Page 1

Operator’s Manual

®

4-Cycle

PROPANE POWERED TRIMMER

Models: 104.79212

104.79211

16.4 oz. / 465 g propane bottle

not included

For assistance with assembly

or operation call:

1-800-235-5878

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Homan Estates, IL 60179, U.S.A.

Visit our web site: www.sears.com/craftsman

769-03546

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• TROUBLESHOOTING

• WARRANTY

Page 2

SERVICE AND SAFETY

CRAFTSMAN

4-CYCLE PROPANE TRIMMER

TABLE OF CONTENTS

Service and Safety ..................................................................... 2

Safe Operation Rules ................................................................. 3

Understanding your trimmer ................................................... 4

Assembly ....................................................................................... 5

Oil Information .............................................................................. 6

Understanding Propane ........................................................... 7

Installing the Propane Canister .............................................. 8

Installing Attachments ............................................................... 9

Starting / Stopping ..................................................................... 10

Operation ....................................................................................... 11

Maintenance ................................................................................ 12

Cleaning and Storage ............................................................... 17

Troubleshooting ........................................................................... 17

Specications .............................................................................. 18

Warranty ......................................................................................... 19

SPARK ARRESTOR NOTE

NOTE:

For users on U.S. Forest Land and in the states of

California, Maine, Oregon, and Washington. All U.S.

Forest Land and the state of California (Public Resources

Codes 4442 and 4443), Oregon, and Washington require

by law that certain internal combustion engines operated

on forest brush and / or grass-covered areas be equipped

with a spark arrestor, maintained in eective working

order, or the engine be constructed, equipped and

maintained for the prevention of re. Check with with

your state or local authorities for regulations pertaining

to these requirements. Failure to follow these requirements could subject you to liability or a ne. This unit is

is factory equipped with a spark arrestor.

WARNING:

When using this unit, you must follow these

safety rules. Please read these to ensure

the safety of the operator and any bystanders.

Please keep these instructions for later use.

IMPORTANT SAFETY INSRUCTIONS

READ ALL INSTRUCTIONS BEFORE OPERATING

• Inspect the unit before use. Replace damaged parts.

• Check for fuel leaks. Make sure all fasteners are in place

and secure. Replace parts that are cracked, chipped,

or damaged in any way. Do not operate the unit with

loose or damaged parts.

• Carefully inspect the area before starting the unit.

Remove all debris and hard or sharp objects such as

glass, wire, etc.

• Be aware of the risk of injury to the head, hands and

feet.

• Clear the area of children, bystanders, and pets. At

a minimum, keep all children, bystanders, and pets

outside a 50 feet (15 m.) radius; there still may be a risk

to bystanders from thrown objects. Bystanders should

be encouraged to wear eye protection. If you are

approached, stop the unit immediately.

• Use only Craftsman red medium thickness (85908)

or black wide thickness (85909) replacement lines.

Never use metal reinforced line, wire or rope.

These can break o and become dangerous projectiles.

• Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments

or repairs before using unit.

All information, illustrations, and specications in this

manual are based on the latest production information

available at the time of printing. We reserve the right to

make changes at any time without notice.

WARNING:

When servicing, use only identical

replacement parts. Use of any other

parts may create a hazard or product

damage.

• Do not operate this unit when tired, ill, under the

inuence of alcohol, drugs or medications.

• This unit is intended for adult use only. Do not allow

children or untrained individuals to use the unit.

• Familiarize yourself with the controls and proper use of

your trimmer prior to using.

2

Page 3

SAFE OPERATION RULES

• Never start or run the unit inside a closed room or build -

ing. Breathing exhaust fumes can be fatal. Operate this

unit only in a well ventilated outdoor area.

• Wear safety glasses or goggles that meet ANSI Z87.1

standards and are marked as such. Wear ear/hearing

protection when operating this unit. Wear a face or dust

mask if the operation is dusty.

• Wear heavy long pants, boots, gloves and a long sleeve

shirt. Do not wear loose clothing, jewelry, short pants,

sandals or go barefoot. Secure hair above shoulder

level.

• The cutting attachment shield must always be in place

while operating the unit as a trimmer. Do not operate

unit without proper line installed.

• This unit has a clutch. The cutting attachment remains

stationary when the engine is idling. If it does not, have

the unit adjusted by a Sears or other qualified service

dealer.

• Adjust the handle to your size in order to provide the

best grip.

• Be sure the cutting attachment is not in contact with

anything before starting the unit.

• Do not operate the engine faster than the speed needed

to cut, trim or edge. Do not run the engine at high speed

when not cutting.

• Always stop the engine when cutting is delayed or when

walking from one cutting location to another.

• If you strike or become entangled with a foreign object,

stop the engine immediately and check for damage. Do

not operate before repairing damage. Do not operate

the unit with loose or damaged parts. Stop the unit,

switch the engine to o, and disconnect the spark plug

for maintenance or repair.

• Use only identical replacement parts and accesories

designed for this line trimmer.

Use of any other

parts or accessories could lead to serious injury

to the user, or damage to the unit, and void your

warranty

• Keep unit clean of vegetation and other materials. They

may become lodged between the cutting attachment

and shield.

• To reduce fire hazard, replace a faulty muffler and spark

arrestor. Keep the engine and muffler free from grass,

leaves, excessive grease or carbon buildup.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position

whenever pulling the starter rope. The operator and

unit must be in a stable position while starting. Refer to

Starting/Stopping Instructions (p.10).

• Only use this tool for its intended purpose.

• Do not overreach. Always keep proper footing and balance.

• Always hold the unit with both hands when operating.

Keep a firm grip on both handles or grips.

• Keep hands, face, and feet at a distance from all moving

parts. Do not touch or try to stop the cutting attachment

when it rotates.

• Do not touch the engine, gear housing or muffler. These

parts get extremely hot from operation, even after the

unit is turned o.

WARNING:

The engine exhaust from this product

contains chemicals known to the state of

California to cause cancer, birth defects

or other reproductive harm.

OTHER SAFETY WARNINGS

• Never store a unit with propane canister attached inside

a building where vapor may reach an open flame or

spark.

• Allow the engine to cool before storing or transporting.

Be sure to secure the unit while transporting.

• Store the unit in a dry area, locked up or up high to

prevent unauthorized use or damage, out of the reach

of children.

• Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use, see Cleaning and Storage instruc-

tions. (p.19)

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

SAVE THESE INSTRUCTIONS

3

Page 4

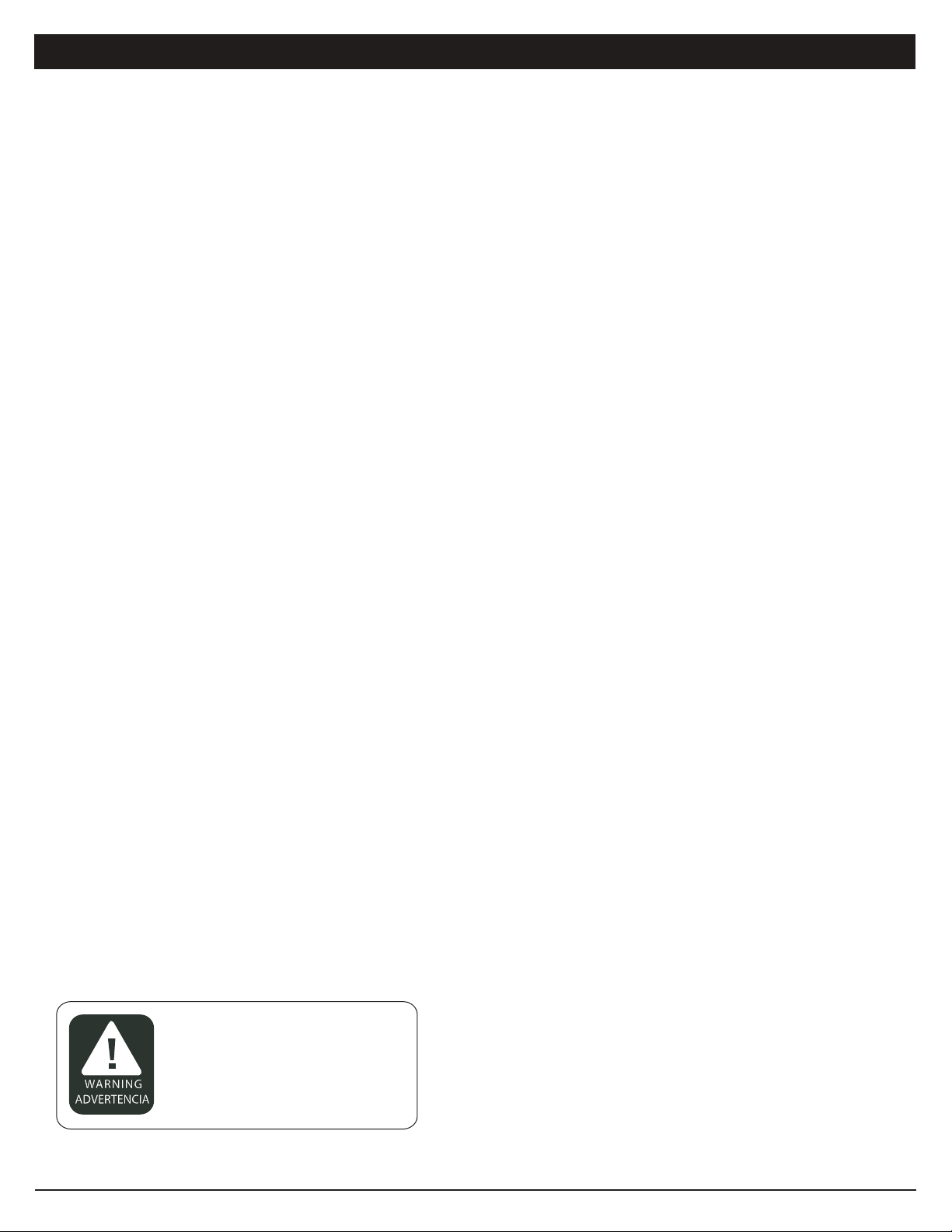

UNDERSTANDING YOUR TRIMMER

SAFETY & INTERNATIONAL SYMBOLS

This operator’s manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator’s manual for complete safety, assembly, operating and maintenance and repair information.

WARNING: Indicates danger, warning or caution.

May be used in conjunction with other symbols or

pictographs.

WARNING: READ OPERATOR’S MANUAL:

Read the operator’s manual(s) and follow all warnings

and safety instructions. Failure to do so can result in

serious injury to the operator and/or bystanders.

WEAR EYE AND HEARING PROTECTION WARNING:

Thrown objects and loud noise can cause severe eye

injury and hearing loss. Wear eye protection meeting

ANSI Z87.1 standards and ear protection when

operating this unit. Use a full face shield when needed.

OIL : Refer to operator’s manual for the proper type of oil.

ON / OFF STOP CONTROL ON / START / RUN

ON / OFF STOP CONTROL OFF or STOP

KEEP BYSTANDERS AWAY WARNING:

Keep all bystanders, especially children and pets, at

least 50 feet (15 m) from the operating area.

HOT SURFACE WARNING:

Do not touch a hot mufer, gear housing or cylinder. You

may get burned. These parts get extremely hot from operation. They remain hot for a short time after the unit turned o.

THROWN OBJECTS AND ROTATING CUTTER CAN

CAUSE SEVERE INJURY WARNING:

Do not operate without the cutting attachment shield in

place. Keep away from the rotating cutting attachment.

Hassle Free™

Cutting Head

Attachment

Shaft

Upper Handle

Attachment

Coupler

Fast Idle

Lock

On / Off

Control

Anti-Kickback

Bar

SHARP BLADE WARNING:

Sharp blade on cutting attachment shield. To prevent

serious injury, do not touch the line cutting blade.

Starter Rope

Grip

Air Filter

Cover

Throttle

Control

Safety

Trigger

Muffler Guard

Spark Plug

Cover

Shaft Grip

Propane Canister

This illustration may differ from your unit.

For example, the picture shows a straight

shaft; your unit may have a curved shaft.

4

Page 5

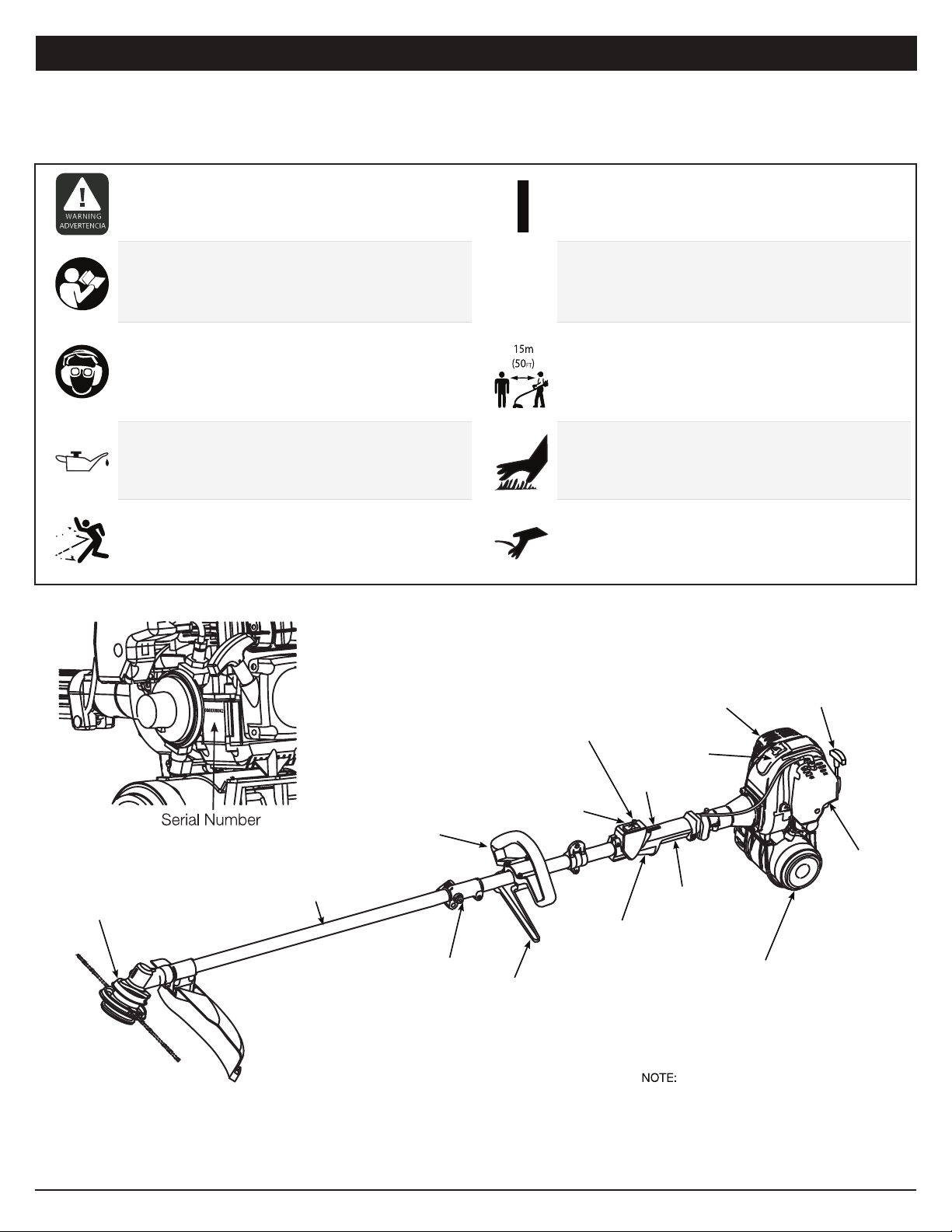

ASSEMBLY

WARNING:

To prevent serious injury, never operate the

trimmer without the cutting attachment

in place.

TOOL KIT

Your unit is provided with a tool kit (Fig.1). This tool kit

consists of the following:

4 mm Allen Wrench

5 mm Allen Wrench

8 & 10 mm Wrench

Four 5 mm Screws

with captive washers

Four Washers

Phillips Screw Driver/

Socket Wrench

Straight Shaft models

include 2 Plate Washers

Fig. 1

INSTALLING CUTTING ATTACHMENT SHIELD

Use the following instructions if the cutting attachment

shield on your unit is not installed. Use only the

instructions that apply to the type of shaft and shield

that your unit is equipped with.

FOR CURVED SHAFT TRIMMERS

Place the cutting attachment shield and spacer against

tube as shown in (Fig.2). Use the 2 screws provided

to clamp the cap and shield onto the tube. Tighten the

screws evenly. Make sure the shield does not touch

any rotating parts.

Cutting Attachment Shield

Spacer

FOR STRAIGHT SHAFT TRIMMERS

Place the cutting attachment shield onto the shaft

mount. Install using provided hardware in the sequence

as shown (Fig.3).

Shaft Mount

Cutting Attachment Shield

Plate Washer

Washer

Lock Washer

Attaching Screws

Fig. 3

INSTALLING THE UPPER HANDLE AND SAFETY BAR

1. Locate the 4 screws included in the tool kit.

2. Assemble the upper handle, safety bar and 4 attaching

screws as shown in (Fig.4). Position the handle parts

evenly over the rubber sleeve on shaft. Do not completely tighten.

3. While holding the unit in the operating position (Fig.

14), position the upper handle to the location that provides you the best grip.

4. Tighten the clamp screws evenly, until the upper handle

is secure.

Attaching

Screws

Upper Handle

Rubber Sleeve

Cap

Attaching Screws

Washer

Fig. 2

Safety Bar

Fig. 4

5

Page 6

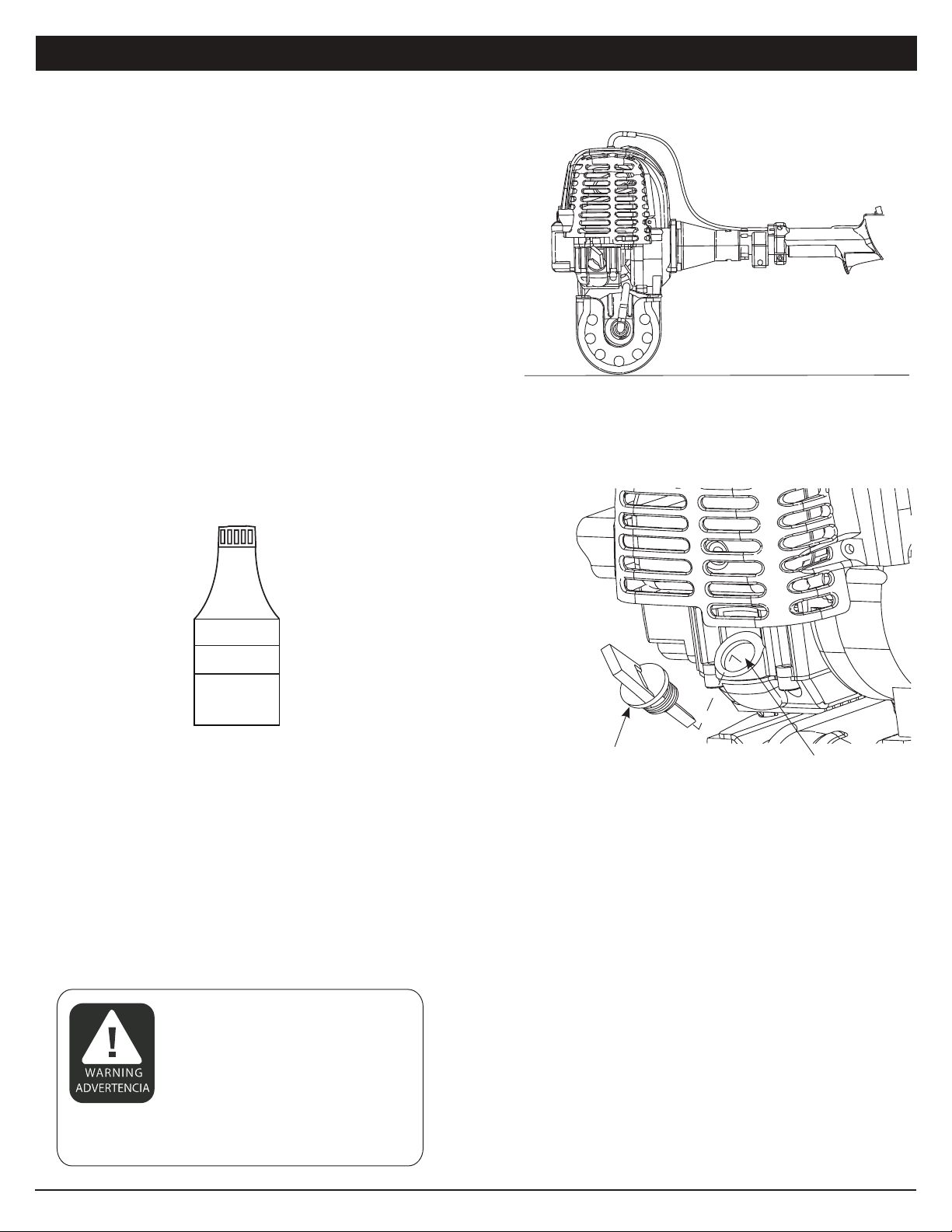

OIL INFORMATION

Oil ll plug/dipstick

Oil Fill Hole

Fig. 7

RECOMENDED OIL TYPE

Using the proper type and weight of oil in the crankcase

is extremely important. Check the oil before each use

and change the oil regularly. Failure to use the correct oil,

or using dirty oil, can cause premature engine wear and

failure. Use a high-quality SAE 10W-30 weight oil of API

(American Petroleum Institute) service class SF, SG, SH.

ADDING OIL TO THE CRANKCASE:

INITIAL USE

NOTE: This unit is shipped without oil in the crankcase.

In order to avoid damage to the unit, put oil in the

crankcase before you attempt to start the unit.

Your unit is supplied with one 2.5 uid oz. (75 mL) bottle

of SAE 10W- 30 SF, SG or SH oil (Fig. 5).

1. Unscrew the top of the bottle of oil and remove the

paper seal covering the o

(Fig. 5).

pening. Replace the top.

2. Place the unit on a level surface (Fig. 6).

Fig. 6

3. Remove the oil plug / dipstick from the crankcase (Fig.7).

4. Pour the entire bottle of oil into the oil ll hole (Fig.7).

4-Cycle Motor Oil

Fig. 5

NOTE: Save the bottle of oil. It can be used to measure

the correct amount during future oil changes. See

Changing The Oil (p.13).

WARNING:

Overlling crankcase may cause hot oil to drip

from air lter, and smoke to come out from the

exhaust. Check and maintain the proper oil

level in the crank case; it is important and

cannot be over emphasized. Check the oil

before each use and change as needed.

See Changing the Oil (p.13).

Check oil before each use and change as needed. Refer

to Changing the Oil (p.13).

5. Wipe up any oil that may have spilled and reinstall

the oil plug/dipstick.

6

Page 7

UNDERSTANDING PROPANE

SAFETY WARNINGS FOR PROPANE UNITS

NOTE: Use propane only in containers specically

designed and approved for this unit. Propane is a

combustible gas; it is colorless and thus invisible to the

naked eye. Propane has a harmless odorant added so

that it is possible to smell it. The propane odorant

makes the propane smell like sulfer or rotten eggs.

If at any time the smell of propane is identied,

turn o the engine. If the leak persists, remove the propane canister. Never attempt to operate a unit that has

a suspected leak. Always remove the propane canister

from any unit that has a suspected leak.

CARBON MONOXIDE HAZARD

Burning propane makes Carbon Monoxide (CO). CO is

invisible, has no smell and can kill you. Operating your

trimmer in an enclosed area can be dangerous.

1. Use only in well ventilated areas. If you experience

headache, drowsiness, or nausea, turn unit o and

get fresh air quickly.

2. Never use where people are sleeping.

3. Follow unit instructions for proper use.

HANDLING & STORAGE

1. Keep out of reach of children.

2. Never expose cylinder to heat, sparks, or ame.

Never leave in direct sunlight. Never store at temperatures above 120 degrees (49 degrees C).

3. Never store in living spaces.

4. Always use cylinder until it is completely empty.

5. Never rell a disposable cylinder. Relling may cause

an explosion. Federal law forbids transportation if re lled, imposes a penalty up to $500,000, and 5 years

imprisonment (49 U.S.C. 5124).

6. Never put in luggage or take on trains or aircraft.

7. To discard, contact local refuse hauler or recycle center.

Never put in re or incinerator. Do not puncture. If

your cylinder was purchased with a “Green Key” * or

similar device, install it when empty and cylinder may

be recycled with other steel items.

NOTE: FIRE/EXPLOSION HAZARD

Contains enough gas to cause serious re, explosion,

and burns. To reduce chance of leak, re, or explosion:

BEFORE USE

1. Check propane cylinder and trimmer seals. Never use

with damaged or missing seals. Discard cylinder if dirt

or rust particles are in valve area.

2. Turn trimmer o.

3. Attach cylinder outdoors away from pilot lights, ames,

sparks or other ignition sources. These sources can

ignite leaking gas.

4. Hand tighten only. Never use tools to tighten. Overtightening can damage seals.

5. Check for leaks. Put soapy water on connections.

Look for bubbles. Listen for hiss of escaping gas. Feel

for extreme cold. Smell for rotten egg odor. Do not

use if leaking.

6. Read and follow trimmer instructions.

DURING USE

Never use near pilot lights, ames, sparks, or other

ignition sources. They can ignite leaking gas.

AFTER USE

1. Turn trimmer o and let cool.

2. Detach cylinder when not in use.

3. Detach outdoors away from pilot lights, ames, sparks,

or other ignition sources; they can ignite leaking gas.

4. Replace cylinder cap to keep valve clean.

IN CASE OF FIRE

1. Leave area quickly and call 911 or your local re depart-

ment for help.

2. Let re burn out.

* Green Key- is a trademark of the Coleman company

7

Page 8

INSTALLING THE PROPANE CANISTER

WARNING:

Propane is highly amable, and its vapors

can explode if ignited.

Take the following precautions.

USE THE CORRECT PROPANE CANISTER

Always use Propane canisters or “Bottles” that are the

correct size. The 17 ounce or 16.4 ounce canisters that

are approximately 3-7/8 inch in diameter are the cor rect canisters (Fig.8). Do not use the smaller diameter

canisters as they will not latch securely to the unit and

vibration may cause damage to the trimmer and potentially result in a dangerous leak.

16.4 OZ. / 465 g

Fig. 8

CANISTER

ATTACHING THE PROPANE CANISTER

1. Make sure the engine is o.

2. If the propane canister to be installed has a protective plastic cap over the threaded end, remove it.

Make sure the canister clamp is in the un-latched

position.

Propane

Connector

Fig. 9B

REMOVING THE PROPANE CANISTER

1. Make sure the engine is o.

2. Un-latch the bottle clamp and push canister against the

guard exposing the propnae connector. Remove the

propane connector by turning it counterclockwise.

3. Remove the empty canister.

4. Dispose of empty propane canisters in accordance

to Federal, State and local Regulations.

WARNING:

Never attempt to force a connector onto

a propane canister that has improper or

damaged threads.

3. Insert the threaded end of the propane canister into

the clamp as far as it will go (Fig. 9A). Insert the propane connector onto the threaded end of the canister and screw it

onto threads clockwise (Fig. 9B). Screw it until snug.

Do not over tighten. It may be normal to hear or smell

a slight momentary leak of propane as the connector

is being screwed in. Make sure that the connector is

installed tight enough that any leakage stops. Hand

tight is sufcient. Slide canister back so all of fuel line

components are behind the guard and latch the canister

clamp.

Guard

Canister

Clamp

WARNING:

This container and by-products of

the combustion of its contents contain

chemicals known to the state of

California to cause cancer, birth

deects, or other reproductive harm.

WARNING:

Extrememly amable re/explosion.

Hazard contents under pressure.

Carbon monoxide hazard.

WARNING:

Propane is extremely amable. Vapor

may explode. Always stop the engine

and allow it to cool before replacing

the propane canister. Do not smoke.

Keep sparks and open ames at a

distance from the area.

Fig. 9A

8

Page 9

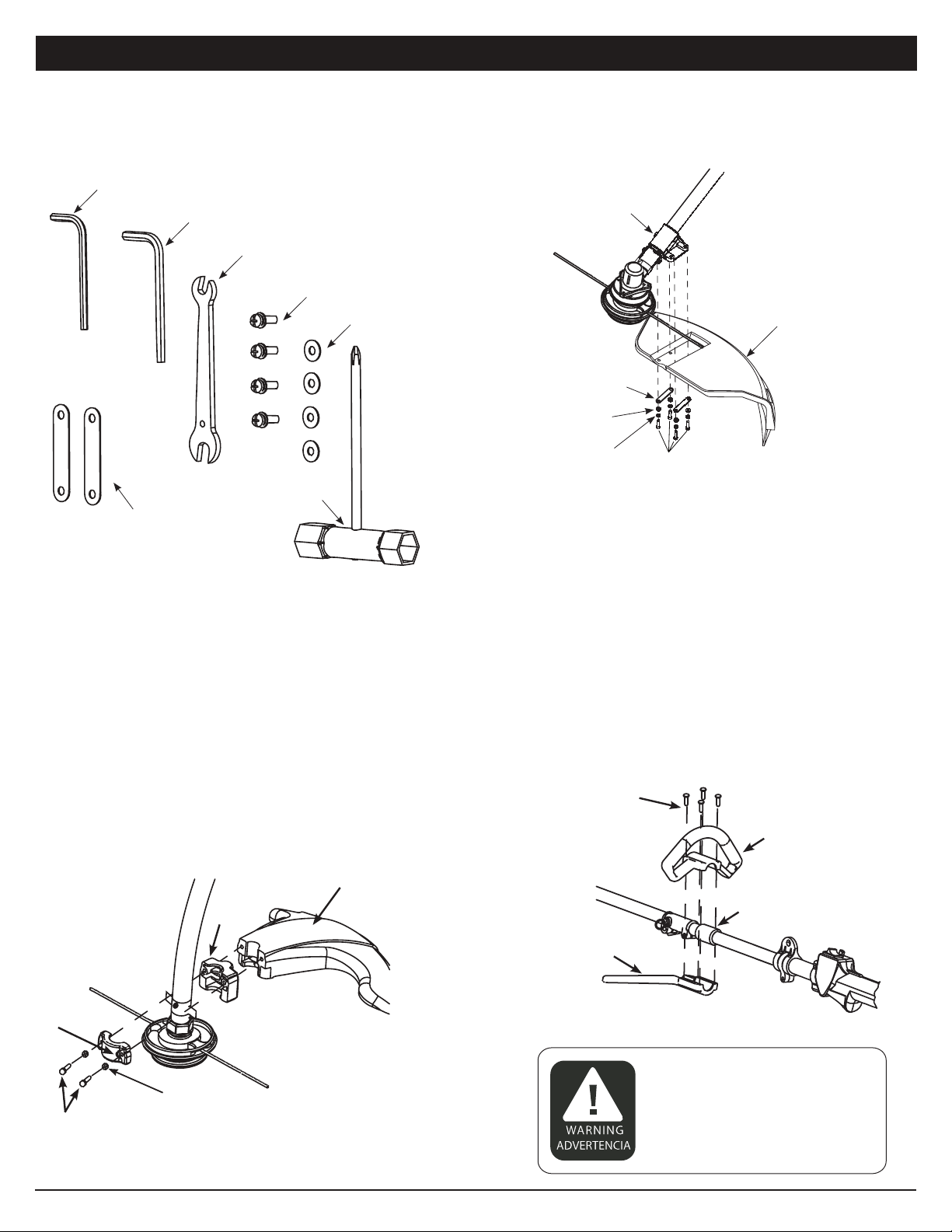

INSTALLING ATTACHMENTS

AVAILABLE CUTTING ATTACHMENTS

Brushcutter attachment..................................................358.79244

Edger attachment..............................................................358.79240

Cultivator attachment......................................................358.79241

Blower attachment............................................................358.79242

Pruner attachment.............................................................358.79245

INSTALLING CUTTING ATTACHMENTS

Your unit is provided with the Hassle-Free™ Cutting

Head attachment shaft.

NOTE: Place the unit on the ground or on a work bench

to make accessory installation or removal easier.

1. Turn knob counterclockwise to loosen (Fig.10).

2. While rmly holding the attachment shaft, push it straight

into the attachment coupler (Fig.10).

NOTE: Aligning the release button with receiving hole will

help installation (Fig.10).

Attachment

Coupler

Receiving Hole

Line up parts

Release Button

EDGING POSITION

For edging, lock the release button of the cutting

attachment into the 90° edging hole (Fig.11), so that the

engine remains in the upright position while operating.

90° Edging

Hole

Fig. 11

REMOVING CUTTING ATTACHMENTS

1. Turn the knob counterclockwise to loosen (Fig.12).

2. Press and hold the release button (Fig.12).

3. While rmly holding the upper shaft housing, pull

the cutting attachment or add-on straight out of the

coupler (Fig.12).

Attachment

Shaft

Upper Shaft

Housing

Knob

Fig. 10

3. Turn the knob clockwise to tighten (Fig. 11). The unit is

ready to use.

NOTE:

• Lock the release button in the receiving hole and

securely tighten the knob before operating this unit.

• Except for edging, attachments are to be used in the

receiving hole only. Using the wrong hole could lead

to personal injury or damage to the unit.

• Always install the attachment so that the engine is

upright (propane tank on bottom) when unit is oper ated. A secondary receiving hole is provided for use of

a trimmer being used for edging only. No other acces sory should be used in this secondary hole (90° edging

hole) ( Fig.11).

Coupler

Release Button

Fig. 12

WARNING:

To avoid serious injury and damage to the unit,

shut o the unit before removing or installing

attachments.

9

Page 10

STARTING / STOPPING

STARTING INSTRUCTIONS

1. Check the oil level in the crankcase. Refer to Checking

the Oil Level ( p.12).

2. Turn switch to ON position (Fig.14).

NOTE: If your unit is equipped with a spring loaded type

ON/OFF switch, it will always remain in the ON position.

3. Place trimmer rmly on the ground or a very sturdy

work surface. Make sure cutting head is clear of all

objects. Make sure all bystanders are a minimum of

50 feet (15m) away. Do not attempt to start near pilot

lights or any open ame. Do not smoke. Grasp the

starter rope handle with one hand and the handle

pole with the other hand ( Fig.13).

Start/On(I)

Stop/O

Safety trigger

Throttle Control

Fig. 14

Fast Idle

Lock

NOTE: When starting the engine in very hot or cold

conditions it may be necessary to squeeze the throttle

control while pulling the starter rope.

STOPPING INSTRUCTIONS

1. Release your hand from the throttle control. Allow the

engine to cool down by idling.

Fig. 13

4. With the unit in the starting position, do not squeeze

the throttle control (Fig.14). Then pull the rope

smoothly and briskly. The engine should start. A cold

engine should start with 3-5 pulls. A warm engine

should start on the rst pull.

NOTE: On the very rst use, it may take extra pulls to ll

the fuel system with propane.

5. Squeeze the throttle control slightly to warm up the

engine for 15 to 30 seconds. In cold weather, move

the throttle slowly until the engine warms up for 30 to

60 seconds.

2. If your unit is equipped with a spring loaded ON/

OFF switch, press and hold the button on OFF until

the unit stops. Otherwise, push the switch to the o

position.

3. When done using the trimmer for the day, disconnect

the propane canister from the unit.

WARNING:

Avoid accidental starting. Make sure you are in the starting

position when pulling the starter rope (Fig. 13). To avoid

serious injury, the operator and unit must be in a stable

position while starting. Make sure that any add-on item is

installed correctly and secure before starting the unit.

WARNING:

Always wear eye, hearing, foot and body

protection to reduce the risk of injury when

operating this unit.

NOTE: This unit is provided with a Fast Idle Lock (Fig. 14). If

experiencing starting diculties under regular conditions,

squeeze the throttle control, then push and hold the Fast

Idle lock forward while releasing the throttle trigger. Then

start the unit.

10

Page 11

OPERATION

OPERATING YOUR TRIMMER

Before operating the unit, stand in the operating position

(Fig. 15). Check for the following:

• The operator is wearing eye protection and proper

clothing.

• With a slightly bent right arm, the operator’s right

hand is holding the shaft grip.

• The operator’s left arm is straight, and left hand holding

the upper handle.

• The unit is at waist level.

• The cutting attachment is parallel to the ground and

easily contacts the grass without the need to bend over.

HOLDING THE TRIMMER

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent upon:

1. Proper adherence to explained trimming techniques

2. What vegetation is cut

3. Where vegetation is cut

For example, the line will wear faster when trimming

against a foundation wall as opposed to trimming

around a tree.

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky weeds

• Forcing the line into objects such as walls or fence posts

NOTE: This unit is equipped with an Anti-Kickback bar.

This bar helps protect you from “kick-back” which may

occur during operation. The Anti-Kickback bar hits the

side of your leg when the trimmer jumps back, prevent-

ing the cutting head to contact the operator.

Fig. 15

TIPS FOR BEST TRIMMING RESULTS

• For best trimming results, operate unit at full throttle.

• Keep the cutting attachment parallel to the ground.

• Do not force the cutting attachment. Allow the tip

of the line to do the cutting, especially along walls.

Cutting with more than the tip will reduce cutting

efficiency and may overload the engine.

• Cut grass over 8 inches (200 mm) by cutting from top

to bottom in small increments to avoid premature line

wear or engine drag.

• Slowly move the trimmer into and out of the cutting

area at the desired height. Move either in a forward-

backward or side-to-side motion. Cutting shorter

lengths produces the best results.

11

Page 12

MAINTENANCE

WARNING:

To prevent extensive engine wear and

damage to the unit, always maintain the

proper oil level in the crankcase. Never

operate the unit with the level below the

bottom of the dipstick.

WARNING:

When servicing, use only identical

replacement parts. Use of any

other parts may create a hazard

or cause product damage.

FREQUENCY MAINTENANCE REQUIRED REFER TO

BEFORE STARTING ENGINE

EVERY 10 HOURS

PAGE 13

FIRST CHANGE AT 10 HOURS

EVERY 25 HOURS THEREAFTER

PAGE 13

EVERY 25 HOURS

EVERY 25 HOURS

CHECK OIL

CLEAN AND RE-OIL AIR FILTER

CHECK OIL

CHECK OIL

CHECK SPARK PLUG POSITION GAP

ROCKER ARM CLEARANCE ADJUSTMENT

PAGE 6

PAGE 13

PAGE 14

PAGE 16

Perform these required maintenance procedures at

the frequency stated in the table. These procedures

should also be a part of any seasonal tune-up.

NOTE: Failure to maintain your trimmer at the recommended schedule may result in poor performance

and/or cause permanent damage to your trimmer

NOTE: Some maintenance procedures may require

special tools or skills. If you are unsure about these

procedures call 1-800-235-5878 for assistance.

NOTE: Maintenance, replacement, or repair of the

emission control devices and system may be performed

by any non-road engine repair establishment, individual

or authorized service dealer.

Oil Fill Plug/Dipstick

O-ring

Full

Add

Fig. 16

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper

oil level in the crankcase cannot be overemphasized.

Check oil before each use:

1. Stop the engine and allow to cool.

2. Place the unit on a at, level surface to get a proper

oil level reading.

3. Keep dirt, grass clippings and other debris out of the

engine. Clean the area around the oil ll plug/dipstick

before removing it.

4. Remove the oil ll plug/dipstick and wipe o oil. Rein-

sert it all the way back in.

5. Remove the oil ll plug/dipstick and check the oil level.

Oil should be between the add and ll marks (Fig. 16).

6. If the level is low, add a small amount of oil to the oil

ll hole (Fig.17) and recheck. Repeat this procedure

until the oil level reaches the full mark of the dipstick.

NOTE: Do not overll the unit.

NOTE: Make sure the O-Ring is in place on the oil ll plug/

dipstick when checking and changing the oil (Fig. 16).

Oil Fill Plug/

Dipstick

Oil Fill Hole

12

Fig. 17

Page 13

MAINTENANCE

CHANGING THE OIL

For a new engine, change the oil after the rst 10 hours

of operation. Change the oil while the engine is still

warm but not hot. The oil will ow freely and carry

away more impurities.

1. Unplug spark plug wire to prevent accidental starting.

2. Remove the oil ll plug/dipstick.

3. Pour the oil out of the oil ll hole and into a container

by tipping the unit to its side (Fig. 18). Allow ample

time for complete drainage.

CLEANING THE AIR FILTER

Clean and re-oil the air lter every 10 hours of operation.

It is an important item to maintain. Failure to maintain

your air lter properly can result in poor performance or

can cause permanent damage to your engine.

1. Remove the phillips head screw in the air lter cover.

Then pull the air lter cover out and upwards (Fig.20) .

2. Remove the air lter (Fig. 20).

Air Filter

Air Filter

Cover

Screw

Air Filter

Base Plate

Fig. 18

NOTE: Wear gloves to prevent injury when handling the

unit.

4. Wipe up any oil residue on the unit and clean up any

oil that may have spilled. Dispose of the oil according

to Federal, State and local regulations.

5. Rell the crankcase with 2.5 uid oz. (75 mL) of SAE

10W-30 SF, SG, or SH oil.

NOTE: Use the bottle saved from initial use to measure

the correct amount of oil. The bottle measures

approximately 2.5 uid oz. (75 mL) (Fig. 16).

Check the level with the dipstick. If the level is low,

add a small amount of oil and recheck. Do not overll

6. Replace the oil ll plug/dipstick.

7. Reconnect the spark plug boot.

4-Cycle Motor Oil

Fig. 20

3. Wash the lter in detergent and water. Rinse the lter

thoroughly and allow it to dry.

4. Apply enough clean SAE 10W-30 motor oil to lightly

coat the lter.

5. Squeeze the lter and remove excess oil.

6. Replace the lter.

NOTE: If the unit is operated without the air lter, you

will VOID the warranty.

7. Reinstall the air lter cover. Position the hooks on the

top of the air lter base plate into the slots at the top

of the lter cover.

8. Swing the cover until the air lter cover snaps into

place and replace the screw.

WARNING:

To avoid serious personal injury, be sure

to turn the unit o before servicing it.

Fig. 19

13

Page 14

CARBURETOR ADJUSTMENT

The idle speed of the engine is adjustable. An idle adjustment screw is on the rear side of the carburetor (Fig.

21).

NOTE: Careless adjustments can seriously damage

your unit. Only a Sears or other qualied dealer should

make carburetor adjustments.

CLEAN AIR FILTER

The condition of the air lter is important to the operation of the unit. A dirty or oil saturated air lter will

restrict air ow. This is often mistaken for an out of

adjustment carburetor. Check the condition of the air

lter before adjusting the idle speed screw. Refer to

Cleaning Air Filter (p.13).

MAINTENANCE

Idle Adjustment

Screw

Fig.21

REPLACING THE SPARK PLUG

ADJUST IDLE SPEED SCREW

If, after checking the fuel and cleaning the air lter, the

engine still will not idle, adjust the idle speed screw as

follows:

1.Start the engine and let it run at a high idle for a

minute to warm up. Refer to Starting/Stopping (p.10)

instructions.

2. Release the throttle trigger and let the engine idle. If

the engine stops, use a small phillips or at blade to

turn the idle speed screw in, clockwise, 1/8 of a turn

at a time (as needed) until the engine idles smoothly.

NOTE: The cutting attachment should not rotate when

the engine idles.

3. If the cutting attachment rotates when the engine

idles, turn the idle speed screw counterclockwise

1/8 of a turn at a time (as needed), to reduce idle

speed. Checking the fuel, cleaning the air lter, and

adjusting the idle speed should solve most engine

problems. If not and all of the following are true,

check the spark plug for proper gap and condition.

Use NGK CMR6A or Champion RCJ6Y replacement

spark plugs.

The correct air gap is 0.02 in. (0.5 mm). Remove the

plug after every 25 hours of operation and check its

condition.

1.Stop the engine and allow it to cool. Remove the

spark plug cover. Grasp the plug wire rmly and pull

the cap from the spark plug.

2.Clean dirt from around the spark plug. Remove the

spark plug from the cylinder head by using a 5/8 in.

socket, turning it counterclockwise.

3.Replace cracked, fouled or dirty spark plug. Set the

air gap at 0.02 in. (0.5 mm.) using a feeler gauge

(Fig 22).

4.Install a correctly-gapped spark plug in the cylinder

head. Turn the 5/8 in. socket clockwise until snug.

If using a torque wrench torque to: 110-120 in. lb.

(12.3-13.5 N-m)

NOTE: Do not over tighten.

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

If problem still occurs, have the carburetor adjusted by

a Sears or other qualied service dealer.

WARNING:

Do not sand blast, scrape, or clean

spark plug electrodes. Grit in the

engine could damage the cylinder.

0.02 in.

(0.5 mm)

Fig.22

14

Page 15

MAINTENANCE

LINE REPLACEMENT

For Hassle-Free™ Cutting Head

Always use Craftsman Hassle Free XTRA QUIET Spiral

Line. Choose the line size best suited for the job at

hand. Red colored line is designed for cutting grass

and small weeds. Black colored line is designed for

cutting larger weeds and light brush.

NOTE: Before inserting new line into the holes in the

cutting head, identify the proper holes by following

the directions on the glide plate (Fig. 23). Do not

attempt to remove the cutting head from the unit

when replacing line.

1. Insert both ends of your line into the insertion

holes in the side of the cutting head (Fig. 23).

Trimming

Line

Insertion

Holes

Positioning

Tunnel

3. Pull the ends of the line until the line bend is centered

between the two insertion holes and rmly against the

side of the cutting head (Fig. 25).

Fig. 25

4. Correctly installed line will be the same length on both

sides.

NOTE: Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky weeds

• Forcing the line into objects such as walls or fence post

Glide Plate

Fig. 23

2. Push the bend in the line until the ends of the line

push through the positioning tunnels (Fig. 24).

Fig. 24

15

Page 16

MAINTENANCE

ROCKER ARM CLEARANCE ADJUSTMENT

1. Remove the four screws on the engine cover with a

phillips head screw driver (Fig. 26).

2. Remove the engine cover.

3. Disconnect the spark plug wire.

4. Clean dirt from around the spark plug. Remove the

spark plug by using tool provided, turn counterclockwise. This requires partial dissasembly of the engine.

If you feel unsure or unqualied to perform this,

take the unit to

NOTE: Inspect the valve to rocker arm clearance with a

feeler gage after the rst 25 hours of operation. The

engine must be cold when checking or adjusting the

valve clearances. This task should be performed in a

clean dust free environment.

Engine cover

screws

a Sears or other qualied service dealer.

Engine cover

screws

8. Pull the starter rope slowly to bring the piston to

the top of its travel, (this position is known as top

dead center).Check that the piston is at the top of

its travel by looking down into the spark plug hole.

Both valves should be closed and the rocker arms

should move freely. If this statement is not true,

repeat this step until top dead center is acheived

before proceeding to the next step.

9. Slide a feeler gage between the rocker arm and the

valve return spring. Measure the distance between

the rocker arm and valve stem (Fig. 28) Take care

to only measure the free play. It is very easy to

insert too thick a feeler gauge and accidentally

depress the valve and valve return spring. Measure

both the intake and exhaust valve distances.

Adjusting Screws

Jam Nuts

Rocker Arm

Feeler Gauge

Exhaust Valve

Intake Valve

Valve Return

Spring

Fig. 26

5. Clean dirt from around the rocker arm cover.

6. Remove the three screws holding the rocker arm

cover with a phillips head screwdriver.

7. Remove the rocker arm cover and gasket (Fig. 27).

Rocker Arm Cover

Screws

Rocker Arm

Cover

Fig. 27

WARNING:

To prevent serious injury, never perform maintenance

or repairs with unit running. Always service and repair

a cool unit. Disconnect the spark plug wire to ensure

that the unit cannot start.

Fig. 28

10. Check the spark plug and reinstall, see Replacing

the Spark Plug (p.14).

11. Reinstall the spark plug wire.

IF THE CLEARANCE IS NOT WITHIN SPECIFICATION

1. Loosen the jam nut and turn the adjusting screw

as necessary. To increase the clearance, turn the

adjusting screw counterclockwise. To decrease

the clearance, turn the adjusting screw clockwise.

2. Tighten the jam nut when the clearance is set.

3. Recheck the both clearances. Readjust if necessary.

4. Reinstall the rocker arm cover using a new gasket.

5. Tighten cover screws evenly until snug.

6. Reinstall the engine cover checking the alignment of

the cover. Tighten the four engine cover screws until

snug.

• The recommended clearance for both intake and

exhaust is 0.076-0.152mm (0.003-0.006in).

• Use a standard automotive 0.127mm (0.005in) feeler gage.

16

Page 17

CLEANING AND STORAGE

CLEANING

Use a small brush to clean the outside of the unit. Do

not use strong detergents. Household cleaners that

contain aromatic oils such as pine and lemon, and sol vents such as kerosene, can damage plastic housing or

handle. Wipe o any moisture with soft cloth.

STORAGE

• Remove propane canister.

• Never store the unit with attached propane canister where

fumes may reach an open ame or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store unit out of reach of children.

WARNING:

To avoid serious injury, always turn

your o and allow it to cool before

you service it.

LONG TERM STORAGE

1. Remove propane canister.

2. Allow the engine to cool. Remove the spark plug and

put 5 drops of high quality motor oil into the cylinder.

Pull the starter rope slowly to distribute the oil. Rein -

stall the spark plug.

NOTE: Remove the spark plug and drain all of the oil

from the cylinder before attempting to start the trimmer

after storage.

3. Change the oil, referring to Changing the Oil (p.13).

Dispose of the old oil in accordance to Federal, State

and Local regulations.

4. Thoroughly clean the unit and inspect for any loose

or damaged parts. Repair or replace damaged parts

and tighten loose screws, nuts or bolts. The unit is

ready for storage.

TRANSPORTATION

• Allow the engine to cool before transporting.

• Secure the unit while transporting.

• Remove propane canister.

TROUBLESHOOTING

ENGINE WILL NOT START

CAUSE ACTION

Empty propane canister

Bad spark plug

ENGINE WILL NOT IDLE

CAUSE

Air filter is plugged

Improper carburetor adjustment

ENGINE WILL NOT ACCELERATE

CAUSE

Cutting attachment bound with grass

Dirty air filter

ENGINE LACKS POWER OR STALLS WHEN CUTTING

CAUSE

Bad spark plug

Install full canister

Replace the spark plug

ACTION

Replace or clean the air filter

Adjust according to the carburetor

adjustment section or take to a Sears or

other qualified service dealer for an adjustment

ACTION

Stop the engine & clean the cutting attachment

Clean or replace the air filter

ACTION

Replace the spark plug

IF FURTHER ASSISTANCE IS REQUIRED, CONTACT A SEARS OR OTHER QUALIFIED SERVICE DEALER.

17

Page 18

SPECIFICATIONS

ENGINE*

ENGINE TYPE AIR-COOLED 4-CYCLE

DISPLACEMENT 25.4 CC

CLUTCH TYPE

OPERATING R.P.M.

IDLE SPEED

IGNITION TYPE ELECTRONIC

IGNITION SWITCH

VALVE CLEARANCE

SPARK PLUG GAP

LUBRICATION

CRANKCASE OIL CAPACITY

FUEL

CARBURETOR

STARTER

PUSH ON/ OFF SWITCH

0.003-0.006 INCHES (0.076-0.152 mm)

0.02 INCHES (0.5 mm)

2.5 FLUID OZ. (75 mL)

PROPANE 16 OZ. / 465 G CANISTER

CHOKE-LESS, ALL POSITION

PULL START WITH AUTO REWIND

CENTRIFUGAL

6,800-9,300 R.P.M.

3,000-3,400 R.P.M.

SAE 10W-30 OIL

MUFFLER

THROTTLE

SAFETY LOCK WITH MANUAL SPRING RETURN

BAFFLED WITH GUARD

DRIVE SHAFT AND HOUSING

DRIVE SHAFT HOUSING

THROTTLE CONTROL

APPROXIMATE UNIT WEIGHT

CUTTING MECHANISM HASSLE FREE ™ CUTTING HEAD

CUTTING HEAD DIAMETER 4-1/4 INCHES (108 mm)

TRIMMING LINE

CUTTING PATH DIAMETER 14 INCHES (356 mm)

RED MEDIUM (71-85908) OR BLACK LARGE (71-85909)

ALUMINUM TUBE

FINGER-TIP TRIGGER

13.1-14.9 LBS

*ALL SPECIFICATIONS ARE BASED ON THE LATEST PRODUCT INFORMATION AT THE TIME OF PRINTING.

WE RESERVE THE RIGHT TO MAKE CHANGES AT ANY TIME WITHOUT NOTICE.

18

Page 19

WARRANTY STATEMENT

CRAFTSMAN FULL WARRANTY

If this Craftsman product fails due to a defect in material or workmanship within two years from the date of purchase, return it to any Sears store,

Parts and Repair Service Center, or other Craftsman outlet in the United States for free repair (or replacement if repair prove s impossible).

This warranty applies for only 90 days if this product is ever used for commercial or rental purposes.

This warranty covers ONLY defects in materal and workmanship. Sears will NOT pay for:

• Expendable items that can wear out from normal use within the warranty period, such as cutting line, lters or spark plugs.

• Repairs necessary because of accident or failure to operate or maintain the product according to all supplied instructions.

• Preventive maintenance, or repairs necessary due to improper fuel mixture, contaminated or stale fuel.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Homan Estates, IL 60179

Repair Protection Agreements

Congratulations on making a smart purchase. Your new Craftsman® product is designed and manufactured for years of dependable

operation. But like all products, it may require repair from time to time. That’s when having a Repair Protection Agreement can save you

money and aggravation.

Here’s what the Repair Protection Agreement* includes:

Expert service by our 10,000 professional repair specialists

Unlimited service and no charge for parts and labor on all covered repairs

Product replacement up to $1500 if your covered product can’t be xed

Discount of 10% from regular price of service and related installed parts not covered by the agreement; also, 10% o regular price of

preventive maintenance check

Fast help by phone – we call it Rapid Resolution – phone support from a Sears representative. Think of us as a “talking owner’s manual.”

Once you purchase the Repair Protection Agreement, a simple phone call is all that it takes for you to schedule service. You can call anytime

day or night, or schedule a service appointment online.

The Repair Protection Agreement is a risk-free purchase. If you cancel for any reason during the product warranty period, we will provide a

full refund. Or, a prorated refund any time after the product warranty period expires. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional information in the U.S.A. call 1-800-827-6655.

*Coverage in Canada varies on some items. For full details call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and other major home items, in the U.S.A. or

Canada call 1-800-4-MY-HOME

®

.

19

Page 20

Get it fixed, at your home or ours!

Your Home

For expert troubleshooting and home solutions advice:

www.managemyhome.com

For repair – in your home – of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

®

1-800-4-MY-HOME

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

(1-800-469-4663)

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of your nearest

Sears Parts & Repair Service Center

1-800-488-1222 (U.S.A.) 1-800-469-4663 (Canada)

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparación

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR

(1-888-784-6427)

®

Au Canada pour service en français:

1-800-LE-FOYER

(1-800-533-6937)

www.sears.ca

MC

® Registered Trademark / TM Trademark /

® Marca Registrada / TM Marca de Fábrica / SM Marca de Servicio de Sears Brands, LLC

MC

Marque de commerce / MD Marque déposée de Sears Brands, LLC © Sears Brands, LLC

SM

Service Mark of Sears Brands, LLC

Loading...

Loading...