Page 1

Operator's anuai

CRRFTSM N

ZTS

Zero-Turn Mower

2-Bin Bagger Attachment

Model No.

107.249130 (Twin Bagger / 52" Mower)

CAUTION: Before using this product, read

the manual and follow all its Safety Rules

and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

For anwers to your questions about this

product, call:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pm, Mon- Sat

Nota: Una traducci6n en espaSol de este Manual

del Operador puede encontrarse en la pagina 35.

1737732-D

Rev.: D

Date 08/2009

Page 2

Page 3

Tableof Contents

Operator Safety .................................................................... 4

GeneralWarnings ................................................................................. 4

SafetyDecals........................................................................................ 4

Assembly............................................................................ 5

Counterweight installation .................................................................... 5

Hitch Installation................................................................................... 6

Upright Support Installation.................................................................. 6

Cover Installation.................................................................................. 7

TubeAssembly..................................................................................... 8

Operation............................................................................ 10

Collector Installation............................................................................. 10

Attach CollectorBags............................................................................ 10

Operation.............................................................................................. 11

Collector Removal................................................................................. 12

Storage.............................................................................. 12

RepairParts........................................................................ PTS-1

Hardwareidentification &TorqueSpecifications............................ PTS-6

NOTE. In these instructions, "left" and "right" are referencedfrom the operating

position.

3

Page 4

OperatorSafety

ReadthesesafetyruJesandfoiJowthemcJoseJy.Failureto obeythese rules couJdresult in lossof controJof unit,

severepersonal injuryor deathto you, or bystanders,or damageto propertyor equipment.The,_,triangJe in text

signifiesimportantcautionsor warningswhichmust be followed.

GeneralWarnings

* Know the unit's controls and how to stop quickly. READ

THEOPERATOR'SMANUALS.

, Readand obeyall safety decals.

Onlyallow responsible adults, who arefamiliar with the

instructions, to operatethe unit.

Disengagethe PTO.Shutoff the engine andwait for

all moving parts to stop before attaching, adjusting, or

disconnecting any part ofthe collection system.

Checkthe collection systemto make sureit is bolted

tightly to the unit.

DONOToperate the unit without eitherthe entiregrass

catcheror the deflector inplace.

Turn off the PTOto disengagethe blades when not

mowing.

DONOTmow in reverseunless absolutely necessary.

Always look down and behind before andwhile travelling

in reverse.

DONOTturn sharply whentravelling alongsidea building

or any object. Slow down before turning.

DONOTcarry passengers.

When collection system is removed from the mower

deck,the deflector must be properly installed.

Collectorbags are subject to deterioration andwear

during normal use. inspectthe bagperiodically for tears,

holes, or weak spots and replacewith a new bagthat

meetsmanufacturer's durability standards.

, Foraddedstability and to preventtipping or loss of

control:

a.Use reducedspeedon uneven ground andwhen

turning corners.

b. Reduceloadson hillsides. It is recommendedthat the

collection system be kept only half full when negotiating

anyslopes. Start mowing on slopeswhen the collection

system is empty.

c. Mow up anddown the face of slopes; neveracross

the face of any slope.

o Never operate onslopesgreater than17.6% (10°).

Safety Decals

Severalsafety labelsare installed on the unit to remindyou

of important information while you are operatingyour unit.

All DANGER,WARNING, CAUTIONand instructional mes-

sageson your rider, attachments and mower should be

carefully read andobeyed. Personalbodily injury can result

whenthese instructions arenot followed. Thesafetydecals

below areon your product.

If anydecals are lost or damaged, replacethem at once.

Seeyour localdealerfor replacements.

Theselabelsare easily appliedand will act as a con-

stant visual reminderto you,and others who may usethe

equipment,to follow the safety instructions necessaryfor

safe,effective operation.

Attachment Decal

Decal- WARNINGThrown ObjectsHazard

PartNumber 1732819

Page 5

Assembly

,_l_ WARNING:Beforebeginning anyservicework turn

off the PTO,set the parking brake,turn off the ignition,

and disconnect the spark plug wire(s).

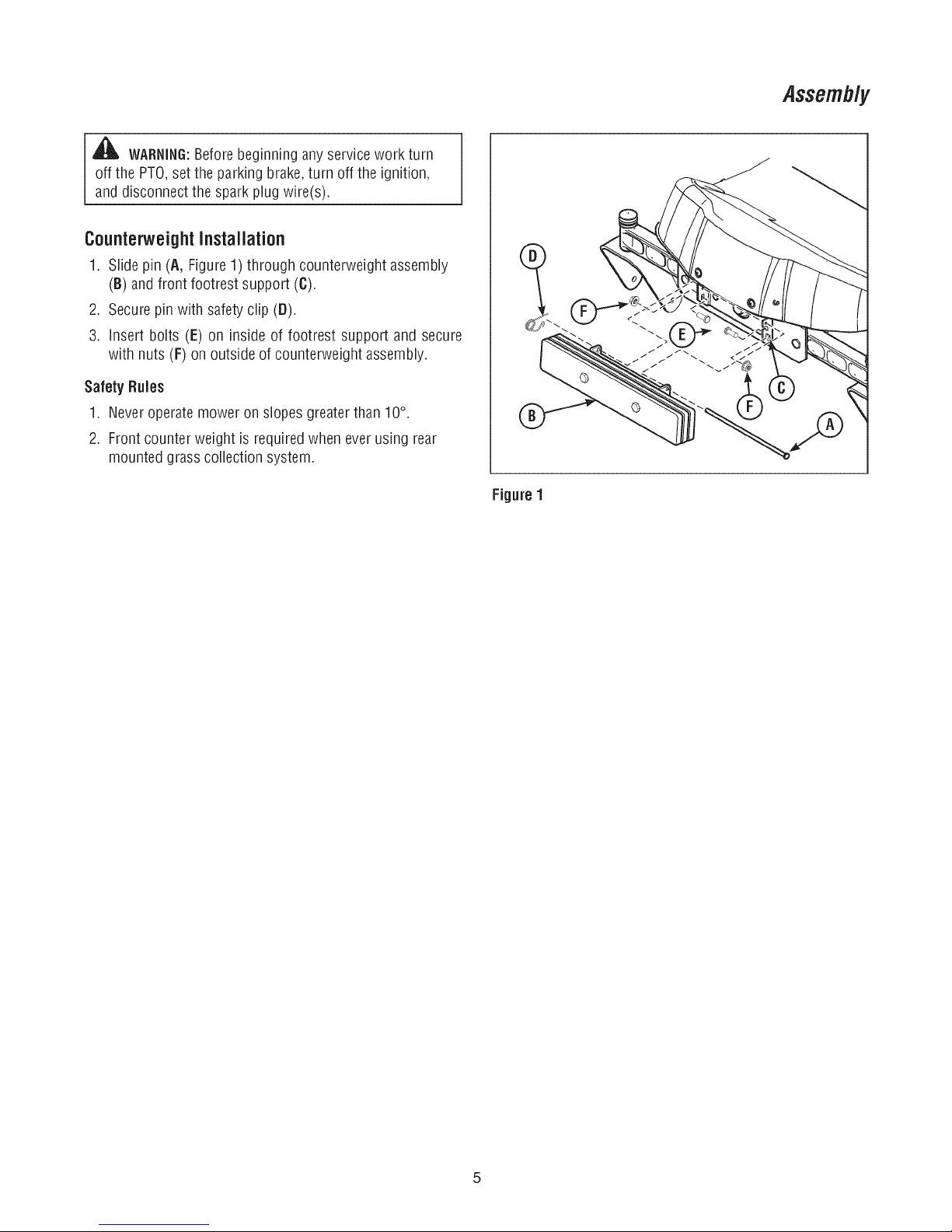

Counterweight Installation

1. Slide pin (A, Figure1) through counterweight assembly

(B) and front footrest support (6).

2. Securepin with safety clip (D).

3. insert bolts (E) on inside of footrest support and secure

with nuts (F) on outside of counterweightassembly.

Safety Rules

1. Neveroperate mower on slopes greater than 10°.

2. Front counter weight is required when ever using rear

mounted grass collection system.

1

Figure 1

Page 6

Assembly

9

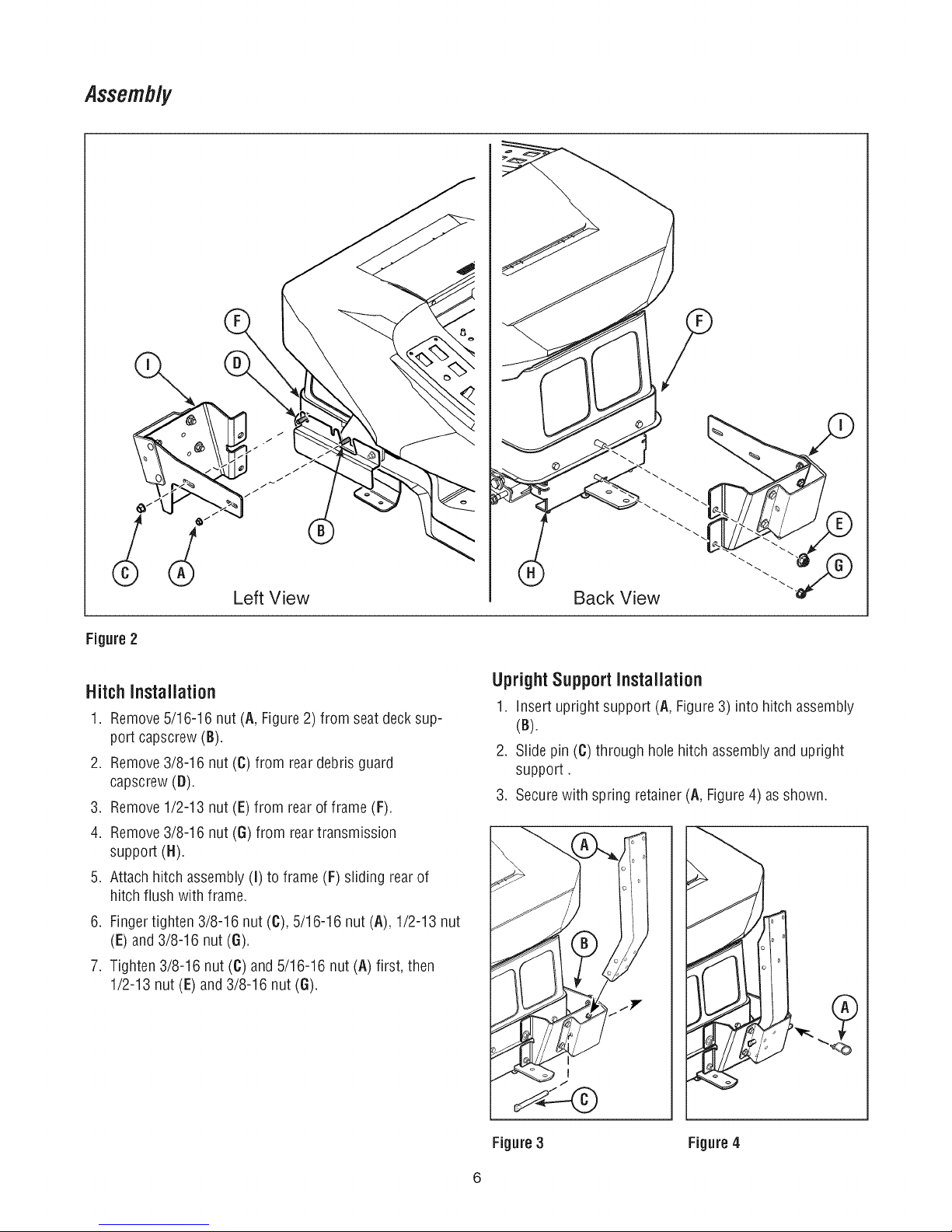

Figure2

HitchInstallation

1. Remove5/16-16 nut (A, Figure2) from seat deck sup-

port capscrew (B).

2. Remove3/8-16 nut (C) from reardebris guard

capscrew(D).

3. Remove1/2-13 nut (E) from rear of frame (F).

4. Remove3/8-16 nut (G) from rear transmission

support (H).

5. Attach hitch assembly (I) to frame(F) sliding rearof

hitch flush with frame.

6. Fingertighten 3/8-16 nut (C), 5/16-16 nut (A), 1/2-13 nut

(E) and 3/8-16 nut (6).

7. Tighten 3/8-16 nut (C)and 5/16-16 nut (A) first, then

1/2-13 nut (E)and3/8-16 nut (6).

Back View

UprightSupport Installation

1. insert upright support (A, Figure3) into hitch assembly

(B).

2. Slide pin (C) through holehitch assemblyand upright

support.

3. Securewith spring retainer (A, Figure4) as shown.

J

Figure 3 Figure 4

Page 7

Assembly

Figure5

CoverInstallation

1. Attach cover assembly (A, Figure5) to bagsupport

bracket(B) using cover hinge pivots (0). Securecover

assemblyto bag support bracketusing hinge pins (D)

and hair pins (E) as shown.

Page 8

Assembly

Tube Assernbiy

AdapterInstallation

1. Removeexisting hardwarefrom wheel bracket (A, Figure

6).

2. Replacewith carriage bolt (B) spacer(C), washer (D)

andsecure with nut (E).

3. Slide lowertube (A,Figure7) underneathdeflector

mounting bracket(B). Side tab (C)of chute fits insidethe

mower deck (D).

Figure 7

Figure 6

4. Rotate latch (A, Figure8) into pocket (B) of hardware

assembly (C}.

Figure 8

Page 9

Assembly

5. Fromthe inside of deck, install 1/4' carriagebolt (A,

Figure9) and secure with a 1/4-20 flange nut (B).

6. Fitthe other side of lower tube (A, Figure 10) onto car-

riage bolt and securewith spacer (B) and knob (C).

Figure 9

Assemble Upper & IVliddieTube

1. Slide the upper tube (A, Figure11) into cover (B)

aligning ridge(C)with cutout (D) as shown.

Figure 11

2. Slide middletube (A, Figure12) into upper tube (B) and

secure with screw (C).

3. Slide middletube (A) over lower tube (D). Fit hole in

strap (E) over pin (F).

Figure 10

Figure 12

Page 10

Operation

Collectorinstallation

1. Mount the hitchand frame assembly (A, Figure 13) onto

reartractor frame.

2. Slidethe uppertube (B) into cover (C) aligning ridge (D)

with cutout (E) as shown.

3. Raisethe cover (C).

4. Attach collector bags(F) using grass baghanger (G) to

bag hangerpost.

Note: It may be necessaryto fold seat forward to allow

cover to stay in the raisedposition.

Figure 13

Attach CollectorBags

1. Raisethe cover (A, Figure14).

2. Attach collector bags(B) using grass bag hanger (C) to

bag hangerpost (D).

Note: It may be necessaryto fold seatforward to allow

cover to stayin the raised position.

Figure 14

10

Page 11

BeforeOperation

Clearthe lawn of all sticks, stones, wire and other debris

which maybe caught or thrown bythe mower blades.

Checkgrass condition, if wet,wait until later in the day.

If grass is wet, the grass catcheris likelyto become

plugged.

Forefficient bagging, air circulation underthe mower

deck,through the chute and into the bag isvery impor-

tant.

Forthis reason, BEFOREYOUBEGINMOWINGyou

should makecertain the underside of the mower and

the underside of the catcherlid arefree from grass and

debris.

Makesure that there is a snug fit between mower deck,

blower housing, tubes, and grass catcher cover.

Operation

Mowingwiththe Catcher

Alwaysoperate with throttle at full speedwhen mowing.

Grassshould becut often, and not too short. If grass istoo

long or lush it maybe necessaryto keepground speedto a

minimum or to cut only half the width of the mower to pre-

vent clogging. If grass is long, operatewith mower in high

cutting position for first pass,cutting againin a lower posi-

tion on a second pass.

Do notopen the coverwith mowerengaged.

If a large amount of cut grass is spilling out from under

deck,the tube may be plugged or the bagsmay be full--

discontinue mowing, stopthe unit, disengagethe PTO,shut

off the engineand then empty the catcher or clearthe tube.

_ WARNING:ALWAYSshut off the tractor. Disengage

the PTO,andallow allmoving parts to stop BEFORE

disconnecting or clearingtube, or emptying catcher.

Beforeleavingthe operator's position for any reason,

engagethe parking brake,disengage the PTO,stop the

engine and removethe key.

To reducefire hazard,keepthe engine, rider and mower

free of grass, leavesand excessgrease.Do not stop

or park rider overdry leaves,grass or combustible

materials.

After Operation

Removeany debris from the screen on the underside of the

lid.

Theblower housing and tube should be removed for clean-

ing.

inspectthe grass bags for wear or damage. Makesure that

there is asnug fit betweenmower deck,blower housing,

tubes, and grass catchercover.

CAUTION:Do not leavegrass in bagger containers.

Emptycontainers after each useand before storing.

Failureto do so may result in spontaneouscombustion

which could develop into afire.

_ CAUTION:Beforeyou begin operating the unit be

certain you havereadall of the safety and operational

information of this instruction sheet, as well asthe

Operator's Manualfor thetractor and anyother

attachments.

NOTE. Neveroperateon slopes greaterthan 17.6% (10°).

11

Page 12

Operation

CollectorRemoval

For operationwithout bagger, the mower deflector MUST

be properly installedin the down position and retainedby

_ CAUTION:Operation WithoutBagger

the spring latch.

1. Lift up cover (A, Figure15), then removeand empty bags

(B).

2. Removehitch and frame assembly (C) from rearof

tractor.

.

Loosenmiddle tube strap from lower tube (D) and

remove middle/ uppertube assembly (E).

4.

Lift discharge deflector (F). Rotatelatch (G) upward on

front of lower chute.

5.

Pull lower chute away from mower.

Figure15

/

/

//

Storage

Storing The GrassCatcher

Cleanthe grass catcherthoroughly using a mild detergent

(other products may damagethe tube). Removeanydebris

from the screenon the undersideof the lid.

If paint has beenscratched on metal parts,touch up with

paint, or apply a thin film of oil to preventcorrosion.

Store in a dry area.Drythoroughly beforestoring for along

period of time. Alwaysstore awayfrom moisture.

12

Page 13

RepairParts

PTS - 1

Page 14

2-Bin Bagger Group - 52 inch 107.249130

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Assemble

6, 43, 57, 66

43

\

34

\

Support

Ref

15

49

53 26

Assemble

4, 36, 39, 44 /,

47, 52, 56, 61,63 /

7 36

44 10

47

\

Assemble

10, 14, 17,31,32,

45, 46, 55

32

14

\

52" Mower Housing

PTS - 2

Page 15

2-Bin Bagger Group - 52 inch 107.249130

REF NO PART NO. QTY.

1 004X24MA 3

2 004X71MA 1

3 7036433SM 1

4 054407ZMA 2

5 054416ZMA 1

6 054537MA 1

7 054563MA 1

8 1734190ASM 1

9 1931317SM 1

10 1672023ASM 2

11 1960685SM 1

12 7036404SM 1

13 1734229SM 1

14 1703764SM 2

15 2176012SM 2

16 1737764AYP 1

17 1703807ASM 2

18 1738033YP 1

20 1737844AYP 1

21 1960044SM 1

22 1922130SM 2

23 1734191ASM 3

24 7200008SM 1

25 310088MA 2

26 1734776YP 1

27 ..... 1

28 ..... 1

29 1737838AYP 1

31 1733491SM 2

32 1733709SM 2

34 1733885SM 1

36 1734223YP 1

37 1734299SM 1

39 1736026YP 1

43 1736656YP 1

44 1736886AYP 2

45 1917356SM 4

46 1917372SM 4

47 1918196SM 2

48 1927557SM 2

49 1723244SM 1

DESCRIPTION

SCREW, Truss-Head, 1/4-20 x 1/2"

SCREW, Truss-Head, 1/4-20 x 1"

MOUNT, Strap

PIN, Cover Hinge

HANDLE CONNECT, Tube

HNADLE, Plastic

PIN, Latch

BRACKET, Front Weight Mount

BOLT, Carriage, 1/4-20 x 3/4"

CLAMP, 1/2" Diameter Rod

NUT, Conical, 25-20

NUT,Weld, 10-24

PIN, Hinge

BAG, Grass 15.9 X 16.5

RETAINER, Spring

UPSTOP, Deflector

HANGER, Grass Bag

TRIM, 31-1/2"

HITCH, Bagger

WASHER, 5/16, 1-1/40D

CAPSCREW, Hex-Head, 3/8-16 x 2-1/4"

WEIGHT, Counter

ROD, Seat Hinge

BOLT, Shoulder, .250X.312.25

BOOT, Bagging, 46/52 Mower

MYLAR OVERLAY, ID Sticker

ID STICKER

BRACKET, Upright Mount

HOOP, Twin Catcher, 1/2" Diam.

EDGING, 12"

ELBOW, Upper Tube

SUPPORT, Upright

TUBE, Clear

CROSS SUPPORT, Twin

COVER ASSEMBLY, Twin Bagger

PIVOT, Hinge

LOCKWASHER, Spring, 5/16

NUT, Hex, 5/16 x 18

PIN, Quick

NUT, Hex-Flange, 5/16

SPACER

Footnotes

PTS - 3

Page 16

2-Bin Bagger Group - 52 inch 107.249130

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Assemble

6, 43, 57, 66

43

\

34

\

Support

Ref

15

49

53 26

Assemble

4, 36, 39, 44 /,

47, 52, 56, 61,63 /

7 36

44 10

47

\

Assemble

10, 14, 17,31,32,

45, 46, 55

32

14

\

52" Mower Housing

PTS - 4

Page 17

2-Bin Bagger Group - 52 inch 107.249130

REF NO PART NO. QTY.

50 1737765AYP 1

51 1708511SM 1

52 1928352SM 10

53 1928372SM 4

54 1930642SM 2

55 1931333SM 6

56 1931349SM 8

57 1933896SM 2

58 1921333SM 1

59 1960223SM 1

61 1960252SM 5

63 1960294SM 6

66 1960404SM 3

69 2171600SM 1

70 7026257MA 1

71 1960698SM 1

72 1738295YP 1

73 7091627YP 1

DESCRIPTION

LATCH

SPACER

NUT, Hex-Flange, Whiz, 3/8-16

NUT, Hex-Flange, 1/4-20

NUT, Hex-Flange, Top-Lock, 1/4-20

BOLT, Carriage, 5/16-18 x 3/4"

BOLT, Carriage, 3/8-16 x 7/8"

NUT, Hex-Lock, Nylon-Insert, 10-24, 1/4-20

BOLT, Carriage, 5/16-18 x 1, G5

BOLT, Carriage, 5/16-18 x 1-1/4, G5

BOLT, Carriage, 1/4-20 x 5/8"

NUT, Hex-Flange, Whiz, 1/4-20

SCREW, Truss-Head, Phillips, 10-24 x 3/4"

STRAP, HOOD, Black Rubber

WASHER, Wave

BOLT, Carriage, 1/4-20 X 1, G5

KNOB, 5-Point, 1/4-20

WASHER, Flat, 9/32 X 1

Footnotes

PTS - 5

Page 18

Hardwareidentification& TorqueSpecifications

Common Hardware Types

Hex Head Capscrew

Carriage Belt

€(((((((((((((((((((0

Standard Hardware Sizing

When a washer or nut is identified as 1/2", this is the

Nominal size, meaning the inside diameter is 1/2 inch; if a

second number is present it represent the threads per inch

When bolt or capscrew is identified as 1/2 - 16 x 2", this

means the Nominal size, or body diameter is 1/2 inch; the

second number represents the threads per inch (16 in this

example, and the final number is the body length of the

bolt or screw (in this example 2 inches long).

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

m_

Washer

Leckwasher

O Hex Nut

Nut, 1/2"

Inside

- ¢o

Diameter

m_

Screw, 1/2 x 2 I

m_

m_

m_.o

od,J I

Diameter I B°dy_____. |/

_ength _

__@

Torque Specification Chart

FORSTANDARD MACHINE HARDWARE (Tolerance _+20%)

_raarddeware G 0 Q

SAEGrade2 SAEGrade5 SAEGrade8

Size Of in/Ibs in/Ibs

Hardware ft/I bs ft/Ibs Nm.

8-32

8-36

10-24

10-32

1/4-20

1/4-28

5/16-18

5/16-24

3/8-16

3/8-24

7/16-14

7/16-20

1/2-13

1/2-20

9/16-12

9/16-18

5/8-11

5/8-18

3/4-10

3/4-16

7/8-9

7/8-14

1-8

1-12

1. These torque values are to be used for all hardware

excluding: Iocknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2. Recommended seating torque values for Iocknuts:

a. for prevailing torque Iocknuts - use 65% of grade 5

torques.

b. for flange whizlock nuts and screws - use 135% of

grade 5 torques.

3. Unless otherwise noted on assembly drawings, all torque

values must meet this specification.

Nm. ft/Ibs Nm.

19

20

27

31

66

76

11

12

20

23

30

35

50

55

65

75

102.0 120 163.2

90

122.4 150 204.0

100

136 180 244.8

160

217.6 260 353.6

180

244.8 300 408.0

140

190.4 400 544.0

155

210.8 440 598.4

220

299.2 580 788.8

240

326.4 640 870.4

in/Ibs

2.1 30 3.4

2.3 31 3.5

3.1 43 4.9

3.5 49 5.5

7.6 8 10.9

8.6 10 13.6

15.0 17 23.1

16.3 19 25.8

27.2 30 40.8

31.3 35 47.6

40.8 50 68.0

47.6 55 74.8

68.0 75 102.0

74.8 90 122.4

88.4 110 149.6

NOTES

41 4.6

43 4.9

60 6.8

68 7.7

12 16.3

14 19.0

25 34.0

27 34.0

45 61.2

50 68.0

70 95.2

80 108.8

110 149.6

120 163.2

150 204.0

170 231.2

220 299.2

240 326.4

386 525.0

420 571.2

600 816.0

660 897.6

900 1,244.0

1,000 1,360.0

Wrench & Fastener Size Guide

1/4" Bolt or Nut

Wrench--7/16"

5/16" Bolt or Nut

Wrench--I/2"

3/8" Bolt or Nut

Wrench--9/16"

PTS - 6

7/16" Bolt or Nut

Wrench (Bolt)--5/8"

Wrench (Nut)--11/16"

1/2" Bolt or Nut

Wrench--3/4"

Page 19

Briggs & Stratton Yard Power Products Group

Copyright © 2009 Briggs & Stratton Corporation

Milwaukee, Wl USA. All Rights Reserved

Loading...

Loading...