Page 1

OPERATING INSTRUCTIONS

AND PARTS LIST FOR

CRAFTSMAN

JOINTER

4_/_INCH

Model Number 103.23340

This is the model number of your Jointer. It will be found

on a platelocated on the right side of the front table,

Always mention this model number when communicating

with us regarding your Jointer or when ordering parts.

......................HO'4V TO ORDER REPAII-4 PARTS _ -

All parts listed herein may be ordered through Sears, Roebuck

and Co. or Simpsons-Sears Limited. When ordering parts by mail

from the mail order house which serves the territory in which you

live, selling prices will be furnished on request or parts will be

shipped at prevailing prices and you will be billed accordingly.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOL-

LOWING INFORMATION AS SHOWN IN THIS LIST:

1. The PART NUMBER.

2. The PART NAME.

3. The MODEL NUMBER.

4. The NAME of item.

This list is valuable. It will assure your being able to

obtain proper parts service. We suggest you keep it with

other valuable papers.

SEARS, ROEBUCK and CO.--U.S.A.

SIMPSONS-SEARS LIMITED--CANADA

LITHOGRAPHED IN U. S.A.

SOURCE FORM 29939

Page 2

OPERATING INSTRUCTIONS AND PARTS LIST FOR

MODEL NUMBER 103.23340

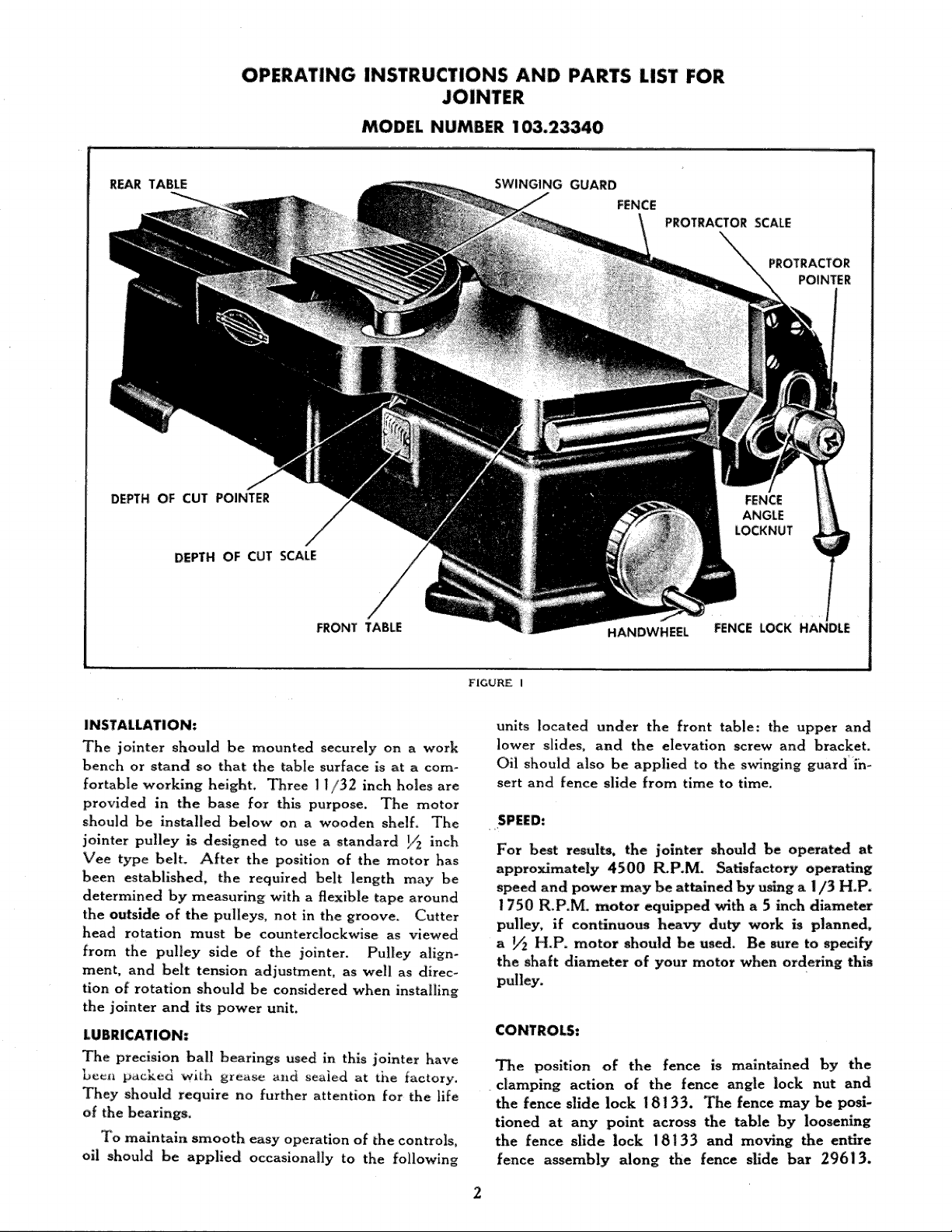

REAR TABLE

DEPTH OF CUT POINTER FENCE

DEPTH OF CUT SCALE

FRONT TABLE

SWINGING GUARD

FENCE

PROTRACTOR SCALE

ANGLE

HANDWHEEL FENCE LOCK HANDLE

PROTRACTOR

POINTER

INSTALLATION:

The jointer should be mounted securely on a work

bench or stand so that the table surface is at a com-

fortable working height. Three 11/32 inch holes are

provided in the base for this purpose. The motor

should be installed below on a wooden shelf. The

jointer pulley is designed to use a standard ]/_ inch

Vee type belt:. After the position of the motor has

been established, the required belt length may be

determined by measuring with a flexible tape around

the outside of the pulleys, not in the groove, Cutter

head rotation must be counterclockwise as viewed

from the pulley side of the jointer. Pulley align-

ment, and belt tension adjustment, as well as direc-

tion of rotation should be considered when installing

the jointer and its power unit.

LUBRICATION:

The precision ball bearings used in this jointer have

beet_ packed with grease slid sealed at the factory.

They should require no further attention for the life

of the bearings.

To maintain smooth easy operation of the controls,

oil should be applied occasionally to the following

FIGURE I

units located under the front table: the upper and

lower slides, and the elevation screw and bracket,

Oil should also be applied to the swinging guard ih-

sert and fence slide from time to time.

SPEI:D:

For best results, the iointer should be operated at

approximately 4500 R.P.M. Satisfactory operating

speed and power may be attained by using a I/3 H.P.

1750 R.P.M. motor equipped with a 5 inch diameter

pulley, if continuous heavy duty work is planned,

a _ H.P. motor should be used. Be sure to specify

the shaft diameter of your motor when ordering this

pulley.

CONTROLS:

The position of the fence is maintained by the

clamping action of the fence angle lock nut and

the fence slide lock 18133. The fence may be posi-

tioned at any point across the table by loosening

the fence slide lock 18133 and moving the entire

fence assembly along the fence slide bar 29613.

Page 3

The fence lock handle is designed so that it may be

disengaged after use on the lock nut and will hang

in a neutral position as shown. The angle between

the fence and the table may be changed for beveling

operations by loosening the fence angle lock nut. The

angle selected for the bevel cut is indicated on the

protractor scale. After changing the fence position

as described above, check carefully that the fence

angle lock nut is secure before proceeding with a cut-

ting operation.

The handwheel when turned will raise or lower the

front table, thus regulating the depth of cut as in-

dicated by the depth of cut pointer and scale.

ADJUSTMENTS:

If at any time the cut obtained should vary from that

indicated on the depth of cut scale the following

adjustment may be made. Set the front and rear

tables at the same level and check with a straight-

edge. Loosen the screw X2951 holding the pointer

29719, and shift the pointer until it indicates zero

on the scale. Tighten the screw securely after making

the above adjustment°

If a 90 ° setting of the fence angle protractor does

not produce square cuts the fence may be reset square

with the table by using an accurate tri-square. After

the 90 ° relation between the fence and table has been

established, the screw X2951 holding the protractor

pointer may be loosened and the pointer reset at 0.

If a gouge or step is produced at the end of a cut

it is an indication that the rear table is too low.

Likewise. the cut may diminish or taper as the work

is pushed through as a result of a high rear table.

Either of these conditions may be rectified by aligning

the table surfaces in the following manner. Lay a

straightedge across both tables as shown in figure 2.

By adjusting any of the six leveling jacks 18516 as

needed, set the tables so that they are level and in

the same plane, so that when the cutter head is

turned slowly by hand, the knives -will touch the

straightedge lightly at either side of the table. The

leveling jacks 18516 may be adjusted by loosening

the lock screws X232. After the jacks have been

adjusted and the tables are in their proper relation

to each ether and to the cutter head, hold the jacks

with a wrench so that they will not turn while re-

tightening the lock screws.

Trial cuts should be made after any adjustment

or repositioning to make sure that no other control

unit has been disturbed and that all controls are

f,,ncHonin_ it) proper r_lztion to each other.

Note: After a few hours of operation tighten all

pulley set screws.

SHARPENING THE BLADES:

The three 4_ inch high speed steel cutter knives

1812 7 will give satisfactory cutting surface for many

hours of operation without reg_nding, if they are

honed occasionally with a fine abrasive stone to re-

touch the edge. This operation can be performed as

shown in figure 3. It is not necessary to remove the

cutter blades from the head. Before honing, cover

part of the stone with paper as shown to prevent

injury to the table surface. For satisfactory results,

the original bevel angle must be maintained on the

knives. With the handwheel adjust the front table

level so that the stone when resting on the table will

touch the full width of the knife bevel. Secure the

cutter head in the desired position by inserting a

wooden wedge between it and the table as shown.

Place the paper-covered portion of the stone on the

table and by moving the stone back and forth, hone

the full length of each knife in turn.

The small burr on the flat side of the blades may

be removed by a few light strokes with a fine abrasive

stick or a piece of emery cloth.

CAUTION !

To insure safe operation of the machine, blades

should not be reinstalled which have been ground

down to less than 9/16 inch in width.

RESETTING BLADES:

if the blades are removed from the cutter head, ex-

treme care should be exercised at time of replace-

ment.

Set both tables at the same level---check with an

accurate straight-edge as shown in fig 2. The dis-

tance from the table surfaces to the cutter head

should be the same at each end of the cutter head.

Adjustment of the tables may be made with the

leveling jacks as explained under "'adjustments".

Install the blades so that they project 1/16 inch

at left hand end of the cutter head. The edges should

project slightly above the level of the table surfaces.

Clamp the blades lightly in position. The flat point of

each set screw must engage the bevel on the face of

each wedge. See inset, Fig. 2. With the straightedge

REAR CUTTER STRAIGHTEDGE SET FRONT

FIGURE 2

SCREW TAB|E

L

Page 4

ABRASIVE STONE

on the table as shown in fig. 2, tap the blades into the

cutter head with a piece of hardwood until the knife

edge just touches the straightedge lightly at either end

of the blade as the cutter head is turned by hand.

When all three blades have been aligned in the above

manner, tighten the nine set screws" securely.

OPERATION:

The swinging guard shown in figure i should be in

operating position at all times except during rabbet_

ing operations at which time it may be removed by

lifting it straight up out of its hexagonal socket in

the front table.

CUT

FIGURE 4

FIGURE

3

For the rabbeting operations, the fence is shifted

from its normal position at the right hand edge of

the table to the desired position on the left hand

side. The width of cut is determined by the dis-

tance from the end of the cutter knives to the fence.

(See figure 4).

Face planing or surfadng is the most common

function of the jointer, yet extreme care must be exer-

cised during this operation. The depth of cut should

be determined by the width of the material; the _der

the material, the less the cut. In most cases a 1/32

cut will produce the best surface.

Deeper cuts should be made in successive passes

across the cutter head until the full depth has

been attained. The work should be advanced

through the guard to the cutter head with a smooth

slow feed. Place both hands on top of the work

piece, the left hand pressing the piece firmly against

the rear table surface, the right hand exerting the

feed pressure over the front table.

When cutting pieces over three feet in length,

the most uniform cut _ll be maintained by support-

ing the piece at table height after it leaves the rear

table surface.

Warped stock should be cut on the concave side

for best results. To avoid pitting or torn grain it is

advisable, wherever possible, to determine which

Page 5

way the grain emerges on the surface of a piece of

wood. The direction of feed should be governed

accord:ngly; the grain should emerge on the lower

surface of the piece and should point toward the

front of the jolnter.

When surfacing thin stock (_ inch or less), a

push block should always be used.

Because of the cut-out in the lower edge of the

fence, designed for clearance at a maximum depth

of cut setting, a guide surface is not available beyond

the cutter head when surfacing stock less than

inch thick, It may be necessa_ to clamp an auxiliary

face to the fence if a guide is needed under the

above circumstance. This "'face piece" should be

PARTS LIST

attached after the front table position has begn estab-

lished, and should rest on the rear table surface,

The function of the fence in the beveling operation

has been described in the paragraph on controls.

The s_nging guard was incorporated for your

safetyuuse it to its best advantage.

To be sure you will make a depth of cut as

planned, always lower the table beyond the depth

wanted and then crank the table up to the correct

depth.

An interesting booklet covering special opera-

tions which may be performed on your jointer is

available.

Part No.

18127

18133

18231

18437

18516

18620

18711

18713

18716

18922

29109

29110

29201

29202

29204

29212

29216

29220

29412

29413

29414

29416

29419

29421

29422

29423

29424

29425

29613

29615

29618

29622

29624

Pa_ Name

Cutter blades _ Purchase from nearest

Sears retail store or mail order house,-Ask

for Cat, No, 9-2291

Fence Slide Lock Handle

Ball Bearing

Washer

Leveling Jack

Hand Wheel with Set Screw

Clevis

Pin

Bracket

Protractor Pointer

Cutterhead Ass*y Complete--_|ncludes

blades, wedges, and set screws

Swinging Guard

Cutter Head with Set Screws

Base with Depth of Cut Scale and Retain-

ing Rings No. 29722

Front Table

Rear Table

Fence Slide

Pulley with Set Screw _ Purchase from

nearest Sears retail store or mail order

house. 2 inch single groove V-pulley

inch bore. Ask for Cat:. No. 9-280t--1/_

inch bore.

Fence Angle Lock Nut

Spacer

Protractor

Swinging Guard Insert

Lower Slide

Upper Slide

Gib, R. H.

Gib, L H.

Fence

Fence Angle _ck Handle

Fence Slide Bar

Elevating Screw

Wedge

Stud

Arbor

*Standard hardware items_may be purchased locally.

Part Na_ Pa_ Name

29712

29715

29717

29718

29719

29722

29723

29724

29811

*XI09

Fibre Washer

Link

Depth of Cut Scale

Bracket

Depth of Cut Pointer

Retaining Ring

Spacer

Snap Ring

Spring

Set Screw--No. 10--24 x ¼ Slotted Hd.

Cup Point

_XI21

Setf!crew_5i16--24 x _Socket Hd.

Dog Point

aXi62

Set Screw_20 x 5_ Slotted Hd. Half

Dog Point

*X174

Set Screw 5/1_18 x _ Socket Hd, Cup

Point

aXI76

Set Screw 5/16_24 x ½ Socket Hd. Cup

Point

aX205

*X210

*X212

*X232

X330

Cap Screw 5/16_18 x _ Hex Hd.

Cap Screw I/_20 x I Hex Hd.

Cap Screw 5/16_18 x 11/_ Hex Hd.

Cap Screw 5/16_ 18 x l _ Hex Hd.

Math. Screw _16 x I_ Phillips-Fil-

lister Hd.

_X420

_X516

X546

*X547

*X605

_X611

*X629

_XII01

*XI326

*X1403

*X2450

Hex Nut 1_--20,

Math. Screw No. 8--32 x V4 Round Hd,

Math. Screw 1_20 x _ Fillister Hd.

Mach. Screw No. t0_24 x 1_ Round Hd.

Lock Washer 1A I.D. x _ O,D.

Lock Washer 5/16 i.D, x t/_ O,D,

Plain Washer 5/32 I,D. x 5/16 O,D.

Cotter Pin 1/16 x 1/2

Drive Screw No. 4 x 3/16

Allen Wrench 5/32

External Lock Washer No. I 0 I.D. x 13/32

O.D.

_X2951

Mach. Screw No, 6_32 x 1_ Round Hd.

_is sheet is intended for instruction and repair pa_s only and is not a packing slip.

The parts shown and |istd may in¢lude aecesaories not necessarily part of this t_i,

5

Page 6

291 (210

29416

29202

18437

18516

29204

29719

X627--

X2951

29811

29718

X516-_

X1403-

X176

18127

29618'

X121

29722

29220

fX330

18133

29421

Xll01

18716

X420

29715

18711

X210

29422

29419

29423

X2450

X547

18231

.29722

X61

29724 /

x--29615

29717

_---X232

29109 ASSEMBLY

FIGURE 5

6 29909-2--10-54---4,800

Loading...

Loading...