Craftsman 11319760 Owner’s Manual

Sears

owners

manual

MODEL NO.

113.19760

Serial

Number

Model and serial

number may be found

at the front of the base.

You should record both

model and serial number

in a safe place for

future use.

CAUTION:

Read GENERAL

and ADDITIONAL

SAFETY

INSTRUCTIONS

carefully

CRRFTSMRNo

IO-INCH

RADIAL SAW

• assembly

• operating

• repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. 6.'4722 Printed in U.S.A.

FULL ONE YEAR WARRANTY ON CRAFTSMAN RADIAL SAWS

If within one year from the date of purchase, this Craftsman Radial Saw fails due to a defect in material or

workmanship, Sears will repair it, free of charge.

Warranty service is available by simply contacting the nearest Sears store or Service Center throughout the

United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

SEARS, ROEBUCK AND CO.

BSC 41-3

SEARS TOWER

CHICAGO, IL 60684

general safety instructions for power tools

1. KNOW YOUR POWER TOOL 13.

Read the owner's manual carefully. Learn its

application and limitations as well as the specific

potential hazards peculiar to this tool.

2. GROUND ALL TOOLS 14.

This tool i_ equipped with an approved 3-conductor

cord and a 3-prong grounding type plug to fit the

proper grounding type receptacle. The green conductor 15.

in the cord is the grounding wire. Never connect the

green wire to a live terminal.

3. KEEP GUARDS IN PLACE

in working order, and in proper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations or

expose them to rain. Keep work area well lighted.

Provide adequate surrounding work space. 19.

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work

area.

8. MAKE WORKSHOP KID-PROOF

- with padlocks, master switches, or by removing

starter keys. 20.

9. DON'T FORCE TOOL

It will do the job better and safer at the rate for which

_t was designed.

10. USE RIGHT TOOL

Don't force tool or attachment to do a job it was not

designed for

11. WEAR PROPER APPAREL

Do not wear- loose clothing, gloves, neckties or jewelry

(rings, wrist watches) to get caught in moving parts.

Nonslip footwear is recommended. Wear protective 21.

hair covering to contain long hair. Roll long sleeves

above the el bow.

12. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANSI Z87.1 ) at 22.

all times. Also, use face or dust mask if cutting

operation is dusty, and ear protectors (plugs or muffs)

during extended periods of operation.

SECURE WORK

Use clamps or a vise to hold work when practical. It's

safer than using your hand, frees both hands to operate

tool.

DON'T OVERREACH

Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories.

16. DISCONNECT TOOLS

before servicing; when changing accessories such as

blades, bits, cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before plugging

in.

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. Follow the instructions that accompany

the accessories. The use of improper accessories may

cause hazards.

NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if the

cutting tool is accidentally contacted.

Do not store materials above or near the tool such that

it is necessary to stand on the tool to reach them.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that

is damaged should be carefully checked to ensure that it

will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may 'affect its operation. A guard or

other part that is damaged should be properly repaired

or replaced.

DIRECTION OF FEED

Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off. Don't leave tool until it comes to a

complete stop.

additional safety instructions for radial saws

CAUTION: Always disconnect the power cord before

removing the guard, changing the cutting tool, changing the

set-up or making adjustments. Shut off motor before

performing layout work on the saw table.

WARNING: DO NOT CONNECT POWER CORD UNTIL

THE FOLLOWING STEPS HAVE BEEN

SATISFACTORI LY COMPLETED:

I. Assembly and alignment.

II. Examination and operating familiarity with ON-OFF

switch, elevation control, yoke index and lock bevel

index and lock, carriage lock, guard clamp screw,

spreader and antikickback device, and miter index and

lock.

III. Review and understanding of all Safety Instructions and

Operating Procedures thru-out manual.

INSTALLATION

1. Set carriage lock before moving the saw.

2. Bolt the saw to the floor if it tends to slip, walk, or

slide during normal operation.

3. Mount the saw so the table is approximately 39" above

the floor.

4. Mount the saw so the arm slopes slightly downward to

the rear so the carriage will not roll forward due to

gravity.

MINIMIZE ACCIDENT POTENTIAL

Most accidents are caused by FAILURE TO FOLLOW

setup and operating instructions:

(A) GENERAL

-Avoid awkward hand positions, where a sudden slip

could cause a hand to move into a sawblade or other

cutting tool. Never reach in back of or around the

cutting tool with either hand to hold down the

workpiece, or for any other reason; DO NOT place

fingers or hands in the path of the sawblade.

- Never_ saw, dado, mold, or rabbet unless the proper

guard is installed and set up as instructed.

NOTE THE FOLLOWING DANGER LABELS

WHICH APPEAR ON THE FRONT OF THE YOKE

AND GUARD: r

DANGER: FOR YOUR OWN SAFETY INJURY DO ;

READ AND UNDERSTAND OWNER'S MANUAL BEFORE OPERATING MACHINE NOT FEED [

1, WEXnSAFETY _OGGLES. 4. USE"_JSH STICK FOR NARAOWWORK ! MATEm*L

3. KNOWNOW TO AVO_O"KICKBACKS ' S. ALLOW TOOL TOSTOP REFORE ADJUSTING

2. KEEPHANDS OUTOFPATH OFSAWBLAOE S. NEVERREACHAROUNO THE SAWSLAOE ' INTO i

WARNING: pOSITION AFTER EACH CROSSCUT TYPE O € OPERATION. I THiS I:NO

TO Avoid I_URY RETURNCARmAG_ TO THE FULL _AR I_OOL _ROM

If any part of this radial saw is missing or should

break, bend or fail in any way, or any electrical

component fai! to perform properly, shut off power

switch, remove cord from power supply and replace

damaged, missing and/or failed parts before resuming

operation.

- IF YOUR SAW MAKES AN UNFAMILIAR NOISE

OR IF IT VIBRATES EXCESSIVELY CEASE

OPERATING IMMEDIATELY UNTIL THE

SOURCE HAS BEEN LOCATED AND THE

PROBLEM CORRECTED.

-WARNING: DO NOT ALLOW FAMILIARITY

(GAINED FROM FREQUENT USE OF YOUR

SAW) TO BECOME COMMONPLACE. ALWAYS

REMEMBER THAT A CARELESS FRACTION OF

A SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY.

-Before starting work, verify that no play exists

between the column & column support, or in the

carriage, and that arm, yoke, and bevel locks/clamps

are tight.

DANGER

i CUTTING .

--A large proportion of saw accidents is caused by use

of the wrong type blade, dull, badly set, improperly

sharpened cutting tools, by gum or resin adhering to

cutting tools, and by sawblade misatignment

out-of-parallel with the fence. Such conditions can

cause the material to stick, jam (stall the saw) or

"KICKBACK" at the operator. NEVER ATTEMPT

TO FREE A STALLED SAW BLADE WITHOUT

FIRST TURNING THE SAW "OFF". If the

sawblade is stalled or jammed, shut saw "'OFF",

remove workpiece, and check sawblade squareness to

table surface and to the fence, and check for heel.

Adjust as indicated.

--CAUTION: DO NOT cycle the motor switch "ON'"

and "OFF" rapidly, as this might cause the sawblade

to loosen. In the event this should ever occur, allow

the saw blade to come to a complete stop and

re-tighten the arbor nut normally, not excessively.

-- Do not leave a long board unsupported so the spring

of the board causes it to shift on the table. Provide

proper support for the workpiece, based on its size

and the type of operation to be performed. Hold the

work firmly against the fence.

- Never use a length stop on the free end or edge of the

workpiece whether crosscutting or ripping. Never

hang onto or touch the free end of workpiece when

crosscutting, or a free piece that is cut off while

power is "ON" and/or the saw blade is rotating. In

short, the cut-off piece in any "thru-sawing"

operation must never be confined - it must be

allowed to move laterally.

-- Make sure your fingers do not contact the terminals

when installing or removing the plug to or from a live

power source.

- Never climb on the saw, or climb near the saw when

power is "ON". Never leave the saw with power

"ON", or before the cutting tool has come to a

complete stop. Lock the motor switch and put away

the key when leaving the saw.

-Do not use any blade or other cutting tool marked

for an operating speed lower than 3450 RPM. Never

use a cutting tool larger in diameter than the diameter

for which the saw was designed. For greatest safety

and efficiency when ripping, use the maximum

diameter blade for which the saw is designed, since

under these conditions the spreader is nearest the

blade.

- Never turn your saw "ON" before clearing the table

or work surface of all objects (tools, scraps of wood,

etc.) except the workpiece and related feed or

support devices for the operation planned.

- DO NOT perform layout, assembly, or setup work on

the table while the cutting tool is rotating.

-Never perform any operation "FREE HAND". This

term means feeding the sawblade into the workpiece

or feeding the workpiece into the sawblade or other

cutting tool without using the fence or some other

device which prevents rotation or twisting of the

workpiece during the operation. Never "RIP" in the

crosscut position. Never make a miter cut with the

arm in the 90 ° crosscut position.

- Never lower a revolving cutting tool into the table or

a workpiece without first locking the Carriage Lock

Knob. Release the knob only after grasping the Yoke

Handle. Otherwise the cutting tool may grab the

workpiece and be propelled toward you.

-The sawblade, dado, or other cutting tool must be

3

additional safety

removed from the saw arbor before using the

accessory shaft (rear end of the saw motor). NEVER

operate the saw with cutting tools (including sanding

accessories) installed on both ends of the saw arbor.

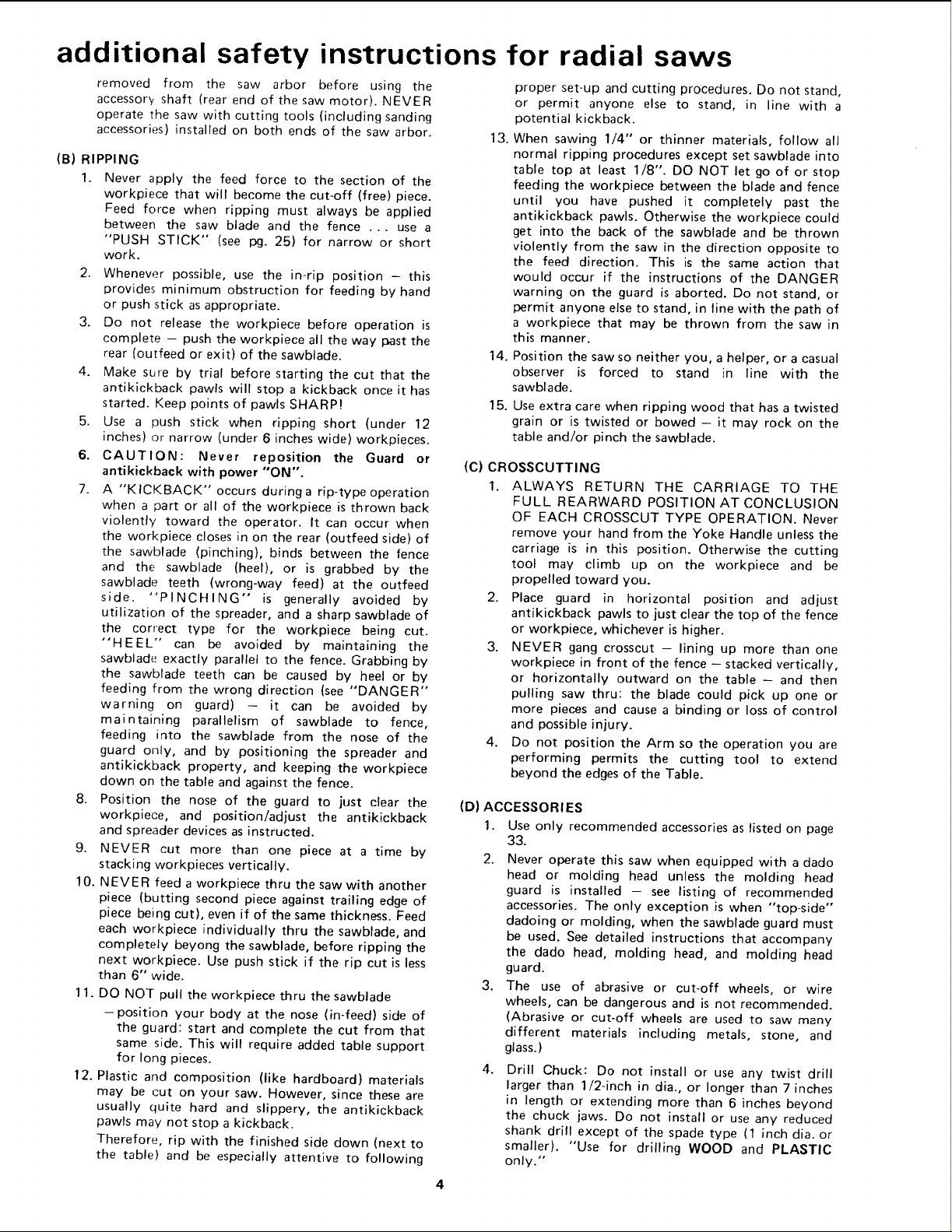

(B) RIPPING

1. Never apply the feed force to the section of the

workpiece that will become the cut-off (free) piece.

Feed force when ripping must always be applied

between the saw blade and the fence ... use a

"PUSH STICK" (see pg. 25) for narrow or short

work.

2. Whenever possible, use the in-rip position - this

provides minimum obstruction for feeding by hand

or push stick as appropriate.

3. Do not release the workpiece before operation is

complete - push the workpiece all the way past the

rear (outfeed or exit) of the sawblade.

4. Make sure by trial before starting the cut that the

antikickback pawls will stop a kickback once it has

started. Keep points of pawls SHARP!

5. Use a push stick when ripping short (under 12

inches) or narrow (under 6 inches wide) workpieces.

6. CAUTION: Never reposition the Guard or

antikickback with power "ON".

7. A "KICKBACK" occurs during a rip-type operation

when a part or all of the workpiece is thrown back

violently toward the operator. It can occur when

the workpiece closes in on the rear (outfeed side) of

the sawblade (pinching), binds between the fence

and the sawblade (heel), or is grabbed by the

sawblade teeth (wrong-way feed) at the outfeed

side. "PINCHING" is generally avoided by

utilization of the spreader, and a sharp sawblade of

the correct type for the workpiece being cut.

"HEEL" can be avoided by maintaining the

sawblade exactly parallel to the fence. Grabbing by

the sawblade teeth can be caused by heel or by

feeding from the wrong direction (see "DANGER"

warning on guard) - it can be avoided by

maintaining parallelism of sawblade to fence,

feeding into the sawblade from the nose of the

guard only, and by positioning the spreader and

antikickback property, and keeping the workpiece

down on the table and against the fence.

8. Position the nose of the guard to just clear the

workpiece, and position/adjust the antikickback

and spreader devices as instructed.

9. NEVER cut more than one piece at a time by

stacking workpieces vertically.

10. NEVER feed a workpiece thru the saw with another

piece (butting second piece against trailing edge of

piece being cut), even if of the same thickness. Feed

each workpiece individually thru the sawblade, and

completely beyong the sawblade, before ripping the

next workpiece. Use push stick if the rip cut is less

than 6" wide.

11. DO NOT pull the workpiece thru the sawblade

-position your body at the nose (in-feed) side of

the guard: start and complete the cut from that

same side. This will require added table support

for long pieces.

12. Plastic and composition (like hardboard)materials

may be cut on your saw. However, since these are

usually quite hard and slippery, the antikickback

pawls may not stop a kickback.

Therefore, rip with the finished side down (next to

the table) and be especially attentive to following

instructions for radial saws

proper set-up and cutting procedures. Do not stand,

or permit anyone else to stand, in line with a

potential kickback.

13. When sawing 1/4" or thinner materials, follow all

normal ripping procedures except set sawblade into

table top at least 1/8". DO NOT let go of or stop

feeding the workpiece between the blade and fence

until you have pushed it completely past the

antikickback pawls. Otherwise the workpiece could

get into the back of the sawblade and be thrown

violently from the saw in the direction opposite to

the feed direction. This is the same action that

would occur if the instructions of the DANGER

warning on the guard is aborted. Do not stand, or

permit anyone else to stand, in line with the path of

a workpiece that may be thrown from the saw in

this manner.

14. Position the saw so neither you, a helper, or a casual

observer is forced to stand in line with the

sawblade.

15. Use extra care when ripping wood that has a twisted

grain or is twisted or bowed - it may rock on the

table and/or pinch the sawblade.

(C) CROSSCUTTING

1. ALWAYS RETURN THE CARRIAGE TO THE

FULL REARWARD POSITION AT CONCLUSION

OF EACH CROSSCUT TYPE OPERATION. Never

remove your hand from the Yoke Handle unless the

carriage is in this position. Otherwise the cutting

tool may climb up on the workpiece and be

propelled toward you.

2. Place guard in horizontal position and adjust

antikickback pawls to just clear the top of the fence

or workpiece, whichever is higher.

3. NEVER gang crosscut - lining up more than one

workpiece in front of the fence - stacked vertically,

or horizontally outward on the table - and then

pulling saw thru: the blade could pick up one or

more pieces and cause a binding or loss of control

and possible injury.

4. Do not position the Arm so the operation you are

performing permits the cutting tool to extend

beyond the edges of the Table.

(D) ACCESSORIES

1. Use only recommended accessories as listed on page

33.

2. Never operate this saw when equipped with a dado

head or molding head unless the molding head

guard is installed -- see listing of recommended

accessories. The only exception is when "top-side"

dadoing or molding, when the sawblade guard must

be used. See detailed instructions that accompany

the dado head, molding head, and molding head

guard.

3. The use of abrasive or cut-off wheels, or wire

wheels, can be dangerous and is not recommended.

(Abrasive or cut-off wheels are used to saw many

different materials including metals, stone, and

glass.)

4. Drill Chuck: Do not install or use any twist drill

larger than 1/2-inch in dia., or longer than 7 inches

in length or extending more than 6 inches beyond

the chuck jaws. Do not install or use any reduced

shank drill except of the spade type (1 inch dia. or

smaller). "Use for drilling WOOD and PLASTIC

only."

WEAR YOUR

electrical connections

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles complying

with ANSI Z87.1 (shown on Package) before commencing

power tool operation. Safety Goggles are available at Sears

retail or catalog stores.

POWER SUPPLY

1. Motor Specifications

The A-C motor used in this saw is a capacitor-start

non-reversible type having the following specifications:

Voltage ................................. 120

Amperes ................................ 11.5

Hertz (cycles) ............................. 60

Phase ................................ Single

RPM .................................. 3450

Rotation as viewed from saw blade end ... Clockwise

CAUTION: Your saw is wired for 120V operation.

Connect to a 120V, 15-Amp. branch circuit and use a

15-Amp. time-delay fuse or circuit breaker.

This machine must be grounded while in use to protect

the operator from electric shock.

IF YOU ARE NOT SURE THAT YOUR OUTLET IS

PROPERLY GROUNDED, HAVE IT CHECKED BY A

QUALI FlED ELECTRICIAN.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUGS WHEN INSTALLING

OR REMOVING THE PLUG TO OR FROM THE

OUTLET.

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL

HAZARD OF ELECTRICAL SHOCK.

PARTICULARLY WHEN USED IN DAMP

LOCATIONS IN PROXIMITY TO PLUMBING. IF AN

ELECTRICAL SHOCK OCCURS THERE IS THE

POTENTIAL OF A SECONDARY HAZARD SUCH AS

YOUR HANDS CONTACTING THE SAWBLADE.

IF POWER CORD IS WORN OR CUT, OR DAMAGED

IN ANY WAY, HAVE IT REPLACED

IMMEDIATELY.

3-PRONG PLUG

PROPERLY

GROUNDED OUTLET

J

GROUNDING PRONG

This power tool is equipped with a 3-conductor cord

and grounding type plug which has a grounding prong,

Listed by Underwriters' Laboratories. The ground

conductor has a green jacket and is attached to the tool

housing at one end and to the ground prong in the

attachment plug at the other end.

This plug requires a mating 3-conductor grounded type

outlet as shown.

If the outlet you are planning to use for this power tool

is of the two prong type DO NOT REMOVE OR

ALTER THE GROUNDING PRONG IN ANY

MANNER. Use an adapter as shown and always connect

the grounding lug to known ground.

It it recommended that you have a qualified electrician

replace the "nNO prong outlet with a properly grounded

THREE prong outlet.

An adapter as shown below is available for connecting

plugs to 2-prong receptacles. The green grounding lug

extending from the adapter must be connected to a

permanent ground such as to a properly grounded

outlet box.

GROUNDING LUG

3-PRONG f

PLUG

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacle.

.__ ..__- CONNECTEDtOA

mAKESUREt._s _s

KNOWN GROUND

_P O.O

RECEPTACLE

MOTOR SAFETY PROTECTION

NOTE: This motor should be blown out, or "vacuumed",

frequently to prevent sawdust interference with normal

motor ventilation.

1. This tool should be connected to a 120 volt, 15 amp

branch circuit with a 15 amp time delay fuse or circuit

breaker. Failure to use the proper size fuse can result in

damage to the motor.

2. If the motor fails to start, turn the power switch to the

off position immediately. UNPLUG THE TOOL. Check

the saw blade to insure that it turns freely and that its

teeth are not wedged into the table top. After the blade

has been freed, try to start the motor again. If, at this

point, the motor still fails to start, refer to the "Motor

Trouble-Shooting Chart."

3. If the motor should suddenly stall while cutting wood,

the power switch should be turned off, the tool

unpluged and the blade freed from the wood. The

motor may now be restarted and the cut finished.

electrical connections

4.

Frequent opening of fuses or circuit breakers may result

if motor is overloaded, or if the motor circuit is fused

differently from recommendations. Overloading can

occur if you feed to rapidly or if your saw is misaligned

so that the blade heels. Do not use a fuse of greater

capacity without consulting a qualified electrician.

5, Although the motor is designed for operation on the

voltage and frequency specified on motor nameplate,

normal loads will be handled safely on voltages not

more than 10% above or below the nameplate voltage.

Heavy loads, however, require that voltage at motor

terminals equals the voltage specified on nameplate.

6. Most motor troubles may be traced to loose or

incorrect connections, overloading, reduced input

voltage (such as small size wires in the supply circuit) or

to an overly-long supply circuit. Always check the

connections, the load and the supply circuit, whenever

the motor fails to perform satisfactorily. Check wire

sizes and lengths with the table following.

WIRE SIZES

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent

over-heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.) extension cord.

Use only 3 wire extension cords which have 3 prong

grounding type plugs and 3-pole receptacles which accept

the tools plug.

NOTE: For circuits of greater length, the wire size must be

increased proportionately in order to deliver ample voltage

to the saw motor.

Wire Size Required

Length of the

Conductor

Up to 100 feet

100 feet to 200 feet

200 feet to 400 feet

(American Wire Gauge Number)

120 Volt Lines

No. 12

No. 8

No. 6

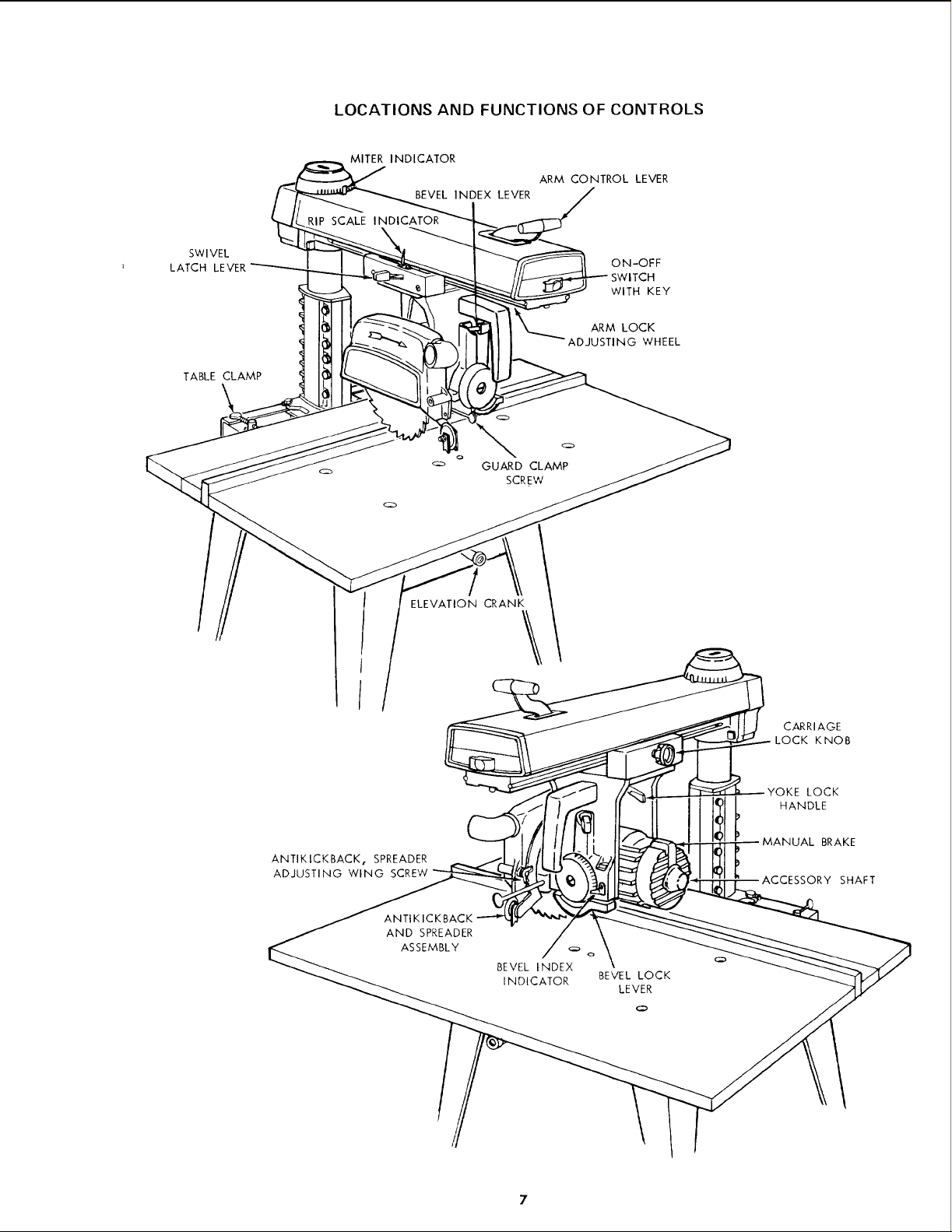

LOCATIONS AND FUNCTIONS OF CONTROLS

MITER INDICATOR

ARM CONTROL LEVER

BEVEL INDEX LEVER

RiP SCALE INDICATOR

SWIVEL

LATCH LEVER

TABLE CLAMP

\

ON-OFF

SWITCH

WITH KEY

ARM LOCK

JSTING WHEEL

GUARD CLAMP

SCREW

ELEVATION CRANK

\

ANTIKICKBACK, SPREADER

ADJUSTING WING SCREW

ANTIKICKBACK

AND SPREADER

ASSEMBLY

BEVEL INDEX

INDICATOR

CARRIAGE

LOCK KNOB

'OKE LOCK

HANDLE

MANUAL BRAKE

SHAFT

BEVEL LOCK

LEVER

7

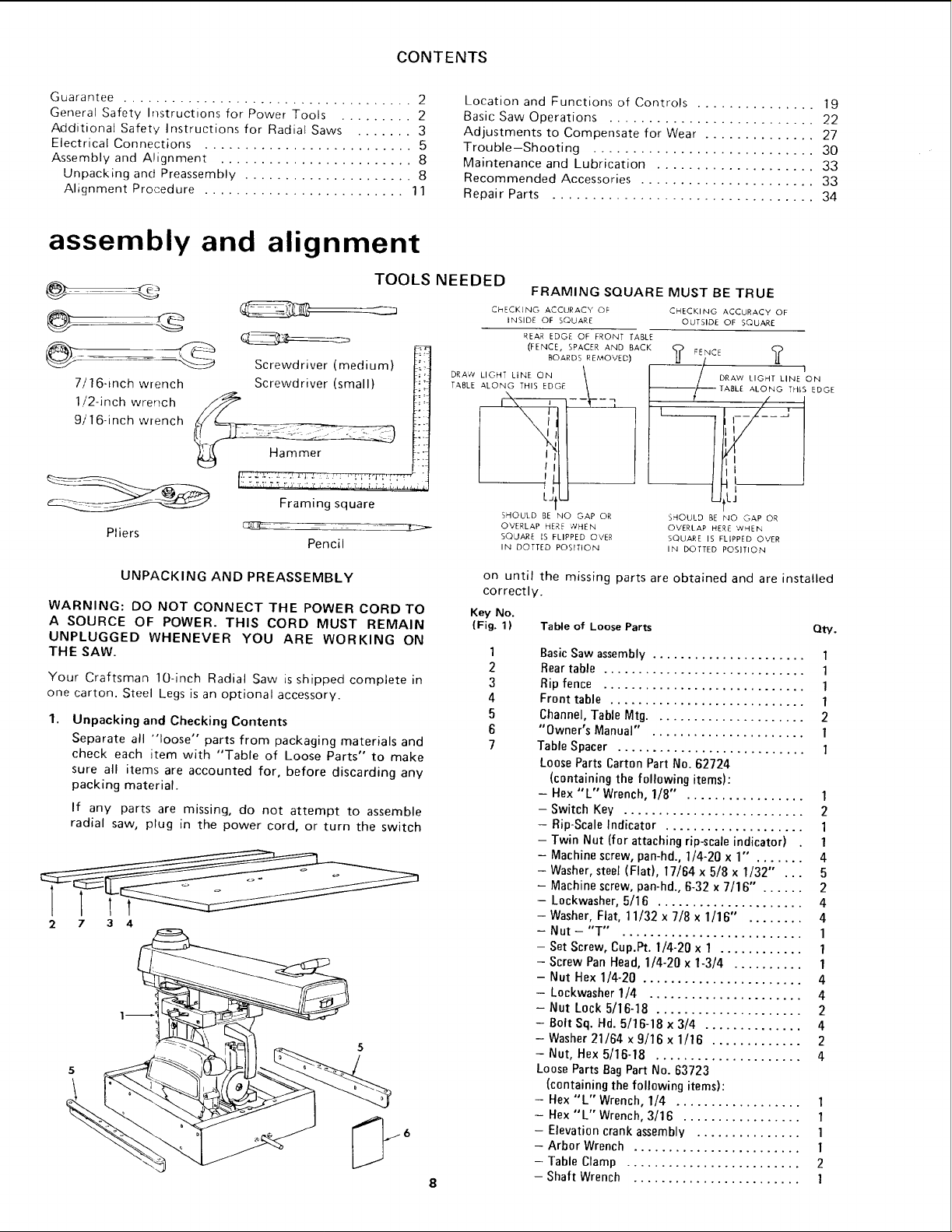

CONTENTS

Guarantee .................................... 2

General Safety Instructions for Power Tools ......... 2

AdditionaJ Safety Instructions for Radial Saws ....... 3

Electrical Connections .......................... 5

Assembly and Alignment ........................ 8

Unpacking and Preassembly ..................... 8

Alignment Procedure ......................... 1 1

assembly and alignment

TOOLS NEEDED

Screwdriver (medium)

7/16-inch wrench

gi 16-inch wrench

1!2-inch wrench __

Pliers

Screwdriver (small)

!.r: RZ'_'_ .L ,/,_ J'J L : _. _' _'r'l'_'l'_'_

I]: TT,_' T T r,.i' "_'," 't ,t,52, ," ? 7.L _ ;, t h J, hJ

Framing square

Pencil

Location and Functions of Controls ............... 19

Basic Saw Operations .......................... 22

Adjustments to Compensate for Wear .............. 27

Trouble-Shooting ............................ 30

Maintenance and Lubrication .................... 33

Recommended Accessories ...................... 33

Repair Parts ................................. 34

FRAMING SQUARE MUST BE TRUE

CHECKING ACCURACY OF

INSIDE OF SQUARE

DR A¢,'

TABLE

REAR EDGE OF FRONT TABLE

(FENCE, SPACER AND BACK

BOARDS REMOVED)

oE\

CHECKING ACCURACY OF

OUTSIDE OF SQUARE

) FENCE (_

/ DRAW LIGHT LINE ON

--/_---- TABL_ ALO_° THI? EDGE

UttJ

SHOULD BE NO GAP OR

OVERLAP HERE ,VHEN

SQUARE IS FLIPPED OVER

IN DOTTED POSITION

SHOULDBENOGAPOR

OVERLAP HERC WHEN

SQUARE IS FLIPPED OVER

IN DOTTED POSITION

I

,

UNPACKING AND PREASSEMBLY

WARNING: DO NOT CONNECT THE POWER CORD TO

A SOURCE OF POWER. THIS CORD MUST REMAIN

UNPLUGGED WHENEVER YOU ARE WORKING ON

THE SAW.

Your Craftsman 10-inch Radial Saw is shipped complete in

one carton. Steel Legs is an optional accessory.

1.

Unpacking and Checking Contents

Separate all "loose" parts from packaging materials and

check each item with "Table of Loose Parts" to make

sure all items are accounted for, before discarding any

packing material.

If any parts are missing, do not attempt to assemble

radial saw, plug in the power cord, or turn the switch

2 7 3 4

on until the missing parts are obtained and are installed

correctly.

Key No.

(Fig. 1) Table of Loose Parts Qty.

1

2

3

4

5

6

7

Basic Saw assembly ...................... 1

Rear table ............................. 1

Rip fence ............................. 1

Front table ............................ 1

Channel, Table Mtg ...................... 2

"Owner's Manual" . ..................... 1

Table Spacer ........................... 1

Loose Parts Carton Part No. 62724

(containing the following items):

- Hex "L" Wrench, 1/8" . ................ 1

- Switch Key .......................... 2

- Rip-Scale Indicator .................... 1

- Twin Nut (for attaching rip-scale indicator) 1

- Machine screw, pan-hd., 1/4-20 x 1" . ...... 4

- Washer, steel (Flat), 17/64 x 5/8 x 1/32" ... 5

- Machine screw, pan-hd., 6-32 x 7/16" . ..... 2

- Lockwasher, 5/16 ..................... 4

- Washer, Flat, 11/32 x 7/8 x 1/16" . ....... 4

-Nut-'T" . ......................... 1

- Set Screw, Cup.Pt. 1/4-20 x 1 ............ 1

- Screw Pan Head, 1/4-20 x 1-3/4 .......... 1

- Nut Hex 1/4-20 ....................... 4

- Lockwasher 1/4 ...................... 4

- Nut Lock 5/16-18 ..................... 2

- Bolt Sq. Hd. 5/16-18 x 3/4 .............. 4

- Washer 21/64 x 9/16 x 1/16 ............. 2

- Nut, Hex 5116-18 ..................... 4

Loose Parts Bag Part No. 63723

(containing the following items):

- Hex "L" Wrench, 1/4 .................. 1

- Hex "L" Wrench, 3/16 ................. 1

- Elevation crank assembly ............... 1

- Arbor Wrench ........................ 1

- Table Clamp ......................... 2

- Shaft Wrench ........................ 1

REMOVE SKIDS FROM BASE

MOUNT SAW TO CRAFTSMAN BASE,

STEEL LEGS, OR FLAT BENCH

Make sure Elevation Crank has proper clearance to rotate.

The saw must be bolted down. Position your saw to slope

slightly rearward, so when the carriage is installed it will not

rol! forward due to gravity.

ATTACH ELEVATION CRANK.

Be sure setscrew is tightened on flat of shaft.

/

ELEVATE ARM TO ITS MAX. HEIGHT.

Remove shipping block and discard.

NG BLOCK

EL[VATION CRANK

(TURN CLOCKWISE)

9

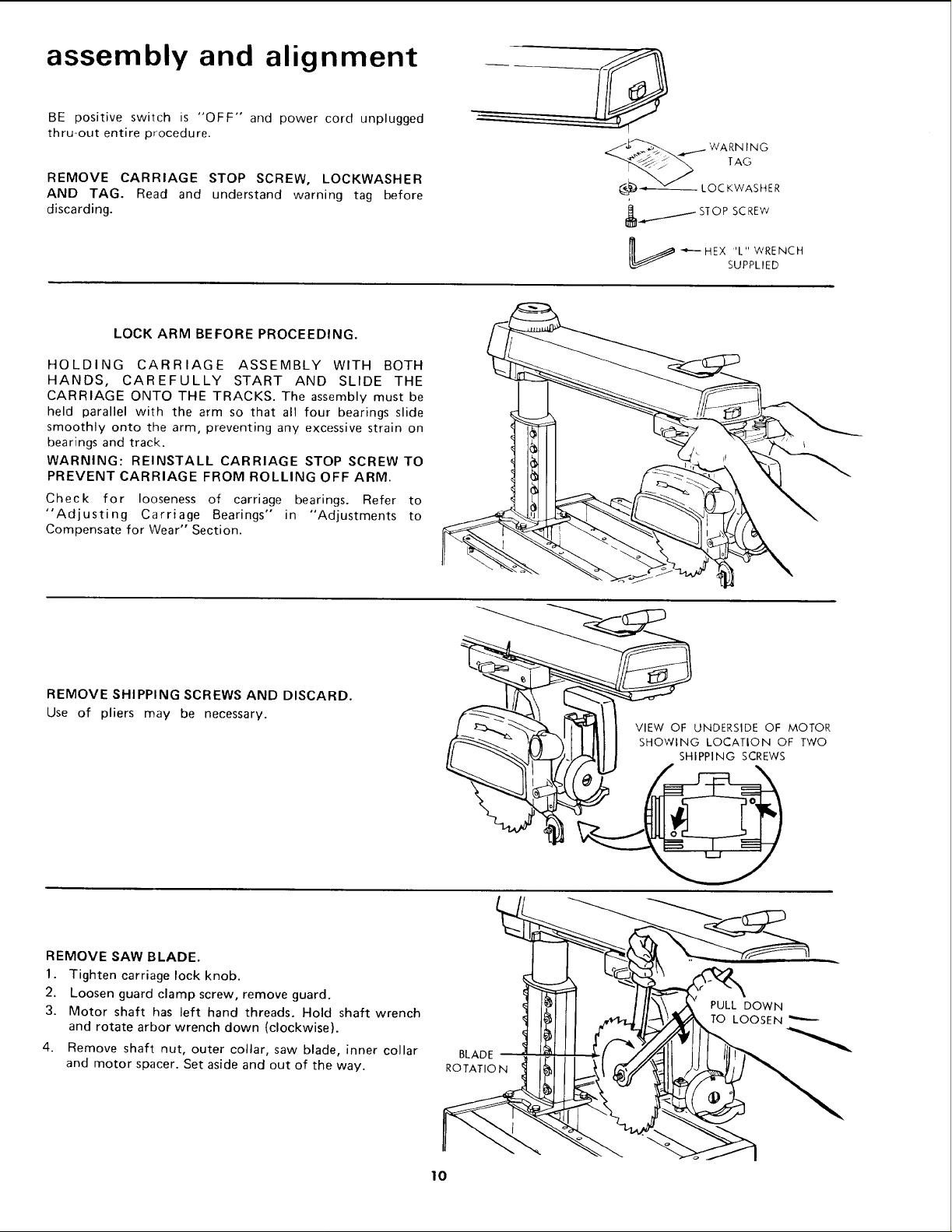

assembly and alignment

BE positive switch is "OFF" and power cord unplugged

thru-out entire procedure.

REMOVE CARRIAGE STOP SCREW, LOCKWASHER

AND TAG. Read and understand warning tag before

discarding.

LOCK ARM BEFORE PROCEEDING.

HOLDING CARRIAGE ASSEMBLY WITH BOTH

HANDS, CAREFULLY START AND SLIDE THE

CARRIAGE ONTO THE TRACKS. The assembly must be

held parallel with the arm so that all four bearings slide

smoothly onto the arm, preventing any excessive strain on

bearings and track.

WARNING: REINSTALL CARRIAGE STOP SCREW TO

PREVENT CARRIAGE FROM ROLLING OFF ARM.

Check for looseness of carriage bearings. Refer to

"Adjusting Carriage Bearings" in "Adjustments to

Compensate for Wear" Section.

WARN INS

TAG

REMOVE SHIPPING SCREWS AND DISCARD.

Use of pliers may be necessary.

REMOVE SAW BLADE.

1. Tighten carriage lock knob.

2. Loosen guard clamp screw, remove guard.

3. Motor shaft has left hand threads. Hold shaft wrench

and rotate arbor wrench down (clockwise).

4. Remove shaft nut, outer collar, saw blade, inner collar

and motor spacer. Set aside and out of the way.

__ __ UNDERSIDE OF MOTOR

_- Tll "_11III I SHOWINGLOCATIONOFTWO

PULL DOWN

TO LOOSEN

BLADE

ROTATIO N

lo

ALIGNMENT PROCEDURE

IMPORTANT:

IN ORDER TO OBTAIN MAXIMUM CUTTING

ACCURACY, THE FOLLOWING SIX STEPS

MUST BE CAREFULLY FOLLOWED.

BECOME THOROUGHLY FAMILIAR WITH

THESE STEPS SO THAT YOU CAN ALWAYS

MAINTAIN YOUR SAW IN PROPER

ALIGNMENT. THE ACCURACY OF EACH

ADJUSTMENT IS ALWAYS DEPENDENT

UPON THE ACCURACY OF THE PRECEDING

ADJUSTMENT.

Afte_ following the 6 step assembly and alignment

procedure and the Basic Saw operation section refer to

Trouble Shooting section if any difficulty is experienced

when performing any sawing operation.

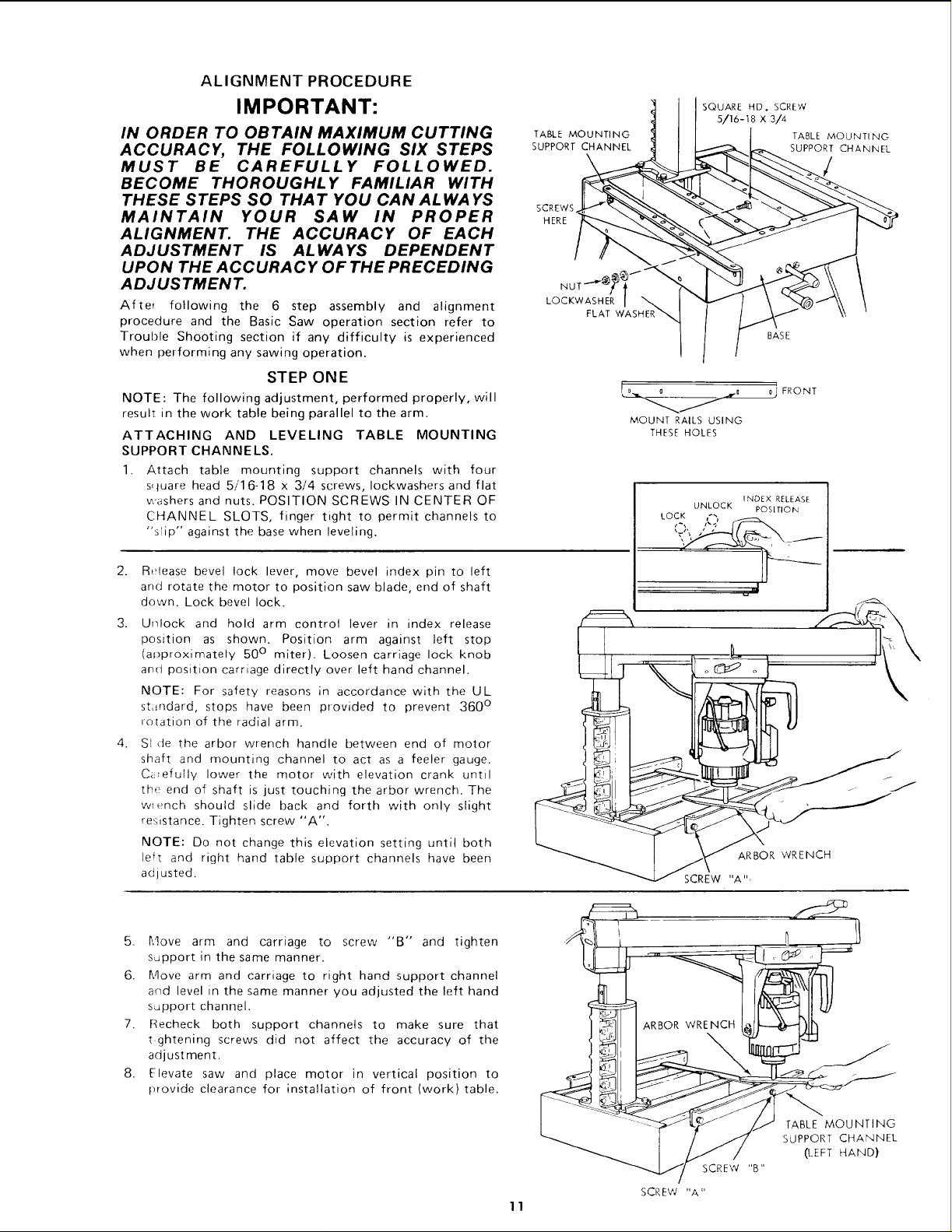

STEP ONE

NOTE: The following adjustment, performed properly, will

result in the work table being parallel to the arm.

ATTACHING AND LEVELING TABLE MOUNTING

SUPPORT CHANNELS.

1. Attach table mounting support channels with four

s_tuare head 5/1 6-18 x 3/4 screws, Iockwashers and flat

washers and nuts. POSITION SCREWS IN CENTER OF

CHANNEL SLOTS, finger tight to permit channels to

"stip" against the base when leveling.

TABLE MOUNTING

SUPPORT CHANNEL

\

SCREWS

HERE

LOCKWASHER /

FLAT WASHER

SQUARE HDo SCREW

s/16-18 x 314

MOUNT RAILS USING

THESE HOLES

UNLOCK POSITION'

LOCK _'_

TABLE MOUNT! NG

SUPPORTCHANNEL

BASE

_ FRONT

INDEX RELEASE

2.

Release bevel lock lever, move bevel index pin to left

and rotate the motor to position saw blade, end of shaft

down. Lock bevel lock.

3.

Unlock and hold arm control lever in index release

position as shown. Position arm against left stop

(approximately 50 ° miter). Loosen carriage lock knob

and position carriage directly over left hand channel.

NOTE: For safety reasons in accordance with the UL

standard, stops have been provided to prevent 360 °

rotation of the radial arm.

4.

SI de the arbor wrench handle between end of motor

shaft and mounting channel to act as a feeler gauge.

C_efully lower the motor with elevation crank until

the end of shaft is just touching the arbor wrench. The

wrench should slide back and forth with only slight

resistance. Tighten screw "A".

NOTE: Do not change this elevation setting until both

left and right hand table support channels have been

adjusted.

5. Move arm and carriage to screw "'B" and tighten

support in the same manner.

6. Move arm and carriage to right hand support channel

arid level in the same manner you adjusted the left hand

support channel.

7. Recheck both support channels to make sure that

t ghtening screws did not affect the accuracy of the

adjustment.

8. Elevate saw and place motor in vertical position to

t_rovide clearance for installation of front (work) table.

ARBOR WRENCH

SCREW "A "_

I _ _ //_ TABLE MO_UNTING

I ' _ SUPPORT CHANNEL

SCREW "B"

11

SCREW "A"

assembly and alignment

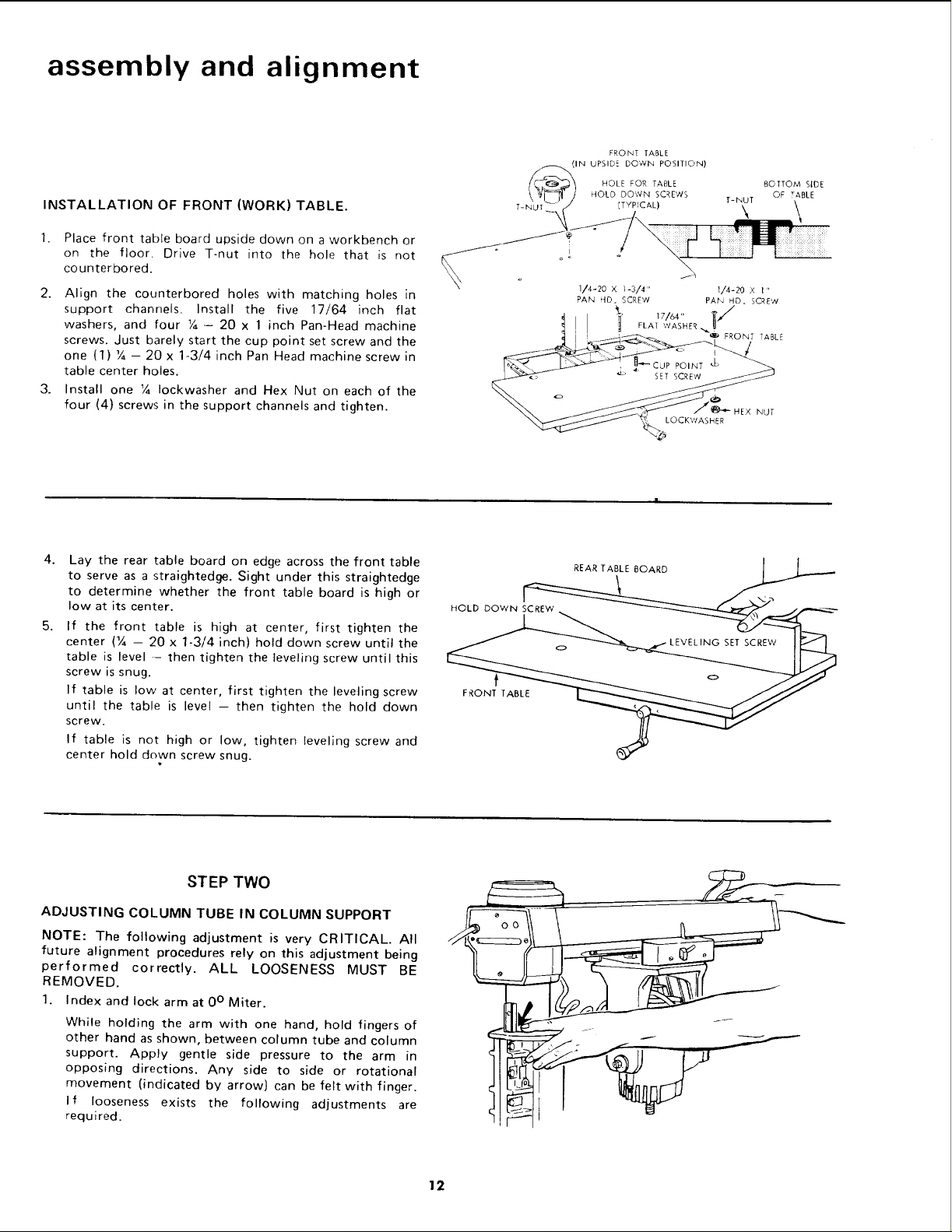

INSTALLATION OF FRONT (WORK) TABLE.

FRONT fABLE

HOLE FOR TABLE BOTTOM SIDE

IN UPSIDE DOWN POSITION)

T-NUT F (TYPICAL) \ \

HOLD DO'NN SCREWS T-NUT OF TABLE

1. Place front table board upside down on a workbench or

on the floor. Drive T-nut into the hole that is not

counterbored.

2. Align the counterbored holes with matching holes in

support channels. Install the five 17/64 inch flat

washers, and four Y_- 20 x 1 inch Pan-Head machine

screws. Just barely start the cup point set screw and the

one (1) ¼ - 20 x 1-3/4 inch Pan Head machine screw in

table center holes.

3. Install one 1/4 Iockwasher and Hex Nut on each of the

four (4) screws in the support channels and tighten.

4.

Lay the rear table board on edge across the front table

to serve as a straightedge. Sight under this straightedge

to determine whether the front table board is high or

low at its center.

5.

If the front table is high at center, first tighten the

center (¼ - 20 x 1-3/4 inch) hold down screw until the

table is level - then tighten the leveling screw until this

screw is snug.

If table is low at center, first tighten the leveling screw

until the table is level - then tighten the hold down

screw.

If table is not high or low, tighten leveling screw and

center hold down screw snug.

.i- _ o L o ;it / t f

HOLD DOWN _ _,,_

FRONT TABLE

/

1/4-20 × _-3/4" 1/4-20 x I"

PAN HD. SCREW PAN HD. SCREW

, FLAT WASHER .._ .

CJP POINT _

LOCKWASHER

REAR TAiLE BOARD

FRONT TABLE

HEX NUT

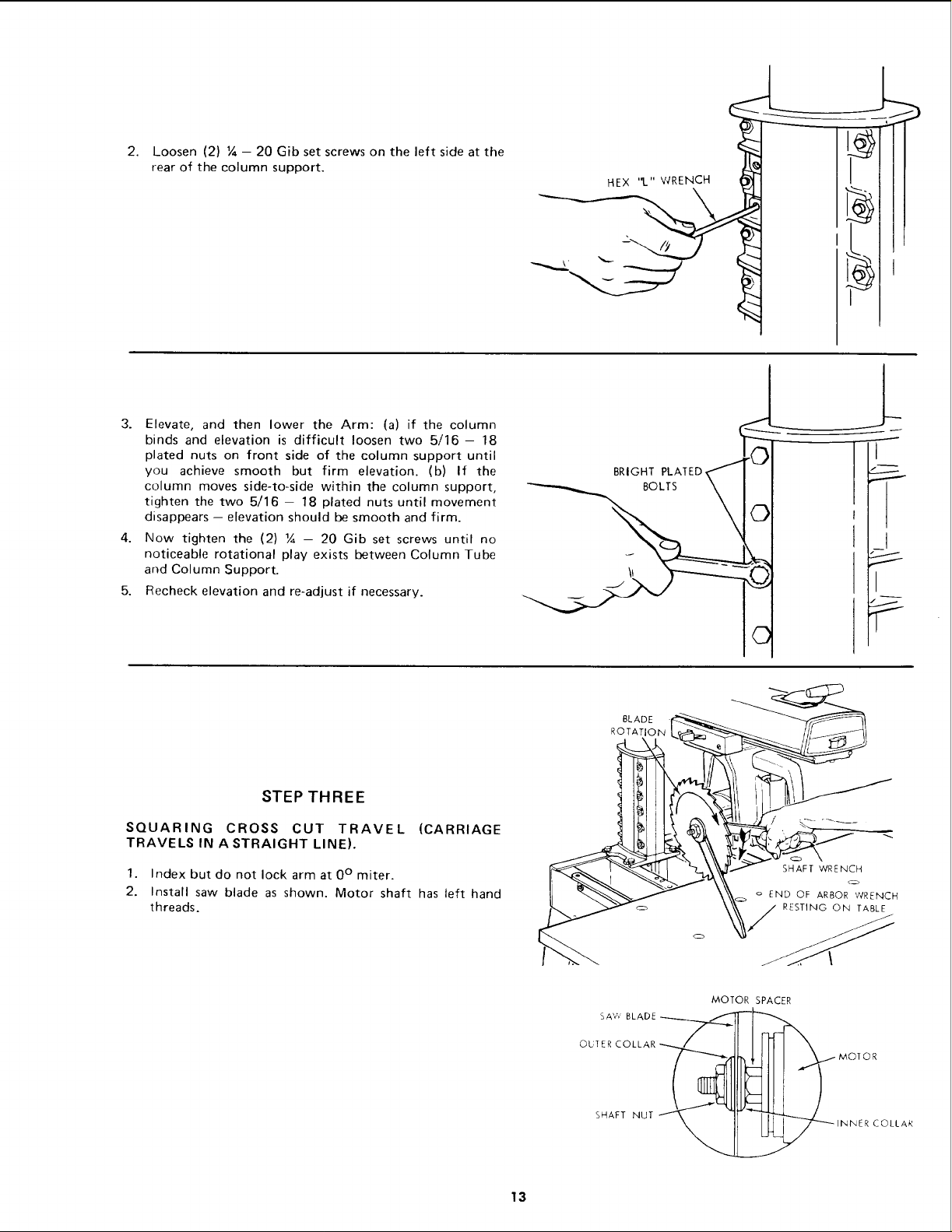

STEP TWO

ADJUSTING COLUMN TUBE IN COLUMN SUPPORT

NOTE: The following adjustment is very CRITICAL. All

future alignment procedures rely on this adjustment being

performed correctly. ALL LOOSENESS MUST BE

REMOVED.

1. Index and lock arm at 0 ° Miter.

While holding the arm with one hand, hold fingers of

other hand as shown, between column tube and column

support. Apply gentle side pressure to the arm in

opposing directions. Any side to side or rotational

movement (indicated by arrow) can be felt with finger.

If looseness exists the following adjustments are

required.

12

2.

Loosen (2) ¼ - 20 Gib set screws on the left side at the

rear of the column support.

3. Elevate, and then lower the Arm: (a) if the column

binds and elevation is difficult loosen two 5/16- 18

plated nuts on front side of the column support until

you achieve smooth but firm elevation. (b) If the

column moves side-to-side within the column support,

tighten the two 5/16 - 18 plated nuts until movement

disappears -- elevation should be smooth and firm.

4. Now tighten the (2) ¼ -- 20 Gib set screws until no

noticeable rotational play exists between Column Tube

and Column Support.

5. Recheck elevation and re-adjust if necessary.

->

OR,O.TPLATED "

\ ©

STEP THREE

SQUARING CROSS CUT TRAVEL (CARRIAGE

TRAVELS IN A STRAIGHT LINE).

1. Index but do not lock arm at 0° miter.

2. Install saw blade as shown. Motor shaft has left hand

threads.

13

SAW BLADE

OUTER COLLAR

SHAFT NUT

_:::_ o END OF ARBOR WRENCH

_/ RESTING ON TABLE

MOTOR SPACER

INNER COLLAR

MOIOR

assembly and alignment

3. Lower arm until saw blade just clears the front table.

Lock the yoke clamp handle and bevel lock lever.

4. Place a framing square on the table as shown and

position the blade and square until the leg of the square

just contacts a tooth of the blade. Mark this tooth.

5. When the carriage is moved back and forth on the arm,

the marked tooth should just touch the square at all

points. If marked tooth moves into square or away

from square the following adjustments are required:

a. Loosen (3) 3/8 - 16 set screws in arm latch at rear

of arm.

b. Move the arm in proper direction to make marked

tooth follow edge of square when the saw blade is

moved along arm in a "cross cut" manner.

c. Lock arm latch.

d. RETIGHTEN (3) setscrews in arm latch as tight as

possible and recheck "cross cut" travel.

BEVEL LOCK

LEVER

TOOTH

HEX "L" WRENCH

(SUPPLIED)

NOTE: This squaring of the cross cut travel will

simultaneously set BOTH of the 45 ° miter index

positions.

e.

Set miter indicator on 0 ° position as shown.

6,

Position the rip (guide) fence, spacer board and rear

table board behind the front table board as shown.

7.

Install the two table clamps in the holes provided for

them at the rear of the saw base, and tighten them

securely.

NOTE: The life of your saw table will be lengthened

considerably if you will cover the front table with a

fitted piece of 1/4 inch plywood. This should be tacked

in place for easy replacement. Use of such a cover will

allow you to do all cutting into the cover, rather than

your table top.

WASHER

REAR TAB

CLAMP

RIP FENCE

SPACER

FRONT TABLE

14

Loading...

Loading...