Page 1

OPERATING

INSTRUCTIONS

AND

PARTS

CRAFTSMAN DRILL

MODEL NUMBER

The

model number

base

near

the

us

regarding your

of

your

column. Always mention this number when communicating with

Drill

Press,

HOW TO

All

parts listed herein

or

SIMPSONS-SEARS LIMITED. When

order house which

furnished

be

WHEN ORDERING

billed

on

request

accordingly.

INFORMATION

1.

The

PART

NUMBER.

2. The

PART

NAME.

serves

or

REPAIR

AS

SHOWN

4. The

may be

the

parts

3. The

103.24521 & 103.24531

Drill

Press

or

when ordering

ORDER

ordered through

territory

will

be

PARTS,

IN

MODEL NUMBER.

NAME

LIST

will

be

found

REPAIR

SEARS,

ordering

in

which

you

shipped

THIS

at

ALWAYS GIVE

LISL

of

item.

FOR

PRESS

on a

plate located

parts.

PARTS

ROEBUCK

parts

by

mail from

live,

selling prices

prevailing prices

THE

103.24521

103.24531

DRILL

PRESS

on the

AND CO.

the

mail

will

be

and you

FOLLOWING

or

will

FOR

SEARS,

IN

CANADA,

COAST

TO

COAST

SERVICE

NATION-WIDE

FROM

SEARS

YOUR CRAFTSMAN POWER TOOLS

SEARS,

SIMPSONS-SEARS

back

pert mechanical service

CRAFTSMAN

If

call

this

ROEBUCK

SIMPSONS-SEARS

RO EBUCK

up

your investment with

and

when

on us to

fine piece

AND

AND CO. and

LIMITED

and

replacement parts.

you

need repairs

protect your investment

of

equipment.

CO. - U.S.A.

LIMITED

in

Canada

quick,

genuine

or

service,

ex-

in

SOURCE

FORM 27979-5AB

Lithographed

in

U.S.A.

Page 2

OPERATING

INSTRUCTIONS

DRILL PRESS

AND

PARTS LIST

FOR

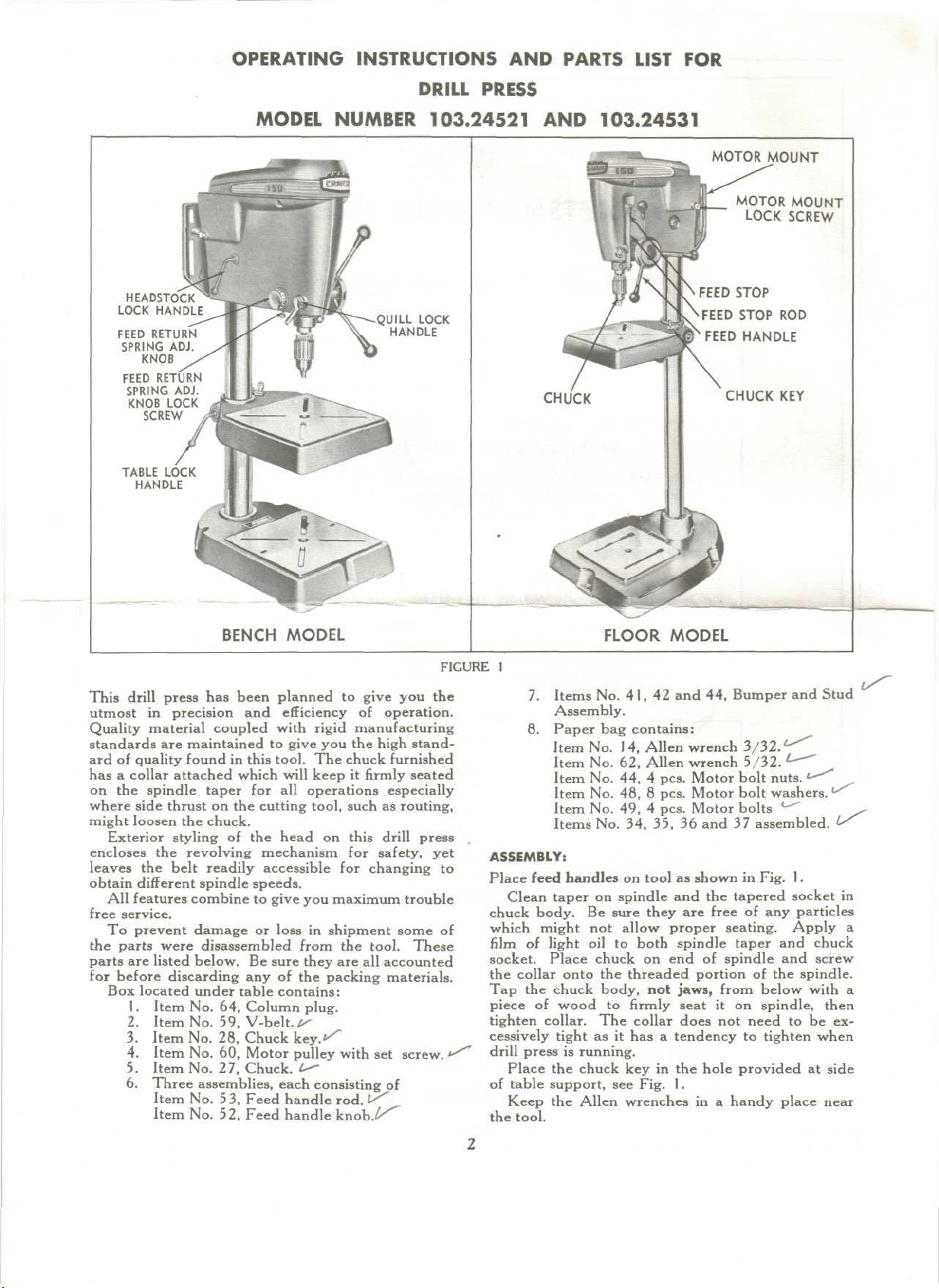

HEADSTOCK

LOCK

HANDLE

FEED

RETURN

SPRING

ADJ.

KNOB

FEED

RETURN

SPRING

KNOB

LOCK

SCREW

TABLE

LOCK

HANDLE

ADJ.

MODEL

NUMBER

HANDLE

103.24521

LOCK

AND

CHUCK

103.24531

MOTOR

FEED

FEED

FEED

MOUNT

MOTOR

LOCK

STOP

STOP

HANDLE

CHUCK

MOUNT

SCREW

ROD

KEY

This

drill press

utmost

in

precision

BENCH

has

been planned

and

MODEL

to

efficiency

Quality material coupled with rigid

standards

ard of

has a

on the

where side thrust

might

Exterior

encloses

leaves

obtain

All

free

To

the

parts

for

before discarding

Box

are

maintained

quality

found

collar attached which

spindle taper

on the

loosen

the

chuck.

styling

the

revolving mechanism

the

belt readily accessible

different

features

spindle

combine

to

in

this tool.

will

for all

cutting tool, such

of the

head

speeds.

to

give

service.

prevent damage

parts

were

disassembled

are

listed below.

or

Be

loss

sure they

any of the

located under table contains:

1.

Item

2.

Item

3.

Item

4.

Item

5.

Item

6.

Three

No. 64,

No.

No. 28,

No. 60,

No.

assemblies, each

Item

No. 53,

Item

No. 52,

Column plug.

59,

V-belt.A Chuck

Motor pulley

27,

Chuck,

Feed handle rod.

Feed

give

you the

The

keep

operations especially

on

for

you

maximum trouble

in

shipment some

from

the

packing materials.

key."''

l^

consistingj>f

handle

give

you the

of

operation.

manufacturing

high stand-

chuck

this

for

furnished

it firmly

as

drill

safety,

seated

routing,

press

changing

tool.

These

are all

with

accounted

set

screw.

FIGURE

yet

to

of

FLOOR

1

7.

Items

8.

Paper

ASSEMBLY:

Place

feed

Clean taper

chuck

body.

which

might

film

of

light

socket. Place chuck

the

collar onto

Tap the

piece

chuck body,

of

tighten collar.

cessively tight

drill

press

Place

the

of

table support,

Keep

the

the

tool.

No. 41, 42 and 44,

Assembly.

bag

Item

No. 1 4,

Item

No. 62,

Item

No. 44, 4

Item

No. 48, 8

Item

No. 49, 4

Items

No. 34, 35, 36 and 37

handles

on

spindle

Be

sure they

not

allow proper seating. Apply

oil to

the

wood

to firmly

The

as it has a

is

running.

chuck

see

Allen wrenches

MODEL

Bumper

contains:

Allen

wrench

Allen wrench 5/32.

pcs. Motor bolt nuts.

pcs. Motor bolt washers.

pcs. Motor bolts

on

tool

as

shown

and the

are

both

spindle

on end of

threaded portion

not

jaws,

seat

collar does

tendency

key in the

Fig.

1.

in a

in

tapered socket

free

of any

taper

spindle

from

it on

not

need

to

hole provided

handy place near

and

Stud

3/32.

*•

assembled.

Fig.

1.

particles

and

chuck

and

screw

of the

spindle.

below with

spindle, then

to be ex-

tighten when

at

side

^

in

a

a

Page 3

INSTALLATION:

Three 1 3/32 inch diameter holes

vided

in the

base

through which bolts

be

inserted

structed bench

To

screws, Fig.

moved.

the

bolts, nuts,

motor mou nt

portion

if

your moto r

rect, place motor

is

on the

spindle must

end of

Mount

so

that

speeds,

be in

pulley,

Tighten

wrench,

it,

position

tighten

Place

excessively,

tool.

Tighten

maintain

Adjust

the

motor

to

secure

or

tool

the

stand.

install motor loosen

1,

unti l

the

motor mount

Fasten

of the

the

motor

and

washers provided

is

reinstalled

mount will

has a

on

l eft

side. Direction

be

clockwise when viewed from pulley

be

switch,

motor moun t

spindle.

the

motor pulley,

the

small diameter

the

largest groove

line with

No.

1.

the

pulley

No. 62. If

the

against

belt around

by

the

pulley

the flat.

sliding

the

on the

smallest

set

screw with

your motor

so

the

the

motor mo unt lock screws

this tension.

the

screw,

is

parallel with

No. 42,

drill

the

to the

on the

down.

and

No. 60, on

is at

groove

that

pulleys

motor mount away

until

the

have

been

or

screws

press

to a

well con-

motor mount

may be re-

m otor mount with

so

that when

tool,

the

For

convenience,

rotation

of

will

so

that

rotation

the

motor

bottom.

For

motor pulley should

on the

the

larger Allen

shaf t

has a flat on

the set

and

tighten,

the

center line

screw will

center line

column.

MOTOR:

A

4 /£

horsepowei^475Q

will

provide

drill

press

s uffic ient

on

duty operation

general work.

a 1

R.P.M^baH

speed

/2

horsepower motor

and

power

For

continuous heavy

bearing

for

is

mended.

SPEED:

The

spindle speeds obtainable with these 4 step pul-

leys

are

shown

SPINDLE

R.P.M.

5000

2390

1280

610

3970

1730

771

2905

1050

in

MOTOR

MOTOR

Fig.

DRILL

PRESS

P UL LEY

PULLEY

FIGURE

2.

RAISED

RAISED

2

ONE

TWO

MOTOR

(1750

R.P.M)

GROOVE -/

GROOVES-'

pro-

may

lock

larger

be

cor-

switch

of the

s haft

normal

spindle

not

fro m

to

of

of the

mutor

your

recom-

I

|

For

slower speeds

available

from

order house.

Ask for

use a

your nearest Sears retail store

Catalog

LUBRICATION:

The

spindle

with

lubricant

for

the

Place

shaft,

No. 54. The oil

on

trie

To

maintain smoothness

vent

rust,

light

cup

tion.

With

backside

below

and

pulley bearings have been packed

and

l ife

a few

of the

will require

bearing.

drops

of oil

occasionally

hole

right han d side

of the

occasionally apply a small amount

grease

of the

the

to the

quill

head

pulley,

quill

still

f ull y

and

apply grease

and to the

extended, reach into

quill.

Occasionally

with

an oil

smooth

sliding action.

wipe

soaked

the

rag to

co lumn,

prevent rust

CONTROLS:

The

chuck

is a

key-type

inch

diameter.

retain

it on the

sity

of

having collet chucks

It is

spindle. This eliminates

velop side thrust while

The

feed stop

unit

and has a

equipped with a lock collar

in

operation, such

provides a means

hole depths bef ore drilling

holes

to the

The

the

feed

as an

assembly,

fast

positioning

and

sliding

The

be

adjusted

CAUTION:

never

be

the

feed

made.

within

adjust

The

1/16

inch graduations, carrying

same depth.

lock screw,

stop collar,

it up or

feed

stop

to the

The top of the

more than

stop collar

If the

the

the

desired

J/g"

allowance, reposition

feed

stop

feed stop

No. 36,

No.

37,

can be

by

adj ust ing

moved

turning

down

to an

collar,

exact depth desired.

J/s"

away

after

an

ad just ment

ad jus tin g

rod is a

gauge, with 5 inches

lock nut.

The

feed handle

chuck 4 inches.

return

action.

The

quill lock handle when tight holds

at any

depth

routing,

quill

lock befo re changing position

The

control

of cut for

surface

table

lock handle

the

barrel locks which grip

When releasing either

care.

Support

it

will

not

drop

is

used

It has an

automatic spring loaded

such operations

grinding, etc. Always release

and

of

these handles

the

part

too

you

rapidly causing damage

tool.

The

feed return adjusting knob controls

tension

make

hinge

allow quicker belt changes.

one

ward

The

on the

motor

the

feed

mount

changing

action incorporated

pulley groove

and

slip

the

belt into

lever.

has

been hinged

of

spindle

in

To

to

another, pivot

the

Multi-Speed

Attachment

or

No.

9A-2338.

no

is

located

f urth er

att entio n

on the

pinion

in the hub

head.

of

operation

while

upper portion

for

such tools that

or for

when

in

place.

on the

the

unit a quarter turn

approxim ate

and to

in a

down posi-

to the

spindle,

of the

table

and

and

m aintain

capacity

of

the

as

routers.

of

presetting

0-1

neces-

drilling several

tightened,

The two

stop

holds

pieces,

rod for

pr.aifir.ri,

No. 34, can

adju sting collar should

fr om

the

a djus tme nt

can not be

shoulder

has

the

unit

been

made

collar.

the

feed

stop

to

raise

and

lower

the

as

shaping,

of

quill.

headstock lock handle

the

column.

do so

wish

to

a dju st

so

to the

the

spring

in

order

speeds

easier.

The

this motor mou nt

move

the

belt

fr om

the

motor for-

desired

grooves.

mail

pre-

of

the

base

/ 2

to

de-

then

of

and

of

and

the

quill

the

with

that

to

will

Page 4

ADJUSTMENTS:

The

followi ng

keep

your

If

the

chuck

to the top of the

becomes

follows;

using

Lock

the

adjusting knob

adjusting

ing

kn ob counter-clockwise

screw. Release

chuck

down.

repeat

the

adj ustme nts

drill

press

automatic

sluggish,

quill

feed

the

the

chuck

lock handle.

firmly

knob lock screw, Fig.

the

If

spring tension

above

a dju s tmen t

may be

at its

most

return

stroke

tension

or if the

may be

at the top of its

Hold

and

release

and

quill

lock handle

until

necessary

eff icient

fails

to

r et ur n action

adjusted

the

feed return

the

feed return

1.

Turn

re-tighten

and run the

is

still

not

it is.

to

operation.

r eturn

the

as

stroke

the

adjus t-

the

lock

sufficien t

sive

commercial operations

high

speed

steel drills alth ough more expensive,

prove

to be the

are

possible plus longer

The

solid center wood

ing

aro und a solid center

better tool

The fluted bit is an

bit.

It has two flutes

edge

and

spur.

The

best

bit for

wood

is the

spur machine bit.

tracks nicely

and

produces

hole.

For

larger holes, a hole

metal

or

wood. This

and

teeth around

the

blade.

Also,

for

large holes

may

be

used. When

wood

bit is

must

have

will

not

may be filed

Countersinking

plished

the

cleanest

tinuous

used

the

threads removed

enter

the

o ff. (See Fig.

by

using

cut and

operation.

in the

wood

in

the

cutt ing

excellent

each

high

qual ity

bit has a

outer

in

the

expansion

drill

too

wood

double

will

are to be

as

higher operating speeds

edge

bit has a

but

carries

ter min ating

machine

It is the

an

exceptionally smooth

saw is

available

center drill

rim

wood

pe rfo rmed,

life.

single

flute

two

spurs.

all

purpose wood

in a

drilling

stif fe st

for

for

similar

an

to a saw

expansion

bit or any

press,

the

screw point

f rom

it so

rapidly.

These

3.)

may

best

be

accom-

lip

style.

It

will

not gum up

u nder con-

will

tur n-

cutting

in

drill,

either

pilot

bit

hand

that

it

threads

give

FIGURE

To

change

or

headstock lock handle (Fig.

and

rotate table

Item

51 ,

180°.

the

locked position

lock,

Re-insert

CAUTION: Headstock

be

securely supported when changing locked position

of

handles.

The

Quill Lock Handle, (Fig.

of

operation should point

change

screw,

tate

set

the

mount

ens

the

to

the

position

of the

remove handle

to

correct position. Replace handle

screw.

Belt

tension

adj ustment

motor moun t lock screws

away

fro m

the

tool. Excessive tension short-

bearing

motor

prevent slippage

life,

causes excessive belt wear

of

power. Tension should

at

3

of

table lock h andle

1) ,

remove handle

item

67, or

and

or

headstock lock,

tighten lock handle.

table assembly should

1 ) for

down

when locked.

handle, loosen

fro m

hex

head screw

is

made

and

by

moving

be

normal operating

greatest ease

the set

and ro-

and

tighten

loosening

the

motor

and

just

enough

speeds

feeds.

Tighten pulley

set

screws

af ter

a few

hours

operation.

TYPES

OF

BITS:

A

variety

of

bits

are

available

for use in

your drill

press.

For

metal

prove adeq uate

drilling

for the

the

standard twist drill will

home

-work

shop.

If

exten-

To

robs

and

Length

of

Cutting

must

be

e quo t

DRILL

SHARPENING:

When grind in g twist

efficiency

cised.

tained,

length,

center

should

included,

cluded,

gradually

ance

of the

The

dead

that

is, the

Fig.

4.

line

of the

be

approximately

for

for

wood.

behind

at the

heel

drill,

center

Also

drill

metal

The

the

is

OPERATION:

Chuck

removal;

If

at any

time

you

loosen

the

it.

This

Do not

you

chuck holding collar

will

force

may

att empt

damage

to

the

the

lips

FIGURE

drills,

4

in

extreme

of the

order

care

point must

cutting lips must

their angle

must

and 35

cutting

cutti ng

about

1 2

wish

to

60

in

be

equal.

degrees,

degrees,

lip

edge

degrees.

remove

should

and

chuck

drive

spindle

or

from

wedge

or

bearings.

the

Heel

of

Cutting

Lip

to

maintain

should

be

be

be the

relation

The

12 0

70

degrees

be

so

that

the

the

chuck merely

continue

spindle taper.

the

chuck

the

exer-

main-

same

to the

angle

degrees

in-

relieved

clear-

to

turn

off as

Page 5

For

extensive

table

of

34

inch plywood will

added work area

of

you r work . Fasten

press

table with

table

also provides a good

shaping

It

drills

material

ing

reverse

through

hole,

fen ce,

af f o r d s

protection

break through

When

drilling

un der

and

mutila tio n

Another

metho d

the

work piece when

and finish the

For

drilling

the

f eed

pivot pins

the

to a

stop nut s

use on

woodworking,

prove

and the

counter sunk

the

prote ction

the

plywood table

screws. This

surface

and

for the

drill press table when

work piece.

from

for

other similar units.

through wood, a piece

work piece

as the

of

pr eserving

hole

d efinite

will

eliminate splinter-

drill p oint breaks through.

the

surf ace

the

point

of

f rom

opposite side.

depth,

such

may be set to the

an

auxiliary

its

worth

shi fting

to the

drill

auxiliary

mou nting

of

scrap

is to

drill breaks

as a

blind

desired

in

a

depth

by

lowering

of

the

work

piece

hole desired.

A

straight piece clamped

or

fence,

has

the

same distance

grooving,

many uses,

fluti ng

or

SAFETY:

The

work piece should

table, either

its

turning with

pensive

and is

work.

The

be

used

work

piece

by

clamps, pins,

the

means

readily

for

of

adaptable

drill

vise

cylindrical work.

as it may

the

drill

to a

mark

on the

corresponding

to the

as in

from

an

edge

to the

table,

drilling

or as a

several holes

milling.

be

held securely

or a

vise,

to

drill. A drill

vise

is an

hol ding many varieties

for use

or a

V-block

In

break drills

with cylindrical

should always

any

case secure your

and fly off the

depth

as a

guide

on the

prevent

of

edge

of

guide

for

inex wo rk

table.

Key

No.

1

2

3

4

5

6

7

8

9

10

1 1

12

13

14

1 5

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

3 1

32

33

34

35

36

37

Part

No.

27415

18413

18212

18414

18415

27727

38617

27217

18604

38632

18512

18120

*X-18I

*X-1407

27623

38628

1851

18410

18429

18422

182

I I

27625

27813

*X-277

38422

27130

38623

**I8I29

*X-413

*X-420

*X-605

27812

27627

27631

38881

27628

27629

PART NAME

Spindle

Pulley

Spindle & Pulley

Pulley

Ball

Inner

Snap Ri ng

Outer Snap Ring

Panel

Panel

Screw

Drill

Head Frame

Hand

Knob

Quill

Lock Sleeve

Quill Lock

-Lock

Hand le

Set

Screw

Allen Wrench 3/ 32

Lock

Handle

Head Lock Sleeve

Knob

1

Lock Screw

Spindle

C ollar with

Washer-Rubber

Washer

Quill

Bearing

Quill

Quill

Gasket

Cap

Screw

Feed

Stop

Spindle

Ass'y.

Chuck

Chuck

Key

Hex

Nut

Hex

Lock

Snap

Feed Stop

Feed

Spring

Lock

Feed

Jam

Nut

"4-20

Washer

Ring

Stop

Screw

Stop Collar

Sleeve

Bearing

Screw

aiuLSei

No.

"4-20

Bracket

J4

Rod

Adjusting Collar

Screw

1 0 -24 x %Soc.

Set

Screw

x 1

J/2 Hex

^-16

Amer.

Std.

Head Cone

Head

PARTS

Pt.

LIST

Key

No.

38

39

40

41

42

43

44

45

46

47

48

49

50

5 1

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

Part

No.

*X-170

18513

18421

27814

27632

38790

*X-417

38460

38876

38692

*X-601

*X-309

X-205

38629

18916

27626

27310

18915

27617

38631

*X-565

**X-1467

38390

»X-3609

'X-1400

27219

27717

38633

38627

38626

27621

27622

27340

27350

38211

*X-185

27104

27979

PART

NAME

Set

Screw

5/ I 6 - 1

8 x

Pinion Shaft Retaining Screw

Washer

Fibre

Bumper

Threaded Stud

Motor

Support Base

Hex Nut

Motor

Roll

Rod Plain

Mack.

Cap

Head

Feed Handle Knob

Feed Handle

Hub,

Feed Return Spring

Pin

Quill Lock

Mach.

V-Belt

Motor

Set

Allen

Table

Column

Lock

Table

Table Lock

Column

Column

Base

Base

Base

Set

Spindle Pulley Ass'y.

Instruction

5/16 -18

Mount

Pin

Motor Support

Washer

Bolt

57 1

Screw

5 / lb -1 8- %

Lock

Rod

Pinion, Sprin g

Screw

No.

1/2

x 45

Pulley with

Screw

5 / 1 6- 18 x '/2 Soc. Head

Wrench

Plug

Handle

Lock Sleeve

for

Model

for

Model

for

Model 1 03. 24 5 2 1 only

for

Model

Lock Shoe

Screw

^/i~

Sheet

Y2 Soc.

Ass'y

Complete

1 I

/ 3 2 I.D.

6-18i-LSquare

8- 32 x %

inches long

5 /32

103 .24 531

I 3 x 1 ^ Square Head

and

x I I

Hex. Head

& Pin

Set

Screw

1 0 3 . 2 4 5 2 1

1 0 3 . 24531

Parts

Hd.

/ 1 6 O.D.

Ass'y.

Rd.

only

only

only

List.

Cone

Head

Head

Pt.

This

The

*Items

houses.

sheet

parts

'Standard

are

regu lar stock

May

is

intended

shown

and

hardware

also

for

listed

For

Illustration—See

in

be

ordered

instruction

may

include

page

6

items—may

Sears h ardware departments

as

repair

and

accessories

repair

be

purchased

parts

parts

not

by

part number provided.

only

and is not a

necessarily

locally.

and

mail order

part

packing

of

this

slip.

tool.

Page 6

—72

SPINDLE

ASS'Y.

PULLEY

45

MOTOR

INCLUDES

MOUNT

COMPLETE

ITEMS

41

ASS'Y.

THRU

49

Loading...

Loading...