Craftsman 113196221, 113196421, 113196321 Owner’s Manual

S Save This Manual'_

For Future Reference

owner's

manual

MODEL NO.

113.196221

113.196321

SAW WITHLEGS

or

113.196421

CONTRACTOR'S SAW

Serial

Number.

Model and serial numbers

may be found at the front

of the base.

You should record both

model and serial number in

a safe place for future use.

_'_E_A/F_S/ I:RI1FT$MRN

10-1NCH RADIAL SAW

FORYOUR

SAFETY:

• assembly

READ ALL

• operating

INSTRUCTIONS

CAREFULLY

• repair parts

\

Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Part No. SP5667 Printed in U.S.A.

Table of Contents

Section Title ................................................................................ Page

Safety ........................................................................................................................ 3

Introduction ............................................................................................................ 12

Assembly ................................................................................................................ 12

Adjustments ............................................................................................................ 19

Alignment ............................................................................................................... 28

Controls .................................................................................................................. 37

Electrical Connections ........................................................................................... 42

Crosscutting ............................................................................................................ 45

Ripping ................................................................................................................... 49

Cutting Aides ......................................................................................................... 58

Accessories ............................................................................................................. 61

Maintenance ........................................................................................................... 63

Troubleshooting ..................................................................................................... 65

Repair Parts ............................................................................................................ 70

FULL ONE YEAR WARRANTY ON CRAFTSMAN STATIONARY TOOL

If, this stationary tool fails due to a defect in material or workmanship within one

year from the date of purchase, CONTACT THE NEAREST SEARS SERVICE

CENTER IN THE UNITED STATES and Sears will repair it, free of charge. This

warranty applies only while this product is in the United States.

If this Radial Saw is used for commercial or rental purposes, this warranty will

apply for ninety days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

SEARS, ROEBUCK AND CO., DEPT 817WA, Hoffman Estates, IL 60179 U.S.A.

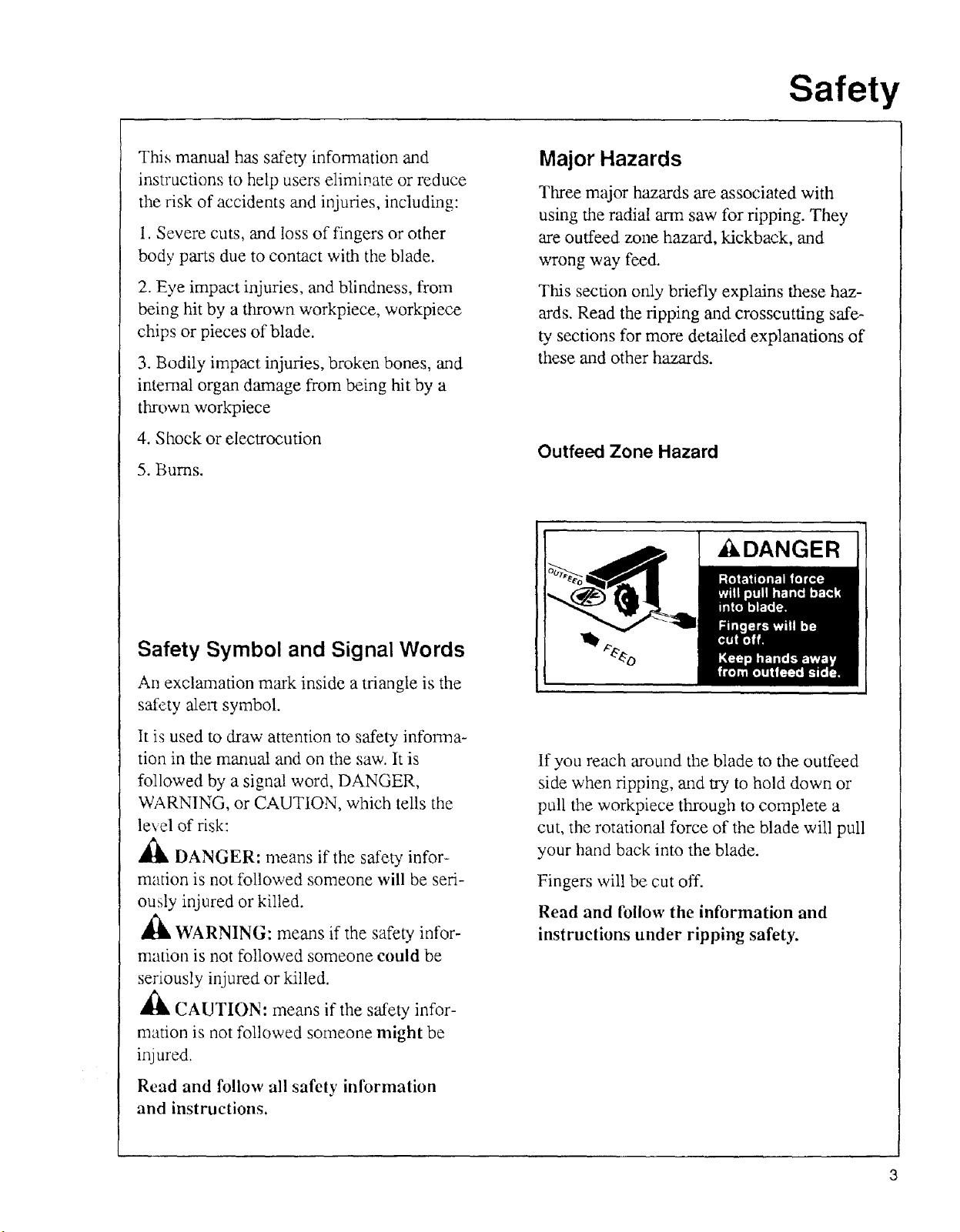

Safety

This manual has safety information and

instructions to help users eliminate or reduce

the risk of accidents and injuries, including:

i. Severe cuts, and loss of fingers or other

body parts due to contact with the blade.

2. Eye impact injuries, and blindness, from

being hit by a thrown workpiece, workpiece

chips or pieces of blade.

3. Bodily impact injuries, broken bones, and

internal organ damage from being hit by a

thrown workpiece

4. Shock or electrocution

5. Bums.

M_or Hazards

Three major hazards are associated with

using the radial arm saw for ripping. They

are outfeed zone hazard, kickback, and

wrong way feed.

This section only briefly explains these haz-

ards. Read the ripping and crosscutting safe-

ty sections for more detailed explanations of

these and other hazards.

Outfeed Zone Hazard

Ai_kDANGER

Safety Symbol and Signal Words

An exclamation mark inside a triangle is the

safety alert symbol.

It is used to draw' attention to safety info_Tna-

tion in the manual and on the saw. It is

followed by a signal word, DANGER,

WARNING, or CAUTION, which tells the

level of risk:

,_ DANGER: means if the safety infor-

mation is not followed someone will be seri-

ously injured or killed.

A

,_ WARNING: means if the safety infor-

mation is not followed someone could be

seriously injured or killed.

A

,_ CAUTION: means if the safety infor-

mation is not followed someone might be

inj are&

Read and follow all safety information

and instructions.

If you reach around the blade to the outfeed

side when ripping, and try to hold down or

pull the workpiece through to complete a

cut, the rotational force of the blade will pull

your hand back into the blade.

Fingers will be cut off.

Read and follow the information and

instructions under ripping safety.

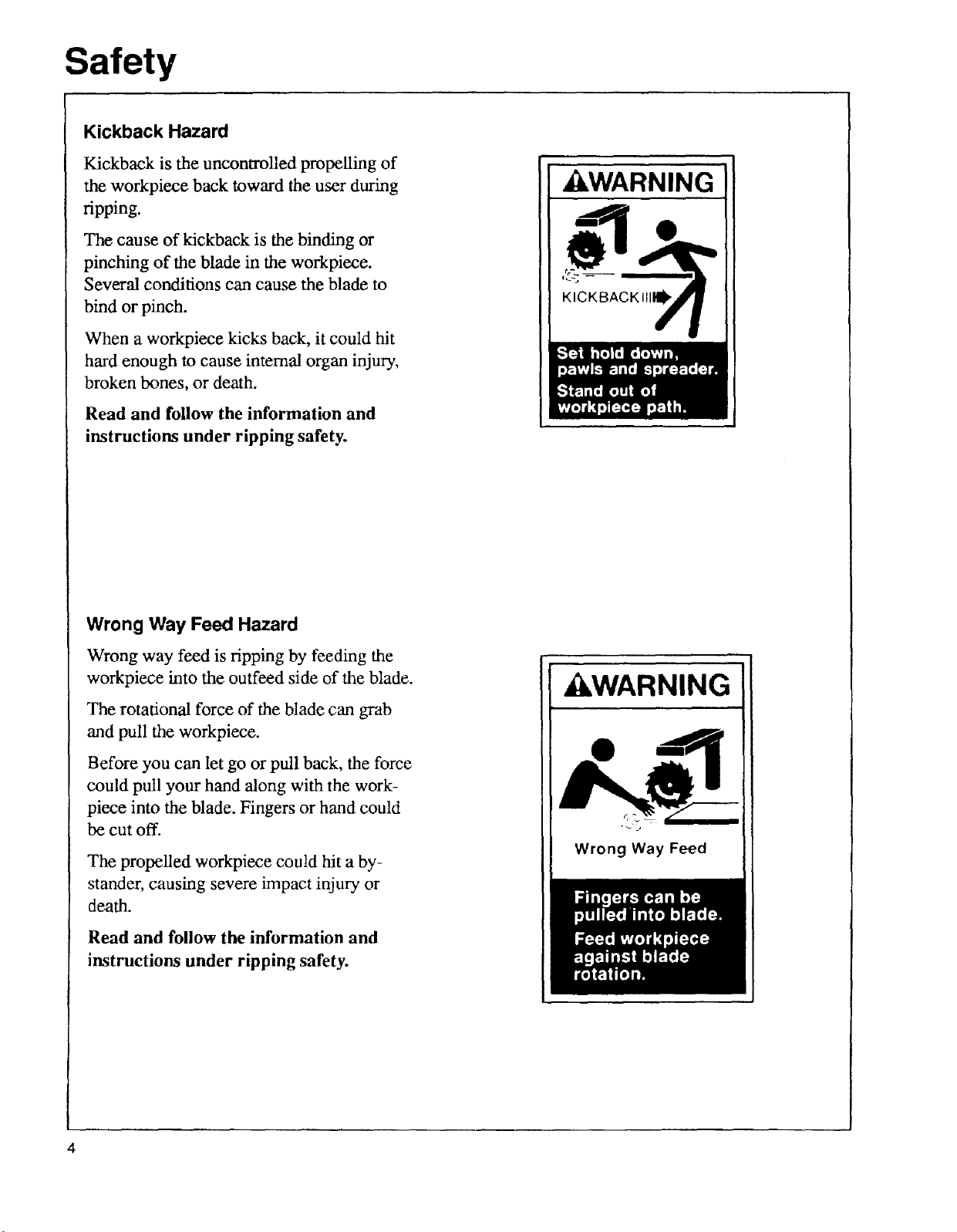

Safety

Kickback Hazard

Kickback is the uncontrolled propelling of

the workpiece back toward the user during

ripping.

The cause of kickback is the binding or

pinching of the blade in the workpiece.

Several conditions can cause the blade to

bind or pinch.

When a workpiece kicks back, it could hit

hard enough to cause internal organ injury,

broken bones, or death.

Read and follow the information and

instructions under ripping safety.

WARNING

KICKBACKIII_

Wrong Way Feed Hazard

Wrong way feed is ripping by feeding the

workpiece into the outfeed side of the blade.

The rotational force of the blade can grab

and pull the workpiece.

Before you can let go or pull back, the force

could pull your hand along with the work-

piece into the blade. Fingers or hand could

be cut off.

The propelled workpiece could hit a by-

stander, causing severe impact injury or

death.

Read and follow the information and

instructions under ripping safety.

WARNING

Wrong Way Feed

4

Guard Function and Features

The guard is a very important safety feature,

designed to reduce the risk of injury associ-

ated with blade contact. Install the guard

correctly. Follow the specific instructions

in the ripping and crosscutting sections to

set and use the guard correctly for each

ty pe of cut.

Guard Features Include:

Safety

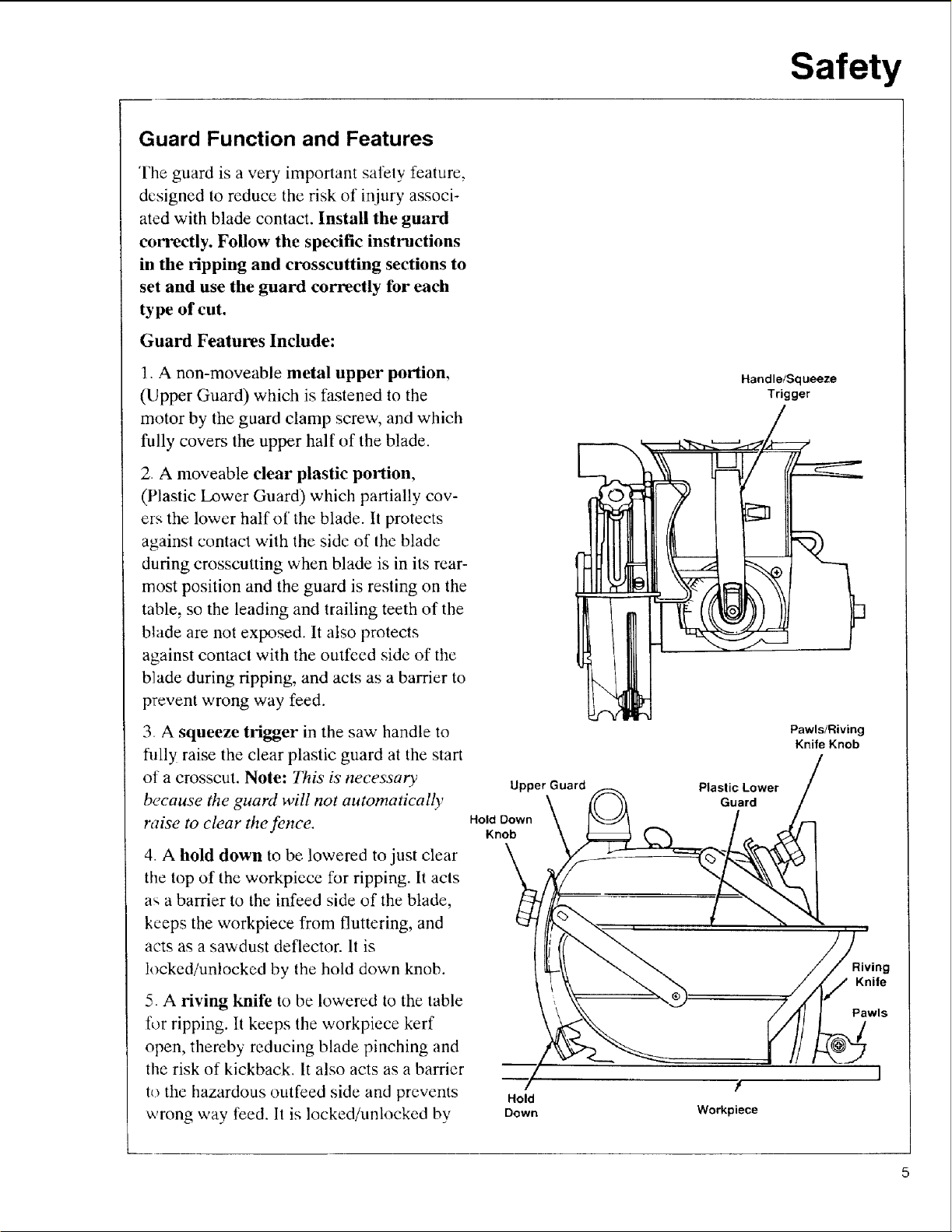

1 A non-moveable metal upper portion,

(Upper Guard) which is fastened to the

motor by the guard clamp screw, and which

fully covers the upper half of the blade.

2. A moveable clear plastic portion,

(Plastic Lower Guard) which partially cov-

ers the lower half of the blade. It protects

against contact with the side of the blade

during crosscutting when blade is in its rear-

most position and the guard is resting on the

table, so the leading and trailing teeth of the

blade are not exposed. It also protects

against contact with the outfced side of the

blade during ripping, and acts as a barrier to

prevent wrong way feed.

3 A squeeze trigger in the saw handle to

rally raise the clear plastic guard at the start

of a crosscut. Note: 1"his' is necessary

because the guard will not automatically

raise to clear the fence.

4. A hold down to be lowered to just clear

the top of the workpiece for ripping. It acts

a_ a barrier to the infeed side of the blade,

keeps the workpiece from fluttering, and

acts as a sawdust deflector. It is

locked/unlocked by the hold down knob.

5 A riving knife to be lowered to the table

for ripping. It keeps the workpiece kerf

open, thereby reducing blade pinching and

the risk of kickback. It also acts as a barrier

to the hazardous outfeed side and prevents

wrong way feed. It is locked/unlocked by

Upper Guard

Hold Down

Knob

Hold

Down

Handle!Squeeze

Trigger

Pawls/Riving

Knife Knob

Plastic Lower

Guard

Riving

Knife

Pawls

?

Workpiece

Safety

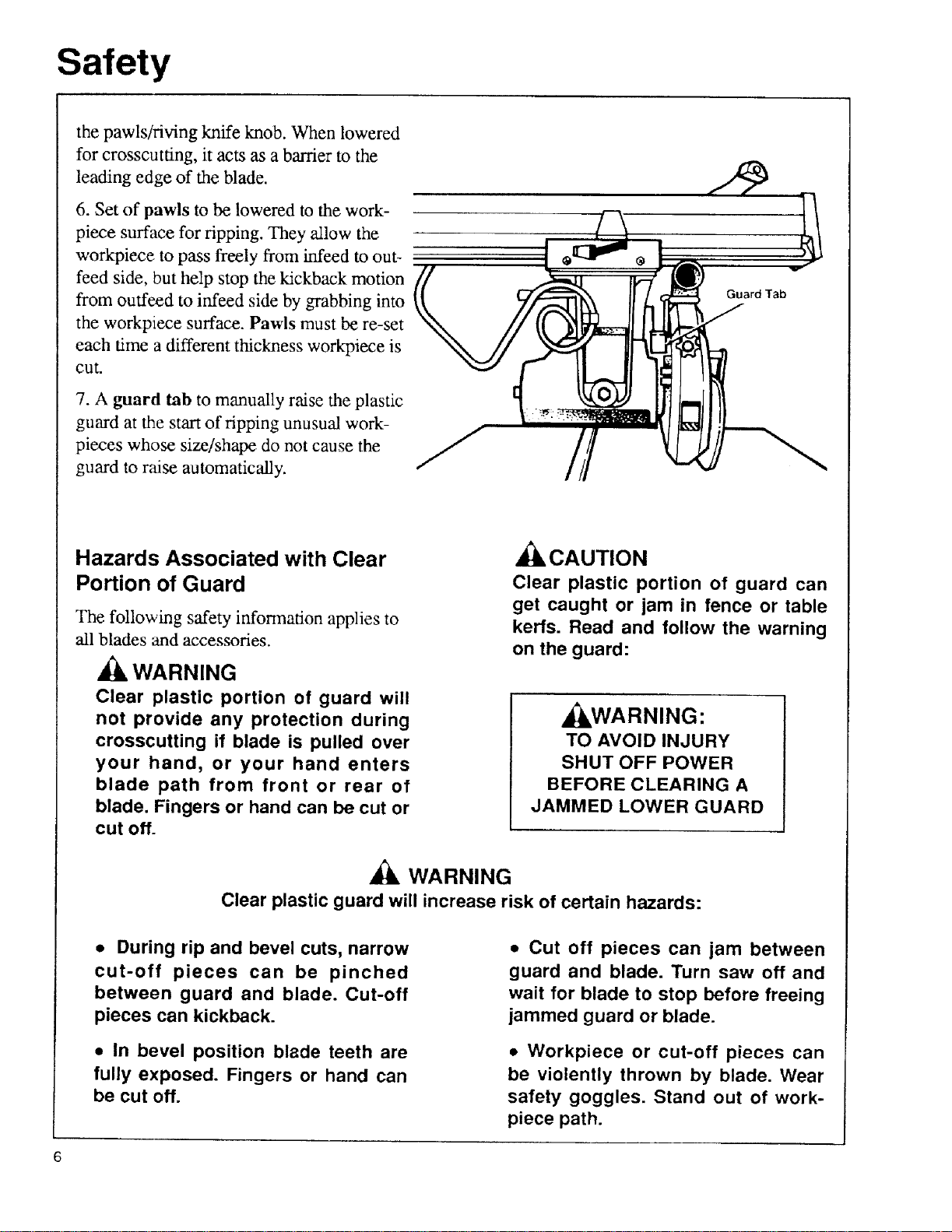

the pawls/riving knife knob. When lowered

for crosscutting, it acts as a barrier to the

leading edge of the blade.

6. Set of pawls to be lowered to the work-

piece surface for ripping. They allow the

workpiece to pass freely from infeed to out-

feed side, but help stop the kickback motion

from ouffeed to infeed side by grabbing into

the workpiece surface. Pawls must be re-set

each time a different thickness workpiece is

cut.

7. A guard tab to manually raise the plastic

guard at the start of ripping unusual work-

pieces whose size/shape do not cause the

guard to raise automatically.

Guard Tab

Hazards Associated with Clear

Portion of Guard

The following safety information applies to

all blades and accessories.

WARNING

Clear plastic portion of guard will

not provide any protection during

crosscutting if blade is pulled over

your hand, or your hand enters

blade path from front or rear of

blade. Fingers or hand can be cut or

cut off.

Clear plastic guard will increase risk of certain hazards:

• During rip and bevel cuts, narrow

cut-off pieces can be pinched

between guard and blade. Cut-off

pieces can kickback.

_CAUTION

Clear plastic portion of guard can

get caught or jam in fence or table

kerfs. Read and follow the warning

on the guard:

,_WARNING:

TO AVOID INJURY

SHUT OFF POWER

BEFORE CLEARING A

JAMMED LOWER GUARD

WARNING

• Cut off pieces can jam between

guard and blade. Turn saw off and

wait for blade to stop before freeing

jammed guard or blade.

• In bevel position blade teeth are

fully exposed. Fingers or hand can

be cut off.

• Workpiece or cut-off pieces can

be violently thrown by blade. Wear

safety goggles. Stand out of work-

piece path.

Safety Instructions

Read and follow all safety instructions.

Personal Safety Instructions

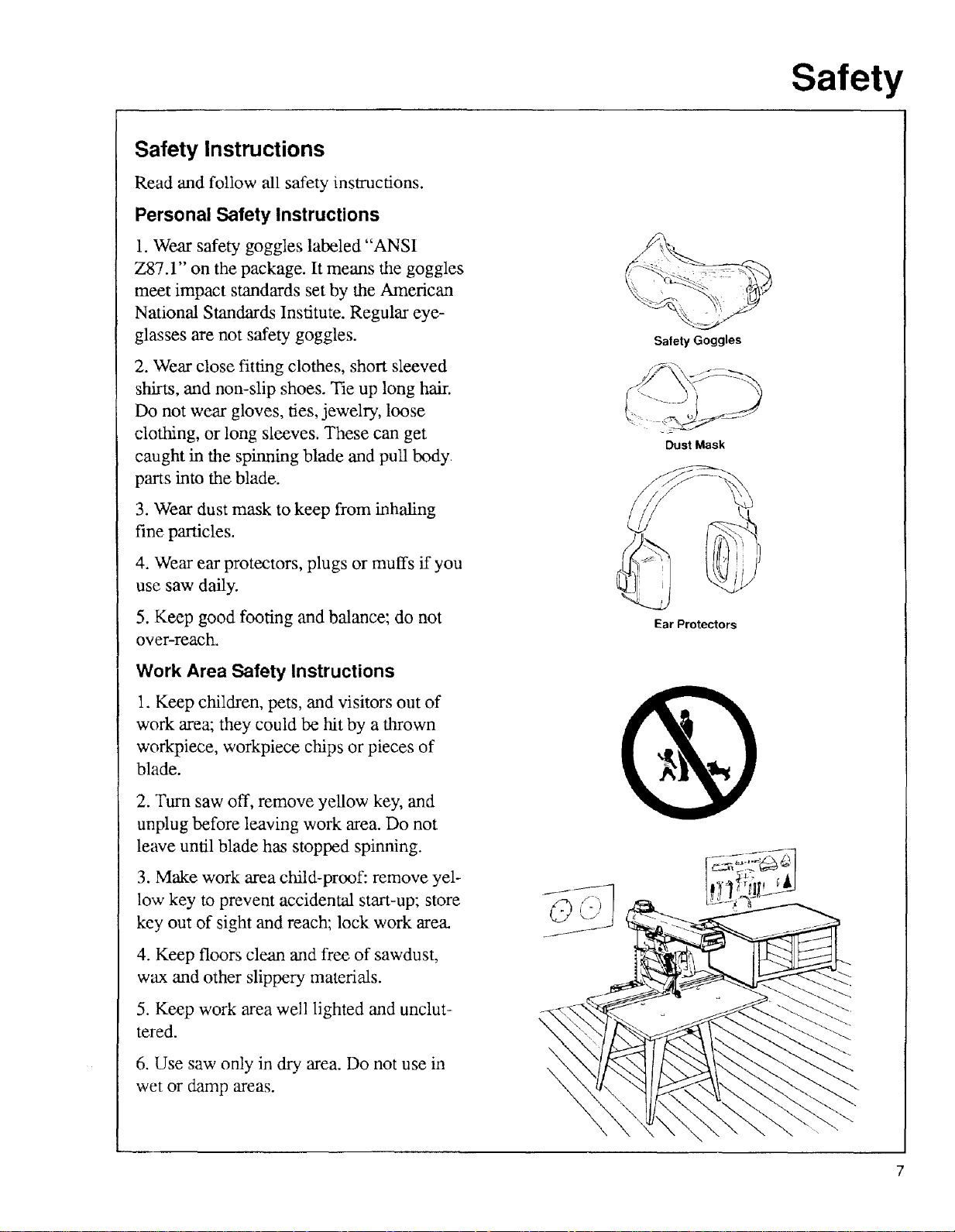

1. Wear safety goggles labeled "ANSI

Z87.1" on the package. It means the goggles

meet impact standards set by the American

National Standards Institute. Regular eye-

glasses are not safety goggles.

2. Wear close fitting clothes, short sleeved

shirts, and non-slip shoes. Tie up long hair.

Do not wear gloves, ties, jewelry, loose

clothing, or long sleeves. These can get

caught in the spinning blade mad pull body

parts into the blade.

3. Wear dust mask to keep from inhaling

fine particles.

Safety

Safety Goggles

Dust Mask

4. Wear ear protectors, plugs or muffs if you

use saw daily.

5. Keep good footing and balance; do not

over-reach.

Work Area Safety Instructions

1. Keep children, pets, and visitors out of

work area; they could be hit by a thrown

workpiece, workpiece chips or pieces of

blade.

2. Turn saw off, remove yellow key, and

unplug before leaving work area. Do not

leave until blade has stopped spinning.

3. Make work area child-proof: remove yel-

low key to prevent accidental start-up; store

key out of sight and reach; lock work area.

4. Keep floors clean and free of sawdust,

wax and other slippery materials.

5. Keep work area well lighted and unclut-

tered.

6. Use saw only in dry area. Do not use in

wet or danap areas.

Ear Protectors

\

\

\

Safety

Saw Safety Instructions

1. Use guard, pawls and riving knife accord-

ing to instructions. Keep them in working

order.

2. Routinely check saw for broken or dam-

aged parts. Repair or replace damaged parts

before using saw. Check new or repaired

parts for alignment, binding, and correct

installation.

3. Unplug saw before doing maintenance,

making adjustments, correcting alignment,

or changing blades.

4. Do not force saw. Use saw, blades and

accessories only as intended.

5. Have yellow key out and saw switched off

before plugging in power cord.

6. Before turning on saw, clear table of all

objects except workpiece to be cut and nec-

essary fixtures, clamps, or feather-boards.

7. If blade jams, turn saw off immediately,

remove yellow key, the free blade. Do not

try to free blade with saw on.

8. Turn saw off if it vibrates too much or

makes an odd sound. Correct any problem

before restarting saw.

9. Do not layout, assemble, or setup work

with saw on, or while blade is spinning.

10. Keep saw table clean.

11. Store items away from saw. Do not

climb on saw or stand on saw table to reach

items because saw can tip over.

Workpiece Safety Instructions

1. Cut only wood, woodlike or plastic mate-

fins. Do not cut metal.

2. Cut only one workpiece at a time.

Stacking or placing workpieces edge to edge

can cause user to lose control of workpiece.

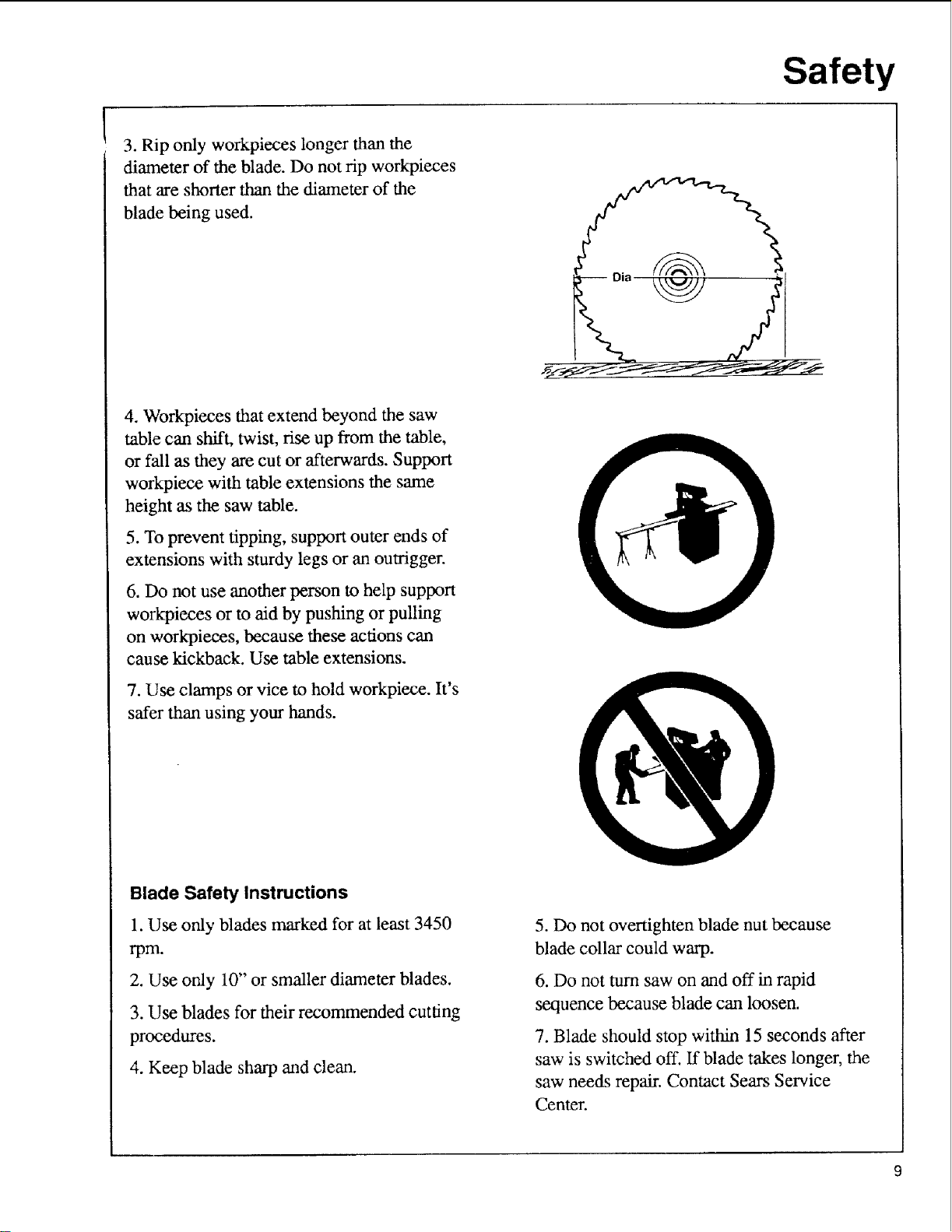

3. Rip only workpieces longer than the

diameter of the blade. Do not rip workpieces

that are shorter than the diameter of the

blade being used.

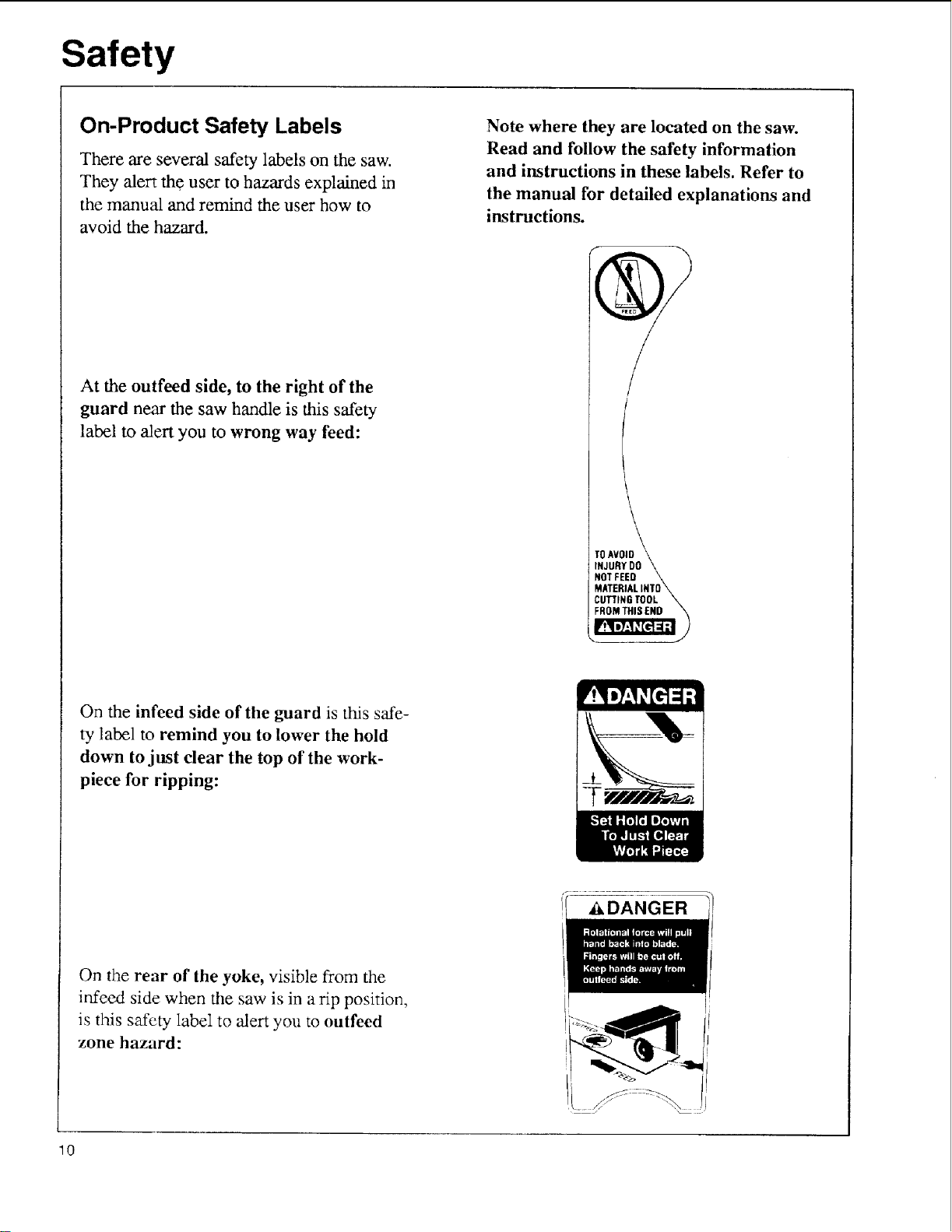

4. Workpieces that extend beyond the saw

table can shift, twist, rise up from the table,

or fall as they are cut or afterwards. Support

workpiece with table extensions the same

height as the saw table.

Safety

5. To prevent tipping, support outer ends of

extensions with sturdy legs or an outrigger.

6. Do not use another person to help support

workpieces or to aid by pushing or pulling

on workpieces, because these actions can

cause kickback. Use table extensions.

7. Use clamps or vice to hold workpiece. It's

safer than using your hands.

Blade Safety Instructions

1. Use only blades marked for at least 3450

rpm.

2. Use only 10" or smaller diameter blades.

3. Use blades for their recommended cutting

procedures.

4. Keep blade sharp and clean.

5. Do not overtighten blade nut because

blade collar could warp.

6. Do not turn saw on and off in rapid

sequence because blade can loosen.

7. Blade should stop within 15 seconds after

saw is switched off. ff blade takes longer, the

saw needs repair. Contact Sears Service

Center.

Safety

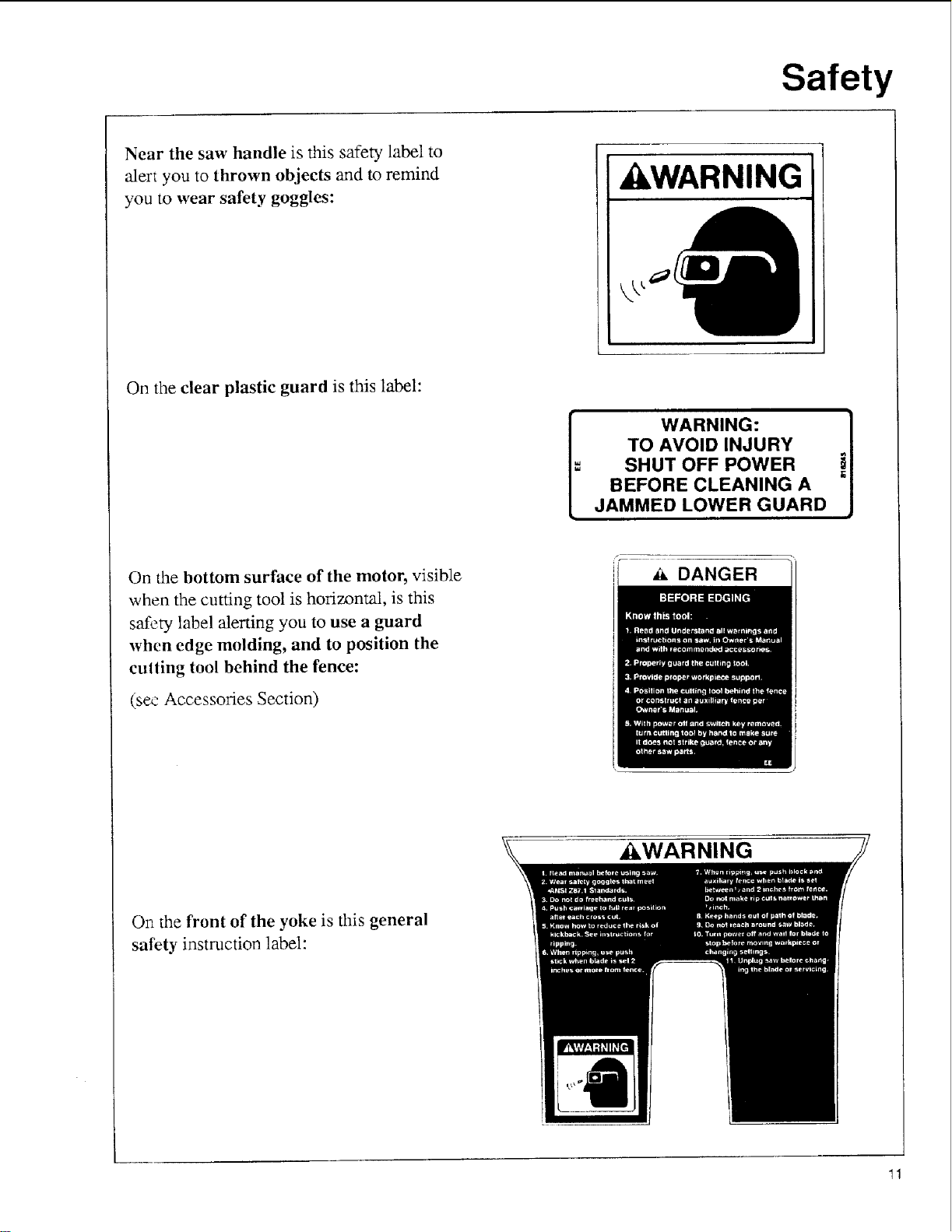

On-Product Safety Labels

There are several safety labels on the saw.

They alert the user to hazards explained in

the manual and remind the user how to

avoid the hazard.

At the outfeed side, to the right of the

guard near the saw handle is this safety

label to alert you to wrong way feed:

Note where they are located on the saw.

Read and follow the safety information

and instructions in these labels. Refer to

the manual for detailed explanations and

instructions.

/

I

TOAVOID \\

INJURYDO \,.

NOT FEED \

MATERIALINTO\

I CUTTINGTOOL

On the infeed side of the guard is this sde-

ty label to remind you to lower the hold

down to just clear the top of the work-

piece for ripping:

On the rear of the yoke, visible from the

infeed side when the saw is in a rip position,

is this safety label to alert you to outfeed

zone hazard:

10

_DANGER

Near the saw handle is dais safety label to

"alert you to thrown objects and to remind

you to wear safety goggles:

On the clear plastic guard is this label:

Safety

,&WARNING

TO AVOID INJURY

=

SHUT OFF POWER !

BEFORE CLEANING A

JAMMED LOWER GUARD ,,

WARNING: I

On the bottom surface of the motor, visible

when the cutting tool is horizontal, is this

safety label alerting you to use a guard

when edge molding, and to position the

culling tool behind the fence:

(see Accessories Section)

On the front of the yoke is dais general

safety instruction label:

DANGER

,_WARNING

11

Assembly

Introduction

In order to get the most enjoyment out of your radial saw it is important that the machine by properly

assembled, adjusted, and aligned. This procedure, although not difficult, takes time; perhaps eight

hours or longer for the inexperienced user. However, after this initial set-up a weekly tune-up can be

completed in approximately ten minutes by checking the alignment and only adjusting those settings

which are incorrect.

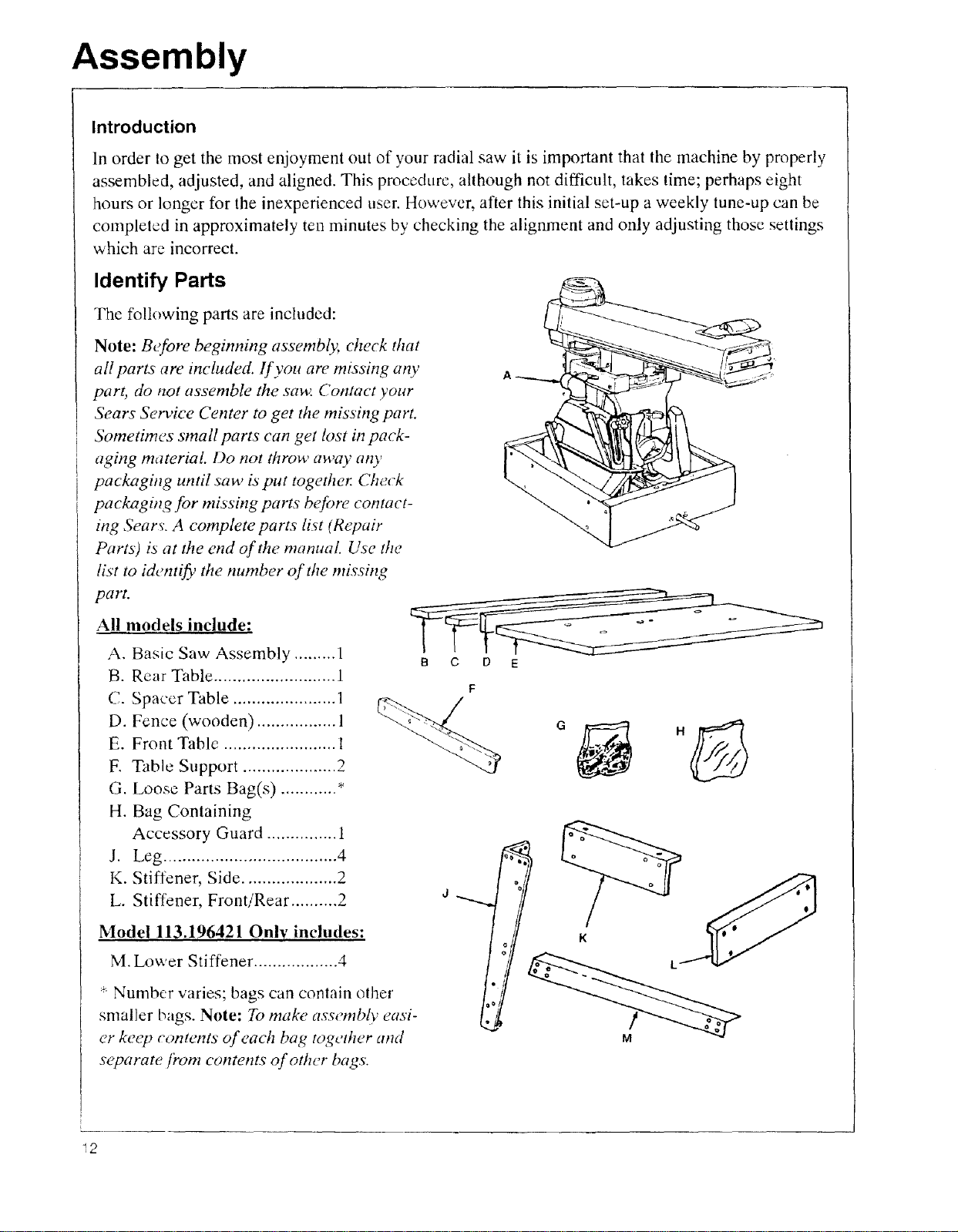

Identify Parts

The following parts are included:

Note: Before beginning assembly, check that

all parts are included. If you are missing any

part, do not assemble the saw Contact your

Sears Service Center to get the missing part.

Sometimes small parts can get lost in pack-

aghzg material Do not throw away arty

packagi,g until saw is put together. Check

pacl_zgh_g for missh_g parts before contact-

ing Sears. A complete parts list (Repair

Parts) is at the end of the manual. Use the

list to identify the number of the missing

part.

All models include:

A. Basic Saw Assembly ......... 1

B. Rear Table .......................... 1

C. Spacer Table ...................... 1

D. Fence (wooden) ................. 1

E. Front Table ........................ 1

F. Table Support .................... 2

G. Loose Parts Bag(s) ............ *

H. Bag Containing

Accessory Guard ............... 1

J. Leg ..................................... 4

K. Stiffener, Side .................... 2

L. Stiffener, Front!Rear .......... 2

Model 113.196421 Only includes:

M. Lower Stiffener .................. 4

* Number varies; bags can contain other

smaller bags. Note: To make assembly easi-

er keep contents of each bag tog_¢ther and

separate from contents of other bags.

B C D

F

d

K L

_2

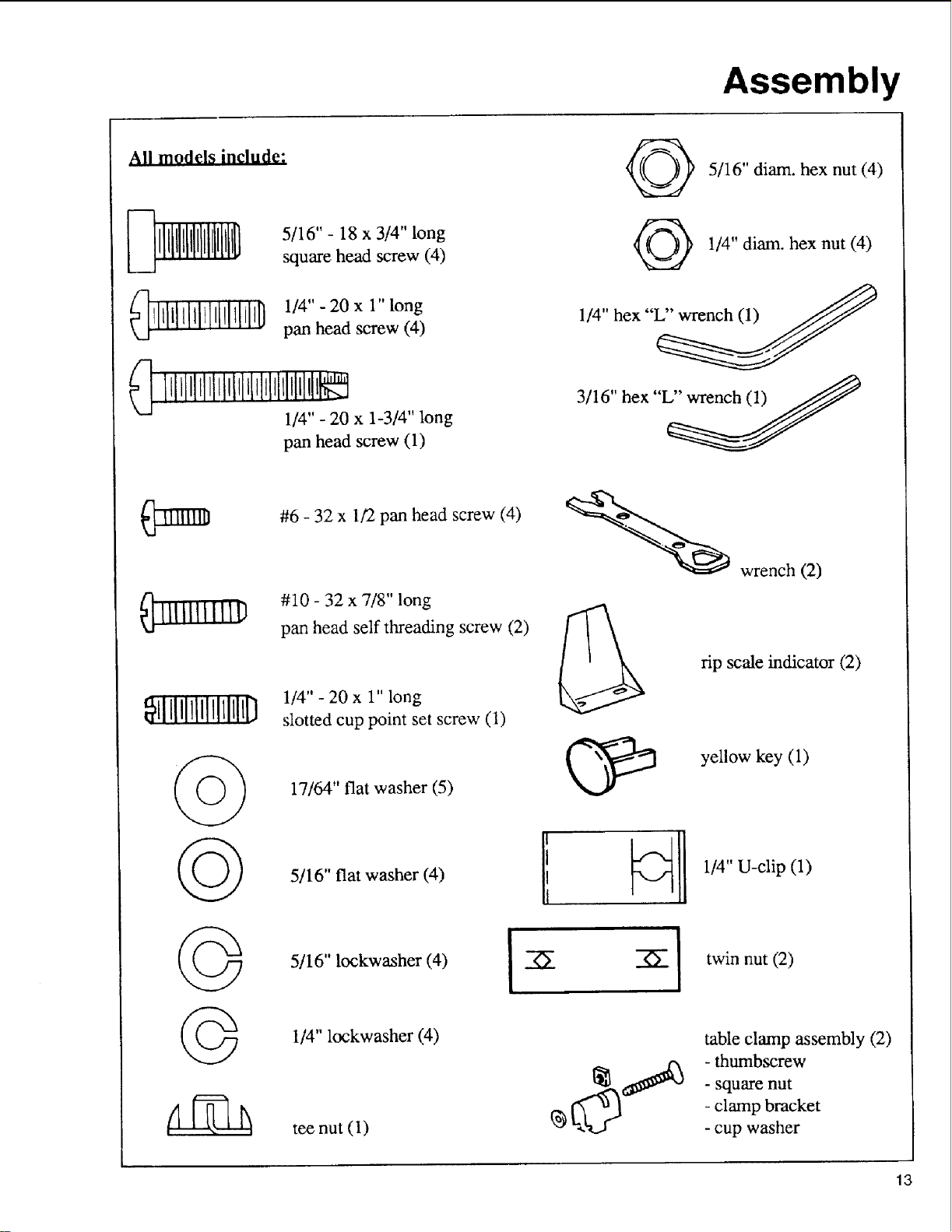

All models include:

5/16" - 18 x 3/4" long

square head screw (4)

Assembly

5/16" diam. hex nut (4)

1/4" diam. hex nut (4)

_llqqillllll[tllllliO1/4"-20x 1"long

pan head screw (4)

_ IillJllilll_liH_l_l_lilllllil,lt_

1/4" - 20 x 1-3/4" long

pan head screw (1)

#6 - 32 x 1/2 pan head screw (4)

#10 - 32 x 7/8" long

_lllllllllll)

_illllllllltlllllil7

pan head self threading screw (2)

1/4" - 20 x 1" long

slotted cup point set screw (1)

1/4" hex "_

3/16" hex "L'_

wrench (2)

rip scale indicator (2)

yellow key (1)

©

©

©

17/64" fiat washer (5)

5/16" flat washer (4)

5/16" lockwasher (4)

1/4" lockwasher (4)

tee nut (1)

i

1/4"U-clip (1)

--6"

] twin nut (2)

table clamp assembly (2)

- thumbscrew

- square nut

- clamp bracket

- cup washer

13

Assembly

C)

@

crank

1/4" diam. x 5/8" long

truss head screw (24)

(40 for 113.196421)

leveling foot (4)

3/8" diatn, hex nut (8)

5/16" diam. hex nut

(4)

©

@

@

arm cap

1/4" external tooth

lockwasher (24)

(40 for 113.196421)

5/16" diam. external

lockwasher (4)

11/32" x 11/16" x 1/16"

washer (8)

1/4" diam. hex nut

©

(40 for 113.196421)

Tools needed for Assembly and Alignment

7116" Wrench

@' _ 1,'2" Wrench

@ ........ @ 9/16"Wrench

Small Hammer

(24)

15/16" Wrench

5/16" diam. x 5/8" long

hex head screw (4)

Wrench

Pliers Phillips Screwdriver

Pencil

I

Medium Screwdriver

Framing Square

14

Assembly

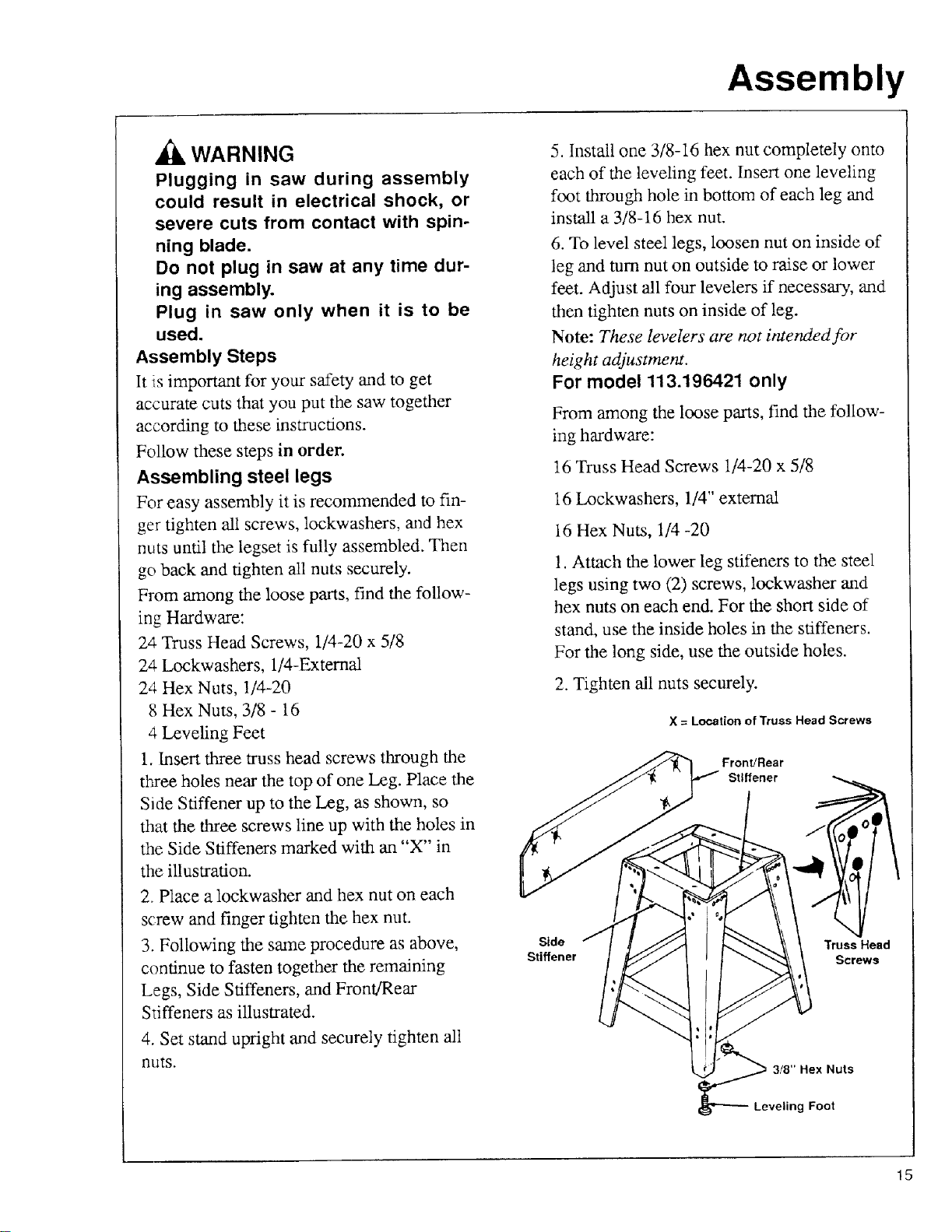

_k WARNING

Plugging in saw during assembly

could result in electrical shock, or

severe cuts from contact with spin-

ning blade.

Do not plug in saw at any time dur-

ing assembly.

Plug in saw only when it is to be

used.

Assembly Steps

It is important for your safety and to get

accurate cuts that you put the saw together

according to these instructions.

Fol!ow these steps in order.

Assembling steel legs

For easy assembly it is recommended to fin-

ger tighten all screws, lockwashers, and hex

nuts until the legset is fully assembled. Then

go back and tighten all nuts securely.

From among the loose parts, find the follow-

ing Hardware:

24 Truss Head Screws, 1/4-20 x 5/8

24 Lockwashers, 1/4-External

24 Hex Nuts, !/4-20

8 Hex Nuts, 3/8 - 16

4 Leveling Feet

1. Insert three truss head screws through the

three holes near the top of one Leg. Place the

Side Stiffener up to the Leg, as shown, so

that the three screws line up with the holes in

the Side Stiffeners marked with an "X" in

the illustration.

2. Place a lockwasher and hex nut on each

screw and finger tighten the hex nut.

3. Following the same procedure as above,

continue to fasten together the remaining

Legs, Side Stiffeners, and Front/Rear

Stiffeners as illustrated.

5. Install one 3/8-16 hex nut completely onto

each of the leveling feet. Insert one leveling

foot through hole in bottom of each leg and

install a 3/8-16 hex nut.

6. To level steel legs, loosen nut on inside of

leg and turn nut on outside to raise or lower

feet. Adjust all four levelers if necessary, and

then tighten nuts on inside of leg.

Note: These levelers" are not intended for

height adjustment.

For model 113.196421 only

From among the loose parts, find the follow-

ing hardware:

16 Truss Head Screws 1/4-20 x 5/8

16 Lockwashers, 1/4" external

16 Hex Nuts, 1/4 -20

!. Attach the lower leg stifeners to the steel

legs using two (2) screws, lockwasher and

hex nuts on each end. For the short side of

stand, use the inside holes in the stiffeners.

For the long side, use the outside holes.

2. Tighten all nuts securely.

X = Location of Truss Head Screws

Front/Rear

Stiffener

Side Truss Head

Stiffener Screws

4. Set stand upright and securely tighten all

nuts.

3/8" Hex Nuts

Leveling Foot

15

Assembly

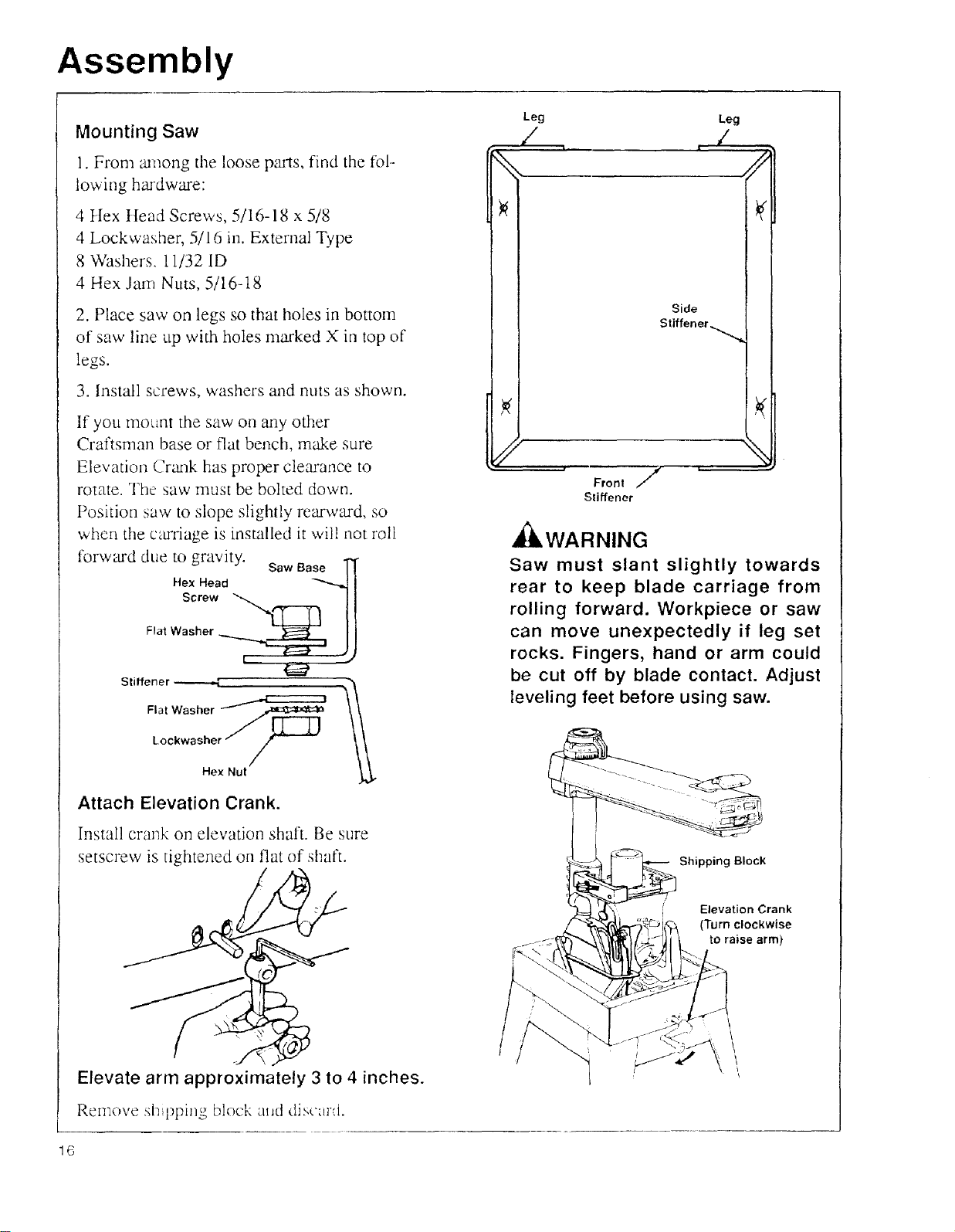

Mounting Saw

1. From _mlong tile loose p'-w'ts,find the fol--

lowing hmdware:

4 ttex tlead Screws, 5/16-18 x 5/8

4 Lockwasher, 5/16 in. External Type

8 Washers, 11/32 ID

4 Hex Jam Nuts, 5/16-t8

2. Place saw on legs so that holes in bottom

of saw line up with holes marked X in top of

legs.

3. Install screws, washers and nuts as shown.

If you mount the saw on any other

Craftsman base or Slat bench, make sure

Elevation Crm_k has proper clearance to

rotate. The saw must be bolted down.

Position saw to slope slightly rearward, so

when tile carriage is installed it will not roll

forward due to gravity. SawBase

Hex Head _ I

Stiffener

Flat Washer

Leg Leg

/ , ,/

%, //

Front /

Sliffener

_WARNING

Saw must slant slightly towards

rear to keep blade carriage from

rolling forward. Workpiece or saw

can move unexpectedly if leg set

rocks. Fingers, hand or arm could

be cut off by blade contact. Adjust

leveling feet before using saw.

Lockwasher

Hex Nut

Attach Elevation Crank.

Install crank on elevation shaft. Be sure

setscrew is tightened on flat of shaft.

Elevate arm approximately 3 to 4 inches.

Remove shipping block mid discurd.

16

Shipping Block

Elevation Crank

(Turn clockwise

to raise arm)

\

\

\

\

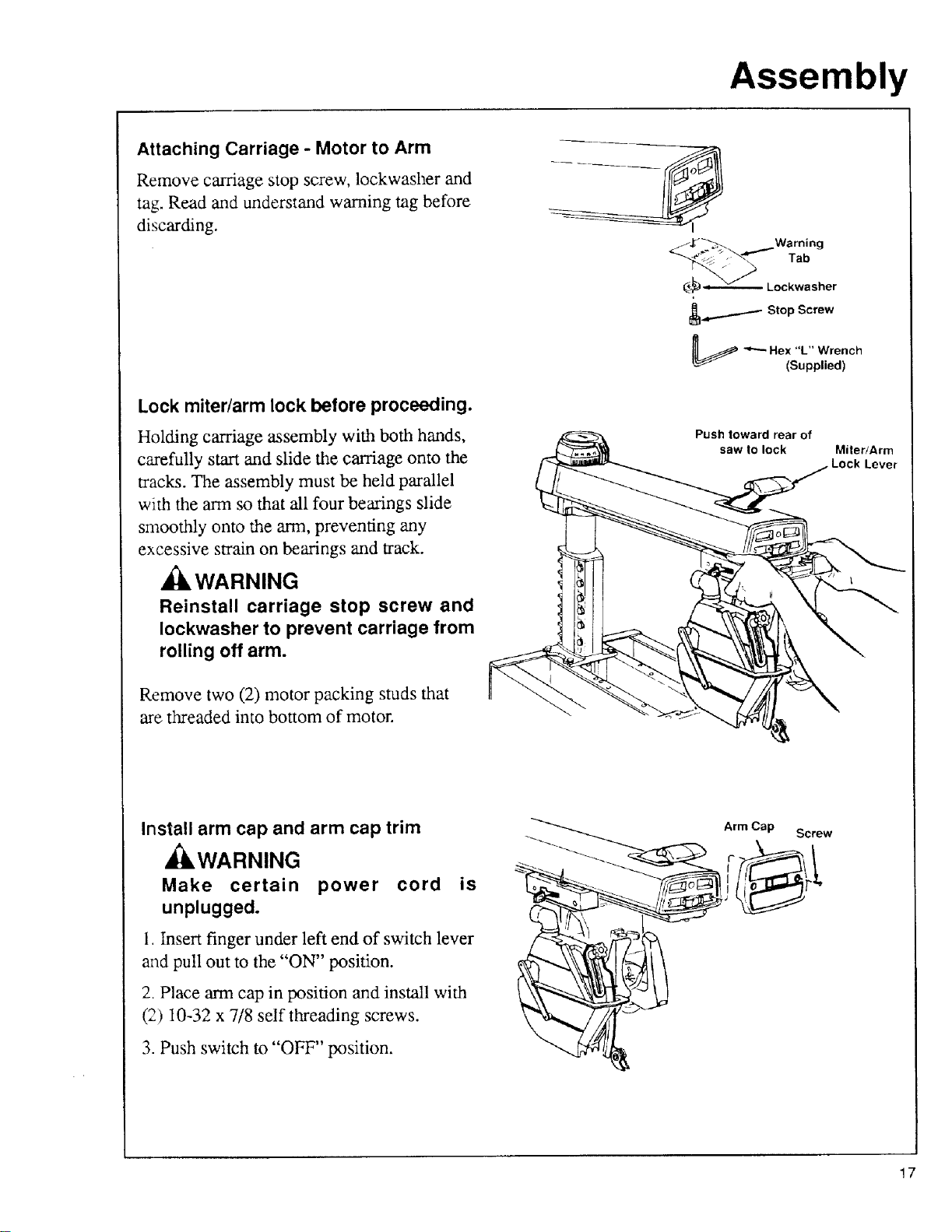

Attaching Carriage - Motor to Arm

Remove carriage stop screw, lockwasher and

tag. Read and understand warning tag before

discarding.

Assembly

Warning

Tab

(_j_ Lockwasher

_,.......,._-_ Stop Screw

Lock miter/arm lock before proceeding.

Holding carriage assembly with both hands,

carefully start and slide the carriage onto the

tracks. The assembly must be held parallel

with the arm so that all four bearings slide

smoothly onto the arm, preventing any

excessive strain on bearings and track.

WARNING

Reinstall carriage stop screw and

Iockwasher to prevent carriage from

rolling off arm.

Remove two (2) motor packing studs that

are threaded into bottom of motor.

_ "'-'- Hex "L" Wrench

Push toward rear of

saw to lock

(Supplied)

Miter/Arm

Lever

Install arm cap and arm cap trim

,_WARNING

Make certain power cord is

unplugged.

1 Insert finger under left end of switch lever

and pull out to the "ON" position.

2 Place arm cap in position and install with

(2) 10-32 x 7/8 self threading screws.

3. Push switch to "OFF" position.

Arm Cap

Screw

17

Assembly

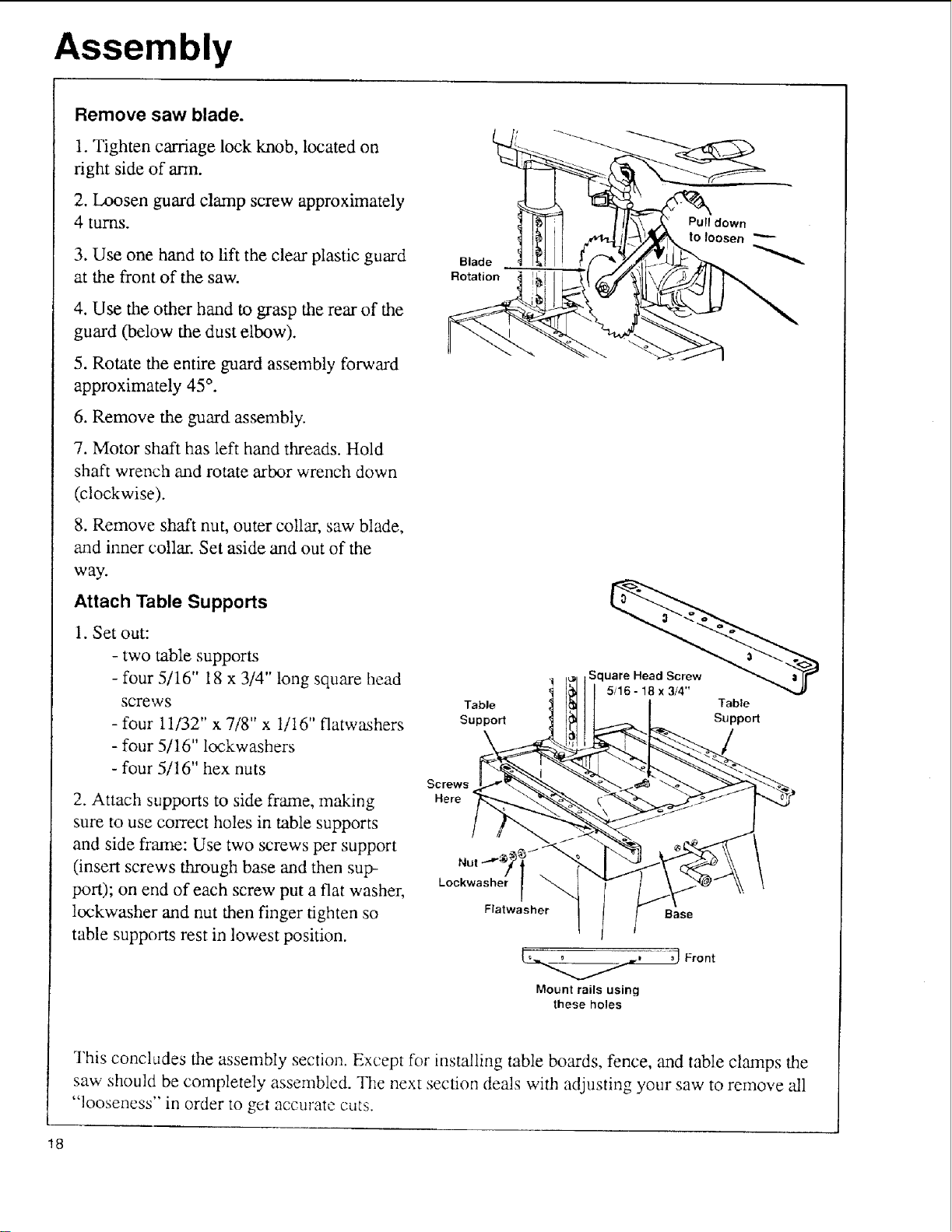

Remove saw blade.

1. Tighten carriage lock knob, located on

right side of ann.

2. Loosen guard clamp screw approximately

4 turns.

3. Use one hand to lift the clear plastic guard

at the front of the saw.

4. Use the other hand to grasp the rear of the

guard (below the dust elbow).

5. Rotate the entire guard assembly forward

approximately 45°.

6. Remove the guard assembly.

7. Motor shaft has left hand threads. Hold

shaft wrench and rotate arbor wrench down

(clockwise).

Purl down

to |oo_er}

Blade

Rotation

8. Remove shaft nut, outer collar, saw blade,

and inner collar. Set aside and out of the

way.

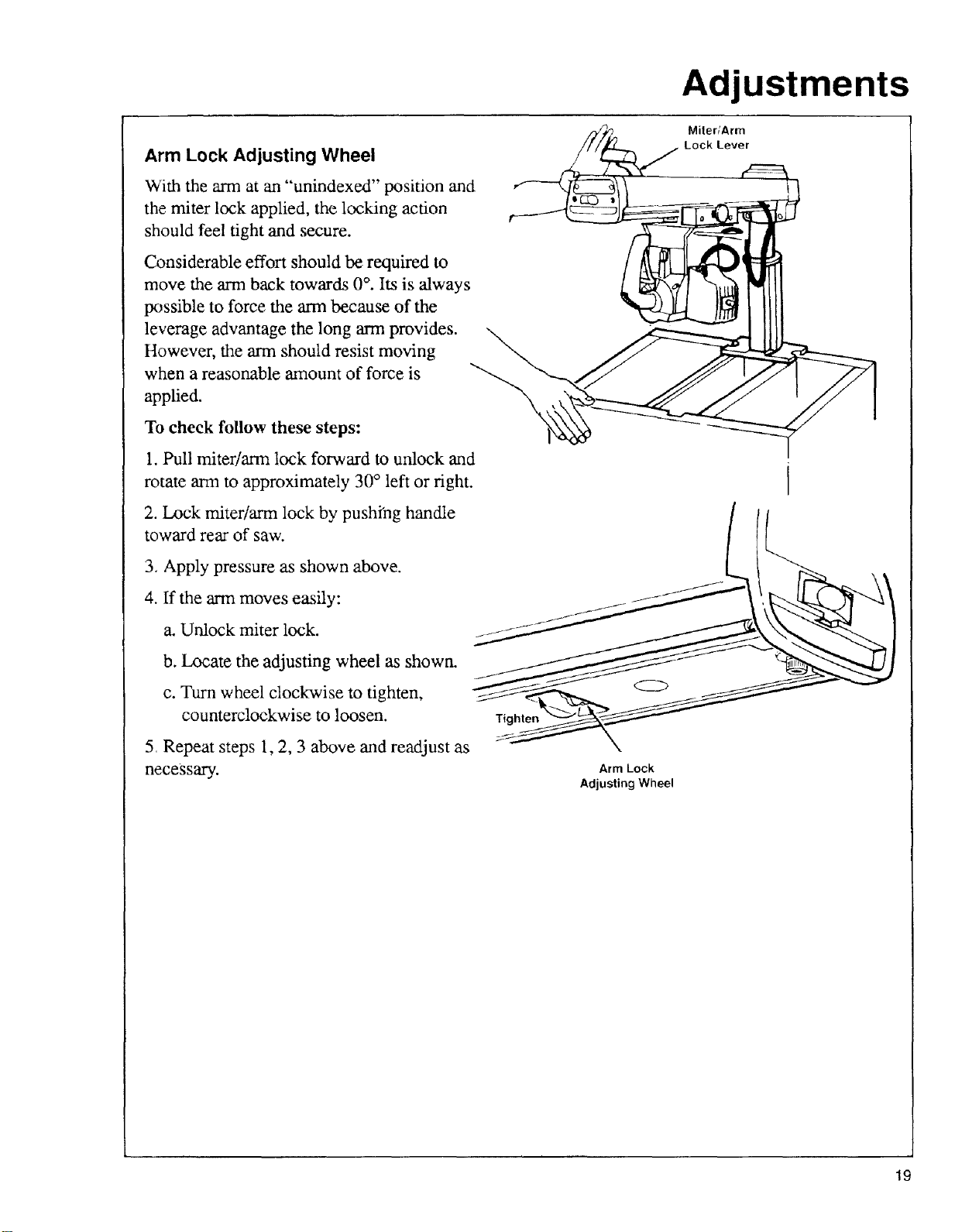

Attach Table Supports

1. Set out:

- two table supports

- four 5/16" 18 x 3/4" long square head

screws

- four 11/32" x 7/8" x 1/16" flatwashers

- four 5/16" lockwashers

- four 5/16" hex nuts

2. Attach supports to side frame, making

sure to use correct holes in table supports

and side frame: Use two screws per support

(insert screws through base and then sup-

port); on end of each screw put a flat washer,

lockwasher and nut then finger tighten so

table supports rest in lowest position.

SCreWS

Here

Lockwasher

Table

Support

\

Nut ""_

Flatwasher

Table

Support

Base

_] Front

Mount rails using

these holes

This concl_tdes the assembly section. Except for installing table bonds, fence, and table clamps the

saw should be completely assembled. The next section deals with adjusting your saw to remove 'all

"looseness" in order to get accurate cuts.

18

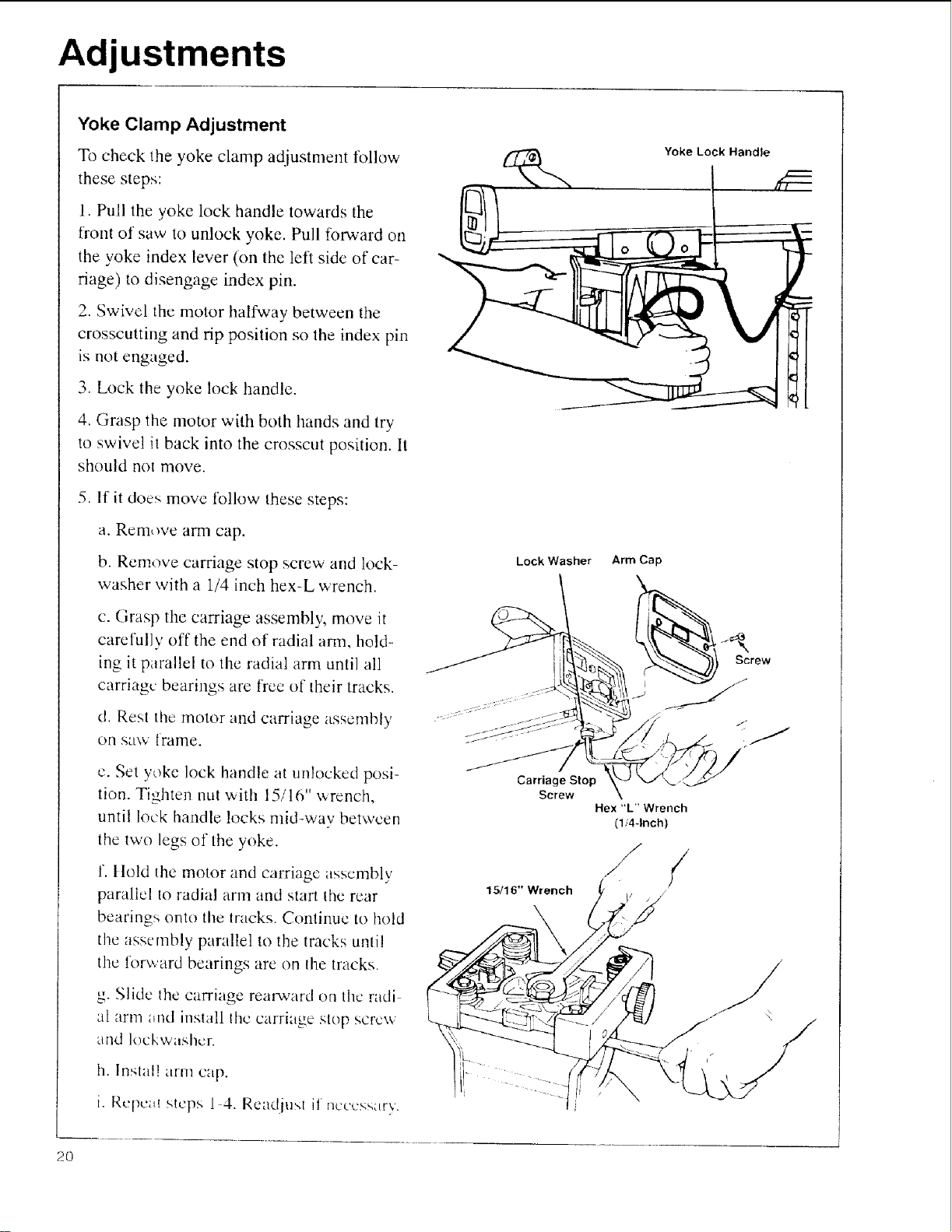

Arm Lock Adjusting Wheel

With the arm at an "unindexed" position and

the miter lock applied, the locking action

should feel tight and secure.

Considerable effort should be required to

move the ann back towards 0 °. Its is "always

possible to force the arm because of the

leverage advantage the long arm provides.

However, the arm should resist moving

when a reasonable amount of force is

applied.

To check follow these steps:

1. Pull miter/arm lock forward to unlock and

rotate ann to approximately 30° left or right.

2. Lock miter/arm lock by pushfng handle

toward rear of saw.

Adjustments

Miter/Arm

Lock Lever

3. Apply pressure as shown above.

4. If the arm moves easily:

a. Unlock miter lock.

b. Locate the adjusting wheel as shown.

c. Turn wheel clockwise to tighten,

counterclockwise to loosen.

5 Repeat steps 1, 2, 3 above and readjust as

necessary.

Arm Lock

Adjusting Wheel

19

Adjustments

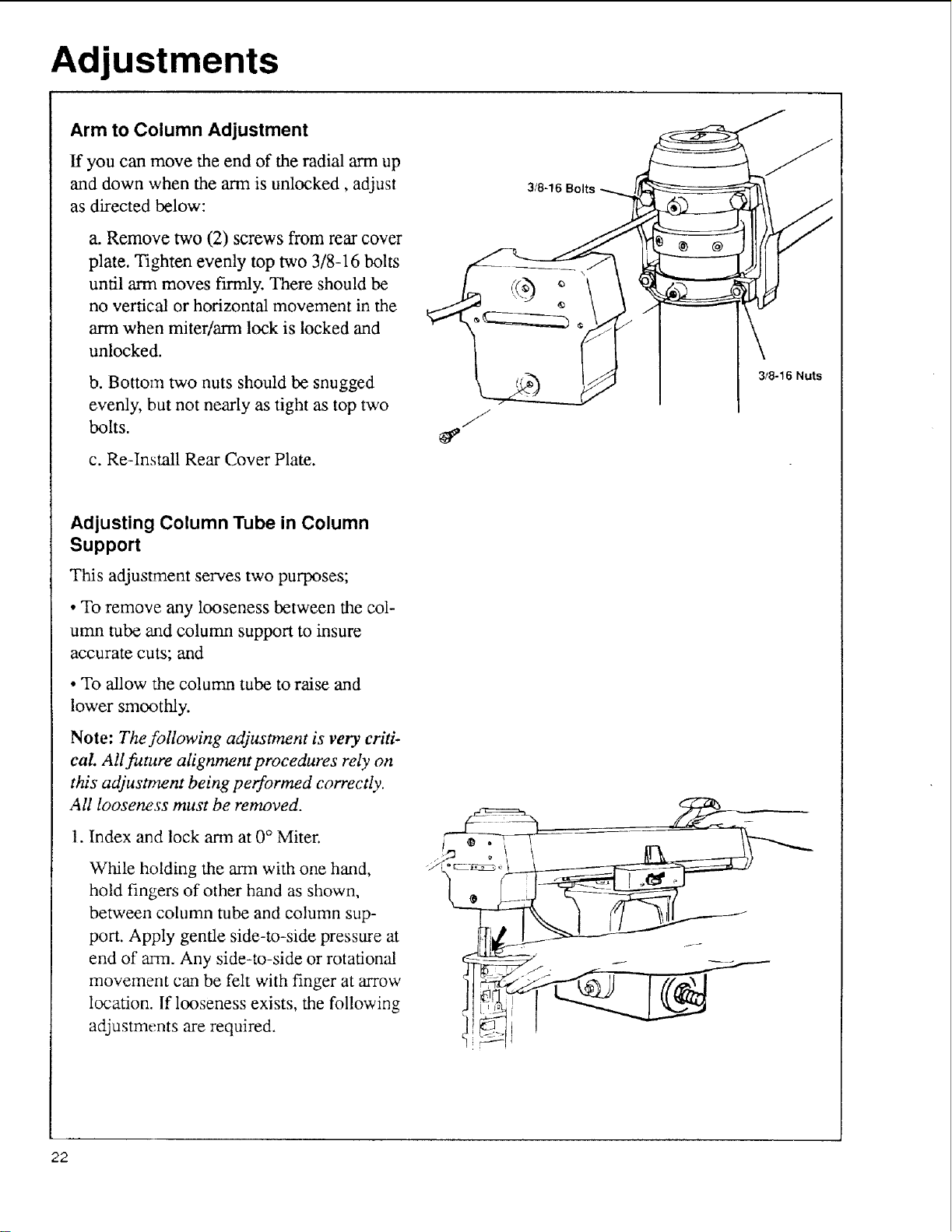

Yoke Clamp Adjustment

To check the yoke clamp adjustment follow

these steps:

1. Pull the yoke lock handle towards the

front of saw to unlock yoke. Pull forward on

the yoke index lever (on the left side of car-

riage) to disengage index pin.

2. Swivel the motor halfway between the

crosscutting and rip position so the index pin

is not engaged.

3. Lock the yoke lock handle.

4. Grasp the motor with both hands and try

to swivel it back into the crosscut position. It

should not move.

5_

If it does move tbllow these steps:

Yoke Lock Handle

a. Rein,we arm cap.

b. Remove carriage stop screw and lock-

washer with a 1/4 inch hex-L wrench.

c. Grasp the carriage assembly, move it

careful] v off the end of radial ann, hold-

ing it parallel to the radial arm until all

carriage bearings are free of their tracks.

d. Rest lhe motor and carriage assembly

on saw frame.

e. Set yoke lock handle at unlocked posi-

tion. Tighten nut with 15/16" x_,renctl,

until lock handle locks mid-way between

the two legs of the yoke.

f. ltold the motor and carriage assembly

parallel to radial arm and starl the rear

bearings onto the tracks. Continue to hold

the assembly parallel to the tracks unlil

the forward bearings are on the tracks.

Lock Washer

Carriage Stop

Screw

15/16" Wrench

Arm Cap

Screw

Hex "L" Wrench

(1i44nch)

/

/

g. Slide the carriage rearward on the radi

a[ arn-t tmlld install the carriage stop screw

and lockwashcr.

h. Instal! arm cap.

i. Rcpcul steps 1 4. Read usl if nccc_<s',try.

2O

I

Adjustments

Bevel Lock Lever

The purpose of the bevel lock lever is to

lock the motor at any angle. To check follow

these steps:

1. Unlock the bevel lock lever. Move the,

bevel index pin to the left and rotate the saw

to approximately 30 °. Lock the bevel lock

lever.

2. Use both hands as shown and try to force

the motor out of position. If the motor

moves, the bevel lock lever needs to be

tightened. On the other hand if it is extreme-

ly hard to lock the bevel lock lever it has

been over -tightened.

3. Follow these steps to adjust:

a. Remove the socket set screw with hex

wrench as shown.

b. Use the bevel lock lever as a wrench to

tighten or loosen the clamp bolt. Do not

over tighten.

c. Repeat steps 1 and 2. Re-adjust if nec-

essary

d. Replace bevel lock lever in the locked

position.

e. Tighten the set screw.

l 1

©

Bevel

Index

Pin

Bevel

Lock

Lever

\

[_ Bevel Lock

Lever

Lockwasher

Note: The clamp bolt has a left handed

thread. Therefore, to increase the clamping

effect, rotate the bevel lock lever - when

used as a wrench -from right to left, or

clockwise when viewed from above. If you

accidentally rotate it the wrong way and dis-

engage the bolt from the matching steel nut,

it will be necessary to remove the Yoke

Handle, and Bevel Scale, in order to rein-

stall the bolt into the nut.

1/8" Hex "C" Wrench

\

Bevel Lock Lever

In Locked Position

21

Adjustments

Arm to Column Adjustment

If you can move the end of the radial arm up

and down when the ann is unlocked, adjust

as directed below:

a. Remove two (2) screws from rear cover

plate. Tighten evenly top two 3/8-16 bolts

until arm moves firmly. There should be

no vertical or horizontal movement in the

arm when miter/arm lock is locked and

unlocked.

b. Bottom two nuts should be snugged

evenly, but not nearly as tight as top two

bolts.

c. Re-Install Rear Cover Plate.

3/8-16 Bolts

3/8-16 Nuts

Adjusting Column Tube in Column

Support

This adjustment serves two purposes;

• To remove any looseness between the col-

umn tube and column support to insure

accurate cuts; and

• To allow the column tube to raise and

lower smoothly.

Note: The following adjustment is very criti-

cal All future alignment procedures rely on

this adjustment being performed correctly.

All looseness must be removed.

1. Index and lock arm at 0 ° Miter.

While holding the arm with one hmad,

hold fingers of other hand as shown,

between column tube and column sup-

port. Apply gentle side-to-side pressure at

end of arm. Any side-to-side or rotational

movement can be felt with finger at arrow

location. If looseness exists, the following

adjustments are required.

22

Adjustments

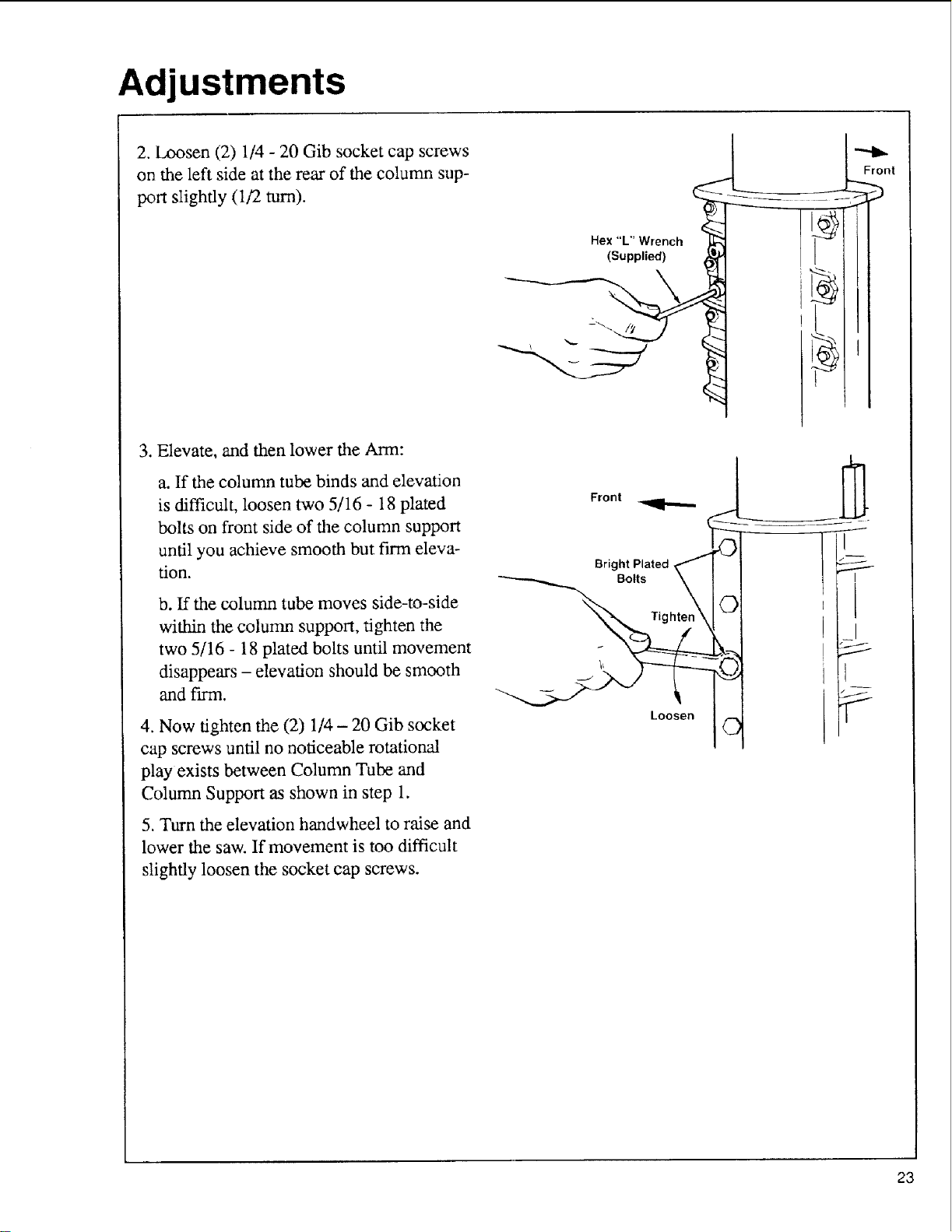

2. lax)sen (2) 1/4 - 20 Gib socket cap screws

on the left side at the rear of the column sup-

port slightly (1/2 turn).

3. Elevate, and then lower the Ann:

a. If the column tube binds and elevation

is difficult, loosen two 5/16 - 18 plated

bolts on front side of the column support

until you achieve smooth but firm eleva-

tion.

b. If the column tube moves side-to-side

within the column support, tighten the

two 5/16 - 18 plated bolts until movement

disappears - elevation should be smooth

and firm.

-

Hex "L" Wrench _ _ "_

(Supplied) 1_ I

Front

J

5

Bright Plated

Bolts

1

Front

/

t

4. Now tighten the (2) 1/4 - 20 Gib socket

cap screws until no noticeable rotational

play exists between Column Tube and

Column Support as shown in step 1.

5. Turn the elevation handwheel to raise and

lower the saw. If movement is too difficult

slightly loosen the socket cap screws.

©

23

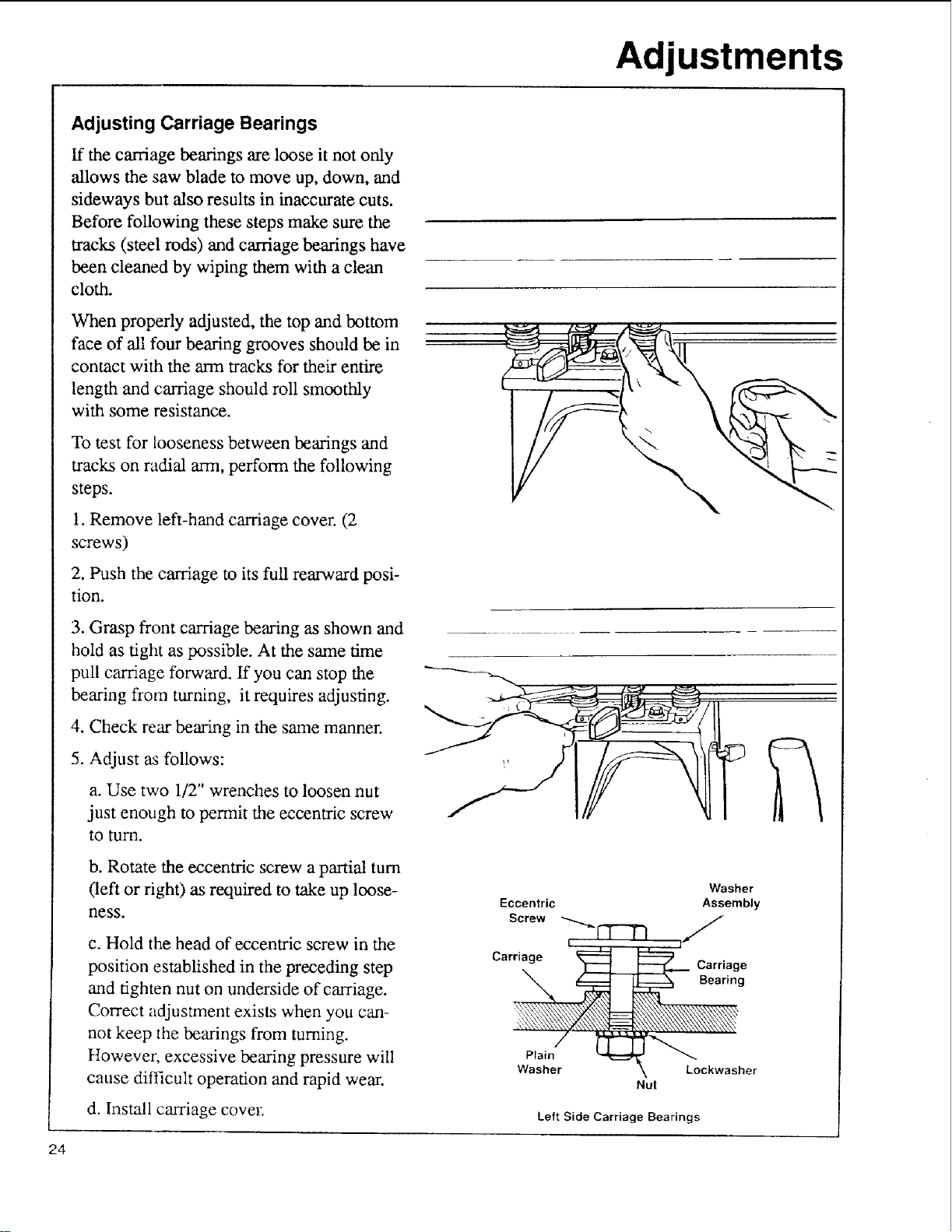

Adjusting Carriage Bearings

ff the carriage bearings are loose it not only

allows the saw blade to move up, down, and

sideways but also results in inaccurate cuts.

Before following these steps make sure the

tracks (steel rods) and carriage bearings have

been cleaned by wiping them with a clean

cloth.

When properly adjusted, the top and bottom

face of all four bearing grooves should be in

contact with the arm tracks for their entire

length and carriage should roll smoothly

with some resistance.

To test for looseness between bearings and

tracks on radial arm, perform the following

steps.

Adjustments

1. Remove left-hand carriage cover. (2

screws)

2. Push the carriage to its full rearward posi-

tion.

3. Grasp front carriage bearing as shown and

hold as tight as possible. At the same time

pull carriage forward. If you can stop the

bearing from turning, it requires adjusting.

4. Check rear bearing in the same manner.

5. Adjust as follows:

a. Use two 1/2" wrenches to loosen nut

just enough to permit the eccentric screw

to turn.

b. Rotate the eccentric screw a partial turn

Oefl or right) as required to take up loose-

ness.

c. Hold the head of eccentric screw in the

position established in the preceding step

and tighten nut on underside of carriage.

Correct adjustment exists when you can-

not keep the bearings from turning.

However, excessive bearing pressure will

cause difficult operation and rapid wear.

Eccentric

Screw

Carriage

Plain

Washer Loekwasher

Nut

Washer

Assembly

Carriage

Bearing

d. Install carriage cove1;

24

Left Side Carriage Bearings

Loading...

Loading...