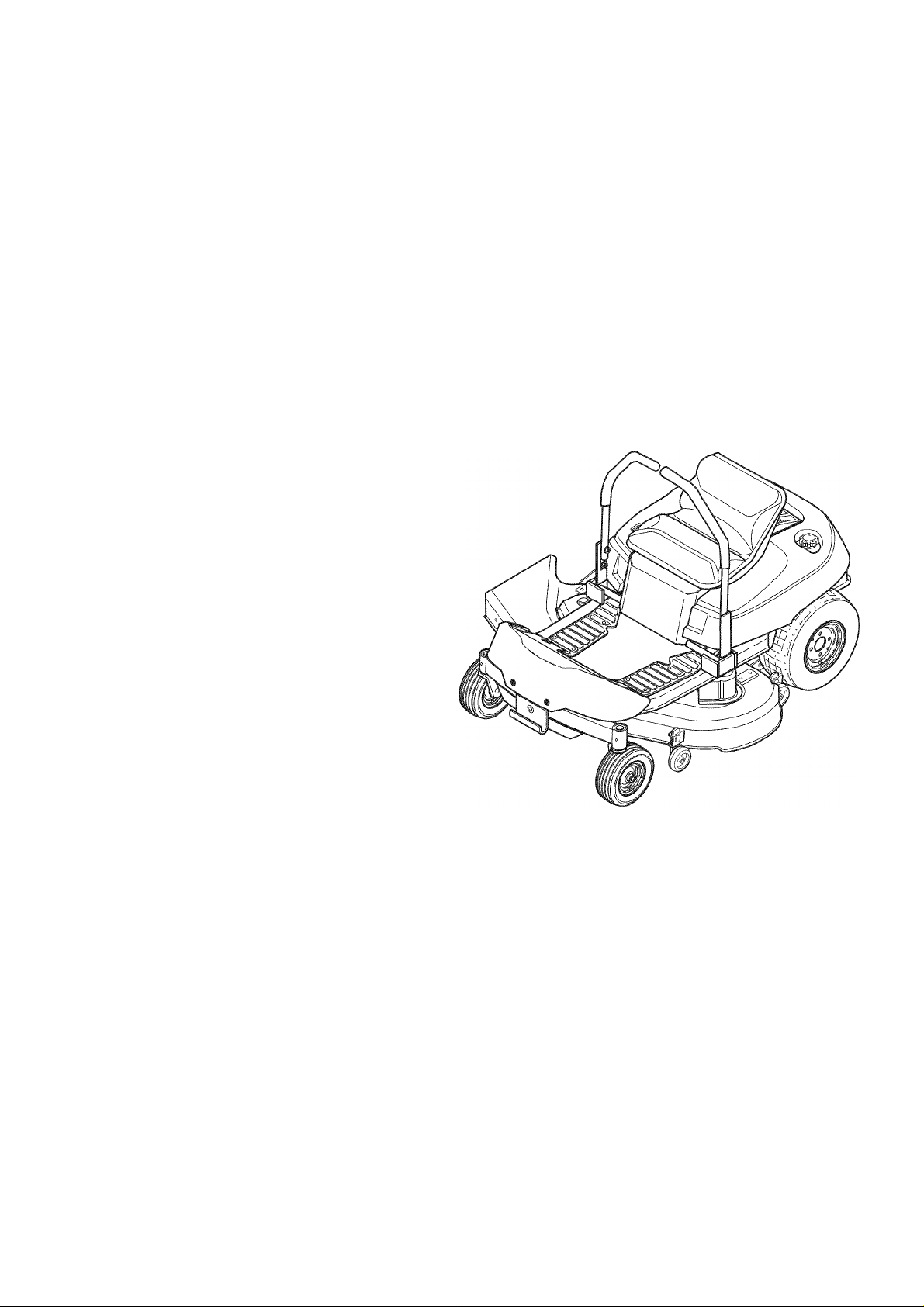

Page 1

Operator’s Manual

CRRFTSMRN

6000

Zero-Turn Rear Engine Riders with Electric Start

Model No.

107.289920 (26HP Briggs & Stratton Engine with 52” Mower)

CAUTION: Before using this product, read

the manual and follow all its Safety Rules

and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

For answers to your questions about this

product, call:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pm, Mon - Sat

Nota: Una traducción en español de este Manual

del Operador puede encontrarse en la página 39.

7103149

Revision F

Rev. Date 04/2009

Page 2

Page 3

TABLE OF CONTENTS

Warranty Statement...................................................3

Safety Rules & Information.......................................4

Identification Numbers..............................................9

Assembly..................................................................10

Pre-Operation...........................................................14

Operation..................................................................15

Maintenance.............................................................22

Service & Adjustments

...........................................

NOTE: In this manual, “left” and “right” are referred to as seen from the operating position.

31

Storage......................................................................36

Specifications...........................................................36

Troubleshooting.......................................................37

Spanish Operator’s Manual

Repair Parts.......................................................PTS-1

Hardware and Torque Specifictions

Repair Protection Agreement.Inside Back Cover

Service Numbers

.......................................

....................................

..............

PTS-42

Back Cover

39

WARRANTY

CRAFTSMAN FULL WARRANTY

When operated and maintained according to all supplied instructions, if any non-expendable part of this riding equip

ment fails due to a defect in material or workmanship within two years from the date or purchase, call 1-800-659-5917

to arrange for free in-home repair.

The frame and front axle will be repaired free of charge for five years from the date of purchase if defective in material

or workmanship.

All of the above warranty coverage applies for only 90 days from the date of purchase if this riding equipment is ever

used for commercial or rental purposes.

In all cases, if repair proves impossible, the riding equipment will be replaced free of charge with the same or an

equivalent model.

The battery will be replaced free of charge for 90 days from the date of purchase if defective in material or workman

ship (our testing proves that it will not hold a charge).

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

• Expendable items that become worn during normal use, including but not limited to blades, spark plugs, air

cleaners, belts, and oil filters.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by towing objects

beyond the capability of the riding equipment, impacting objects that bend the frame or crankshaft, or over

speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage

caused by improper storage, failure to use the proper grade and amount of engine oil, failure to keep the deck clear

of flammable debris, or failure to maintain the riding equipment according to the instructions contained in the opera

tor's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In

general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Page 4

SAFETY RULES AND INFORMATION

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

A

This mowing deck is capable of amputating hands and feet and throwing objects.

The triangle ^ in text signifies important cautions or warnings which must be followed.

GENERAL OPERATION

1. Read, understand, and follow all instructions in the

manual and on the unit before starting.

2. Do not put hands or feet near rotating parts or under

the machine. Keep clear of the discharge opening at

all times.

3. Only allow responsible adults, who are familiar with

the instructions, to operate the unit (local regulations

can restrict operator age).

4. Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown by the

blade(s).

5. Be sure the area is clear of other people before mow

ing. Stop the unit if anyone enters the area.

6. Never carry passengers.

7. Do not mow in reverse unless absolutely necessary.

Always look down and behind before and while travel

ling in reverse.

8. Never direct discharge material toward anyone. Avoid

discharging material against a wall or obstruction.

Material may ricochet back toward the operator. Stop

the blade(s) when crossing gravel surfaces.

9. Do not operate the machine without the entire grass

catcher, discharge guard (deflector), or other safety

devices in place and operational.

10. Slow down before turning.

11. Never leave a running unit unattended. Always disen

gage the blades (PTO), set parking brake, stop

engine, and remove keys before dismounting.

12. Disengage blades (PTO) when not mowing. Shut off

engine and wait for all parts to come to a complete

stop before cleaning the machine, removing the grass

catcher, or unclogging the discharge guard.

13. Operate the machine only in daylight or good artificial

light.

14. Do not operate the unit while under the influence of

alcohol or drugs.

15 Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the unit

into a trailer or truck.

17. Always wear eye protection when operating this unit.

18. Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the equipment safely

enough to protect themselves and others from injury.

19. Follow the manufacturer’s recommendations for wheel

weights or counterweights.

20. Keep in mind the operator is responsible for accidents

occurring to other people or property.

21. All drivers should seek and obtain professional and

practical instruction.

22. Always wear substantial footwear and trousers.

Never operate when barefoot or wearing sandals.

23. Before using, always visually check that the blades

and blade hardware are present, intact, and secure.

Replace worn or damaged parts.

24. Disengage attachments before: refueling, removing

an attachment, making adjustments (unless the

adjustment can be made from the operator’s posi

tion).

25. When the machine is parked, stored, or left unattend

ed, lower the cutting means unless a positive

mechanical lock is used.

26. Before leaving the operator’s position for any reason,

engage the parking brake (if equipped), disengage

the blades (PTO), stop the engine, and remove the

key.

27. To reduce fire hazard, keep the unit free of grass,

leaves, & excess oil. Do not stop or park over dry

leaves, grass, or combustible materials.

28. It is a violation of California Public Resource Code

Section 4442 to use or operate the engine on or near

any forest-covered, brush-covered, or grass-covered

land unless the exhaust system is equipped with a

spark arrester meeting any applicable local or state

laws, ether states or federal areas may have similar

laws.

29. OSHA regulations may require the use of hearing

protection when exposed to sound levels greater than

85 dBA for an 8 hour time period.

ACAUTION

This machine produces sound levels in

excess of 85 dBA at the operator’s ear and

O

Wear hearing protection when operating this

machine.

can cause hearing loss though extended

periods of exposure.

TRANSPORTING AND STORAGE

1. When transporting the unit on an open trailer, make

sure it is facing forward, in the direction of travel. If

the unit is facing backwards, wind lift could damage

the unit.

2. Always observe safe refueling and fuel handling prac

tices when refueling the unit after transportation or

storage.

3. Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an igni

tion source (such as a furnace, water heater, etc.)

and cause an explosion. Fuel vapor is also toxic to

humans and animals.

4. Always follow the engine manual instructions for

storage preparations before storing the unit for both

short and long term periods.

5. Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

6. Never store the unit or fuel container inside where

there is an open flame or pilot light, such as in a

water heater. Allow unit to cool before storing.

Page 5

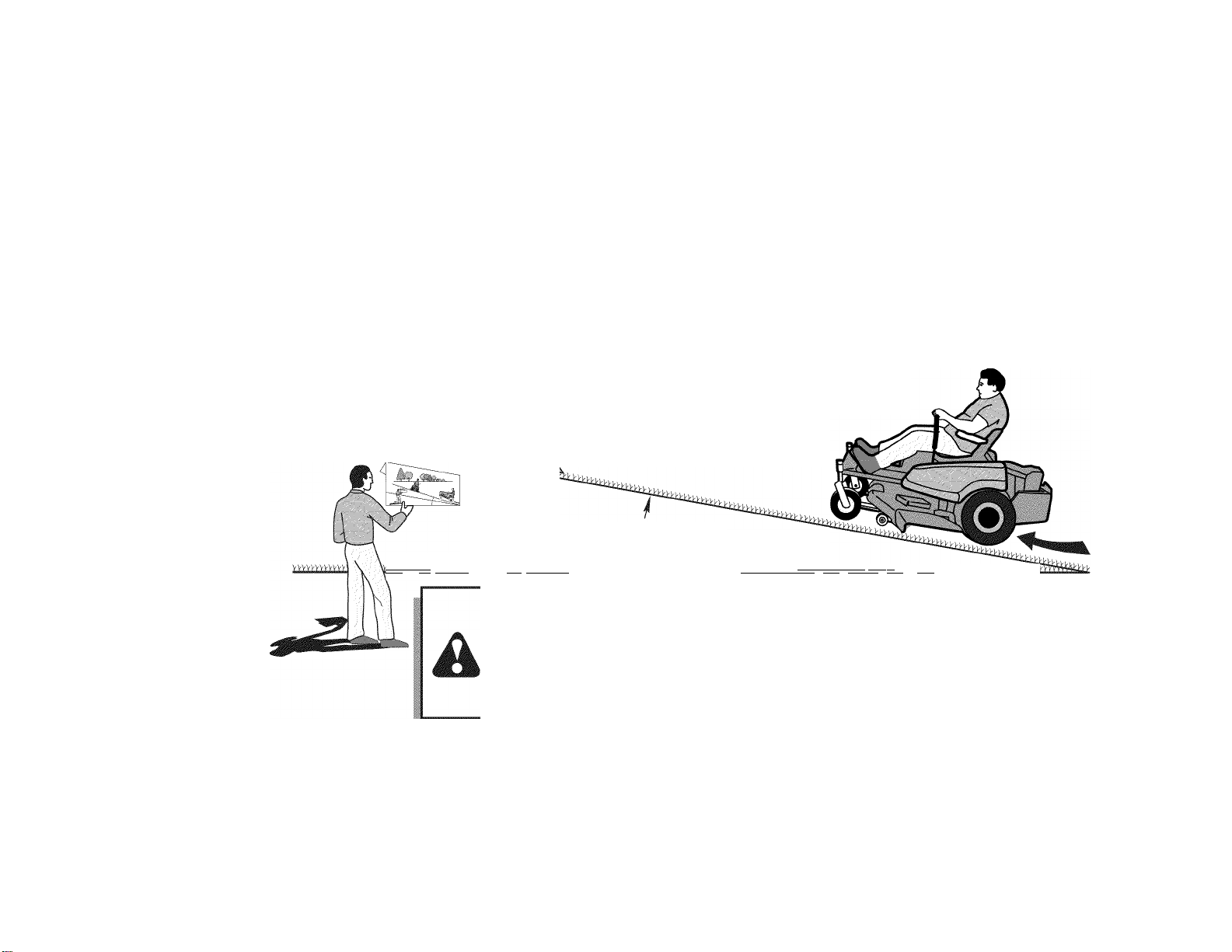

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tip

over accidents, which can result in severe injury or death.

Operation on all slopes requires extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not operate

on it.

Control of a walk-behind or ride-on machine sliding on a

slope will not be regained by the application of the brake.

The main reasons for loss of control are: insufficient tire

grip on the ground, speed too fast, inadequate braking, the

type of machine is unsuitable for its task, lack of awareness

of the ground conditions, incorrect hitching and load distri

bution.

1. Mow across slopes, not up and down.

2. Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Tall grass can hide obstacles.

3. Choose a slow speed so that you will not have to stop

or change speeds while on the slope.

4. Do not mow on wet grass. Tires may loose traction.

5. Never mow down slopes.

6. Avoid starting, stopping, or turning on a slope. If tires

lose traction (i.e. machine stops forward motion on a

slope), disengage the blade(s) (PTC) and drive slow

off the slope.

7. Keep all movement on slopes slow and gradual. Do

not make sudden changes in speed or direction,

which could cause the machine to rollover.

8. Use extra care while operating machines with grass

catchers or other attachments; they can affect the

stability of the unit. Do not use on steeps slopes.

9. Do not try to stabilize the machine by putting your

foot on the ground (ride-on units).

10. Do not mow near drop-offs, ditches, or embank

ments. The mower could suddenly turn over if a

wheel is over the edge of a cliff or ditch, or if an edge

caves in.

11. Do not use grass catchers on steep slopes.

12. Do not mow slopes if you cannot back up them.

13. See your authorized dealer/retailer for recommenda

tions of wheel weights or counterweights to improve

stability.

14. Remove obstacles such as rocks, tree limbs, etc.

15. Use slow speed. Tires may lose traction on slopes

even through the brakes are functioning properly.

16. Do not turn on slopes unless necessary, ana then,

turn slowly and gradually uphill, if possible. Never

mow down slopes.

TOWED EQUIPMENT (RIDE-ON UNITS)

1. Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

Follow the manufacturer’s recommendations for

2.

weight limit for towed equipment and towing on

slopes. See attaching a trailer under OPERATION.

Never allow children or others in or on towed equip

3.

ment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Do not shift to neutral and coast down hill.

^WARNING

Never operate on slopes greater than 17.6 percent

(10°) which is a rise of 3-1/2 feet (106 cm) vertically in

20 feet (607 cm) horizontally.

Select slow ground speed before driving onto slope.

Use extra caution when operating on slopes with rearmounted grass catchers.

Mow across the face of slopes, not up and down,use

caution when changing directions and DO NOT

START OR STOP ON SLOPE.

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and the mowing activity. Never assume that children will

remain where you last saw them.

1. Keep children out of the mowing area and under the

watchful care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Before and during reverse operation, look behind and

down for small children.

4. Never carry children, even with the blade(s) off. They

may fall off and be seriously injured or interfere with

safe unit operation. Children who have been given

rides in the past may suddenly appear in the mowing

area for another ride and be run over or backed over

by the machine.

5. Never allow children to operate the unit.

6. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Period and

Air Index information on the engine emissions label.

IGNITION SYSTEM

1. This spark ignition system complies with Canadian

standard ICES-002.

Page 6

SUGGESTED GUIDE FOR SIGHTING SLOPES FOR SAFE OPERATION

IVVVVV

-vvvvvvvvv}wv\)l ^\)uvvf \vvvvvl^lvvvvvvv>I Vvvvv^

^vv vvvvvvvvvvvvvvvvv vvvvvvvvvvvvvvvvv vvvvvvvvvvvvv

ONLY RIDE UP AND DOWN HILL,

NOT ACROSS HILL

CD

10 DEGREES MAX

j^mmmmivyyvvvvvvvvvvvvyvyvvvyyvvvvyvvyvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvyvvvvvvvvvvmmmmmmmmiCLmmmmammmm;

WARNING: To avoid serious injury, operate your unit up and

down the face of slopes, never across the face. Do not operate

on slopes greater than 10 degrees. Make turns gradually to

prevent tipping or loss of control. Exercise extreme caution

when changing direction on slopes. Braking may be affected by

attachments. Reduce speed on slopes.

1. Fold this page along dotted line indicated above.

2. Hold page before you so that its left edge is vertically parallel to a tree

trunk or other upright structure.

3. Sight across the fold in the direction of hill slope you want to measure.

4. Compare the angle of the fold with the slope of the hill.

Page 7

SERVICE AND MAINTENANCE

Safe Handling of Gasoline

1. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

2. Use only approved gasoline containers.

3. Never remove the gas cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. Never fuel the machine indoors.

5. Never store the machine or fuel container where there

is an open flame, spark, or pilot light such as near a

water heater or other appliance.

6. Never fill containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on

the ground away from your vehicle before filling.

7. Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possi

ble, then refuel such equipment on a trailer with a

portable container, rather than from a gasoline dis

penser nozzle.

8. Keep nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is com

plete. Do not use a nozzle lock-open device.

9. If fuel is spilled on clothing, change clothing immedi

ately.

10. Never over-fill the fuel tank. Replace gas cap and

tighten securely.

11. Use extra care in handling gasoline and other fuels.

They are flammable and vapors are explosive.

12. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

13. Replace all fuel tank caps and fuel container caps

securely.

Service & Maintenance

1. Never run the unit in an enclosed area where carbon

monoxide fumes may collect.

2. Keep nuts and bolts, especially blade attachment

bolts, tight and keep equipment in good condition.

3. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if

they are not functioning properly.

4. Keep unit free of grass, leaves, or other debris build

up. Clean up oil or fuel spillage, and remove any fuelsoaked debris. Allow machine to cool before storage.

5. If you strike an object, stop and inspect the machine.

Repair, if necessary, before restarting.

6. Never make adjustments or repairs with the engine

running.

7. Check grass catcher components and the discharge

guard frequently and replace with manufacturer’s rec

ommended parts, when necessary.

8. Mower blades are sharp. Wrap the blade or wear

doves, and use extra caution when servicing them.

9. Check brake operation frequently. Adjust and service

as required.

10. Maintain or replace safety and instructions labels, as

necessary.

11. Do not remove the fuel filter when the engine is hot

as spilled gasoline may ignite. Do not spread fuel line

clamps further than necessary. Ensure clamps grip

hoses firmly over the filter after installation.

12. Do not use gasoline containing METHANOL, gasohol

containing more than 10% ETHANOL, gasoline addi

tives, or white gas because engine/fuel system dam

age could result.

13. If the fuel tank must be drained, it should be drained

outdoors.

14. Replace faulty silencers/mufflers.

15. Maintain or replace safety and instruction labels as

necessary.

16. Use only factory authorized replacement parts when

making repairs.

17. Always comply with factory specifications on all set

tings and adjustments.

18. Only authorized service locations should be utilized

for major service and repair requirements.

19. Never attempt to make major repairs on this unit

unless you have been properly trained. Improper

service procedures can result in hazardous operation,

equipment damage and voiding of manufacturer’s

warranty.

20. On multiple blade mowers, take care as rotating one

blade can cause other blades to rotate.

21. Do not change engine governor settings or over

speed the engine. Operating the engine at excessive

speed can increase the hazard of personal injury.

22. Disengage drive attachments, stop the engine,

remove the key, and disconnect the spark plug wire(s)

before: clearing attachment blockages and chutes,

performing service work, striking an object, or if the

unit vibrates abnormally. After striking an object,

inspect the machine for damage and make repairs

before restarting and operating the equipment.

23. Never place hands near the moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans are typically located on top

of the transaxle).

24. Units with hydraulic pumps, hoses, or motors: WARN

ING: Hydraulic fluid escaping under pressure may

have sufficient force to penetrate skin and cause seri

ous injury. If foreign fluid is injected into the skin it

must be surgically removed within a few hours by a

doctor familiar with this form of injury or gangrene

may result. Keep body and hands away from pin

holes or nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, and not hands, to

search for leaks. Make sure all hydraulic fluid con

nections are tight and all hydraulic hoses and lines

are in good condition before applying pressure to the

system. If leaks occur, have the unit serviced imme

diately by your authorized dealer.

25. WARNING: Stored energy device. Improper release

of springs can result in serious personal injury.

Springs should be removed by an authorized techni

cian.

26. Models equipped with an engine radiator: WARNING:

Stored energy device. To prevent serious bodily injury

from hot coolant or steam blow-out, never attempt to

remove the radiator cap while the engine is running.

Stop the engine and wait until it is cool. Even then,

use extreme care when removing the cap.

Page 8

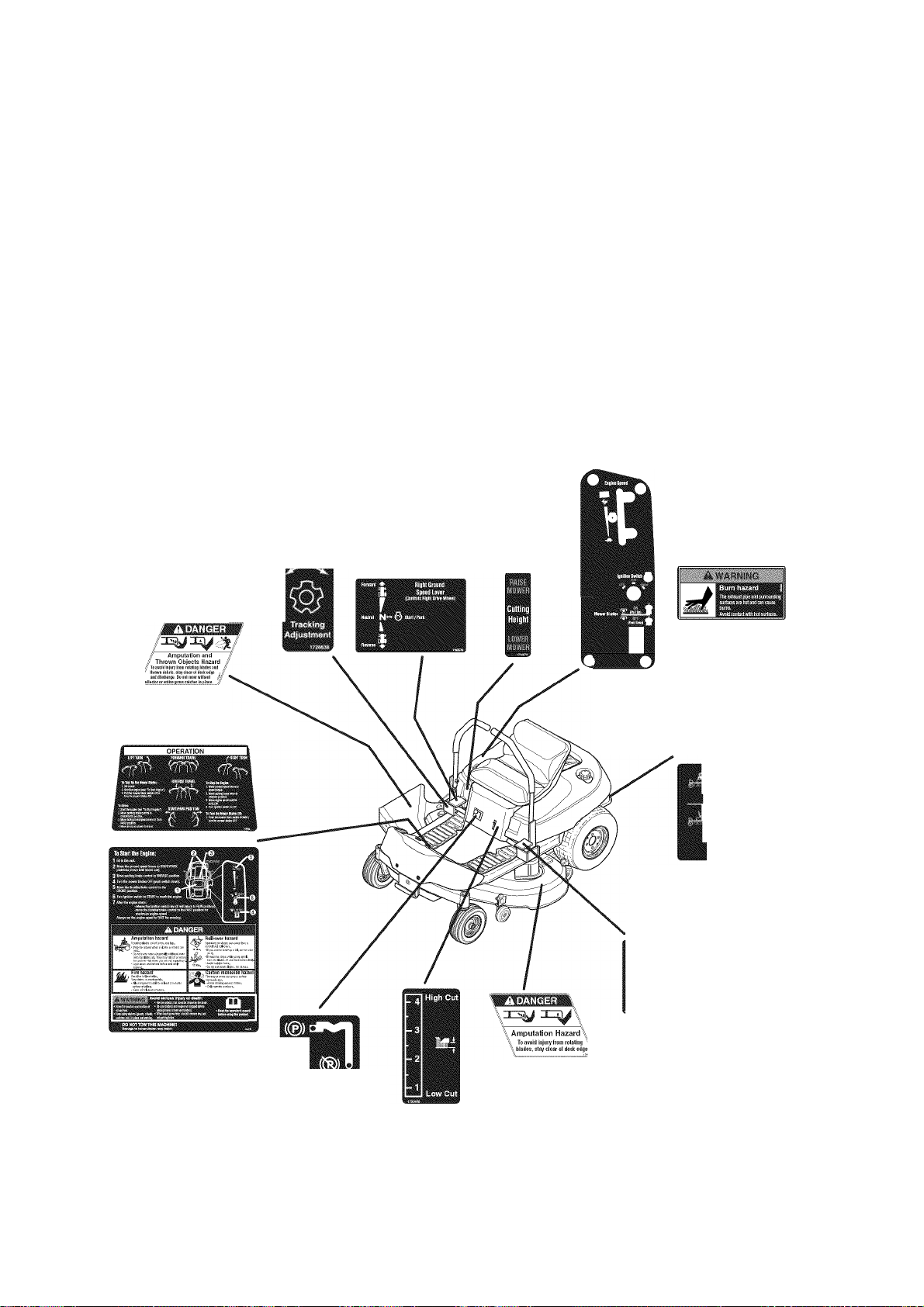

SAFETY & OPERATION DECALS

This unit has been designed and manufactured to pro

vide you with the safety and reliability you would expect

from an industry leader in outdoor power equipment

manufacturing.

Although reading this manual and the safety instructions

it contains will provide you with the necessary basic

knowledge to operate this equipment safely and effec

tively, we have placed several safety labels on the unit to

remind you of this important information while you are

operating your unit.

All DANGER, WARNING, CAUTION and instructional

messages on your rider and mower should be carefully

Decal -Tracking

Adjustment

Part No.

1726638SM

Decal - Amputation and

Thrown Objects Hazard

Part No. 1704277SM

Decal - Ground

Speed Lever

PartNo.7102576YP

read and obeyed. Personal bodily injury can result when

these instructions are not followed. The information is for

your safety and it is important! The safety decals below

are on your rider and mower.

If any of these decals are lost or damaged, replace them

at once. Contact a Sears Parts & Service Center for

replacements.

These labels are easily applied and will act as a constant

visual reminder to you, and others who may use the

equipment, to follow the safety instructions necessary for

safe, effective operation.

Decal - Control Panel

Part No. 7103082YP

Decal - Cutting

Height Switch

Part No.

1734276SM

Decal - Hot Surfaces

Part No. 1734273SM

(Located on RH side)

Decal - Operation, Upper

Part No. 7102575YP

Decal - Operation, Lower

Part No. 7103185YP

Decal - Parking Brake

Part NO.7102578YP

Decal - Cutting Hazard

Part No. 1734672SM

(Located on rear frame)

Decal - Transmission

Release

Part No. 1734532SM

(Located on rear frame)

Decal - Ground Speed Lever

Part No. 1734270SM

Decal - Amputation Hazard

Part No. 1704276SM

Decal - Cutting Height

Indicator

Part No. 1734335SM

Page 9

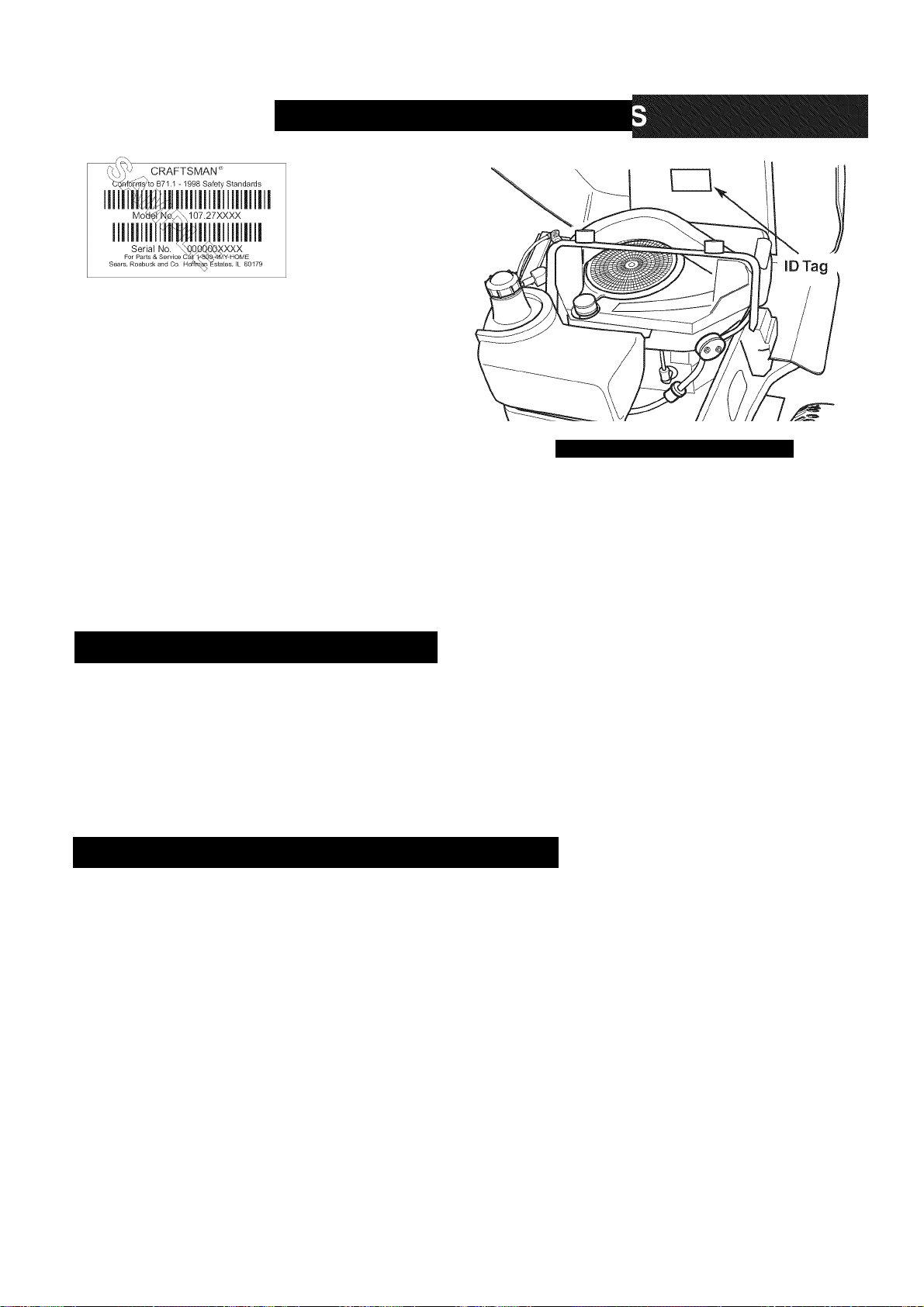

IDENTIFICATION NUMBER

When contacting the service center for replacement

parts, service, or information you MUST have these

numbers.

Record your model name/number, manufacturer's

identification numbers, and engine serial numbers in the

space provided for easy access.

The identification tag is located on the underside of the

seat. Tilt the seat forward to access the ID tag.

For answers to your questions about this product, call:

1-800-659-5917

Sears Craftsman Flelp Line, 5 am - 5 pm,

Monday-Saturday.

PRODUCT REFERENCE DATA

Model Description Name/Number

Stock Number Unit Serial Number

Date Purchased

OPTIONAL ACCESSORIES

See your local Sears retailer to purchase the following

accessories:

Two Bin Grass Collector

• Headlight Kit

• Front Bumper Kit

LITERATURE PACKAGE CONTENTS

Keys

Quick Start Guide (English and Spanish)

Operator’s Manual & Parts Book (English and Spanish)

bngine Make

Engine Type/Spec

ENGINE REFERENCE DATA

bngine Model

Engine Code/Serial Number

Page 10

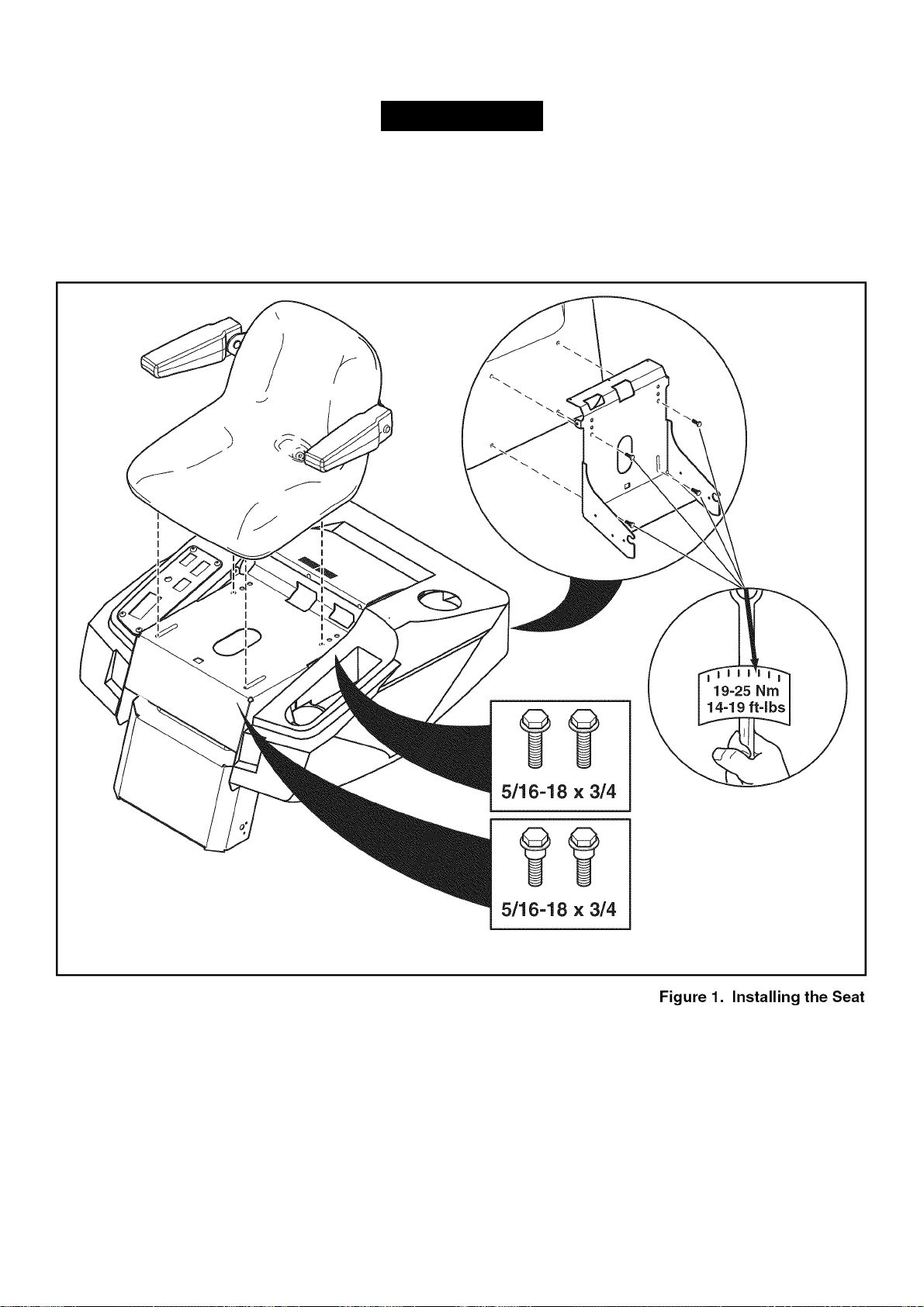

ASSEMBLY

INSTALLING THE SEAT

1. Raise the seat base (see Figure 1).

2. Align the holes in the seat bottom with the holes in

the seat base.

3. Secure the seat to the seat base with two 5/16-18 x

3/4 serrated head bolts for the rear seat slots, and

two 5/16-18 X 3/4 shoulder bolts for the front slots.

4. Tighten to 14-19 ft-lbs (19-25 Nm).

10

Page 11

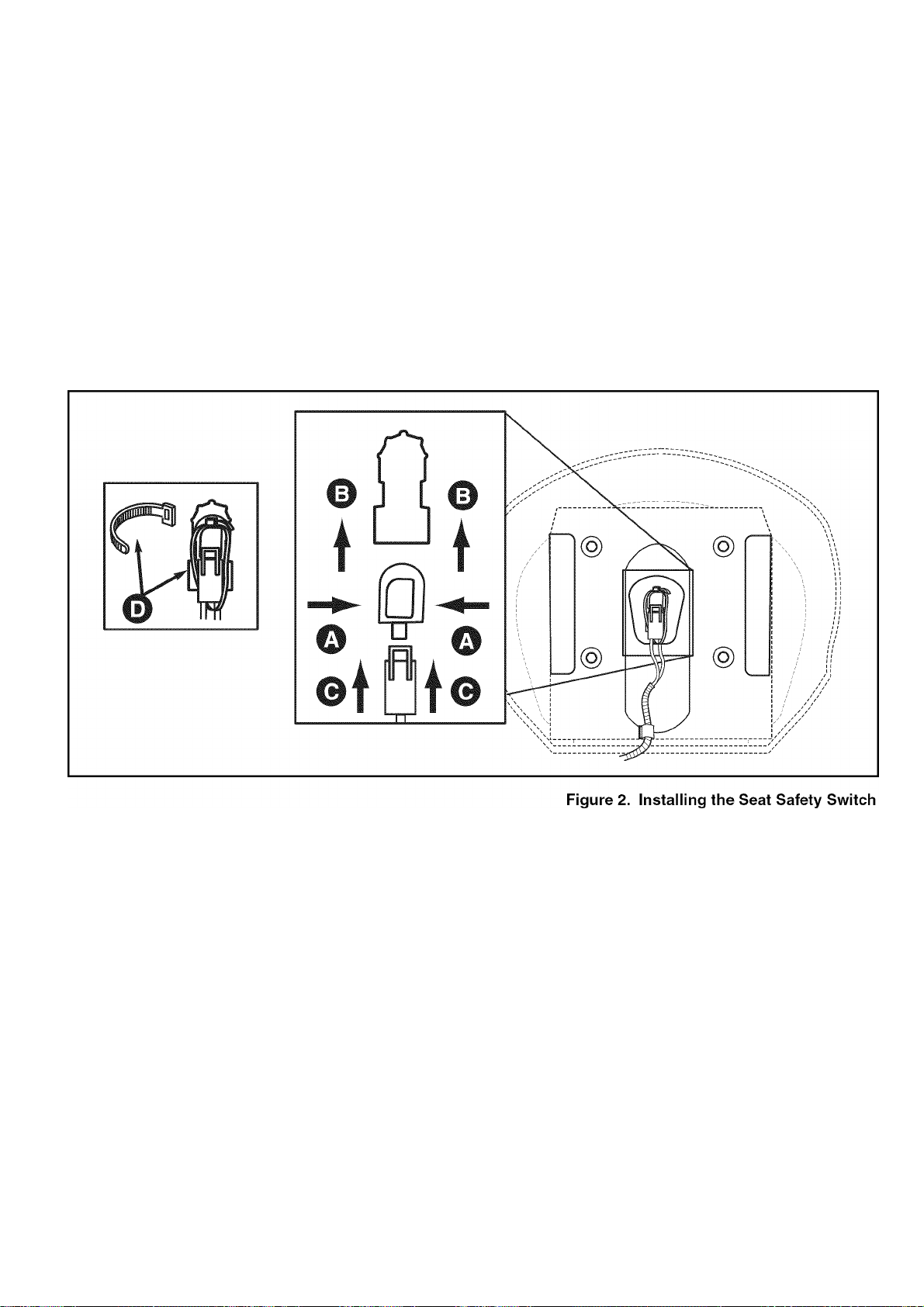

INSTALLING THE SEAT SAFETY

SWITCH

1. Squeeze the side clips of the safety switch (A, Figure

2), and insert the switch into the slot (B) in the seat

bottom. Be sure to slide the switch fully forward.

2. Connect the harness terminal housing (C) to the seat

switch.

3. Loop the wire tie (D) around both the switch body and

the terminal housing.

11

Page 12

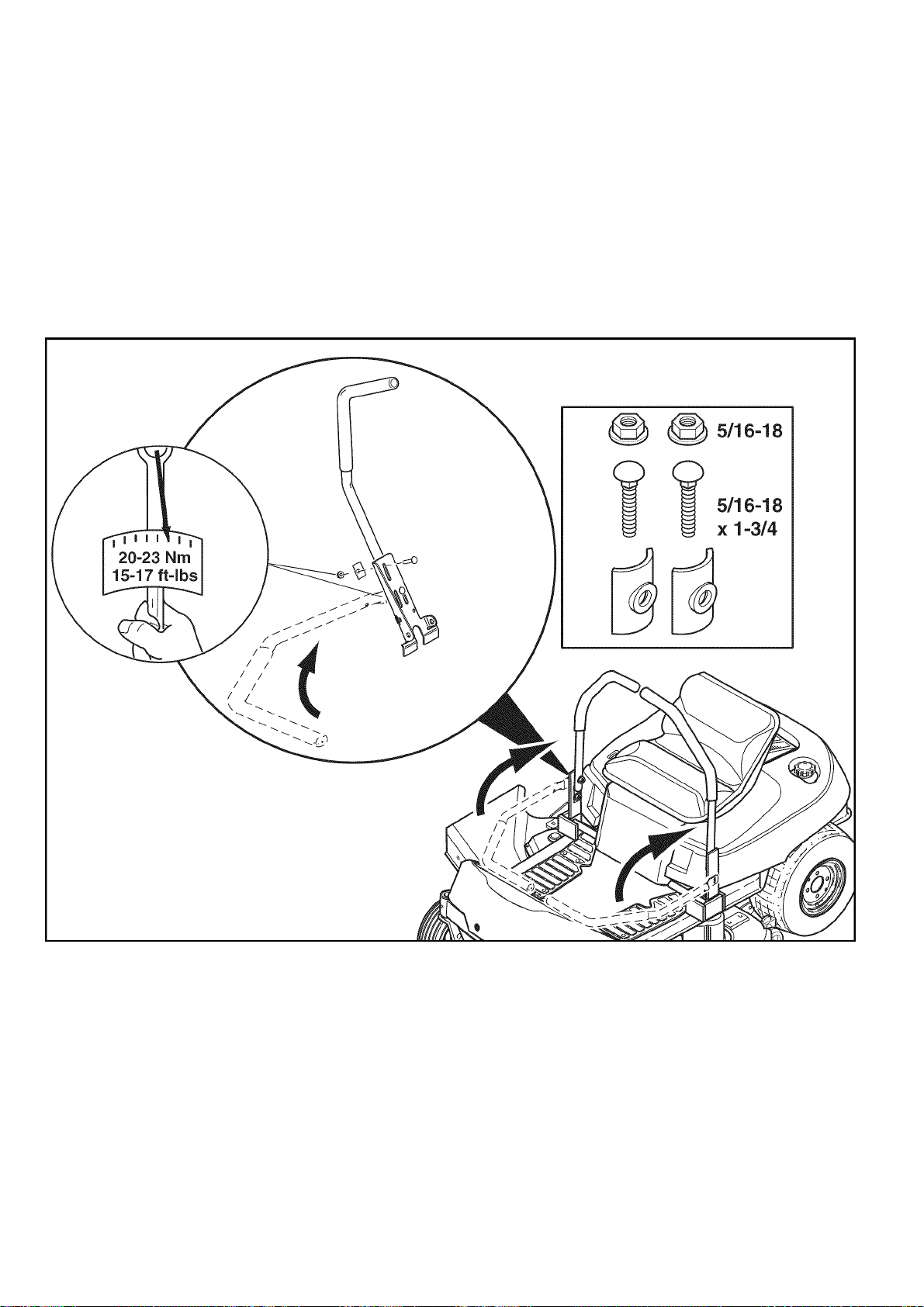

SETTING UP THE GROUND SPEED CONTROL LEVERS

1. Loosen (do not remove) the hardware securing the

ground speed control levers to the lever bases (see

Figure 3).

2. Raise the levers, aligning the upper hole in each lever

with the upper slotted hole in the lever base.

3. Install the hardware as shown in Figure 3. Tighten to

15-17ft-lbs (20-23 Nm).

NOTE: Ground speed control levers must be adjusted

prior to use. Refer to the “Ground Speed Control

Adjustment” section.

Figure 3. Setting Up the Ground Speed Control Levers

12

Page 13

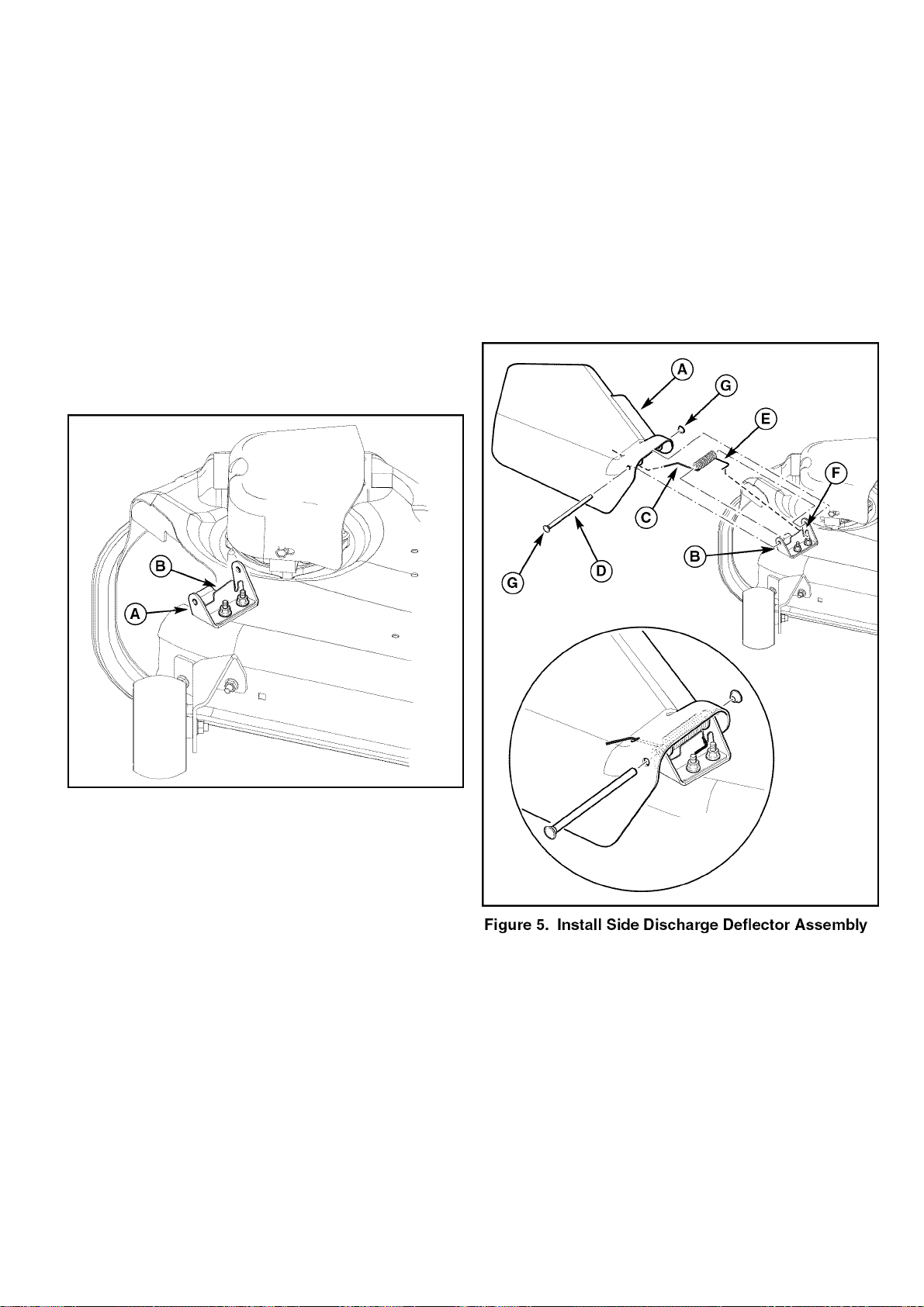

INSTALLING THE SIDE DISCHARGE DEFLECTOR

NOTE: The deflector hinge (A, Figure 4) and bracket (B)

come installed on the mower deck from the factory.

Awarning

Installation of the side discharge deflector is

required for proper and safe operation. Failure to

install the side discharge deflector can result in

injury or death.

3. Insert the hinge rod (D) through one end of the

deflector assembly and hinge, through the torsion

spring, and out through the other end of the deflector

assembly and hinge.

NOTE: Make sure that the shorter end of the torsion

spring (E) hooks into the notch of the deflector bracket

(F)-

4. Firmly install one push nut (G) onto each side of the

hinge rod.

Figure 4. Deflector Hinge and Bracket

A. Deflector Hinge

B. Bracket

1. Lay the deflector assembly (A, Figure 5) inside the

deflector hinge (B) on the right side of the mower

deck. Align the holes in the deflector with the holes in

the hinge.

2. Insert the longer end of the torsion spring (C)

through the slotted hole in the deflector.

A. Deflector Assembly

B. Deflector Hinge

C. Torsion Spring - Longer End

D. Hinge Rod

E. Torsion Spring - Shorter End

F. Deflector bracket

G. Push Nut (2)

13

Page 14

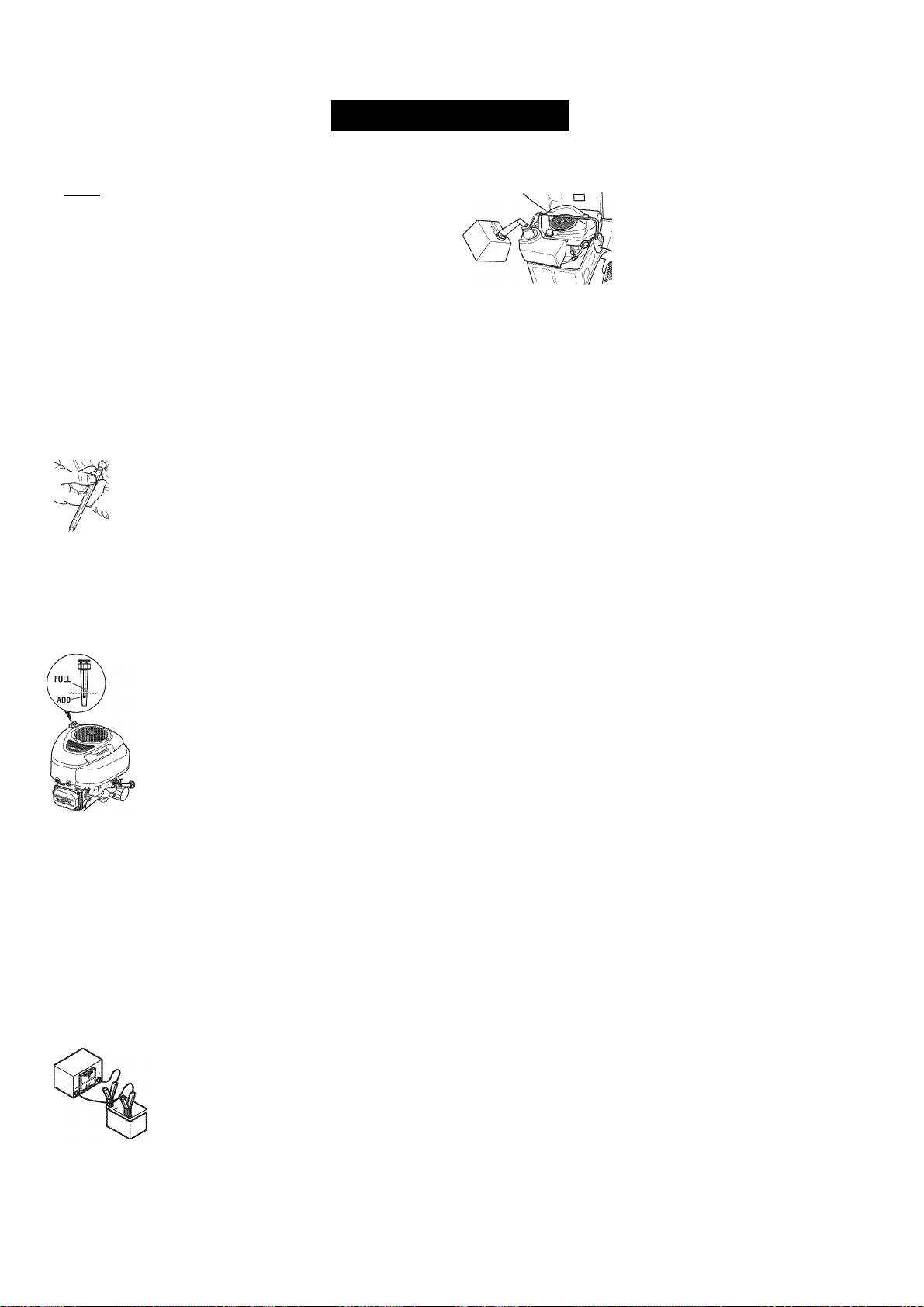

PRE-OPERATION

Remove the Packaging Materials

BPHia

.......

Remove the cardboard from the crate.

Remove any steel branding securing the

- unit to the crate. Locate the manual

‘"'is''' packet.

■ ■ Read the Operator’s Manual

Locate the operator's manual in the

manual packet. You should always read and follow the

instructions in the operator's manual. Proper care,

performance tips, and safety information are located in

this important document.

Check the Tire Pressure

Reduce the tire pressures to the

jj pressures shown below. Tires are over

, inflated for shipping purposes and must

be set to the correct pressures for

optimum traction.

Rear Tire Pressure: 10-12 PSI

Front Tire Pressure: 18-20 PSI

Check Engine Oil Level

Fill-Up with FRESH Gasoline

Lift the seat deck to access the

fuel cap and tank.

Remove the fuel tank cap and fill

the tank with fresh fuel. After

fueling, securely install the cap

and wipe up any fuel that may

have spilled. See the Operator's Manual for fuel

recommendations.

The single most common service issue is stale or

contaminated fuel! Fuel should not be more than 30

days old. Use fuel stabilizer to extend the life of your

fuel, and always store fuel in an approved, sealed, plastic

gas can. Stale fuel clean-out is not covered under your

warranty.

Fuel Tank Capacity: 4.0 Gallons (15,14 L)

Start the Engine and Drive the Unit Off the Crate

Refer to the STARTING THE ENGINE and DRIVING

PRACTICE sections of this manual for information on

starting the unit and driving it off the crate.

Note: Engine is shipped with oil. Add

10W-30 premium engine oil if oil level is

low. See MAINTENANCE for complete

engine oil specifications and maintenance

reguirements.

Lift the seat deck (Figure 17) to access

the engine compartment.

Clean the area around the dip stick/oil fill

tube. Remove the dip stick from the oil fill

tube and wipe the dip stick with a clean rag.

Insert the dip stick into the oil fill tube (thread in or push

down completely).

Remove and check the engine oil level. Oil level should

be between Full and Add marks. If necessary, add oil to

the oil fill tube.

Replace and fully secure the dip stick.

Charge the Battery

Lift the seat deck to access the battery.

If the unit is being put into service after

the month and year indicated on the

battery date tag (located on top of

battery) charge the battery for one hour

at 6-10 amps. Refer to the SERVICE &

ADJUSTMENTS section of this manual for battery

charging information.

14

Page 15

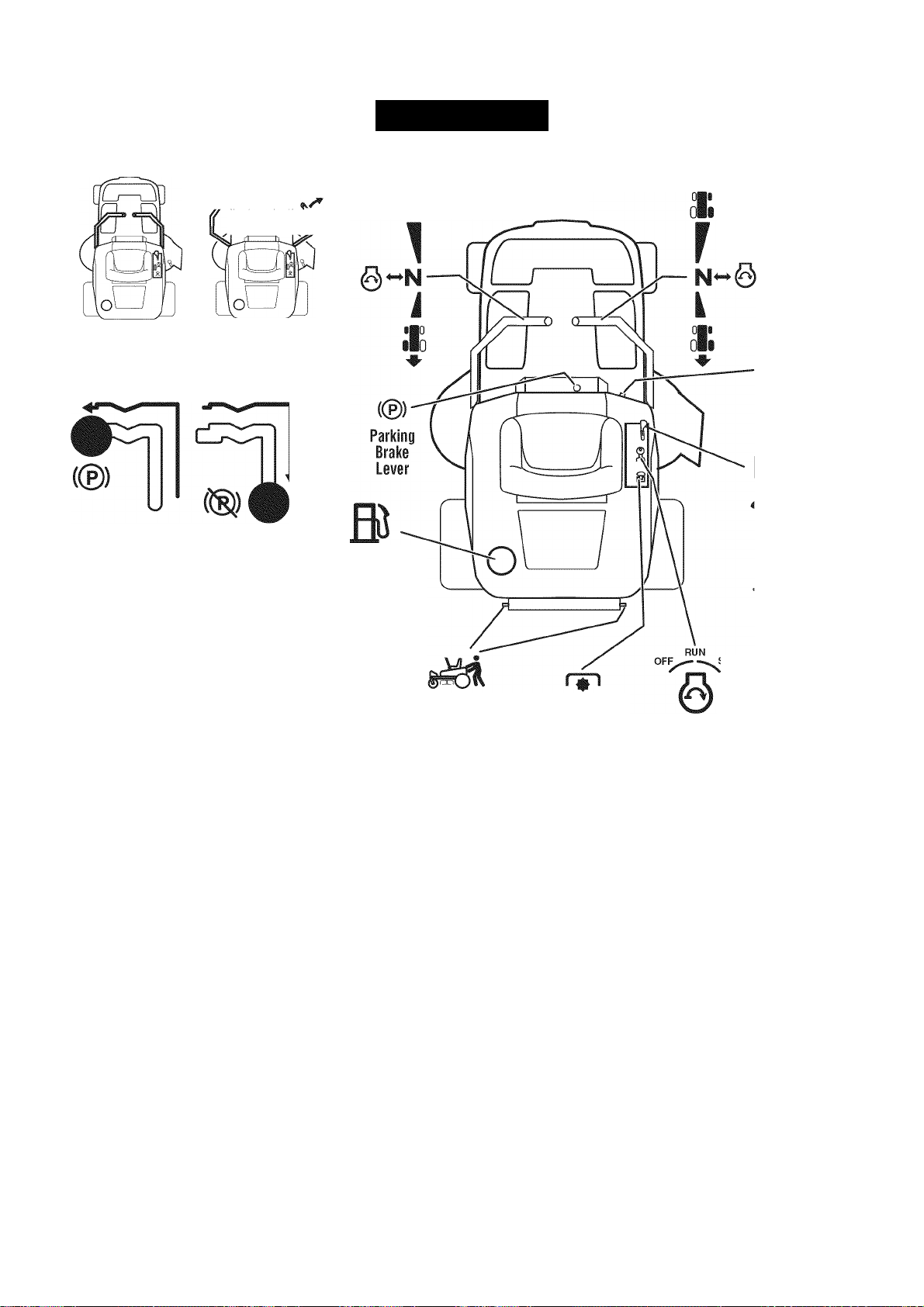

OPERATION

Ground Speed Levers -

DRIVE Positons

Parking Brake Lever -

ENGAGE Positon

..«P

JU U

Ground Speed Levers -

START/PARK Positons

Parking Brake Lever -

DISENGAGE

Positon

Fuel Tank

Cap

Left

Ground Speed

Control Lever

Right

Ground Speed &

Parking Brake

Lever

Mower

lUpl Cutting

Height

Switch

Choke

Engine

Speed

(Fast)

Engine

Speed

(Slow)

CONTROL FUNCTIONS

The information below briefly describes the

function of individual controls. Starting, stop

ping, driving, and mowing require the combined

use of several controls applied in specific

sequences. To learn what combination and

sequence of controls to use for various tasks

please read the entire section.

Ground Speed Levers

These levers control the ground speed of the rider. The

left lever controls the left rear drive wheel and the right

lever controls the right rear drive wheel.

Pushing the levers out to the side, away from the opera

tor’s lap (top inset. Figure 6), is the proper position for

starting the rider. Pulling the levers in across the opera

tor’s lap puts the levers in DRIVE positions.

From DRIVE position, moving a lever forward increases

the FORWARD speed of the associated wheel. Pulling

back on a lever increases the REVERSE speed. The fur

ther a lever is pushed, the faster the drive wheel will turn.

See DRIVING PRACTICE for steering instructions.

Transmission

Release Levers

START

Mower Biade

Switch

___

Parking Brake Lever

Move the parking brake lever (bottom inset. Figure 6) up

and across and into the locking notch to engage and lock

the parking brake. Move the parking brake lever across

and down to disengage the parking brake. The engine

will not start unless the parking brake is engaged.

NOTE: The parking brake must be disengaged before

operating the ground speed ievers.

Ignition

ignii

Swiwitch

Figure 6. Controls

Throttle/Choke Control (Choke0-Matic)

The throttle/choke controls the engine speed and choke.

Move the throttle/choke to the FAST position to increase

engine speed and SLCW position to decrease engine

speed. Always operate at full throttle. Move the throt

tle/choke control to the CFICKE position for starting a

cold engine. A warm engine may not require choking.

15

Page 16

Mower Cutting Height Switch

To increase the mower cutting height (raise the mower

deck), press the top of the yellow cutting height switch.

To decrease mower cutting height (lower the mower

deck), press the bottom of the switch. Mower cutting

height range is approximately 3-3/4” to 1-1/2” (9,5 to 3,8

cm). The cutting height gauge indicates the position of

the mower deck. The cutting height gauge is located on

the front of the rider, just behind the driver’s left leg.

Ignition Switch

The ignition switch starts and stops the engine; it has

three positions:

OFF Stops the engine and shuts off the

electrical system.

RUN All ows the engine to run and powers the

electrical system.

START Cranks the engine for starting.

NOTE: Never leave the ignition switch in the RUN posi

tion with the engine stopped. This drains the battery.

Mower Blade Switch

The yellow mower blade switch turns the mower blades

on and off. To turn the mower blades ON, pull the switch

up. To turn the mower blades OFF, push the switch down.

Always set the engine speed control to FAST before turn

ing the mower blades ON, and while mowing.

Transmission Release Levers

The transmission release levers deactivate the transmis

sions so that the unit can be pushed by hand. See

PUSHING THE UNIT BY HAND for operational informa

tion.

Fuel Tank

To remove the fuel tank cap, turn it counterclockwise.

GENERAL OPERATING SAFETY

Before first time operation:

• Be sure to read all information in the Safety and

Operation sections before attempting to operate this

rider and mower.

• Become familiar with all of the controls and how to

stop the unit.

• Drive in an open area without mowing to become

accustomed to driving the unit.

^WARNING

If you do not understand how a specific control

functions, or have not yet thoroughly read the

CONTROL FUNCTIONS section, do so now.

Do NOT attempt to operate the rider without first

becoming familiar with the location and function

of ALL controls.

16

Page 17

CHECKS BEFORE STARTING

• Check that the crankcase oil is filled to full mark on

dipstick.

• Fill the fuel tank with fresh fuel.

FUEL RECOMMENDATIONS

For daily operation: Use only unleaded gasoline with a

pump sticker octane rating of 87 or higher. Gasohol (up

to 10% ethyl alcohol, 90% unleaded gasoline by volume)

is approved as a fuel. Methyl Teriary Butyl Ether (MTBE)

and unleaded gasoline blends (up to a maximum of 15%

MTBE by volume) are approved as a fuel. No other gasoline/alcohol or gasoline/ether blends are approved. Do

not use fuel additives other than fuel stabilizer.

For storage: CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can attract mois

ture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system

of an engine while in storage.

To avoid engine problems always use fuel stabilizer,

especially before storage of 30 days or longer. Use fresh

fuel next season. See STORAGE instructions for addi

tional information.

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur. To add fuel:

1. Remove the fuel cap (B, Figure 7).

2. Fill the tank. Do not overfill. Leave room in the tank for

fuel expansion.

3. Install and hand tighten the fuel cap.

Figure 7. Pre-Start Checks

A. Fuel Tank Cap

A WARNING

Never operate on slopes greater than 17.6 percent

(10°) which is a rise of 3-1/2 feet (106 cm)

vertically in 20 feet (607 cm) horizontally.

Select slow ground speed before driving onto a

slope. Use extra caution when operating on

slopes with a rear-mounted grass catcher.

Mow across the face of slopes, not up and down.

Use caution when changing directions and DO

NOT START OR STOP ON A SLOPE.

^WARNING

Never allow passengers to ride on the unit.

Before leaving the operator’s position for any

reason, engage the parking brake, disengage the

PTO, stop the engine and remove the key.

To reduce fire hazard, keep the engine, rider and

mower free of grass, leaves and excess grease.

Do not stop or park rider over dry leaves, grass or

combustible materials.

Gasoline is highly flammable and must be

handled with care. Never fill the tank when the

engine is still hot from recent operation. Do not

allow open flame, smoking or matches in the area.

Avoid over-filling and wipe up any spills.

A WARNING -TRAILERS

Do not load this zero-turn rider on a trailer or

truck using two separate ramps. Only use a single

ramp that is at least one foot wider than the width

of the rear wheels of this rider. This rider has a

zero turning radius and the wheels could fall off

the ramps, or the rider could tip over injuring the

operator or bystanders.

17

Page 18

EMERGENCY STOPPING

In the event of an emergency the engine can be stopped

by simply turning the ignition switch to STOP. Use this

method only in emergency situations. For normal engine

shut down follow the procedure given in STOPPING THE

RIDER AND ENGINE.

STOPPING THE RIDER & ENGINE

1. Return the ground speed control levers to

START/PARK positions to stop rider movement.

2. Engage the parking brake.

3. Turn off the mower blades by pushing the mower

blade switch down to the OFF position.

4. Move the engine speed control to SLOW position and

turn the ignition switch to OFF. Remove the key.

STARTING THE ENGINE

1. While sitting in the seat, make sure the mower blade

switch is OFF, the ground speed control levers are

locked in START/PARK positions, and the parking

brake is engaged.

2. Move the throttle/choke control to the CHOKE posi

tion for starting a cold engine. A warm engine may

not require choking.

3. Insert the key into the ignition switch and turn it to

START to crank the engine.

4. After the engine starts, release the key. It will return to

the RUN position.

5. Move the throttle/choke to the FAST position to

increase engine speed and SLOW position to

decrease engine speed. Always operate at full throt

tle.

6. Warm the engine by running it for at least a minute

before turning on the mower blades, or driving the

unit.

ALWAYS operate the unit with the throttle/choke

control set to FAST when mowing or driving.

NEVER engage the mower blades with the engine

speed set to SLOW.

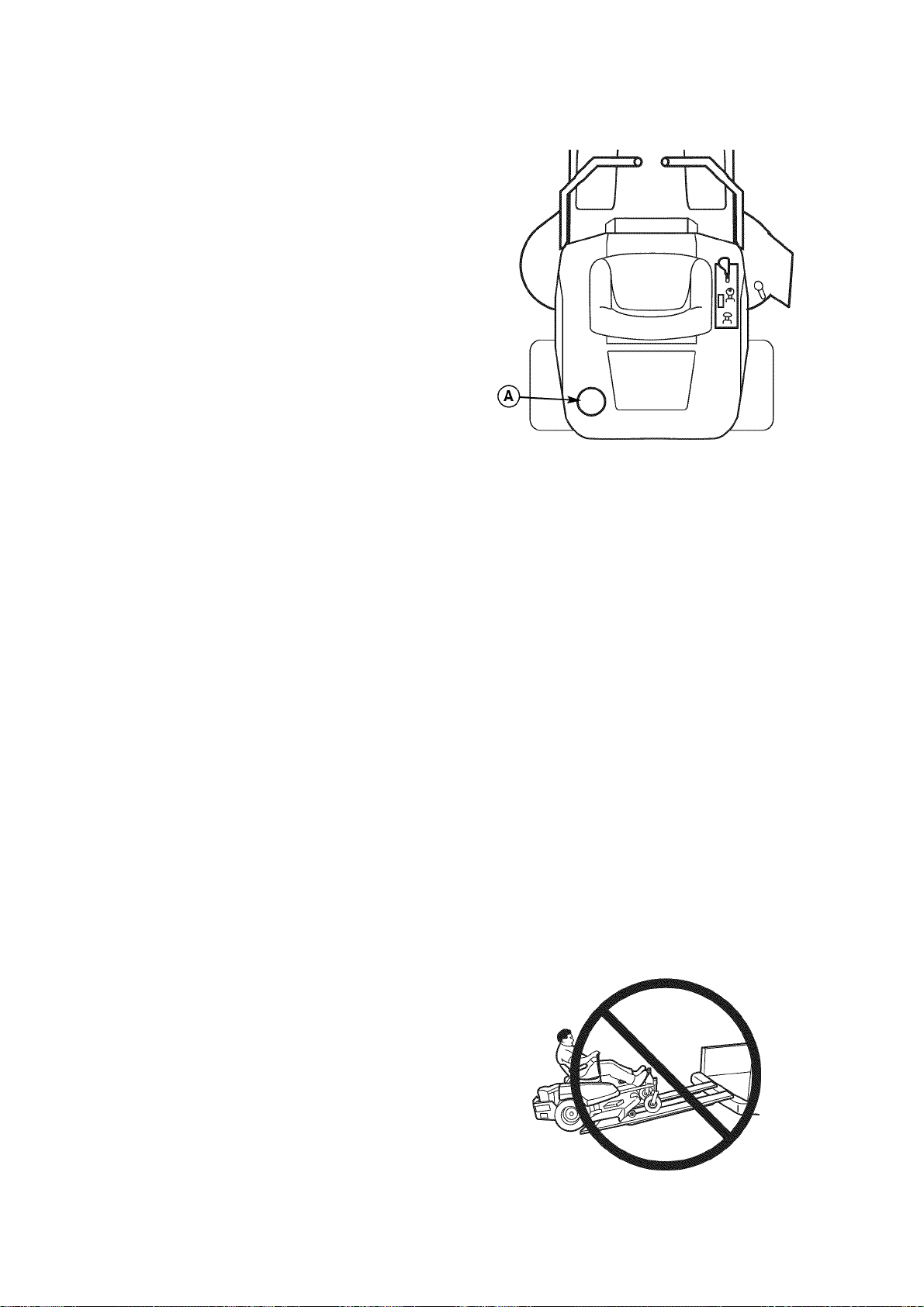

PUSHING THE RIDER BY HAND

NOTE: Do not disengage the transmission if parked on a

siope

1. Turn the mower blades OFF, push the ground speed

control levers out to their START/PARK positions,

engage the parking brake, turn the ignition switch

OFF,

remove the key, and wait for all moving parts to

stop.

2. Locate the transmission release levers (C, Figure 8)

at the rear of the unit.

3. Pull both levers back and down to release the trans

missions (position B, Figure 8).

4. Pull the ground speed control levers in to their DRIVE

positions, and disengage the parking brake.

The rider can now be pushed by hand.

5. After moving the rider, set the ground speed control

levers to START/PARK, engage the parking brake,

and push both transmission release levers forward to

re-engage the transmissions (position A, Figure 8).

DO NOT TOW RIDER

Towing the unit will cause transmission dam

0

age. Do not use another vehicle to push or

pull this unit. Do not use this unit to push or

pull another vehicle or object.

MOWING

1. start the engine (see STARTING THE ENGINE).

2. Set the mower cutting height to the desired setting

using the mower cutting height switch.

3. Set the engine speed control to FAST.

4. Turn the mower blades ON (pull switch up).

5. Disengage the parking brake.

6. Move the ground speed control levers in from

START/PARK positions to drive positions (levers in

across the operator’s lap).

7. Begin mowing. See DRIVING PRACTICE.

8. When finished, turn the mower blades OFF (push

switch down).

9. Stop the rider and engine (see STOPPING THE

RIDER AND ENGINE).

Figure 8. Transmission Release Levers

A. Drive Position

B. Push Position

C. Transmission Release Levers

18

Page 19

DRIVING PRACTICE -

BASIC DRIVING

WARNING: Never operate on slopes greater than 17.6%

(10°). See SLOPE OPERATION in the safety section.

Zero turn riders operate differently from other four

wheeled vehicles. The drive wheels are also your steer

ing wheels. If you cannot drive the unit on a hill, you will

not be able to steer the unit on it. Operating zero turn

units on slopes requires extra caution.

The lever controls of the zero turn rider are very respon

sive, and learning to gain a smooth and efficient control

of the rider’s forward, reverse, and turning movements

will take some practice.

Spend some time going through the following maneuvers

and becoming familiar with how the unit accelerates,

travels, and steers - before you begin mowing - is

absolutely essential to getting the most out of the zero

turn rider.

Locate a smooth, flat area of your lawn - one with

plenty of room to maneuver. (Clear the area of objects,

people and animals before you begin.) Operate the unit

at mid-throttle during this practice session (ALWAYS

operate at full throttle when mowing), and turn slowly to

prevent tire slippage and damage to your lawn.

We suggest you begin with the Smooth Travel procedure

to the right, and then advance through the forward,

reverse, and turning maneuvers.

A WARNING

Do not mow in reverse unless absolutely

necessary. Always look down and behind before

and while travelling in reverse.

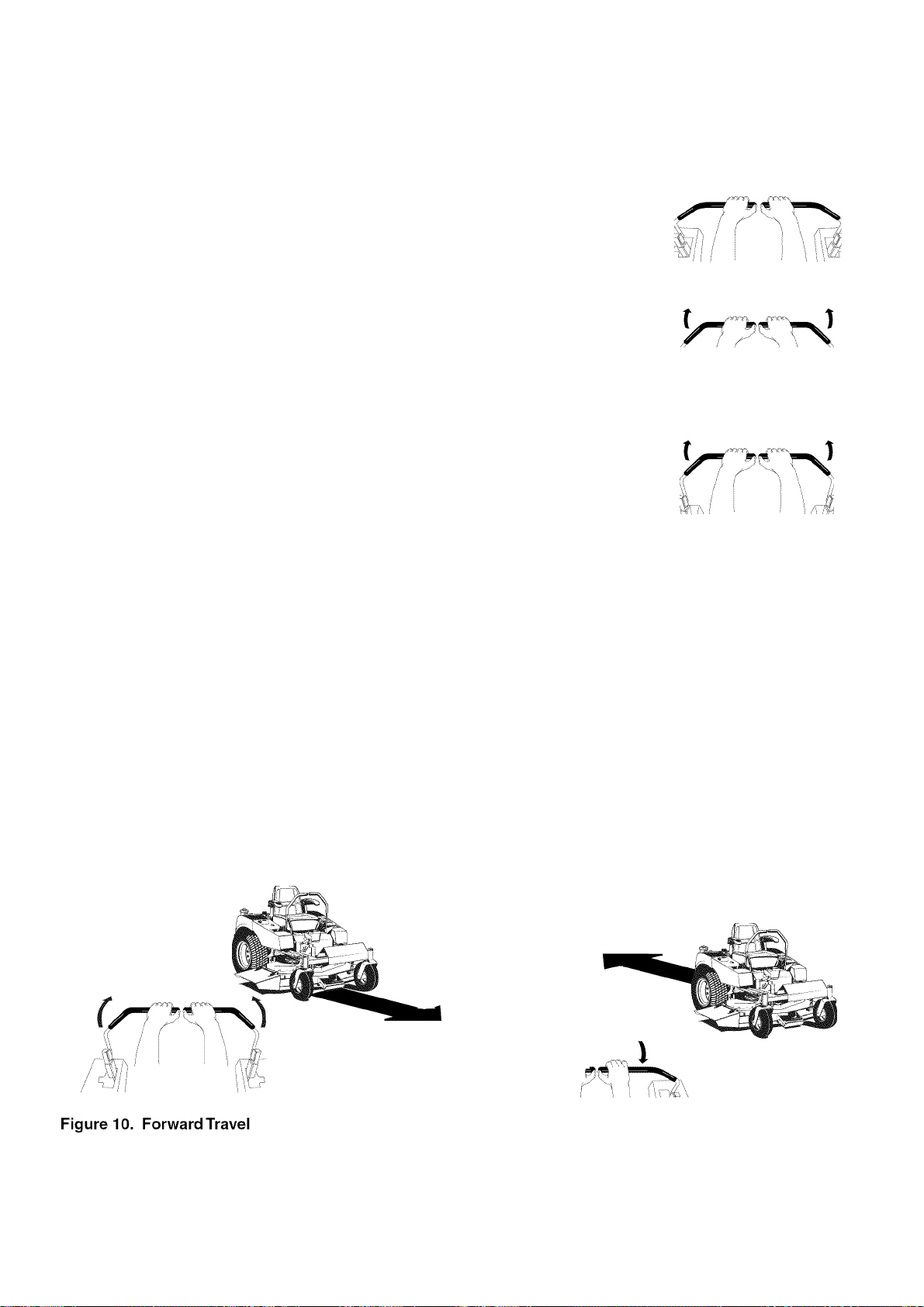

Smooth Travel

The lever controls of the

zero turn rider are

highly responsive.

The BEST method of

handling the ground

speed control levers is in

three steps - as shown

in Figure 9.

FIRST place your hands

onto the levers as

shown.

SECOND, to go forward

gradually push the levers

forward with your palms.

THIRD, to speed up

move the levers farther

forward. To slow down

smoothly, slowly move

the levers back toward

neutral.

Figure 9. Move Control

Levers Gradually

Forward Travel Practice

Gradually move both ground speed control levers evenly

FORWARD from neutral (see Figure 10). Slow down and

repeat.

Reverse Travel Practice

LOOK DOWN & BEHIND, then gradually move both

ground speed control levers evenly BACK from neutral

(see Figure 11). Slow down and repeat.

NOTE: Practice backing up for severai minutes before

attempting to do so near objects. The rider turns as

sharpiy in reverse as when going forward, and backing

up straight takes practice.

Forward Travel

Reverse Travel

i

~77?T

Figuren. Reverse Travel

19

Page 20

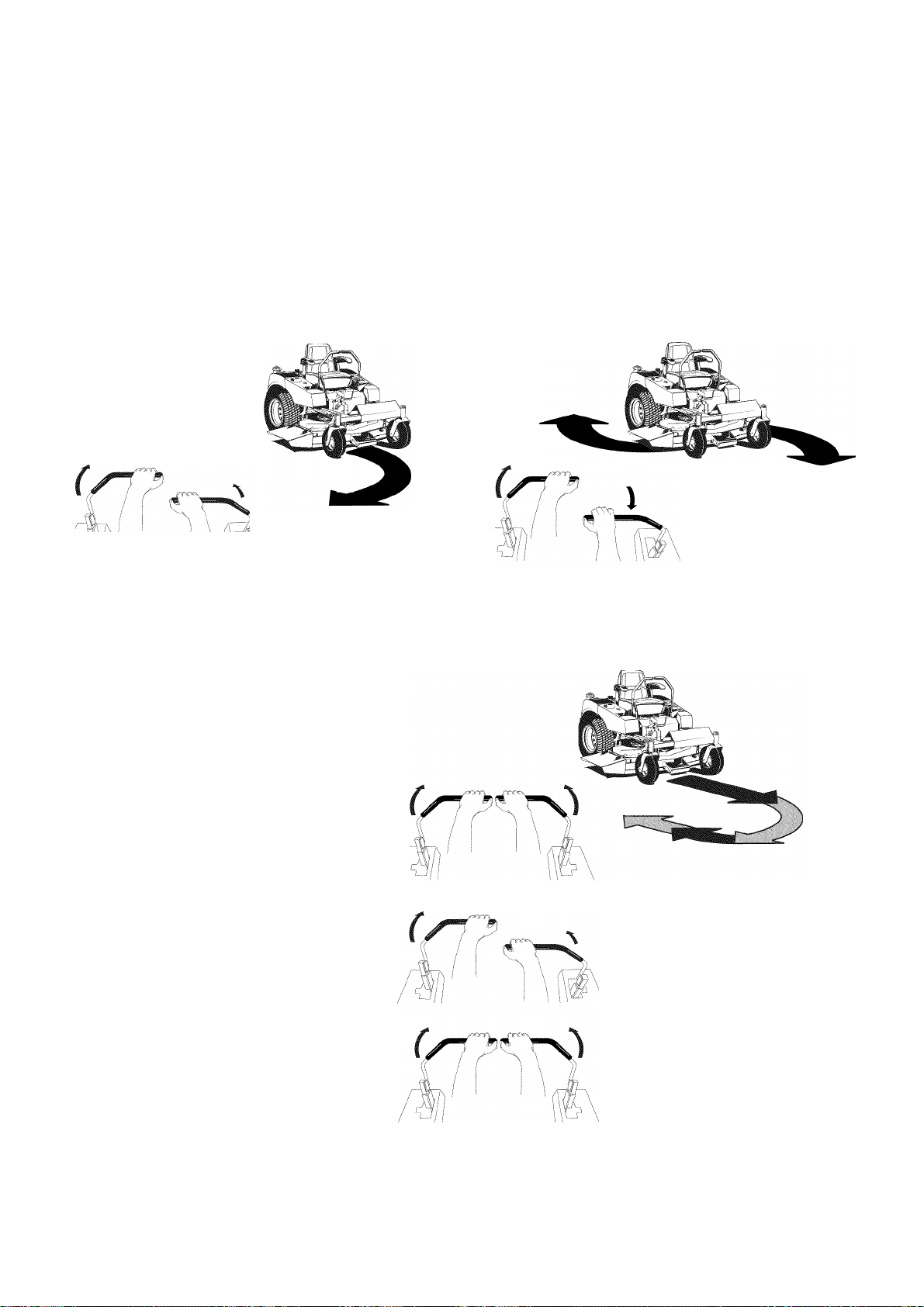

Practice Turning Around a Corner

Practice Turning In Place

While traveling forward allow one handle to gradually

return back toward neutral (see Figure 12). Practice sev

eral times before mowing.

NOTE: To prevent damaging your lawn by pivoting direct

ly on the tire tread, it is best to keep both wheels going at

least slightly forward.

Executing Turns

Figure 12. Right Turn

ADVANCED DRIVING

To “zero turn” means to turn in place. To turn in place,

gradually move one ground speed control lever forward

from neutral and one lever back from neutral simultane

ously (see Figure 13). Repeat several times.

Turning In Place

Figure 13. Turning in Place

Executing an End-Of-Row Zero Turn

Your zero turn rider’s unique ability to turn in

place allows you to turn around at the end of

a cutting row rather than having to stop and

make a Y-turn before starting a new row.

For example, to execute a right end-of row

zero turn:

1. Slow down at the end of the row.

2. Move the LEFT ground speed control

lever forward slightly while moving the

RIGHT ground speed control lever back to

center and then slightly back from center

(see Figure 14). Be sure to keep both

wheels moving to avoid turf damage.

3. Begin mowing forward again.

This technique turns the rider RIGHT and

slightly overlaps the row just cut - eliminating

the need to back up and re-cut missed grass.

/4s you become more familiar and experi

enced with operating the zero turn rider, you

will learn more maneuvers that will make your

mowing time easier and more enjoyable.

Remember, the more you practice, the bet

ter your control of the rider will be!

Figure 14. Executing an End-Of-RowTurn

20

Page 21

MOWER DECK REMOVAL & INSTALLATION

NOTE: Perform mower removal and installation on a

hard, level surface such as a concrete floor.

A WARNING

After lowering the mower cutting height, engage

parking brake, turn off the mower blades, turn the

ignition switch to STOP, and remove key before

attempting to install or remove the mower.

Removing the Mower Deck

1. Turn the mower blades OFF, put the ground speed

control levers in START/PARK position, turn the igni

tion OFF, and wait for all moving parts to stop.

2. Pivot the front wheels forward.

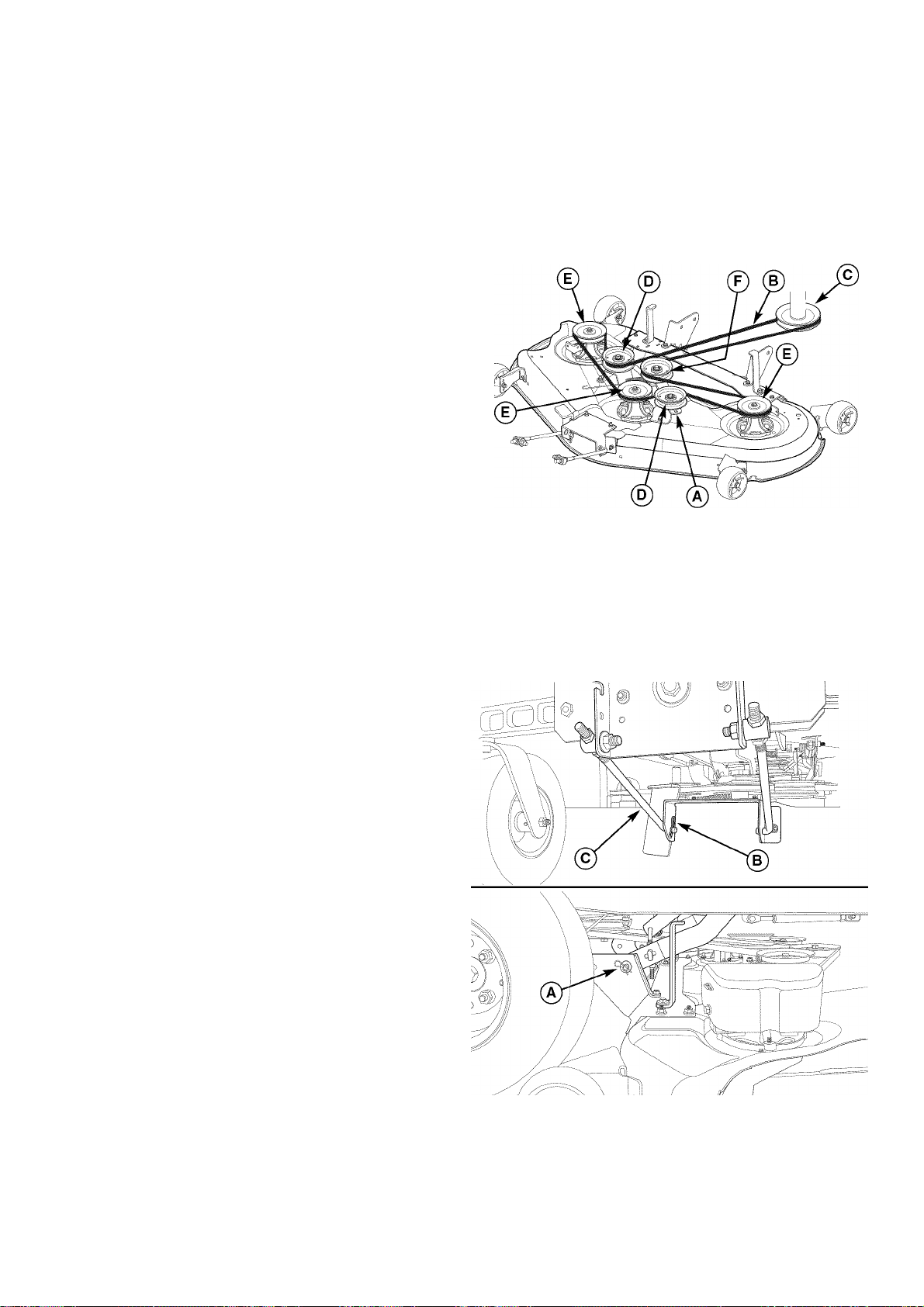

3. Insert ratchet into 3/8” (9.5 mm) square in idler pulley

arm (A, Figure 15) and pull to release belt tension.

Remove the mower belt (B) from engine drive pulley

(C).

4. Turn the ignition switch from OFF to RUN without

starting the engine.

5. Use the mower cutting height switch to raise the

mower deck.

6. Place 4x4 wood blocks under the front and rear lip of

the mower deck to securely support it.

7. Use the mower cutting height switch to fully lower the

mower so that is it resting on the 4x4 wood blocks.

8. Turn the ignition switch to OFF and remove the key.

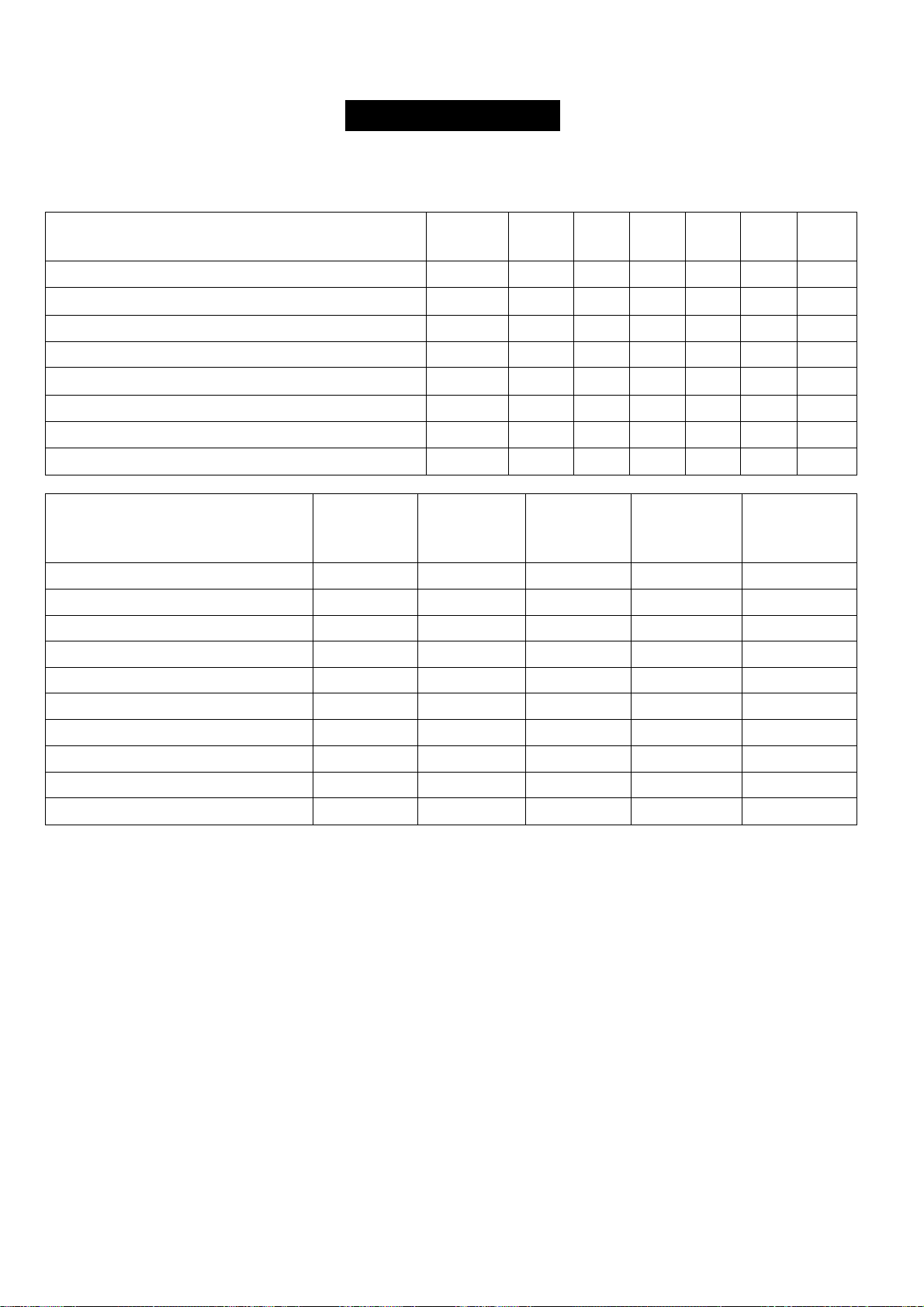

9. Remove the hair pin clip (A, Figure 16) securing the

rear mower lift arm. Separate the lift arm from the

mower deck. Repeat for both sides of mower.

10. Remove hair pin clip (B) securing the front hitch rod

(C). Separate the front hitch rod from the mower

deck. Repeat for both sides of mower.

11. Slide the mower deck out from under the rider.

6. Turn the ignition switch OFF and remove the key.

Remove the 4x4 wood blocks.

7. Insert ratchet into 3/8” (9.5 mm) square hole in idler

pulley arm (A, Figure 15) and pull to release belt ten

sion. Install the mower belt (B) as shown in Figure 15.

Figuréis. Mower Belt Routing

A. Idl er Pulley Arm

B. Mower Belt

C. Engine Drive Pulley

D. Fixed Idler Pulley (2)

E. Arbor Drive Pulley (3)

F. Adjustable Tension Idler Pulley

Installing the Mower Deck

1. Slide the mower deck under the right side of the rider.

Slide the mower forward and hook the front hitch rod

(C, Figure 16) to the front mower deck hooks.

2. Install the front hitch rods and secure with hair pin

clips (B).

3. Slide the mower deck backwards and connect the

rear lift arms to the mower deck. Secure with hair pin

clips (A).

4. Insert the key into the ignition switch. Turn the switch

from OFF to RUN without starting the engine.

5. Use the cutting height switch to raise the mower until

it is no longer resting on the 4x4 wood blocks.

Figuréis. Mower Hitch Components

A. Hair Pin Clip, Rear

B. Hair Pin Clip, Front

C. Front Hitch Rod

21

Page 22

MAINTENANCE

MAINTENANCE SCHEDULE

The following schedules should be followed for normal care of your rider and mower.

RIDER MAINTENANCE, All Models

Clean Debris from Rider and Engine Compartment *

Clean Debris from Engine Cooling Areas & Air Filter *

Check Tire Pressure

Lubricate Rider & Mower *

Clean Deck & Check/Replace Mower Blades

Clean Battery & Cables

Check Rider Safety System **

Check / Adjust PTC Clutch

ENGINE MAINTENANCE,

26HP Briggs & Stratton

Check Engine Oil Level * •

Service Air Pre-Cleaner * •

Change Oil * •

Service Air Filter * •

Change Oil & Filter * •

Clean Cooling Fins * •

Replace Air Filter * •

Replace Spark Plug •

Replace Fuel Filter f •

Check Valve Clearance f

8 Hours or

Daily

Before

Each Use

•

•

25 Hours or

Every

Season

Spring

&Fall8Hours25Hours

•

•

•

• • •

50 Hours or

Every

Season

100 Hours or

Every

Season

100

Hours

•

200

Hours

•

Yearly

Yearly

•

* More often in hot (over 85° F: 30° C) weather or dusty operating conditions.

** Check the function of the safety system after the unit has been stored for 30 days or longer,

t These services should be performed by Sears or other qualified service dealer.

22

Page 23

Rider Maintenance Items

A WARNING

Move the ground speed levers to START/PARK

positions, engage the parking brake, turn the

mower blades OFF, turn the ignition switch OFF,

and wait for all moving parts to stop before

accessing the engine compartment or performing

any maintenance procedures.

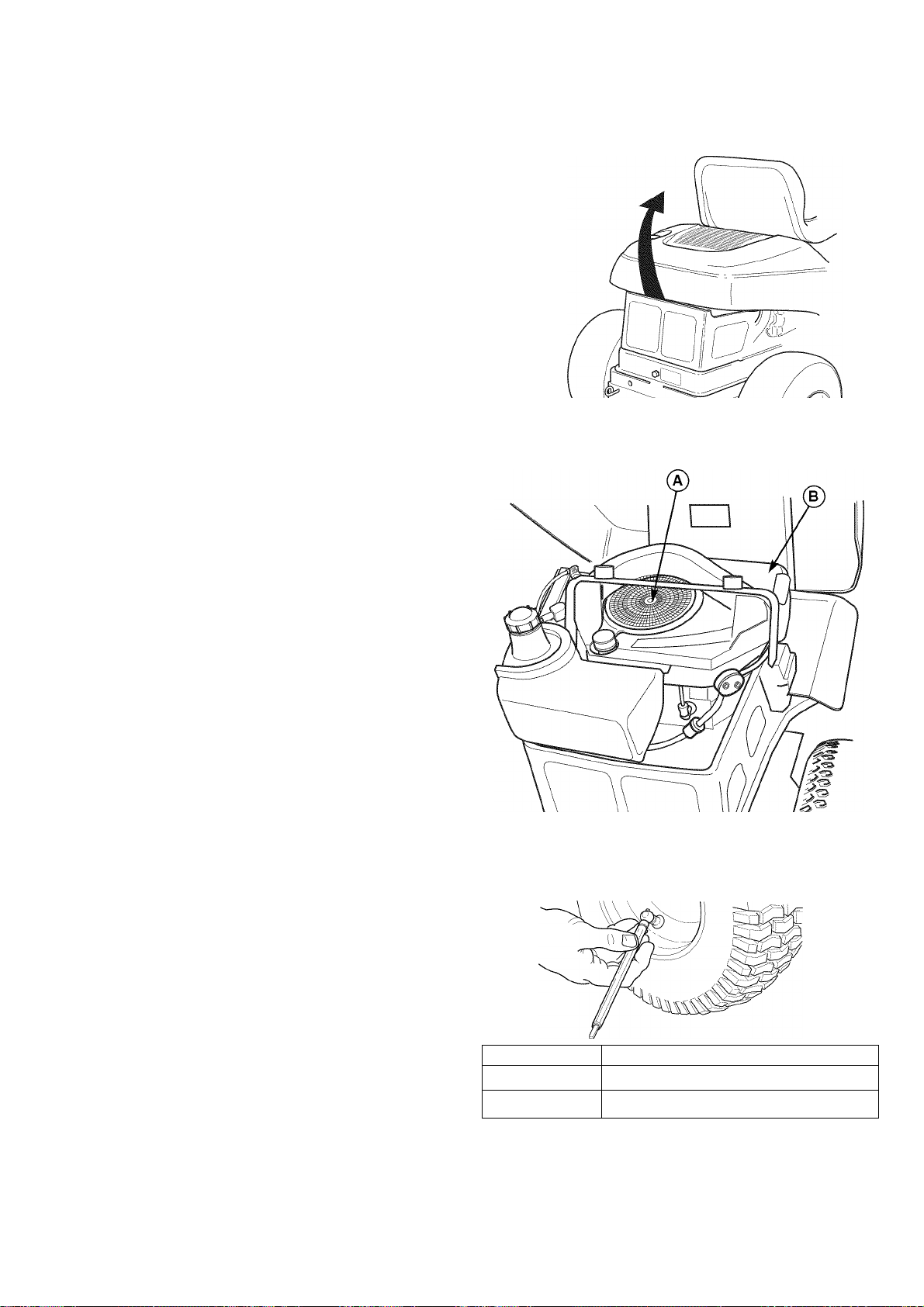

ACCESSING THE ENGINE COMPARTMENT

Lift up on the back edge of the seat deck to access the

engine compartment (see Figure 17).

CLEAN DEBRIS FROM RIDER AND

ENGINE COMPARTMENT

Service Interval: Before each use.

CAUTION: If debris is not removed from the engine

compartment and other hot surfaces, it creates a fire

hazard. Before starting the unit at the beginning of the

mowing session, remove any grass clippings, dirt,

leaves, or other debris from the unit. Also clean out the

engine compartment.

Figure 17. Accessing the Engine Compartment

CLEAN DEBRIS FROM ENGINE COOLING AREAS AND AIR FILTER

Service Interval: Before each use.

CAUTION: If debris is not removed from the engine

compartment and other hot surfaces, it creates a fire

hazard. Before starting the unit at the beginning of the

mowing session, lift the seat deck and clean any debris

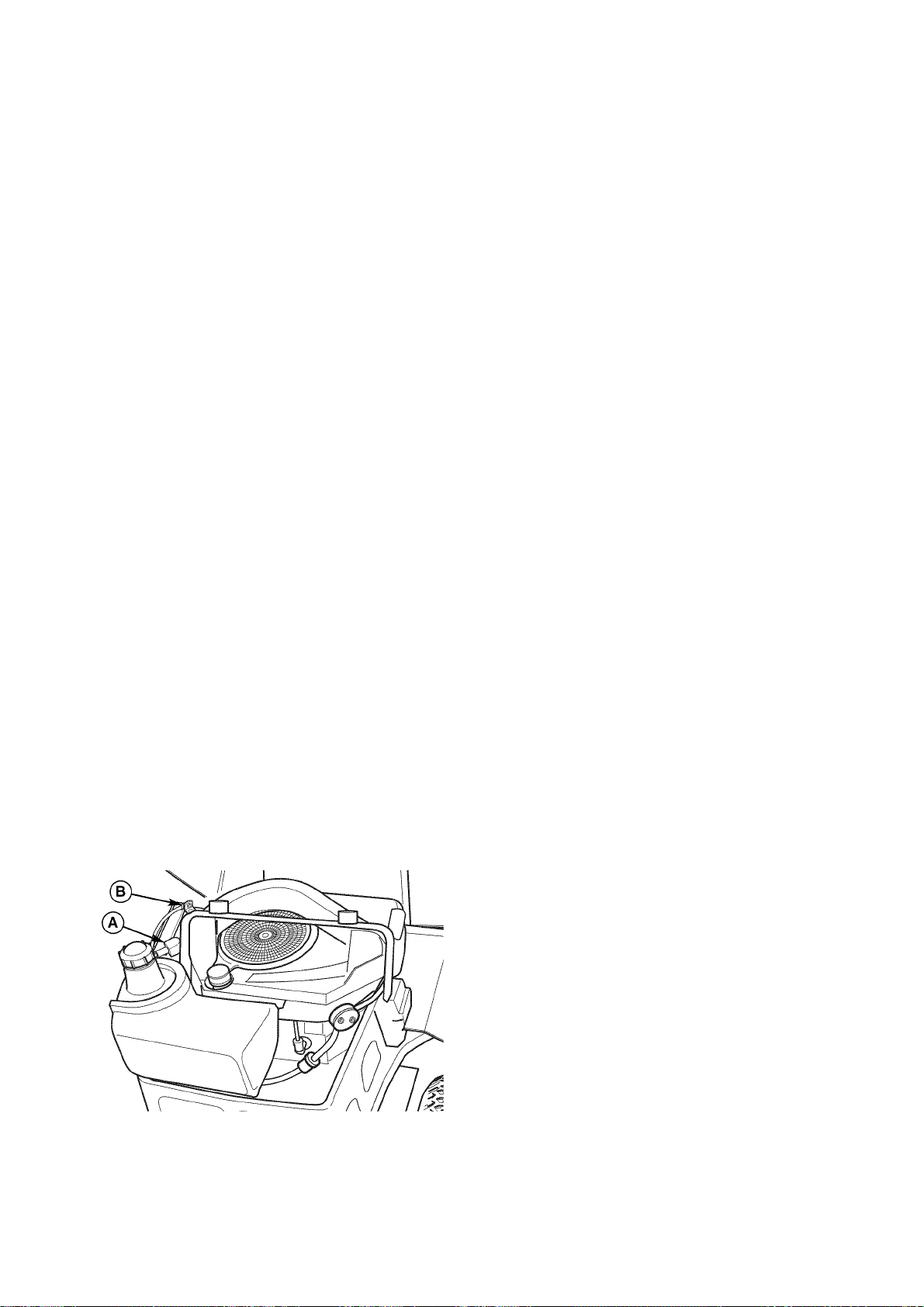

from the intake screen on top of the engine (A, Figure

18), exposed engine cooling fins, and around the air filter

assembly. Also open the air filter cover (B) and remove

any debris that has accumulated in the air filter compart

ment.

CHECKTIRE PRESSURE

Service Interval: 25 Hours.

Tire pressure should be checked periodically, and main

tained at the levels shown in Figure 19. Note that these

pressures may differ slightly from the “Max Inflation”

stamped on the side-wall of the tires. The pressures

shown provide proper traction, improve cut quality, and

extend tire life.

Figure 18. Engine Compartment

A. Intake Screen

B. Air Filter Cover

Tire Pressure

Front 18-20 psi (1,24-1,38 bar)

Rear 10-12 psi (,69-,83 bar)

Figure 19. Tire Pressures

23

Page 24

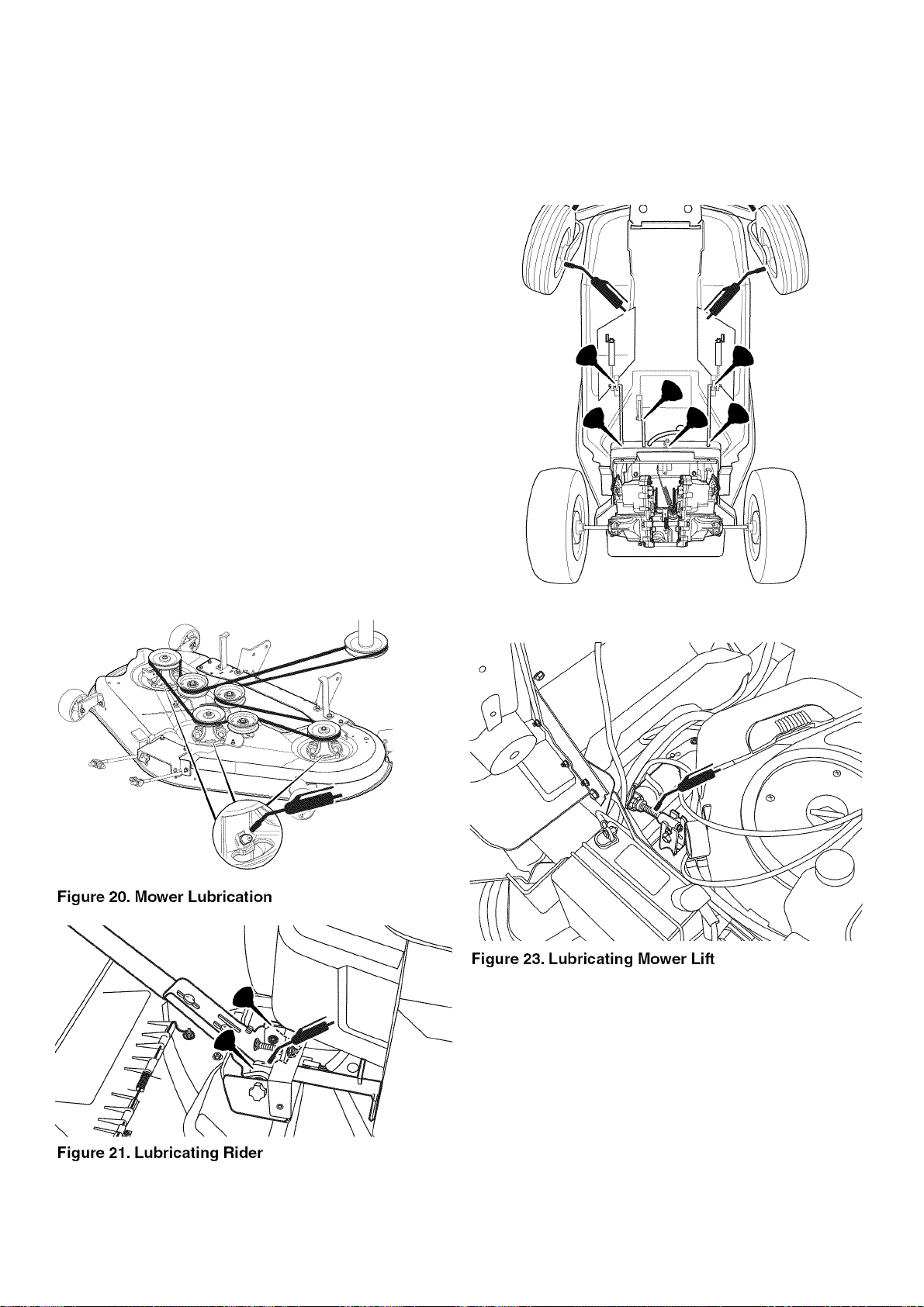

LUBRICATION

Service Interval: 25 hours.

Lubricate the unit at the locations shown in Figures 20

through 23 as well as the following lubrication points.

Grease:

/ • front wheel grease fittings

I • front wheel bushings

A • mower arbors

Use grease fittings when present.

Not all greases are compatible. Use automotive-type lithi

um grease.

Oil:

• hydro linkage

1 • brake linkage

• frame pivot points

• mower deck height adjustment linkage

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off

belts and pulleys. Remember to wipe fittings and sur

faces clean both before and after lubrication.

Figure 22. Lubricating Rider

24

Page 25

CLEAN DECK &

CHECK / REPLACE MOWER BLADES

Service Interval: 25 hours or as required.

A WARNING

For your personal safety, do not handle the sharp

mower blades with bare hands. Careless or

improper handling of blades may result in serious

injury.

A WARNING

For your personal safety, blade mounting

capscrews must each be installed with a spring

washer, then securely tightened. Torque blade

mounting capscrew to 45-55 ft-lbs (61-75 Nm).

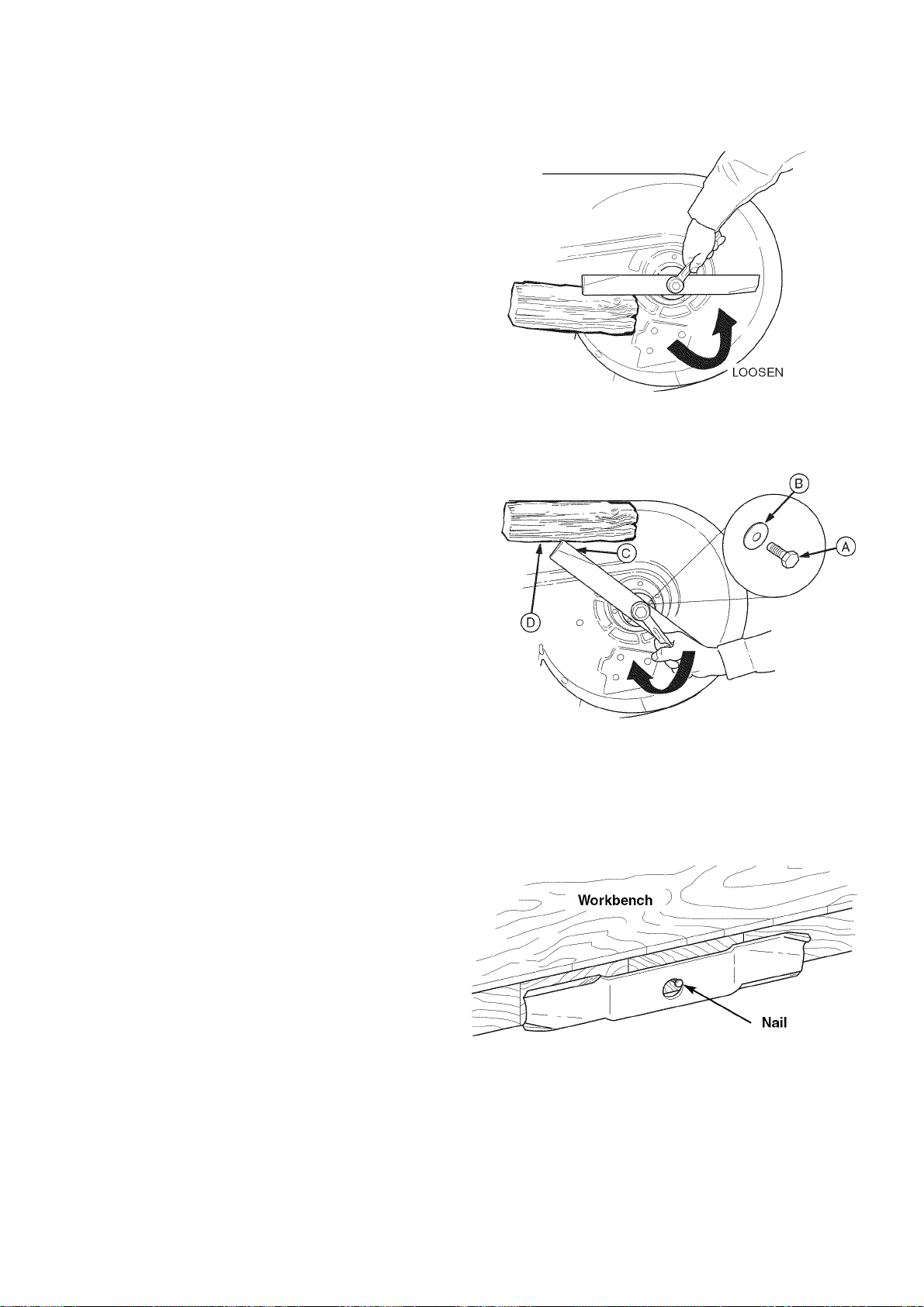

1. Remove mower deck (see “Mower Deck Removal” in

the OPERATION section).

2. Remove blade to inspect it or to safely access the

underside of the mower deck (see Figure 24). Use a

block of wood to prevent blade rotation while loosen

ing the capscrew by turning it counterclockwise.

3. Remove the capscrew (A, Figure 25), spring washer

(B), and blade.

4. Clean the underside of the mower deck.

5. Inspect the blades for nicks or dull edges. Use a file

to sharpen blade to a fine edge. If the blade is dam

aged, it must be replaced.

6. Balance the blade as shown in Figure 26. Center the

blade’s hole on a nail lubricated with a drop of oil. A

balanced blade will remain level. If the blade is not

balanced, continue to sharpen the heavy side until it

balances.

7. Reinstall the blade with the lift wings (C, Figure 25)

pointing up toward the mower deck as shown.

8. Reinstall the spring washer (B) and capscrew (A).

Use a wooden block (B) to prevent blade rotation

while tightening the capscrew (A) to 45-55 ft-lbs (61

75 Nm). Turn capscrew clockwise to tighten.

Figure 24. Blade Removal

Figure 25. Blade Installation

A. Blade Capscrew

B. Spring Washer

C. Lift Wings

D. 4x4 Wood Block

Figure 26. Balancing the Blade

25

Page 26

CLEANING THE BATTERY AND CABLES

A WARNING

Corrosion hazard.

Batteries contain acid. Always keep the

battery upright and do not spill the

electrolyte. Avoid contact with skin and

eyes.

Explosion hazard.

Changing the battery produces explosive

hydrogen gas. Only charge the battery in a

well ventilated area, away from any ignition

source such as a water heater, electric

motor, or a lit cigarette.

Wear Protective Equipment

Always wear gloves and safety glasses

when handling the battery and battery

cables.

Service Interval: 100 Hours

1. Disconnect the cables from the battery, negative

cable first (B, Figure 27).

2. Remove the rubber strap securing the battery, and

remove the battery.

3. Clean the battery and battery compartment with a

solution of baking soda and water.

4. Clean the battery terminals and cable ends with a

wire brush until shiny.

5. Reinstall the battery and secure with the rubber strap.

6. Reattach the battery cables: first attach the positive

cable (see A, Figure 27), then attach the negative

cable (B).

7. Coat the cable ends and battery terminals with petro

leum jelly or non-conducting grease.

CHECK RIDER SAFETY

SYSTEM

A

Service Interval: Every 100 hours, every spring/fall,

and after storage of 30 days or longer.

This unit is equipped with safety interlock switches.

These safety systems are present for your safety. Do

not attempt to bypass safety switches, and never tamp

er with safety devices. Check their operation regularly.

Operational SAFETY Checks

TEST 1 — ENGINE SHOULD NOT CRANK IF:

• Mower blades switch is ON, OR

• Ground speed control levers are not in their

START/PARK positions, OR

• Parking brake lever is in DISENGAGE position.

TEST 2 — ENGINE SHOULD CRANK IF:

• Mower blade switch is OFF, AND

• Ground speed control levers are in their

START/PARK positions, AND

• Parking brake lever is in ENGAGE position.

TEST 3 — ENGINE SHOULD SHUT OFF IF:

• Operator rises off seat with the mower blade switch

ON, OR

• Operator rises off seat with the ground speed levers

in DRIVE positions, OR

• Operator rises off seat with the parking brake in

DISENGAGE position, OR

• Operator moves the left and/or right ground speed

control lever out of its START/PARK position with

the parking brake lever in ENGAGE position.

TEST 4 — BLADE BRAKE CHECK

The mower blades and mower drive belt should come

to a complete stop within five seconds after the mower

blade switch is turned OFF. If mower drive belt does

not stop within five seconds, contact your local author

ized dealer.

NOTE: Once the engine has stopped, the mower blade

switch must be turned OFF, the ground speed control

levers must be locked in their START/PARK positions,

and the parking brake lever must be in the ENGAGE

position in order to start the engine.

Figure 27. Engine Compartment

A. Positive (+) Battery Cable

B. Negative (-) Battery Cable

A WARNING

If the unit does not pass a safety test, do not oper

ate it. See your local authorized dealer. Under no

circumstance should you attempt to defeat the pur

pose of the safety interlock system.

26

Page 27

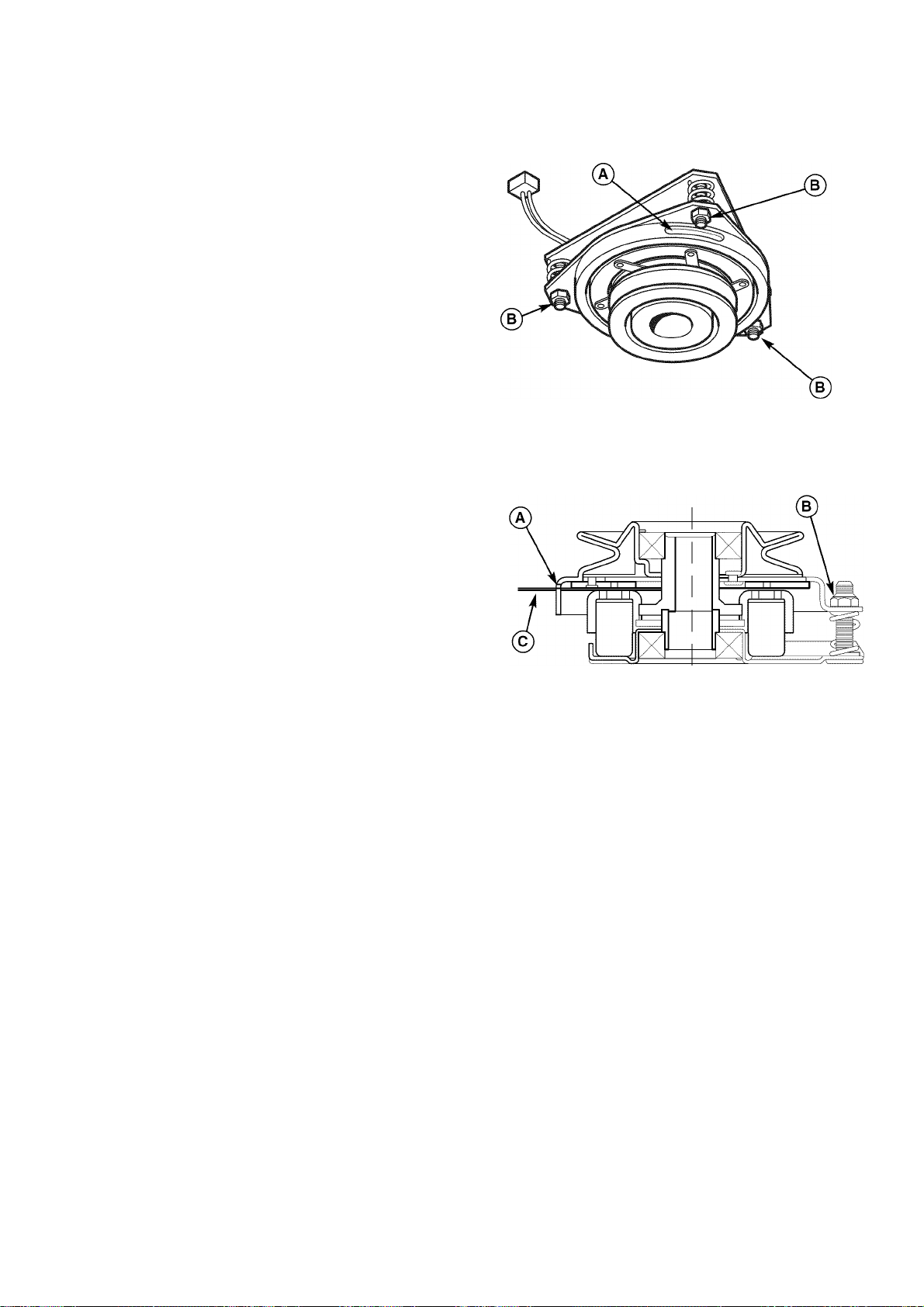

CHECK / ADJUST PTO CLUTCH

A WARNING

To avoid serious injury, perform adjustments only

with engine stopped, key removed and tractor on

level ground.

Service Interval: 200 Hours.

The Power Take Off (PTO) clutch drives the mower

blades. The PTO clutch is engaged and disengaged by

the mower blade switch. Check the PTO clutch adjust

ment every 200 hours of operation. Also perform the fol

lowing procedure if the clutch is slipping, will not engage,

or if a new clutch has been installed.

1. Remove key from ignition switch and disconnect

spark plug wires to prevent the possibility of acciden

tal starting while the PTO is being adjusted.

2. Note the position of the 3 adjustment windows (A,

Figure 28) in the side of the brake plate and the

nylock adjustment nuts (B).

3. Insert a .012”-.015” (2,5-4 mm) feeler gauge (C)

through each window, positioning the gauge between

the rotor face and the armature face as shown in

Figure 29.

4. Alternately tighten the adjustment nuts (B, Figure 29)

until the rotor face and armature face just contacts

the gauge.

5. Check the windows for an equal amount of tension

when the gauge is inserted and removed, and make

any necessary adjustments by tightening or loosen

ing the adjustment nuts.

NOTE: The actual air gap between the rotor and arma

ture may vary even after performing the adjustment pro

cedure. This is due to dimensional variations on compo

nent parts, and is an acceptable condition.

6. Check the mower blade stopping time. The mower

blades and mower drive belt should come to a com

plete stop within five seconds after the electric PTO

switch is turned off. If adjustment does not stop a

mower braking problem, replace the electric PTO

clutch.

Figure 28. PTO Clutch Adjustment

A. Adjustment Window (Qty. 3, one shown)

B. Adjustment Nut (3)

Figure 29. Adjust PTO Clutch

A. Window

B. Adjustment Nut

C. Feeler Gauge

27

Page 28

Engine Maintenance Items

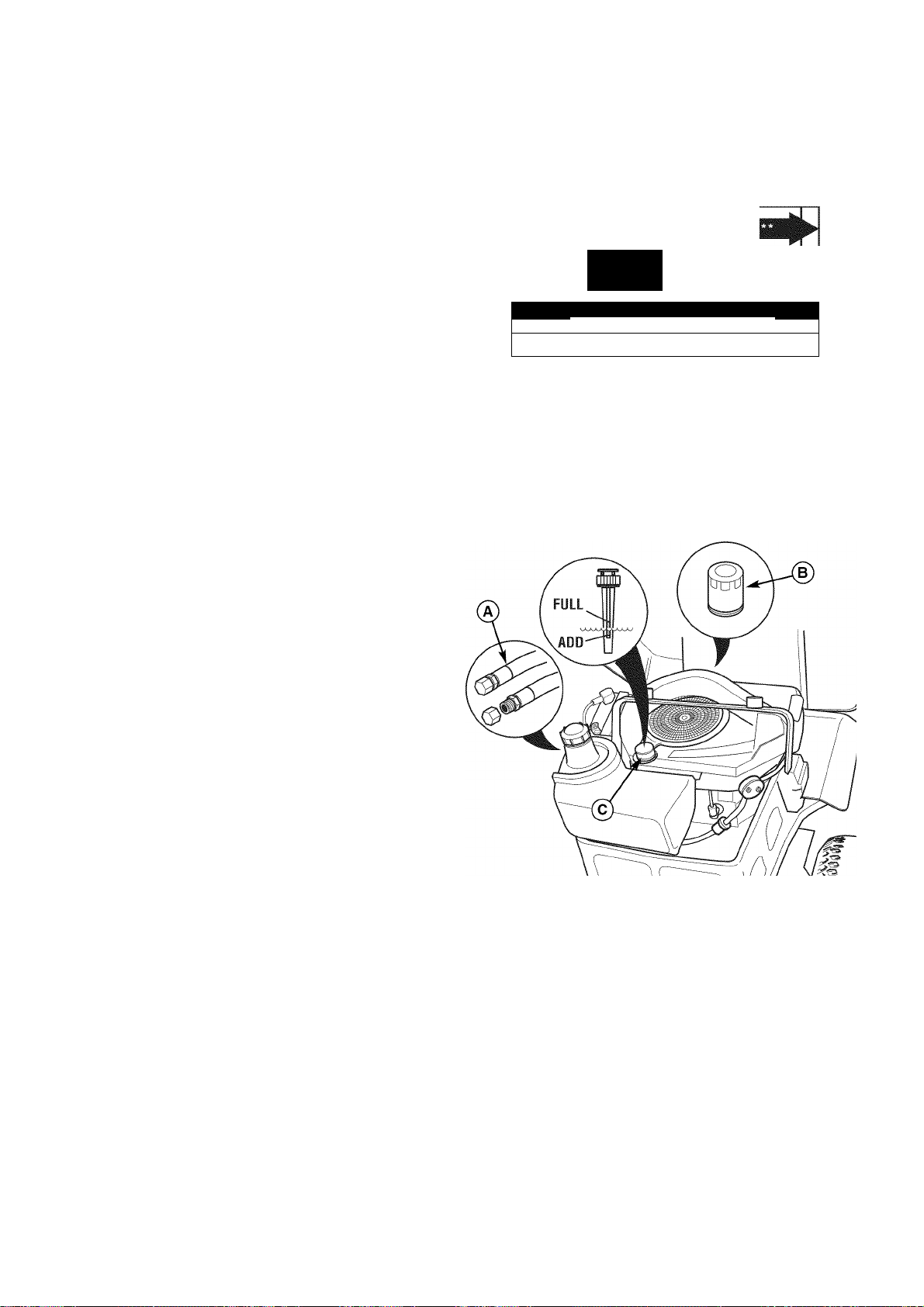

CHECK ENGINE OIL LEVEL

Service Interval: Before each use, and every 8 hours.

1. Turn the engine off, and set the parking brake lever to

ENGAGE.

2. Clean the area around the dip stick (C, Figure 31).

3. Remove the dip stick (C) and clean it with a paper

towel.

4. Insert the dip stick back into the engine. Thread the

cap back into the tube (D).

5. Remove the dip stick and read the oil level. The oil

level should be between the “FULL” and “ADD” marks

(D). If not, add oil according to the oil recommenda

tions chart (Figure 30).

CHANGE ENGINE OIL

Service Interval: 50 hours or once per season.

NOTE: Change engine oil while the engine is warm. Run

the engine for a few minutes, then shut the engine off

and allow it to cool from hot to warm.

1. Clean the area around the dip stick (C, Figure 31)

and oil drain tube (A).

2. Remove the oil drain plug (A) from the end of the oil

drain tube. Remove the dip stick (C). Allow ample

time for complete drainage.

3. Reinstall the oil drain plug (A) and route the hose

next to the engine.

4. Fill the crankcase with oil. See CHECK ENGINE OIL

LEVEL above.

5. Start and run the engine at SLOW speed for 30 sec

onds. Stop the engine and recheck the oil level.

Use oil classified API Service Class SF,

SG, SH, SJ or better with SAE Viscosity:

5W-30

10W-30

Conventional*

w

•F -2010 20 32 40 60 80

•C -30 -18 -7 0 4 16 27 38

‘CAUTION: Air cooled engines run hotter than automotive engines.

The use of non-synthetic multi-viscosity oils (5W-30,10W-30, etc.)

in temperatures above 40° F (4°C) will result in higher than normal

oil consumption. When using a multi-viscosity oil, check oil level

more freguently.

“CAUTION: SAE 30 oil, if used below 40° F (4°C), will result in hard

starting and possible engine bore damage due to inadeguate

lubrication.

Figure 30. Recommended Engine Oil

Synthetic 5W-30.10W-30

1

\

100

CHANGE ENGINE OIL & FILTER

Service Interval: 100 hours or once per season.

NOTE: Change engine oil while the engine is warm. Run

the engine for a few minutes, then shut the engine off

and allow it to cool from hot to warm.

1. Clean the area around the dip stick (C, Figure 31)

and oil drain (A).

2. Remove the oil drain plug (A) and dip stick (C). Allow

ample time for complete drainage.

3. Remove the oil filter (B). Discard the filter.

4. Using a drop of oil on your finger tip, wet the rubber

gasket on the bottom of the new filter.

5. Turn the filter clockwise until the rubber gasket meets

the filter base. Then turn 1/2 to 3/4 turn more.

Figure 31. Oil Change

A. Oil Drain Tube

B. Oil Filter

C. Dip Stick

6. Reinstall the oil drain plug (A).

7. Fill the crankcase with oil. See CHECK ENGINE OIL

LEVEL above.

8. Start and run the engine at SLOW speed for 30 sec

onds. Stop the engine and recheck the oil level.

9. Test run the engine to check for leaks. Stop the

engine for 1 minute, then recheck the oil level.

28

Page 29

REPLACE AIR FILTER

Service Interval: Every 25 hours or as required.

1. Loosen the air filter cover screws (A, Figure 32) and

remove the air filter cover.

Figure 32. Air Filter Cover

A. Air Filter Cover Screws

Figure 33. Air Filter Removal

A. Filter Cartridge

■

2. Locate the air filter cartridge (A, Figure 33). Pull up

on the front edge of the cartridge until it snaps out of

place.

3. Inspect the cartridge for dirt or damage.

If the thin foam sleeve surrounding the filter is dam

aged, replace the filer. DO NOT oil the foam sleave or

cartridge. If there is oil of heavy dirt on the cartridge,

replace it.

DO NOT use pressurized air or solvents to clean the

filter cartridge.

Remove any dirt from the air filter housing.

4. Replace the cartridge by aligning the hole of the car

tridge with the air vent (A, Figure 34).

5. Push the cartridge in toward the engine until it snaps

into place.

6. Reinstall the air filter cover and tighten the screws (A,

Figure 32).

ip

■

Figure 34. Air Filter Installation

A. Filter Cartridge

29

Page 30

REPLACE SPARK PLUG

Service Interval: Every 100 hours.

Replacement Spark Plug: 491055S

Spark Plug Gap: .030” (.76mm)

1. Stop the engine and allow it to cool.

2. Clean the area around the spark plug.

3. Remove the spark plug.

4. Check the spark plug gap. It should be .030” (.76

mm) (see Figure 35).

5. Reinstall the plug into the cylinder head. Tighten the

plug to 180 in-lbs (20 Nm).

CLEAN COMBUSTION CHAMBER

Service Interval: 100-400 hours

In order to maintain emission compliance, we recom

mend that after every 100-400 hours of operation that

you have an authorized Briggs & Stratton or Sears

Service Center remove combustion deposits from the

cylinder, cylinder head, top of piston, and around the

valves.

.030”

(.76 mm)

30

Page 31

SERVICE & ADJUSTMENTS

GROUND SPEED CONTROL LEVER ADJUSTMENT

The control levers have three adjustments:

To Adjust Control Lever Height: Pull the levers in

across the operator’s lap to their DRIVE positions.

Loosen the mount bolts (D, Figure 36) and raise or lower

the levers to the desired position. Tighten the mounting

bolts.(D).

To Adjust Control Lever End Gap: The control lever

end gap should be adjusted so that the levers do not

contact each other when placed in DRIVE positions.

Loosen the jam nut (A, Figure 36) and adjust the length

of the carriage bolt (B) so that the levers do not contact

each other. Repeat on the opposite side. Tighten the jam

nut (A) to lock the carriage bolt in position.

To Adjust Operator Clearance: The space between the

operator and the control levers can be increase by

removing the lower mounting bolt (D, Figure 36), pivoting

the lever forward, and reinstalling the capscrew through

the control lever and forward slot (C). Repeat with the

other ground speed lever.

SPEED BALANCING ADJUSTMENT

Figure 36. Control Lever Adjustment

A. Jam Nut

B. Carriage Bolt

C. Forward Slot

D. Mount Bolts

E. Knob

If the rider veers to the right or left when the ground

speed control levers are in the maximum forward posi

tion, the top speed of the right lever can be balanced by

turning the adjustment knob (E, Figure 36). Loosen the

jam nut and turn the knob COUNTERCLOCKWISE to

increase speed or CLOCKWISE to decrease speed.

Tighten the jam nut when complete.

CUTTING HEIGHT ADJUSTMENT

To increase the mower cutting height (raise the mower

deck), press the top of the mower cutting height switch

(A, Figure 37). To decrease mower cutting height (lower

the mower deck), press the bottom of the switch. Mower

cutting height range is 3-3/4” to 1-1/2” (9,5-3,8 cm). The

cutting height gauge indicates the position of the mower

deck. The cutting height gauge (B) is located on the front

of the rider, just behind the driver’s left leg.

PTO CLUTCH ADJUSTMENT

See CHECK / ADJUST PTO CLUTCH in the

Maintenance Section.

Figure 37. Cutting Height Adjustment

A. Cutting Height Adjustment Switch

B. Cutting Height Gauge

31

Page 32

BRAKE ADJUSTMENT

1. Stop the unit, set the ground speed levers to

START/PARK positions, set the parking brake lever to

the ENGAGE position, turn the ignition OFF, and wait

for all moving parts to stop. Remove the key.

2. Set both transmission release levers to the PUSH

position. (Refer to “Pushing the Rider by Hand”.)

3. Push the rider forward to make sure both transmis

sion brakes are fully engaged and both rear wheels

are locked in the stationary position (no rotation).

4. Locate the brake rod (A, Figure 38) and adjustment

nut (B).

5. Measure the parking brake spring. Its compressed

length, with the parking brake lever in the ENGAGE

position, should be 3-1/2” (8,89 cm). Adjust the spring

length by turning the adjustment nut (B), if necessary.

A WARNING

Corrosion hazard.

Batteries contain acid. Always keep the

battery upright and do not spill the

electrolyte. Avoid contact with skin and

eyes.

Explosion hazard.

Changing the battery produces explosive

hydrogen gas. Only charge the battery in a

well ventilated area, away from any ignition

source such as a water heater, electric

motor, or a lit cigarette.

Wear Protective Equipment

Always wear gloves and safety glasses

when handling the battery and battery

cables.

BATTERY CHARGING

A dead battery or one too weak to start the engine may

be the result of a defect in the charging system or other

electrical component. If there is any doubt about the

cause of the problem, contact your local dealer. If you

need to replace the battery, follow the steps under

Cleaning the Battery & Cables in the Regular

Maintenance Section.

Figure 38. Brake Adjustment

A. Brake Rod

B. Adjustment Nut

C. Return Spring (Removed for Illustration Only)

D. Return Spring Hole

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the safety rules sections of this book. Charge

the battery until fully charged (until the specific gravity of

the electrolyte is 1.250 or higher and the electrolyte tem

perature is at least 60° F). Do not charge at a rate higher

than 10 amps.

ENGINE ADJUSTMENTS

The engine is designed to deliver the correct perform

ance under all operating conditions. Any adjustments

must be performed by a Sears or other qualified service

dealer.

32

Page 33

MOWER DECK LEVELING ADJUSTMENTS

A WARNING

Before adjusting the mower, turn the mower

blades OFF, turn the ignition switch OFF, remove

the key, and allow all moving parts to stop.

Disconnect the spark plug wire and fasten it away

from the spark plug.

Side to Side Leveling

If the cut is uneven, the mower may need leveling.

Unequal or improper tire pressure may also cause an

uneven cut. See CHECK TIRE PRESSURE.

1. With the mower installed, place the rider on a

smooth, level surface such as a concrete floor. Turn

the front wheels straight forward. Turn the engine off,

set the ground speed control levers to PARK, and

wait for all moving parts to stop.

2. Check for bent blades and replace if necessary.

3. Check the tire pressures. See CHECK TIRE PRES

SURE.

4. Set the cutting height to mid position. Arrange the

mower blades so that they are pointing from side-toside (Figures 39 & 40).

5. Measure the distance between the tips of the outside

blades and the ground (Figure 40). If there is more

than 1/8" (3 mm) difference between the measure

ments on each side, proceed to Step 6. If the differ

ence is 1/8" (3 mm) or less, proceed to Front To Back

Leveling.

6. Side-to-side leveling is accomplished using the

threaded rods (A, Figure 41) and trunnion (B) on the

right and left rear sides of the mower deck. Loosen

the jam nuts (C) and adjust the nuts up or down to

adjust the mower level. When complete, tighten the

jam nuts against the trunnion to lock the adjustment

in place.

'<> -

/

Figure 39. Orient Blades Side-to-Side

Figure 40. Measure Blade Tips to Ground

A. Mower Deck

B. Blade Tip

C. Level Ground

Figure 41. Side-to-Side Leveling

A. Threaded Rod

B. Trunnion

C. Jam Nuts

33

Page 34

..

_

..

Figure 42. Orient Blades Front-to-Back

Front To Back Leveling

If the cut is uneven, the mower may need leveling.

Unequal or improper tire pressure may also cause an

uneven cut. See CHECK TIRE PRESSURE.

1. Turn the blades front-to-back as shown in Figure 42.

Measure the distance from the ground to front tip of

center blade, and from ground to rear tips of left hand

and right hand blades (Figure 42). Front tips should

be 1/8"-1/4" (3-6 mm) higher than rear tips. If not, pro

ceed to Step 2.

2. The front hitch rod (A, Figure 43) is used to adjust

front-to-back leveling. To raise or lower the front of the

mower deck, loosen the two rear jam nuts (B) on both

sides of the front hitch rod (A). Adjust the front jam

nuts (C) on both sides of the front hitch rod (A) to

adjust the mower deck level. When adjusted correctly,

tighten the rear jam nuts (B) to lock the front hitch rod

in place.

MOWER BELT REPLACEMENT

1. Park the rider on a level surface. Disengage the PTO,

turn off the engine and set the ground speed control

levers to PARK. Remove the key.

2. Remove belt covers.

3. Insert ratchet into 3/8” (9.5 mm) square hole in idler

pulley arm (A, Figure 44) and pull to release belt ten

sion.

4. Remove the mower drive belt (B) from the engine

drive pulley (C).

5. Remove the belt from the remaining deck pulleys.

NOTE: It is not necessary to remove the mower deck

to replace the belt.

6. Install the new mower belt as shown in Figure 44.

Figure 43. Front-to-Back Leveling

A. Front Hitch Rod

B. Rear Jam Nut

C. Front Jam Nut

Figure 44. Mower Belt Routing

A. Idl er Pulley Arm

B. Mower Belt

C. Engine Drive Pulley

D. Fixed Idler Pulley (2)

E. Arbor Drive Pulley (3)

F. Adjustable Tension Idler Pulley

34

Page 35

MOWER DECK WASHOUT PORT

NOTE: The washout port allows you to connect a typical

garden hose to the trim side (L.H.) of the mower deck to

remove grass and debris from the underside. This

ensures proper and safe operation of the mower.

1. Place the lawn tractor on a smooth level surface.

A WARNING

Before running the mower, make sure the hose is

properly connected and does not come into contact

with the blades. When the mower is running and the

blades are engaged, the person cleaning the mower

deck must be in the operator position, and there are

no bystanders. Failure to follow these precautions

may result in serious injury or death.