Page 1

FOR CDI_RE[{_ SELLING PEICE_

ORDERING L_0PJ_iATI N.

i

SEARS, ROEBUCK an

FOBM I08-2

Page 2

t

i

- -2 -

Page 3

Part

Number Name of Part

486-18 Protractor Clamp Pin Spring

486-25 Shaft Collar Assembly

592-36 Wrench

6864 _'ig Saw Blade .Replaced by X-1125

68:)9 Motor Support' Clip .....

10511 Protractor Lock Wrench

12321 Protractor Clamp Nut

12455 Chuck Housing--Lower ......................

12456 Blade Centering Cover

12457 Socket Head Clamp Screw

12460 Chuck Assembly--Lower

12462 Slotted Head Set Screw

12464 Threaded. Plug

12504 Table Insert

12512 Chuck Jaw Housing Lock Nut

12513 Chuck Jaw Stationary

Upper ..... Replaced by 15172

Lower Replaced by 12460 plus 12464

12514 Chuck Jaw Movable

Upper .... Replaced by 15172

Lower .................. Replaced by 12A60 plus 12464

_251_uck Jaw Pilot

/

Upper _Replaced by 15172 V"

Lower ........................... Replaced by 12460 plus 12464

12554 Machine File Jaw Screw ..... Replaced by 12460 plus 12464

12555 Chuck Jaw Clamp Screw

Upper .............................. Replaced by 15172

Lower Replaced by 13460 plus 12464

12556. J'aw Clamp Screw Pin . _;

Upper ....................................... Replaced by 15172

Lower ....................... Replaced by 12460 plus 12464

13030 Protractor ........................................ Replaced by 130_0

13035 Table Protractor Guide Screw, Short

13037 Protractor Guide--Front ........... Replaced by 15113

Rear ............. Replaced by 151_8

13038 Table Protractor Clamp Replaced by 14021

13039 Table Stop Link __.Not Used !

13041 Protractor Scale "-

13050 Protractor Assembly ...........................................

14021 Table Protractor Clamp "

14048 Mitre Gage Pointer

14059 "Table Protractor Lock Screw .... Replaced by X-316 []

14069 Protractor Clamp Pin--Rear" I

14082 Mitre Gage Plunger Assembly '_!

15001 Base ................................................................. [

15002 Arm ....................................................

15003 Table II

15006 Table Support ................................. Replaced by 15173 !i

151;07 Boot Retainer ........................ _ ........................... i

15008 Lower Guide Rod Bracket ........................

15009 Yoke ................................................................

15011 Yoke Pin ................................................. ._ ................ I

15013 Lower Guide Rod ............. Replaced by 15107 _i

15015 Pulley Shaft ............................... Replaced by 15145 ,,

15017 Crank Case Cover ...............................

15018 Mounting Insulator ...............................................

i_._-_ Pump Tube ........................................Replaced by 15085 i,

15023 Pbtmp Tube Cap ...............................................

15024 PumI¢ Leather ...................................................

15025 Pump S'_ring ..................................

15026 Lower Gtfide Rod Spring .._'-_.',.----'._.'_.Z,.'_..._ .............. Not Useo

15030 Upper Go(de Tube Assembly ...........................................

15031 Pump Tube Support ............................... i

15032 Pump Tube Sopport Pilot ...............................

15033 Pump Tube Support Pilot Lock Screw .......

15034Saw Guide Rod ............................... I

15035 Thrust Roller Holder Guide )

15036 Saw Thrust Roller ..............................

15037 Thrust Roller Holder

15038 Hold Down Spring ............................

15043 Thrust Roller Pin

15044 Crank Case Gasket

15049 Boot Spring ................................ 7,....... .L__

15050 Protractor Lock Plunger Housing _crew

15051 Boot

15053 Motor Pulley .....................................

15054 Jig Saw Pulley .........................................

15055 Thrust Roller Holder Support .....................

15056 Motor Support

15057v Belt _,,_32",'---?.s'Z?..Z__ZT.-Z.'_..-Z-:._'_i,'ia_'%-_,_l_55

15059 Pump Spring Guide ._.

15062 .law Clamp Screw Pin--Upper ............... Replaced by 15172 ii

--Lower Replaced by 12460 pins 12464 r

15066 P_Imp Leather Washer'

15072 Motor Adjustment Bracket .............................

15074 Motor Adj. Bracket Thumb Screw ...... Replaced by 15114

15075 Saw Guide Rod Lock Knob Assembly .....................

15076 Crank Case Assembly Includes 15004 (1) X-8!4 (1)

Crank Assembly .- ...... Replaced by 15145

Sleeve ......................................

Assembly ....... Replaced by 15172 j/

.law Assembly ................ Replaced by 15172

Assembly Replaced by 12460 plus 12464

includes 15022. (I) 15070 (!)

15073 (1) ---_ ..........................................

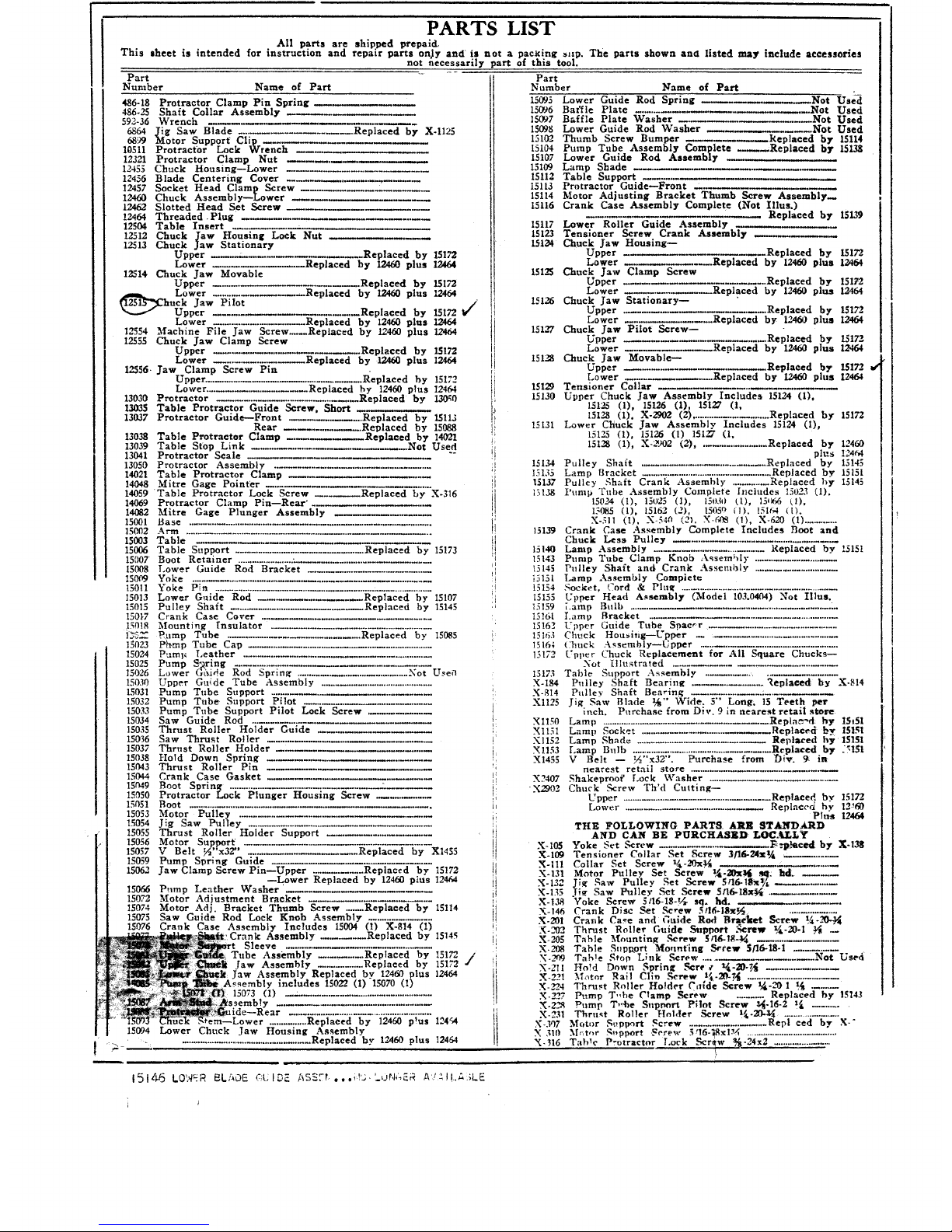

PARTS LIST

All parts are shipped prepaid,

This sheet is intended for instruction and repair parts onJy and is not a pac_ting _np. The parts shown and listed may include accessories

not necessarily part of this tool.

.............. Replaced by 12460 p_us 12454

15094 Lower Chuck Jaw Housing Assembly

• ...................................................... Replaced hy 19.2460 plus 12464

,,i

15 I.d..6 LO'>/_ R BLADE _;l.; I DE ASS?!.,. ,it'.;. '_,_)t,I,_?_.R A'!-' ! I.A _LE

Part

Number Name of Part

15095 Lower Guide Rod Spring

15096 Baffle Plate

15097

15098

15102-

15104

15107

15109

15112

15113

15114

15116

X2407

X2902

X-105

X-109

X-Ill

X-131

X -132

X-135

X.t38

X- 146

X-201

X-202

X-_5

X.L_8

X.2nw

X-211

X.221

X- 2"24

X-2_

X-22_

X-231

_-307

X ,31(I

X-H6

-_.Not Use-d

..... Not Used

Baffle Plate Washer Not Used

Lower Guide Rod Washer ........ Not Used

Thumb Screw Bumper .Replaced by 15114

Pump Tube Assembly Complete Replaced by 15138

Lower Guide Rod Assembly

Lamp Shade

Table Support ........

Protractor Guide--Front

Motor Adjusting Bracket Thumb Screw Assembly_

Crank Case Assembly Complete (Not Illus.)

Replaced by 15139

15117 Lower Roller Guide Assembly

15123 Tensioner Screw Crank Assembly

15134 Chuck Jaw Housing--

Upper _Replaced by 15172

Lower Replaced by 12460 plus 12464

151"_ Chuck Jaw Clamp Screw

Upper ...... Replaced by 15172

Lower Replaced by 12460 plus 12464

15126 Chuck Jaw Stationary--

Upper .... Replaced by 15132

Lower ............... Replaced by 12460 plus 12464

15127 Chuck Jaw Pilot Screw--

Upper .Replaced by 15172

Lower Replaced by 12460 plus 12464

15128 Chuck Jaw Movable--

Upper _Replaced by 15172.

Lower ............... Replaced by 12460 plus 12464

15129 Tensioner Collar

15130 Upper Chuck `law Assembly Includes 15124 (1),

151_ (I), 15126 (I), 15127 (I.

15128 (I), X-2902 (2) ........................ Replaced by 15172

15131 Lower Chuck Jaw Assembly Includes 15124 (I),

15125 (1), 15126 (1) 15127 (1,

15128 (1), X-_)02 (2) .................... Replaced by 12460

plus 124_4

15134 Pulley Shaft .......................................... Replaced by 13145

13135 Lamp Ilracket ................................................ Replaced by 15151

15137 Pulley _haft Crank Assembly .............. Replaced by 15145

15138 Pump Tube Assembly Contptete Includes 15023 (I),

15024 (1), 15025 (1), 15030 1l), 19k66 (1),

15085 (1), 15162 (2), 15050 IlL 151€k4 IIL

X-311 (I), X-540 (21, X-(_ (1), X-620 (1) ............

15139 Crank Case Assembly Complete Includes Boot and

Chuck Less Pulley ..........................................

15140 Lamp Assembly ................................... Replaced by 15151

15143 Pump Tube Clamp Knob Assembly ............................

15145 Pulley Shaft and Crank Assembly .............................

"_,5151 Lamp Assembly Complete

15154 Socket, Cord & Plu_ ...........................................................

I5155 Upper Head Assembly (Model 10,L0404) Not Illus.

15159 ;.amp Bulb

I5!61 Lamp Bracket ....................................................

15162 Upper Guide Tube Spae_'r- .....................................

15163 Chuck Housi,g--Uppor .........................................

15164 Chuck Assembly--Upper ............................................

15172 Upper Chuck Replacement for All Square Chucks--

Not Hlustrated .................................

15173 Table Support Assembly ..........................

X-184 Pulley Shaft Bearing ................ Replaoed by X.814

X-814 Pulley Shaft Bearing .................... :...........

X1125 Jig Saw Blade _" Wide. 5" Long, 15 Teeth per

incb. Purcbase from Die. 9 in nearest retail store

XlI50 Lamp ...........................................Repla_'d by 15t51

XI151 Lamp Socket ................................ Replaoed by 15151

X1152 Lamp Shade ............................... Replaced by 15151

X1153 Lamp Bulb .................................................... Replaced by _3151

X1455 V Belt -- ½"x32". Purchase from Die. 9. in

nearest retail store ...........................................

Shakeprooi' Lock Washer ................................

Chuck Screw Th'd Cutting--

Upper ............................................ Replaced bY 15172

Lower ............................................ Replaced by 12_60

Plus 12464

THE FOLLOWING PARTS. ARE STANDARD

AND CAN BE PURCHASED LOC,_I_Y

Yoke Set Scrcw ./_.'p_ecd by X-138

Tensioner Collar Set Screw 3/16-24xSA

Collar Set Screw _/_-20x_

Motor Pulley Set Screw a&-20x!4 _ hd_ .....

Jig Saw Pulley Set Screw 5tl6-1$X_i

.li_ Saw Pulley Set Screw 5t16-1_x_ .................

Voke Screw 5t16-18-t4 sq. hd.

Crank Disc Set Screw 5116-18x_j

Crank Ca_e and Guide Rod BraCket _creg"_)_:'-_

Thrust Roller Guide ._pport :qcrew _x/_-20-1 _ __

Table Mounting Screw 5rl&!8-_ ................

Table Supgort Mo,tnt'ing Screw $/16-18-1 ...........

Tab!e Stop Link Screw .................... Not Used

Ho!d Down Sprinlt .%err € 141-21}-_t ....................

.Motor Rail Clln Serew t_-20.M ..........................

Thrust Roller Holder Ca{de Screw t_t-20 1 1/_ .....

Pl:mp T-be Clamp Screw ......... Replaced by 15143

Pomp T,,_e Sttpl_rt Pilot Screw _-16-2 t_ ..........

Thrust Roller Holder Screw 1,_-20-_4 ......................

Motor Svpport Screw ........................ Repl ced by X-"

.M_t¢_r ,q-pport Screw 5q6-_Sxl_6 ....................................

Table Protractor Lock Scr_w,,S_-24x2 .........................

Page 4

X-I17 "Motor Support Screw Nut 5:1o--;.g ..............................

X 420 Roller lttJ.'dcr _;ul,le Screw N;_t _.-_1_ ........................

X_4.'I Motor Rail Clip Screw Nut 1-/,-20 Sq. l,id .................

X-432 Protractor (;i.Iide ._z,_trew Nut _-24 ...................................

X-4.t3 Protractor Scale Screw Nut No. 4-40 ..............................

X-436, Lamp Bracket Screw Nut No. 5-40 ........ R,_'ae'_-d by"

X-51t Pump Leather Retaining Screw No. t0-24x_ ...........

X-512 ProtraO:'r Pointer Screw No. 8-32x_ .............................

XL523 Shadt, Soppm't Screw No. 5-40x5_16.. ..................................

X-524 Protractor Scale Screw No. 4-40x_il ..............................

X-540 Guide Tube Spacer _:rew No. 6-32x3/1_ ........................

X-(_H Motor 3,lotmting Screw Washer 5116 Std ................

X-605 :Hold Down Spring Lk. Washer % Std .................. ;'-.

X-_Xi Boot Shield Washer _,_ Std .............................................

X-@_7 Crank Case Washer V4 Std. ........................................

X-608 Leather Retainer Sc. Lk. Washer all6 Std ...........

15131

,i

t

X-c,_:_ ._:l_p Bracket Screw Wash.'' 3116 Std .......................

X-611 Tah'.t Mounting Screw Lk .... a_her 5/10 Std ..........

X-M5 l.anlp ihacket Spacing Wa*i,er 1_ Std ..................

X-61G ProT_ Guide Screw Lk. \_asher -_ Std ..................

X-61_ Pump Tube Clamp Screw Washer 5.,16 Std ..............

X-ol8 Protractor Scale Lk. Washer No. 4 Std ......... Not r!sed

X 619 Plunger Housit'.g Lk. Washer No. 5 Std ...................

X620 Pure> Leather _'rew Washer 13164-1 .........................

X1019 Lamp Bracket _Itg. Screw 3/16--24x}_ ...... ._ .............

Xii03 Clamp Piu Cotter Pin 1116 Std ...........................

XI_0 Lamp Braeket Mtg. Se. Nut 3/I6--24 ..................

X1304 Lower Grade Rod Cheek Ball 9!32 .............................

X.!400 Ailen Wrench 5/32 Across Flats ....................

X-2501 Filier Pipe UL Pipe Coupling ...................

X-2a01 Filler gbow ,_ Std Elbow ..................

X-2701 Plug l_t Pipe Plug (Male) ................................

THE FOLLOWING PARTS ARE SOLD SEPARATELY AS ACCESSORIES

RIP FENCE AND TABLE EXTENSIONS

227.8 I1 12320 Lock Rod Nipple ......................................... Replaced by 12330

I

12330 Lock Rod Nipple ...................................................

! 15029 Ftnee Guide--Front .........................................

I 15021 Fence Guide-Rear .......................................

15046 "Fable Extension--Front ..............................

i{ X-l15 Aligning Screw ............................................

:I X-209 Equalizer Clamp Screw .............................

!i X-428 Lock Rod Nut, Fence Guide Nut

[ X-605 Fence Gnide Screw Lock W_tsher,

Equalizer Screw Lock Washer

ii X-517 Fence Screw

_ X-MS Equalizer Screw Plain Washer

!i X-I101 Cotter Pin ................. :............................. Not Used

15t_h) Complete Unit ....................... See Sears Catalog No,

12&;4 Fence Guide Spacer .............................................

12255 Fence Guide _erew--Long ...............................................

12256 Fence Guide Screw--Short ...........................................

I22t£1 Fence Sub-Assembly--Long ..................................

12263 Fenee End--Front ...............................................

12200 Rip Fence Equalizer ................................................

12_a Rip Fence Clamp Lever ....................................

!2272 Table Extension--Long ...........................................

t2__Jl Fence Assembly Complete .............................. ;.........

12315 t;euce End_Rear ..........................................................

12317 Rip Fence Lock Rod_Long ..............................

IZH8 Rip Fence Clamp--Rear ...............................................

12319 Rip Fence Clam9 llolt .........................................................

LOWER ROLLER GUIDE ASSEMBLY--COMPLETE

F'rat Complete l_'nit ....................................................................... Not Used , X420 Holder Screw Nut ..............................................

15t!7 Lower Rolh-r Guide Assembly Inelt!des 15036 (11, i X-o01 Hinder Support Screw Washer ...... Supplied with tool

15037 I1), 15043 (1). X-202 (1), X-_27 (11 1 X-oil5 Holder Screw Lock \Vasher ............... Supplied with tool

X-420 II) ......................................................................... - X-607 Holder Screw Washer ....................................

15036 Saw Thrust Roller ............................................................. It X-61l Holder Support Screw Lock..,Washer Supplied with tool

]5!}37 Thrust Roller Holder .................................................... '!I X-208 Support Screw .............................. S'pplied with tool

13t_43 Thru_;t Roller Piu ................................................................ i X-224 ttolder Screw ........................................... Replaced by X-202

X-2{12 IIohler Screw ..............................................................................

¥ILING lAWS

iSt_-Coml_te-Unit ............................. Rep!aced by 12460 plus 12464 it 12560 Jaw Clamp Screw .................. Replaced by !2460 plus 12-,64

_2=45 Movable Jaw ................................ Replaced.by 1240) plus 12464 i! 15080 Filing Jaw Housing ............. Replaced by 12460 plus 12_0

1!:,46 ._Stati}_.n.a_ry Jaw.,_. ......................... Replaced by 12463 phts 1_64

THE FOLLOWING PARTS ARE SOLD AS ACCESSORIES ONLY

X-If5 X-2R4 X-208

X202

I. o

12260

"12315 12317

X-209 X-420 X-428 X-517 X-605 X-607 _615 12254 12255

12263 12270

15020

F@ : t_ "

_ °_' ..... 15021

12269

12318 12319

12560 15036

r

.I i

15046

12256 ,

'I

_ XlIOI

12272

12320 12545 12546

12330

15037 15043

15060 15117 15091

Page 5

2050-M

PARTS LIST FOR LOWER CHUCK FURNISHED AS A SUBSTITUTE FOR THE OLD

STYLE SQUARE JAWED TYPE USED ON MODELS i03.0403 AND 103.0404

' I

31102

,, r

11617

o ®

18518 18519

X- 1400

©

12464

r-------_

18938

NO.

31102

31617

18917

18518

PART NAME

Chuck Assembly Complete

Chuck Housing

Blade Centering Cover

Socket Head Clamp Screw

No. PART NAME

18519 Slotted Head Set Screw

X-1400 Allen Wrench

12464 Threaded Plug

18938 Chuck Shoe

INSTALLATION INSTRUCTIONS

i. Unscrew and remove the !ower chuck, holding the washers under the top of the

boot in place.

2. Remove the washers and nut_ No. 12512, from the old chuck stem and place them

on the new chuck. (See sketch)

3- Screw the plug, No. 12464, into the lower guide rod turning it with a small

screw driver until it seats. (See sketch)

4. Assemble chuck to tool as per following sketch:

31102

L j______"/ 12512

Flat Washer .... --'2'-_-_---_--_---- Lock Washer

k

/i .! b Boot

/ JJ;....'t

IMPORTANT NOTICE

This new style chuck may be used to hold machine files or sabre saws. To insert

these tools first remove the blade centering cover, No. 18917, and chuck shoe#

No. 18938, by removing the screws 18518, 18519. Use only the set screw 18519 to

hold files or sabre saws. For regular blades use Allen wrench for locking the

blade in chuck. Whenever re-assembling chuck keep the relative position of 18518,

18519 and 18938 the same as originally assembled.

Page 6

OPERATING INSTRUCTIONS FOR 24 INCH JIG SAW

LUBRICATION

To prepare for shipping, the oil has been removed from this tool. Do not run until refilled with a good grade

of oil similar to S.A.E. No. 30. To refill, remove the pipe plug from filler pipe in front of crank case and pour in

SLIGIITLY LESS THAN ONE PINT OF OIL.

TIIIS FILLING OF OIL SHOULD LAST INDEFINITELY, BUT IF MORE OIL IS ADDED, POUR IN

ENOUGH TO HAVE IT JUST VISIBLE AT THE BOTTOM OF THE FILLER PIPE.

Any oil in excess of the above amount will be wasted as same will pass from crank case either through

breather hole or vents around piston rod until required level is reached. The crank case mechanism and main bear-

ing are lubricated by means of an oil pressure system. The pressure is produced by a simple pump arrangement

in combination with the mechanism in crank case which pumps and forces the oil from the bottom of the crank

case to all parts requiring lubr'cation in the crank case.

The square upper pump piston rod should be oiled or greased and a few drops of oil should be applied through

the hole in the pump tube cap occasionally.

Periodic greasing of the table trunnions is recommended.

:_ :_- REASSEMBLY INSTRUCTIONS

This jig saw has once been completely aszemblzd at the factory and to avoid breakage through rough hand-

ling while in transit the table has been removed.

Looking at the under side of this table you wil_. note that one pair of trunnion bosses is close to one edge of

the table. To reassemble table, p:ace the tab!e on the trunnions with these bosses toward the back.

The four mounting screws are in the cloth bag. Place the plain washer next to the trunnion boss, then the

lock washer before tightening screws.

The blade has been pushed up into the upper chuck to avoid breakage.

CAUTION. For shipping purposes the upper pump tube assembly has been lowered and the cIamp bolt tight-

ened.

To raise or turn this tube loosen the clamp bolt and move the assembly by hand.

Do not turn pump tube with WRENCII OR PLIERS.

SPEEDS

The large pulley ismounted with large d:ameter next to the crank case and the small pulley is mounted on

a 1750 R.P.M. motor with the small diameter adjacent to the motor. This will give approxin:ate speeds of 1750_

1284--926 and 657. 926 and 1284 are the recommended speeds. A 1/3 horsepower motor is recommended for this

Sav,_. , _.-

PULLEY ON CRANK CASE MUST RUN IN DIRECTION INDICATED BY ARROW SIIOWN ON OUT-

SIDE OF CRANK CASE SIIAFT BEARING HOUSING.

MOTOR I_IOUNTING

The motor mounting is in two parts, the front eltd b_ing the conventional floating type pivoted in adjustable

clips. The rear part has an adjusting screw so weight or motor can berelieved from the belt and b_arings.

,. . , PUMP MECHANISM

The upper guide tube and pump mechanism is mounted in a housing which is fastened in the overarm by

means of taper pointed screws which reginter against the angular surfaces of a grcove in a pivot pilot which is

bolted to thd housing.

Loosening the "screws p:rmits the entire a=sembly to be turned radially. Removing the screws permits the

removal of the assembly. Air for blowing dust away from the work is provided through a tube concealed in the

pump tube. Additional air is exhau=ted th'ough chuck jaws in upper guide tube.

The graduations on the pump tube signify the length of saw blades and the pounds pressure of the spring at

the top of the stroke. For examp',e, when using a 5" blade the 5"--6½# mark should register at the top edge of

housing.

PUMP TUBEPOINTER

-ALIGNING MARKS

/jso

FIG.

For radial alignment the vertical line thrDugh graduation on the tube must register w:th the poin._er on sup-

port housing located 45 ° to the right from the front.

Fasten the tube secure!y in this posi._ion. For ripping turn_he entire pump tube assembly ar_i saw blade roll-

er guide 90 ° to the right so that vart'cai line on the tuba lines up with pointer.

%

F-O B.M 109.2

Page 7

m¢

JIG SAW WITH TENSIONER--MODEL 103.0404 ONLY

A blade tensioner is provided so that correct tensioRcan be obtained when using various sizes of blades.

Tension can be varied with blade in place and while machine is in operation.

Improper tension wiU cause vibration which will disappear when correct point is reached.

To increase or decrease the tension of the saw blade, loosen pump tube clamp screw and turn ball crank to

the right or left. Lock clamp screw when desired tension is reached.

$AW 13LAD_ I_OLLE_ GLTID_ AND IIOI_D DOWN _P I_I1N_

To move roller guide toward and away from the saw loosen bolt A in Fig. 2 and slide the a_semb'.y to the

desired position. To move the roller laterally loosen the bolt B and slide the roller and hold down spring to the

groove selected. _--A

TO CIIUCK SAW BLADES

1. Place blade in the lower chuck and tighten socket head clamp screw. --B

2. Turn drive pulley uI,til the lower chuck is raised to its highest position. FIG.2

3. Loosen pump tube clamp screw and set pump tube at proper position for length of saw blade b_ing insert-

ed.

4. While in this position insert blade in upper chuck by pulling down upper chuck slightly and tightening

the clamp screw.

6, Turn pulley over by hand to make eertaln that the sprlng in head i_ under tenslon at the top of stroke.

Failure to observe this condition will resu:t in pounding.

Install blade with cutting teeth pointing downward.

Blade will work best with cutting edge square with table.

Maximum thickness to cut with 5" blade is _A". For thicker material use longer blades and raise pump tube.

Blades up to 10" long can be used without changing the setting for 5" blades, but the blade mu_t be put through

the upper chuck starting from below the table through the table insert.

FILING

The round shank files to be used in this machine, listed in the Sears Power Tool Catalog, are held in the lower

chuck. To insert a file remove the chuck screws and lift off the blade centering cap. Place file in chuck and

fasten securely by tightening slotted set screw only against the file shank. The table may be tilted to file angles

or to correc_ for any bow in the file,

TABLE

To tiltthe table unlock the front trunnion by pulling the lever wrench on to hexagon nut. Loosen. Pull

plunger stop for important angular positions, intermediate angles must be lined up wlth the pointer. Rrlock wlth

lever wrench on nut. The pointer on the graduated protractor is adjustable if necessary to correct any error on

protractor with the table top.

OVERARM

Marks on the top of the overm'm and pump tube housing at the joint permits the entire housing aszembly to

be returned to its normal alignment.

Overarm is pivoted at the rear of the base so it can be swung to the right or left or entirdy removed by

loosening the stud which clamps it to the base, The distance from the center of the saw to the inside of arm per-

mits full 24" cuts.

At the overarm pivot, joinb at the rear end of the base a mark determines the normal sawing alig'nm_nt of

the arm.

RUBBER MOUNTING INSULATORS

Place one in each cored recess on the inside corners of base: These rubbers will help to level your saw and

deaden sounds which ,nay be transmitted through your mount_n_ stand or bench.

SABRE SAWING ACCESSORY

Loosen blade _n upper chuck. Remove roller guide and hold-down spring by taking out the screw at the b0t-

tom. Loosen acorn nut on rear of upper arm and move arm to either side. Tilt table to the left 45 ° . With long

screw through slot, line up roller guide with small support casting (Part No. 15055) included with extra part_."

Fasten this assembly to boss underneath the table and behind the blade. Return table to horizontal position.

ADDITIONAL ACCESSORIES AVAILABLE

FENCE AND TABLE EXTENSIONS

Provision is made in the ends of the table for attaching fence guides and ext_nsion_ for the front _nd sides

of the table. These extensions increase the table size from 14-3/16" square to 18-31_16 " x 25-1,_ ". The table space

in front of the saw is increased from 7-_/_" to 11-_/_ ".

Loading...

Loading...