Craftsman 11210872 Owner’s Manual

Operator's Manual

2.8 Amp Compact

Multi-Purpose/Plunge Action

3-in. Circular Saw

with Laser Trac TM

Model No.

112.10872

Z_ CAUTION: Read, understand and follow

all Safety Rules and Operating Instructions

in this Manual before using this product_

Sears, Roebuck and Co.,

Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman ®webslte: www.sears.com/craftsman

• WARRANTY

• SAFETY

• UNPACKING

• DESCRIPTION

• OPERATION

• MAINTENANCE

Warranty ................................................................................... Page 2

Safety Symbols .......................................................................... Page 3

Safety Instructions ...................................................................... Pages 4-11

Glossary of Terms ....................................................................... Pages 11-12

Unpacking ................................................................................. Page 13

Description ......................................................................................... Pages 14-15

Operation ........................................................................................... Pages 16-31

Maintenance ...................................................................................... Pages 31-32

Troubleshooting ................................................................................. Pages 33-34

Accessories ....................................................................................... Page 35

Repair Parts ....................................................................................... Pages 35-38

Sears Repair Parts Phone Numbers ................................................. Back Cover

ONEYEAR FULLWARRANTY ON CRAFTSMAN ®PRODUCT

tf this Craftsman Tool fails due to a defect in material or workmanship

within one year from the date of purchase, RETURN ITTO ANY SEARS

STORE OR PARTS AND REPAIR CENTER OR OTHER CRAFTSMAN

OUTLET IN THE UNITED STATES FOR FREE REPAIR (OR

REPLACEMENT IF REPAIR PROVES IMPOSSIBLE),

This warranty does not include expendable parts such as lamps, batteries,

bits or blades

if this Craftsman product is used for commercial or rental purposes,

this warranty applies for only 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may have other rights,

which vary from state to state.

Sears, Roebuck and Coo, Hoffman Estates, IL 60179

SAVETHESE INSTRUCTIONSI

READ ALL INSTRUCTIONSI

chemicals known to the State of California to cause cancer and birth

,4k WARNING: Some dust created by using power tools contains

defects or other reproductive harm.

The purpose of safety symbols is to attract your attention to possible dangers.

The safely symbols, and the explanations with them, deserve your careful attention

and understanding, The symbol warnings DO NOT by themselves eliminate any

danger,The instructions and warnings they give are nosubstitutes for proper accident

prevention measures,

manual, Including al! safety alert symbols such as "DANGER", "WARNING" and

"CAUTION", BEFORE using this saw. Failure to follow all instructions listed below

A WARNING: BE SURE to read and understand all safety instructions in this

may result in electric shock, fire and/or serious personal injury.

SYMBOL MEANING

l / e_ sAFETY ALERT sYMBOL: IndIcates DANGER'WARNING'OR 1

[-_ DANGER: Failure to obey this safety warning WILL result in |

[ _WARNING ] Failure to obey this safety warning CAN result In death or I

,'_ CAUTION I Failure to obey this safety warning MAY result In personal I

DAMAGE PREVENTION AND INFORMATION MESSAGES

These Informuser of important Information and/or Instructions thatcould lead to

equipmentor other property damage _fnotfollowedoEach message ts preceded by the word

"NOTE:" as in the example below:

NOTE: Equipment and/or property damage may result If these Instructions are

not followed.

CAUTION.Maybe usedIn conjunctionwith other symbolsorplctographe.

WEAR YOUR

death or serious Injury to yourself or to others. Always follow

the safety precautions to reduce the risk of fire, electric shock

and personal Injury.

serious Injury to yourself or to others. Always follow the safety

]

precautions to reduce the risk of firs, electric shock and

persons! Injury.

injury to yourself or others or property damage, Always follow

l

the safety precautions to reduce the risk of fire, electric shock

and personal Injury,

_WARNING: The operation of any tool with s ¢lmular

btade can result in foreign objects being thrown into your

eyes, which can result In severe eye damage. Before

beginning power tool operation, ALWAYS wear safety

goggles or safety glasses with aide shield and s full-face

shield when needed. We recommend a Wide V|slon Safety

Meek for use over eyeglasses or standard safety glasses

with side shield, available at Sears Stores or other

Craftsman Outlets.

1

l

|

t

J

z_WARNING: BESURE to read and understand all Instructions In this manual t

beforeusing this circular saw. Failureto follow all Instructionsmay result In t

hazardous radiation exposure, electric shock,fire and/or serious personalInjury,!

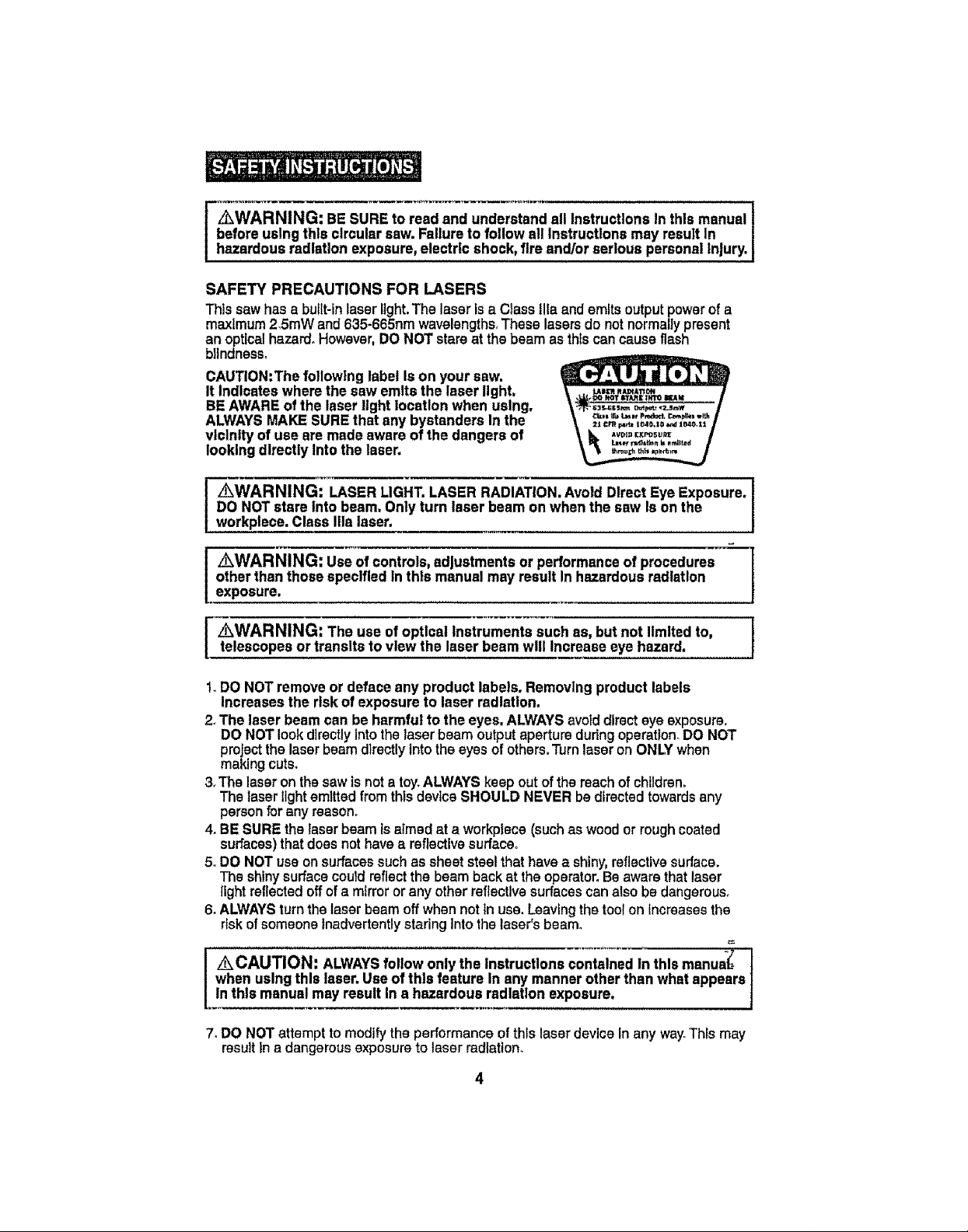

SAFETY PRECAUTIONS FOR LASERS

Thissaw hasa built-inlaser light.The laserisa ClassIlia and emits outputpower of a

maximum 2.5mWand 635-665nmwavelengths.These lasersdo notnormallypresent

an opticalhazard.However,DO NOT stareat the beam asthiscancauseflash

blindness,

CAUTION:The following label Ison your saw.

It Indicates where the sawemits the laser light,

BEAWARE ofthe laser light location when using,

ALWAYSMAKE SUREthat any bystandersIn the

vlclnlty of use are made aware of the dangers of

looking directly Into the laser.

2t Cf'R _ 1040,10 _¢4 1 _10,t_t

A_tD [KPOSU_1_

_WARNING: LASER LIGHT.LASER RADIATION.Avoid DlrectEye Exposure.

DO NOTstare Into beam. Only turn laserbeam on when the sew Isonthe

workplece. Class Ilia laser.

z_WARNING: Useof controls,adjustments or performanceof procedures ]

other than those speclfled in this manual may result In hazardousradiation

exposure.

I WARNING: The use of opticalinstruments such as, but not limitedto, ]

telescopes or transits to view the laserbeam will Increase eye hazard.

f

!

t_DO NOTremoveor defaceany product labels. Removing product labels

Increasesthe risk of exposure to laser radlatlon,

2.The laserbeam can be harmful to the eyes,ALWAYSavoiddirect eye exposure.

DONOT look directly Intothelaser beam output aperture during operation_DO NOT

project the laserbeam directlyInto the eyes of others,Turn laser onONLYwhen

making cuts.

3.The laser on the sawis nota toy.ALWAYS keep outof the reach of children,

Thelaser light emitted fromthis devlca SHOULDNEVER bedirected towardsany

personforany reason.

4. BESURE the laserbeam is aimed at a workptece (suchas wood or roughcoated

surfaces) that does not havea reflective surface.

5. DO NOTuse on surfaces such assheet steel that have a shiny,reflectivesurface.

Theshiny surfacecould reflectthe beamback at the operator°Be awarethat laser

light reflected off of a mirror or any other reflective surfaces can also bedangerous.

6. ALWAYSturn the laser beam offwhen not in use. Leavingthe toolonIncreasesthe

risk of someoneinadvertently staring Intothe laser'sbeam°

_CAUTION' ALWAYSfollow only the Instructions contained In this manua-(_

when usingthis laser,Useof this feature In anymanner otherthan whatappears

In this manualmay result In a hazardousradiation exposure,

7. DO NOTattemptto modify the performance ofthis laserdevice inany way.Thlsmay

resultina dangerousexposureto laser radiation.

SAFETY PRECAUTIONS FOR LASERS cont.

8. ALWAYSuse only the accessories that are recommended by Sears for use withthis

product°Use of accessories that havebeen designedfor use with other laser tools

could result in serious Injury.

9. For further Information regarding lasers, refer to ANSI-Z136.1 The STANDARD FOR

THE SAFEUSEOF LASERS,avaUabiefromthe LaserInstituteof America (407)380-1553.

WORK AREA SAFETY

1.Keep your work area clean and well lit.Clutteredworkbenchesanddarkareas

invite accldents.

2, DONOT operate powertools In explosiveatmospheres, such as In the presence

of flammable liquids, gases, or dust, Powertools createsparks whichmayIgnite

thedust orfumes_

3,Keep bystanders,children and visitors awaywhile operating a powertool,

Distractions can causeyouto losecontrol_

4. Make your workshop chlidproofwithpadlocksand master switches.Lock

tools awaywhen not inuse.

5, MAKESURE the work area hasample fighting so you can see the work and that

thereare no obstructionsthatwillinterferewithsafeoperationBEFORE usingyoursaw,

PERSONAL SAFETY

1_KNOWyourpower tool. Read theoperator'smanual carefully.Learnthesaw's

applicationsand limitations, aswellas the specificpotential hazardsrelated to this tool,

2. STAYALERT, watch whatyou are doing and use common sensewhen operating

a powertool

3oDO NOT usetool white tired or under the influenceof drugs,alcohol or medlcatlono

A moment ofinattentionwhiteoperatingpower toolsmay result insertouspersonalInjury,

4. DRESSproperly, DO NOT wearlooseclothing or Jewelry.PuUback tong hair.Keep

yourhair, clothing, and gloves away from moving parts.Air vents often cover moving

parts and shouldalso be avoided.Looseclothing,jewelryor long hair can becaught

Inmovlng parts.

5.AVOIDaccidentalstarting. Besure switchls in"OFF" positionbeforeplugging lm

DONOTcarry tools with yourfinger ontheswitch.Carrying tools withyourfinger on the

switchor plugging in toolsthat have the switchInthe "ON" position Invltesaccidents.

6.REMOVE adjustingkeys orwrenches before turning the tool "ON". A wrench

that Isleftattached to a rotatlng part of the tool may resultIn personalinjury,

7,Do not overreach.Keep proper footing and balance at all times. Properfooting

and balance snabresbetter control of thetoolinunexpected sJtcattons.

8oALWAYSSECUREYOURWORK. Usa clampsor a vise to hold work when practical.

It is saferthan usingyour hand and freesboth hands to operate tool.

9oUSE SAFETY EQUIPMENT.Always wear eye protection.Dustmask, non-skidsafety

shoes,hard hat, or hearing protection mustbe usedfor appropriate conditions°

t0. DO NOTUSE ON A LADDER or unstable support. Stable footingon asol]d surface

enables better control of the tool in unexpectedsituations.

5

TOOL USE AND CARE SAFETY

/_WARNING: BE SUREto read and understand all instructions before

operating this saw. Failureto follow all instructionslisted below may result in

1_ALWAYSuse clamps or other practicalways to secure and support the

workplece to a stable platform. Holdtngtheworkby handor againstyourbodyis

unstableand maylead tolossofcontrol

2oDO NOTforce the tool. Usethe correct tool andblade for your application.

The correcttool and blade willdothejobbetter and saferat the rate forwhichItis

deslgnedo

3. DO NOT use the tool If switchdoes not turn It "On" or "Off", Any toolthat cannot

be controlled with the switch tsdangerous and mustbe repaired°

4, DISCONNECTthe plug from the powersource before making any adjustments,

changing accessories or storing the tool, Such preventivesafetymeasures reduce

theriskofstartingthetoolaccidentally.

5. NEVER leave the tool running,ALWAYSturn tt off, DO NOT leave the tool untilIt

comesto a completestop.

6. STOREIdle tools out of the reach of children and other untrained persons.

Toolsare dangerous inthe handsof untrainedusers°

7. MAINTAINtoolswith care. Keepcutting toolssharp end clean,Properlymaintained

toolswithsharp cuttingedgesare less likelyto bindandare easiertocontrol

8.CHECK for mlsailgnmentor bindingof moving pads, breakage of pads, andany

otherconditionthatmay affectthe tool'soperation.If damaged, have thetoolserviced

beforeusing.Manyaccidentsare causedby poorlymaintainedtools.

g°USE ONLYaccessories that are recommended for this tool, Accessoriesthatmay

be suitable forone tool maybecome hazardous when usedon another tool.

10.KEEPblade guards In place and in good working order,

Jelectricshock,fire and/or serious personal injury.

ELECTRICAL SAFETY

_WARNING: Do not permit fingers to touch theterminals ofplug when

Installingor removingthe plugfrom the outlet,

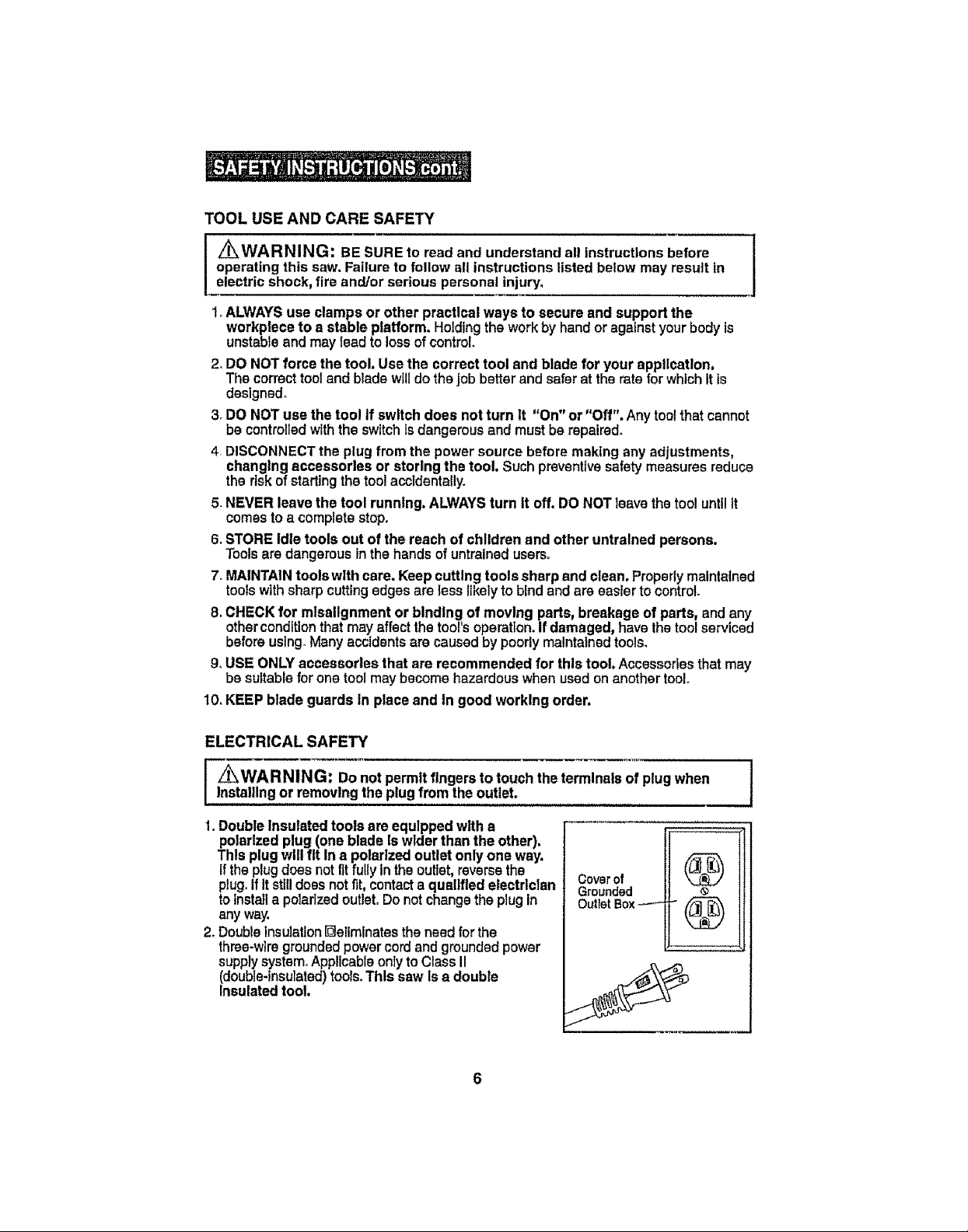

1.Double Insulated tools areequipped with a

polarizedplug (one blade Is wider than the other),

Thls plugwill fit In a polarized outlet only one way,

Ifthe plugdoes not fit fully inthe outlet,reversethe

plug.If Itstill doesnot fit, contacta qualifiedelectrician

to Installa polarizedoutlet. Do notchangethe plug in

anyway.

2.Doubleinsulation[]eliminates theneed forthe

three-wiregroundedpower cordend grounded power

supplysystem.Applicableonly to Class Ii

(double-insulated)tools. This saw Isa double

Insulated tool,

Cover of

Grounded

Outlet Box _ (_

ELECTRICAL SAFETY cont.

_WARNING: DoubleInsulationDOESNOTtake the placeof normalsafety

precautionswhen operating thistool.

3.BEFORE plugging in thetool,BE SUREthat the outlet voltage supplied tswlthin the

voltage marked on the tool's data plate. DO NOT use"AConly"rated toolswith a DC

powersupply°

4.AVOID body contactwith groundedsurfaces, suchas plpes,radiators,rangesand

refrigerators.There isan increasedrtskof electricshockifyourbody tsgrounded_

5,DO NOT expose powertools to rain orwet conditionsor use power tools In wet

or damplocetlons. WaterenteringapowertoolwfilIncreasethe riskof slectdcshock.

6. INSPECT tool cords for damage.Have damaged toolcords repalredat a Sears

ServiceCenter°BE SUREto stayconstantlyaware ofthecordlocation and keep itwell

away from the moving blade.

7.DONOT abuse the cord.NEVER usethe cord to carry the tool by or pull the plug

from the outlet.Keepcordawayfrom heat,otl,sharpedgesormoving parts°Replace

damagedcordsimmediately.Damagedcordsincreasethe riskofelectricshock_

EXTENSION CORDS

Usea proper extension cord. ONLYuse cordslisted by UnderwritersLaboratories(UL)_

Otherextensioncordscancausea dropin line voltage,resulting ina lossofpowerand

overheatingoftool.

Forthis tool an AWG (AmericanWire Gauge)size ofat least 14-gauge is recommended

for anextension cord of 25-ft.or lessinlength. Use 12-gauge for an extensioncord of

50-ft,Extension cords 100..ft,or longer are not recommended,Remember, a smaller

wire gauge size has greater capacity than a larger number(14-gaugewirehas more

capacitythan 16-gauge wire;12-gauge wirehas more capacitythan14-gauge)oWhen In

doubt usa the smaller number.

Whenoperatinga powertooloutdoors, usean outdoorextensioncordmarked"W-A" or

"W".These cords are ratedfor outdoor use andreduce the risk of electrlc shock.

Z_ CAUTION= Keep the extensioncord clearof the working area. Positionthe /

cordso that Itwill not get caught on the workplece,tools orother obstructions

whileyou areworklngwith a powertool,

Z_WARNING: Checkextensioncords before each use.if damaged replace ]

Immediately.Never usetool with a damagedcord since touchingthe damaged

areacould causeelectrical shock,resulting In seriousInjury.

J

J

SAFETYSYMBOLSFORYOURTOOL

Thelabelonyourtoolmay Include the following symbols.

V...............................................................................Volts

A..............................................................................Amps

Hz.............................................................................Hertz

W.............................................................................Watts

mln..........................................................................Minutes

.............................................................................Alternatingcurrant

............................................................................Directcurrent

no............................................................................No-loadspeed

[] .............................................................................ClassII construction,DoubleInsulated

.../mln.........................................................................Revolutionsor StroPsper minute

L_o............................................................................Indicatesdanger,warningorcaution.

It means attentlonl Yoursafetyis Involvedo

SERVICE SAFETY

1.If any part of thissaw Is missing or should break, bend,or fall In any way;

or shouldany electricalcomponent fall to perform properly;SHUT OFFthe power

switch and removethe saw plugfrom thepowersource and havethe missing.

damaged or failedpartsreplacedBEFORE resumingoperation.

2. Tool service must be performedonlyat a Sears Partsand Repair Center,Service

or maintenanceperformedbyunqualifiedpersonnelcouldresult In a riskof injury.

3. When servicing atool, use only Identical replacement parts. Follow Instructions

Inthe maintenance section of this manual. Useof unauthorizedpartsorfailureto

follow maintenanceInstructionsmay createa risk ofelectricshockor injury.

SAFETY RULES FOR THE MULTI-PURPOSE/PLUNGE ACTION

3-IN. CIRCULAR SAW

onthe trigger switchand the otherhandon the handle/motor housing.If both

I _ Keep hands awayfrom cuttingareaand blade. Keep one hand

handsare holding the saw, theblade cannotcut them.

[Z_ CAUTION: Bladescoast after saw Is switched off. ]

1, KEEPyour body positioned to either side of the sawblade and not in direct line

with the saw blade. Kickbackcouldcausethesawto jump backwards.

(See"Ktckback...What CausesItandWaystoHelpPreventIt"onpages1B.19 and20).

2.DO NOT reach underneath the workplece.The blade extendsbeneaththe

workplacewhencuttingandcouldcauseinjury.

base DONOT coverthe blade.The bladeIs below the lowerblade guardend base

l _r_j.-=J"_ When sawingthrough aworkplece,the lower bladeguard and

(Pagi_25).ALWAYSKeepyourhands andfingers awayfrom thecuttingarea.

CAUTION: This circularsaw DOESNOThave the standard RETRACTABLE

LOWERBLADE GUARDSystemfound on standard circularsaws. ONTHIS saw

the lowerblade guard Isan Integralpart of thesaw's base(cutting platform)and

ONLYenclosesthe blade when it Is ABOVE thebase.

8

SAFETY RULES FOR THE MULTI-PURPOSE / PLUNGE ACTION

3-IN. CIRCULAR SAW cont.

/_ CAUTION: When the blade Is plunged below the base to makethe cut,

the blade Is entirelyexposed underneath the workplace until It cuts through and

clearsthe workplece;at this point the blade guardand base wilt automatically

"DROP" downand lock the bladeABOVE the base,enclosing the blade Inthe

upperand lower bladeguard.

CAUTION: FAMILIARIZEYOURSELFWITHTHIS BLADE GUARDSYSTEM

and the PLUNGEACTION (loweringblade to desired depth) BEFORE USING

THIS SAW (See Page 18,Figs. 4 and 4e).

3_CHECK the Blade Guard Release Leverand the LowerBlade Guardand Base

BEFOREeach use, DO NOT OPERATE the saw if the }owerblade guard and base

does notmove freely and DROPDOWN INSTANTLY,and the bladeguard release

leverdoes net automatically engage the upperblade guard, AFTER cut Ismade

and blade c{earstheworkptece(See Page18 and 19).

Lower BladeGuard and Base in the raised positionexposingthe blade.This

would notallow the lower Blade Guard and BaseAssembly to function properly

I z_ CAUTION: Never clamp or tiethe BladeGuard Release Lever and the

after the cuttingoperation, Increasing the risk of serious personal Injury.

4.ONLYUSE themanual Blade Guard Release Lever to false the base, loweringthe

bladeto the desired depth-of-cut whenbeginning the cuttingoperatlon_

5_If the sawIsaccidentally dropped, theblade guard releaseleverand the lower blade

guard and base could be damaged or broken. Lower and raisethe blade manually

(seepage 18, Figs.4 and 4a) to be sure the release lever,guard andbase all operate

properly.

6otf the BladeGuardRelease Leveror LowerBlade Guard and Baseor anyother part of

the saw isnot operating properly,thesaw MUST BEserviced before use.

7.ALWAYSmake sure that the LowerBlade Guardand Basets covering the blade, and

the Blade GuardRelease Leverhas engaged and lockedthe blade ABOVE the base

BEFOREplacingthe saw down on a workbenchor floor,

Placingthe sawdown beforethe lower blade guard andbase andblade guard release

leverhaveproperly closed and lockedcould leavethe blade exposed below thebase,

Increasingthe riskof seriouspersonal Injury. Make noteof the timeIt takes for the

blade to stopsplnnlng and the guard, base and release leverto dropand lockintothe

guarded position,

8.NEVER holdthe piece being cut Inyour hands or across yourlegs, It isimportantto

support theworkplace propedy tnorder to minimizebody exposure, bladebinding, or

loss of control

9-HOLDTOOL by Insulatedgripping surfaces (handle/saw's body)when performing an

operationwherethe cutting tool may contact hidden wiring orIts own cord.Contactwith

a "llve" wire wLllmake the exposed metalparts of thetool "live"and shockthe operator.

SAFETY RULES FOR THE MULTI-PURPOSE /PLUNGE ACTION

3-IN. CIRCULAR SAW cont.

10rALWAYSclampthe workplece securelyso It will not move whenmaking the cut.

11oWhen ripping, ALWAYSUSE arip fence orstraight edge guide.This Improves

the accuracy of the cut andreducesthe chance of the blade binding.

saw; correct size,shape and arbor hole. Other blades could runerratically and

[ WARNING: ONLY USEthe blades that are designated for use with this

cause loss of control, resulting In serious Injury (see pages 16 and 17).

12,NEVER use damagedor Incorrectblade washersor bolts. The bladewashers

and bolts were specially designed for yoursaw,for optimumperformance and

safety of operation,

13_ONLYUSE the designatedblades for cuffing the type of material forwhichthey

are recommended. Cutting materialsthat are NOTrecommended could cause

blade breakage and lossof control,resulting In serious Injury,

14,NEVER cut more than one pieceat a time. DO NOT STACKmore than one

workplece on the worktable at a time.

15,AVOIDawkward operations and hand positions where a suddenslip could

cause your hand to moveinto the blade.

16.NEVER reach Into the cutting pathof the blade.

/_ WARNING: Some dust created by using power tools contains chemicals

known to the State of California to cause cancer and birth defects or other

reproductive harm_Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products_

• Arsenic and chromium, from chemically treated lumber.

Your risk from these exposures varies, depending upon how often you do this

type of work.To reduce your exposure to these chemicals:

• Work in a well-ventilatedarea°

,,Work with approved safety equipment,such as those dust masks thatare specially

designed tofilter out microscopic particles..

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling

and other construction activities.Wear protective clothing and wash exposed

areas with soap and water.

Allowing dust to get tntoyour mouth, eyes, or lay on the skin may promote absorption of

harmful chemicals.

Z_ WARNING: Use of this tool can generate and/or disburse dust, which may

cause serious and permanent respiratory or other Injury. Always use NIOSH/OSHA

approved respiratory protection appropriate for the dust exposure. Direct particles

away from face and body.

I0

ADDITIONAL RULES FOR SAFE OPERATION

Z_ WARNING: BE SURE to read and understand all instructions, Failure to

follow all instructions listed below may result in electric shock, fire and!or serious

personal injury,

1. Know your power tool. Read operator's manual carefutlyo Learn the applications

and limitations, as well as the specific potential hazards related to this tool Following

this rule wilt reduce the risk of electric shock, fire or serious injuryr

2 ALWAYS wear safety glasses or eye shields when using this saw, Everyday

eyeglasses have only impact-resistant lenses; they are NOT safety glasses

3, PROTECT your lungs. Wear a face mask or dust mask ifthe operation is dusty

4, PROTECT your hearing. Wear appropriate personal hearing protection during use,

Under some conditions noise from this product may contribute to hearing loss.

5. ALL VISITORS AND BYSTANDERS MUST wear the same safety equipment that the

operator of the saw wears

6 INSPECT the tool cords periodically and if damaged have them repaired at your

nearest Sears Service Center. BE AWARE of the cord location,

7 ALWAYS check the tool for damaged parts. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine if it will operate

properly and perform itsintended function.Check for misalignment or binding of

moving parts, breakage of parts, and any other condition that may affect the tool's

operation. A guard or other part that is damaged should be properly repaired or

replaced at a Sears Service Center_

8. INSPECT and remove all nails from workpiece before sawing.

9, SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to instruct

others who may use thls tool. tf someone borrows this tool, make sure they have

these instructions also,

Spindle

The shaft on which a blade or cutting tool is mounted Also cailed the Arbor

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in one minute.

Saw Blade Path

The area over, under, behind or in front of lhe blade, as itapplies to the workpiece,

That area which will be or has been cut by the blade

Set

The distance that the saw blade tooth is bent (or set) outward from the face of the blade

Plunge Cutting

A cutting operation in the middle or interior of a workpiece, where the blade is lowered

down into the workpiece to make a pocket cut,,

Miter Cut

A cutting operation made with the blade at any angle other than 90° to the fence.

11

Compound Miter Cut

A compound miter cut is a cut made using a miter angle and a bevel angle at the same

time.

Cross Cut

A cutting or shaping operation made across the grain of the work piece°

Bevel Cut

A cutting operation made with the blade at any angie other than 90° to the miter table.

Dado Cut

A non-through cut wllich produces a square-sided notch or trough in the workpiece

(requires special blade).

Chamfer Cut

A cut removing a wedge from a block of wood so the end (or part of the end) is angled at

other than 90 °.

Ripping or Rip Cut

A cutting operation along the lengthof the workpiece,or cutting along the grain.

Freehand Cut

Performing a cut without using a fence, miter gauge, fixture, work clamp, or other proper

device to keep the workpiece from twisting or moving during the cut

Through Sawing

Any cutting operation where the blade extends completely through the thickness of the

workpiece.

Non-Through Cuts

Any cutting operation where the b_ade does not extend completely through the thickness

of the workpiece, like a dado cut.

Leading End (or Edge)

The end (edge) of the workpiece that the blade entersfirst

Kerr

The material removed by the blade in a through cut or the siot produced by the blade in

a non-through or partial cuL

Kickback

A hazard that can occur when the blade binds or stalls, throwing the saw back toward

operator_

Workptece or Material

The item on which the cutting operation is being done The surfaces of a workpiece are

commonly referred to as faces, ends and edges.

Gum

A sticky, sap-based residue from wood products.

Resin

A sticky, sap-based substance that has hardened.

12

Z_ WARNING: Yoursaw should NEVERbe connected to the powersoume

when you are assembling pads, maldngadjustments,Installingor removing

blades,cleaning or when It isnot In use.Disconnectingthe sawwill prevent

accidentalstarting, which could causeseriouspersonal Injury.

I. Remove theSaw from the case and JnspectIt carefully to makesurethat no breakage

or damage has occurred duringshlpplngo

2.There Is a blade storage area inthe case wherea General Purpose Blade islocated

with "PwoHexWrenches used forinstalling or changing blades,Inspect the blade

carefullyto make sure that no breakage,crackingor other damage has occurred,

3oThe EdgeGuide is force-fitted into thetop of the lidof the Storage/Carrying Case,

4,The Non-Scratch Base Cover Is force_fittedIntothe top lid of the case_

5oThsVac Hose Adapter is force-fittedIntothebottom of thecase.

6.If any oftheparts aredamaged ormissfng (refer to PARTSLIST below), return

thesaw toyour nearest Sears store or Craftsmanoutlet to havethe sawreplacedo

L_ WARNING: If any partsare mlsslng,DONOT operatethis saw unt, the

missing parts are replaced. Failure todo socould resultIn possibleserious

personalInjury.

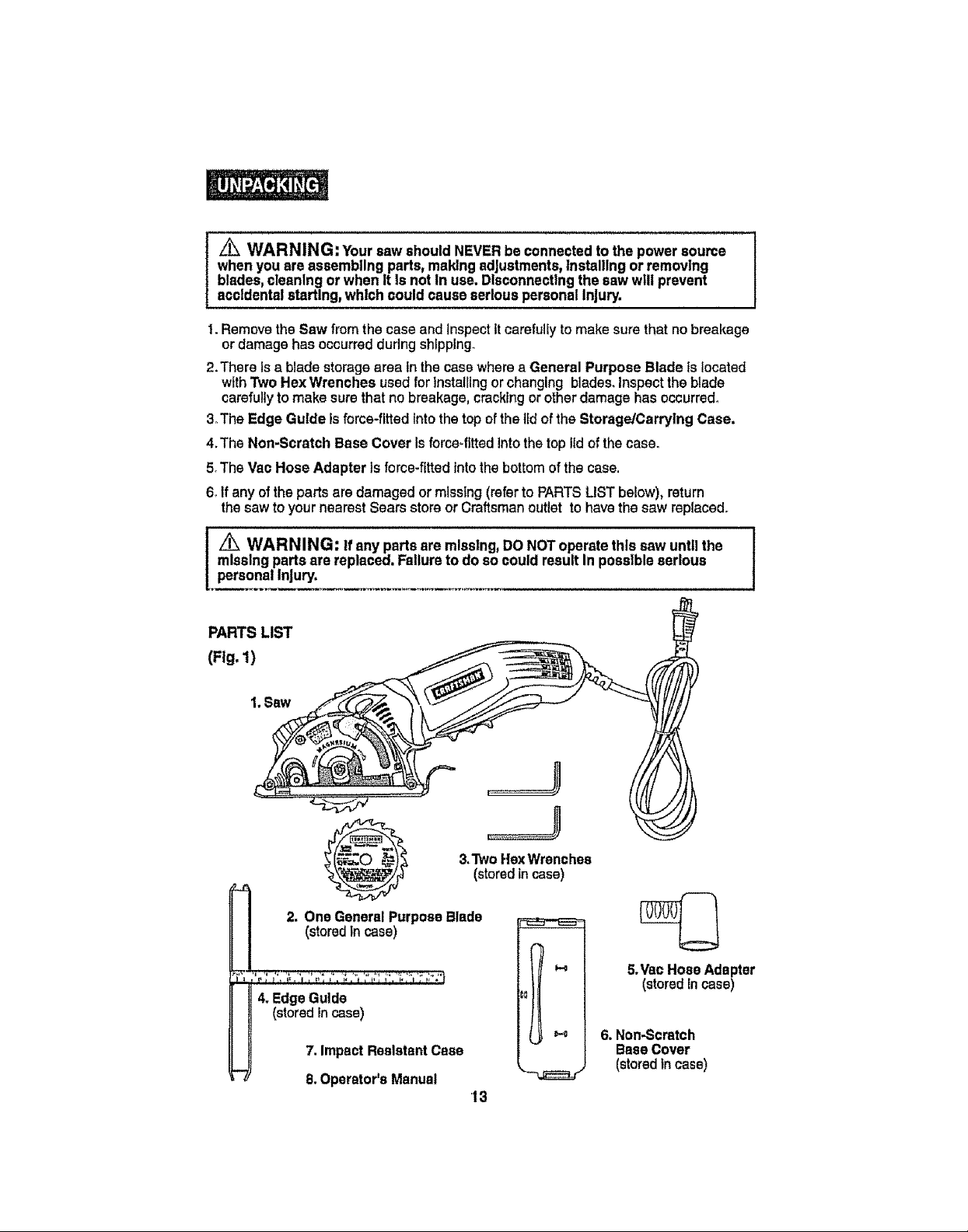

PARTS LIST

(Fig. 1)

1.Saw

J

7. ImpactResistantCase

8,Operator'sManual "-'-_r

13

5.Vae HoseAdapter

(stored incase)

6. Non-Scratch

Base Cover

(stored incase)

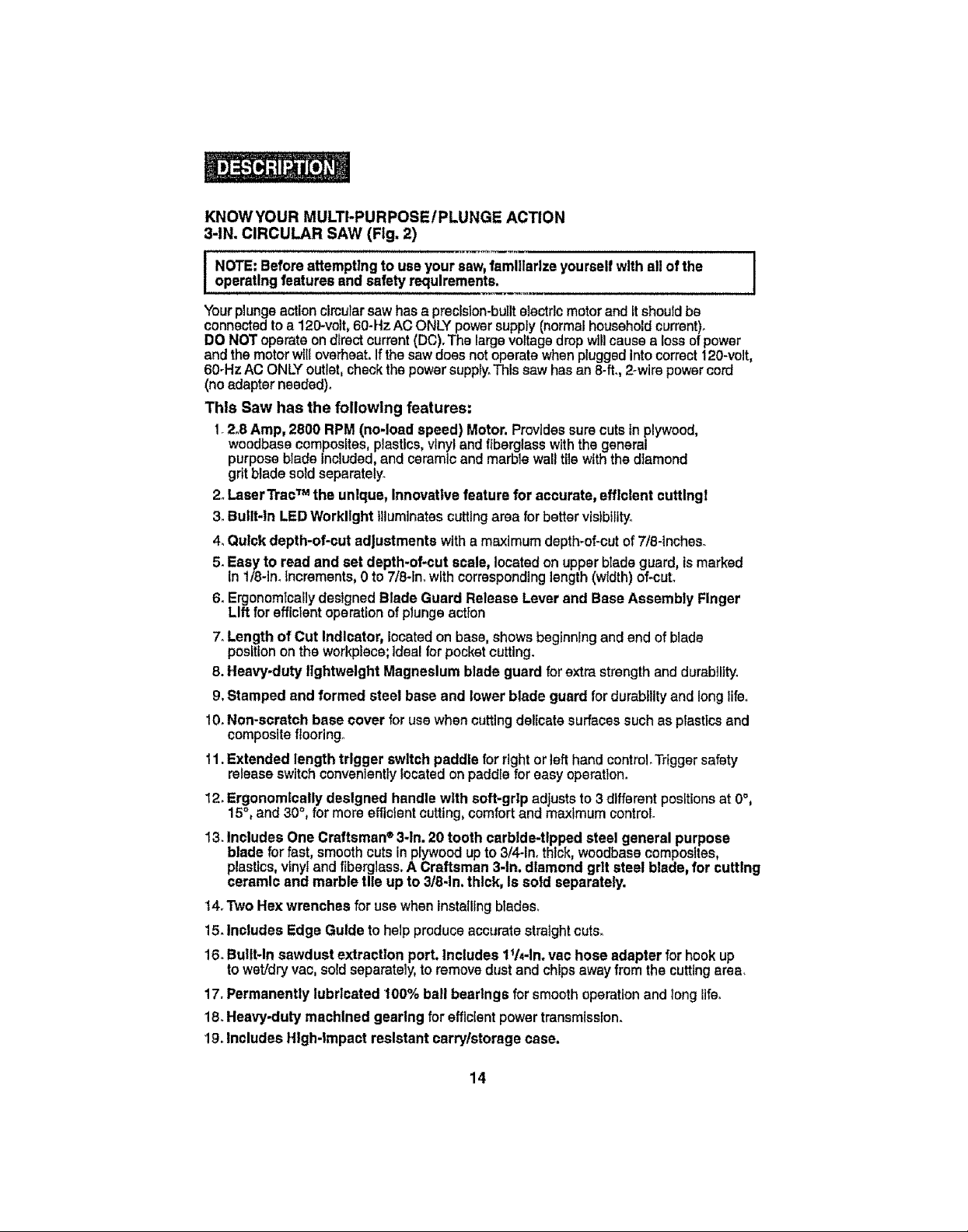

KNOWYOUR MULTI-PURPOSE/PLUNGE ACTION

3-IN. CIRCULAR SAW (Fig. 2)

l NOTE:Beforeattemptingto useyour saw_familiarizeyourselfwith allof the

operatingfeatures and safetyrequirements,

Yourplunge actioncircularsawhasa precision-builtelectricmotorand Itshouldbe

connectedto a 120-volt,60-Hz ACONLY power supply(normalhouseholdcurrent).

DO NOToperate ondirect current (DC).The largevoltage drop willcause a lossof power

and the motorwill overheat.Ifthe sawdoes notoperate whenpluggedintocorrect 120-volt,

60*HzAC ONLYoutlet, checkthe powersuppiyoThis saw hasan 8-ft., 2*wirepowercord

(no adapter needed).

This Saw has the following features:

1.2.8 Amp, 2800 RPM(no-load speed) Motor. Provtdessurecuts fnplywood,

woodbase composites,plastics,vinyl andfiberglass withthe general

purpose blade Included, and ceramicand marblewalt tile withthediamond

grit blade soid separately_

2. LaserTracTM the unique, Innovativefeature for accurate,efficient cuttlngl

3. Built-in LEDWorkllghtilluminatescuttingarea forbetter vistbitityo

4. Quick depth-of-cut adjustments witha maximumdepth-of-cut of7/8-inches.

5. Easy to read and setdepth-of-cut scale, located onupper btadeguard, ismarked

in 1/8-in.increments,0 to7/8-In.withcorrespondinglength(width)of-cuL

6. ErgonomtcallydesignedBlade Guard Release Lever and BaseAssembly Finger

Lift forefficient operation of plunge action

7. Length of Cut Indicator, located onbass, shows beginningand end of blade

position onthe workpleca; idea!forpocket cutting.

8. Heavy-dutyllghtwelght Magnesium blade guardfor extra strength and durability.

9, Stamped and formed steel base and lower blade guard fordurability and longlife.

10,Non-scratch base cover for use when cutting delicatesurfaces such as plastics and

composite flooring.

11.Extendedlength trigger switchpaddle forright or lefthand control,Triggersafety

releaseswitch convenlentlylocated on paddle for easyoperation.

12. Ergonomlcallydesigned handlewith soft-grlpadjusts to3 different positions at 0°,

15°,and 30°, for more efficientcutting,comfortandmaximum control.

13. IncludesOne Craftsman®3-In. 20 tooth carbide-tippedsteel general purpose

bladefor fast, smoothcutsin plywoodupto3/4-1n,thick,woodbasecomposites,

plastics,vinyland ftberglass.A Craftsman3-In. diamond grlt steel blade,for cutting

ceramic and marbletile up to 3/8-1n.thick, Issold separately.

_4.Two Hexwrenches for use when Installingblades_

15.Includes Edge Guidetohelp produceaccuratestraightcuts.

16. Bullt-lnsawdust extraction port. Includes lib-In, vac hose adapter forhookup

towet/dryvac, soldseparately,to removedustand chipsawayfrom thecuttingarea,

17.Permanently lubricated 100% ball bearings for smoothoperationand longlife.

18.Heavy-duty machined gearlng for efficient powertransmission.

lg. Includes High-Impact resistant carry/storage case.

14

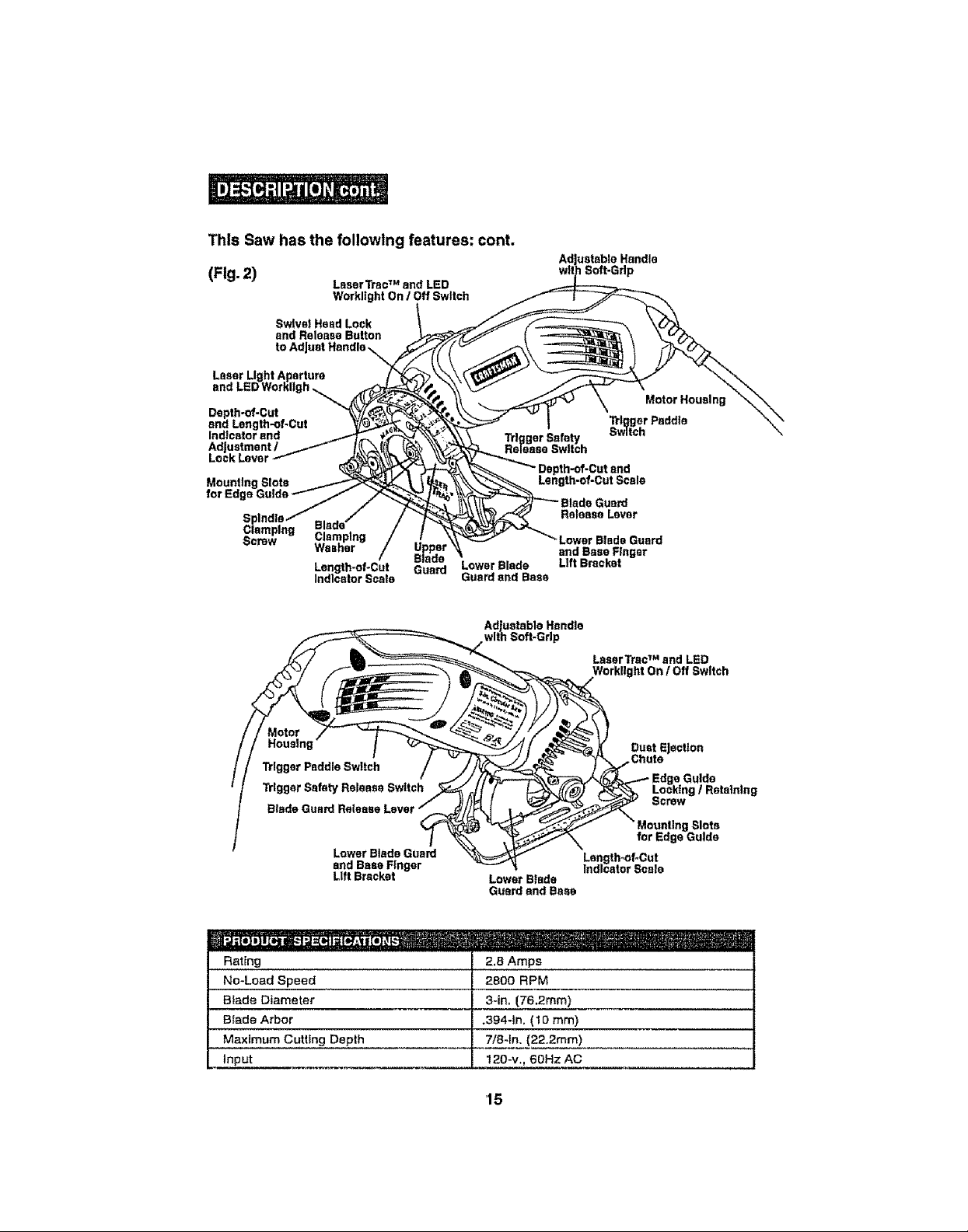

This Saw has the following features: cont.

(Fig.2)

Laser Light Aperture

and LEDWorkllgh

Depth-of-Cut

and Length-of-Cut

Indicator and

Adjustment /

Lock Lever

for Edg_

iplng

Screw Clamping

Laser Tta¢TM and LED

Workllght On / Off Switch

Washer Upper

Length-of-Cut Guard

Indicator Scale

Blade

Lower Blade

Guard sod Base

Adjustable Handle

with Soft-Grip

uetsble Handle

Soft-Grip

" Lower Blade Guard

and Base Finger

Lift Bracket

LaserTrac TM and LED

Workllght On / Off Switch

Motor

Housing

"l_lggerPaddle Switch

Blade Guard Release

Lower Blade Guard

and Base Finger

Lift Bracket

Rating

No-Load Speed

Biade Diameter

Blade Arbor

Maximum Cutting Depth

Input

Lower Blade

Guard and Base

2.8 Amps

2800 RPM

3-in, (76,2mm)

.3g4-1n. (1o ram)

7/8-1n. (22.2mm)

120-v., 60Hz AC

'15

Dust Ejection

,Chute

Mounting Slots

for Edge Gulde

Length_of*Cut

Indicator Scale

a Guide

I / Retaining

_WARNING: Never use a damaged or Incorrect blade washer or bolt.The

blade washer and bolt were specially designed for your saw,for optimum

performance and safe operation.A 3-Inch blade Isthe maximumblade capacity

of your saw. A largerthan 3-Inchblade will come Incontact with the blade

guard.Also, NEVERuse a bladethat Is so thick that it preventsthe outer blade

washer fromengaging with the flat side of the spindle. Bladesthat are toolarge

or toothick can result In an accident causing serious Injury.

,,,,,,,,,,,, ,, ,,,,, ,i,

_WARNING: ONLY USE the saw blades designated for use with this saw.

Using anyother blade could result Inan accident causing serious Injury.See

page 17for designatedblades andrecommended uses.

_WARNING: Only use the Craftsman ®3-In. 20 tooth carbide-tipped steel

general purpose blade (9-61272 Included), to cut wood, plywood up to _-ln.

thick, woodbase composites, plastics, vinyl and fiberglass. A Craftsman 3-In.

diamond grit steel blade (9-61273 sold separately) Is for cutting ceramic and

marble tile up to 3/8-1n. thlck (See Fig. 3b).

SAW BLADES

All saw blades need to be keptclean, sharp andproperlysetin orderto cutefficiently.

Using a dull blade places a heavyload onthe saw and Increases the danger of kickback.

Keepextra bladeson hand,so sharp blades are alwaysavaiIable_Gum and wood pitch

hardened on the blade slows the saw down, Use gum and pitch remover,hotwater or

kerosene to removethem, DO NOT use gasotlne_

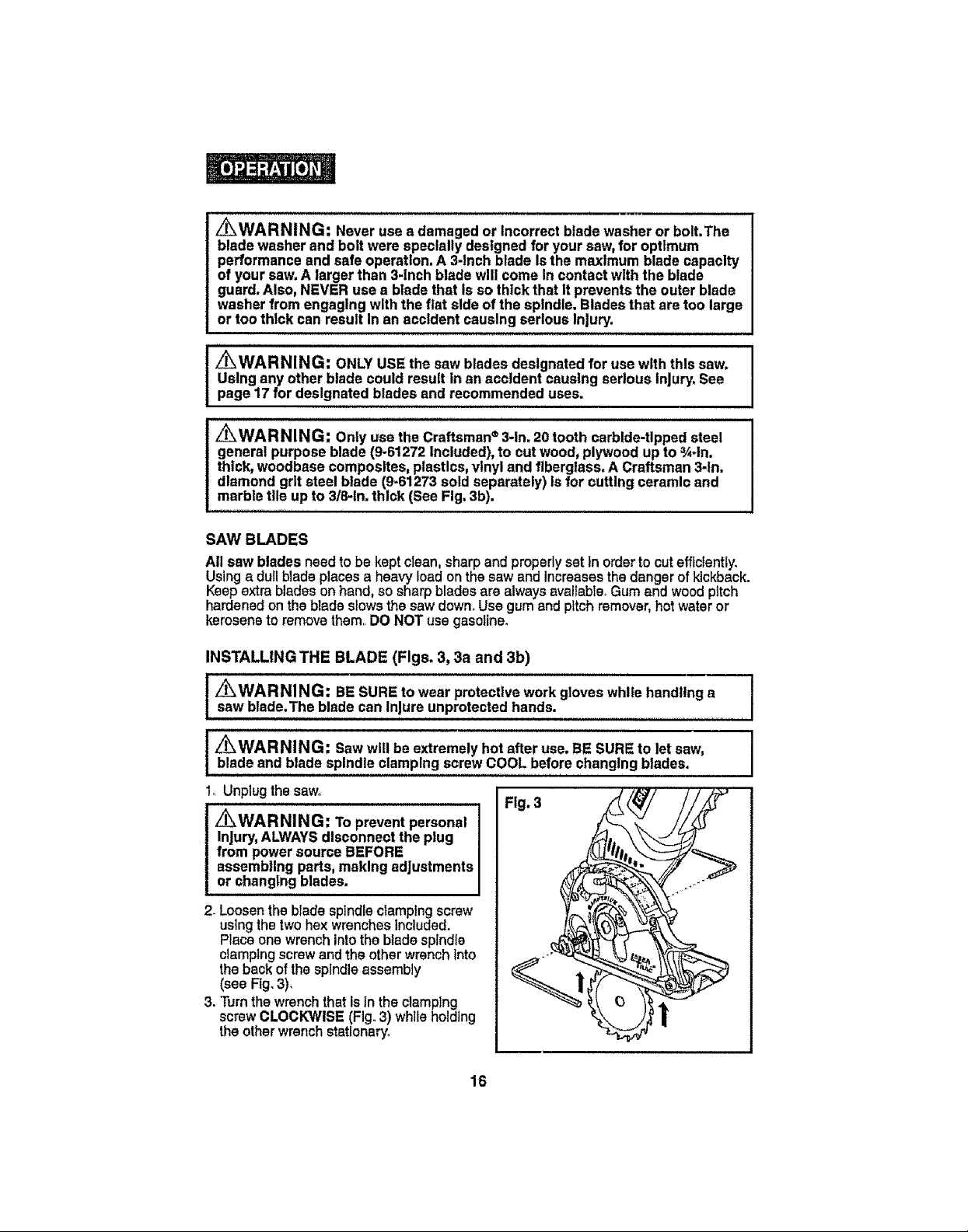

INSTALLING THE BLADE (Figs. 3, 3a and 3b)

,/_WARNING: BE SURE to wear protective work gloves while handling a

saw blade.The blade can Injure unprotectedhands.

L_WARNING: SawwiUbe extremely hot after use. BE SUREto let saw,

blade and blade spindle clamping screw COOL beforechanging blades.

,= ,, = ,= ,,,,,,l, ,,,,,,,,,,,,,,,,,, ,,,, ,, , ,

1oUnplugthesaw.

Fig. 3

z_WARNING: Topreventpersonal

Injury,ALWAYSdisconnect the plug

from powersource BEFORE

assembling parts,making adjustments

or changingblades.

2. Loosenthe blade spindle clampingscrew

usingthe two hex wrenches Included.

Place one wrench intothe bladespindle

clamping screw and the other wrench Into

the back of thespindle assembly

(see Fig.3),

3. Turnthe wrench that Isfn the clamping

screw CLOCKWISE (Fig.3) while holding

the otherwrench stationary.

16

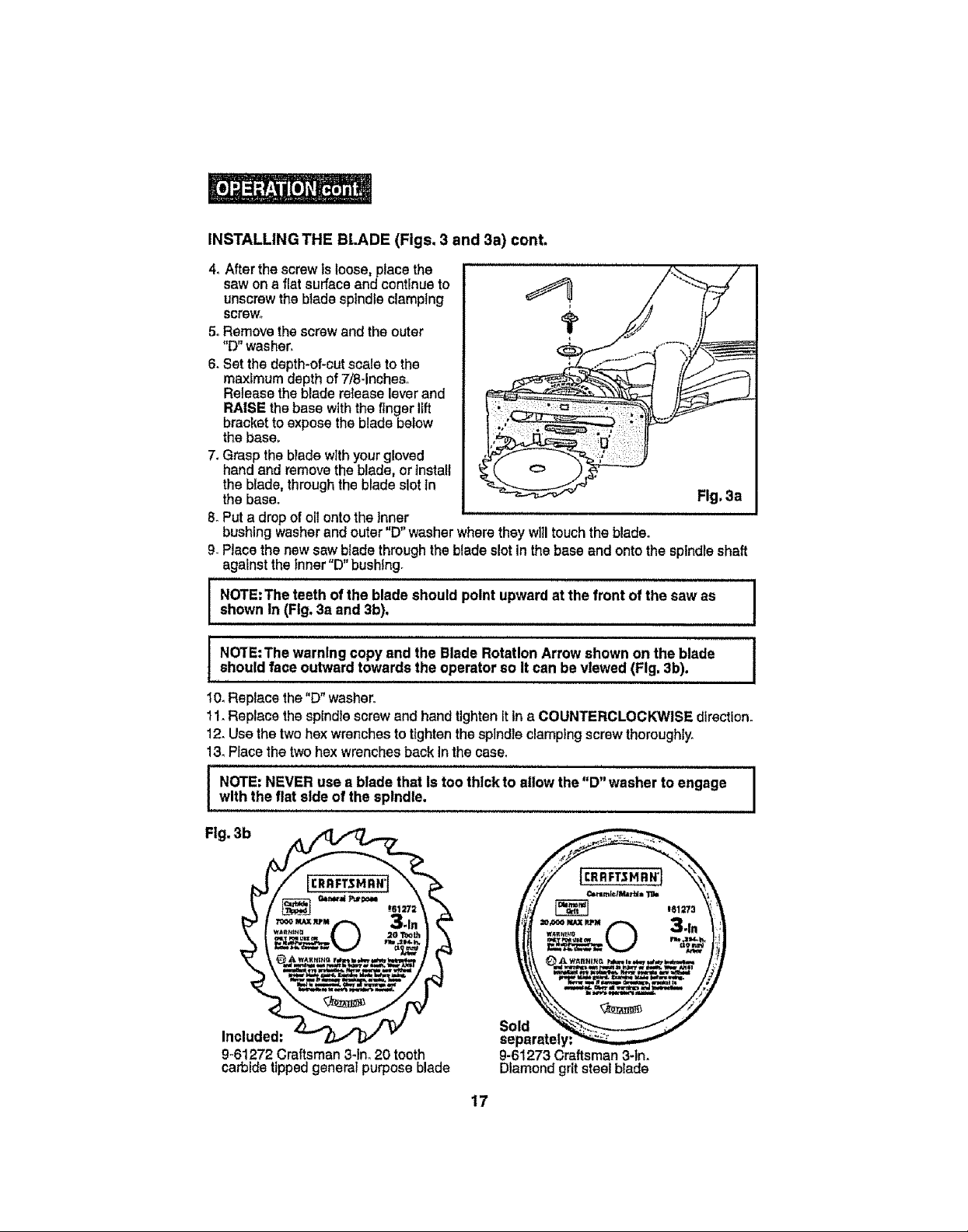

INSTALLINGTHEBLADE(Figs,3and3a)conL

4. After the screw ts loose, place the

saw on s fiat surfaceand continueto

unscrewthe blade spindle clamping

screv_,

5oRemovethescrew and the outer

"D"washer.

6. Setthe depth-of-cut scale to the

maximum depth of 7!8-incheso

Releasethe blade releaselever and

RAISEthe basewith the finger lift

bracketto expose the blade below

the base.

7. Graspthe blade with your gloved

hand and removethe blade, or install

the blade,throughtheblade slot tn

thebase. Fig. 3a

8. Puta drop of oilonto the Inner

bushing washerand outer"D" washer where they will touch the blade°

9. Placethe new sawblade through the blade slot inthe base and onto the spindle shaft

against the Inner"D" bushtng.

NOTE:The teeth ofthe bladeshould point upward at the front of the sawas

shown In (Fig, 3a and 3b).

NOTE:The warning copy and the Blade Rotation Arrow shown onthe blade

shouldface outwardtowards the operator so It can be viewed (Fig. 3b).

i, u, ,, ,

10.Replace the "D" washer.

11.Replace the spindle screwand hand tightenit ina COUNTERCLOCKWISEdirection.

12.Usethe two hexwrenches to tlghtenthe spindle clamptngscrew thoroughly.

13.PEacethe twohex wrenches back in the case.

I NOTE:NEVER use s bladethat Istoo thick to allowthe "D" washer to engage

with the flat side of the spindle,

Fig. 3b

Included:

9-61272 Craftsman 3-In. 20 tooth

carbide tipped general purpose blade

Sold

separately

9-61273 Craftsman 3-1n.

Diamond grit steelblade

17

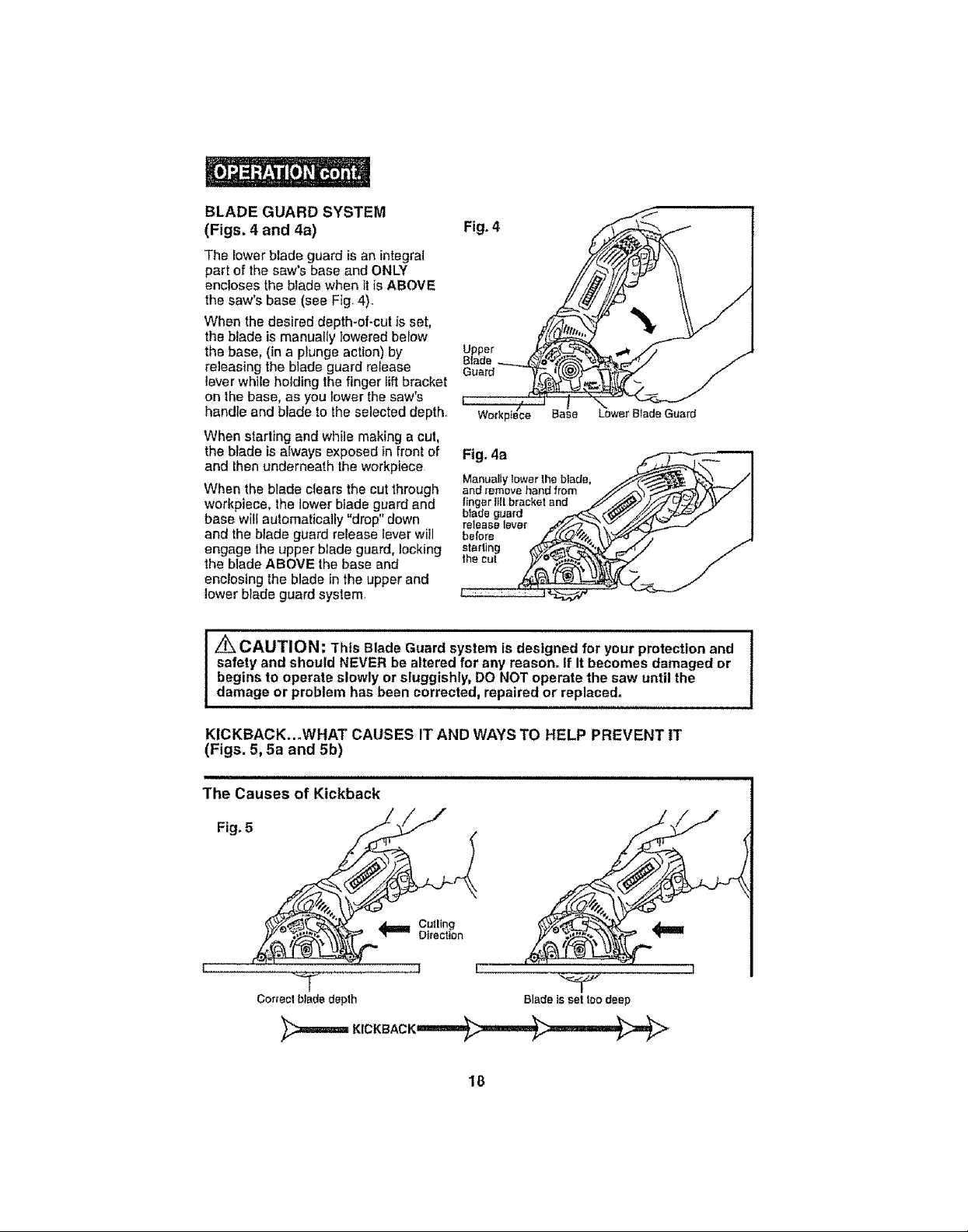

BLADE GUARD SYSTEM

(Figs. 4 and 4a)

The iower blade guard isan integral

part of the saw's base and ONLY

encloses the blade when itis ABOVE

the saw's base (see Fig_4)_

When the desired depth-of-cut is set,

the blade is manually lowered berow

the base, (in a plunge action) by

releasing the blade guard release

lever wh]ie holding the finger lift bracket

on the base, as you lower the saw's

handle and blade to the selected depth,

When starling and while making a cut,

the blade is always exposed in front of

and then underneath the workpiece

When the blade clears the cut through

workpiece, the lower blade guard and

base will automatically "drop" down

and the blade guard release lever will

engage the upper blade guard, locking

the blade ABOVE the base and

enclosing the blade in the upper and

lower blade guard system,

Fig. 4

Upper

Blade

Guard

Fig. 4a

Manually lower the blade,

and remove hand from

fing t and

blade guard

release lever

before

starlin;

the cu!

Z_ CAUTION: 1"his Blade Guard system is designed for your protection and

safety and should NEVER be altered for any reason, If It becomes damaged or

begins to operate slowly or sluggishly, DO NOT operate the saw until the

damage or problem has been corrected, repaired or replaced°

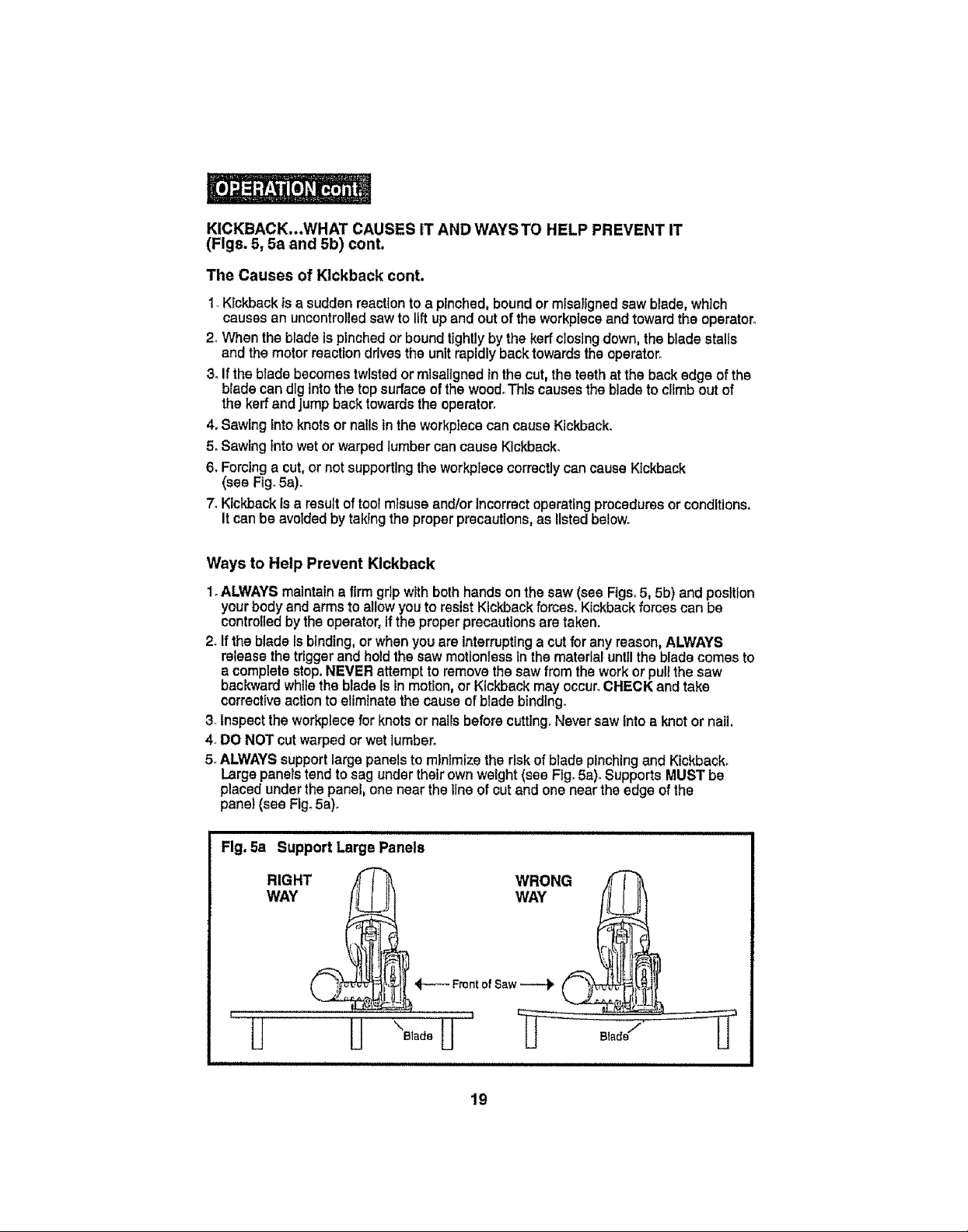

KICKBACK..°WHAT CAUSES IT AND WAYS TO HELP PREVENT IT

(Figs. 5, 5a and 5b)

The Causes of Kickback

Fig, 5 _f_

! |

"_t"-=" Direction

T

Cor_ec!b_ededeplh

18

BladeissetIoodeep

1

KICKBACK..WHAT CAUSES IT AND WAYS TO HELP PREVENT IT

(Figs. 5, 5a and 5b) cont.

The Causes of Kickback cont.

1+KickbackIs asudden reactionto a pinched, bound or mtsalignedsawblade, which

causes an uncontrolled saw to lift up and outof the workplace andtoward the operator_

2. When the bladeispinchedor bound tightlyby the kerrcioslng down, the bladestalls

and the motor reaction ddves the unit rapidly backtowards the operator_

3. If the blade becomes twisted or misaltgnedin the cut, the teethat the backedge of the

btade candig intothe topsurface of the wood+Thiscauses the blade to climb out of

the kerf and Jumpback towardsthe operator,

4. Sawingintoknots ornails inthe workplace can causeKickback,

5, Sawingintowet or warped lumbercan cause Kickback.

6, Forcing a cut, ornot supporting the workplace correctlycan cause Kickback

(see Fig°5a).

7. Kickback Isa result of tool misuse and/or incorrectoperatingprocedures or conditions.

It canbe avoidedby taking the proper precautions, as listed below.

Ways to Help Prevent Kickback

1.ALWAYSmaintain afirm gdp withboth hands onthe saw (see Figs.5, 5b) andposition

yourbody and armsto allowyou to resistKickbackforces. Kickbackforces canbe

controlledbythe operator,ifthe properprecautionsaretaken.

2+Ifthe bladeis binding,or whenyouare interruptinga cutfor anyreason,ALWAYS

releasethetriggerand holdthe saw motionless Inthe materialuntil the blade comesto

a complete stop.NEVER attempt to removethe sawfrom thework orpull the saw

backwardwhile the blade is inmotion, orKickback mayoccur.CHECK and take

corrective actionto eliminatethe causeof blade binding.

3. Inspectthe workplece for knots or nails beforecuttlng°Neversaw into a knotor nail.

4+DO NOT cut warped or wet lumber+

5+ALWAYSsupport large panelsto mlnlmize the risk of bladepinchingand Kickback,

Large panels tend to sag undertheirown weight(see Fig. 5a)°SupportsMUST be

placed under the panel, one near the line of cut andone nearthe edge of the

panel (see Fig.5a)°

Rg. 5a Support Large Panels

I ,

H

lJ "o,+U u ,o°Ju

19

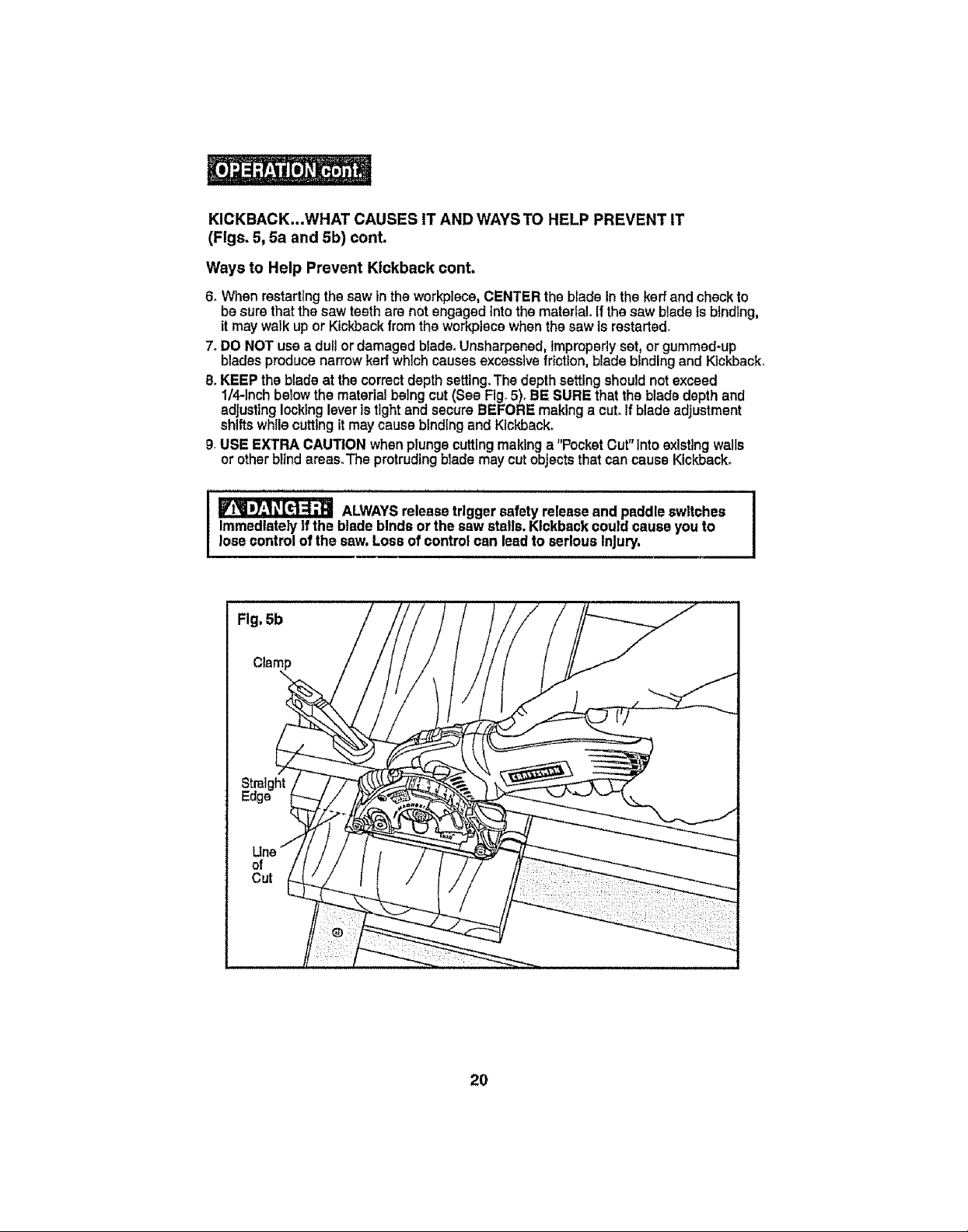

KICKBACK...WHAT CAUSES IT AND WAYS TO HELP PREVENT IT

(Figs. 5, 5a and 5b) cont.

Ways to Help Prevent Kickback cont.

6. When restartingthe sawinthe workplece, CENTERthe blade Inthe keff andcheckto

be sure thatthe saw teeth arenot engagedInto the material. If thesaw blade is binding,

itmaywalk up or Kickback from the workplece whenthe saw is restarted_

7oDO NOTuse a dull ordamaged bladeoUnsharpened, Improperlyset, or gummed-up

bladesproduce narrow kerr which causes excessivefriction, blade btndlng and Kickback.

8.KEEP the blade at the correct depthsetting. Thedepth setting should not exceed

1/4-Inchbelowthe material being cut (See Fig. 5). BE SURE that the bladedepth and

adjusting locking leveris tight and secure BEFOREmaklng a cut. If bladeadjustment

shiftswhilecuttingitmaycause binding and Kickback.

9.USE E,I_TRACAUTION when plunge cutting makinga "PocketCut"Intoexisting walls

or ether bitndareas.The protruding blademay cut objects thatcan cause Kickback.

Immediatelyifthe blade bindsor the saw stalls,Kickbackcould cause you to

_ ALWAYSreleasetrigger safetyreleaseand paddleswitches

lose control ofthe saw.Loss ofcontrolcan leadto serious Injury,

Fig, 5b

20

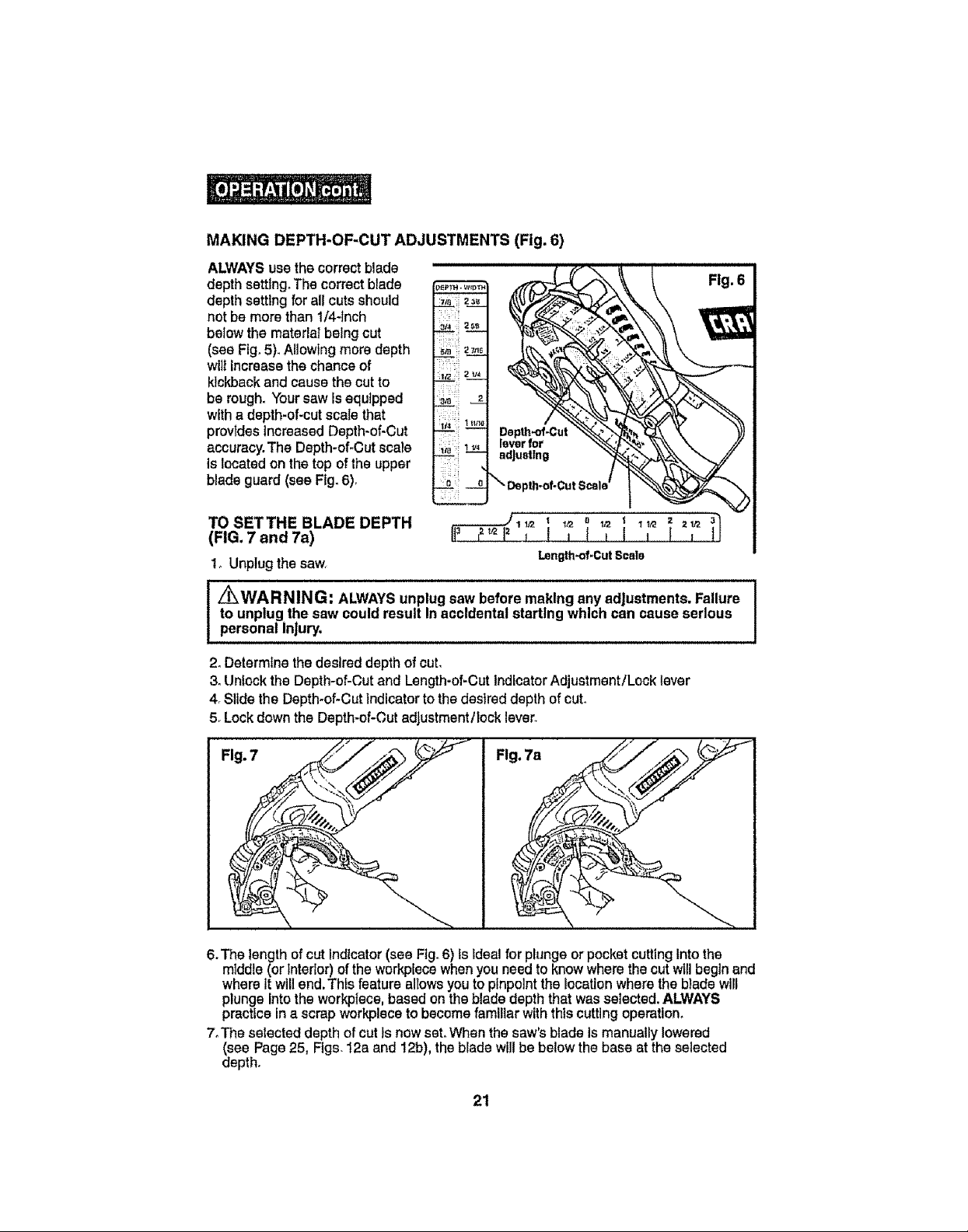

MAKINGDEPTH-OF-CUTADJUSTMENTS(Fig.6)

ALWAYSuse the correct blade

depthsetting. The correct blade

depthsetting forall cutsshould

not be more than 1/4-Inch

belowthe material being cut

(see Fig.5). Allowing more depth

wilt increase the chance of

kickbackand causethe cut to

be rough. Yoursaw isequipped

with a depth-of-cut scale that

provtdesincreasedDepth-of-Cut

accuracy.The Depth-of*Cutscale

Islocated onthetop ofthe upper

blade guard (see Fig.6).

TO SETTHE BLADE DEPTH

(FIG. 7 and 7a)

1o Unplug the saw Length-of.CutScald

to unplug the saw could result Inaccidental starting which can cause serious

[ _WARNING: ALWAYSunplug saw before making any adjustments. Failure

personal injury.

2. Determine the desired depthof cut,

3. Unlockthe Depth-of-Cutand Length-of-CutIndicatorAdjustment/Lock lever

4. Slide the Depth-of-Cutindicatorto the deslred depth ofcut.

5. Lock downthe Depth-of-Cut adjustment/lock lever.

Fig, 7

(,

6.The length ofcut indicator(see Fig. 6)ts idealfor plungeor pocketcutting Into the

m]ddle(orinterior) oftheworkpfecewhenyouneedto knowwherethecutwillbegin and

whereit willend.This feature allows youto pinpointthe locationwheretheblade will

plungeInto theworkplace,based ontheblade depththat wasselected.ALWAYS

practiceina scrap workplaceto becomefamiliarwiththis cuttingoperation.

7_The selecteddepth of cut isnowset.When thesaw'sblade ismanually lowered

dSeePage 25, Figs.t2a and 12b),the blade will be below the base at the selected

epth.

Fig. 7a

, t , I , t , H

l

21

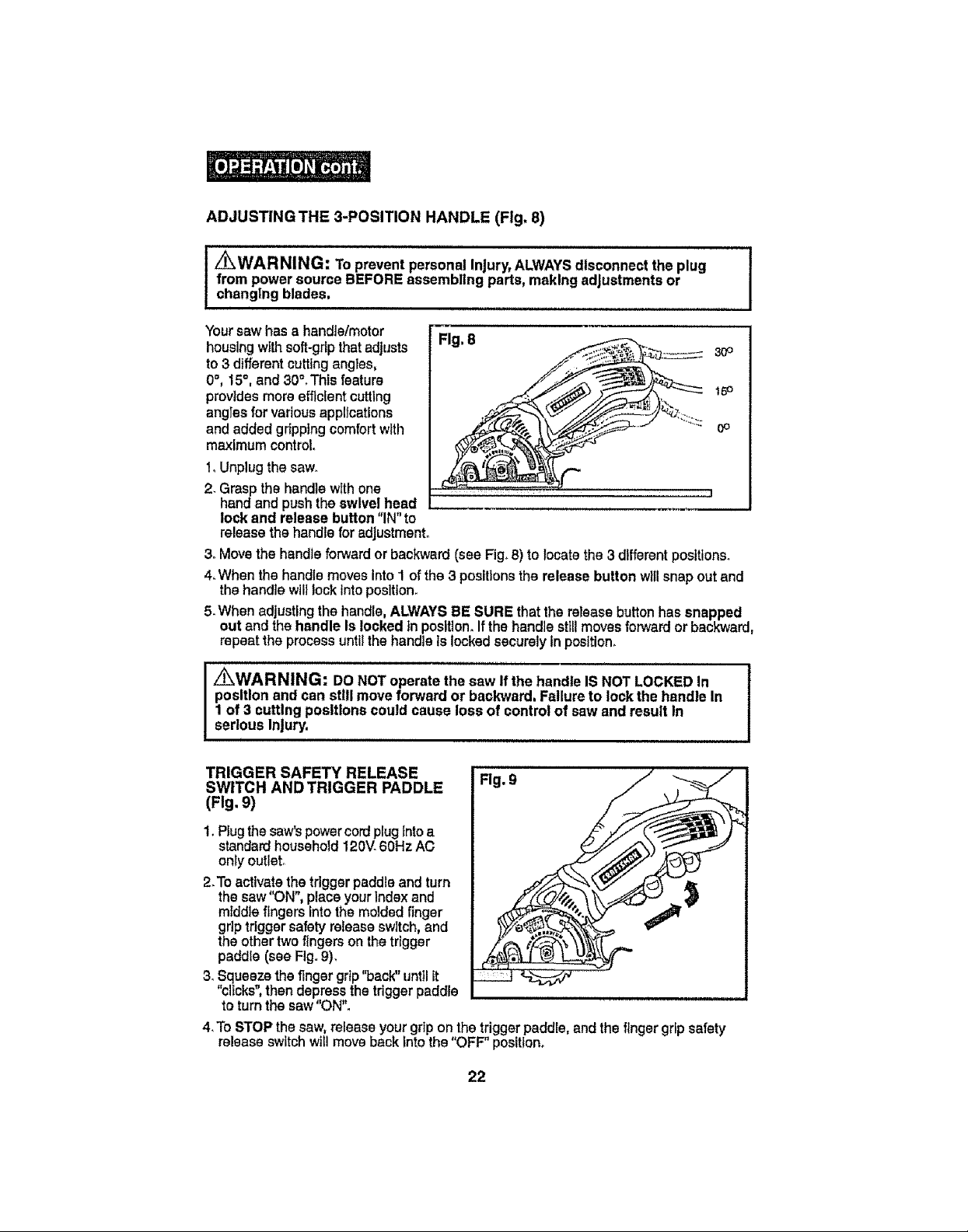

ADJUSTING THE 3-POSITION HANDLE (Fig. 8)

Z_WARNING: To prevent personal Injury,ALWAYSdisconnect the plug

from power source BEFOREassembling parts, making adjustments or

changing blades,

i

Your saw has a handle/motor

housingwithsoft-gripthat adjusts

to 3 differentcutting angles,

0°, 15°,and 30".This feature

provides moreefficient cuttlng

angles for vadous applications

and addedgripping comfort with

maximum control.

1,Unplugthe saw.

2. Graspthehandle with one ............................ j

handand pushtheswivelhead

lock and release button"IN"to

release thehandlefor adjustment.

3. Movethe handleforwardor backward (seeFig.8) to locatethe 3differentpositions.

4_Whanthe handlemovesinto1 of the 3positionsthe release button willsnapoutand

thehandlewilllockintoposition.

5.When adjustingthehandle,ALWAYSBESURE thatthe reteasebutton hassnapped

out and the handle Is lockedin position.Ifthe handle st_llmovesforward or backward,

repeatthe processuntilthe handleIs locked securely inposition.

Fig, 8

3O°

15o

0o

_WARNING: DO NOToperate the saw If the handle IS NOT LOCKED In

position and can still moveforward or backward. Failure to lockthe handle In

1 of 3 cutting positions could cause lossof control of sawand result in

serious Injury.

TRIGGER SAFETY RELEASE

SWITCH AND TRIGGER PADDLE

(Fig. 9)

Fig. 9

1.Plugthe saw'spowercordplug Intoa

standardhousehold 120V.60Hz AC

only outlet°

2.To activate thetdggerpaddleandturn

thesaw "ON",placeyourIndex and

middle fingersintothe molded finger

griptriggersafetyreleaseswitch,and

theothertwo fingersonthetrigger

paddle(see Fig.9).

3_Squeeze the fingergrip"back"untilit

"clicks",then depress the trigger paddle

to turn the saw"ON",

4,To STOP the saw,releaseyour grip on the trigger paddle, and the finger grip safety

releaseswitchwtl!move back Intothe "OFF"position.

22

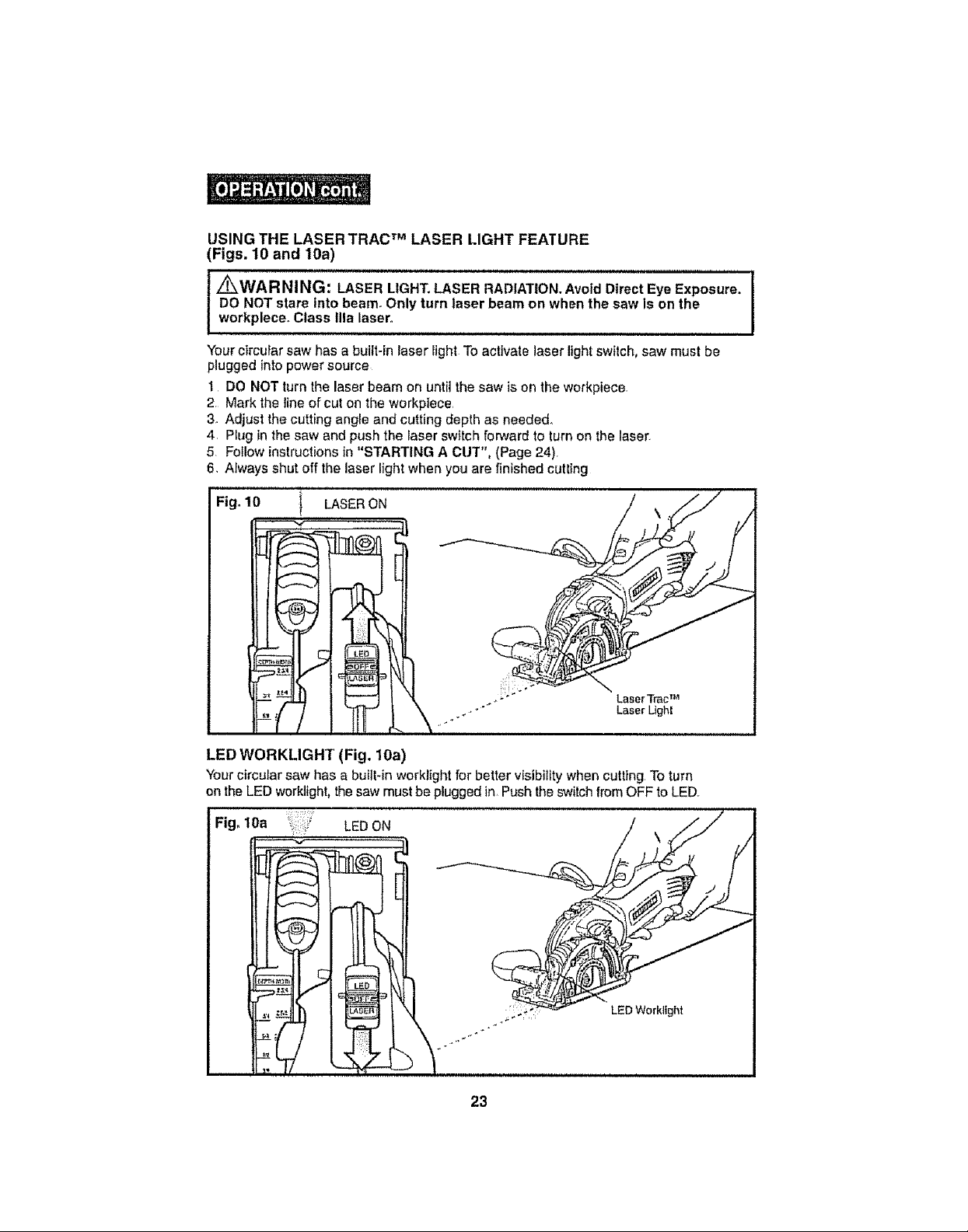

USING THE LASER TRAC TM LASER LIGHT FEATURE

(Figs. 10 and 10a)

DO NOT stare into beam, Only turn laser beam on when the saw is on the

i _WARNING: LASER LIGHT. LASER RADIATION. Avoid Direct Eye Exposure.

workplece. Class Ilia laser°

................................................................... i

ll,l,,,ll i,,Hllll L

Yourcircular saw has a built-in laser light To activate laser light switch, saw must be

plugged into power source

1 DO NOT turn the laser beam on until the saw is on the workpiece.

2, Mark the line of cut on the workptece,

3. Adjust the cutting angle and cutting depth as needed.,

4 Plug in the saw and push the iaser switch forward to turn on the laser.

5. Follow instructions in "STARTING A CUT", (Page 24)

6. Always shut off the laser light when you are finished cutting

Fig. 10 1 LASER ON

Laser TracTM

LaserLight

LED WORKLIGHT (Fig, 10a)

Your circular saw has a built-in worklight for better vtsibi/lty when cutting To turn

on the LED work]ight, thesaw must be plugged in, Push the switch from OFF to LED°

Fig. 10a LED ON

23

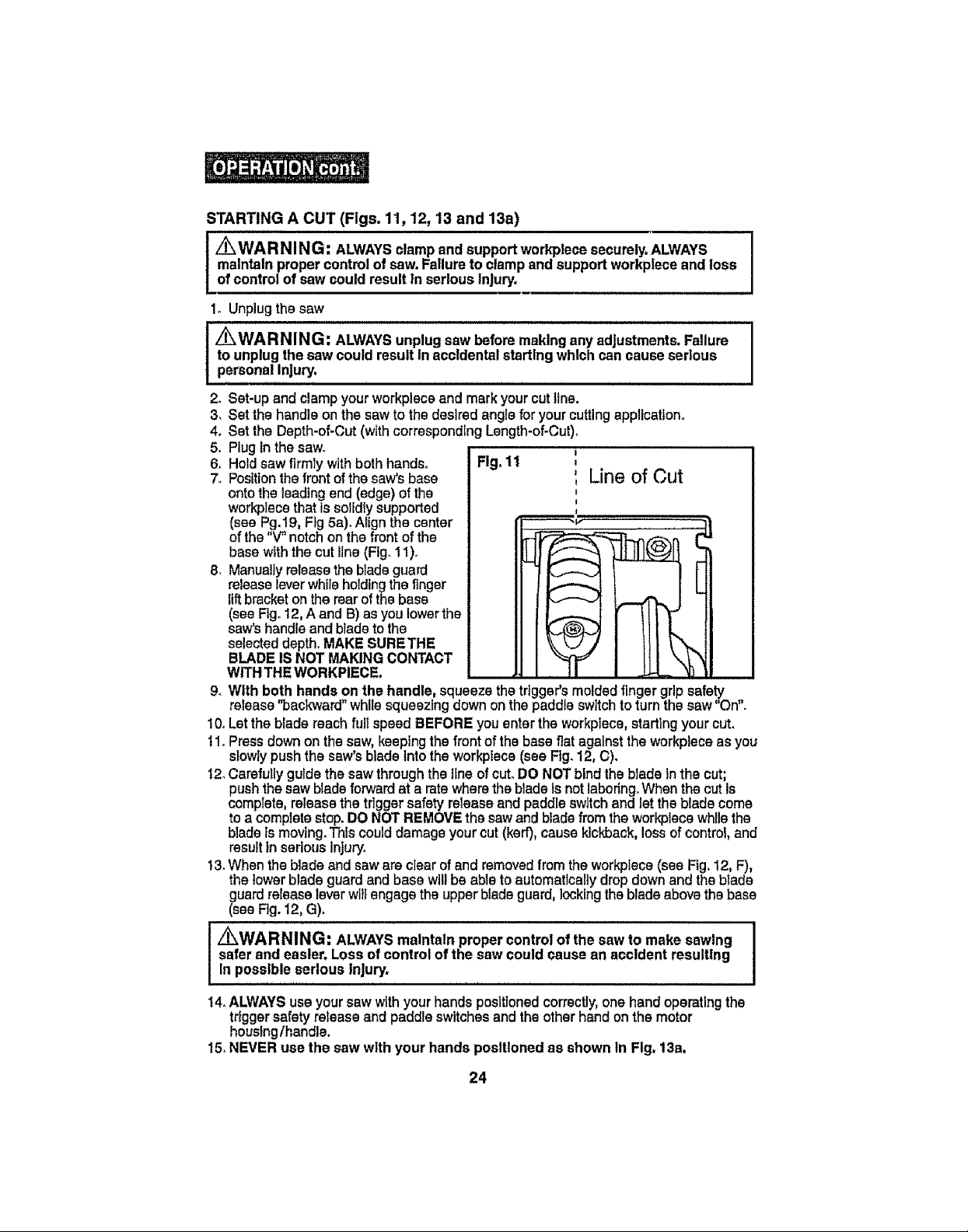

STARTING A CUT (Figs. 11, 12, 13 and 13a)

/_ WA R NING: ALWAYSclampand supportworkplecesecurely,ALWAYS

maintainproper control of saw.Failureto clampand supportworkpleceand loss

of controlof saw could resultin serious injury.

1o Unplug the saw

to unplugthe sawcould resultin accidentalstartingwhich can causeserious

_ _WARNING: ALWAYSunplugsaw beforemakinganyadjustments.Failure

personalInjury,

2_Set-upand clampyour workplaceand mark your cutline.

3. Set the handle on the saw to the desired anglefor your cuttingapplication.

4. Set the Depth-of-Cut (withcorresponding Length-of-Cut).

5. Plug In the saw°

6o Hold sawfirmly with both hands. Fig, 11

7_ Positionthe frontofthe saw's base Line of Gut

ontothe leading end (edge)of the

workplacethat is solidlysupported

(seePg.19, Ffg5a)oAlign the center

of the"V" notchon the front of the

base with the cut line(Fig°11)o

8. Manuallyreleasethe bladeguard

releaseleverwhile holdingthe finger

lift bracketon the rear ofthe base

(seeRgo12,A and13)as you lowerthe

saw'shandle andblade to the

selecteddepth,MAKE SURETHE

BLADEIS NOT MAKINGCONTACT

WITHTHEWORKPIECE.

9_With both hands on the handle, squeezethe tdgger'smoldedfingergripsafety

release"backward"whilesqueezing down onthe paddleswitch toturnthe saw"On".

I0oLetthe blade reach fulIspeedBEFORE you enterthe workplace,starting your cut.

t !oPressdown on the saw, keepingthe front of the base flatagainst theworkplece as you

slowlypushthe saws bladeintothe workplace(seaFig. 12, C).

12.Carefully guidethe saw through the lineof cut. DO NOT bind the bladeInthe cut;

pushthe sawbladeforward ata ratewhere theblade is not laboring.Whenthe cutIs

comptets, release the trigger safety releaseendpaddle switchand let the bladecome

to a completestop.DO NOTREMOVEthe saw and bladefrom the workplace while the

blade is moving.This could damageyour cut(kerf),cause kickback, lossof control,and

resultin serious injury.

t3. Whenthe bladeand saware clear of andremovedfrom the workplace (see Fig.12, F),

thelowerblade guardand base willbe abteto automaticallydrop downand the blade

guardreleaseleverwiltengagethe upperbladeguard, lockingthe bladeabovethe base

(seeFig.12, G).

_WARNING: ALWAYS maintain proper controlof the saw to make sawing I

safer and easier. Loss ofcontrol of the sew could cause an accident resulting

In possible serious injury,

i i i i i ii ii i i

14.ALWAYSuseyoursaw withyour handspositionedcorrectly,one hand operatingthe

triggersafetyreleaseand paddleswitches and theotherhandonthe motor

housing/handle,

15.NEVER use the saw with your hands positioned as shown In Fig, 13a,

24

I

Loading...

Loading...