Craftsman 10716574 Owner’s Manual

Owner's Manual

AIR COMPRESSOR

1.2 Gallon Portable Air Compressor

Model No. 107.16574

®

CAUTION:

Before using this product,

read this manual and follow

all its Safety Rules and

Operating Instructions.

• Safety Instructions

• Assembly & Operation

• Maintenance

• Troubleshooting Guide

• Storage

• Parts List

• Espa_ol, p. 16

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.craftsman.com

6/13/2013

Part No. 9039584

1_.'I:]|: [o]_ [a_o]_/ i:_ _/ _'_

WARRANTY ............................................................................ 2

SPECIFICATIONS ................................................................... 2

SAFETY SYMBOLS ................................................................ 3

GENERAL SAFETY INSTRUCTIONS .................................. 3-4

SPECIFIC SAFETY INSTRUCTIONS .................................. 4-5

ELECTRICAL SAFETY ............................................................ 6

Extension Cords ............................................................... 6

Electrical Connection ....................................................... 6

Speed and Wiring ............................................................. 6

Grounding Instructions ..................................................... 6

GLOSSARY ............................................................................. 7

ASSEMBLY ............................................................................. 7

Packing list ....................................................................... 7

Unpacking ........................................................................ 7

OPERATION ............................................................................ 8

Know your Air Compressor .............................................. 8

Breaking in the pump ........................................................ 9

Applications ..................................................................... 10

How to use your Air Compressor ................................... 10

Using the inflation hose with Thumb-lock connector ...... 10

Draining the Tank ............................................................ 11

Checking the Safety Valve .............................................. 11

iv,v/.*1_ ;_:I _/ Ik'd

MAINTENANCE .................................................................... 12

General Maintenance ..................................................... 12

Lubrication ...................................................................... 12

STORAGE ............................................................................. 13

TROUBLESHOOTING .......................................................... 14

PARTS LIST .......................................................................... 15

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE "(EAR from the date of purchase, this product is warranted against any defects in material or workmanship.

A defective product will be replaced free of charge.

For warranty coverage details to obtain free replacement, visit the web page: www.craftsman.com/warranty

This ONE "(EAR warranty isvoid if this product is ever used while providing commercial services or if rented to another

person. For 90 DAY commercial or rental use terms, see the Craftsman warranty web page.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

[,,,,___o]_,,,",]

Running Horsepower ......................................................... 3/4 HP

Air Tank Capacity ........................................................ 1.2 gallons

Air Pressure ............................................................ 135 PSI max.

Air Delivery .................................................. 1.8 SCFM @ 90 PSI

...................................................................... 2.6 SCFM @ 40 PSI

Duty Cycle ..................... 50% - 5 minutes ON and 5 minutes OFF

Lubrication ....................................................................... Oil-Free

Gauges ................................................................ 1.5 in. diameter

Input .......................................... 120 V, 60 Hz, AC only, 9.5 Amps

Net Weight (compressor only) ........................................ 19.9 lbs.

A •

The information listed below should be read and understood by the operator. This information is given to protect the user while

operating and storing the air compressor. We utilize the symbols below to allow the reader to recognize important information about

their safety.

Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

Read and understand all instructions. Failure to follow all

instructions listed below may result in electric shock, fire, and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit, Cluttered benches

and dark areas invite accidents. The floor must not be slippery

from wax or dust.

• Do not operate power tools in explosive atmo-spheres,

such as in the presence of flammable liquids, gases, or

dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while

operating tools. Distractions can cause you to lose control.

• Operate the air compressor in an open area at least 18 in.

away from any wall or object that could restrict the flow of

fresh air to ventilation openings.

ELECTRICAL SAFETY

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges, and refrigerators. There is an increased risk

of electric shock if your body is grounded.

• Don't expose power tools to rain or wet conditions. Water

entering a power tool wilt increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the

tool or pull the plug from an outlet. Keep the cord away

from heat, oil, sharp edges, or moving parts. Replace

damaged cords immediately. Damaged cords increase the

risk of electric shock.

• When operating a power tool outside, use an outdoor

extension cord marked "W-A" or "W". These cords are

rated for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

• Eye protection which conforms to ANSI specifications

and provides protection against flying particles both

from the FRONT and SIDE should ALWAYS be worn by

the operator and others in the work area when loading,

operating, or servicing this tool. Eye protection is required

to guard against flying fasteners and debris, which could

cause severe eye injury.

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

_o]_l

(Without Safety Alert Symbol) Indicates a situation that may

result in property damage.

The brass components of this product contain lead, a chemical

known to the state of California to cause birth defects (or other

reproductive harm).

(California health & safety code § 25249.5, et seq.)

• The employer and/or user must ensure that proper eye

protection is worn. We recommend a Wide Vision Safety

Mask for use over eyeglasses or standard safety glasses

that provide protection against flying particles both from the

front and side. Always use eye protection which is marked to

comply with ANSI Z87.1.

• Additional safety protection will be required in some

environments. For example, the working area may include

exposure to a noise level which can lead to hearing damage.

The employer and user must ensure that any necessary

hearing protection is provided and used by the operator and

others in the work area. Some environments wilt require

the use of head protection equipment. When required, the

employer and user must ensure that head protection marked

to comply with ANSI Z89.1 is used.

• Stay alert, watch what you are doing, and use common

sense when operating a power tool. Do not use tools

while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power

tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of

the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. A dust

mask, nonskid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

• Do not use on a ladder or unstable support. Stable

footing on a solid surface enables better control of the tool in

unexpected situations.

TOOL USE AND CARE

• Do not exceed the pressure rating of any component in

the system.

• Protect material lines and air lines from damage or

puncture. Keep the hose and power cord away from sharp

objects, chemical spills, oil, solvents, and wet floors.

• Check hoses for weak or worn condition before each use,

making certain all connections are secure. Do not use if

a defect is found. Purchase a new hose or take to a qualified

service center for examination and repair.

• Release the pressure within the system slowly. Dust and

debris may be harmful.

• Store idle tools out of the reach of children and other

untrained persons. Tools are dangerous inthe hands of

untrained users.

• Maintain tools with care. Follow maintenance instructions.

Properly maintained tools are easier to control.

• Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may

affect the tool's operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly

maintained tools.

• Never point any tool toward yourself or others.

• Keep the exterior of the air compressor dry, clean, and

free from oil and grease. Always use a clean cloth when

[,,,__o,] _"9'_I=l=luuk'dII_F,,,_o_

cleaning. Never use brake fluids, gasoline, petroleum-based

products, or any strong solvents to clean the unit. Following

this rule will reduce the risk of deterioration of the enclosure

plastic.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel may result in a risk of injury.

• Disconnect the power supply, open the drain valve to

decompress the tank and allow water to drain, and allow

the air compressor to become cool to the touch before

servicing. Turn the pressure regulator knob fully counter

clockwise after shutting off the compressor.

• When servicing a tool, use only identical replacement

parts. See Parts List in this manual. Follow the

instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow the Maintenance

instructions may create a risk of injury.

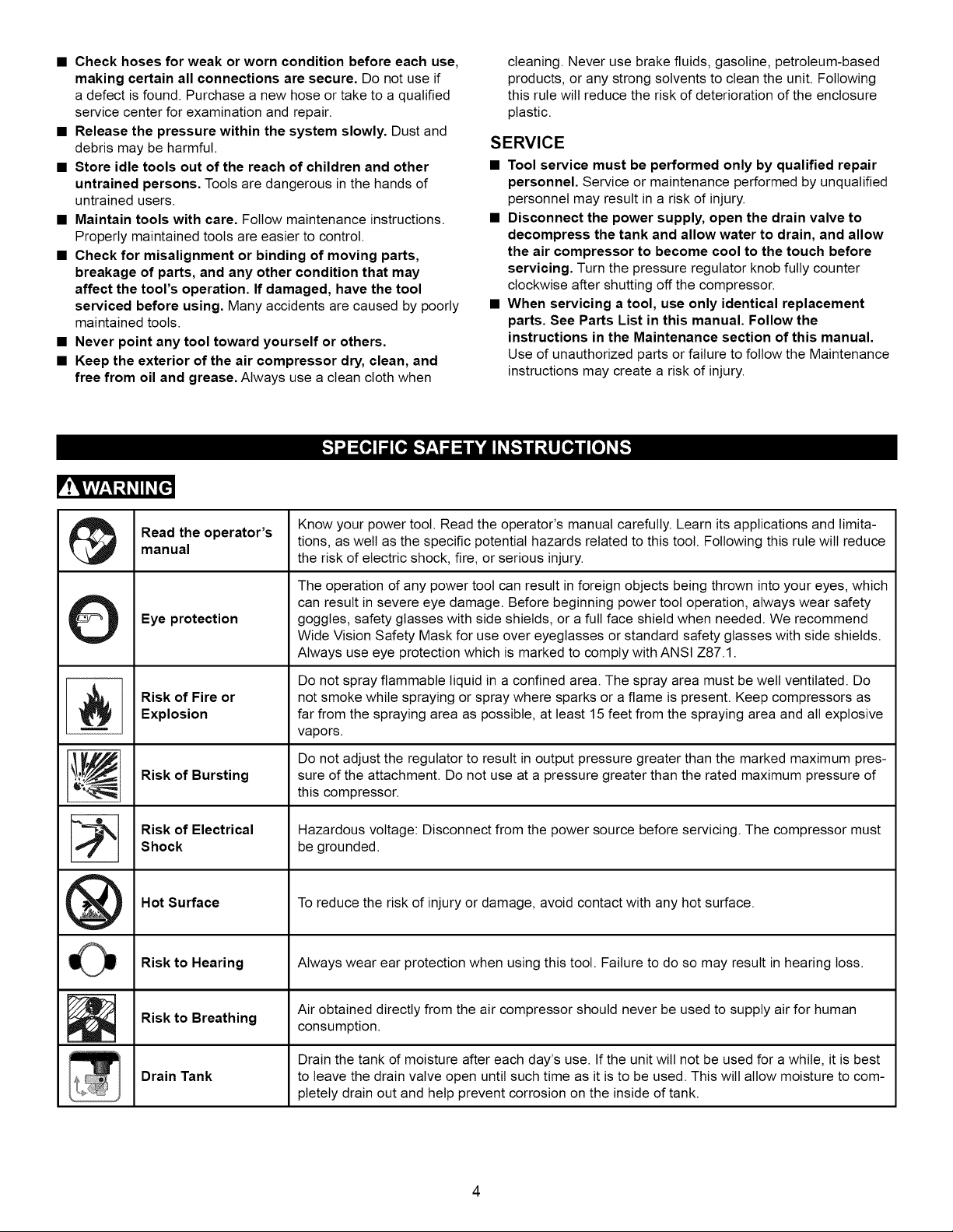

w

A

2._'I!' !1

_y

v

II J

Read the operator's

manual

Eye protection

Risk of Fire or

Explosion

Risk of Bursting

Risk of Electrical

Shock

Hot Surface

Risk to Hearing

Know your power tool. Read the operator's manual carefully. Learn its applications and limita-

tions, as well as the specific potential hazards related to this tool. Following this rule will reduce

the risk of electric shock, fire, or serious injury.

The operation of any power tool can result in foreign objects being thrown into your eyes, which

can result in severe eye damage. Before beginning power toot operation, always wear safety

goggles, safety glasses with side shields, or a full face shield when needed. We recommend

Wide Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields.

Always use eye protection which is marked to comply with ANSI Z87.1.

Do not spray flammable liquid in a confined area. The spray area must be well ventilated. Do

not smoke while spraying or spray where sparks or a flame is present. Keep compressors as

far from the spraying area as possible, at least 15 feet from the spraying area and all explosive

vapors.

Do not adjust the regulator to result in output pressure greater than the marked maximum pres-

sure of the attachment. Do not use at a pressure greater than the rated maximum pressure of

this compressor.

Hazardous voltage: Disconnect from the power source before servicing. The compressor must

be grounded.

To reduce the risk of injury or damage, avoid contact with any hot surface.

Always wear ear protection when using this tool. Failure to do so may result in hearing loss.

Risk to Breathing

Drain Tank

Air obtained directly from the air compressor should never be used to supply air for human

consumption.

Drain the tank of moisture after each day's use. If the unit will not be used for a while, it is best

to leave the drain valve open until such time as it is to be used. This will allow moisture to com-

pletely drain out and help prevent corrosion on the inside of tank.

r.Mr. uhhKo

• If connected to a circuit protected by fuses, use time-delay

fuses with this product.

• To reduce the risk of electric shock, do not expose to rain.

Store indoors.

• Inspect the tank yearly for rust, pin holes, or other

imperfections that could cause it to become unsafe. Never

weld or drill holes in the air tank.

• Make sure the hose is free of obstructions or snags.

Entangled or snarled hoses can cause loss of balance or

footing and may become damaged.

• Use the air compressor only for its intended use. Do

not alter or modify the unit from the original design or

function.

• Always be aware that misuse and improper handling of

this tool can cause injury to yourself and others.

• Never leave a tool unattended with the air hose attached.

• Do not operate this tool if it does not contain a legible

warning label.

• Do not continue to use a tool or hose that leaks air or

does not function properly.

• Always disconnect the air supply and power supply before

making adjustments, servicing a tool, or when a tool is not in

use.

• Do not attempt to pull or carry the air compressor by the

hose.

• Your tool may require more air consumption than this air

compressor is capable of providing.

• Always follow all safety rules recommended by the

manufacturer of your tool, in addition to all safety rules

for the air compressor. Following these rules will reduce the

risk of serious personal injury.

• Never direct a jet of compressed air toward people or

animals. Take care not to blow dust and dirt towards

yourself or others. Following this rule will reduce the risk of

serious injury.

• Protect your lungs. Wear a face or dust mask if the operation

is dusty. Following this rule will reduce the risk of serious

personal injury.

• Do not use this air compressor to spray chemicals. Your

lungs can be damaged by inhaling toxic fumes. A respirator

may be necessary in dusty environments or when spraying

paint. Do not carry while painting.

• Inspect tool cords and hoses periodically and, if

damaged, have repaired at a qualified service center.

Constantly stay aware of cord location. Following this rule

will reduce the risk of electric shock or fire.

• Never use an electrical adaptor with this grounded plug.

• Check damaged parts. Before further use of the air

compressor or air tool, a guard or other part that is

damaged should be carefully checked to determine

that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or

other part that is damaged should be properly repaired or

replaced by a qualified service center. Following this rule

will reduce the risk of shock, fire or serious injury.

• Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. A wire

gauge size (A.W.G.) of at least 14 is recommended for an

extension cord 50 feet or less in length. A cord exceeding

100 feet is not recommended. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier

the cord. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

• Save these instructions. Refer to them frequently and use

them to instructothers who may use this air compressor. If

you loan someone this tool, load them these instructionsalso.

A •

EXTENSION CORDS

NOTE: Avoid use of extension cords.

1. For optimum performance, plug the compressor power cord

directly into a grounded wall socket. Do not use an extension

cord unless absolutely necessary. Instead, use a longer air

hose to reach the area where the air is needed.

2. If use of an extension cord cannot be avoided, the cord should

be no longer than 50 feet and be a minimum wire size of 12

gauge (AWG). Do not use a 16 or 14 gauge extension cord.

3. Use only a 3-wire extension cord that has a 3-blade grounding

plug, and a 3-slot receptacle that wilt accept the plug on the

product. Make sure your extension cord is in good condition.

An undersized cord wilt cause a drop in line voltage, resulting

in loss of power and overheating. The smaller the gauge

number, the heavier the cord.

4. When working with the air compressor outdoors, use an

extension cord that is designed for outside use. This is

indicated by the letters "WA" on the cord's jacket.

5. Before using an extension cord, inspect it for loose or exposed

wires and cut or worn insulation.

Keep the extension cord clear of the working

area. Position the cord so that it wilt not get caught on lumber,

tools, or other obstructions while you are working with a power

tool. Failure to do so can result in serious personal injury.

into a matching outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

2. Do not modify the plug provided. If it wilt not fit the outlet, have

the proper outlet installed by a qualified electrician.

3. The conductor with insulation having an outer surface that

is green with or without yellow stripes is the equipment-

grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-

grounding conductor to a live terminal.

4. Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

5. Replace a damaged or worn cord immediately.

Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

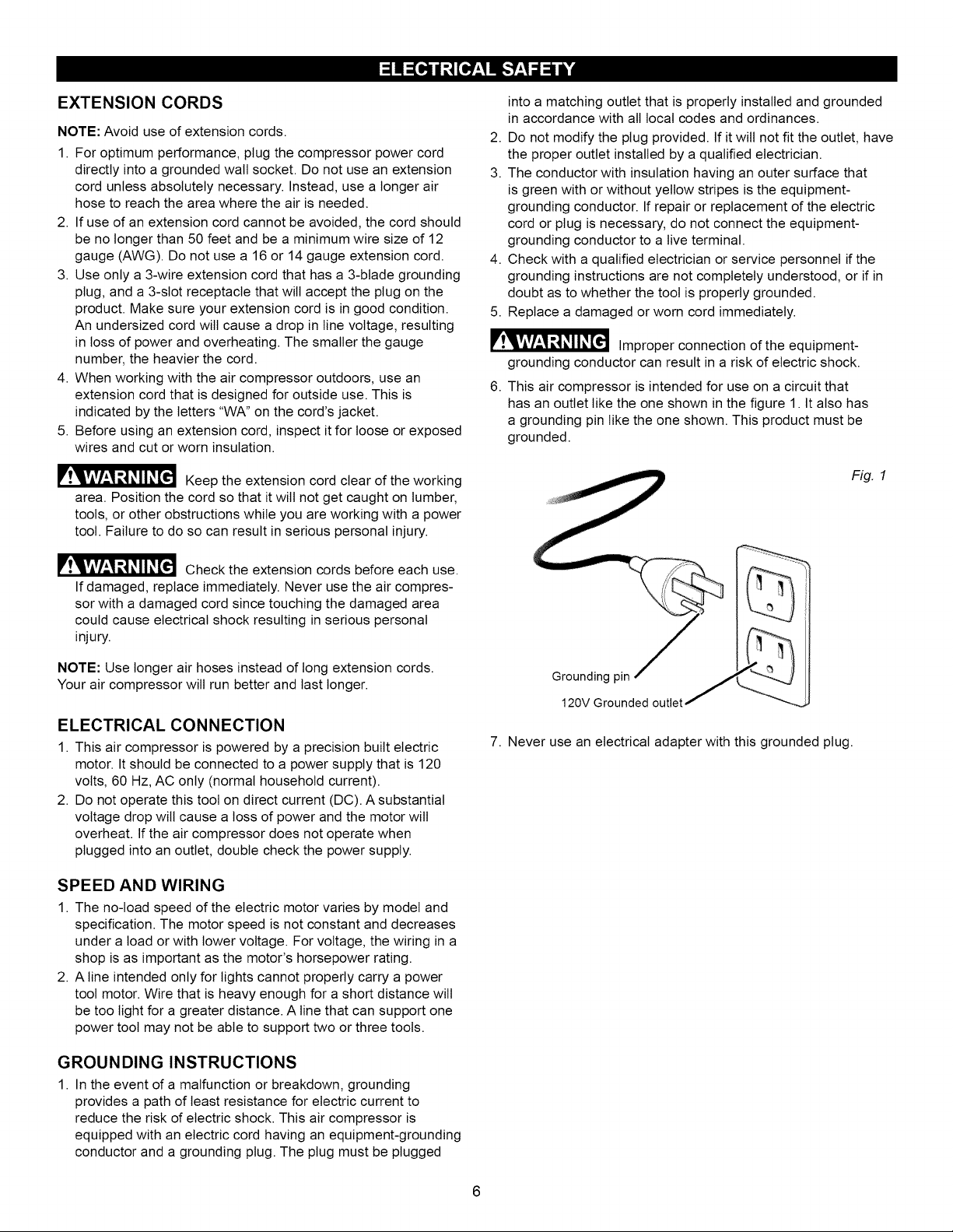

6. This air compressor is intended for use on a circuit that

has an outlet like the one shown in the figure 1. It also has

a grounding pin like the one shown. This product must be

grounded.

Fig. 1

Check the extension cords before each use.

If damaged, replace immediately. Never use the air compres-

sor with a damaged cord since touching the damaged area

could cause electrical shock resulting in serious personal

injury.

NOTE: Use longer air hoses instead of long extension cords.

Your air compressor will run better and last longer.

ELECTRICAL CONNECTION

1. This air compressor is powered by a precision built electric

motor. It should be connected to a power supply that is 120

volts, 60 Hz, AC only (normal household current).

2. Do not operate this tool on direct current (DC). A substantial

voltage drop wilt cause a loss of power and the motor will

overheat. If the air compressor does not operate when

plugged into an outlet, double check the power supply.

SPEED AND WIRING

1. The no-load speed of the electric motor varies by model and

specification. The motor speed is not constant and decreases

under a load or with lower voltage. For voltage, the wiring in a

shop is as important as the motor's horsepower rating.

2. A line intended only for lights cannot properly carry a power

tool motor. Wire that is heavy enough for a short distance wilt

be too light for a greater distance. A line that can support one

power tool may not be able to support two or three tools.

Grounding pin

120V Grounded outlet

7. Never use an electrical adapter with this grounded plug.

GROUNDING INSTRUCTIONS

1. In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This air compressor is

equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

AirFilter

Porouselementcontainedwithinametalorplastichousing

attachedtothecompressorcylinderheadwhichremoves

impurityfromtheintakeairofthecompressor.

AirTank

Cylindricalcomponentwhichcontainsthecompressedair.

CheckValve

Devicethatpreventscompressedairfromflowingbackfromthe

airtanktothecompressorpump.

Cut-InPressure

The tow pressure at which the motor will automatically restart.

This compressor cut-in pressure is 105 + 5 PSI.

Cut-Off Pressure

The high pressure at which the motor will automatically shut off.

This compressor cut-off pressure is 135 + 5 PSI.

Electric Motor

Device which provides the rotational force necessary to operate

the compressor pump.

On/Off Power Switch

Control which turns the air compressor on or off. The pressure

switch wilt not automatically start and control the compressor

unless the manual on/off switch is in the ON ( 1) position.

NPT (National Pipe Thread)

National Pipe Thread is a U.S. standard for tapered (NPT) or

straight (NPS) threads used to join pipes and fittings.

A thread sealing tape must be used to provide a leak-free seal on

pipe threaded connections.

Pressure Switch

Automatically controls the on/off cycling of the compressor. It

stops the compressor when the cut-off pressure in the tank is

reached and starts the compressor when the air pressure drops

below the cut-in pressure.

PSI (Pounds Per Square Inch)

Measurement of the pressure exerted by the force of the air. The

actual psi is measured by a pressure gauge on the compressor.

Pump

Produces the compressed air with a reciprocating piston

contained within the cylinder.

Regulator Pressure Gauge (Outlet pressure)

Displays the current line pressure. Line pressure is adjusted by

rotating the pressure regulator knob.

Safety Valve

Prevents air pressure in the air tank from rising over a

predetermined limit.

SCFM (Standard Cubic Feet Per Minute)

A unit of measure of air delivery.

L/min (Liter Per Minute)

A unit of measure of air delivery.

Tank Pressure Gauge

Indicates the pressure in the air tank.

Thermal Overload Switch

Automatically shuts off the compressor if the temperature of the

electric motor exceeds a predetermined limit.

Pressure Regulator Knob

Regulates the outgoing pressure from the air outlet to the tool. It

is possible to increase or decrease the pressure at the outlet by

adjusting this control knob.

I'-'I,,!-1=1_,_I:t _'d

PACKING LIST

• Air compressor

• Coil hose

• 1/4 in. quick coupler (2 pcs.)

• Blow gun

• Thread sealing tape

• Long inflation chuck

• Tire gauge

• Owner's manual

Duty Cycle

Duty Cycle refers to a percentage of time which the air

compressor can run continuously while performing a task before

needing to rest or cool down. Example: A 50% duty Cycle

compressor must rest for 5 minutes after running continuously for

5 minutes.

UNPACKING

This product has been shipped completely assembled.

• Carefully remove the compressor from the box. Make sure

that all items listed in the packing list are included.

• Inspect the compressor carefully to make sure no breakage

or damage occurred during shipping.

• Do not discard the packing material until you have carefully

inspected and satisfactorily operated the tool.

If any parts are missing do not operate the

compressor or air tools until the missing parts are replaced.

Failure to do so could result in possible serious personal

injury.

Do not attempt to modify this tool or create

accessories not recommended for use with this toot. Any

such alteration or modification is misuse and could result in

a hazardous condition leading to possible serious personal

injury.

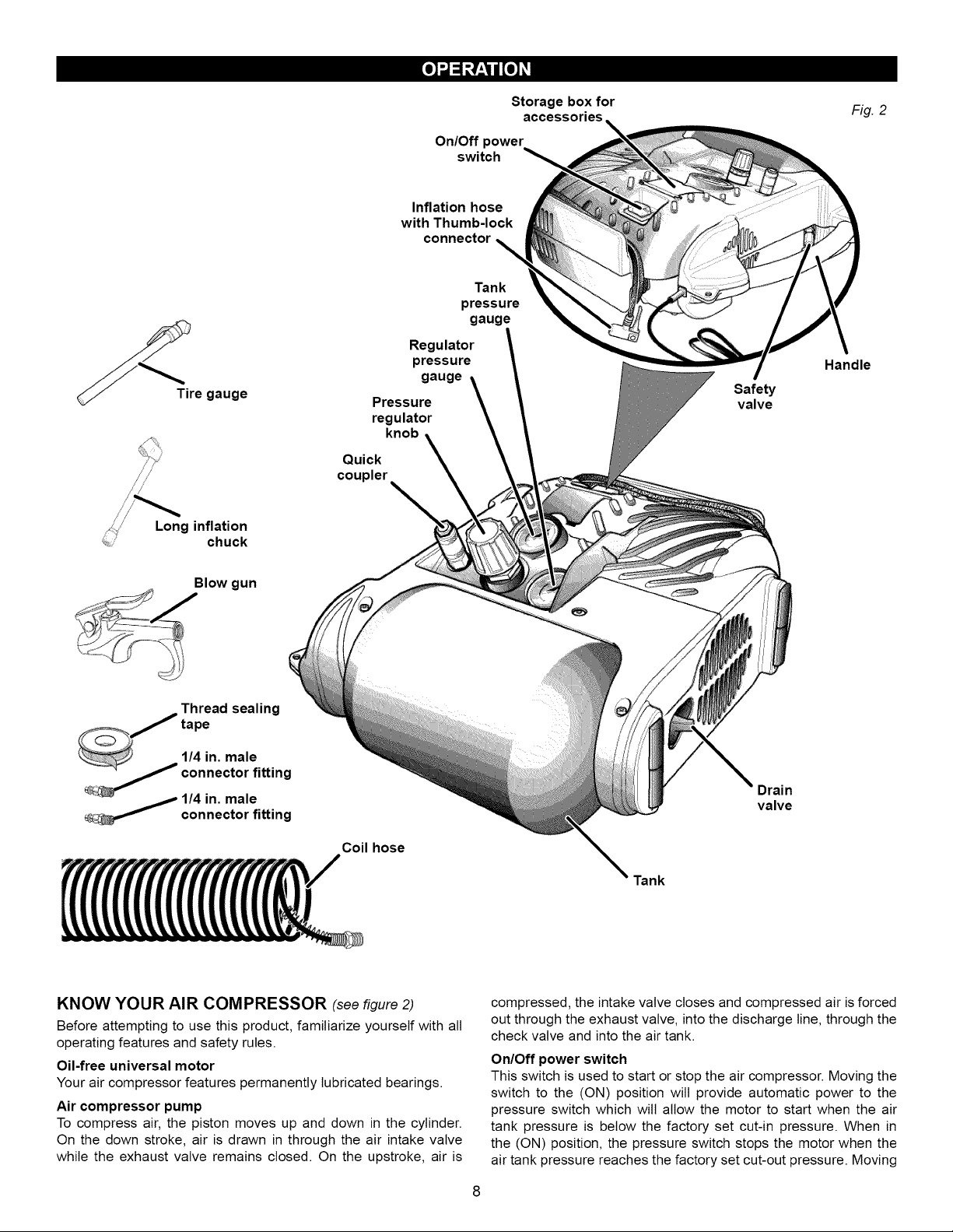

Tire gauge

Quick

coupler

On/Off power

Inflation hose

with Thumb-lock

connector

Regulator

pressure

gauge

Pressure

regulator

knob

switch

Tank

pressure

gauge

Storage box for

accessories Fig. 2

Handle

Safety

valve

_,_, chuck

Long inflation

Blow gun

Drain

valve

Coil hose

Tank

KNOW YOUR AIR COMPRESSOR (seefigure 2)

Before attempting to use this product, familiarize yourself with all

operating features and safety rules.

Oil-free universal motor

Your air compressor features permanently lubricated bearings.

Air compressor pump

To compress air, the piston moves up and down in the cylinder.

On the down stroke, air is drawn in through the air intake valve

while the exhaust valve remains closed. On the upstroke, air is

compressed, the intake valve closes and compressed air is forced

out through the exhaust valve, into the discharge line, through the

check valve and into the air tank.

On/Off power switch

This switch is used to start or stop the air compressor. Moving the

switch to the (ON) position wilt provide automatic power to the

pressure switch which wilt allow the motor to start when the air

tank pressure is below the factory set cut-in pressure. When in

the (ON) position, the pressure switch stops the motor when the

air tank pressure reaches the factory set cut-out pressure. Moving

theswitchtothe(OFF)positionwillremovepowerfromthemotor

andstoptheaircompressor.

Pressure regulator knob

Use the pressure regulator knob to adjust the amount of air being

delivered through the hose.

The air pressure coming from the air tank is controlled by the

regulator knob. Turn the pressure regulation knob clockwise to

increase discharge pressure, and counterclockwise to decrease

discharge pressure. Follow tool operating instructions for

recommended pressure range.

Regulator pressure gauge

The current line pressure is displayed on the regulator pressure

gauge. This pressure can be adjusted by rotating the pressure

regulator knob.

Safety valve

This valve is designed to prevent system failures by relieving

pressure from the system when the compressed air reaches a

predetermined level. The valve is preset by the manufacturer and

must not be modified in any way. To verify the valve is working

properly, pull on the ring. Air pressure should escape. When the

ring is released, it will reset.

Tank pressure gauge

The tank pressure gauge indicates the pressure of the air in the

tank.

Drain valve

The drain valve is used to remove moisture from the air tank after

the air compressor is shut off.

Motor thermal overload protector

This air compressor is equipped with a thermal overload device

which wilt turn the air compressor off automatically, if the air

compressor becomes overheated. If the motor turns OFF

repeatedly, check for the following possible causes first: Low

Voltage from the outlet. Lack of proper ventilation or outside air

or room temperature too high. Extension cord too long or wrong

gauge wire used.

To reset the air compressor:

• Turn the air compressor off.

• Unplug the air compressor, and allow it to cool for 30 minutes.

• Plug the air compressor into an approved outlet.

• Turn the air compressor on.

Air filter intake

This filter is designed to clean air coming into the pump and

requires no maintenance when operated in accordance with the

warnings and operating instruction outlined in this manual. To

ensure the pump continually receives clean, cool, dry air do not

operate this compressor in dust filled atmosphere. Ventilation

openings must be kept free from obstructions.

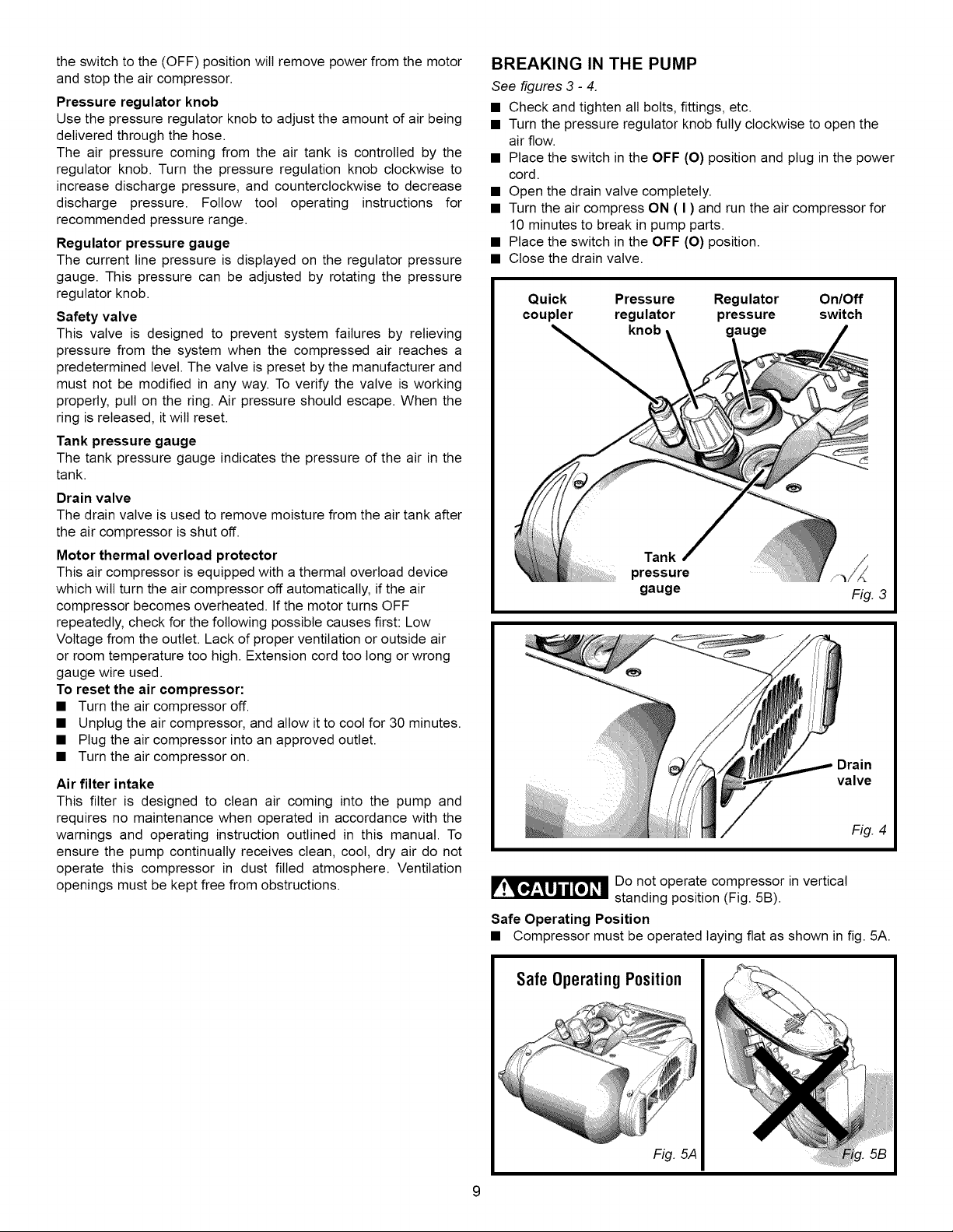

BREAKING IN THE PUMP

See figures 3 - 4.

• Check and tighten all bolts, fittings, etc.

• Turn the pressure regulator knob fully clockwise to open the

air flow.

• Place the switch in the OFF (O) position and plug in the power

cord.

• Open the drain valve completely.

• Turn the air compress ON ( I ) and run the air compressor for

10 minutes to break in pump parts.

• Place the switch in the OFF (O) position.

• Close the drain valve.

Quick Pressure Regulator On/Off

coupler regulator pressure switch

knob gauge

Tank

pressure

gauge

Do not operate compressor in vertical

standing position (Fig. 5B).

Safe Operating Position

• Compressor must be operated laying flat as shown in fig. 5A.

Fig. 3

Drain

valve

Fig. 4

SafeOperating Position

Fig. 5A

Loading...

Loading...