Page 1

Heating

Products

Commercial

Furnace

Installation

And

Operator’s

Manual

Nov-99

Page 2

Cox systems are shipped “ready to use”. All Employ qualified, experienced installers, to

necessary standard equipment, controls, and wiring insure the safe and efficient operation of your

are packaged with the heating systems. heating system.

Use the supplied furnace and burner manual,

together, to install the system.

TABLE OF CONTENTS

PACKING PROCEDURE…………2 SEQUENCE OF OPERATION…….. 8

FURNACE ASSEMBLY MAINTENANCE………………….. 9

DRAWINGS ….………………….. 3

WIRING DIAGRAM……………….10

FURNACE SPECIFICATIONS..…4

MISCELLANEOUS……………….. 11

CLEARANCES……………………5 A. FILTER RACK ……………….. 11

B. DRAFT HOOD ……………….. 11

INSTALLATION INSTRUCTIONS C. OIL BURNER BLAST TUBE

A. GENERAL ...………………….. 5 LOCATION ………………….11

B. FLUE………...…………………5 D. BLEEDER TUBE …………….. 12

C. COMBUSTION AIR

SUPPLY ……………………… 6

D. BLOWER ADJUSTMENT…… 6

E. BURNER INSTALLATION…. 7

PACKING

1 – Package - 1 – Package-

Prewired and tested furnace assembly: Gas or oil burner:

1- Heat exchanger/combustion chamber and 1- Oil or gas burner and controls

casing 1- Oil nozzle

1- Blower and pulley 1- Instruction manual and literature

1- Motor and pulley 1- Gas burner mounting flange

1- Belt (2 on dual drives)

1- Instruction envelope and (2) wiring diagrams

1- Fan limit installed 1 – Package-

1- Oil burner mounting flange Draft control or draft hood

NOTE: Actual packing may vary according to sizes, weights, models, custom jobs, etc. Optional

equipment may or may not be packed separately.

FOR YOUR SAFETY FOR YOUR SAFETY

If you smell gas: Do not store or use gasoline

1. Open windows or other flammable vapors

2. Don’t touch electrical switches and liquids in the vicinity of

3. Extinguish any open flame this or any other appliance.

4. Immediately call your gas supplier.

DO NOT DESTROY THIS MANUAL

Please read carefully and keep in a safe place for future reference.

2

Page 3

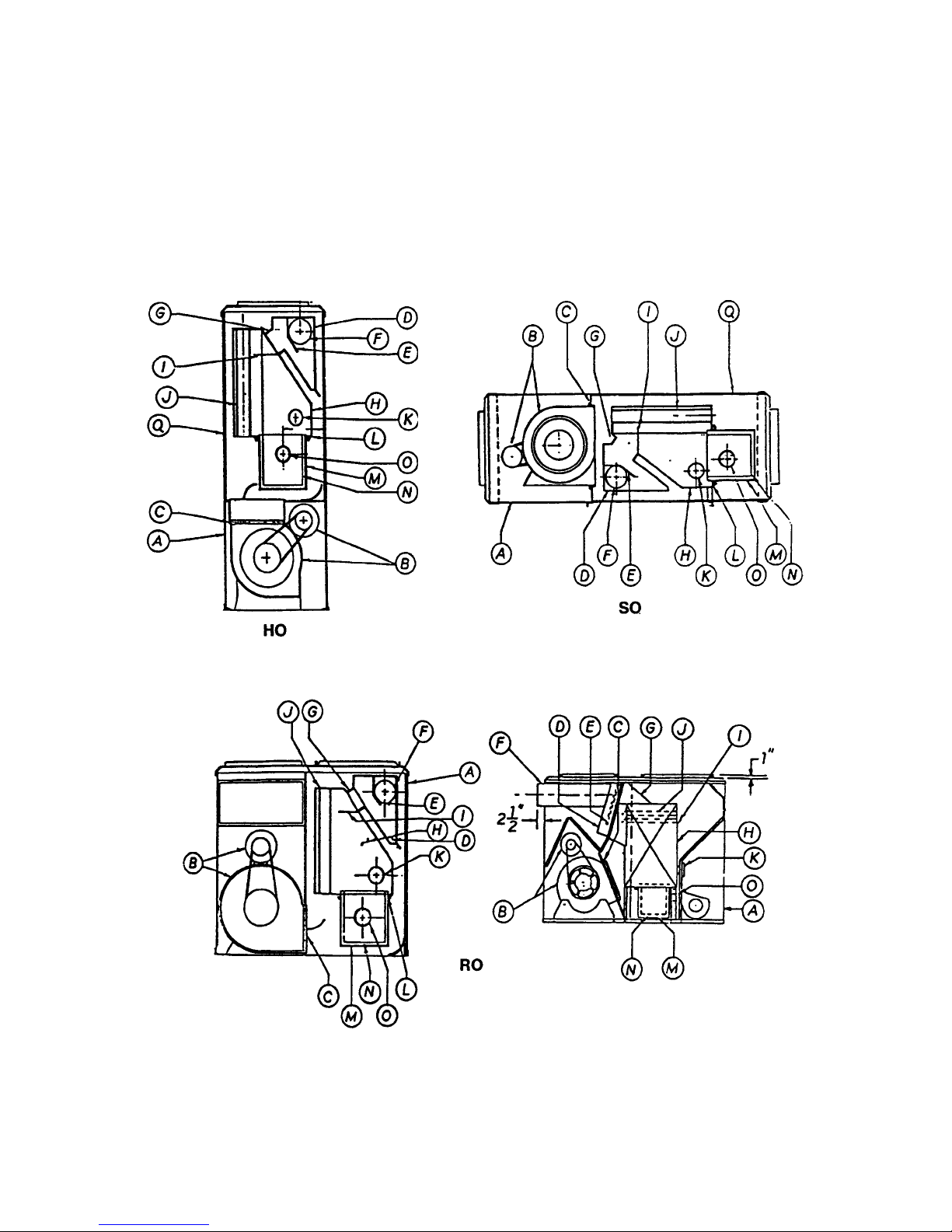

ASSEMBLIES

A. Casing Jacket F. Stack

B. Fan and Motor

C. Felt Pad Exc

D. Radiator I. Heat Exchanger Baffle N. Refractory Lining

E. Radiator Baffle O. Burner Port

G. C

H. Heat hanger M. Combustion Chamber

onnector L. Fiberglass Rope Seal

J. Air Tubes

K. Inspection Port

3

Page 4

SPECIFICATIONS

SO Series (Hor

izontal Units)

Model SO-300 400

utput BTU/HR 2 300,000 ,000 O

put-Gas BTU/HR 281,250 375,000 500,000

In

Input-Oil GPH 2.00 2.50 3.50

CFM @ .33WC ESP 2400 3000 4400

Blower Motor HP 3/4 1 1-1/2

Stack Diameter (in.) 9 10 12

SO-225 SO-

25,000 400

HO Series (High-Boy Units)

Model

Output BTU/HR 225,000 300,000 400,000

Input –Gas BTU/HR 281,250 375,000 500,000

Input-Oil GPH 2.00 2.50 3.50

CFM @ .33 WC ESP 2400 3400 4400

Blower Motor HP 3/4 1 1-1/2

Stack Diameter (in.) 9 10 12

HO-225 HO-300 HO-400

LO-Series (Low-Boy Units)

Model LO-225 LO-300 LO-400

Output BTU/HR 225,000 300,000 400,000

Input-Gas BTU/HR 245,000 375,000 500,000

Input-Oil GPH 2.00 2.50 3.50

CFM @ .33 WC ESP 2400 3400 4800

Blower Motor HP 3/4 1 1-1/2

Stack Diameter (in.) 9 10 12

NOTES: 1. Gas burner through 40 ,000 BTU are AGA listed.

2. Oil Burner is UL listed

0

.

3. Rights retained to cha e specifications and ratings

without notice or liability.

ng

4

Page 5

CLEARANCES

Un nstruction,

less materials used in building co

and/

or application of the heating equipment are of

such

a nature that local authorities to require

othe

rwise, the clearance about the furnace should be:

ABO

VE-6”, SIDES AND REAR-6”, FRONT-48”,

FLU

E PIPE-18”.

W

RNING: LO Models must be placed on non-

A

com

bustible flooring only.

SO

(Horizontal) clearances

Ma

be installed in an alcove with the following

y

clea

rances to unprotected combustible material:

6” a

ove furnace casing, bonnet or plenum.

b

6” above horizontal warm air duct within 6” of

furn

ace.

48”

from front of furnace.

18” om flue pipe in any direction.

fr

6” f

rom back of furnace.

6” f right side of furnace.

rom

6” f

rom any side of plenum.

6” f floor.

rom

INSTALLATION

A.

General

1.

When burner is furnished with separate flange,

caution should be used to insure the air tube

penetrating the chamber to within ½” of the

inside chamber surface. (Don’t push in too

).

far

2. agram. One

Wire burner as per wiring di

diagram is fixed to the inside of the

opy is placed with this manual.

and a c

3.

See installation and operation instructions for

lower drive adjustment in D.5.

b

4.

OIL MOTOR according to instructions on

tor.

mo

5.

Suspend SO units by means of inserting hanging

ds through hanging lugs on furnace. Mount

ro

LO models on non-combustible floor only.

6. ing to NFPA standards

Must be installed accord

for installation of oil burning equipment.

phlet No.31 or NO. 54 for gas.

Pam

7.

Must be installed according to Building Code

andards for the installation of heat producing

St

appliances: heating, ventilating, air-

nditioning, warm air heating and ventilating

co

systems

.

blower door

Area of

room shall be not less than twice the area of the flue

outlet.

Ready access shall be provided for

components in service.

Draft regulator shall bear the listed mark

The combination fan and limit control sh

control listee’s name and listed marking.

The safety control shall bear the contro

name, listed markings and group designat

SO-300 and SO-400 “Air filters shall

mounted on the unit or in the air duct syst

ONLY.

8. Must be installed according to NFPA sta

for the installation of air-conditioning, warm air

heating and ventilating systems.

9. Air requirement into the furnace room for

satisfactory combustion is an area not smaller

than twice the cross sectional area of the flue

pipe. See burner manual.

B. Flue

The chimney must be in good condition

cracks or openings or obstructions in the f

sufficient height to prevent a down dr

installing an oil burner, the smoke pipe and

should be thoroughly cleaned and re

required.

Minimum recommended chimney sizes: Oil

Two gallons of oil per hour and under …..

Two to three gallons of oil per hour…8”x1

Over three gallons of oil per hour….12”x1

All manual dampers sho

smoke pipe before an oil b

lts the draft should beresu

inches at the inspection door and from .05 to .06

the ventilating opening into the furnace

all electrical

ing.

all bear the

l listee’s

ion.

not be

em.” UL

ndards

without

lue and of

aft. Before

chimney

paired if

8”x8”

2”

2”

uld be removed from the

urner is installed. For best

preferably from .02 to .03

5

Page 6

inches at the stack.

measu

red with any good draft gauge.

Excessive draft causes high stack temperatures and

consequently a waste of fuel. Therefore, a reliable

draft regulator is strongly recommended for

p

ractically all installations. Proper, uniform draft

insures efficient, economical operation of the burner.

A good draft regul

sh

ort time through a substantial savings in fuel costs.

Minimum recommended chim

Draft Hood &

Input/hour

Up to 120,000…………………………... 5”

120,001-180,000………………………….. 6

180,001-250,000………………………….. 7”

250,001320,001-410,000…………

410,001-510,000……………………

510,001-610,000…………

610,001-730,000………………………

730,001-860,000……………

860,001-1,000,0

1,

NOTE:

contains more than

pipe and

C.

OIL

D install in rooms with insufficient air to

sup ly combustion. Occasionally, it is necessary to

inst

to ent less

atmospheric air pressure in the room. If there is a

lack flame will be

yellow and formation of soot will occur in heating

unit ldings of conventional frame, brick or

stone construction without utility rooms, basement

win

adeq r

operation of the barometric draft control. For

inst

outs he outside

should be made with a free cross sectional area of

twic

each

GPH

the ng by at least four percent. The

ro

xhaust fans. Do not install an exhaust fan in this

e

ro

320,000………………………….. 8”

000,001-1,140,000……………………… 15”

If the flue pipe exceeds 10 ft. in length, or

draft hood

Combustion Air Supply

o not

p

all windows or louvers in a door to these rooms,

obtain sufficient air and to prev

of combustion air, the burner

. In bui

dows, or stair doors, infiltration is normally

uate to provide air for combustion and fo

allation in an enclosed utility room with an

ide wall, a fresh air opening to t

e the area of the flue outlet of 100 sq. inches for

gallon nozzle size (Example: 10x10 for 1.00

). For each 1,000 feet above sea level, increase

fresh air openi

om should be isolated from any area served by

om.

The draft may be accurately

ator will usually pay for itself in a

ney sizes: Gas

Flue Pipe Size

”

……………….. 9”

…….. 10”

……………….. 11”

….. 12”

…………….. 13”

00………………………... 14”

2 elbows use next size larger

.

GAS

Fresh air requirement into the furnace room for

atisfac

s

for each 1,000 BTU input and a minimum of 100 sq.

in.

tory combustion is 1 square inch of free area

D. Blower Adjustment

Because the Cox Heating unit is so versatile in its

application, it is impossible to be specific in

commending blower speed. Obvi

re

quantity and quality of the duct work and the manner

in which it is applied affects the air delivery.

To adjust blower speed to the applied conditions, it

is recommended that the thermostat be set at highest

setting to gain prolonged burner operation. By

f thermometers, adjust the blower speed

eans o

m

ntil the temperature rise through the unit is equal to

u

5 degrees – 80 degrees (difference in temperature

7

etween air entering and leaving the unit).

b

Unless the temperature of the air entering the units

excessively high (75 degrees or more) such

is

djustment will result in continued burner operation

a

ith a high limit setting of 180 degrees to 200

w

egrees. Should it be impossible to gain an 85

d

egree temperature rise through the unit, the

d

dications are that the fan is running too fast for the

in

en

int ded application of the furnace. Should the air

n

bei g su pplied to the unit be at a temperature higher

than

95 degrees, the indications are that the heated

ir rcuited back to

leaving the unit is being short cia

th

e unit. The remedy is revision of the supply

system, return system, or both.

In

many instances, it will be possible to adjust the

low thermostat to highest

er speed by setting the

b

ti purposes of continued burner operation

t ng (for

se

during adju

200 degrees, increasing then, the blower speed until

the burner no longer cuts out on high limit. Should

the burner cycle on high limit setting, indications are

that the duct static pressure is higher than intended

by the manufacturer, or the temperature of the air

being supplied the unit is excessive. This latter

method is

foregoing paragraph which will be applied

better qualified installer. Should the blowe

cut out, indications are: inadequate firing rate, fa

off setting too high, overload of motor, too

temperature air supplied to the unit or a combin

of same. Duct heaters have a minimum air

requirement as given in “Furnace Specification”

Section Chart.

NOTE: Do not exceed motor rating.

6

stment) and limit control 180 degrees to

not as reliable as that described in the

ously, the

by the

r

r moto

n

high

ation

Page 7

E. Burner Installation

OIL

Equipment – The following equipment shall be

available on each oil burner installation before the

tests are started:

1) Where the oil rate is not indicated on the

nozzle tip, a suitable device for determining

the rate in terms of gallons per hour fed to the

burner shall be used. This may be in the form

of a graduated glass vessel.

2) A suitable flue gas analyzer for determining

the percentage of CO2 in the flue gases.

3) A suitable draft gauge graduated in

hundredths of an inch of water.

4) A suitable thermometer to indicate the

gas temperatures.

5) Provision for inserting a thermometer in

pipe as follows: Not more than 12” from

furnace outlet, measured on the center li

the flue pipe, there shall be a hole not m

than ½” diameter, located at the side of

pipe on the center line so that

thermometer may be inserted horizontally.

The thermometer is to be placed so that

the

ensitive element is one fourth of the pipe diameter

s

rom the far side of the flue pipe. The opening around

f

he thermometer shall be sealed to prevent air

t

eakage. This same

l opening may be used for

checking draft and sampling flue gases.

ocedure – The test procedure is as follows:

Test Pr

1 e burner shall be operated and the fuel rate

) Th

adjusted to that required for the particular

installation.

2

) The draft then shall be adjusted to meet the

burner manufacturer’s specifications, both over

the fire and at the breeching. Refer to

“Installation Instructions” Section, B.

3

) Combustion air adjustments are to be made to

give the highest CO2 without visible smoke

(unburned carbon) at the chimney. If the

minimum required percentage of CO2 cannot be

obtained in the breeching, it will be permissible

to take CO2 over the fire, which will be

acceptable. In this event, both CO2 readings

shall be recorded after 10 minutes of operation.

Readings – During the period of operation to permit

flue gas temperature to reach maximum, periodic

readings of draft CO2 and oil rate shall be taken and

the average recorded on the certificate.

All controls and limiting devices shall be checked

for prop

er operation.

flue-

flue

the

n

e of

ore

the

the

Air for

Combustion – There must be openings into

the furnace room to admit free air to maintain

combustion, minimum opening of not less than twice

the area of flue outlet of furnace.

Size – The burner shall be of adequate size for the

furnace and the connected

mended on the oil bu

recom

installer. Models and Firing Rate : See “Furnace

Specification” Section.

heating load as

rner certificate by the

Certificate – Following installation of the burner,

certain test data shall be obtained and recor

e installer on the oil burner certificate to be placed

th

with each oil burner installation. The test shall cover

the following points: CO2 in the flue gas by

analysis, draft, stack temperature, firing rate, and

smoke.

Requirements – The standard requirements as

approved by the industry as follows:

1) CO2 – The CO2 in the flue gas by analysis

shall not be less than 8%.

2) Draft - The draft shall be in accordance with

specifications in the manufacturer’s

installation manual. An automatic draft

regulator or its equivalent is required.

3) Stack Temperature – The stack temperature

shall be measured on the furnace side of

automatic draft regulator and not more than

12 inches from the smoke connection. The

stack temperature shall be measured at the

certified firing rate. If an automatic draft

regulator is built into the furnace, such

regulator shall be clos

temperature is measured.

4) Firing rate – The firing rate shall be based on

the burner manufacturer’s recommendation

for the existing total connected load. Burner

shall be fired at that rate.

5) Smoke – During the above test, there shall be

no visible smoke at the chimney.

6) Installation Manual – The burner shall be

installed in accordance with manufacturer’s

installation manual.

Fuel Tank Connections – Pipe connections between

fuel tank and the oil burner should be made with 3/8”

copper tubing and brass fittings, however, galvanized

pipe is quite satisfactory. All joints should be sealed

with key paste or other good oil resisting compound,

and pulled up tight. Where fuel tank is installed in a

basement, a one-pipe system to the burner will be

found entirely satisfactory.

When fuel ta

nnections should be arranged so they will not be

co

oken if the tank should settle. Always use a good

br

leak-proof check valve in the suction lin

7

nk is buried underground, all pipe

ed when the stack

e.

ded by

Page 8

Adjusting the Burner – Afte

rn

b

u er, tank, and controls have been completed and

all wiring ca

1) Leave line switch open and set thermostat well

above room temperature.

2) Make sure that the resetting device on the control

panel is in operating position.

Set can at gauge port or bleeder tube opening to

3)

ca

pu

res

switch and replace plug or gauge.

Close line switch. The burner then should start.

4)

Check oil pressure and adjust, if necessary, to

5)

100 lbs.

Adjust air shutter on burner so that flame burns

6)

clean with slightly smoky tips. Burner is shipped

with air shutter closed.

Start and stop the burner several times by

7)

op

8) Cl

ad

sh

AS

G

Size – The burner shall be adequate size for the

furnace and the connected heating load as

recommended on the gas burner certificate by the

installer. Models and BTU input rating: See “Furnace

Specification” Section.

refully checked.

tch oil. Close line switch and allow burner to

mp oil until flows clear. If control locks out,

et, and when oil comes out clear, open line

ening and closing main line switch.

ose main line switch and change thermostat

justment to below room temperature. Burner

ould stop.

r the installation of the

SEQUENCE OF OPERATION

OIL

Thermostat calls for heat. 1.

2. Protector relay energizes motor and ignition

transformer.

Pump supplies fuel to nozzle.

3.

Burner ignites.

4.

Furnace blower activates at blower “ON” setting.

5.

Area is heated and thermostat is satisfied.

6.

Protector relay de-energizes burner components.

7.

Furnace blower continues to operate until fan

8.

limit “OFF” setting.

9. End of cycle.

Certificate – Following the installation of the burner

certain test data shall be obtained and recorded by the

installer on the gas burner certificate to be placed wit

each gas burner installation. The

fo

llowing points: CO2 in the flue gas by analysis, draft,

stack temperature, firing rate.

test shall cover the

h

Requirements – The standard requirements as

approved by the industry are as follows:

1) CO2 – The CO2 in

not be less than 8%.

2) Draft – The draft shall be in accordance with

specifications in the manufacturer’s installation

manual. An automatic draft regulator or it’

equivalent is required.

3) Stack Temperature – The stack temperature shall

be measured on the furnace side of automatic draft

regulato

smoke connect

measured at the certified firing rate. If an automatic

draft regulator is built into the furnace, such

regulator shall be closed when the stack

te perature is measured.

4)

Firing Rate – The firing rate shall be based on the

burner manufacturer’s recommendation for the

ex

at

5)

Smoke – During the above test, there shall be no

vi ible smoke at the chimney.

6) In

in

ma

r and not more than 12 inches from the

m

isting total connected load. Burner shall be fired

that rate.

s

stallation Manual – The burner shall be in stalled

accordance with manufacturer’s installation

nual.

the flue gas by analysis shall

ion. The stack temperature shall be

GAS

1. h

T

ermostat calls for heat.

2.

Burner motor starts and spark ignition begins.

3. i

lot valve opens.

P

4.

Pilot ignites.

5. Fla

6. M .

7. Burner ignites.

8. Furnace blower activates at blower “ON” limit

9. Area is heated and the thermostat is satisfied.

10. Thermostat de-energizes burner components.

11. Furnace blower continues to operate until fan

12. End of cycle.

me sensor proves pilot.

ain gas valve is opened

setting.

limit “OFF” setting.

,

s

8

Page 9

MAINTENANCE

Servicing the Burner – After the burner installation

been put in service, it shou

has ld be rechecked during

the first two weeks to make certain that it is

tioning properly. Note the com

func bustion is proper

and there are no gas or oil leaks, also that the

rent controls perform correctly.

diffe

OIL

ery oil burner should be serviced a Ev t least once a

year, preferably at the beginning of the heating

season.

1) Remove electrode assembly and clean, replace

nozzle.

Oil motor.

2)

Check all oil lines con

3) nections and make sure

that there are no leaks.

Clean strainers in fuel unit.

4)

5) Test starting and stopping of burner by moving

thermostat.

Make certai

6) n that fire burns clean and that draft

gulator is in good working order and adjusted

re

r proper amount of draft.

fo

GAS

Every gas burner should be serviced at least once

a year, preferably at the beginning of the heating

season.

1) Check and adjust electrode assembly.

2) Oil motor.

3) Check all gas lines connections and make

sure that there are no leaks.

4) Test starting and stopping of burner by

moving thermostat.

5) Make certain that fire burns cle

draft regulator is in good working order and

adjusted for proper amount of draft.

N

OTE: For complete burner operation

i nual.

nstructions see th e respective burner ma

an and that

Employ only qualified personnel to service heating

equipment. For safety, the main power switch must

be in the “OFF” position.

1. Air filters – Inspect filters monthly and replace

or clean when necessary.

Oiling – Oil the burn2. er motor and blower motor

according to the instructions on the motors. The

blower bearing may be permanently lubricated

and sealed and require no oil or grease.

3. Belts – Check belts for wear and proper tension.

Belts may stretch or wear and require

replacement. Belt tension may be checked by,

depressing the belt at a point halfway between

the pulleys. The belt should travel one inch.

Burner – Refer to the manual that was supplied

4.

with the burner for speci

nozzles should be replaced at least once in a

season. Gas orifices should be cleaned yearly.

Electrodes should be checked and set according

to the burn

housing should be cleaned if necessary.

er manual. The blower wheel and

fic information. Oil

5. Combustion – Using proper equipment, recheck

for proper and efficient combustion (No CO, or

less than #

1 smoke, 8-9% CO2).

9

Page 10

10

Page 11

11

Page 12

12

Loading...

Loading...