Page 1

OPERATING

INSTRUCTIONS

AND PARTS

I,IST FOR

CRAFTSMAN

BEI,T

AND DISC

SANDER

6INCH

Model Number

f

03.?;25jOO

HOW TO

OI?DER

REP.S,IR P^A.RTS

All

parts

listed herein rnay be ordered

through

Sears,

Roebuck

and Co. or Sirnpsons, Sears

Lirnited. When ordering

parts

by rnail

frorn the

rnail

order

house which serves the territory

in

which

you

live,

selling

prices

will

be

furnished on

reguest

or

parts

will be

shipped

at

prevailing

prices

and

you

will

be billed

accordingly.

WHEN

ORDERING

REPAIR PARTS, AITWAYS GM

THE

FOIJ-

IJOWING

INFORMATION AS SHOWN

IN THIS IIIST:

l. The PART

NUMBER.

2.

The PART NAI\[E.

3.

The MODEIJ NUMBER.

4. The NAME of

itern.

SEARS,

ROEBUCK and

CO.-L.S.A.

This

is

the

rnodel nurnber of

your

Sander.

It

will

be

found on a

plate

on

the base.

Always

rnention

this

rnodel

nurnber

when conununicating

with us

regarding

your

Sander or

when

ordering

parts.

This

list is

valuable.

It wiII

to obtain

proper

parts

service.

with

other

valuable

papers.

assure

your

being

able

We

suggest

you

lreep it

SIMPSONS,

SEARS

I,IMITED-CANADA

LITHOGRAPHED

IN

U.

S.

A.

SOURCE

FORM 47919

Page 2

OPERATING INSTRUCTIONS AND

PARTS LIST FOR

SANDER

Model Number

lO3.225OO

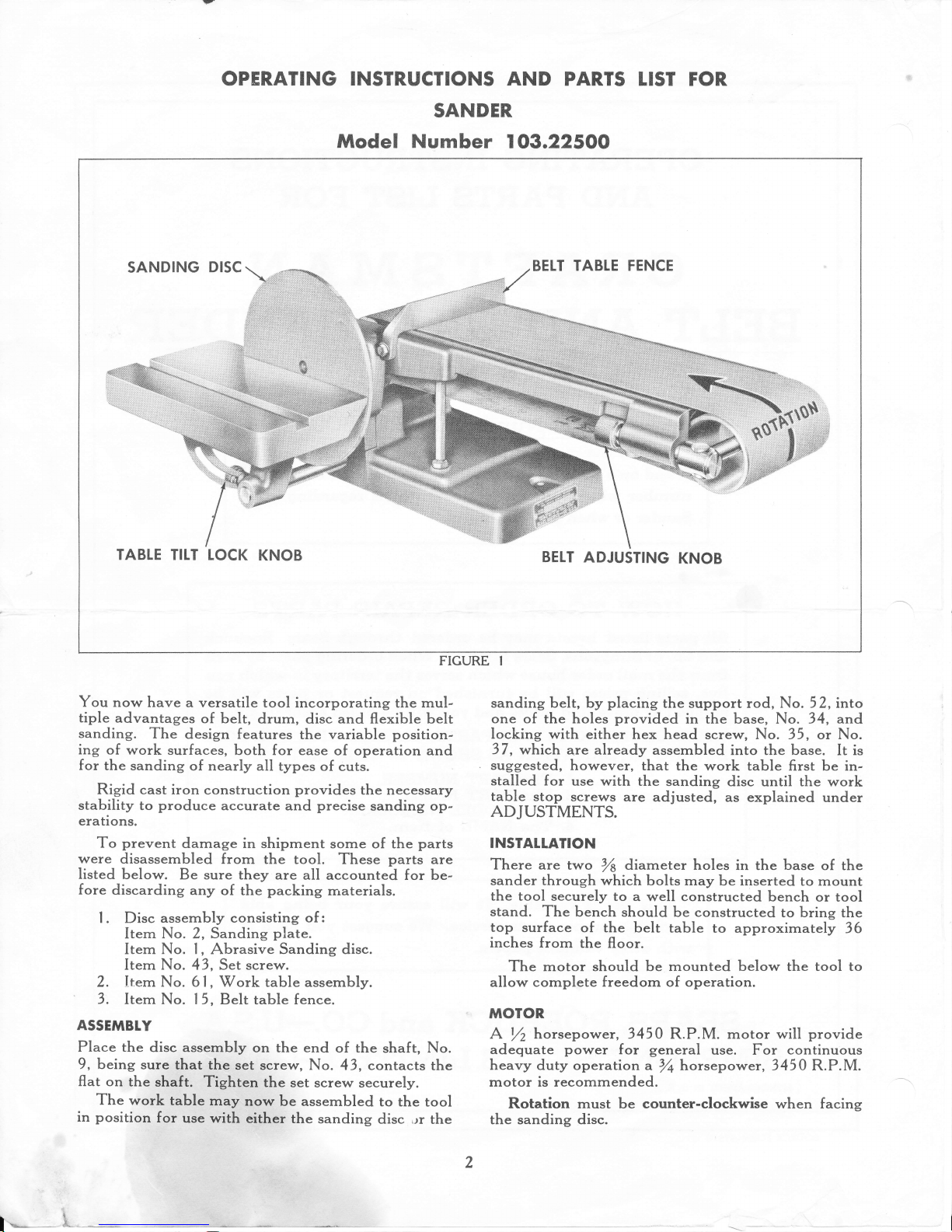

SANDING

DISC

FENCE

TABLE

TILT LOCK

KNOB

BELT

ADJUSTING

KNOB

TABTE

FICURE

I

You now

have

a versatile

tool incorporating the mul-

tiple

advantages

of

belt,

drum, disc and fexible belt

sanding.

The

design features

the variable

position-

itg of

work surfaces,

both for

ease

of operation and

for

the sanding

of

nearly all

types

of

cuts.

Rigid

cast iron

construction

provides

the

necess

ary

stability

to

produce

accurate

and

precise

sanding

op-

erations.

To

prevent

damage in

shipment

some of the

parts

were

disassembled

from

the

tool. These

parts

are

listed

below.

Be sure they

are all

accounted for be-

fore

discarding

any

of the

packing

materials.

|

.

Disc

assemblv consisting

of

:

Item No. 2, Sanding

plate.

Item

No. l,

Abrasive

Sanding

disc.

Item

No.

43, Set screw.

2. Item No. 61, Work

table assembly.

3.

Item No.

15, Belt

table fence.

ASSEMBLY

Place the

disc assembly

on the end

of the

shaft,

No.

9

,

being

sure

that the

set

scr€w, No.

43, contacts

the

fat

on

the

shaft.

Tighten

the set

screw

securely.

The

work

table

may

now

be assembled

to the

tool

in

position

for

use with

either

the

sanding

disc

,rr

the

sanding belt, by

placing

the support rod,

No. 52,

into

one

of the holes

provided

in

the

base,

No.

34, and

locking with

either hex head

screw, No. 35,

or

No.

37,

which

are already

assembled

into the base.

It

is

suggested,

however,

that the

work table first

be

in-

stalled for

use with

the

sanding

disc

until

the

work

table

stop screws

are

adjusted, as explained

under

ADJUSTMENTS.

INSTALLATION

There are two

V's

diameter

holes in the base

of the

sander through which

bolts may

be inserted

to mount

the tool

securely to

a

well

constructed

bench

or tool

stand.

The

bench

should be constructed

to

bring

the

top

surface

of the

belt

table

to approximately

36

inches

from

the

floor.

The

motor should

be mounted

below

the tool to

allow

complete

freedom

of operation.

MOTOR

A

Yz

horsepower, 3450

R.P.M. motor

will

provide

adequate

power

f

or

general

use. For

continuous

heavy

duty operation

a

%

horsepower, 3450

R.P.M.

motor is recommended.

Rotation

must

be

counter-clockwise when

facing

the

sanding disc.

*---*

h-

Page 3

3q5o

fzlrnn

lr4oroA.

dl

L"

P,Ju1€V

SPEED

For best

perf

ormance

this tool

should

run at

8p-

proximately

2700

R.P.M. This

speed

is

attained

by

using

a 2 inch

diameter

motor

pulley

with a

Yz

inch

V-groove.

Be

sure

to

specify

the

shaft

diameter

of

your

motor

when

ordering

the

motor

pulley.

BETT

Use a

standard

%

inch V-belt.

To

determine the

belt

length

place

rhotor

and

tool

in operati.g

posi-

tion

and measure

around

the outside

of

the

pulleys

with

a steel tape.

Do

not measure

in

the

grooves.

TUBRICATION

This

sander

is equipped

with

precision

type, sealed

ball

bearings.

These

bearings

were

packed

with

grease

at

the factory

and

require

no additional

lubri-

cation

for

the

life

of

the bearing.

To

maintain

smooth

and

easy

operation

of the

controls,

oil

the

following

parts

occasionally

with any

good

grade

machine

oil:

|

. Belt

adjusting

knobs

Nos.

23 and 33

where

they

enter

the

casting.

2.

Pulley support

pins

Nos.

25 and

29 where

they

enter

the

casting.

coNTROTS

The sanding

belt

may

be

raised from

horizontal to

vertical

position

after

loosenittg

the

two belt table

pivot

lock

bolts,

No.

I 0.

Always tighten

these

bolts

securely before

operation

in any

position.

The belt

adjustir,g knobs

align

the iCler

pulley,

No.

27

,

to

keep the

sanding belt

running

true over.

the

pulleys

and centered

on the

belt table.

These

knobs

also

control

the tension

of

the

sanding

belt.

The table

tilt

lock knob

locks

the

work

table

at any

desired degree

of tilt from 0o

to 45".

The

belt table fence

provides

a backup

for the

work

piece

when

using the

sanding

belt.

T-t(e

RPA

wl

z'i,

faufrl

oil.)

:roaL

2.

Apply

belt tension

by turning

the

two belt ad-

justing

knobs

clockwise.

While

applying

ten-

sion

keep

the idler

pulley

approximately

p?r-

allel

with

the

drive

pulley.

When

proper

ten-

sion

has

been

applied

you

should

be able

to

deflect

the

belt,

as

shown

in

Fig.

2,

ErpproX-

imately

Yz

of

an inch.

Align

the

sanding

belt

so

that

it will

track

on

the

approximate

centers

of the

two

pulleys

and remain

in

one

position

on

the

pulleys,

as

follows:

|

.

Rotate the

belt

bv hand

in

the

correct

direc-

tion,

as

shown

in

Fig.

|

.

2.

If

the belt

tends

to

run

off

to the right,

turn

the

right

hand

knob

clockwise.

If

the

belt

tends

to run

off

to the

left,

turn

the

left

hand

knob

clockwise.

3.

Recheck

the

belt

tension

and

adjust

if

fi€c€s-

sary

by turning

both

knobs

an

equal

amount.

4. The

tool

should

now

be

ready

to

operate.

If,

under

power,

the

belt

does

not track

propetly,

make

very

minor

adjustment

of

the

knobs

while

the

tool

is

in

operation.

When

installirg

new

sanding

belts

follow

the

above

steps.

Be

sure

the arrow

on

the inside

of the

belt

points

in

the

same

direction

as

the

rotation

arrow

shown

in

Fig.

l.

NOTE:

Tighten

all

pulley

set

scre\ rs

after

a

few

hours

of operation.

The

work

table

stop

screws

may

require

adjust-

ment

to

obtain

the

90"

and

45"

settings.

If adjust-

ment

is necessary,

it

may

be

accomplished

as f

ollows:

| . Loosen

the table

tilt lock

knob, No.

5

3, and

using

a combination

square

set the

work table

exactly

square

with

the

sanding

ciisc.

R e-

tighten

knob.

2. Loosen

hex

nut,

No. 50,

and

turn

the square

head

set scr€w,

No.

5

|

,

until it

contacts

tlre

rib

on the

underside

of the

table.

Re-tighten

the

hex

nut,

while

holding

screw

in this

ptsition.

3. Repeat

the above procedure

f or

the 45 "

stop

screw,

No.

59.

CAUTION:

In

placing

the work

table

assemblv

on

the

tool, keep

the

edge

of the

table

as

close

as

pos-

sible to

the

sanding

surface

to eliminate

the

J.rr-

ger

of

thin

work

becomittg

wedged

between

the

table

and

the sanding

surface.

The socket

head

set

screw,

No.

5

5

,

secures

the

table

support, No.

49,

to the

support

rod, No.

52,

and also

serves

as the

lock

stud for

the table

tilt

lock

knob.

If adjustment

of this

stud

is

necessary

loosen

the

tilt

knob and

tighten

securely

with

the

Allen

wrench

provided.

The

sanding

belt

table

when

used in

the vertical

position

should be

set square

with

the work

table,

as

follows:

l. After

the

work

table

has been

installed for use

with the

belt,

loosen

the

two belt

table

pivot

Iock

bolts,

No.

| 0.

2.

Place a combination

square

on the

work table

and

pivot

the belt

table until

the two tables

are

90" to each

other.

3.

Re-tighten

pivot

lock bolts.

This

procedure

must

be repeated

each

time

the

position

of the

belt table

has been

changed.

*

"i:;.*

;:'

il"?T:

;:T ?:,'ff"

n :::",|;ni

ff^r:

FIGURE 2

ADJUSTMENTS

Tension

the

sanding belt

before operatirg,

as

fol-

lows:

l. Face the end of the tool with rotation arrow,

see Fig. l,

pointing

away

from

you.

Page 4

ing

operations.

For

extreme

accuracy

the

pro-

tractor

head

should

be

set

in

relation

to

the

sand-

ilg

disc

or belt

table

each

time

a

new

position

is

desired.

OPERATION

The sanding

belt

and

sanding

disc

furnished

with

this

tool are

for

general

use.

They

are

suitable

for

use

on

materials

such

as

metal,

wood,

or

plastics.

Since

a non-hardening

type

of

disc cement-[.as

been

used

to fasten

the

abrasive

paper

to

the spnding

plate,

the

abrasive

disc may

be

quickly

replaced

with

one of

a different

grit.

Drum

sanding

may

be

done

at either

end of

the

sanding

belt

table.

See

Fig.

4 for

a typical

applica-

tion.

Flexible

belt sanding

may

be

done

on the

back

of

the

belt

with

the

belt

table

in

vertical

position,

&s

shown

in

Fig.

5.

Release

the

belt

tension

to

suit the

curve

of

the

work

piece.

Quality

of finish

d.pends

entirely

upon the

abra-

sive

grit

and

the

handling

of the

work.

Highest

qual-

ity

is

obtained

by

first

rough

sanding

with

the coarser

gri_ts,

then

changing

to

finer

grits

and

making

several

light

passes.

Abrasives

are

available

in

three

grits-fine,

rrr€-

dium

and

coarse.

The

belt

and

disc furnished

are

both

medium

grit.

FIGURE

5

SAFETY

Due

to

the functions

of

this

tool

the

revolving

parts

must

remain

exposed.

Be

careful

!

Hold

the

work

firmly

so

that

it

may

not

be

driven

from

your

hands

allowing

them

to

come

in

contact

with

the

abrasive

surfaces.

Use

the

belt

fence

whenever

possible.

Be

sure

the

rotation

is

correct.

Do not

wear

clothes

which

are

loose

or

dangling.

Be

sure

all necessary

adjustments

have

been

made

before

operati.g

tool.

In

installations

requiri.g

a

belt

guard

see

Fig.

6

for further

information.

FIGURE

3

Surface sanding

is

best

accomplished

by

holding

the

work piece

firmly,

but

not

ipplying

too *.r.f,

pressure

to

the

sanding

surface.

The

work

piece

should

be

moved

back

and forth

over

the

sanding

belt

to

maintain

even

belt

\

rear

and

eliminate

groovirg.

Wood

should

be

sanded

with

the

grain.

Use

the

belt

table

fence,

see

Fig.

l,

to

back

rp

the

'work:

If the

work

piece

is

lorg"i

than

the

b.li

sur-

.,fice, remove

the f.rr..

to

allowJull

use of

the

belt.

Exra long

work

should

be supported

as

shown

in

Fig. 3, to

eliminate

sag.

Disc

sanding

has

rough

ends

of

wood.

FIGURE

4

its

greatest

usage

in truing

the

Page 5

^

^

"*

e'UaAlS

*.o(\?3

hu

h/.*tr'

cn

il

44--.*4&

EXPLODED

VIEW_MAIN

ASSEMBLY

59\

53

/

WORK

TABTE

ASS'Y

COMPLETE

6l

EXPLODED

VIEW-WORK

TABLE

ASS'Y

Page 6

Item

Order

by

No.

Part

No.

PART

NAME

|

38834

9

In.

dia.

sand

PaPer

disc.

Purchase

from

your nearest

Sears

retail

store

<lr

mail order

house.

Ask

for

Cata'

log

No. 9-2526.

State

grit

wanted

. b

a

'

2

38

180

S"itait

g

pl.tt with

set

screw

^

i/'

3

17

|

7

0

-

Iq-olp..qtley

.qith

".g!

".try

,*ic##**'"@

'rt

{

n

4'.-ffi:

"ft

lo{.tl

rtetarnlng.__T]Bg----

-r-*-zzgrr-

-R;Htrfi

;;fi;--

7

47

616 Belt

table

bushing

8 38833

'Retaining

lins

i

-9*

-

47 61 7_

*_D_nys***-haJt-*:-*-

av

(}

f

ft

t'e f?

(

/'\

l*0-**-*X:ZSl

*"Ca;""'"*

5/16-l I x

l/2hex. hd.

| | X-623

Plain

washer

2l

/64

I.D.

x

t/s

O.D.

l2

|$,IIl

-Refeiprn-s*-Iu1g

*

*Tt**W;;;*

5

Ito-l

I x I hex. head

l4

X-601

Plainwasherll/32

I.D.xll/16

o.D.

Belt table fence

Belt

table support

post

Drive

pulley with set screw

Set

screw

Y4-20

x

5

/

16 socket

head

with

cup

point

Set

screw

5

/16-

l8 x

/2

socket

head

with

cone

point

Belt

table

Ball

bearing

Retaining

ring

Belt

adjusting knob

Swivel

Pulley

support

pin

Set

screw

Y4-20

x

5/16 socket

head

with

cone

point

Idler

pulley

with

set

screw

Idler

bearing

Pulley support

pin

Retaining

swivel

Set

screw 5/16-18 x 5/16 socket

head self

loclcing

with

flat

point

Set

screw

5

/

| 6-1 8 x

/2

socket

head

self

locking

with

dog

point

PARTS

LIST

Item

Order

by

No.

Part

No.

PART

NAME

33

47

618

Belt

adjusting

knob

3 4

47 120

Base

3 5

sX-205

C"p

screw

5

/

16-

1

8 x

/4

hex'

head

36

X-456

Hexj.*nut7/16-14

37

X-236

C.p

""t"*

5/l6'

I I x

2%

hex.

head

3 8

47 2

12

Table

suPport

bracket

39

*X-6

l l

Lock

washer

5

/

16 inch

40

X-33S

Machine

screw

5/16-18

x lsAPhil-

4n

4t

---r-o'-u

jA::nd

head

'-

-42-----K-n9

Sei

screw

5/16-18

x

5/16

socket

head

with

cup

point

43

X-179

Setscrew5/16-18

x5/16

socket

head with

cup

point

44

387

37 Wrench

45

*X-

|

403

Allen

wrench

5

/32

46

47 8l3

Sanding

belt

6 x

48

inches.

Pur-

chase

from

your

nearest Sears

retail

8:;TJ

T,:l

";1ii

l,l

"""r,#o

-?l

4t

3ssi5

HiTil;

w 5/l

6- | 8 *

T+slotted

head

self

locking

with

cone

point

48

38225

Work

table

49

38226

Work

table

support

50

'eX-420

Hex

nut

%-20

5l

*X-

|

l6 Set screw

V4-20

x

I

square

head

52

38653

Work

table

support

rod

53

38654

Work

table

tilt

lock

knob

54

X'60

1

Plainwasherll/32

l.D.xll/16

o.D.

55

X-3606

Set

screw

5/16'18

x

l%

socket

head with

half dog

point

56

X-741

Machinescrew5/16-18

xYz

hex.

hd. with

external

tooth

lock

washer

Work

table

lock

arm

Set screw

5/

| 6- | 8 *

3A

slotted

head

self

locking

with cone

point

Set

screw

Y4-20

x I square

head

Hex

nut

V4-20

Work

table

assembly

complete

| 5

38224

f6 47615

l7

47 190

18 x-t73

t9

x-|70

20

47211

2l

38832

22

38833

23

47 618

24

47

613

25

47 6t

4

26 X-172

27

47180

28

47611

29

476t4

30

47 6t2

3

|

X-3

605

32

4781

|

57

38738

58

38835

59

*X-

l l6

60

tx-420

6 |

38102

*Standard

hardware items_may

be

purchased

locally.

This sheet

is

intended

for

instruction and repair

parts

only

and

is not

a

packing

slip.

The

parts

shown and listed may include accessories

not

necessarily

part

of this tool.

ACCESSORIES

Fig.

6

illustrates

accessories

for

your

sander.

Tool Stand-Qalalog

No. 99-2204

Guard-Q31alog

No. 9

-225

|

Powr

Panl-Catalog

No.

9-2120

6

Loading...

Loading...