Craftsman 10322181 Owner’s Manual

OPERATING iNSTRUCTIONS AND PARTS L|ST FOR

9 raNCH BENCH SAVe/

Model 103.22181

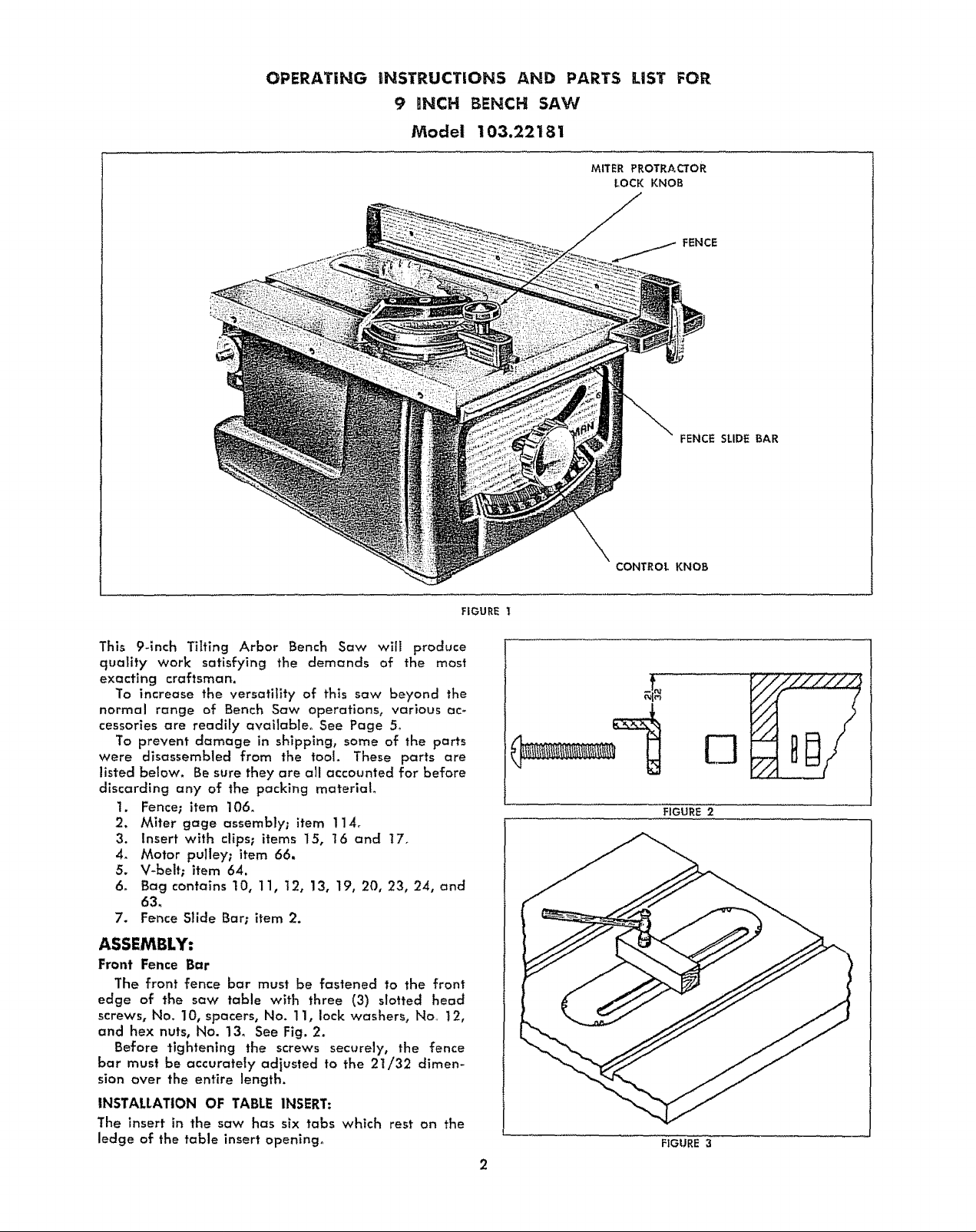

MITER PROTRACTOR

LOCK KNOB

FENCE

FENCE SLIDE BAR

This 9-1nch Tilting Arbor Bench Saw will produce

quality work satisfying the demands of the most

exacting craftsman.

To increase the versatility of this saw beyond the

normal range of Bench Saw operations, various ac-

cessories are readily available° See Page 5o

To prevent damage in shipping, some of the parts

were disassembled from the tool. These parts are

listed below. Be sure they are all accounted for before

discarding any of the packing material.

1. Fence; item 106.

2. Miter gage assembly; item 114.

3. Insert with clips; items 15, 16 and 17o

4. Motor pulley; item 66,

5. V-belt; item 64.

6. Bag contains 10, 11, 12, 13, 19, 20, 23, 24, and

63.

7. Fence Slide Bar; item 2.

ASSEMBLY:

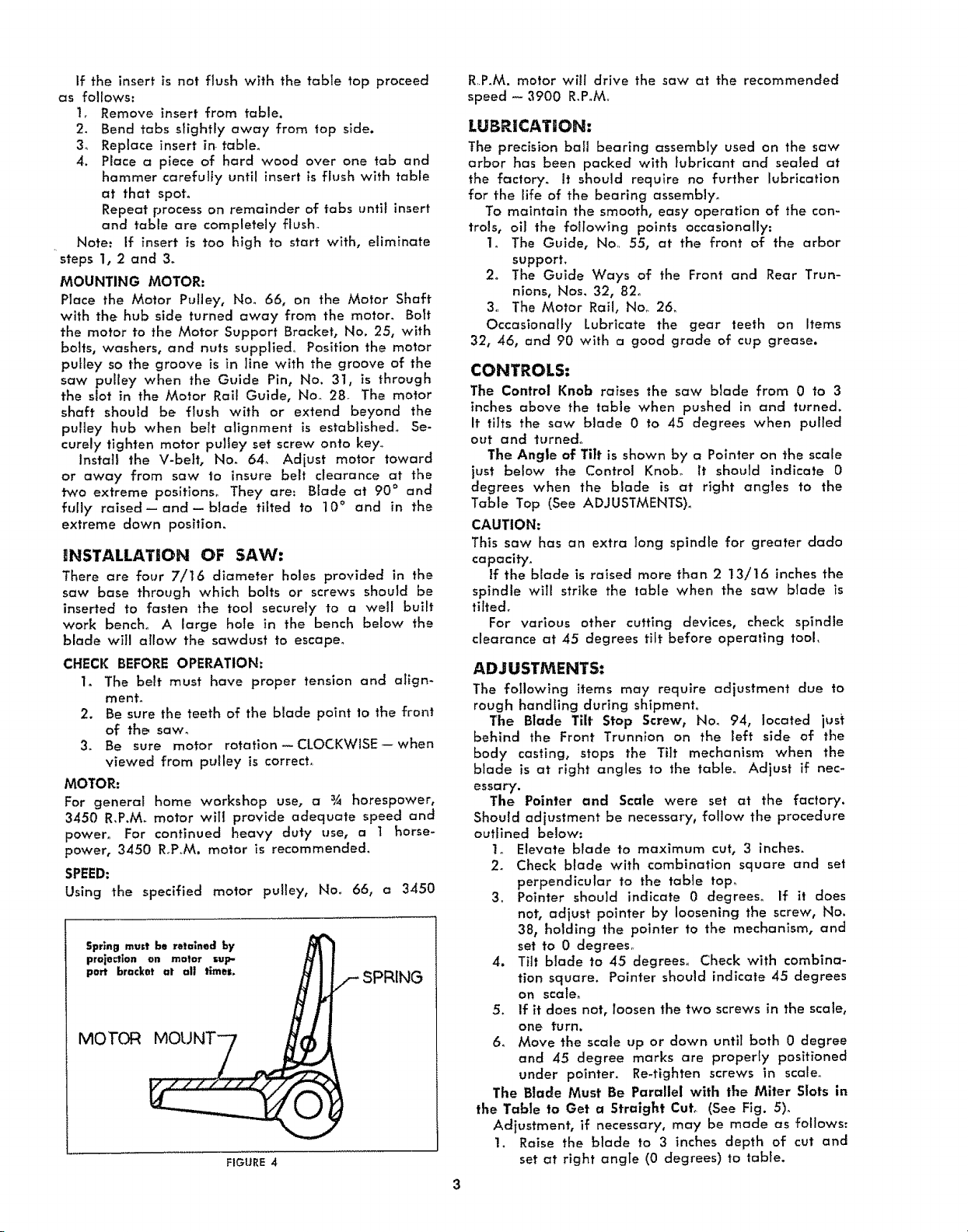

Front Fence Bar

The front fence bar must be fastened to the front

edge of the saw table with three (3) slotted head

screws, No. 10, spacers, No. 11, lock washers, Noo 12,

and hex nuts, No. 13. See Fig. 2.

Before -tightening the screws securely, the fence

bar must be accurately adjusted to the 2t/32 dimen-

sion over the entire length.

INSTALLATION OF TABLE INSERT:

The insert in the saw has six tabs which rest on the

ledge of the table insert opening°

CONTROL KNOB

FIGURE I

FIGURE 2

FIGURE 3

If the insert is not flush with the table top proceed

as follows:

1+ Remove insert from table.

2. Bend tabs slightly away from top side.

3_ Replace insert in+table+

4. Place a piece of hard wood over one tab and

hammer carefully until insert is flush with table

at that spot°

Repeat process on remainder of tabs until insert

and table are completely flush+

Note: If insert is too high to start with, eliminate

•steps 1, 2 and 3.

MOUNTING MOTOR:

Place the Motor Pulley, Nee 66, on the Motor Shaft

with the hub side turned away from the motor. Bolt

the motor to the Motor Support Bracket, No. 25, with

bolts, washers, and nuts supplied° Position the motor

pulley so the groove is in 1ine with the groove of the

saw pulley when the Guide Pin, No. 31, is through

the slot in the Motor Rail Guide, Nor 28r The motor

shaft should be flush with or extend beyond the

pulley hub when belt alignment is established+ Se-

curely tighten motor pulley set screw onto key+

Install the V-belt, No. 64_ Adjust motor toward

or away from saw to insure belt clearance at the

two extreme positions+ They are: Blade at 90 ° and

fully raised-and-blade tilted to 10 ° and in the

extreme down position.

_NSTALLATION OF SAW:

There are four 7/16 diameter holes provided in the

saw base through which bolts or screws should be

inserted to fasten the too! securely to a well built

work bench° A large hole in the bench below the

blade will allow the sawdust to escape+

CHECK BEFORE OPERATION:

1. The belt must have proper tension and align-

ment.

2. Be sure the teeth of the blade point to the front

of the saw_

3+ Be sure motor rotation--CLOCKWISE--when

viewed from pulley is correct.

MOTOR:

For general home workshop use, a _,_ horespower,

3450 R+P.M+ motor will provide adequate speed and

power° For continued heavy duty use, a 1 horse-

power, 3450 R.P.M. motor is recommended_

SPEED:

Using the specified motor pulley, No+ 66, a 3450

SPRING

MOTOR

FIGURE 4

R P.M. motor will drive the saw at the recommended

speed - 3900 R.P°Mo

LUBRICATION:

The precision ball bearing assembly used on the saw

arbor has been packed with lubricant and sealed at

the factory+ It should require no further lubrication

for the life of the bearing assembly°

To maintain the smooth, easy operation of the con-

trols, oil the following points occasionally:

I. The Guide, No, 55, at the front of the arbor

support.

2+ The Guide Ways of the Front and Rear Trun-

nions, Nos. 32, 82°

3, The Motor Rail, No+ 26.

Occasionally Lubricate the gear teeth on Items

32, 46, and 90 with a good grade of cup grease.

CONTROLS:

The Control Knob raises the saw blade from 0 to 3

inches above the table when pushed in and turned.

It tl]ts the saw blade 0 to 45 degrees when pulled

out and turned+

The Angle of Tilt is shown by a Pointer on the scale

just below the Control Knob+ It should indicate 0

degrees when the blade is at right angles to the

Table Top (See ADJUSTMENTS).

CAUTION:

This saw has an extra long spindle for greater dado

capacity+

If the blade is raised more than 2 13/16 inches the

spindle will strike the table when the saw blade is

tilted,

For various other cutting devices, check spindle

clearance at 45 degrees tilt before operating tool,

ADJUSTMENTS:

The foIlowing items may require adjustment due to

rough handling during shipment,

The Blade Tilt Stop Screw, Nod 94, located just

behind the Front Trunnion on the left side of the

body casting, stops the Tilt mechanism when the

blade is at right angles to the table. Adjust if nec-

essary.

The Pointer and Scale were set at the factory.

Should adjustment be necessary, follow the procedure

outlined below:

1+ Elevate blade to maximum cut, 3 inches.

2. Check blade with combination square and set

perpendicular to the table top°

3. Pointer should indicate 0 degrees° If it does

not, adjust pointer by loosening the screw, No.

38, holding the pointer to the mechanism, and

set to 0 degrees°

4. Tilt blade to 45 degrees_ Check with combina-

tion square. Pointer should indicate 45 degrees

on scale.

5. If it does not, loosen the two screws in the scale,

one turn.

6. Move the scale up or down until both 0 degree

and 45 degree marks are properly positioned

under pointer. Re-tighten screws in scale°

The Blade Must Be Parallel with the Miter Slots in

the Table to Get a Straight Cut+ (See Fig. 5).

Adiustment, if necessary, may be macle as follows:

1. Raise the blade to 3 inches depth of cut and

set at right angle (0 degrees) to table.

Loading...

Loading...