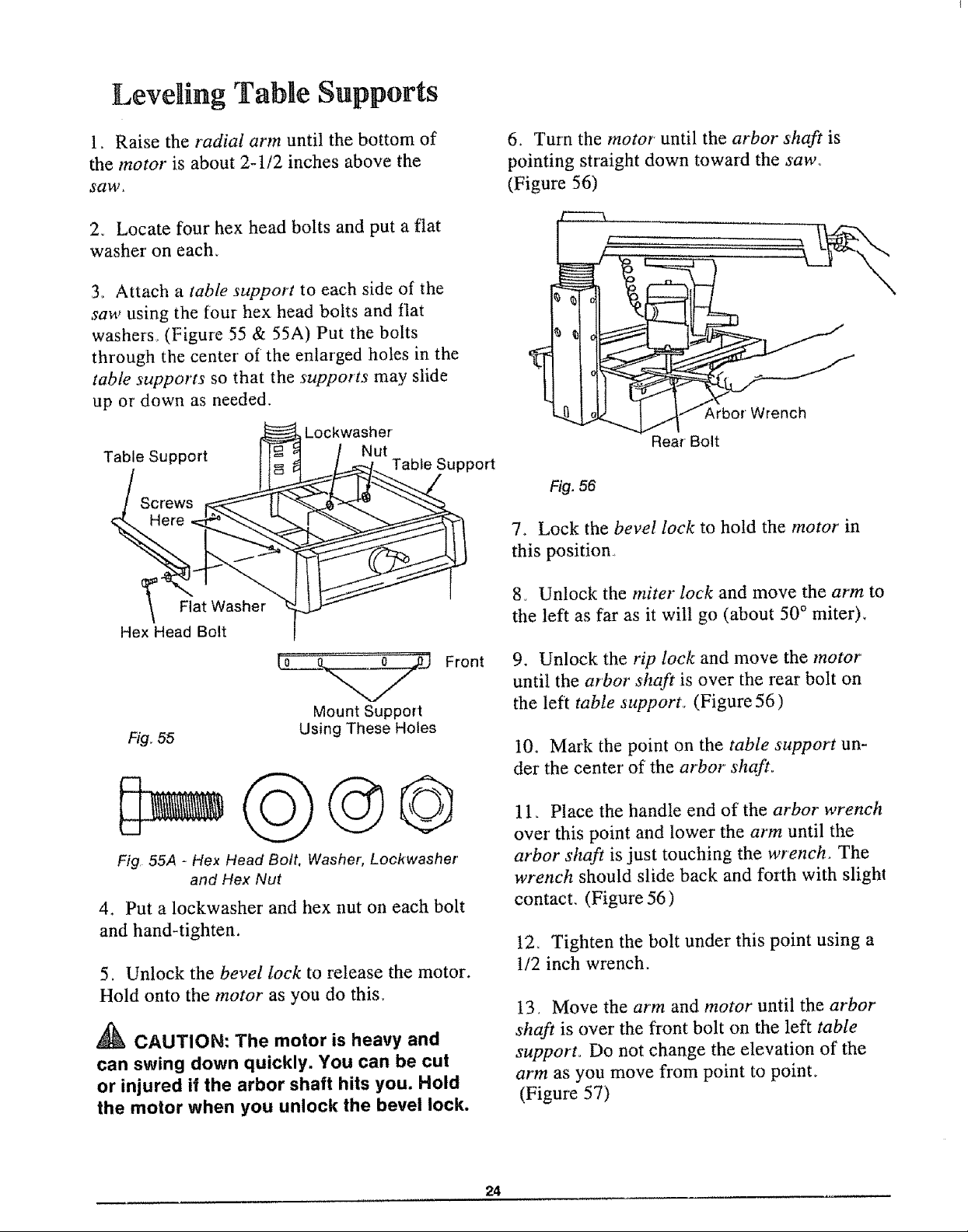

Leveling Table Supports

1o Raise the radial arm until the bottom of

the motor is about 2-1/2 inches above the

saw,

2. Locate four hex head bolts and put a flat

washer on each_

3, Attach a table support to each side of the

saw using the four hex head bolts and flat

washers, (Figure 55 & 55A) Put the bolts

through the center of the enlarged holes in the

table supports so that the supports may slide

up or down as needed.

Lockwasher

Table Support

Screws

Here

Nut

Table Support

6. Turn the motor' until the arbor shaft is

pointing straight down toward the saw°

(Figure 56)

£

Arbor Wrench

Rear Bolt

Fig. 56

74 Lock the bevel lock to hold the motor in

this position,

_" Flat Washer

Hex Head Bolt

(0 (L _ Front

Mount Support

Fig. 55

Fig 55A - Hex Head Bolt, Washer; Lockwasher

and Hex Nut

Using These Holes

4. Put a lockwasher and hex nut on each bolt

and hand-tighten.

5_ Unlock the bevel lock to release the motor.

Hold onto the motor as you do this.

A'k

CAUTION: The motor is heavy and

can swing down quickly. You can be cut

or injured if the arbor shaft hits you. Hold

the motor when you unlock the bevel lock.

8_ Unlock the miter lock and move the arm to

the left as far as it will go (about 50° miter).

9. Unlock the rip lock and move the motor

until the arbor shaft is over the rear bolt on

the left table support. (Figure 56)

I0. Mark the point on the table support un-

der the center of the arbor shaft,,

11. Place the handle end of the arbor wrench

over this point and lower the arm until the

arbor shaft is just touching the wrench. The

wrench should slide back and forth with slight

contact_ (Figure 56)

12_ Tighten the bolt under this point using a

1/2 inch wrench.

t3, Move the arm and motor until the arbor

shaft is over the front bolt on the left table

support° Do not change the elevation of the

arm as you move from point to poinL

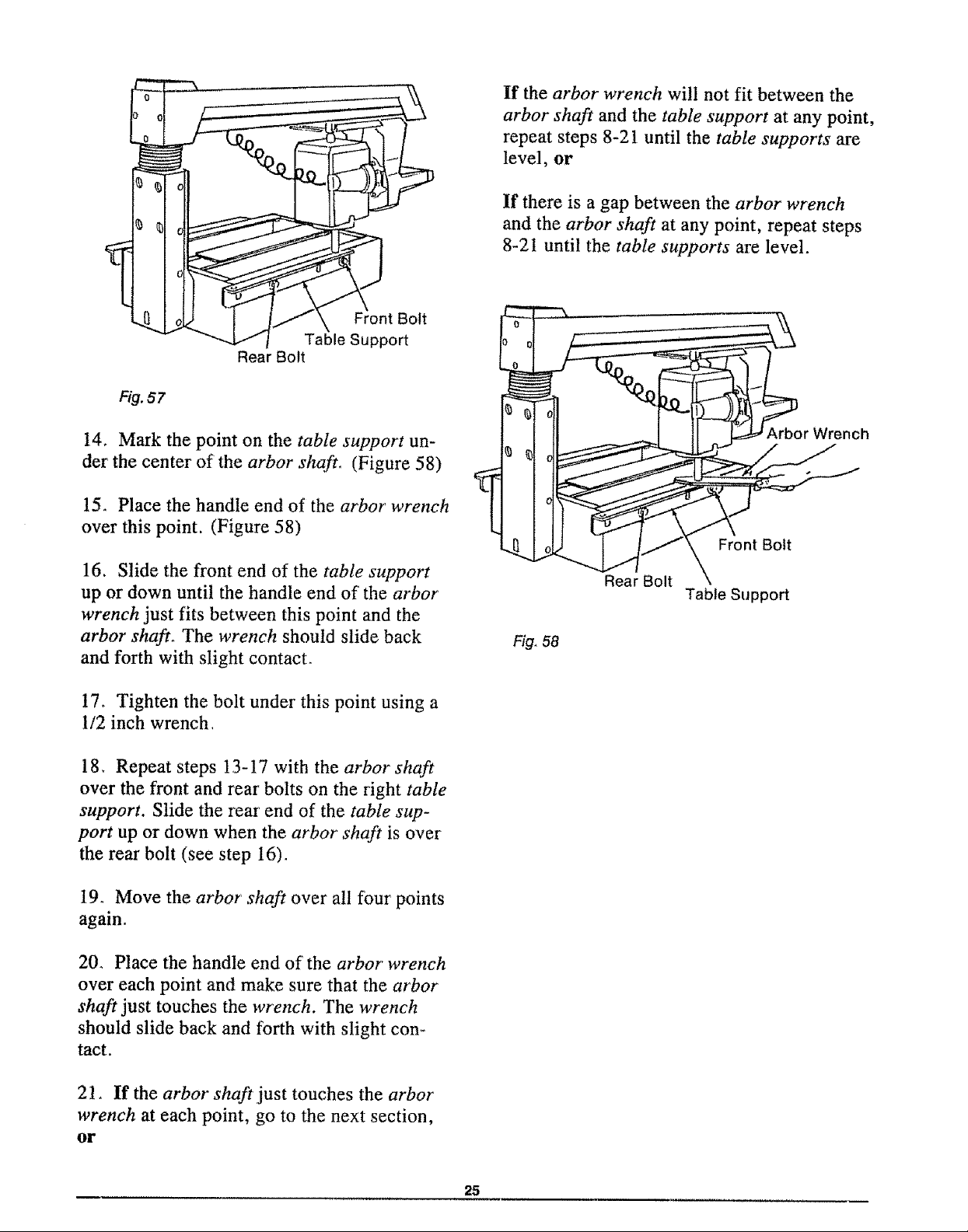

(Figure 57)

24

Rear Bolt

If the arbor wrench will not fit between the

arbor shaft and the table support at any point,

repeat steps 8-21 until the table supports are

level, or

If there is a gap between the arbor wrench

and the arbor shaft at any point, repeat steps

8-2t until the table supports are level.

Front Bolt

Table Support

Fig. 57

14. Mark the point on the table support un-

der the center of the arbor shaft° (Figure 58)

15_ Place the handle end of the arbor wrench

over this point. (Figure 58)

16. Slide the front end of the table support

up or down until the handle end of the arbor

wrench just fits between this point and the

arbor shaft. The wrench should slide back

and forth with slight contacL

17_ Tighten the bolt under this point using a

1/2 inch wrench,

184 Repeat steps 13-17 with the arbor shaft

over the front and rear bolts on the right table

support. Slide the rear end of the table sup-

port up or down when the arbor shaft is over

the rear bolt (see step 16).

t I

r Wrench

Front Bolt

Rear Bolt

Table Support

Fig_58

19. Move the arbor shaft over all four points

again.

20. Place the handle end of the arbor wrench

over each point and make sure that the arbor

shaft just touches the wrench. The wrench

should slide back and forth with slight con-

tact.

21. If the arbor shaft just touches the arbor

wrench at each point, go to the next section,

or

25

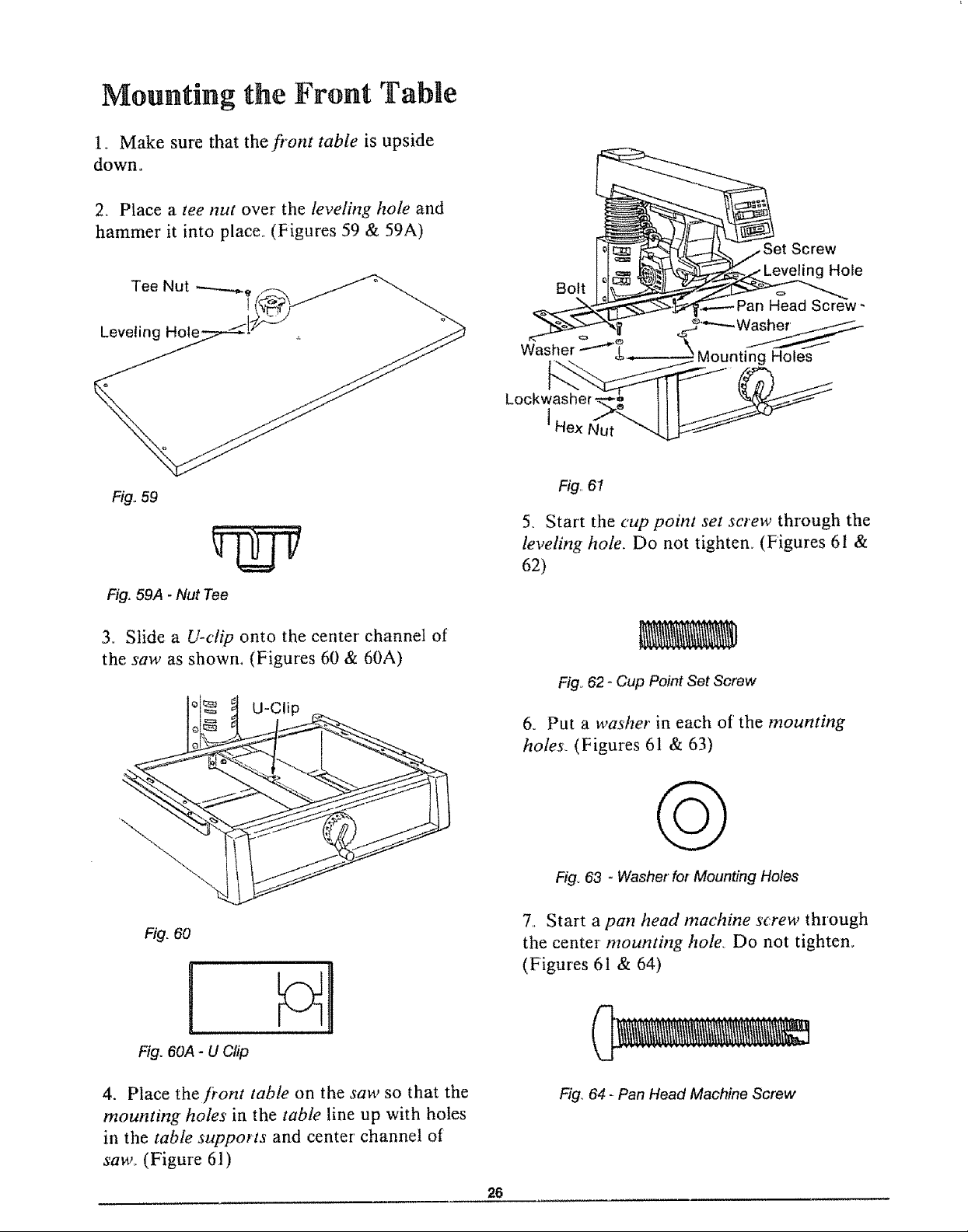

Mounting the Front Table

1_ Make sure that thefi"ont table is upside

down.

2_ Place a tee nut over' the leveling hole and

hammer it into place_ (Figures 59 & 59A)

Tee Nut ---..,-_, ._,)

Fig..59

rNv

Fig, 59A - Nut Tee

3.. Slide a U-clip onto the center channel of

the saw as shown, (Figures 60 & 60A)

U-Clip

Bolt

Fig,,61

5. Start the cup point set screw through the

leveling hole. Do not tighten. (Figures 61 &

62)

Fig_62 - Cup Point Set Screw

& Put a washer in each of the mounting

hotes_ (Figures 61 & 63)

Fig. 60

Fig. 60A- U Clip

4. Place the fi'ont table on the saw so that the

mounting holes in the table line up with holes

in the table supports and center' channel of

saw. (Figure 61)

Q

Fig,,63 - Washer for Mounting Holes

7,. Start a pan head machine screw through

the center mounting hole Do not tighten.

(Figures 61 & 64)

Fig° 64 - Pan Head Machine Screw

26

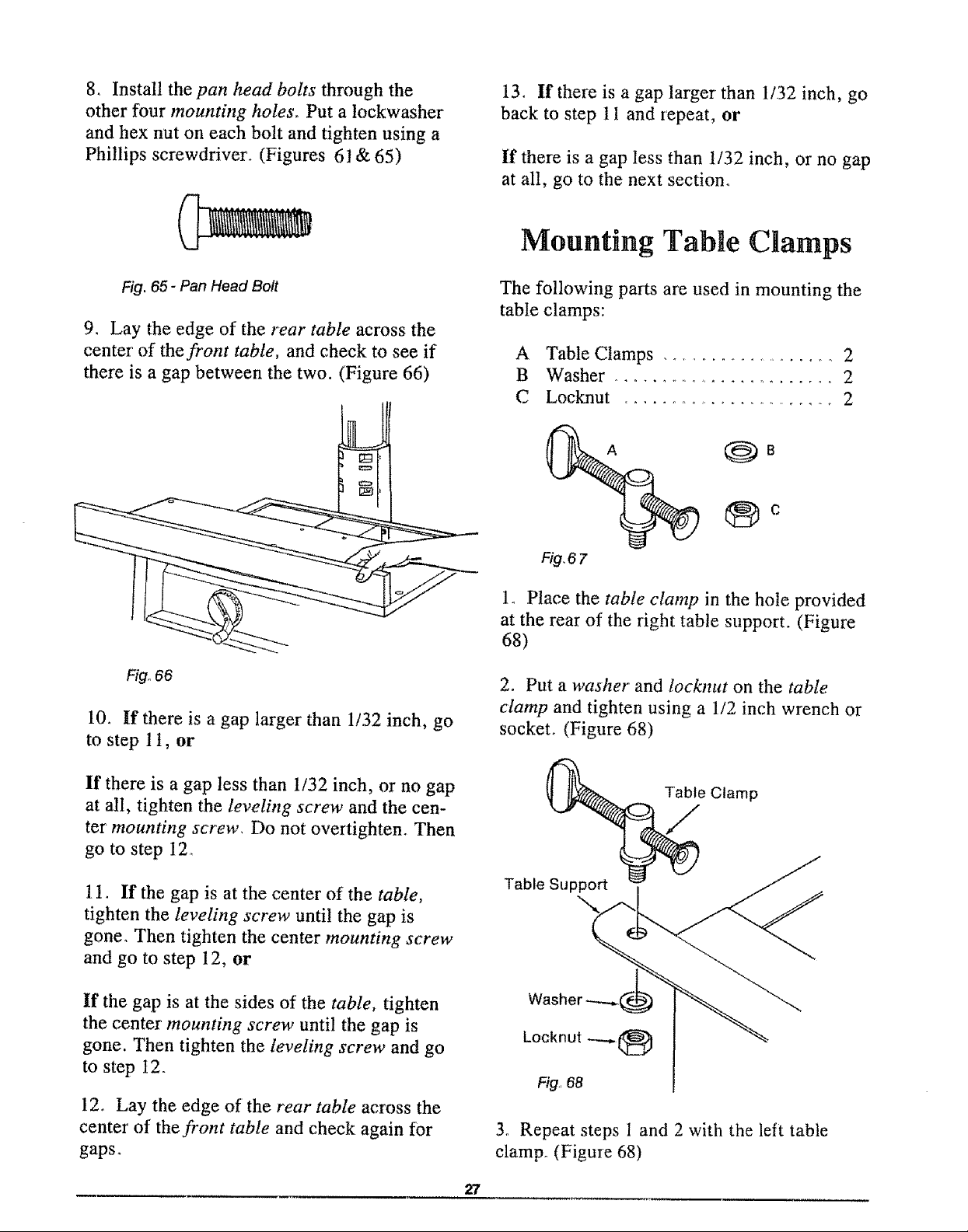

8. Install the pan head bolts through the

other four mounting holes, Put a tockwasher

and hex nut on each bolt and tighten using a

Phillips screwdriver_ (Figures 6] & 65)

13. If there is a gap larger' than 1/32 inch, go

back to step 11 and repeat, or

If there is a gap less than 1/32 inch, or no gap

at all, go to the next section.

Mounting TabLe Clamps

Fig. 65- Pan Head Bolt

9. Lay the edge of the rear table across the

center of the front table, and check to see if

there is a gap between the two. (Figure 66)

Fig°66

10. If there is a gap larger than 1/32 inch, go

to step 1t, or

The following parts are used in mounting the

table clamps:

A Table Clamps .................... 2

B Washer ......................... 2

C Locknut ......................... 2

®°

Fig,67

1. Place the table clamp in the hole provided

at the rear of the right table support. (Figure

68)

2. Put a washer and locknut on the table

clamp and tighten using a 1/2 inch wrench or

socket° (Figure 68)

If there is a gap less than 1/32 inch, or no gap

at all, tighten the leveling screw and the cen-

ter mounting screw, Do not overtighten. Then

go to step 12o

1I. If the gap is at the center of the table,

tighten the leveling screw until the gap is

gone. Then tighten the center mounting screw

and go to step 12, or

If the gap is at the sides of the table, tighten

the center mounting screw until the gap is

gone. Then tighten the leveling screw and go

to step t2.

12. Lay the edge of the rear table across the

center' of the front table and check again for

gaps.

Table_e Clamp

3. Repeat steps 1 and 2 with the left table

clamp° (Figure 68)

27

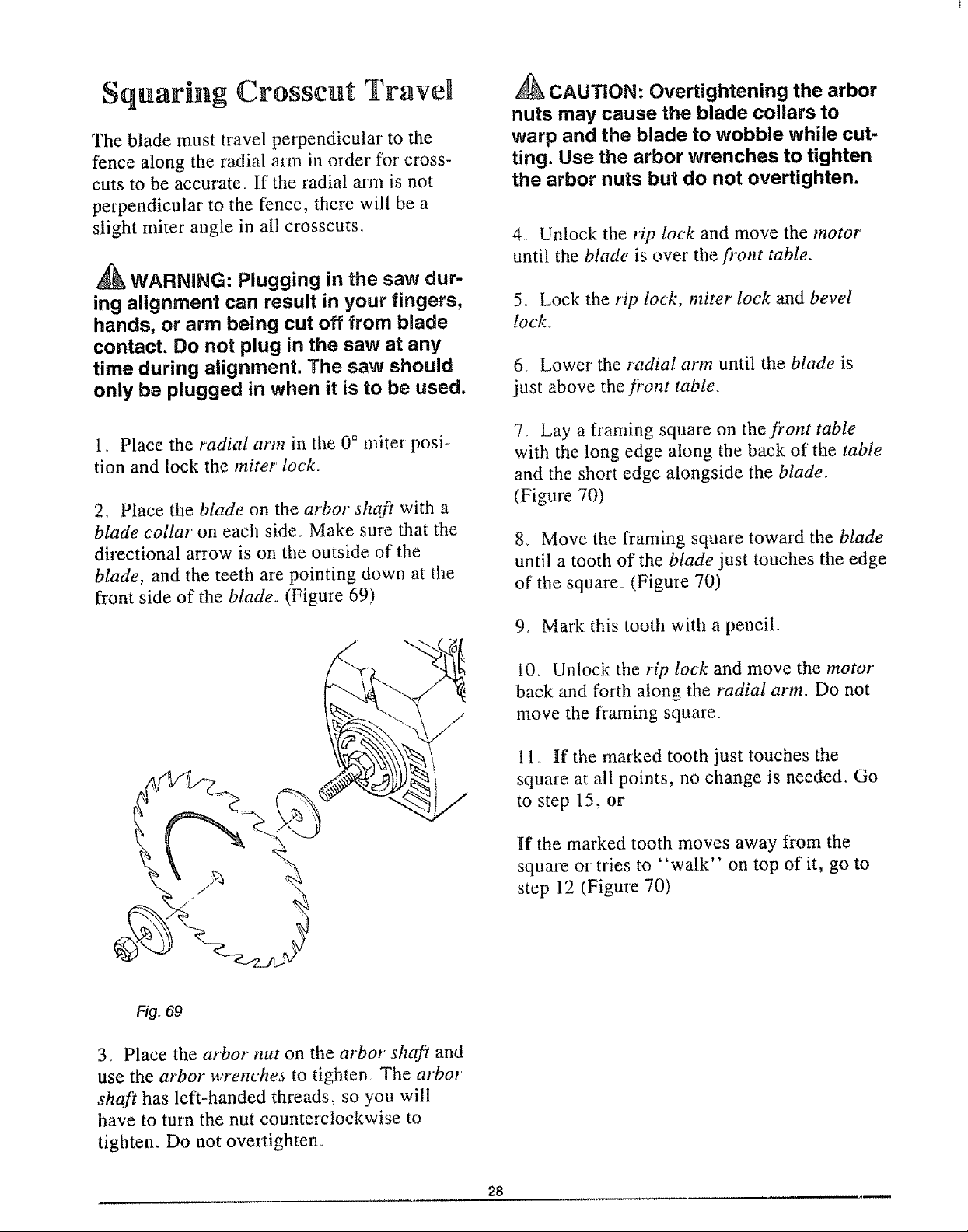

Squaring Crosscut Travel

The blade must travel perpendicular to the

fence along the radial arm in order for cross-

cuts to be accurate. If the radial arm is not

perpendicular to the fence, there will be a

slight miter angle in all crosscuts.

_ WARNING: Plugging in the saw dur-

ing alignment can result in your fingers,

hands, or arm being cut off from blade

contact. Do not plug in the saw at any

time during alignment. The saw should

only be plugged in when it is to be used.

CAUTION: Overtightening the arbor

nuts may cause the blade collars to

warp and the blade to wobble while cut-

ting. Use the arbor wrenches to tighten

the arbor nuts but do not overtighten.

4,, Unlock the rip lock and move the motor

until the blade is over the fi'ont table.

5o Lock the r'ip lock, miter lock and bevel

lock_

6_ Lower the radial arm until the blade is

just above the fi"ont table.

1. Place the radial arm in the 0° miter posi-

tion and lock the miter lock.

2_ Place the blade on the ar'bor shaft with a

blade collar on each side. Make sure that the

directional arrow is on the outside of the

blade, and the teeth are pointing down at the

front side of the blade. (Figure 69)

7.. Lay a f?aming square on thefiont table

with the long edge along the back of the table

and the short edge alongside the blade.

(Figure 70)

8. Move the framing square toward the blade

until a tooth of the blade just touches the edge

of the square. (Figure 70)

9. Mark this tooth with a pencil.

10b Unlock the rip lock and move tile motor

back and forth along the radial arm. Do not

move the framing square.

t 1_. If the marked tooth just touches the

square at all points, no change is needed. Go

to step 15, or

If the marked tooth moves away fl'om the

square or tries to "walk" on top of it, go to

step 12 (Figure 70)

Fig. 69

3., Place the arbor nut on the arbor shaft and

use the arbor wrenches to tighten. The arbor'

shaft has left-handed threads, so you will

have to turn the nut counterclockwise to

tightem Do not overtighten.

28

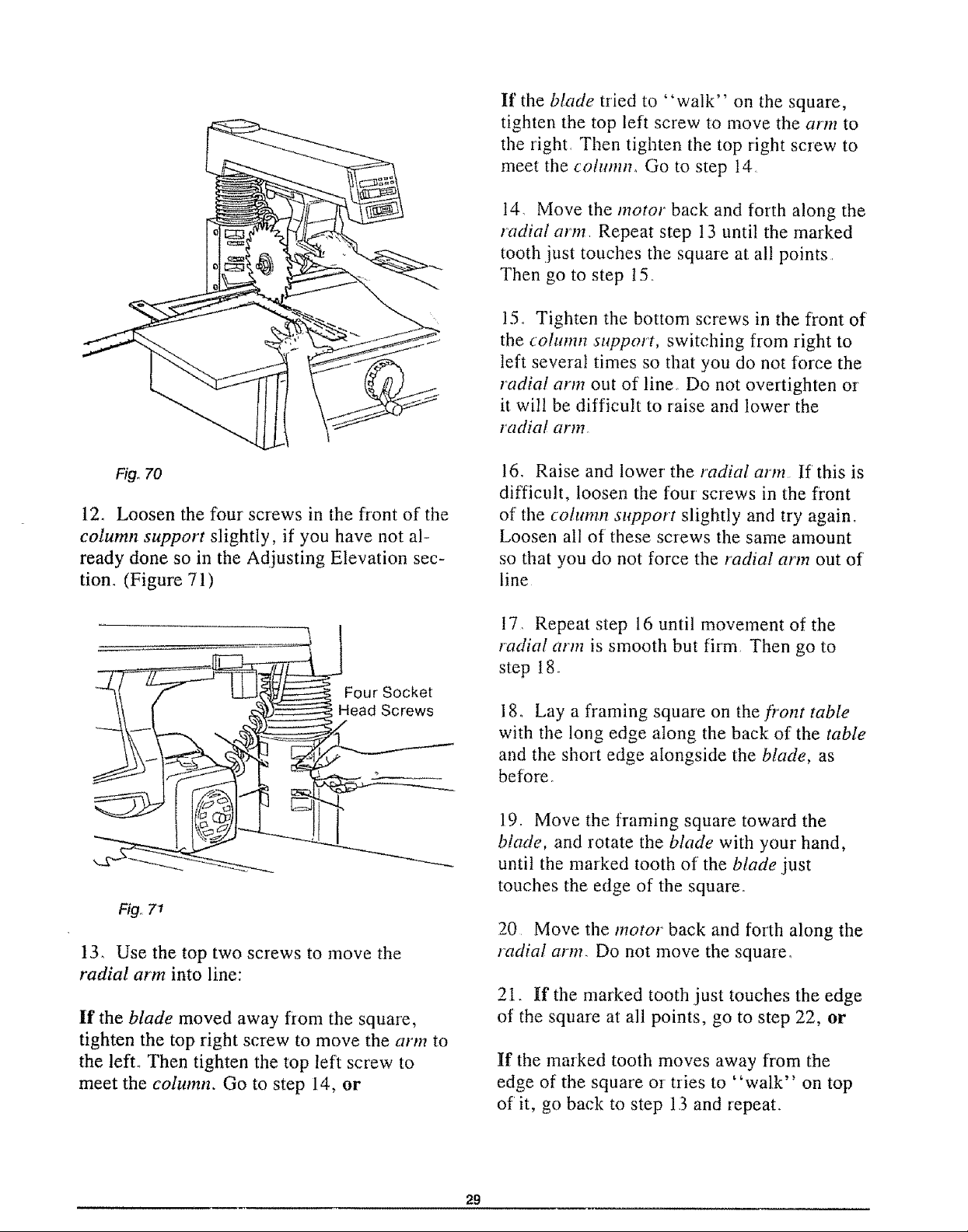

If the blade tried to "walk" on the square,

tighten the top left screw to move the aHn to

the right+ Then tighten the top right screw to

meet the column_ Go to step 14

t4, Move the motor back and forth along the

radial arm. Repeat step 13 until the marked

tooth just touches the square at all points _

Then go to step 15+

15+ Tighten the bottom screws in the front of

the column support, switching from right to

left several times so that you do not force the

radial arm out of line. Do not overtighten or

it will be difficult to raise and lower the

r'adial arm.

Fi9o70

12. Loosen the four screws in the front of the

column support slightly, if you have not al-

ready done so in the Adjusting Elevation sec-

tion. (Figure 71)

Four Socket

Head Screws

Fig,, 7"1

13, Use the top two screws to move the

radial arm into line:

It' the blade moved away from the square,

tighten the top right screw to move the arm to

the left+ Then tighten the top left screw to

meet the column. Go to step 14, or

16,. Raise and lower' the radial arm If this is

difficult, loosen the four screws in the front

of the cohmm support slightly and try again+

Loosen all of these screws the same amount

so that you do not force the r'adial arm out of

line

17. Repeat step 16 until movement of the

radiat arm is smooth but firm Then go to

step t 8

18o Lay a framing square on the front table

with the long edge along the back of the table

and the short edge alongside the blade, as

bef0re_

19_ Move the framing square toward the

blade, and rotate the blade with your hand,

until the marked tooth of the blade .just

touches the edge of the square.

20 Move the motor back and forth along the

radial arm. Do not move the square,

21+ If the marked tooth .just touches the edge

of the square at all points, go to step 22, or

If the mmked tooth moves away from the

edge of the square or+tries to "walk" on top

of it, go back to step 13 and repeat.

29

22° Lock the rip lock, put the spacer, fence

and rear table back in place, lock the table

clamp, and go to the next section.

Squaring Blade to Table

for Crosscutting

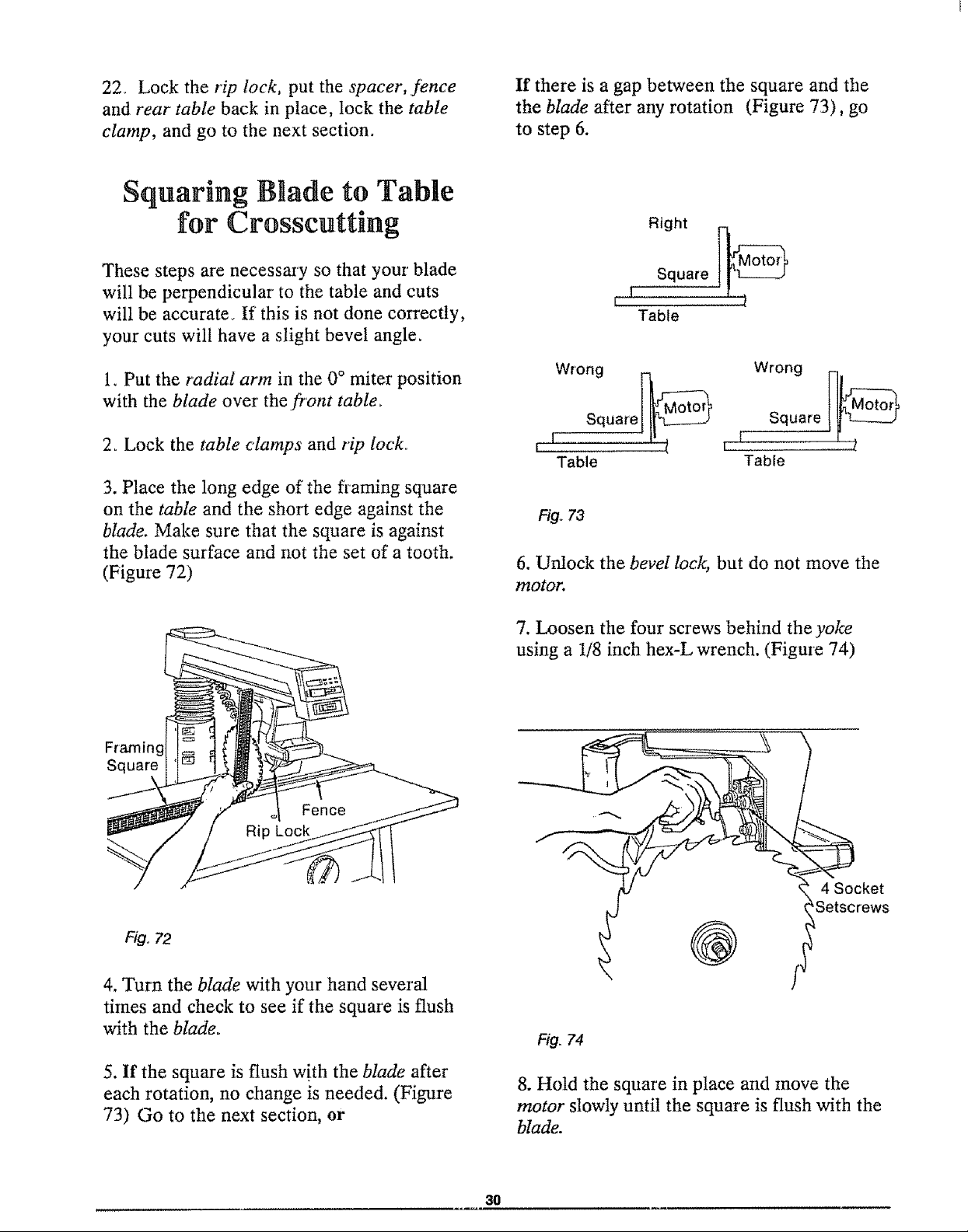

These steps are necessary so that your blade

will be perpendicular to the table and cuts

will be accurate_ If this is not done correctly,

your cuts will have a slight bevel angle.

If there is a gap between the square and the

the blade after any rotation (Figure 73), go

to step 6.

Right

t i Square j_

Table

1. Put the radial arm in the 0° miter position

with the blade over the front table_

2o Lock the table clamps and rip lock.

3. Place the long edge of the framing square

on the table and the short edge against the

blade. Make sure that the square is against

the blade surface and not the set of a tooth.

(Figure 72)

Framing

Square

Wrong _ j_____ Wrong I-]"

Square[ _ Square [_

Table Table

Fig. 73

6. Unlock the bevel lock, but do not move the

motor.

7. Loosen the four screws behind the yoke

using a 1/8 inch hex-L wrench. (Figme 74)

FI#. 72

4. Turn the blade with your hand several

times and check to see if the square is flush

with the blade.

5. If the square is flush with the blade after

each rotation, no change is needed. (Figure

73) Go to the next section, or

1 __Setscrews

f- ® /I

Fig. 74

8. Hold the square in place and move the

motor slowly until the square is flush with the

blade.

30

Loading...

Loading...