Page 1

I

I

OPERATING

INSTBUCTIONS

AND PARTS LIST

FOR

CRAFTSMAN

DRILL

PRESS

MODET NIIMBER 10I.03622

This is the Model

Number of

your

Drill Press. lt will

be

found

on

the

rear

center of lhe Base

Top.

Always menlion this

Model Number

when

communicating

with

us

regardir;g

your

Drill Press or

when

ordering

Pails.

This lisi

is valuable. li will assure your being able

to obtain proper parts

service

at all

times. We suggest you keep it

wiih

other

valuable

papers.

SEARS,

ROEBUCK AI{D CO.

Page 2

OPERATING

INSTRUCTIONS

When unpacking,

be very careful

ro

9o

through all

papers thorouqhly

as no+ to mi*

any

parts.

This drill

press is

desiened io be

used {or all ordinary

work with a

motor havinq

"

speed of approximately

1750 R.P,M. and

with

s,c\ a

mo+or

will

have n:ne dif{"rent speeds

as

{ollo*s: s80, 1300,2440dnd

5200

R.P.M.

wilh

moior in ro'mal

pos;rion

(pulleys

in line);

1000, 1750 and

3300

R.P.M,

with

motor lowereo

on molor base

so thdt +op step

o{

mofor

pulley

lines

up wiih the

secoid sreP on the spindle

pulleyr 760

rnd 4,000 R.P.M. with motor .aised

on

moior

base so

rhai

the

top step

on tho spindle pulley lines r:p with the

lhird s+eP on

rho motor

pulley.

l{ +he direct motor

drive sef'up

is r:sed, the moror should

re'

'olve

in a

cloctwke dnection

when facins ihe

pulley end. lf it revolves

in the opposite directio.,

.everse this accordins

to the manu{acturer's

instructions. When

you are

,ure

the motor revol"es

properly, bolt

it

lo

ADIUSTMENTS

AND

CONTROLS DRILLING

(t)

The

eui

k tocked

in

pos}ion

by

ru,n;rq rhe small lever

located

,.,The

prcper

speed_ Ior drillins depends upo.'

l. The malerial to be

"t

+i,"'t.*", i,""i

p"*-.iil" ti."a.

drilled;

2. the size of the hole; 3. +he kind o{ drill. Generelly speakine,

(2)

rhe rwo knurted nu*s on

rhe.spindte srop

sa!qe

can be,er

ar.aly

li: lJjj;i.

the material and the lareer the drill' the

slower

siould be

desired

position

and locked. ln this

.ay

a definite

"mount

of spindle

havel can be obtained

ard dny rumoer of

holes con be

drilled +o a de-

sired

deprh.

Make sure tha+ the drill runs true when startin-g-ii may he necessary

(3)

spindre Adiusrmenr-rr

ronsi+udinar

pr.y deveropes in rhe.spindre

l:flll::ii!r-i:"';l;r"ti"1"';l''.,'1""'l',"T

l;r"':l"".,tx,: :*;t:

it

may be

eliminared as foilows:

{ll

Re-mc,e

spindle

9Lr..d

a-n! the two

hiqI

a speed,

'esp.ciatty'*trh

rhe la,ser d,ilts-exclssi'e speed

wear

ofl

lock

nut5 on the {eed

srop bracket,

(21

Remove

th; drill'coriex,

dra*J th" +".per-"f

rhe

drill, and |n"v

"*"

f,ri

.,

:prinq

housinq by loosenine

the set

screw on the

b.""k th. d,ili ii"-

unoe*:de of

the boss,

(3)

Remove

{eed lever and

pinion

s[d{t d{ter

roosening +he set screw

in the

:ortar

ad:acen+

-o

+he heai,

l4)

putt

spindle and

Note: W[en drilline bruss, aluminum, lead and other so{t maierials

",rli

a.-'"1",J

"ia

,"-.," i.J.'r,""a.

ist

Loosen

-hkh

.cause.

+he drill ro

'hoe-in",

reduce_ the rEke dnel€ o+ the curtins

,J

,**

r"

""rt",

ai,""rrv

"r.,"

qui

d;d

while

edee by

srindine

rhe drill as shown

in Fis.

a. This reduced roke .nsle

i..i"s *.

,pindte up ag!in+

fhe Lolom

of rhe

is

alrc

delirable vhen,drillins very

hard

materials

because i+ lessens

the

o,rit,

iioii."

il" ."tt"'.

,p'.q"i,'+ rhe inner

race of

strain on

the.drill.

Thir

chanee

males drilline

easier

and ,esults

in

a

il"

l1ifi

s"",iis.

o"

-i

.ll" this

adius+dlent roo

more accuratelv drilled hore'

fhs mounting

braclet. localins it

csntrally on lhe

provided slots. Atlach

the molor pulley

to +he shaft wi*h the large

s+ep on top.

Since +hk drill

press

is a bench model,

it should be securely bolted

in+o

position.

l{

the

base does not iouch rhe

bench top evenly,

place

shims

whe,e

requned.

lf +his

p"ocedure

is nof followed the Sase

may be sprung,

and unsatis-

iactory

cond;tions may

result.

lr +he

coun+erehaf+ and idle. pulley are +o be used rl,e

motor

should revol'e ii

d counreFcloclwise direc+ion

when

{acin9 +he

pulley

end. Bolt rhe

Drill Press to

the

bench 6nd attach the counterohafl

in

position

as shown.

Locate the molor

pulley

on the sh.ft

wirh +he

large end oul

and directly under the counrersha{t.

Bolt

the motor

+o

lhe

bench, put +he belt

in the desired

groove, and

the

Drill Press is

roady

for operation.

When

usinq

the belr

in one

of rhe smaller motor

pulley

9roc,ves,

pull

out

the

counfershaft

+o

keep

the bel+

tigh+.

ihe

quilr

bearine.

Do not maIe thk

adius+ment loo

more dccurarerv drrrred hc

tishr,

(6)

Put

spindle back

inio rhe drill head and

Lubrication: A cultins compound is

reassemble.

essenrial when drillins

pracfically

any

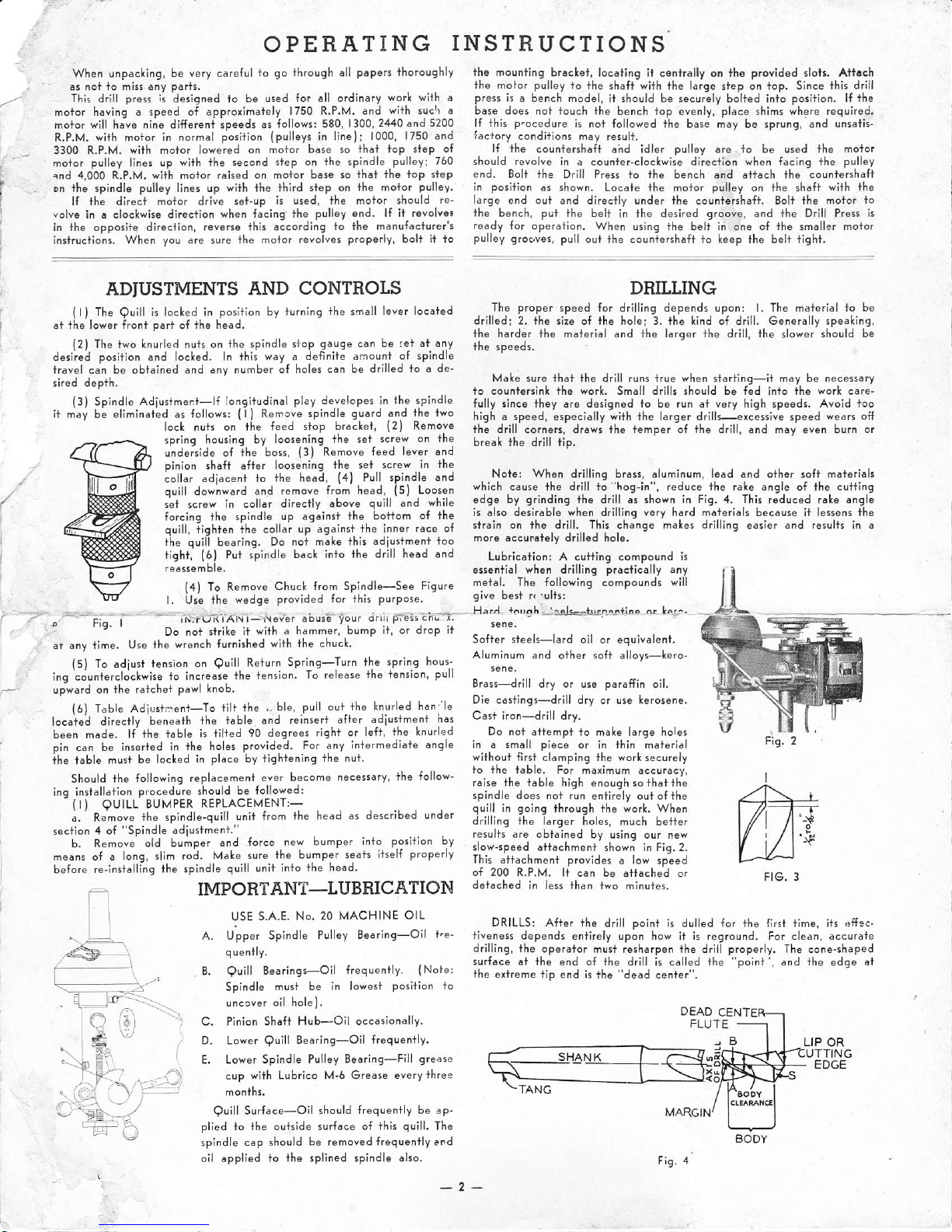

lal

To Reno,e

ChucL {'or Spirdre-See

Fieure

me+al-

The

{ollowing compor:nds

will

l. Use the

-edqe

pro,ided fo' this

pr:rpose.

grve best r.u'ts:

Fio. I

,N.r\,k'Ar\,-.rev'e,.abu,e

yoL, a,,.,

e,.t,,"i;

I

*':1"::""t

''

31---t""n'Ftin"

d l"-'

-

Do no+

strike ;+

wi+h d h6mne",

bump rt, or drop

rt

-

-

ar any time.

u* *"

*,"""i i,,ii't"a

*iri ri"

"t',"1.

sofrer sreels-lard

oil or equivalent.

ls)

To adiust

tension on

Quill

Return

Spring-Turn

the spring hous

AJuminum

'nd

other

so{t

al'ovs-kero-

r"o

'*,"+.,"r.j"1,r'"

i. i"",""i"

+" tensionj

To',elease

+he tensiin.

pull

,ri*".J

""

+.-,"tli"r-p."t

1,.u.

Brass-drill

dry or use

parafiin

oil.

l6) T.ole Adi,r#,-ert-To

ti

t the

ble,

pul.

ou+ the

krurled \an e

Die

canings-drill drv or use le'osene'

r"""ili

i"""rir- i""""ii

rr,"

r"si.'""a rernserf

afrer

ad;u*ment

ras

casr

iron-drilr

dry.

been made.

If the

rable is tilted

90 desrees

right

or left, t}e

knuled Do not aftemPt

to make large holes

shourd

the followins

repla:e.m.ent.e.yel

bicome necessarv,

+he fottow-

'".,"']r'";:L"'ftil:;:il;t.:;:r,;!

ine irstalra+ioi

c199ed19

s!r91ld

1._.f9ll.iy:d,

,pi,ar" a"",

".+

.:u"

enrir;ty ouroflhe

(

I

I QUILL

BUMPER

REPLACEMEN

I:-

l.'nJ..,"

+i",pr"Jr"-q,irr

,"it

+.- *"

r""a as described

,"r".

:l1li,; ?fl"l":l::'*il"Jfll

#ll:i

section

4 of

"spindle

adiusrmen+.'

,",,triu* .sr"i"ua

by ;,i"s .,;

";b. Remo,e

old bunper

and

{orce ne" bumPer

;nto

Posiiion

bv

,io"-ro""a

"++""t.."t

showri inria.z.

m"ars of d lone,

slir

.od. Maie.sure.

rhe. bunper

seats ilselt

ProPerrv

This

"'ri"+;""1

;,;,td;

"

i.;;p1;;

belore

re-installins

tle spindle

quill unit

inio

the head.

o{ 200 R.p.M.

t+ can be

a*ached o.

"i" "."-s"

t,,"*.a

in

Ihe holes

p-"ia.i.

io:

iny internediate

are e

in

a smali pieco or

in thin

-rarerial

Fig'

il,e tubt"

-,+

he locled

in

pldce by tishten:ns

the nu'.

wilhoL,t

first

clampins the

.ork

securely

to the table.

For ma:rimum accuracy,

IMPORT'ANT_LUBRICATION

derached in ress rhan

iwo minures.

USE

S.A.E. No.20

MACHINE

OIL

A. Upper

Spindle Pulley

Bear;n9-Oil

l'e-

DRILLS: Afrer

the drill point is dulled {or ihe lirst lime, i+s

,)ffs..

.'eness

depends

entirely upon how :r is

.e9roLnd.

For clean. accurate

drilling, the

operator rusr rerharpen tre d,i.l prope,ly.

The

cone+haped

su{ace dt

the end o{ the drill is cdlled the

"point',

and the

edqe

at

rhe

extreme rip end is.ihe

"dead

center'.

c.

D.

E.

Quill

Bedrincs-Oil

frequenlly.

(Note:

Sp

ndle must be

in lowes+

posi+io. tc

unccver oil hole)Pinion

Sha{+ Hub-Oil occasionally.

Lower

Quill

Bearine-Oil

{requenily.

Lower Spindle

Pulley Bearins-Fill

erease

cup

with Lubrico M-6 Grease

every+hree

Quill

Surface-Oil

should frequently be:p

plied

to the olrlside

sur{ace of +his

quill.

The

spindle

cap

.hould 6e

removed

frequen+ly end

oil applied

to tie splined spindle also.

FIG.3

DEAD

BODY

-2

-

Page 3

OPERATING

INSTRUCTIONS

(Continued)

MORTISING

.i

'

Fig. 5

Fig. 5

Fis. 1

ln order to penet ate the

qor[

the cuttihg edse

must ha"e the

cor

rect cuttins angle and "1ip clearance" at the cenier

of the drill

{Fi9.7}.

Fig.5 shows a drill ground

with

no lip clearance.

The

portion

of

the

drill behind the cuftinq lip k bearins on

+he me+al being cut and

cre-

ven+s

the cuttihs lip froh bifirs

in. The cutting Iip and

heel

"5'

are ;n

the

same plane.

This drill

will

cut

very

poorly,

i{ at all. Fie.6

shows}ov

fhe

"heel",

+he part

directly back

of cu+ting angle, must

be ground away.

THE PROPERLY GROUND DRILL: Two

'.rles

are

especially impor

tan+

when

grinding drill poink. l.

The

Iip clearance

angle

{Fi9.

8A)

should

be between

l2 and l5 degrees. 2.

The

two cutiins edges

must

ue of

equal

length and an9le. ln Fies.8A,8B,8C,

rhe p,operly ground

dr;ll poink is

sho*n.

Re{er to these

ligures

when

srinding

a drill-they

will

aid in grinding drills

which will

cut rrue*ized

holes with a minimum

Fig.88

Fig.8

Use rhe hollow

chi,el

morti,ins Bi.

tachment and

acce*ories

as slown

in

To

'et

up the

mortking

attachment,

firs+ remove

feed stop bracket

and

put

chisel socket

in its

place. See

Fig. 9.

Remo"e +he

{eed stop

eause,

and in-

sert in the chisel

holder.

Thisfeed stop,

in addilion to servinq

as

a depfh

sause,

prevents

rotalional

play in the

quilt.

Select a mortisinq

chisel

and bi+

o{

desired

siue. lnsert

chisel

in socker'

Slide the

bit up

rhrouqh

rhe chisel

and

{asten in collet

<hucl,

leavins

l/15"

clearance

beiween

the

rPur o{

the bir

and the lo.er

edse

o{ the chisel.

rhis

adiustment

must

be care{ully

made ot

a damaqed

bi+ and

chisel

will result.

Turn the spindle

by

hand to

make sure

that the

bi+ runs

{reely.

-z:-1-.

(A

u

.-/.,\.,,;L^"..

ffiP.+71..

>;q.*.*

Fi9.9

Set the ouide {ence in

position

and clamp

the holder

do'n

lishtlv

aoainst the i"" .,*"". .f +h"

*",k.

AdiL,st

ihe lock

nuls

on +le

reed

+'"o

".,".

snd iake the first cut

slowlv,

Raise the

chi5el

frequeirlv

to

dis;ha.qe-the chips.

Move the

work

alons

+he

guido fence

about

t*o'

thnds ihe

*idth

o{ the

mortis;ne

chisel

and take a

second

cut

This

and succeedino cuts

mav be

taken more rapidlv.

RePedt

+he abo"e

oPe'

aiion un+il the desired

hole is completed

DO

NOT FORCE

THE

CHISEL

THROUGH THE

WORK

TOo IIAPIDLY.

Too

rapid {eed

will cause

burned chisels

and b+s.

USE

THE SLOWER DRILL

SPEEDS

FOR MORTISING.

Fig.8A

Fi9.8C

DOVETAILING

Use do"etailing

attachmen+

ar sho*n

i;ons turaished wjrh

attachment.I

;n our catalog.

(See

lnstnrc-

REAMIN6:

Wlen a hole

mr:st be

accuraie to

wit}:n.002

inch

or

iess, ii

is first <iriileri a

iew iirous.r<iihs

or i'r

ii..l uiii",size.;iiJ

tiea

hand-reamed

or

reamed

with ihe

drill

press to the finkh'diame+er.

For

besl results,

Jollow

'the

same

rules irl

reamins as

{ot drilling. Use

slo*

speeds,

feed in evenly and

be sure lhere

are no burr

on +he reamer+eerh'

'

A rearinq allo.ance

be+.een

.ol0 and

l/64 lnch is t,sually sufficient

{or machine-ieamins

Ioles

with diamete's

o{ t lnch or

les-an

"

lo''

ance

oI t/64 ot th2

nch k

recommended

{or machine-reamine

holes

be+ween

I and

2 inches in diameter.

.OO3

+o .005 inch k usually

allowed

for hand reamins operations.

CAUTION!

L usins the

dr;ll

press for any

PUrPose

o+her than driil'

ine, it is necessary

to make

use o{ special

chucks and

adap+ers.

In usino the various

tvpes o{ mortisinq

bi1s, router

b;ts, do'elailing

b;rs etc.,

ihe op"r"ro-

MAY

use a collet-chucL

rather than the Jacobs

c\uck. On

those drills equipped

-:th

d laPered

sPiidle,

it

is ne.essBrv

to remove

the Jacobs chuck and

rhe rhreaded

collar immedialely

above

't.

To

remove Jacobs chuck

from spindle,

place +he sleel

wedse

bet*een

the chuck

ano the knurled collar

and sirike

tle

wedee

a

sharp blow

*rrh

a hammer.

{See

Fiq. l.}

The

chuck

should be caush+

wirh rhe

le{}

hand

in

perlormins

'thk

operalion.

The coller chuck L

PIaced

on the

taDer,

and +he thre;ded

coilar k rhen

replaced.

There is a small flanse on

rhe

inner

side of this collar

which

vill hold the collet chuck

securely

in

oosition on tie ta Der.

l{

rhe Jacobs chucl

is

useo

wilh

any

tyPe o{ cutter

vhere

ther"

ir d

thru+ cominq on

from rl"e side, the chuck

.ill

be

pulled

ofi

the taper'

Th.s can be-quite

dangerous.

Then +oo,

most

o{

rhese operd+ion,

a'e

done ar a hieh speed,

and a collet

chuck k much lieh+er

and is

pre{-"r

able

{or +he Iiqher sp"ed.

The coller

chuck

grips

the

cutter shank all

the

*ay

around instead ot

at

ius+

tFree

poink.

Eractiy the same

p.ocedure is {ollo*ed in irstal'ins

the shapi"g

adapter

wh;cl

k used

on +he tapered

spirdle drirls

lo cary the shapi"s

WOOD CARVING

AND INLAYING

For

this work, use the

special router

or woodcdrying birs shown

in

our cataloq.

The d.'ll

press

should run at a

speed o{ about 5,000 R

P.M.

or

hiqhe". Hold the

piece

to be

wo*ed firmly ;n one hand

and .un thp

bit into

+he work ihe

proper dep+h. Clamp

+he spindle securely at ih;,

point.

No* holdinq

the

work

wirh

bo'h hands

quide

i+

throush

the

desi"ed

desiqn. FreqL,eatly

in car":ns

the

wo*

is

9r:ided

by a

i;q

sa*

paitern

cul our of

plywood. This

Pattern

is

Ias+en"d

to fhe r.rnde*ide

o{ +he work itsel{.

A

pronq pin proiec+inq

up {rom

rhe

table

runs in +he

paitern

and

guides +he

work.

SHAPING

The head nav be

used in

the normal

position

or

in"erted

as shoan

ir

Fiq. 10. Use the special

extension

rable and spring

cl;ps l;sted

in our

catal;q.

when

the dr;ll

is equipped

*ith

d tdPered

spindle, a special

shopinq

adapter is mounted

on

rhe sPindle and

heid

by

the collar abo'e

the ch;ck.

Be sure to

use +he collar

to hold the shapins

adapter in

place.

See

'Cauiion"

above.

Seleci the

proper

cutters

and lock

securely

on rhe arbor. IMPORTANT:

The direc+ion o{ rotation

should

he

TOWARD the wo* to be cut.

Always

set

the

wood

{aclnss as

close to

ihe

cutter as

possible

to secure

maximum

safety. To feed

worl

from

ihe oppo-

'ire

siCe: L

T!rn

c!t+er

or cutierr

over. 2. Reverse direction of

rotarirn

o{ spindle. 3. Place hold.downs

o"

opposiie side.

(A

re,ersing swhch

wil

6e found to be convenient.)

one thin inner collar

slightly higher than the other collars.

Ou+side of

rhis ;s a bronze hearing <ollar and ou+'ide o{ lhe bearing

collar are a

series o{ steel colldrr.

ln

oper.t:on

rhe

wo+

resr, a9a;n5t the outer

rteel

collar

whkh remains pracficdlly +ationary while lhe spindle

revol"es.

These collar may he mounfed abo"e or belo- the cutfer.

The collars

serue as a depih siop {or the

work preventinq

the cutter

from

"hosging-

in". They should always be used on irregular

work.

ln commencinq the cul on

iresular

wo*

use +he stadins

pin

as a

{ulcrum to

prevent

rhe

work from gefting caughi. Bring tie

work

sradu-

ally in contact

wirh

the cut+er.

Hold +he work firmly and keep i+ in

contact

wi+h rhe

depfh

collar. The shape o{ the

piece will

be

soverned

by

its con+ouri hence +lle

worl

mus+

6e

sawed

ro

the

desired shape

be{ore shapinq. USE ONLY

THE HIGHER SPEEDS FOR SHAPINO.

ln shaping circular

or irregular

wo* |

.i i

-n-

|

tfik shapins fence and hold

downs

.re disp.n,"d

wirh. For +his

work've

Fig. l0

recommend and seii a sef

o{ nened deprh collars. ln rhese sefs

}here is

-3-

Page 4

HOW

TO ONDER

PANTS

EQB

CFAFTSMAN

DBITL

PRESS

MODEL

NUMBER

10I.03622

All

parls

listed

here

may be ordered

through any Sears

relail store

or the

mail order

slore

which serves

lhe

lerritory

in which

you

lire.

When ordering, always

gire

the {ollowing:

'1.

Part number in +hi;list,

2. Pari

name and

price

in

this list'

3.

Model

number,

which is 101.03622, and

which

will

be

found on ihe

plate

on the base

o{ +he drill.

ALI, PARTS ARE SHIPPED

PBEPAID

6a-29

E1D:R,

60 9A

ea3402

60

3l

-

62-5a

5a-20-

6a-24

6A

25

9-729

63-62

60-3A'-

63-64.

6l-65

I

iTi

HEAD ASSEMBLY

splined

splndl€ .. .. .. . .. ..

.. .

..

2.50

Spiidle

ouill

.

3.25

Spindle

Pu ley ...... ............

1.55

Spindle Pullei cuard

t.1o

spi.ole

Feed

oilion

S-dfl .ro

P niol

2 25

ch..k R.l.Eie Co .r

'55

ati"dh

A;iri

Bearins

(2

req.) each

2.05

soindr. PJI €v slee'e

2.40

Spirdle

P- le; Sleeve

Bedi.e

(5m

'

l)

2

aa

llea

re.er da ance Sp

ins

'

.50

Feed

Lever Salan.e

Sprini

Housinq

25

Soind €

ThrLr Col

ar

'30

;;;;4,". a;,d

t.2i

S.i.ar"

P,t .r

Bed'inq

P

ate

'40

iii""i"

p,l.i

s.eevi

Be.-rra

(",ce)

2.t0

ili"J."

s"",i""

spdce, ....

'

. '45

s;i'd," Bedan; L;ck Nrt

.lo

i",cr neteare

-Nrt

40

Feed stoD Srud NJ

(2

req.) ed('

..

..

4)

at;;; i'"#; .

.75

O-_ll.

Cl..p n""al"

(il Ls. ds 5o_2ll

55

swirch

rtaie ...

..

25

switch ..

,-'

t5

g,iti

r".l

.. ...

20

Column

Lock .. .

..

30

SDird e

gLd'o

95

o. ii l"cr stee'e

.70

c"l"mn Lo(^ S eeve

'40

Feed

srop Bra<ke_

'75

F..d rld.ole

riub ..

l'50

;;;; ii;;;i;

i4

';;.)

*.h

.40

Hub

Pin......

.....

...

20

h"-

"

spi'"c

Holsinq

cap

'

'

'55

ii.a

'r.ilai"-

e"tt

tr

;"q.t

... '20

Quitt

e,.p.. ..

.

60

i"*i

g"arri'e

45

Ratchei

Pawi

40

Pjnion

shalt Collar '.

.. . .45

Fe;d Hande

Hub

Lock Soew

... .25

Name

Pldie

(Mdster)

....

... .. ....... .20

R;bber B$hi;q

..

.t2

sb,ino lnol il ;si.led)

i""."oin" cord

s5

Ratcher Piwl Knob

.20

TABLE ASSEMBLY

63-

48

-63'66

BD3A

5

BD3A 53

50 taj

6a-32

6C-5

51 52

BD3C. A

50,48

605

60.6A

8D2B-7

63-t4A

60-t7

50-18

50-20

6l-21

63-22

60-24

60

25

60-26

50-31

60-32

50-38

60-3t

50.4t

60-42

BDIA.42

4t-43A

BD] 44

50-44

4l-45

803-45

50-45

63.45

BrJIA-51

st 52

BD3A.53

60-55C

5t-55

63.62

6l-64

63 65

63-66

5l,99

sD3-105

j-ls7

9-2r4

1-729

PARTS

LIST

\^uind Pti..

....

..

$

.30

.15

.30

.40

40 36

60-42

50-44

50-45

60-29

803M"34

60,40

60

55

5t 57

40-60

40-6t

Column

Lock

Column

LDck 5 eeve

Molor

Bdse

MOTOR BASE

ASSEMBLY

BD2-t0

62 50

BD3A.3

Motor Bdse

Pin

(2

,eq.) edch

BASE

M ISCELLANEOUS

t.55

t.50

4.50

.55

.20

8-45

.55

.30

.75

.55

.55

.24

.55

3.50

.30

t.00

Beli

801-8

50-9

BD t- 10

50,!

I

BD

t- t2

BDIA.23A

6r-34

8Dt-37

BD3-54

Chuck

Releale

Wedse

Drill Chu.k

0' io

%"

Drill Chuck

wren.h

lDLER

ASSEMBLY

(Accessorv)

Motor

Ease

B,.cket

Pin

(2

req.) each

ldler Pulley

(2

req.) each

ldler Pulley

(2

req.) each

ldler Pul

ev Eracket

..

ldler P!lley

Brack€i

5ha

ldler Pulley

Shafi...

i;i:;

iill'"i i;;;i

c..;;;,"

c,p

ti

."q.i

"(...w

wilh Ha nd le

Spind

e Lock

Sc.ew

with

Ha

ldler

Pu lley

Bushinq

ldler Pulley

adi.

B,a(ket

Sears,

Roebucl and Company

Enclosed

flnd my checL

ror

$1.8s

{o'which

plea'e

*nd ne bv

parcel

post rhe followins

parts

for my

Craf+sman

Drill Pres,

Model

Nunber 101.03522.

I ea.

60-29 Molor

Pulley

I ea.

5o-44 Column

Lo.k

5.75

2,2A

_40

60-2

62 2A

40-15

All Pticet

Arc

Stbiecf ta Chdhse

Without Notice

NOTTCE:

This i3 NOT a

pa.kinq

rlip.

The

pads

shown .nd lkred

include

acce$ori€s

thal are

not n€celsrilv

part

of

thi3 tocl.

\OTE:

Siandad

parts,

such ai bolts,

.ut!,

wnsh€B, €tc., are not listed .bove at such

pd.ts

.an be obtdiied

locallv'

eo A:az

l

/,"

BD3-45

/,/

Bor

l2s, Richmond,

lnd.

Loading...

Loading...