Page 1

Operator's Manual

®

CTX Yard Tractor

Model No.

107.250050 (22 Gross HP Briggs & Stratton with 46" Mower)

For answers to your questions about this

product, call Sears Craftsman Help Line

1-800=65g-5g 17.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

1753800

Revision -

Page 2

Page 3

Front Cover ................................................................................................................. 1

Operator Safety .......................................................................................................... 4

Features and Controls ............................................................................................. 10

Operation .................................................................................................................. 13

Safety interlock System Tests ................................................................................. 13

Maintenance ............................................................................................................. 18

Troubleshooting ....................................................................................................... 29

Specifications ........................................................................................................... 31

Warranty .................................................................................................................... 32

Repair Protection Agreement .................................................................................. 33

Service Parts ....................................................................................................... PTS-1

Thank you for purchasing this quality-built CRAFTSMAN mower. We're pleased that you've placed your confidence

in the CRAFTSMAN brand. When operated and maintained according to the instructions in this manual, your

CRAFTSMAN product will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with mowers and

how to avoid them. This product and its approved attachments/accessories are designed and intended only for lawn

work or snow removal and are not intended for any other purpose. It is important that you read and understand these

instructions thoroughly before attempting to start or operate this equipment. Save these original instructions for

future reference.

Where to Find Us

You never have to look far to find support and service for your CRAFTSMAN mower. There are authorized service

dealers in North America who provide quality service. You can contact Customer Service by phone at (800) 659-5917,

or locate a dealer on the Internet at www.craftsman.com.

Mower

Model Number

Serial Number

Engine

Model Type Trim

Date Code

Date Purchased

3

Page 4

Congratulations on purchasing a superior-quality piece of lawn and

garden equipment. Our products are designed and manufactured to

meet or exceed all industry standards for safety.

Power equipment is only as safe as the operator. If it is misused, or

not properly maintained, it can be dangerous! Remember, you are

responsible for your safety and that of those around you.

Use common sense, and think through what you are doing. If you are

not sure that the task you are about to perform can be safely done

with the equipment you have chosen, ask a professional: contact

your local authorized dealer.

ReadtheManual

The operator's manual contains important safety information you

need to be aware of BEFORE you operate your unit as well as

DURING operation.

Safe operating techniques, an explanation of the product's features

and controls, and maintenance information is included to help you get

the most out of your equipment investment.

Be sure to completely read the Safety Rules and Information found on

the following pages. Also completely read the Operation section.

OperatingSafety

Children

Tragic accidents can occur with children. Do not allow them

anywhere near the area of operation. Children are often

attracted to the unit and mowing activity. Never assume that

children will remain where you last saw them. If there is a

risk that children may enter the area where you are mowing,

have another responsible adult watch them.

DO NOT GIVE CHILDREN RIDES ON THIS UNIT! This

encourages them to come near the unit in the future while it

is running, and they could be seriously hurt. They may then

approach the unit for a ride when you are not expecting it,

and you may run over them.

Reverse

Do not mow in reverse unless

absolutely necessary. Always look

down and behind before and while

traveling in reverse

even with the mower

blades disengaged.

Page 5

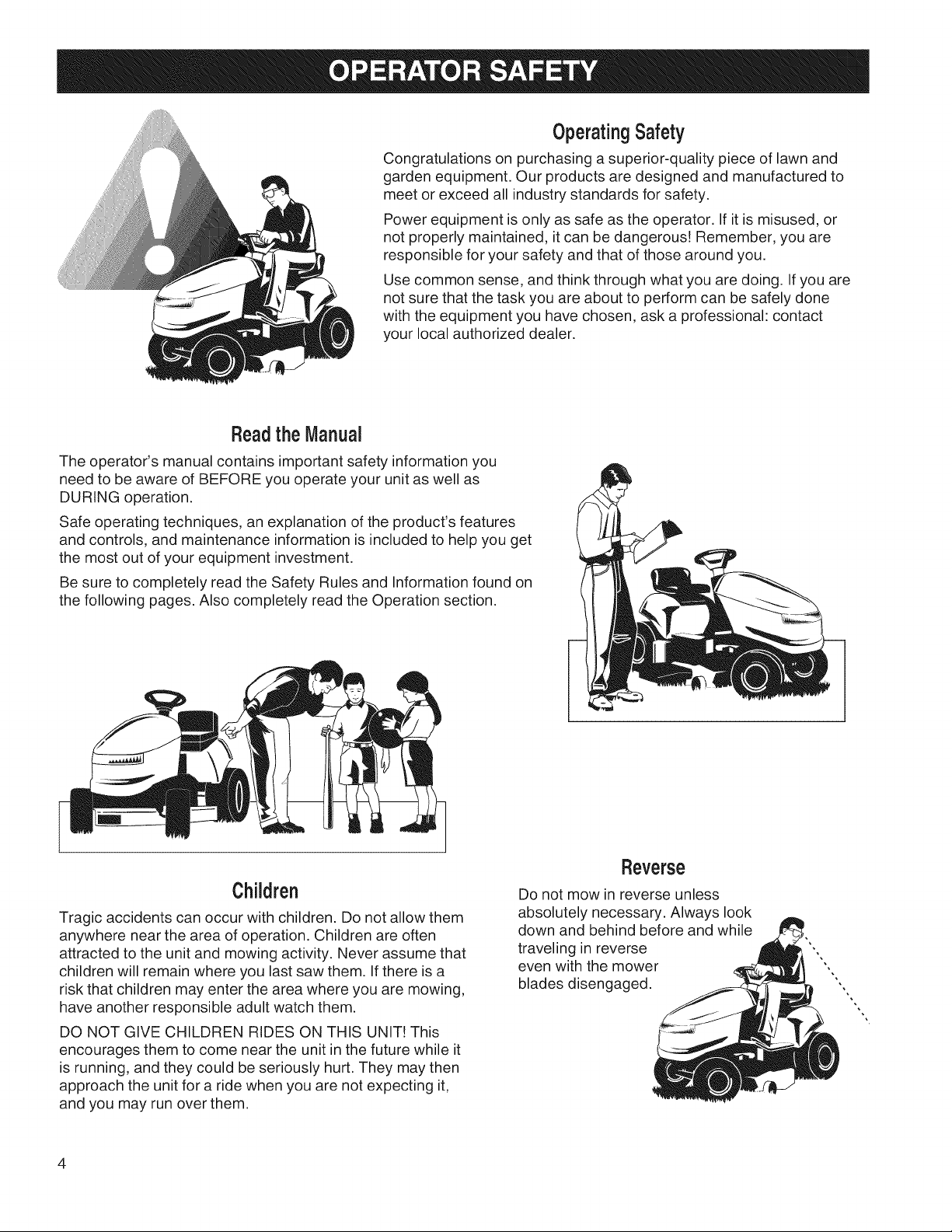

SlopeOperation

You could be seriously injured or even killed if you use thisunit on too

steep an incline. Using the unit on a slope that is too steep or where you

don't have adequate traction can cause you to lose control or roll over.

A good rule of thumb is to not operate on any slope you cannot back up

(in 2-wheel drive mode). You should not operate on inclines with a slope

greater than a 3.5 foot rise over a 20 foot length. Always drive up and

down slopes: never cross the face.

3.5ft

20.0 ft (6,0 m)

Also note that the surface you are driving on can greatly impact stability

and control. Wet grass or icy pavement can seriously affect your ability to

control the unit.

If you feel unsure about operating the unit on an incline, don't do it. It's

not worth the risk.

MovingParts

This equipment has many moving parts that can injure you or someone else.

However, if you are seated in the seat properly, and follow all the rules in this book,

the unit is safe to operate.

The mower deck has spinning mower blades that can amputate hands and feet.

Do not allow anyone near the equipment while it is running!

To help you, the operator, use this equipment safely, it is equipped with an

operator-present safety system. Do NOT attempt to alter or bypass the system.

See your dealer immediately if the system does not pass all the safety interlock

system tests found in this manual.

ThrownObjects

This unit has spinning mower blades. These blades can pick up and throw

debris that could seriously injure a bystander. Be sure to clean up the area to

be mowed BEFORE you start mowing.

Do not operate this unit without the entire grass catcher or discharge guard

(deflector) in place.

Also, do not allow anyone in the area while the unit is running! If someone

does enter the area, shut the unit off immediately until they leave.

Fueland Maintenance

Gasoline is extremely flammable. Its vapors are also extremely flammable

and can travel to distant ignition sources. Gasoline must only be used

as a fuel, not as a solvent or cleaner. It should never be stored any place

where its vapors can build up or travel to an ignition source like a pilot light.

Fuel belongs in an approved, plastic, sealed gas can, or in the tractor fuel

tank with the cap securely closed. Spilled fuel needs to be cleaned up

immediately.

Proper maintenance is critical to the safety and performance of your unit. Be

sure to perform the maintenance procedures listed inthis manual, especially

periodically testing the safety system.

5

Page 6

Readthesesafetyrulesandfollowthemclosely.Failuretoobeytheserulescouldresultinlossofcontrol

ofunit,severepersonalinjuryordeathtoyou,orbystanders,ordamagetopropertyorequipment.

This mowing deck is capable of amputating hands and feet and throwing objects.

The triangle _ in text signifies important cautions or warnings which must be followed.

GENERAL OPERATION

1. Read, understand, and follow all instructions in the

manual and on the unit before starting.

2. Do not put hands or feet near rotating parts or under

the machine. Keep clear of the discharge opening at

all times.

3. Only allow responsible adults, who are familiar with

the instructions, to operate the unit (local regulations

can restrict operator age).

4. Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown by the

blade(s).

5. Be sure the area is clear of other people before

mowing. Stop the unit if anyone enters the area.

6. Never carry passengers.

7. Do not mow in reverse unless absolutely necessary.

Always look down and behind before and while

travelling in reverse.

8. Never direct discharge material toward anyone. Avoid

discharging material against a wall or obstruction.

Material may ricochet back toward the operator. Stop

the blade(s) when crossing gravel surfaces.

9. Do not operate the machine without the entire grass

catcher, discharge guard (deflector), or other safety

devices in place.

10. Slow down before turning.

11. Never leave a running unit unattended. Always

disengage the PTO, set parking brake, stop engine,

and remove keys before dismounting.

12. Disengage blades (PTO) when not mowing. Shut off

engine and wait for all parts to come to a complete

stop before cleaning the machine, removing the grass

catcher, or unclogging the discharge guard.

13. Operate the machine only in daylight or good artificial

light.

14. Do not operate the unit while under the influence of

alcohol or drugs.

15 Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the unit into

a trailer or truck.

17.Always wear eye protection when operating this unit.

18. Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the equipment safely

enough to protect themselves and others from injury.

19. Follow the manufacturer's recommendations for wheel

weights or counterweights.

20. Keep in mind the operator is responsible for accidents

occurring to other people or property.

21. All drivers should seek and obtain professional and

practical instruction.

22. Always wear substantial footwear and trousers. Never

operate when barefoot or wearing sandals.

23. Before using, always visually check that the blades

and blade hardware are present, intact, and secure.

Replace worn or damaged parts.

24. Disengage attachments before: refueling, removing

an attachment, making adjustments (unless the

adjustment can be made from the operator's position).

25. When the machine is parked, stored, or left

unattended, lower the cutting means unless a positive

mechanical lock is used.

26. Before leaving the operator's position for any reason,

engage the parking brake (if equipped), disengage the

PTO, stop the engine, and remove the key.

27. To reduce fire hazard, keep the unit free of grass,

leaves, & excess oil. Do not stop or park over dry

leaves, grass, or combustible materials.

TRANSPORTING AND STORAGE

1. When transporting the unit on an open trailer, make

sure it is facing forward, in the direction of travel. If the

unit is facing backwards, wind lift could damage the

unit.

2. Always observe safe refueling and fuel handling

practices when refueling the unit after transportation

or storage.

3. Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an

ignition source (such as a furnace, water heater, etc.)

and cause an explosion. Fuel vapor is also toxic to

humans and animals.

4. Always follow the engine manual instructions for

storage preparations before storing the unit for both

short and long term periods.

5. Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

6. Never store the unit or fuel container inside where

there is an open flame or pilot light, such as in a water

heater. Allow unit to cool before storing.

Page 7

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tip-over

accidents, which can result insevere injury or death. Operation

on allslopes requires extra caution. If you cannot back up the

slope or ifyou feel uneasy on it,do not operate on it.

Control of a walk-behind or ride-on machine sliding on a

slope will not be regained by the application of the brake. The

main reasons for loss of control are: insufficient tire grip on

the ground, speed too fast, inadequate braking, the type of

machine is unsuitable for its task, lack of awareness of the

ground conditions, incorrect hitching and load distribution.

1. Mow up and down slopes, not across.

2. Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Tall grass can hide obstacles.

3. Choose a slow speed so that you will not have to stop

or change speeds while on the slope.

4. Do not mow on wet grass. Tires may loose traction.

5. Always keep unit in gear especially when traveling

down slopes. Do not shift to neutral and coast

downhill.

6. Avoid starting, stopping, or turning on a slope. If tires

lose traction, disengage the blade(s) and proceed

slowly straight down the slope.

7. Keep all movement on slopes slow and gradual. Do

not make sudden changes in speed or direction,

which could cause the machine to rollover.

8. Use extra care while operating machines with grass

catchers or other attachments; they can affect the

stability of the unit. Do not use on steeps slopes.

9. Do not try to stabilize the machine by putting your foot

on the ground (ride-on units).

10. Do not mow near drop-offs, ditches, or embankments.

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

11. Do not use grass catchers on steep slopes.

12. Do not mow slopes you cannot back up them.

13. See your authorized dealer/retailer for

recommendations of wheel weights or counterweights

to improve stability.

14. Remove obstacles such as rocks, tree limbs, etc.

15. Use slow speed. Tires may lose traction on slopes

even through the brakes are functioning properly.

16. Do not turn on slopes unless necessary, and then,

turn slowly and gradually downhill, if possible.

17. Four Wheel Drive Models: Four Wheel Drive improves

access to dangerously sloped terrain, increasing

the possibility of roll-over. If the machine stops while

going uphill, stop the blades and back down slowly.

Avoid sudden turns.

TOWED EQUIPMENT (RIDE-ON UNITS)

I. Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

2. Followthe manufacturer's recommendations for weight

limit for towed equipment and towingon slopes.

3. Never allow children or others in or on towed equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Do not shift to neutral and coast down hill.

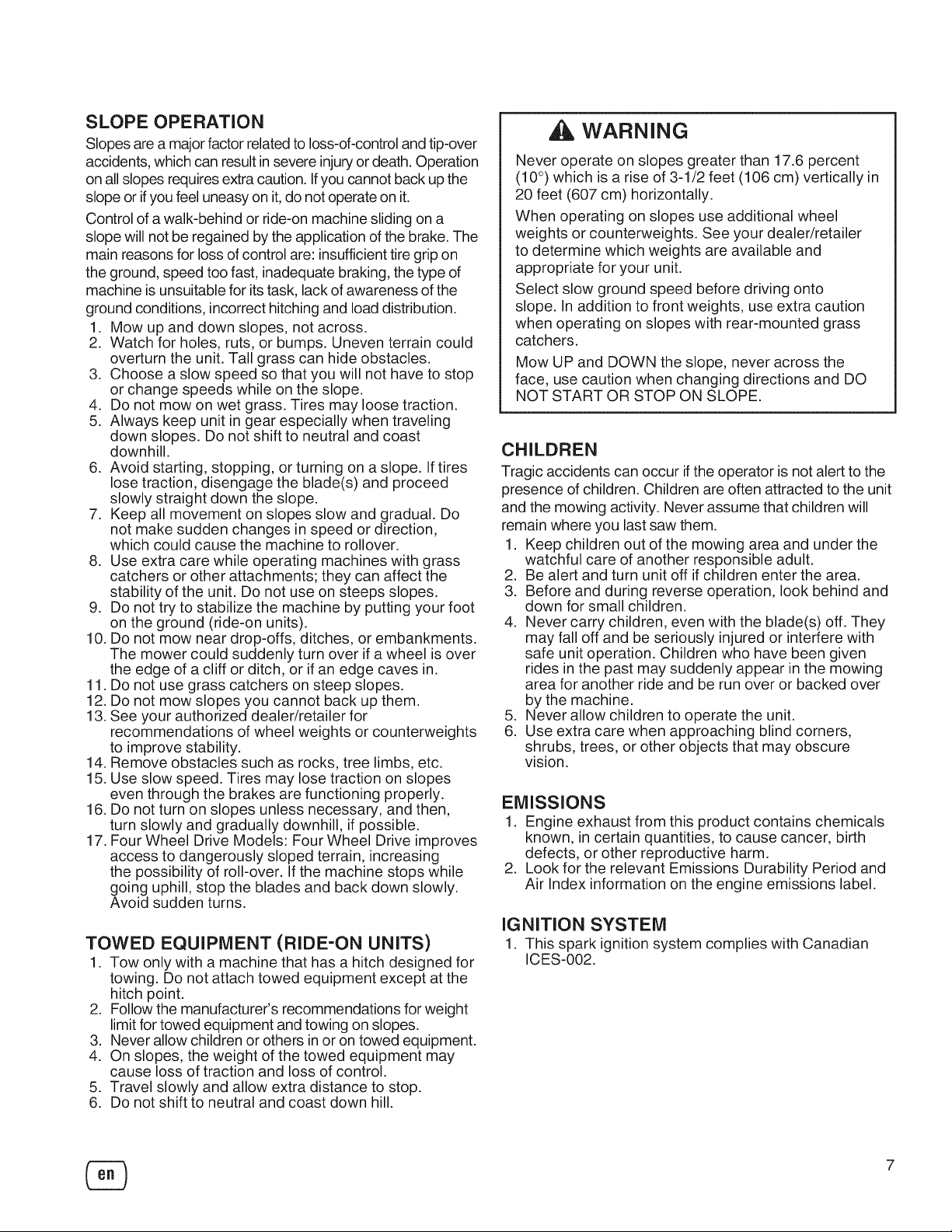

WARNING

Never operate on slopes greater than 17.6 percent

(10 °) which is a rise of 3-1/2 feet (106 cm) vertically in

20 feet (607 cm) horizontally.

When operating on slopes use additional wheel

weights or counterweights. See your dealer/retailer

to determine which weights are available and

appropriate for your unit.

Select slow ground speed before driving onto

slope. In addition to front weights, use extra caution

when operating on slopes with rear-mounted grass

catchers.

Mow UP and DOWN the slope, never across the

face, use caution when changing directions and DO

NOT START OR STOP ON SLOPE.

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and the mowing activity. Never assume that children will

remain where you last saw them.

1. Keep children out of the mowing area and under the

watchful care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Before and during reverse operation, look behind and

down for small children.

4. Never carry children, even with the blade(s) off. They

may fall off and be seriously injured or interfere with

safe unit operation. Children who have been given

rides in the past may suddenly appear in the mowing

area for another ride and be run over or backed over

by the machine.

5. Never allow children to operate the unit.

6. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Period and

Air Index information on the engine emissions label.

IGNITION SYSTEM

1. This spark ignition system complies with Canadian

ICES-002.

7

Page 8

SERVICE AND MAINTENANCE

Safe Handling of Gasoline

1. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

2. Use only approved gasoline containers.

3. Never remove the gas cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. Never fuel the machine indoors.

5. Never store the machine or fuel container where there

is an open flame, spark, or pilot light such as near a

water heater or other appliance.

6. Never fill containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on the

ground away from your vehicle before filling.

7. Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible,

then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser

nozzle.

8. Keep nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzle lock-open device.

9. If fuel is spilled on clothing, change clothing

immediately.

10. Never over-fill the fuel tank. Replace gas cap and

tighten securely.

11. Use extra care in handling gasoline and other fuels.

They are flammable and vapors are explosive.

12. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

13. Replace all fuel tank caps and fuel container caps

securely.

Service & Maintenance

1. Never run the unit in an enclosed area where carbon

monoxide fumes may collect.

2. Keep nuts and bolts, especially blade attachment

bolts, tight and keep equipment in good condition.

3. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if they

are not functioning properly.

4. Keep unit free of grass, leaves, or other debris build-

up. Clean up oil or fuel spillage, and remove any fuel-

soaked debris. Allow machine to cool before storage.

5. If you strike an object, stop and inspect the machine.

Repair, if necessary, before restarting.

6. Never make adjustments or repairs with the engine

running.

7. Check grass catcher components and the discharge

guard frequently and replace with manufacturer's

recommended parts, when necessary.

8. Mower blades are sharp. Wrap the blade or wear

gloves, and use extra caution when servicing them.

9. Check brake operation frequently. Adjust and service

as required.

10. Maintain or replace safety and instructions labels, as

necessary.

11. Do not remove the fuel filter when the engine is hot

as spilled gasoline may ignite. Do not spread fuel line

clamps further than necessary. Ensure clamps grip

hoses firmly over the filter after installation.

12. Do not use gasoline containing METHANOL, gasohol

containing more than 10% ETHANOL, gasoline

additives, or white gas because engine/fuel system

damage could result.

13. If the fuel tank must be drained, it should be drained

outdoors.

14. Replace faulty silencers/mufflers.

15. Maintain or replace safety and instruction labels as

necessary.

16. Use only factory authorized replacement parts when

making repairs.

17.Always comply with factory specifications on all

settings and adjustments.

18.Only authorized service locations should be utilized for

major service and repair requirements.

19. Never attempt to make major repairs on this unit

unless you have been properly trained. Improper

service procedures can result in hazardous operation,

equipment damage and voiding of manufacturer's

warranty.

20. On multiple blade mowers, take care as rotating one

blade can cause other blades to rotate.

21. Do not change engine governor settings or over-

speed the engine. Operating the engine at excessive

speed can increase the hazard of personal injury.

22. Disengage drive attachments, stop the engine,

remove the key, and disconnect the spark plug wire(s)

before: clearing attachment blockages and chutes,

performing service work, striking an object, or if the

unit vibrates abnormally. After striking an object,

inspect the machine for damage and make repairs

before restarting and operating the equipment.

23. Never place hands near the moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans are typically located on top

of the transaxle).

24. Units with hydraulic pumps, hoses, or motors:

WARNING: Hydraulic fluid escaping under pressure

may have sufficient force to penetrate skin and cause

serious injury. If foreign fluid is injected into the skin

it must be surgically removed within a few hours by a

doctor familiar with this form of injury or gangrene may

result. Keep body and hands away from pin holes or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, and not hands, to search

for leaks. Make sure all hydraulic fluid connections

are tight and all hydraulic hoses and lines are in good

condition before applying pressure to the system. If

leaks occur, have the unit serviced immediately by

your authorized dealer.

25. WARNING: Stored energy device. Improper release of

springs can result in serious personal injury. Springs

should be removed by an authorized technician.

26. Models equipped with an engine radiator: WARNING:

Stored energy device. To prevent serious bodily injury

from hot coolant or steam blow-out, never attempt to

remove the radiator cap while the engine is running.

Stop the engine and wait until it is cool. Even then, use

extreme care when removing the cap.

Page 9

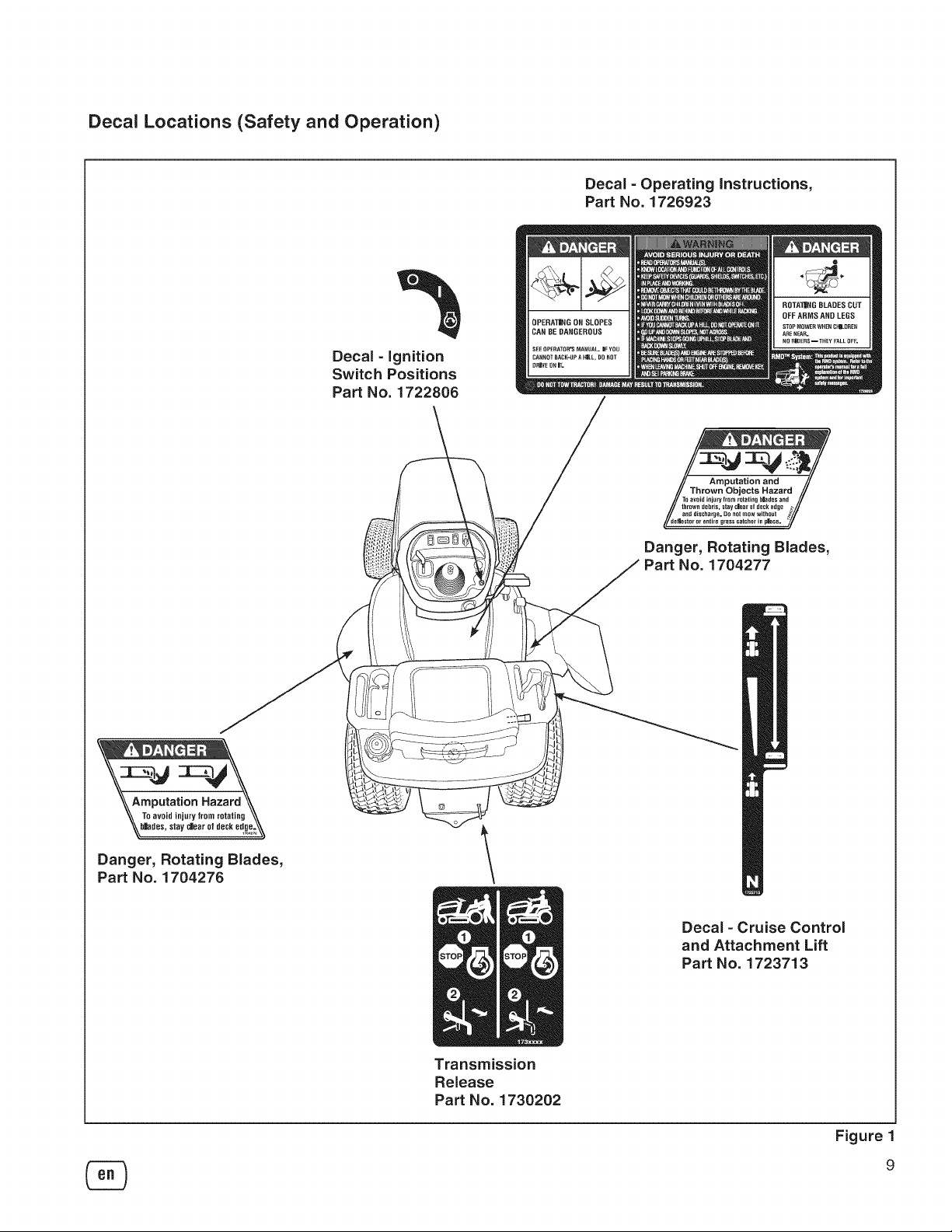

Decal Locations (Safety and Operation)

Decal - ignition

Switch Positions

Part No. 1722808

Decal - Operating instructions,

Part No. 1726923

TO avoid injury from rotating b|ades an] M

thrown debris, stay char ot deck edge

a_l_ discharge. DOnot mow without

_d_e _et_ii! r entire gr_ss catcher in place.

Danger, Rotating Blades,

No. 1704277

reputation Hazard

To avoid injury from rotating \\

bllades,stay _lear of deck edge;,_

Danger, Rotating Blades,

Part No. 1704276

Decal - Cruise Control

and Attachment Lift

Part No. 1723713

Transmission

Release

Part No. 1730202

Figure

9

Page 10

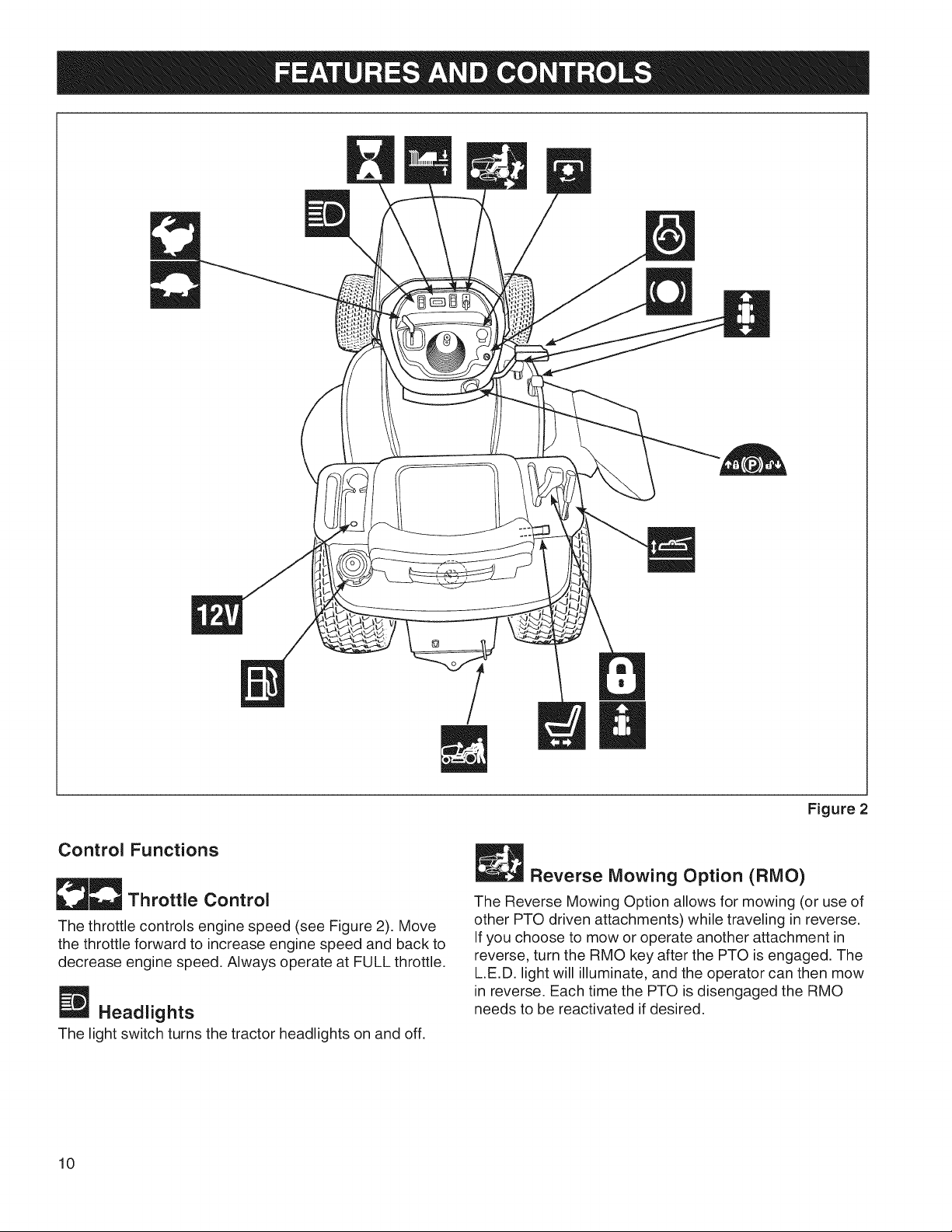

Control Functions

__ Throttle Control

The throttle controls engine speed (see Figure 2). Move

the throttle forward to increase engine speed and back to

decrease engine speed, Always operate at FULL throttle,

Headlights

The light switch turns the tractor headlights on and off.

10

Figure 2

Reverse Mowing Option (RMO)

The Reverse Mowing Option allows for mowing (or use of

other PTO driven attachments) while traveling in reverse.

If you choose to mow or operate another attachment in

reverse, turn the RMO key after the PTO is engaged. The

L.E.D. light will illuminate, and the operator can then mow

in reverse. Each time the PTO is disengaged the RMO

needs to be reactivated if desired.

Page 11

PTO Switch

The PTO (Power Take-Off) switch engages and

disengages attachments that use the PTO. To engage the

PTO, pull UP on the switch. Push DOWN to disengage.

Note that the operator must be seated firmly in the tractor

seat for the PTO to function.

D Cruise Control

The cruise control is used to lock the ground speed

control in forward. Move the lever forward until the

desired ground speed is reached. To disengage the

cruise control move the lever back. In the event you need

to stop quickly, depressing the brake pedal will also return

the cruise control to neutral.

Ignition Switch

The ignition switch starts and stops the engine, it has

three positions:

_OFF

H RUN

_START

NOTE: Never leave the ignition switch in the RUN

position with the engine stopped-this drains the battery.

Stops the engine and shuts off the

electrical system.

Allows the engine to run and powers the

electrical system.

Cranks the engine for starting.

Brake Pedal

Depressing the brake pedal applies the tractor brake.

Ground Speed Pedals

The tractor's forward ground speed is controlled by the

forward ground speed control pedal. The tractor's reverse

ground speed is controlled by the reverse ground speed

control pedal.

Depressing either pedal will increase ground speed. Note

that the further down the pedal is depressed, the faster

the tractor will travel.

Parking Brake

The parking brake knob is used to lock the parking brake

when the tractor is stopped. Fully depressing the brake

pedal and pulling up on the knob engages the parking

brake

Mower Height of Cut Adjustment

The cutting height is adjustable between 1.0" and 4.0"

(2,5 and 10,2 cm).

The cutting height adjustment switch controls the mower

cutting height. This same switch also controls the spout

rotator motor when a snowthrower is installed. The arrows

on the switch correspond to the direction of adjustment

(UP arrow raises cutting height, RIGHT arrow rotates

the spout right, etc). When the adjustment indicator has

reached the end of its travel, release the switch; holding

the switch down will damage the motor.

Attachment Lift Control Lever

When using the mower deck, lift the deck off the ground

while transporting to and from the job site. DO NOT cut

with the mower in the raised, transport position.

The attachment lift control lever raises and lowers

attachments that utilize the tractor's manual lift linkage.

To lower an attachment: pull the lever back slightly,

depress the release button, and push the lever forward

until it locks in the lowered position. To raise an

attachment: push the lever forward slightly, depress the

release button, then pull the lever back until it locks in the

raised position.

Seat Adjustment Lever

The seat can be adjusted forward and back. Move the

lever, position the seat as desired, and release the lever

to lock the seat into position.

Transmission Release Lever

The transmission release lever deactivates the

transmission so that the tractor can be pushed by hand.

See Pushing the Tractor by Hand.

Fuel Tank

To remove the cap, turn counterclockwise. The fuel

gauge is part of the dashboard.

_ Power Outlet

The power outlet is 12V-DC. Accessory must be rated at

9 amps or less.

Hour Meter

The hour meter measures the number of hours the key

has been in the RUN position.

11

Page 12

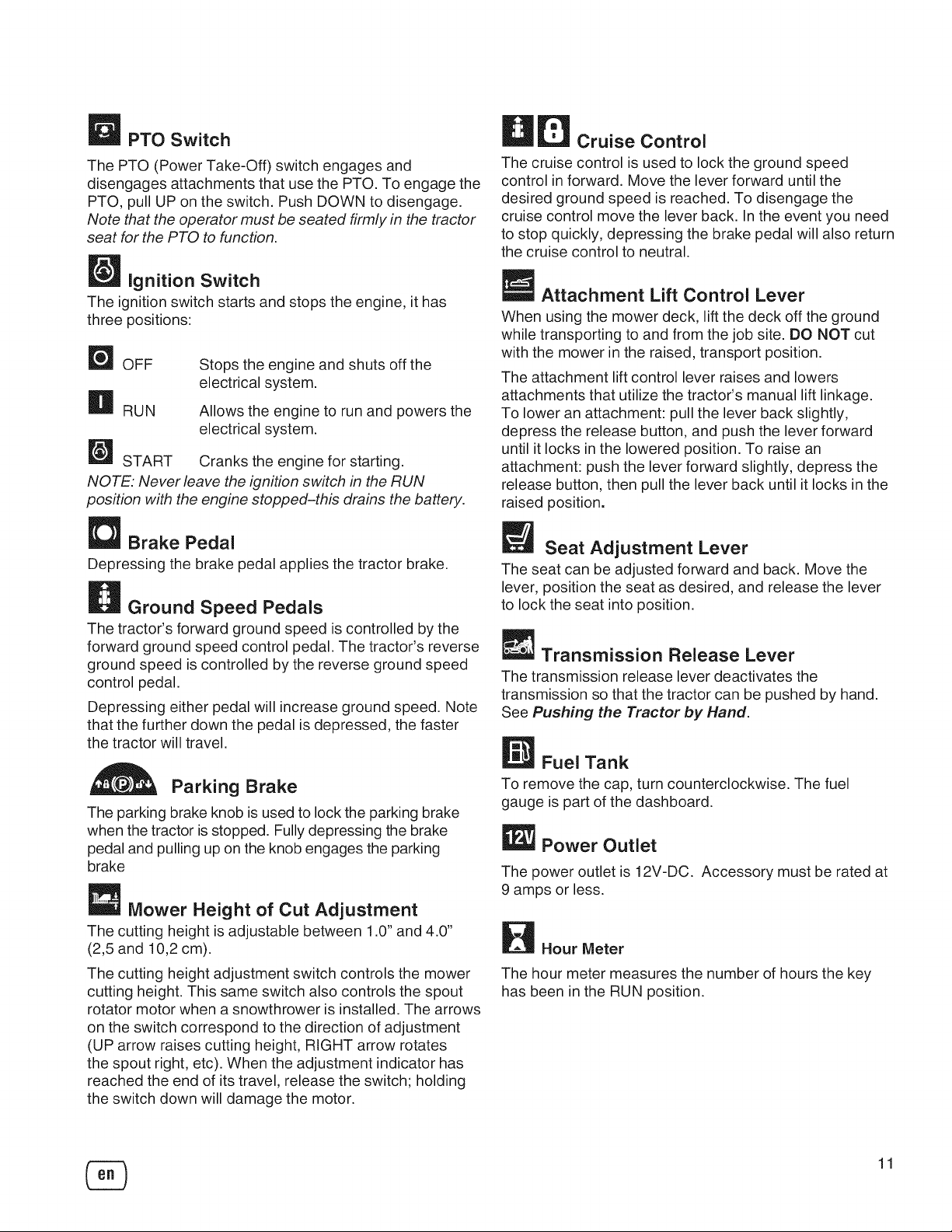

Hourmeter

The hourmeter (Figure 3) measures the number of hours

the key has been in the RUN position. The hourmeter

will flash an initial oil change indicator at 5 hours, and a

lubrication reminder every 50 hours. These reminders

display for approximately two hours and will automatically

reset themselves.

NOTE: The hourmeter will register the passage of time

when the key is in the RUN position, even if the engine

is not running. The hourmeter has a self contained power

source so the total hours are always visible.

,

r_

[ ]

!

HOURS

1

Parking Brake Function

Applying the Parking Brake =See Figure 4. To lock the

parking brake, release the ground speed pedals (A), fully

depress the brake pedal (B), pull UP on the parking brake

knob (C), and then release brake pedal.

Releasing the Parking Brake =See Figure 4. To release

the parking brake, fully depress the brake pedal (B) and

push the parking brake knob (C) DOWN.

\

J

Figure 3

12=Volt Power Outlet

The 12-volt accessory plug is located in the left side pod.

It can be used to power small electronic devices. The

accessory must be rated at 9 amps or less.

NOTE: Operating a 12-volt accessory, especially with

the engine at idle, may cause battery discharge. When

not using the accessory plug it must be covered with

the rubber plug to prevent moisture from causing a short

circuiL Entrance of water into plug can cause a short

circuiL

Figure 4

Advanced Traction Control

What is Advanced Traction Control?

Advanced Traction Control (ATC) is an exclusive feature

of our transmissions that provides improved traction. ATC

applies a preset amount of torque to both rear wheels even

if one starts slipping (a transmission without ATC will lose

traction completely if one rear wheel starts slipping). This

preset torque is just enough to provide additional traction,

and still allow the wheels to turn at different speeds in a tight

turn without damaging the lawn.

What to Expect from Your ATC Tractor

For the most part, while using your tractor you will

not notice ATC working, and you will simply become

accustomed to increased traction an ATC transmission

provides.

Under certain circumstances the ATC system limit can

be exceeded, and one of the rear wheels may slip (for

instance if trying to turn up a hill while accelerating). This

is normal. If you start to lose traction, do not speed up.

Instead, slow to a stop, straighten the steering wheel,

and slowly accelerate. Stopping the tractor allows the

transmission to regain more traction.

12

Page 13

Safety interlock System Tests

This unit is equipped with safety interlock switches and

other safety devices. These safety systems are present

for your safety: do not attempt to bypass safety switches,

and never tamper with safety devices.

WARNING

If the unit does not pass a safety test, do not

operate it. See your authorized dealer.

Test 1 -- Engine should NOT crank if:

• PTO switch is ON, OR

• Brake pedal is NOT fully depressed (parking brake

OFF), OR

• The cruise control lever is NOT in NEUTRAL.

Test 2 -- Engine SHOULD crank if:

• PTO switch is OFF, AND

• Brake pedal is fully depressed (parking brake ON),

AND

° The cruise control lever is in NEUTRAL.

Test 3 -- Engine should SHUT OFF if:

° Operator rises off seat with PTO engaged, OR

° Operator rises off seat with brake pedal NOT fully

depressed (parking brake OFF).

Test 4 -- Check Mower Blade Stopping Time

Mower blades and mower drive belt should come to a

complete stop within five seconds after electric PTO

switch is turned OFF. If mower drive belt does not stop

within five seconds, contact Sears Service.

Test 5 -- Reverse Mow Option (RMO) Check

• Engine should shut off if reverse travel is attempted

if the PTO has been switched on and RMO has not

been activated.

• RMO light should illuminate when RMO has been

activated.

NOTE: Once the engine has stopped, the PTO switch

must be turned off after the operator returns to the seat in

order to start the engine.

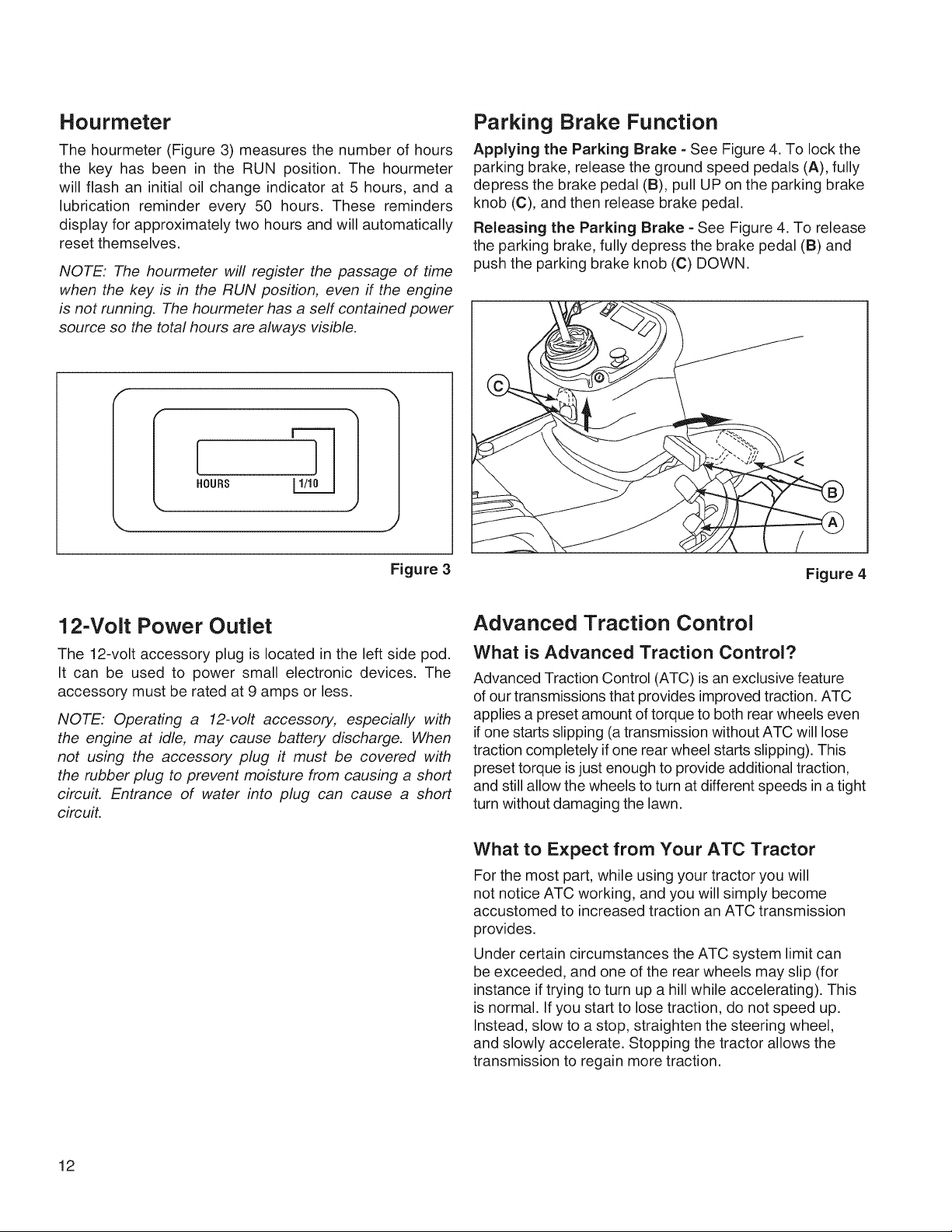

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty

Certified oils for best performance. Other high-quality

detergent oils are acceptable if classified for service SF,

SG, SH, SJ or higher. Do not use special additives.

Outdoor temperatures determine the proper oil viscosity

for the engine. Use the chart to select the best viscosity

for the outdoor temperature range expected.

Below40°F(4°C)theuseofSAE30will resultin hardstarting.

** Above80°F(27°C)the useof10W-30maycauseincreased0il consumption.Check0il

levelmorefrequently.

Checking/Adding Oil

Before adding or checking the oil

• Place engine level.

• Clean the oil fill area of any debris.

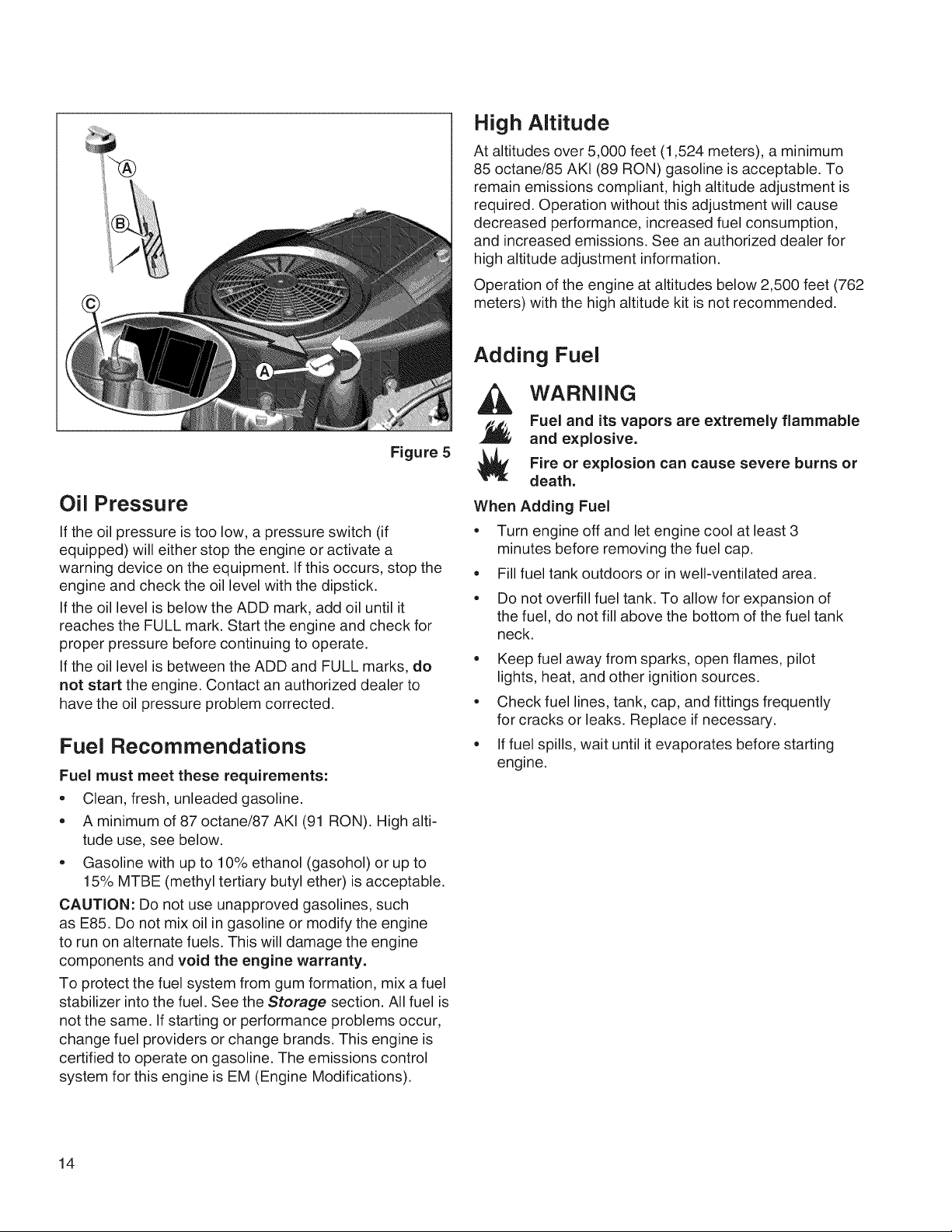

1. Remove the dipstick (A, Figure 5) and wipe with a

clean cloth.

2. Insert and tighten the dipstick.

3. Remove the dipstick and check the oil level. It should

be at the FULL mark (B) on the dipstick.

4. If low, add oil slowly into the engine oil fill (C). Do not

overfill. After adding oil, wait one minute and then

recheck the oil level.

NOTE: Do not add oil at the quick oil drain (if equipped).

5. Replace and tighten the dipstick.

13

!

Page 14

Figure 5

Oil Pressure

If the oil pressure is too low, a pressure switch (if

equipped) will either stop the engine or activate a

warning device on the equipment. If this occurs, stop the

engine and check the oil level with the dipstick.

If the oil level is below the ADD mark, add oil until it

reaches the FULL mark. Start the engine and check for

proper pressure before continuing to operate.

If the oil level is between the ADD and FULL marks, do

not start the engine. Contact an authorized dealer to

have the oil pressure problem corrected.

Fuel Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). High alti-

tude use, see below.

• Gasoline with up to 10% ethanol (gasohol) or up to

15% MTBE (methyl tertiary butyl ether) is acceptable.

CAUTION: Do not use unapproved gasolines, such

as E85. Do not mix oil in gasoline or modify the engine

to run on alternate fuels. This will damage the engine

components and void the engine warranty.

To protect the fuel system from gum formation, mix a fuel

stabilizer into the fuel. See the Storage section. All fuel is

not the same. If starting or performance problems occur,

change fuel providers or change brands. This engine is

certified to operate on gasoline. The emissions control

system for this engine is EM (Engine Modifications).

High Altitude

At altitudes over 5,000 feet (1,524 meters), a minimum

85 octane/85 AKI (89 RON) gasoline is acceptable. To

remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause

decreased performance, increased fuel consumption,

and increased emissions. See an authorized dealer for

high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762

meters) with the high altitude kit is not recommended.

Adding Fuel

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

When Adding Fuel

• Turn engine off and let engine cool at least 3

minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of

the fuel, do not fill above the bottom of the fuel tank

neck.

• Keep fuel away from sparks, open flames, pilot

lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently

for cracks or leaks. Replace if necessary.

• If fuel spills, wait until it evaporates before starting

engine.

14

Page 15

.

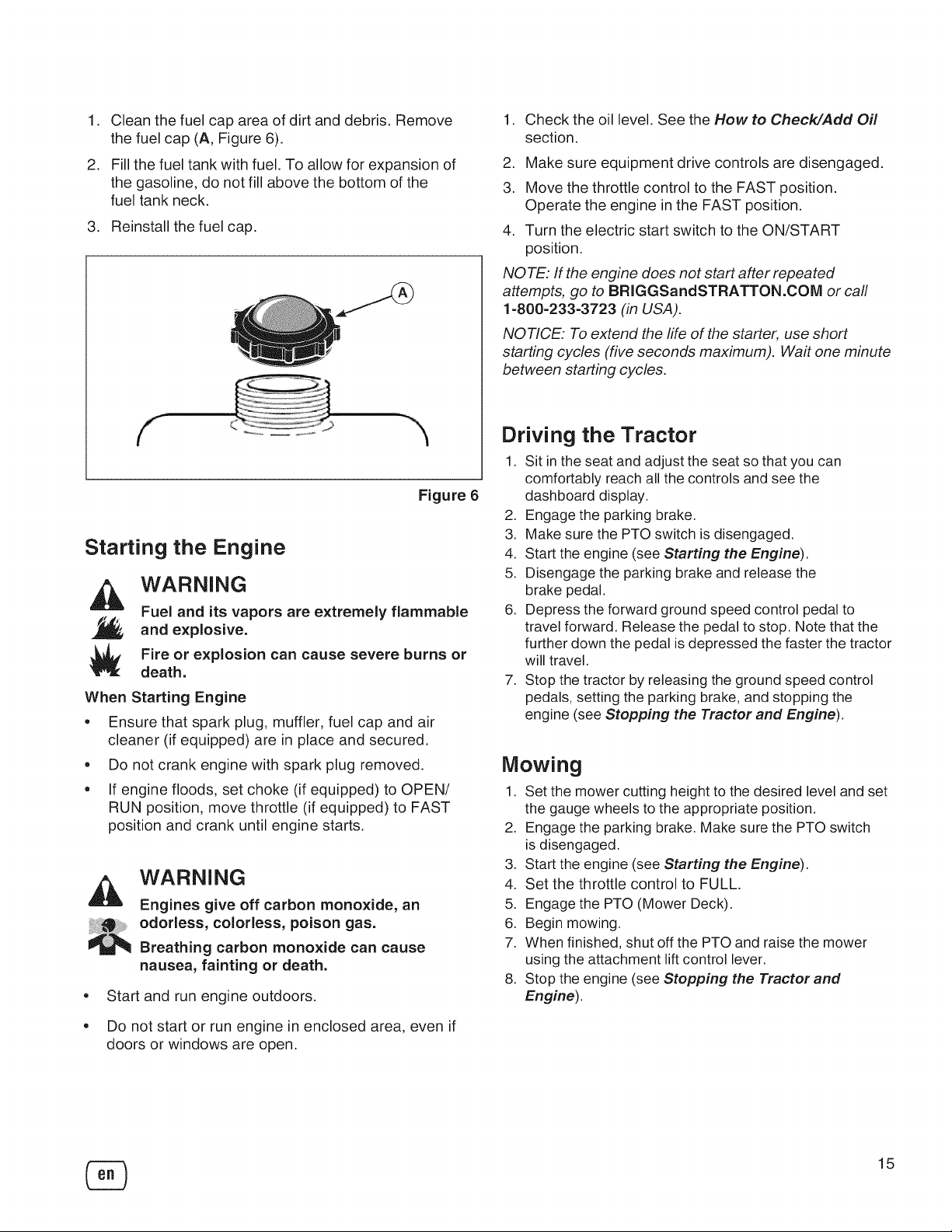

Clean the fuel cap area of dirt and debris. Remove

the fuel cap (A, Figure 6).

.

Fill the fuel tank with fuel. To allow for expansion of

the gasoline, do not fill above the bottom of the

fuel tank neck.

3. Reinstall the fuel cap.

Figure 6

Starting the Engine

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air

cleaner (if equipped) are in place and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN/

RUN position, move throttle (if equipped) to FAST

position and crank until engine starts.

WARNING

Engines give off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause

nausea, fainting or death.

e

Start and run engine outdoors.

e

Do not start or run engine in enclosed area, even if

doors or windows are open.

1. Check the oil level. See the How to Check/Add Off

section.

2. Make sure equipment drive controls are disengaged.

3. Move the throttle control to the FAST position.

Operate the engine in the FAST position.

4. Turn the electric start switch to the ON/START

position.

NOTE: If the engine does not start after repeated

attempts, go to BRIGGSandSTRATTON.COIVI or call

1=800-233=3723 (in USA).

NOTICE: To extend the life of the starter, use short

starting cycles (five seconds maximum). Wait one minute

between starting cycles.

Driving the Tractor

1. Sit in the seat and adjust the seat so that you can

comfortably reach all the controls and see the

dashboard display.

2. Engage the parking brake.

3. Make sure the PTO switch is disengaged.

4. Start the engine (see Starting the Engine).

5. Disengage the parking brake and release the

brake pedal.

6. Depress the forward ground speed control pedal to

travel forward. Release the pedal to stop. Note that the

further down the pedal is depressed the faster the tractor

will travel.

7. Stop the tractor by releasing the ground speed control

pedals, setting the parking brake, and stopping the

engine (see Stopping the Tractor and Engine).

Mowing

1. Set the mower cutting height to the desired level and set

the gauge wheels to the appropriate position.

2. Engage the parking brake. Make sure the PTO switch

is disengaged.

3. Start the engine (see Starting the Engine).

4. Set the throttle control to FULL.

5. Engage the PTO (Mower Deck).

6. Begin mowing.

7. When finished, shut off the PTO and raise the mower

using the attachment lift control lever.

8. Stop the engine (see Stopping the Tractorand

Engine).

15

Page 16

WARNING

The engine will shut off if the reverse ground speed

pedal is depressed while the PTO is on and the

RMO has not been activated. The operator should

always turn the PTO off prior to driving across

on roads, paths or any area that maybe used by

other vehicles. Sudden loss of drive could create a

hazard.

,A WARNING

Mowing in reverse can be hazardous to bystanders.

Tragic accidents can occur if the operator is not

alert to the presence of children. Never activate

RMO if children are present. Children are often

attracted to the unit and the mowing activity.

Mowing in Reverse (RMO)

If an operator chooses to mow in reverse, the RMO system

can be used. To use the Reverse Mowing Option (RMO) turn

the RMO key after the PTO is engaged. The LE.D. light will

illuminate, and the operator can then mow in reverse. Each

time the PTO is engaged the RMO needs to be reactivated if

desired. The key should be removed to restrict access to the

RMO feature.

Attachment Operation in Reverse

If an operator chooses to operate a PTO driven attachment

in reverse, the RMO system can be used. To use the

Reverse Mowing Option (RMO) turn the RMO key after

the PTO is engaged. The L.E.D. light will illuminate, and

the operator can then operate the attachment in reverse.

Each time the PTO is disengaged the RMO needs to be

reactivated if desired. The key should be removed to restrict

access to the RMO feature.

Pushing the Tractor by Hand

1. Disengage the PTO and turn the engine off.

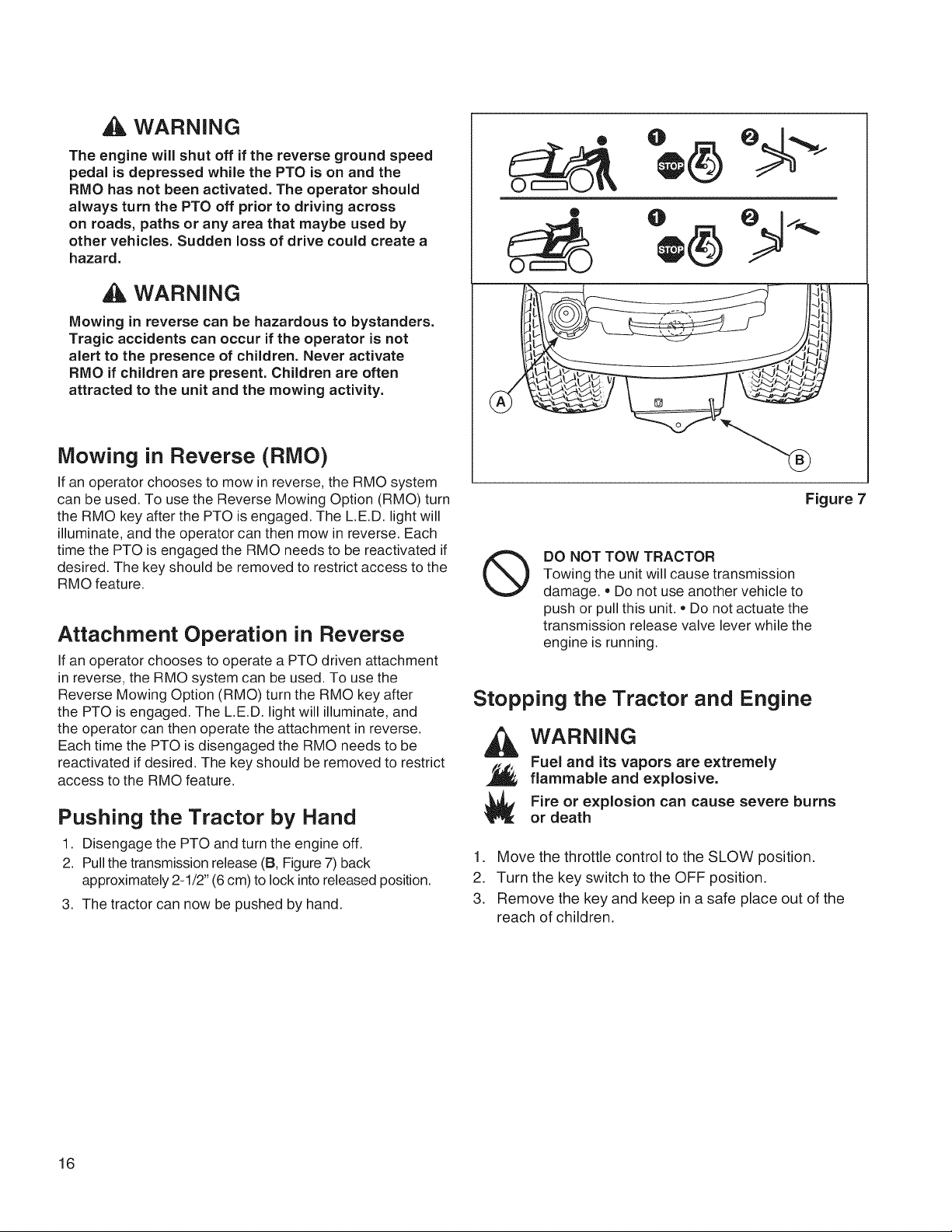

2. Pull the transmission release (B, Figure 7) back

approximately 2-1/2" (6 cm) to lock into released position.

3. The tractor can now be pushed by hand.

O

®

®®

Figure 7

DO NOT TOW TRACTOR

®

Stopping the Tractor and Engine

1. Move the throttle control to the SLOW position.

2. Turn the key switch to the OFF position.

3. Remove the key and keep in a safe place out of the

Towing the unit will cause transmission

damage. =Do not use another vehicle to

push or pull this unit. = Do not actuate the

transmission release valve lever while the

engine is running.

WARNING

Fuel and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe burns

or death

reach of children,

16

Page 17

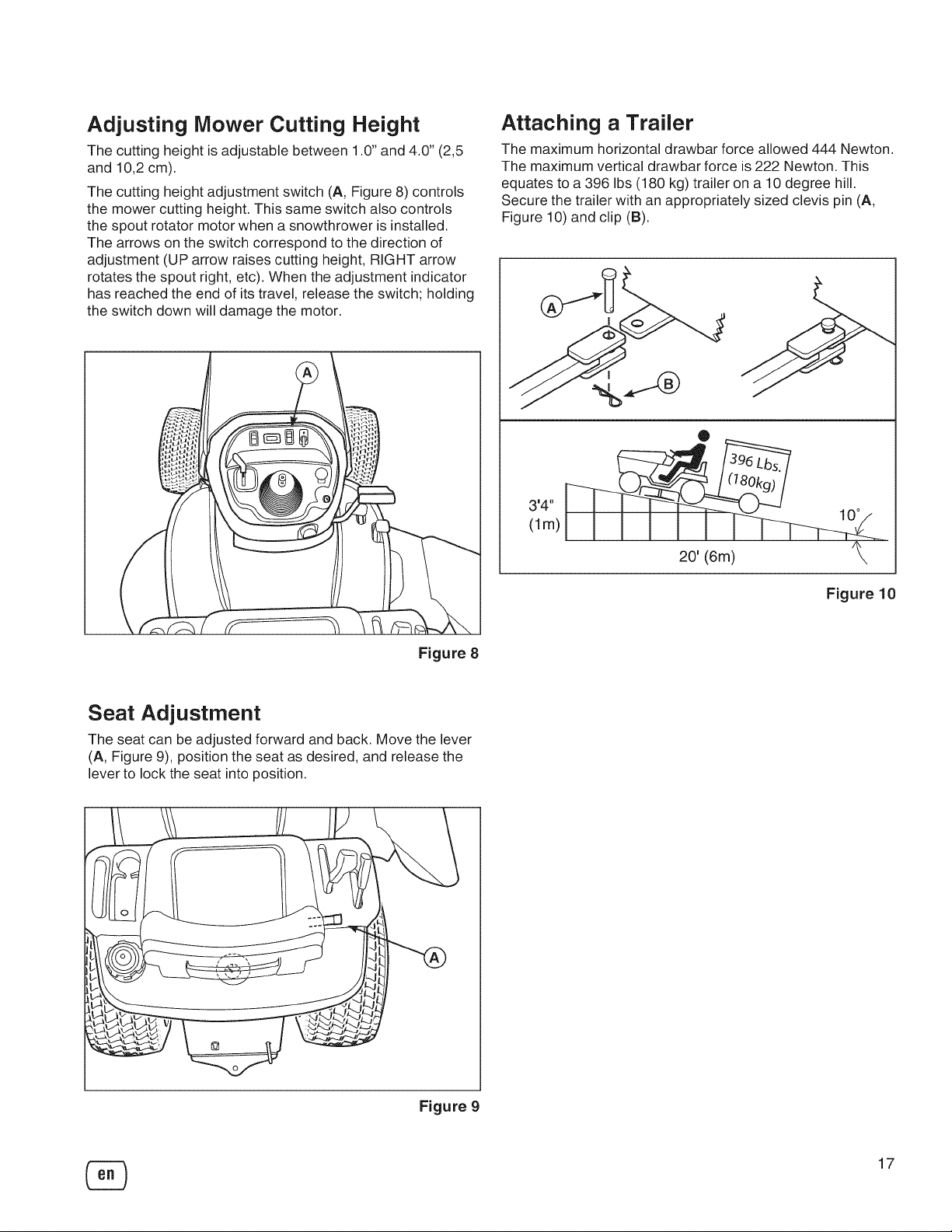

Adjusting Mower Cutting Height

The cutting height is adjustable between 1.0" and 4.0" (2,5

and 10,2 cm).

The cutting height adjustment switch (A, Figure 8) controls

the mower cutting height. This same switch also controls

the spout rotator motor when a snowthrower is installed.

The arrows on the switch correspond to the direction of

adjustment (UP arrow raises cutting height, RIGHT arrow

rotates the spout right, etc). When the adjustment indicator

has reached the end of its travel, release the switch; holding

the switch down will damage the motor.

Attaching a Trailer

The maximum horizontal drawbar force allowed 444 Newton.

The maximum vertical drawbar force is 222 Newton. This

equates to a 396 Ibs (180 kg) trailer on a 10 degree hill.

Secure the trailer with an appropriately sized clevis pin (A,

Figure 10) and clip (B).

®

Figure 8

Seat Adjustment

The seat can be adjusted forward and back. Move the lever

(A, Figure 9), position the seat as desired, and release the

lever to lock the seat into position.

'4"

(lm)

10 °

20' (6m)

Figure 10

Figure 9

17

Page 18

Maintenance Chart

Every 8 Hours or Daily

Check safety interlock system

Clean debris off tractor and mower deck

Clean debris from engine compartment

Every 25 Hours or Annually *

Check mower blade stopping time

Check tractor and mower for loose hardware

Check tire pressure

Every 50 Hours or Annually *

Check tractor brakes

Clean battery and cables

See Dealer Annually to

Lubricate tractor and mower

Check mower blades **

* Whichever comes first

** Check blades more often in regions with sandy soils or

high dust conditions.

First 5 Hours

Change engine oil - see engine manual

Every 8 Hours or Daily

Check engine oil level - see engine manual

Every 25 Hours or Annually*

Clean engine air filter and pre-cleaner **

Every 50 Hours or Annually *

Change engine oil

Replace oil filter

Replace air filter

Replace pre-cleaner

See Dealer Annually to

Inspect muffler and spark arrester

Replace spark plug

Replace fuel filter

Clean engine air cooling system

* Whichever comes first

** Clean more often in dusty conditions or when airborne

debris is present.

Emissions Control

Maintenance, replacement, or repair of the emissions control

devices and systems may be performed by any non-road

engine repair establishment or individual. However, to obtain

"no charge" emissions control service, the work must be per-

formed by a factory authorized dealer. See the Emissions

Warranty.

Check Mower Blade Stopping Time

Mower blades and mower drive belt should come to a

complete stop within five seconds after the electric PTO

switch is turned off.

1. With tractor in neutral, PTO disengaged and operator in

seat, start the engine.

2. Look over the left-hand footrest at the mower drive belt.

Engage the PTO and wait several seconds. Disengage

the PTO and check the amount of time it takes for the

mower drive belt to stop.

3. If mower drive belt does not stop within five seconds, see

your dealer.

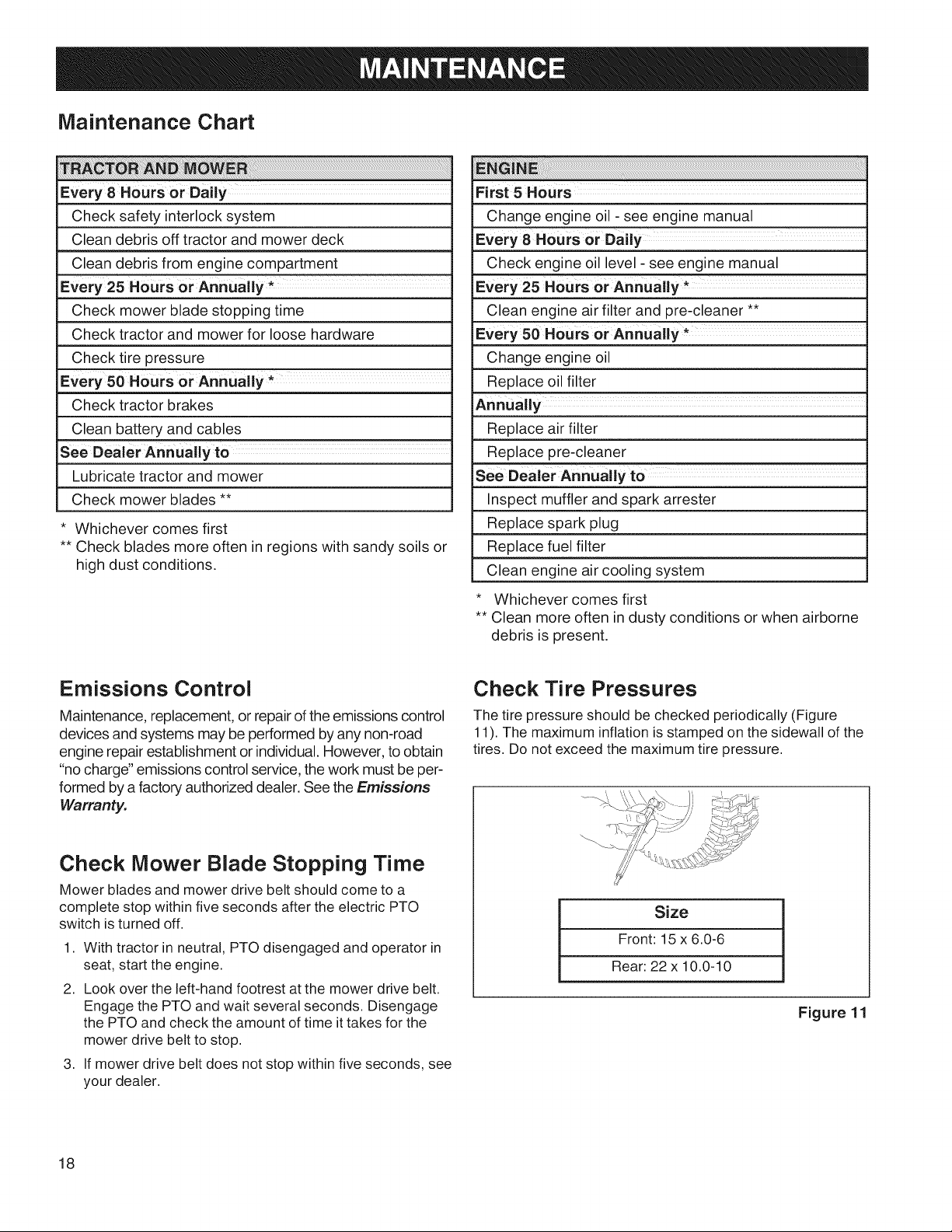

Check Tire Pressures

The tire pressure should be checked periodically (Figure

11). The maximum inflation is stamped on the sidewall of the

tires. Do not exceed the maximum tire pressure.

Size

Front: 15 x 6.0-6

Rear: 22 x 10.0-10

Figure 1

18

Page 19

Electronic Fuel Management System

The Electronic Fuel Management System monitors engine

temperature, engine speed, and battery voltage to adjust

the choke during engine starting and warm up. There are no

adjustments on the system. If starting or operation problems

occur, contact Sears Service.

NOTICE: Make sure to follow the steps below or the

Electronic Fuel Management System could be damaged.

= Never start the engine if the battery cables are loose.

= Turn the key to the off position before disconnecting,

removing and/or installing the battery.

Never use a battery charger to start the engine.

Never disconnect the battery cables while the engine is

running.

When connecting the battery cables, first connect the

positive (+) cable and then connect the negative (-) cable

to the battery.

= When charging the battery, turn the ignition switch to the

off position and disconnect the negative (-) battery cable

from the battery.

= Do not spray water directly on the Electronic Control Unit.

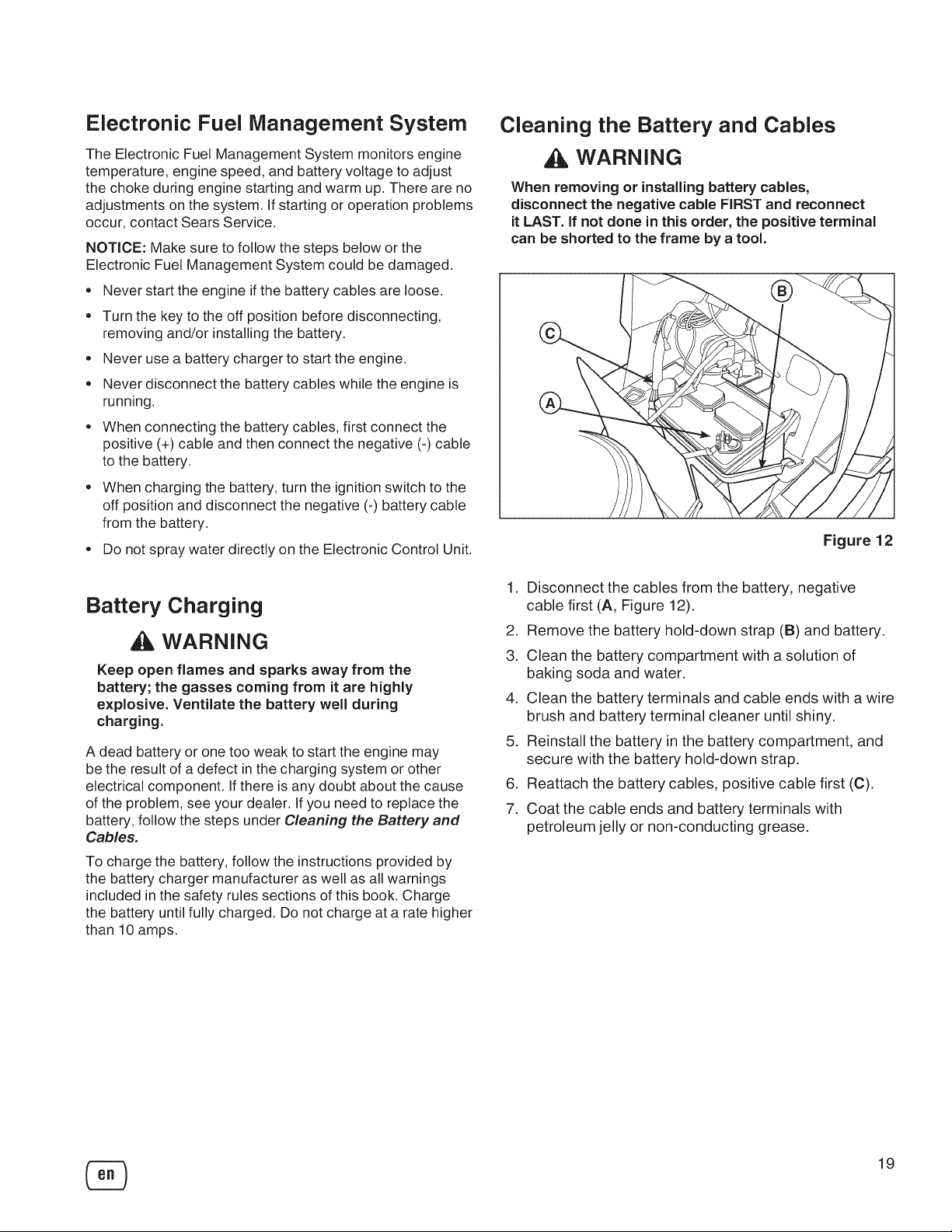

Cleaning the Battery and Cables

WARNING

When removing or installing battery cables,

disconnect the negative cable FIRST and reconnect

it LAST. if not done in this order, the positive terminal

can be shorted to the frame by a tool.

Figure 12

Battery Charging

WARNING

Keep open flames and sparks away from the

battery; the gasses coming from it are highly

explosive. Ventilate the battery well during

charging.

A dead battery or one too weak to start the engine may

be the result of a defect in the charging system or other

electrical component. If there is any doubt about the cause

of the problem, see your dealer. If you need to replace the

battery, follow the steps under Cleaning the Battery and

Cables.

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the safety rules sections of this book. Charge

the battery until fully charged. Do not charge at a rate higher

than 10 amps.

1. Disconnect the cables from the battery, negative

cable first (A, Figure 12).

2. Remove the battery hold-down strap (B) and battery.

3. Clean the battery compartment with a solution of

baking soda and water.

4. Clean the battery terminals and cable ends with a wire

brush and battery terminal cleaner until shiny.

5. Reinstall the battery in the battery compartment, and

secure with the battery hold-down strap.

6. Reattach the battery cables, positive cable first (C).

7. Coat the cable ends and battery terminals with

petroleum jelly or non-conducting grease.

19

Page 20

/

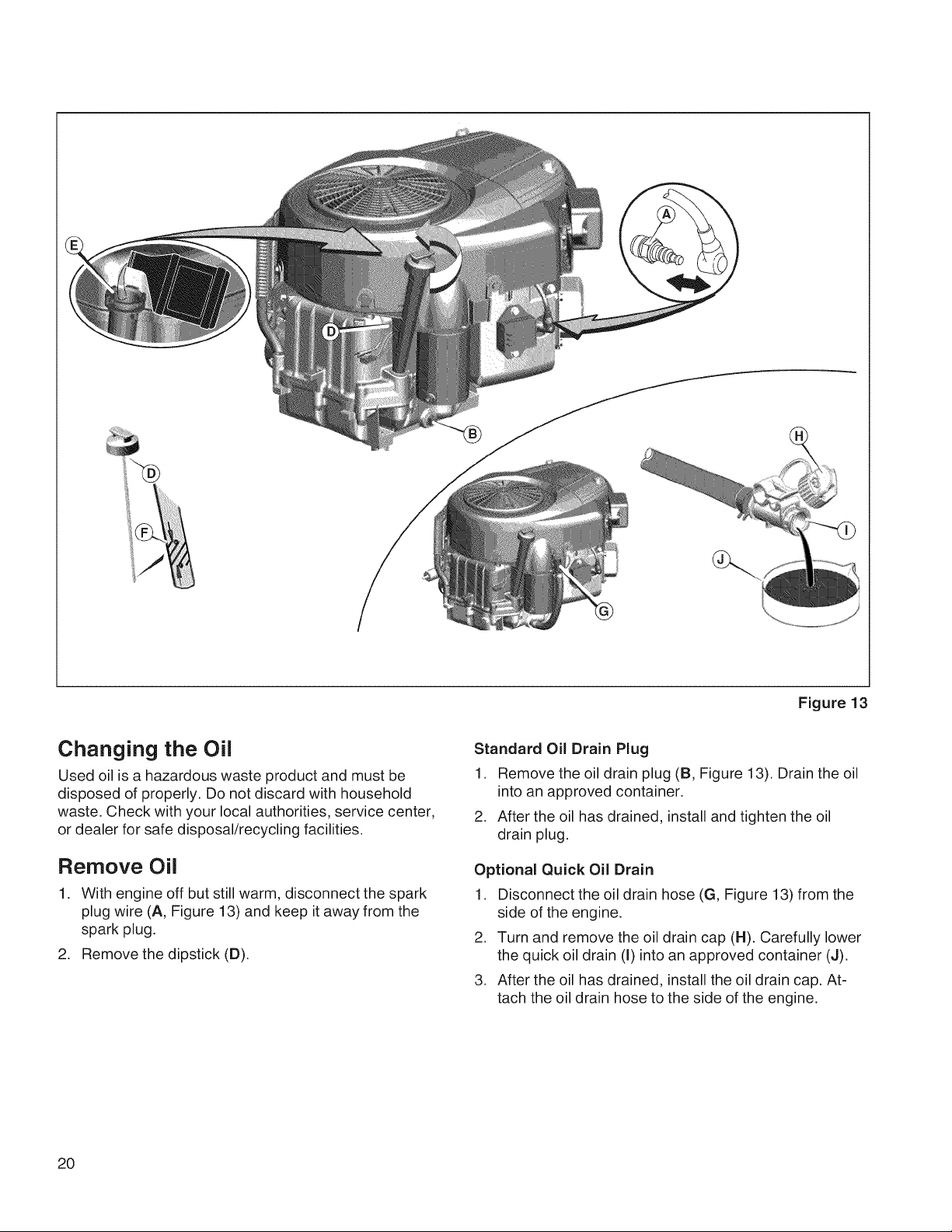

Figure 13

Changing the Oil

Used oil is a hazardous waste product and must be

disposed of properly. Do not discard with household

waste. Check with your local authorities, service center,

or dealer for safe disposal/recycling facilities.

Remove Oil

1. With engine off but still warm, disconnect the spark

plug wire (A, Figure 13) and keep it away from the

spark plug.

2. Remove the dipstick (D).

20

Standard Oil Drain Plug

1. Remove the oil drain plug (B, Figure 13). Drain the oil

into an approved container.

2. After the oil has drained, install and tighten the oil

drain plug.

Optional Quick Oil Drain

1. Disconnect the oil drain hose (G, Figure 13) from the

side of the engine.

2. Turn and remove the oil drain cap (H). Carefully lower

the quick oil drain (I) into an approved container (J).

3. After the oil has drained, install the oil drain cap. At-

tach the oil drain hose to the side of the engine.

Page 21

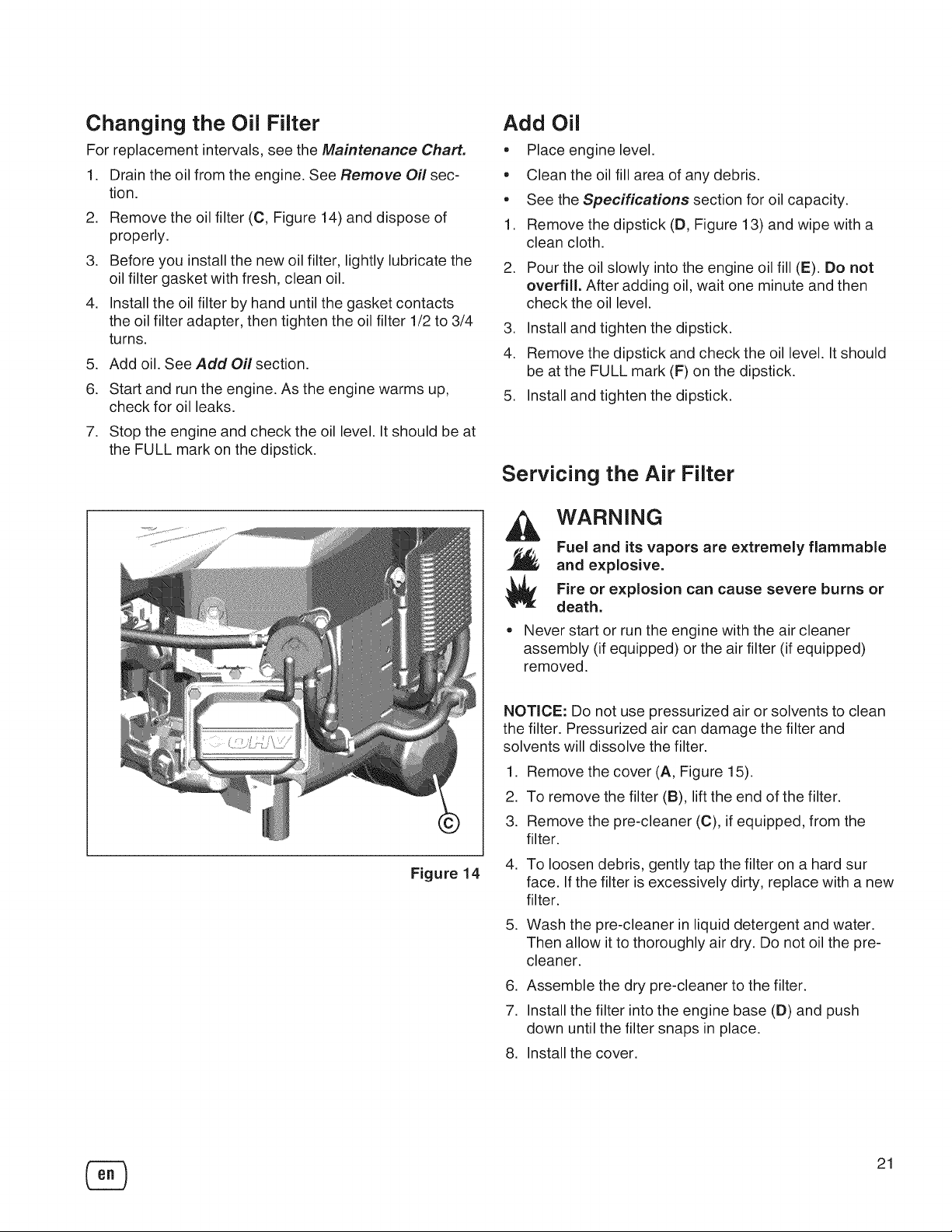

Changing the Oil Filter

For replacement intervals, see the Maintenance Chart.

1. Drain the oil from the engine. See Remove Oil sec-

tion.

2. Remove the oil filter (C, Figure 14) and dispose of

properly.

3. Before you install the new oil filter, lightly lubricate the

oil filter gasket with fresh, clean oil.

4. Install the oil filter by hand until the gasket contacts

the oil filter adapter, then tighten the oil filter 1/2 to 3/4

turns.

5. Add oil. See Add Oilsection.

6. Start and run the engine. As the engine warms up,

check for oil leaks.

7. Stop the engine and check the oil level. It should be at

the FULL mark on the dipstick.

Add Oil

• Place engine level.

• Clean the oil fill area of any debris.

• See the Specifications section for oil capacity.

1. Remove the dipstick (D, Figure 13) and wipe with a

clean cloth.

2. Pour the oil slowly into the engine oil fill (E). Do not

overfill. After adding oil, wait one minute and then

check the oil level.

3. Install and tighten the dipstick.

4. Remove the dipstick and check the oil level. Itshould

be at the FULL mark (F) on the dipstick.

5. Install and tighten the dipstick.

Servicing the Air Filter

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

° Never start or run the engine with the air cleaner

assembly (if equipped) or the air filter (if equipped)

removed.

Figure 14

NOTICE: Do not use pressurized air or solvents to clean

the filter. Pressurized air can damage the filter and

solvents will dissolve the filter.

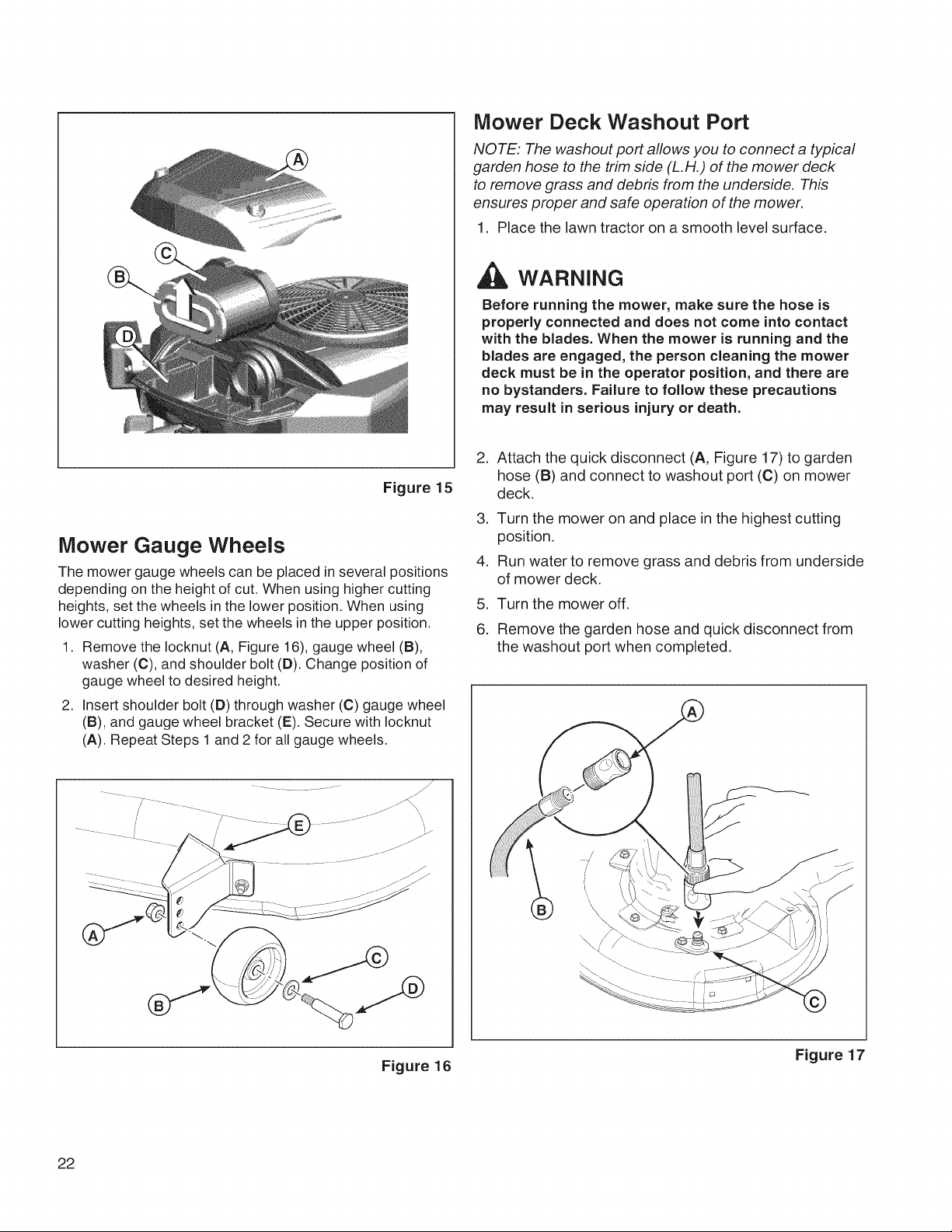

1. Remove the cover (A, Figure 15).

2. To remove the filter (B), liftthe end of the filter.

3. Remove the pre-cleaner (C), if equipped, from the

filter.

4. To loosen debris, gently tap the filter on a hard sur

face. If the filter is excessively dirty, replace with a new

filter.

5. Wash the pre-cleaner in liquid detergent and water.

Then allow it to thoroughly air dry. Do not oil the pre-

cleaner.

6. Assemble the dry pre-cleaner to the filter.

7. Install the filter into the engine base (D) and push

down until the filter snaps in place.

8. Install the cover.

21

Page 22

Figure 15

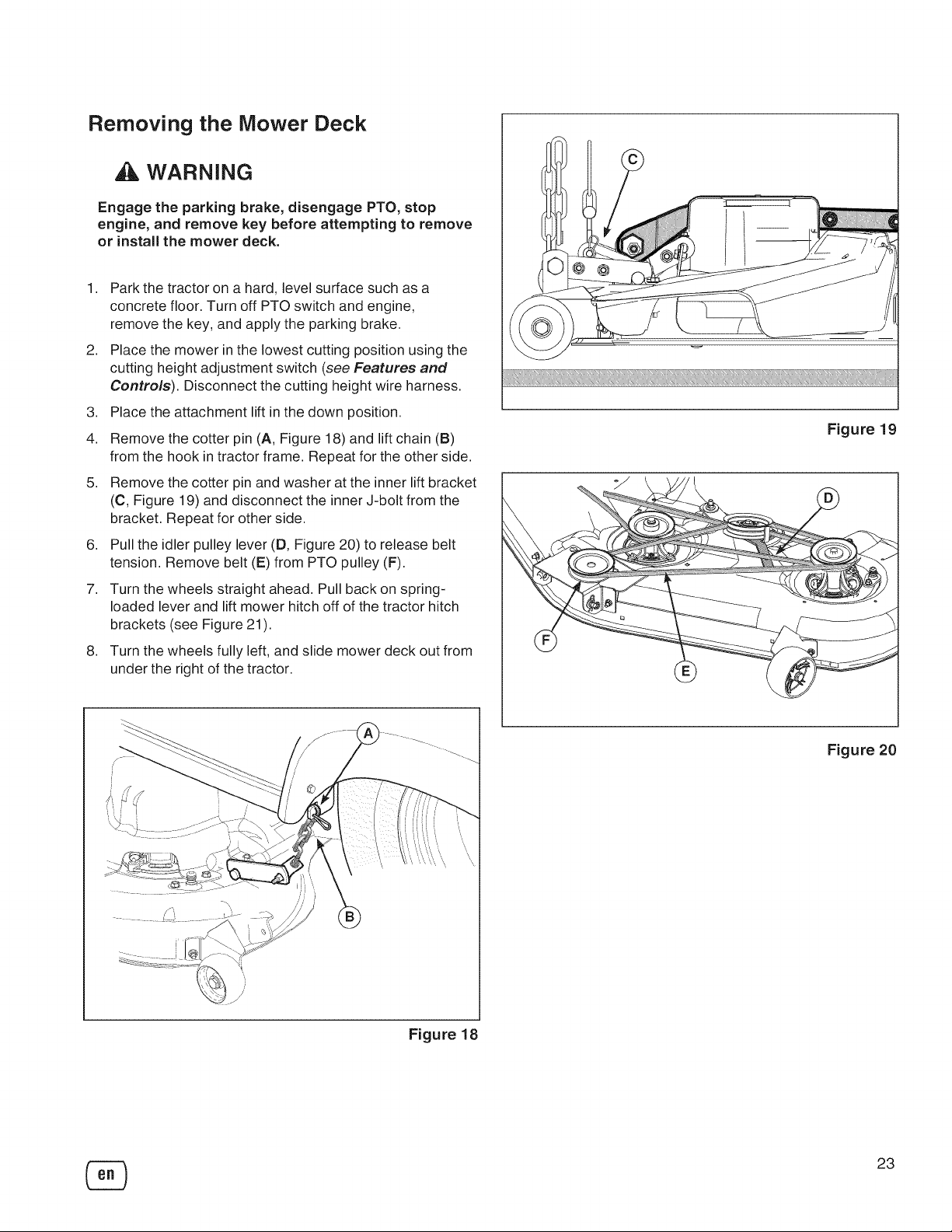

Mower Gauge Wheels

The mower gauge wheels can be placed in several positions

depending on the height of cut. When using higher cutting

heights, set the wheels in the lower position. When using

lower cutting heights, set the wheels in the upper position.

1. Remove the Iocknut (A, Figure 16), gauge wheel (B),

washer (C), and shoulder bolt (D). Change position of

gauge wheel to desired height.

2. Insert shoulder bolt (D) through washer (C) gauge wheel

(B), and gauge wheel bracket (E). Secure with Iocknut

(A). Repeat Steps 1 and 2 for all gauge wheels.

Mower Deck Washout Port

NOTE: The washout port allows you to connect a typical

garden hose to the trim side (L.H.) of the mower deck

to remove grass and debris from the underside. This

ensures proper and safe operation of the mower.

1. Place the lawn tractor on a smooth level surface.

WARNING

Before running the mower, make sure the hose is

properly connected and does not come into contact

with the blades. When the mower is running and the

blades are engaged, the person cleaning the mower

deck must be in the operator position, and there are

no bystanders. Failure to follow these precautions

may result in serious injury or death.

,

Attach the quick disconnect (A, Figure 17) to garden

hose (B) and connect to washout port (C) on mower

deck.

,

Turn the mower on and place in the highest cutting

position.

4.

Run water to remove grass and debris from underside

of mower deck.

5.

Turn the mower off.

6.

Remove the garden hose and quick disconnect from

the washout port when completed.

22

Figure 16

\

\\

\

Figure 17

Page 23

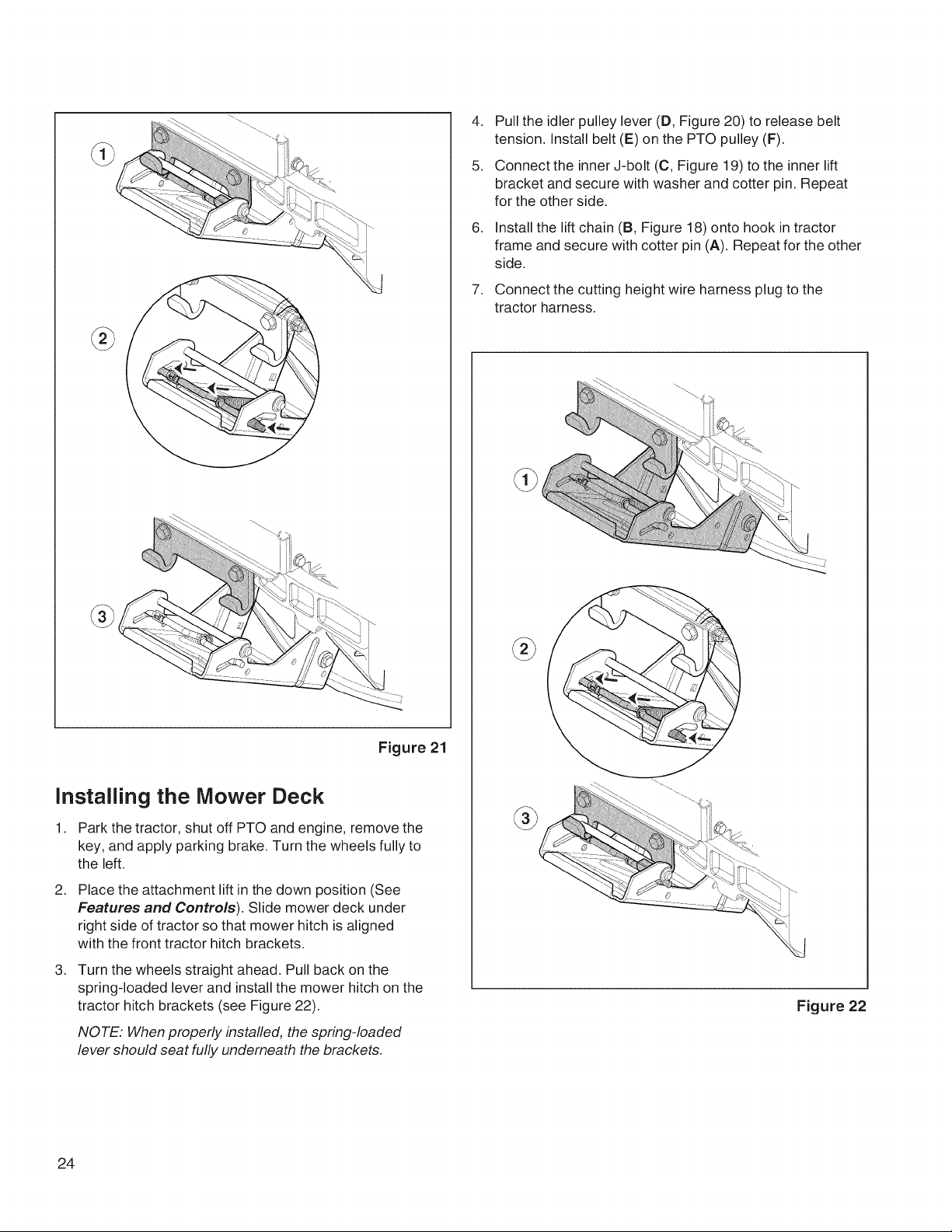

Removing the Mower Deck

WARNING

Engage the parking brake, disengage PTO, stop

engine, and remove key before attempting to remove

or install the mower deck.

1,

Park the tractor on a hard, level surface such as a

concrete floor. Turn off PTO switch and engine,

remove the key, and apply the parking brake.

2,

Place the mower in the lowest cutting position using the

cutting height adjustment switch (see Features and

Controls). Disconnect the cutting height wire harness.

3,

Place the attachment lift in the down position.

4.

Remove the cotter pin (A, Figure 18) and lift chain (B)

from the hook in tractor frame. Repeat for the other side.

5,

Remove the cotter pin and washer at the inner lift bracket

(C, Figure 19) and disconnect the inner J-bolt from the

bracket. Repeat for other side.

6,

Pull the idler pulley lever (D, Figure 20) to release belt

tension. Remove belt (E) from PTO pulley (F).

7,

Turn the wheels straight ahead. Pull back on spring-

loaded lever and lift mower hitch off of the tractor hitch

brackets (see Figure 21 ).

,

Turn the wheels fully left, and slide mower deck out from

under the right of the tractor.

Figure 19

Figure 18

Figure 20

23

Page 24

4,

Pull the idler pulley lever (D, Figure 20) to release belt

tension. Install belt (E) on the PTO pulley (F).

5,

Connect the inner J-bolt (C, Figure 19) to the inner lift

bracket and secure with washer and cotter pin. Repeat

for the other side.

6,

Install the lift chain (B, Figure 18) onto hook in tractor

frame and secure with cotter pin (A). Repeat for the other

side.

7,

Connect the cutting height wire harness plug to the

tractor harness.

0

Figure 21

Installing the Mower Deck

1. Park the tractor, shut off PTO and engine, remove the

key, and apply parking brake. Turn the wheels fully to

the left.

2,

Place the attachment lift in the down position (See

Features and Controls). Slide mower deck under

right side of tractor so that mower hitch is aligned

with the front tractor hitch brackets.

3,

Turn the wheels straight ahead. Pull back on the

spring-loaded lever and install the mower hitch on the

tractor hitch brackets (see Figure 22).

NOTE: When properly installed, the spring-loaded

lever should seat fully underneath the brackets.

Figure 22

24

Page 25

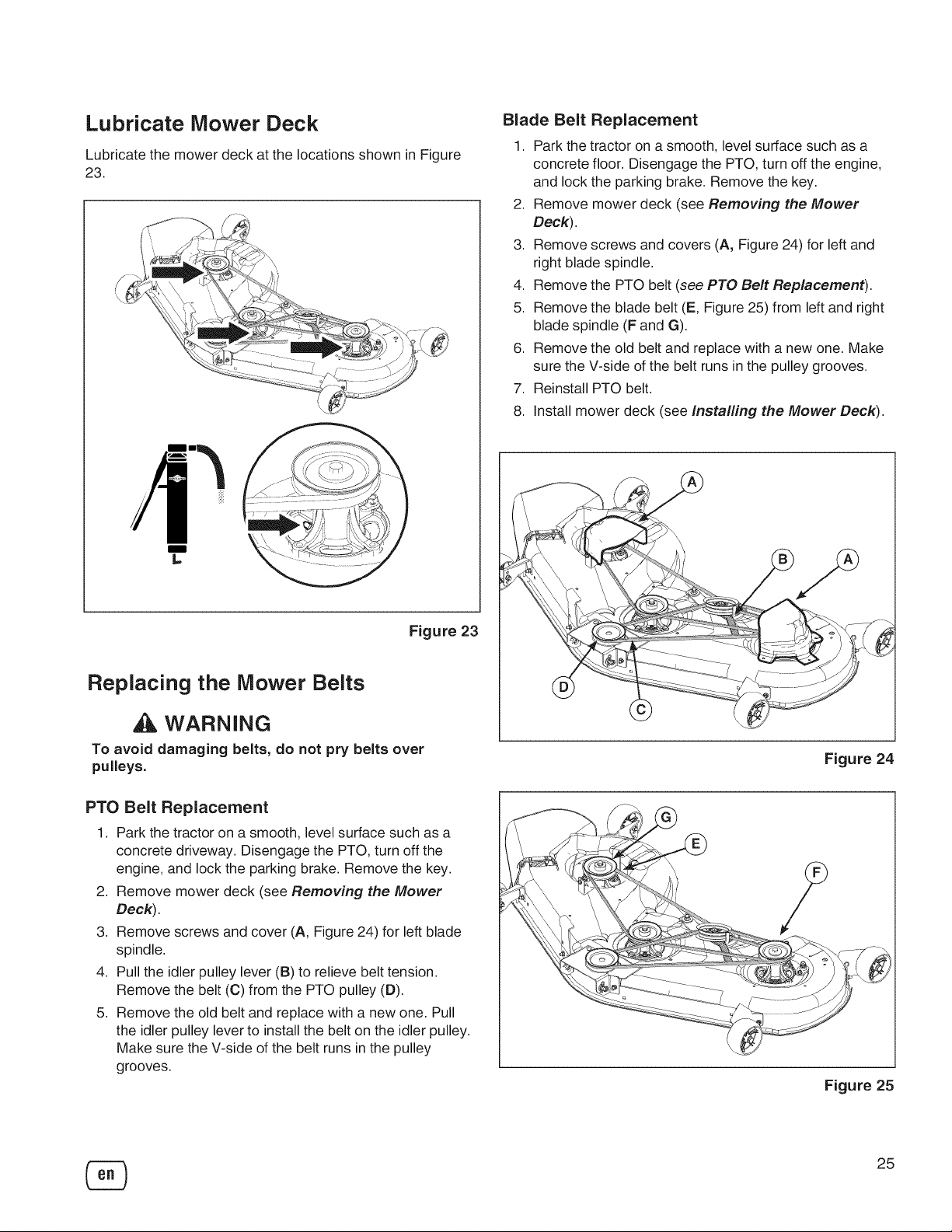

Lubricate Mower Deck

Lubricate the mower deck at the locations shown in Figure

23.

m

Blade Belt Replacement

1. Park the tractor on a smooth, level surface such as a

concrete floor. Disengage the PTO, turn off the engine,

and lock the parking brake. Remove the key.

2. Remove mower deck (see Removing the Mower

Deck).

3. Remove screws and covers (A, Figure 24) for left and

right blade spindle.

4. Remove the PTO belt (see PTO Belt Replacement).

5. Remove the blade belt (E, Figure 25) from left and right

blade spindle (F and G).

6. Remove the old belt and replace with a new one. Make

sure the V-side of the belt runs in the pulley grooves.

7. Reinstall PTO belt.

8. Install mower deck (see Installing the Mower Deck).

Figure 23

Replacing the Mower Belts

WARNING

To avoid damaging belts, do not pry belts over

pulleys.

PTO Belt Replacement

1. Park the tractor on a smooth, level surface such as a

concrete driveway. Disengage the PTO, turn off the

engine, and lock the parking brake. Remove the key.

2. Remove mower deck (see Removing the Mower

Deck).

3. Remove screws and cover (A, Figure 24) for left blade

spindle.

4. Pull the idler pulley lever (B) to relieve belt tension.

Remove the belt (C) from the PTO pulley (D).

5. Remove the old belt and replace with a new one. Pull

the idler pulley lever to install the belt on the idler pulley.

Make sure the V-side of the belt runs in the pulley

grooves.

Figure 24

Figure 25

25

Page 26

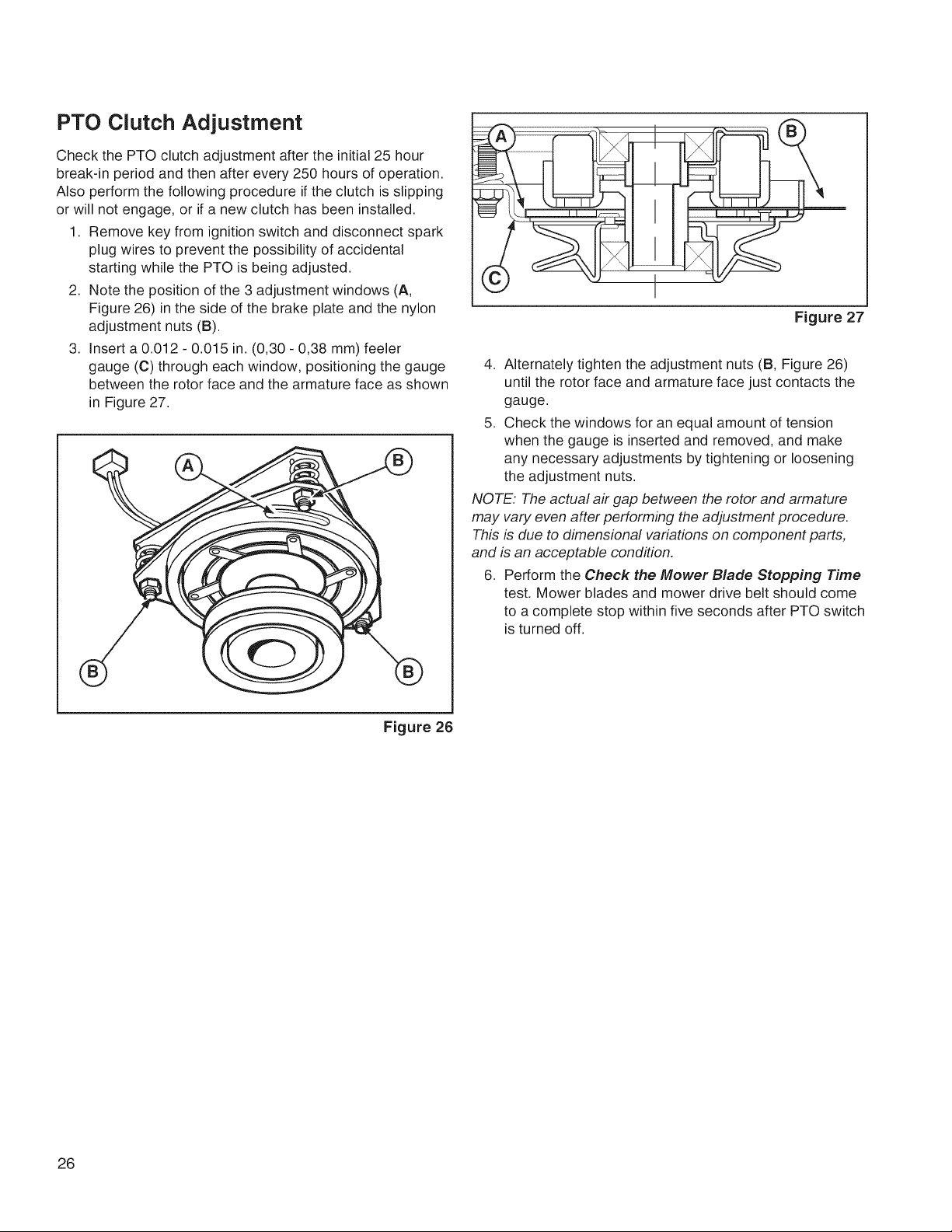

PTO Clutch Adjustment

Check the PTO clutch adjustment after the initial 25 hour

break-in period and then after every 250 hours of operation.

Also perform the following procedure if the clutch is slipping

or will not engage, or if a new clutch has been installed.

1. Remove key from ignition switch and disconnect spark

plug wires to prevent the possibility of accidental

starting while the PTO is being adjusted.

2. Note the position of the 3 adjustment windows (A,

Figure 26) in the side of the brake plate and the nylon

adjustment nuts (B).

3. Insert a 0.012 - 0.015 in. (0,30 - 0,38 mm) feeler

gauge (C) through each window, positioning the gauge

between the rotor face and the armature face as shown

in Figure 27.

Figure 27

4. Alternately tighten the adjustment nuts (B, Figure 26)

until the rotor face and armature face just contacts the

gauge.

5. Check the windows for an equal amount of tension

when the gauge is inserted and removed, and make

any necessary adjustments by tightening or loosening

the adjustment nuts.

NOTE: The actual air gap between the rotor and armature

may vary even after performing the adjustment procedure.

This is due to dimensional variations on component parts,

and is an acceptable condition.

6. Perform the Check the Mower Blade Stopping Time

test. Mower blades and mower drive belt should come

to a complete stop within five seconds after PTO switch

is turned off.

26

Figure 26

Page 27

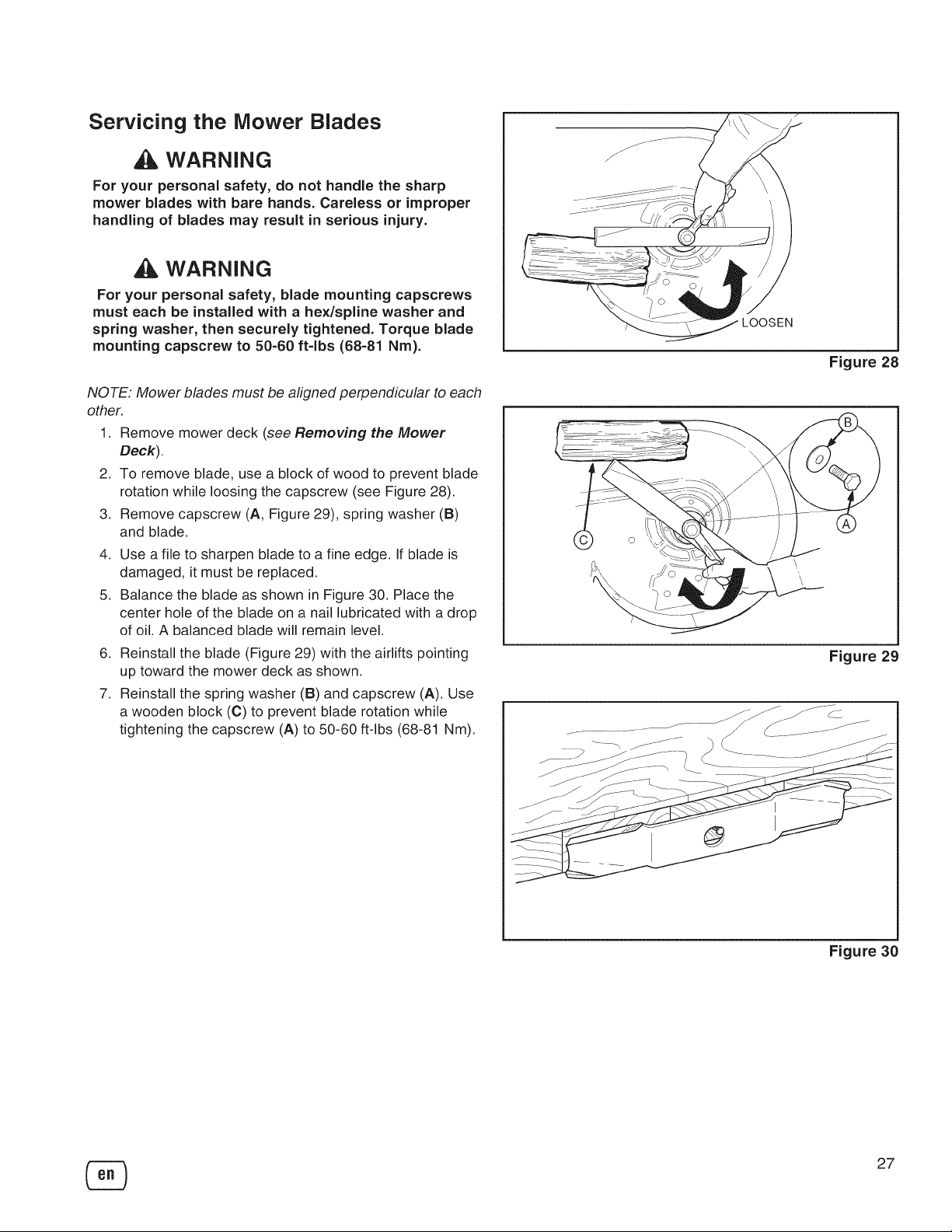

Servicing the Mower Blades

WARNING

For your personal safety, do not handle the sharp

mower blades with bare hands. Careless or improper

handling of blades may result in serious injury.

WARNING

For your personal safety, blade mounting capscrews

must each be installed with a hex/spline washer and

spring washer, then securely tightened. Torque blade

mounting capscrew to 50-60 ft-lbs (68-81 Nm).

NOTE: Mower blades must be aligned perpendicular to each

other.

1. Remove mower deck (see Removing the Mower

Deck).

2. To remove blade, use a block of wood to prevent blade

rotation while loosing the capscrew (see Figure 28).

3. Remove capscrew (A, Figure 29), spring washer (B)

and blade.

4. Use a file to sharpen blade to a fine edge. if blade is

damaged, it must be replaced.

5. Balance the blade as shown in Figure 30. Place the

center hole of the blade on a nail lubricated with a drop

of oil. A balanced blade will remain level.

6. Reinstall the blade (Figure 29) with the airlifts pointing

up toward the mower deck as shown.

7. Reinstall the spring washer (B) and capscrew (A). Use

a wooden block (C) to prevent blade rotation while

tightening the capscrew (A) to 50-60 ft-lbs (68-81 Nm).

LOOSEN

Figure 28

Figure 29

Figure 30

27

Page 28

Storage

WARNING

Never store the unit (with fuel) in an

enclosed, poorly ventilated structure. Fuel

vapors can travel to an ignition source (such

as a furnace, water heater, etc.) and cause an

explosion. Fuel vapor is also toxic to humans

and animals.

When Storing Fuel Or Equipment With Fuel in Tank

° Store away from furnaces, stoves, water heaters or

other appliances that have pilot lights or other ignition

sources because they can ignite fuel vapors.

Equipment

Disengage the PTO, set the parking brake, and remove

the key.

Battery life will be increased if it is removed. Put in a cool,

dry place and fully charged about once a month. If the

battery is left in the unit, disconnect the negative cable.

Fuel System

Fuel can become stale when stored over 30 days. Stale

fuel causes acid and gum deposits to form in the fuel

system or on essential carburetor parts. To keep fuel fresh,

use Briggs & Stratton® Advanced Formula Fuel Treat-

ment & Stabilizer, available wherever Briggs & Stratton

genuine service parts are sold.

For engines equipped with a FRESH START@ fuel cap,

use Briggs & Stratton FRESH START@ available in a

drip concentrate cartridge.

There is no need to drain gasoline from the engine if a

fuel stabilizer is added according to instructions. Run the

engine for 2 minutes to circulate the stabilizer throughout

the fuel system before storage.

Engine Oil

While the engine is still warm, change the engine oil.

Before starting the unit after it has been stored:

• Check all fluid levels. Check all maintenance items.

• Perform all recommended checks and procedures

found in this manual.

• Allow the engine to warm up for several minutes before

use.

28

Page 29

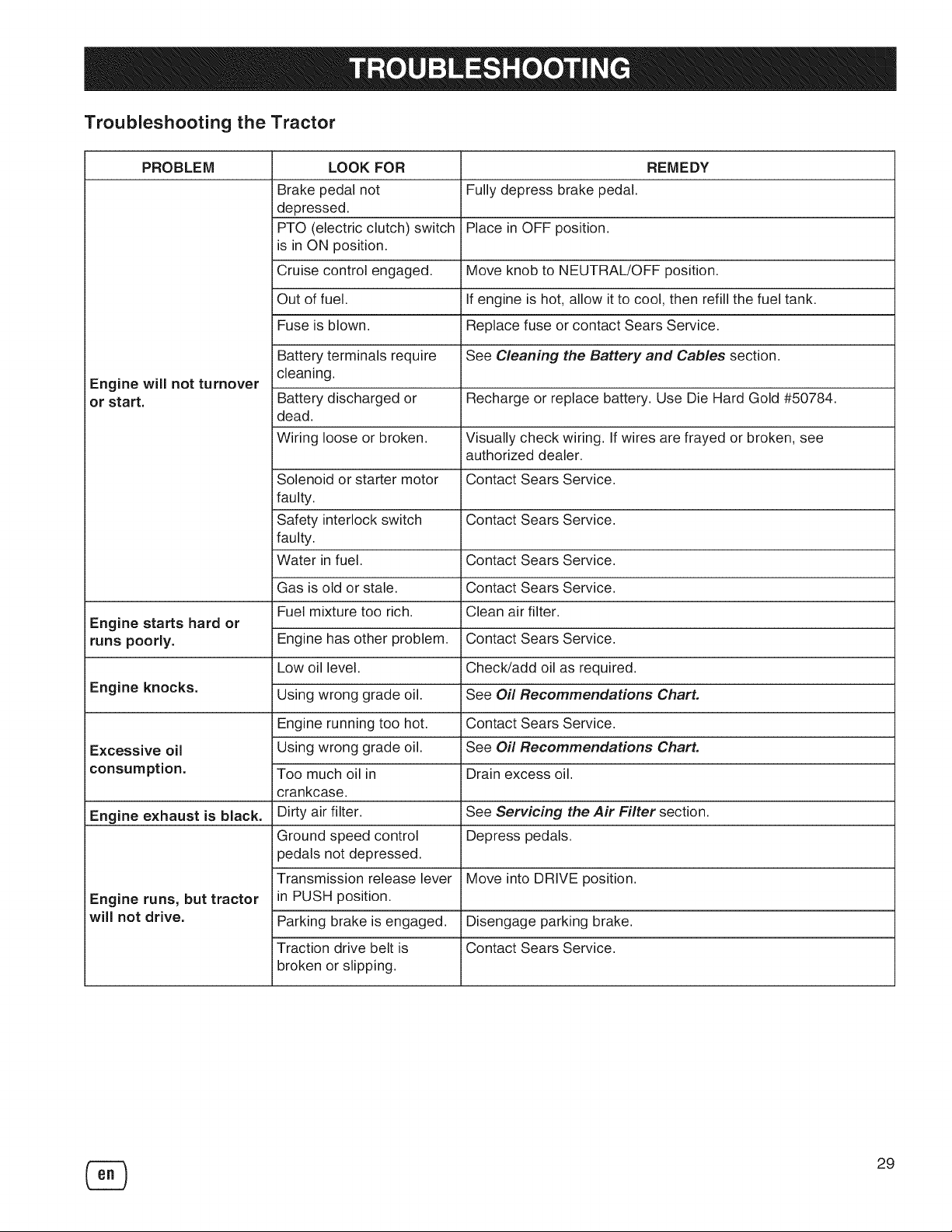

Troubleshooting the Tractor

PROBLEM

Engine will not turnover

or start.

Engine starts hard or

runs poorly.

Engine knocks.

Excessive oil

consumption.

Engine exhaust is black.

Engine runs, but tractor

will not drive.

LOOK FOR

Brake pedal not

depressed.

PTO (electric clutch) switch

is in ON position.

Cruise control engaged.

Out of fuel.

Fuse is blown.

Battery terminals require

cleaning.

Battery discharged or

dead.

Wiring loose or broken.

Solenoid or starter motor

faulty,

Safety interlock switch

faulty,

Water in fuel,

Gas is old or stale,

Fuel mixture too rich,

Engine has other problem,

Low oil level,

Using wrong grade oil,

Engine running too hot,

Using wrong grade oil,

Too much oil in

crankcase.

Dirty air filter,

Ground speed control

pedals not depressed,

Transmission release lever

in PUSH position,

Parking brake is engaged,

Traction drive belt is

broken or slipping,

REMEDY

Fully depress brake pedal.

Place in OFF position.

Move knob to NEUTRAL/OFF position.

If engine is hot, allow it to cool, then refill the fuel tank.

Replace fuse or contact Sears Service.

See Cleaning the Battery and Cables section.

Recharge or replace battery. Use Die Hard Gold #50784.

Visually check wiring. If wires are frayed or broken, see

authorized dealer.

Contact Sears Service.

Contact Sears Service.

Contact Sears Service.

Contact Sears Service.

Clean air filter.

Contact Sears Service.

Check/add oil as required.

See Oil Recommendations Chart.

Contact Sears Service.

See Oil Recommendations Chart.

Drain excess oil.

See Servicing the Air Filter section.

Depress pedals.

Move into DRIVE position.

Disengage parking brake.

Contact Sears Service.

29

!

Page 30

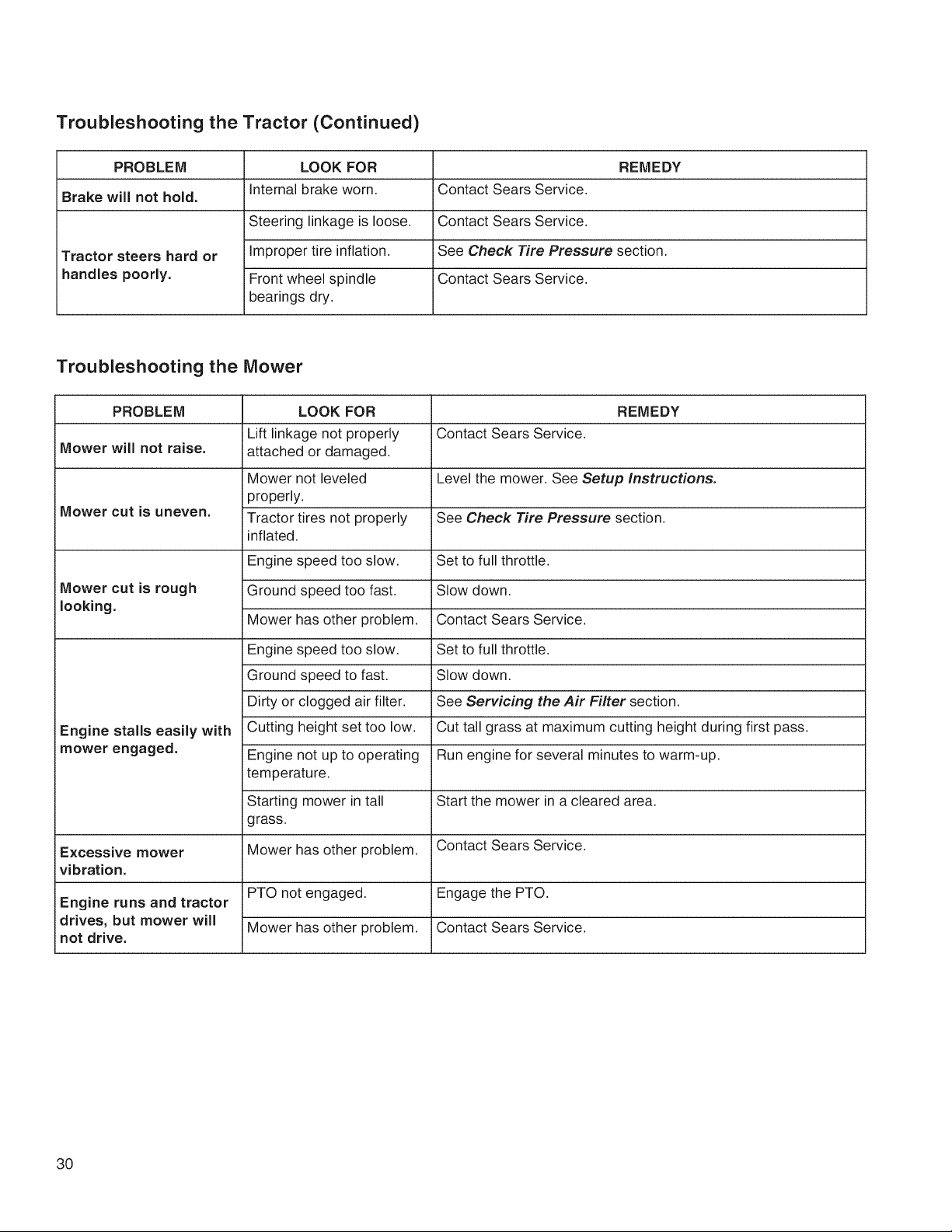

Troubleshooting the Tractor (Continued)

PROBLEM LOOK FOR REMEDY

Brake will not hold. Internal brake worn. Contact Sears Service.

Steering linkage is loose. Contact Sears Service.

Tractor steers hard or Improper tire inflation. See Check Tire Pressure section.

handles poorly. Front wheel spindle Contact Sears Service.

bearings dry.

Troubleshooting the Mower

PROBLEM LOOK FOR REMEDY

Lift linkage not properly Contact Sears Service.

Mower will not raise, attached or damaged.

Mower not leveled Level the mower. See Setup Instructions.

properly.

Mower cut is uneven. Tractor tires not properly See Check Tire Pressure section.

inflated.

Engine speed too slow. Set to full throttle.

Mower cut is rough Ground speed too fast. Slow down.

looking.

Engine stalls easily with Cutting height set too low. Cut tall grass at maximum cutting height during first pass.

mower engaged. Engine not up to operating Run engine for several minutes to warm-up.

Excessive mower Mower has other problem. Contact Sears Service.

vibration.

Engine runs and tractor

drives, but mower will Mower has other problem. Contact Sears Service.

not drive.

Mower has other problem. Contact Sears Service.

Engine speed too slow. Set to full throttle.

Ground speed to fast. Slow down.

Dirty or clogged air filter. See Servicing the Air Filter section.

temperature.

Starting mower in tall Start the mower in a cleared area.

grass.

PTO not engaged. Engage the PTO.

30

Page 31

ENGINE

Briggs & Stratton Type

Make Briggs & Stratton® Hydraulic Fluid

Model ProfessionalSeriesTM Speeds

Horsepower 22Gross HP@3400 +/- 100rpm @3400 rpm

Displacement 40.0cu in. (656 cc) Continuous Torque

Electrical System Alternator: 16 amp DC Reg. Output

Battery: 12volt, 230 CCA

Die HardGold #50784

64 oz (1,9 L)Oil Capacity

CHASSIS

Fuel Tank Capacity

Front Wheels

Rear Wheels

3.6 Gallons (13,6 L)

Tire Size: 15 x 6.0-6

Tire Size: 22 x 10.0-10

K57 TRANSMiSSiON

Hydrostatic Tuff Torq K57

10w 30 Premium Engine Oil

Forward: 0-5.8 MPH (0-9,3 km/h)

Reverse: 0-3.5 MPH (0-5,6 km/h)

159 ft-lbs (216 Nm)

MOWER

Width of Cut

Number of Blades

Base Deck Platform

Cutting Height

Cutting Positions

46" (116,8 cm)

3

Side Discharge

1.0- 4.0 in. (2,5- 10,2 cm)

Infinite

DiMENSiONS

Overall Length

Overall Width

Height

70" (177,8 cm)

56" (142,2 cm)

43" (109,2 cm)

Power Rating

The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of Automotive

Engineers) code J1940 (Small Engine Power & Torque Rating Procedure), and rating performance has been obtained

and corrected in accordance with SAE J1995 (Revision 2002-05). Torque values are derived at 3060 RPM; horsepower

values are derived at 3600 RPM. The gross power curves can be viewed at www.BRIGGSandSTRATTON.COM. Net

power values are taken with exhaust and air cleaner installed whereas gross power values are collected without these

attachments. Actual gross engine power will be higher than net engine power and is affected by, among other things,

ambient operating conditions and engine-to-engine variability. Given the wide array of products on which engines

are placed, the gas engine may not develop the rated gross power when used in a given piece of power equipment.

This difference is due to a variety of factors including, but not limited to, the variety of engine components (air cleaner,

exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (tempera-

ture, humidity, altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations, Briggs & Strat-

ton may substitute an engine of higher rated power for this Series engine.

Parts and Accessories

Contact an authorized dealer for parts and accessories.

(_ 31

Page 32

CRAFTSMAN FULL WARRANTY

FOR THREE YEARS from the date of purchase, all non-expendable parts of this riding equipment are war-

ranted against any defects in material or workmanship. A defective non-expendable part will receive free

in-home repair or replacement if repair is impossible.

FOR FIVE YEARS from the date of purchase, the frame and front axle of this riding equipment are warranted

against any defects in material or workmanship. A defective frame or front axle will receive free in-home re-

pair or replacement if repair is impossible.

FOR 90 DAYS from the date of purchase, the battery (an expendable part) of this riding equipment is war-

ranted against any defects in material or workmanship (our testing proves that it will not hold a charge). A

defective battery will receive free in-home replacement.

ADDITIONAL LIFETIME LIMITED WARRANTY on CAST IRON FRONT AXLE (if equipped)

FOR AS LONG AS IT IS USED by the original owner after the fifth year from the date of purchase, the cast

iron front axle (if equipped) of this riding equipment is warranted against any defects in material or workman-

ship. With proof of purchase, a defective cast iron front axle will receive free in-home replacement.

WARRANTY SERVICE

For warranty coverage details to obtain free repair or replacement, call 1-800-659-5917 or visit the web site:

www.craftsman.com.

In all cases above, if part repair or replacement is impossible, the riding equipment will be replaced free of

charge with the same or an equivalent model.

All of the above warranty coverage is void if this riding equipment is ever used while providing commercial

services or if rented to another person.

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT include:

• Expendable parts (except battery) that can wear out from normal use within the warranty period, includ-

ing but not limited to blades, spark plugs, air cleaners, belts, and oil filters.

Standard maintenance servicing, oil changes, or tune-ups.

Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or

glass.

Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or main-

tenance.

Repairs necessary because of operator abuse, including but not limited to damage caused by towing

objects beyond the capability of the riding equipment, impacting objects that bend the frame, axle as-

sembly or crankshaft, or over-speeding the engine.

Repairs necessary because of operator negligence, including but not limited to, electrical and mechani-

cal damage caused by improper storage, failure to use the proper grade and amount of engine oil, failure

to keep the deck clear of flammable debris, or failure to maintain the riding equipment according to the

instructions contained in the operator's manual.

Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized

(stale). In general, fuel should be used within 30 days of its purchase date.

Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

32

Page 33

Congratulations on making a smart purchase.

Your new Craftsman@ product is designed and

manufactured for years of dependable operation. But like

all products, it may require repair from time to time. That's

when having a Repair Protection Agreement can save

you money and aggravation.

Here's what the Repair Protection Agreement*

includes:

[] Expert service by our 10,000 professional repair

specialists

[] Unlimited service and no charge for parts and

labor on all covered repairs

[] Product replacement up to $1500 if your covered

product can't be fixed

[] Discount of 10% from regular price of service and

related installed parts not covered by the agreement;

also, 10% off regular price of preventive maintenance

check

[] Fast help by phone - we call it Rapid Resolution -

phone support from a Sears representative. Think of

us as a "talking owner's manual."

Once you purchase the Repair Protection Agreement, a

simple phone call is all that it takes for you to schedule

service.You can call anytime day or night, or schedule a

service appointment online.

The Repair Protection Agreement is a risk-free purchase.

If you cancel for any reason during the product warranty

period, we will provide a full refund. Or, a prorated

refund anytime after the product warranty period expires.

Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices

and additional information in the U.S.A. call 1-800-

827=6655.

*Coverage in Canada varies on some items. For full

details call Sears Canada at 1=800=361=6665.

Sears Installation Service

For Sears professional installation of home appliances,

garage door openers, water heaters, and other major

home items, in the U.S.A. or Canada call 1-800-4-MY-

HOME@.

33

Page 34

Your Home

For troubleshooting, product manuals and expert advice:

managemylife

www.managemylife.com

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME ® (1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of your nearest

Sears Parts & Repair Service Center

1-800-488-1222 (U.S.A.) 1-800-469-4663 (Canada)

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparaci6n

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR ®

(1-888-784-6427)

www.sears.com

® Registered Trademark / TMTrademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries

® Marca Registrada / TMMarca de Fabrica de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC in otros paises

MCMarque de commerce / MDMarque d6pos6e de Sears Brands, LLC

Au Canada pour service en fran£ais:

1-800-LE-FOYER Mc

(1-800-533-6937)

www.sears.ca