Page 1

OPERATING INSTRUCTIONS

AND PARTS LIST FOR

BENCH SAW

8-INCH

Model Number 103.22880

This is the model number of your Bench Saw. It will be

found on a plate on the right side o£ the base. Always

mention this model number when communicating with

us regarding your Bench Saw or when ordering parts.

,4 i

REFER "iO THE PAk'FS Li._,'i ©_ k,j

IN THIS BINDER FOR CUP, i",EF4-,'

AVAiLABILiTY, SELL!I<C ['FiC£

AND ORDERING INFORMATION.

D,v. 5-- L_'L;L_<L.c ,_,

•Filing Instructions

File this parts list immediately behind parts list number

103.21790 in the Division 9 Standard Nomenclature

GREY BINDER Volume I.

SEARS, ROEBUCK and CO.

June, 1949

Source Fo_'m 339_9

Page 2

OPERATING INSTRUCTIONS AND PART5 LIST

FOR BENCH 5AW MODEL 103.22880

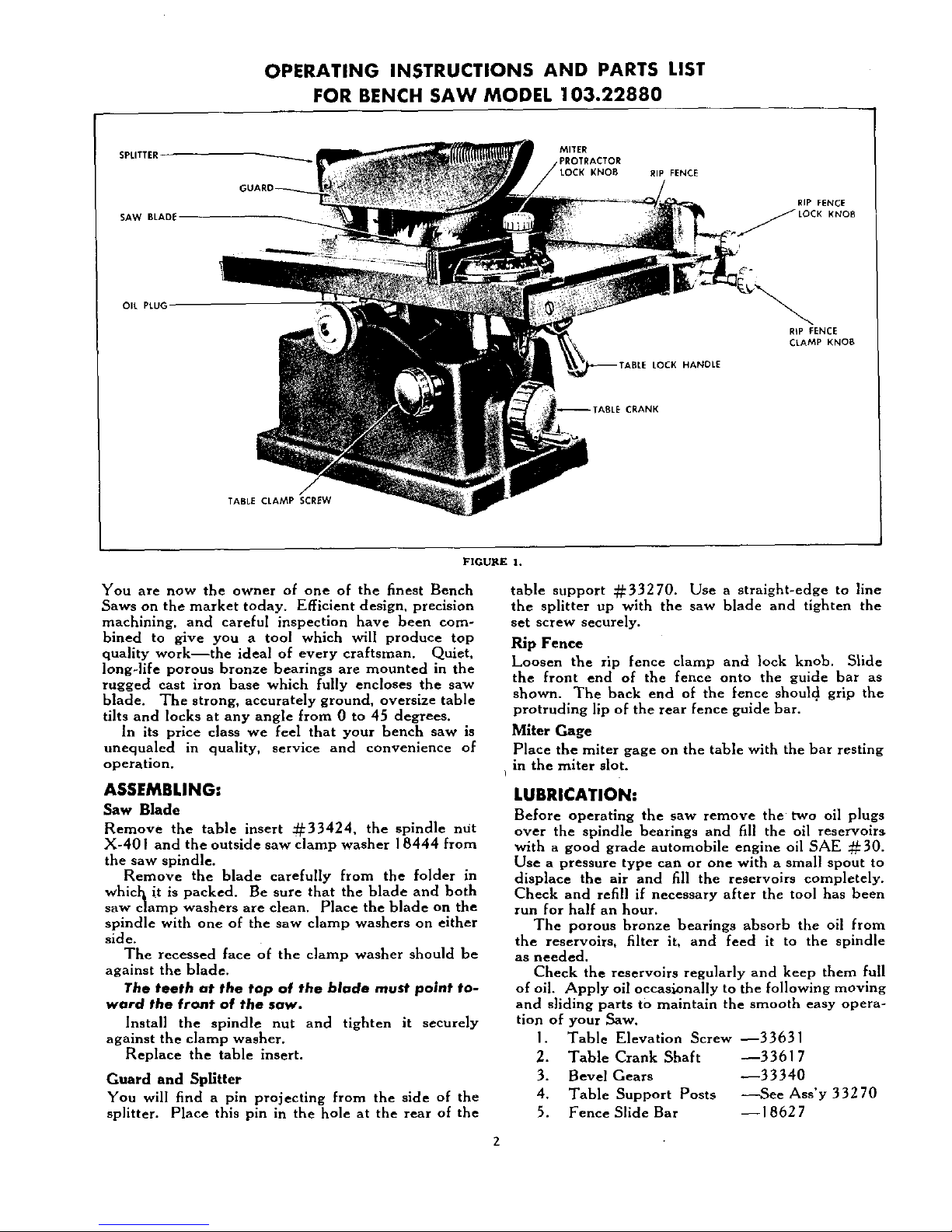

SPLITTER-

SAW BLADE

MITER

LOCK KNOB

RIP FENCE

RIP FENCE

KNOfi

OIL PLUG

HANDLE

R_P FENCE

CLAMP KNOB

"ABLE CRANK

TABLE CLAMP SCREW

FIGURE 1.

You are now the owner of one of the finest Bench

Saws on the market today. Efficient design, precision

machining, and careful inspection have been com-

bined to give you a tool which will produce top

quality work--the ideal of every craftsman. Quiet,

long-life porous bronze bearings are mounted in the

rugged cast iron base which fully encloses the saw

blade. The strong, accurately ground, oversize table

tilts and locks at any angle from 0 to 45 degrees.

In its price class we feel that your bench saw is

unequaled in quality, service and convenience of

operation.

ASSEMBLING:

Saw Blade

Remove the table insert _33424, the spindle ntit

X-401 and the outside saw clamp washer 18444 from

the saw spindle.

Remove the blade carefully from the folder in

whic_ it is packed. Be sure that the blade and both

saw cramp washers are clean. Place the blade on the

spindle with one of the saw clamp washers on either

side.

The recessed face of the clamp washer should be

against the blade.

The teeth at the top of the blade must point to-

ward the front of the saw.

Install the spindle nut and tighten it securely

against the clamp washer.

Replace the table insert.

Guard and Spfitter

You will find a pin projecting from the side of the

splitter. Place this pin in the hole at the rear of the

table support :#:33270. Use a straight-edge to line

the splitter up with the saw blade and tighten the

set screw securely.

Rip Fence

Loosen the rip fence clamp and lock knob. Slide

the front end of the fence onto the guide bar as

shown. The back end of the fence should grip the

protruding lip of the rear fence guide bar.

Miter Gage

Place the miter gage on the table with the bar resting

in the miter slot.

I

LUBRICATION:

Before operating the saw remove the two oil plugs

over the spindle bearings and fill the oil reservoirs

with a good grade automobile engine oil SAE :_30.

Use a pressure type can or one with a small spout to

displace the air and fill the reservoirs completely.

Cheek and refill if necessary after the tool has been

run for half an hour.

The porous bronze bearings absorb the oil from

the reservoirs, filter it, and feed it to the spindle

as needed.

Check the reservoirs regularly and keep them full

of oil. Apply oil occaslonally to the following moving

and sliding parts to maintain the smooth easy opera-

tion of your Saw.

1. Table Elevation Screw --33631

2. Table Crank Shaft --33617

3. Bevel Gears --33340

4. Table Support Posts -----See Ass'y 33270

5. Fence Slide Bar --18627

Page 3

INSTALLATION:

Three I I/32 inch diameter holes are provided in the

base through which your bench saw should be se-

curely fastened with screws or bolts to a well con-

structed work table or bench.

The saw is designed so that you can mount the

motor below the saw out of the way, the belt travel-

ing through a hole cut in the bench. A large hole

in the bench below the blade will allow sawdust to

drop through. A simple deflection panel may be in-

stalled to keep sawdust off the motor.

Note: If you prefer to install the motor behind the

saw on the bench, it will be necessary to block up the

saw approximately 2 I_ inches above the level of the

motor base to provide clearance for the belt at the

rear edge of the table when the recommended

motor and pulleys are used.

MOTOR:

For general use a I/_ horsepower 1750 R.P.M. motor

will drive the saw with sufficient power.

SPEED:

A 5 inch diameter pulley on the 1750 R.P.M. motor

will drive the saw at the recommended speed--4500

R.P.M.

Caution: If a 3450 R.P.M. motor is used it should

be equipped with a pulley not larger than 2 I_ inches

in diameter.

BELT:

The pulley on your bench saw is intended for use with

a I_ inch wide standard V-belt. When the motor

and saw position is established, measure with a flex-

ible tape around the outside of the pulleys, not in the

V-groove, to determine the length of belt needed.

CONTROLS:

The Table Crank when turned raises or lowers the

table in relation to the saw blade to regulate the depth

of cut.

The Table Clamp Screw when tight locks the table

at the selected elevation. This screw must be loose

when making a change in table height.

The Table Lock Handle is a wrench used to lock

the table in place at any angle from 0 ° to 45% To

tilt the table engage the hex socket of the wrench

on the head of the table lock nut 33422 and turn it

counter-clockwise slowly until the table will tilt with

slight hand pressure on the right hand edge. After

the table is locked in position, the handle may be dis-

engaged from the lock nut and will hang in neutral

position.

The angle of tilt is shown by the pointer on the

calibrated protractor scale just behind the handle.

For your convenience the table leveling screw and

45 ° stop screw have been incorporated to automati-

cally stop the table at 90 ° and 45 ° to the blade.

Caution: Always raise the table at least ¼ inch

from the lowest setting before tilting to 45 ° . The

extra long spindle (for greater dado set capacity)

will hit the table insert from below if the table is not

raised before tilting.

The Rip Fence Clamp Knob when tight clamps

the front of the fence to the fence bar and holds the

fence parallel to the saw blade.

The Rip Fence Lock Knob when tight ,locks the

r_ar of the fence in place by gripping the rear fence

baT.

When changing the position of the fence, loosen

both the lock knob and the clamp knob--slide the

fence to the new position--tighten first the clamp

knob, and then the lock knob.

The Miter Protractor Lock Knob locks the Pro-

tractor at any position from 30 ° to 90 ° in either di-

rection. The angle is shown by the pointer on the

calibrated scale of the protractor.

ADJUSTMENTS:

Every adjustment of your bench saw was carefully

checked and tested before the tool left the factory.

However, due to the exposure of the tool to rough

handling during shipment it might be wise to check

the following points before operation to insure accur-

ate results.

1. The Blade Must Be Parallel With the Miter Slots.

Check as shown in figure 2. Measure from the

same side of the same tooth each time.

2.

LOWEkrAI_E

TO'_LL_PTn

OSCU"

_ISTANCESHO_LD

|EE'_'L

5_[ IOOTH

ATTAK_L[VEL

J

I fENCE_U5 T

.OCKrAmALL_L

Wt_H _ITE_

SLOT

rENC_ AOJUITI_'_ ICl[_

FIGURE 2.

Adjustment may be made by loosening the two

cap screws X205 which hold the table to the tilt

protractor until the table will shift slightly when

tapped with a mallet or block of wood. When

the blade and slots are parallel, tighten the two

cap screws securely.

The Fence Must Lock Parallel With The Miter

Slots. Check by sliding the fence to the edge of

the nearest slot. Tighten the clamp knob against

the front bar. (Do not tighten the lock knob),

The fence should remain perfectly parallel with

the slot.

To adjust loosen the two screws just forward of

the lock knob. See figure 2. With the clamp

knob still tight, pivot the fence until it is parallel

with the miter slot along its full length. Retighten

the two screws.

Page 4

. The Table Leveling Screw should stop the table

at right angles to the blade. See figure 3. Check

with an accurate square. If the table is not square

adjustment of the leveling screw

necessary. Tighten the lock nut securely

after turning the screw.

~45 ° STOP

SCREW

TABLE TILT

PROTRACTOR

FIGURE 3.

4. The 45 ° Stop Screw should stop the table at an

angle of 45 ° to the blade. See figure 3. Check

carefully, if adjustment is necessary, tighten the

lock nut securely after turning the screw. It may

be necessary to reset the pointer to indicate the

proper angle on the tilt scale.

5. The Miter Protractor must be square with the bar

when the pointer shows 90 ° on the protractor

scale. Check with an accurate square and reset

the pointer if necessary.

6. The Table Insert should be flush with the table

surface. To-adjust, loosen the two slotted head

screws (X-532) which you can see from the top

of the insert. You will find four small set screws

(X115) coming up through from the bottom of

the table, two against the front and two against

the rear of the insert. By turning these four

screws slightly, the insert may be leveled and

brought flush with the table surface.

CARE OF THE BLADE:

The blade supplied with this bench saw will give

many hours of efficient cutting service in the average

home workshop without requiring sharpening. When

the teeth become blunted and dull, and a definite de-

crease in cutting efficiency is noted, the blade may be

put hack in good condition again as follows:

1. Raise the table until an oilstone laid on the table

surface will just touch the teeth of the blade. Turn

the blade backwards by hand until the ends of

all the small cutting teeth have been touched and

are the same length.

2. With an 8 inch round edge mill file, file the gullets

(space between the teeth) of all teeth of the same

shape to a uniform depth and width. Maintain

the original shape, bevels, and dimensions. Avoid

sharp corners and nicks in the gullets.

.

The top one-quarter of each cutting tooth should

be set at an angle of approximately 10 degrees.

set should be uniform and should alternate

!lt to right on successive teeth. T_he large

require no set--they should be kept

bapproximately 1/64 inch shorter than the cutting

teeth.

File the bevel of each cutting tooth--I 5 to 20

degrees bevel on the inside front face of each

tooth. Maintain the original bevel angle and be

careful not to shorten the teeth,

Blade Wobble is often noticed at slow speeds

starting or stopping the saw. If this does not

at full speed, check the saw blade and

amp washers for dirt or saw dust on the clamping

'rfaces.

Gummy residue can generally be removed with

'ERATION:

provided with this saw may be used for

both cross-cutting and ripping. However, if continu-

ous ripping or continuous cross cutting is planned,

a rip blade or cross cut blade will operate much more

efficiently.

For proper chip clearance and best general results,

the blade should project through the work-piece

approximately I_ inch.

Saw warped stock with the concave or hollow face

d o'*v'n.

Support long work as it leaves the rear of the table.

Avoid back tracking on a cut.

Do not force material into the blade too fast. Use

a straight, direct, steady feed which does not over-

tax the cutting capacity of the blade.

SAFETY:

While the bench saw is one of the most widely used

woodshop power tools, it is by nature of its general

design, one of the most dangerous in the hands of

inexperienced or careless operators. The bench saw

is not, however, an unsafe tool when used with com-

mon sense and good judgment.

Use a push block rather than letting the hands get

closer than 3 inches to the blade on narrow cuts.

Keep the splitter in place whenever possible. Never

hold the hands over the blade when making blind

groove type cuts. Stand to one side when completing

a cut. A loose piece caught by the blade can fly

back with surprising force.

Always stop the saw when removing waste stock

from near the blade, when making adjustments, or

when changing settings.

Do not wear dangling neck ties, loose baggy

sleeves, etc., while operating power tools.

The guard is supplied with this saw for your safety

--use it to its best advantagel

ACCESSORIES for this saw will be listed in your

catalog or can be obtained from your nearest Sears

Retail Store. An interesting and instructive booklet

entitled "The Circular Saw" is also .available. It

explains many handy special operations which may

be performed on your bench saw.

Page 5

PARTS LIST

PART NO.

18035

18128

18419

18444

1852T

18524

18619

18624

18627

18630

18922

18931

18969

18983

18984

_18992

PART NAME

Pulley with Set Screws .................

Pence Clamp ........................

Fence Guide Spacer ...................

Saw Clamp Washer ...................

Lock Knob Washer ...................

Fence Rod Nipple ....................

Fence Lock Knob ....................

Fence Guide Bar--Rear ...............

Fence Guide Bar--Front ...............

Fence Clamp Knob ...................

Table Tilt Pointer ....................

Oil Hole Plug .......................

Fence End--Rear ....................

Fence End--Front ...................

Fence Equalizer ......................

8 inch diameter--_ inch bore Combination

Blade. Purchase from nearest Sears' Retail

Store or Mail Order house .............

ART NO.

33101

33102

33107

PART NAME

Rip Fence Assemh]y complete ......... '

Miter Gage Assemby complete ..........

Ba_e Assembly--includes 2 Bearings 33813,

and 2 Oil Plugs 18931 ................

33110 Spindle ............................

33170 Spindle Collar and Set Screw ...........

33216 Table

............................. /

33240 Miter Bar ..........................

33250 Table Elevation Lock .................

33270 Table Support .......................

33290 Splitter ............................

333 I 0 Collar and Set Screw ..................

33340 Bevel Gear and Set Screw ..............

33360 Handwheel .........................

33412 Table Tilt Lock Handle ................

33414 Table Tilt Protractor .................

33417 Lock Knob .........................

3342 I Miter Protractor .....................

*Parts marked in this manner may he purchased locally.

33270

X-116 X-110

33414

X-601

X-420

33412

X-1400

33813

X-IO0

X-174_, €

33170

18035

1

33250

IO

3334o

33310

33617

1

X-413

33360

FIGURE 4_BASE AND RELATED PARTS

Page 6

PART NO.

33422

33423

33424

33611

33617

33622

33628

33631

33633

33711

33713

33717

33812

33813

_XIO0

_XI02

*XIIO

_XII5

_XII6

_XI24

_X 155

PART NAME

Table Tilt Lock Nut ................ ,

Saw Guard .........................

Table lnoert ........................

Fence Lock Rod .............. "[ ......

Table Crank Shaft ...................

Retaining Screw .....................

Saw Guard Pivot Pin ..................

Lift Screw ..........................

Table Pivot Pin ......................

Base Partition .......................

Miter Protractor Pointer ...............

Fence .............................

Snap Ring ..........................

Spindle Bearing ......................

Set Screw 1_-20 x I_ Slotted Hd. Cup Point.

Set Screw 1_-20 x _ Square Hd. Cup Point

Set Screw 1_-20 x :34 Square Hd. Cup Pt..

Set Screw 10-24 x 3_ Slotted Hd. Cup Point.

Set Screw _-20 x I Square Hd. Cup Point..

Set Screw 5/16-24 x _ Socket Hd. Cup Pt..

Set Screw 10-24 x 3_ Slotted Hd. Cone Point

*Parts marked in the, .... ,her

PART NO. PART NAME

_XI74 Set Screw 5/I 6-18 x 5/I 6 Socket Hd, Cup Pt,

'sX183 Set Screw 10-24 x I/_ Socket Hd, Cup Point

_X205 Cap Screw 5/16-18 x 3_ Hex Hd .........

X244 Cap Screw I/_-20 x ] Fillister Head .......

_'X304 Machine Bolt _-16 x 2 Square Head ......

_X382 Machine Screw _-20 x 3_ ..............

_X401 Hex Nut--1_-20 .....................

'*X413 Hex Nut--_-16 .....................

_'X420 Hex Nut--1_-20 .....................

'_X429 Hex Nut--10-32 .....................

_X512 Machine Screw 8-32 x _ Round Head ....

_X520 Machine Screw 10-32 x I_ Flat Head .....

X532 Machine Screw 10-24 x 7/16 Fillister Head.

_'X539 Machine Screw 10-24 x _ Round Head ....

X546 Machine Screw _-20 x _ Fillister Head . . .

_X601 Plain Washer 5/16 Std .................

_X605 Lock Washer ¼ Std ...................

a'X606 Plain Washer 3_ Std ...................

_X61 I Lock Washer 5/16 Std .................

_X615 Plain Washer I_ Std ...................

¢XI400 Allen Wrench 5/32 ...................

_'XI803 Sheet Metal Screw No. 12 x _ ..........

may be purchased locally.

FENCE ASS'Y 18969

COMPLETE

33101

18524"_

33290__

33628 X-532/_

33424

33717

MITER GAGE

X-382 ASS'Y COMPLETE

33102

X-615

_18630

33240

X-546

33216

X-420

FIGURE 5--TABL_ AND REBATED PARTS

6 6-49--1700

Loading...

Loading...