Page 1

Flow Processor

EC80

CXX-UM-03060-EN-01 (April 2019)

User Manual

Page 2

Flow Processor, EC80

April 2019CXX-UM-03060-EN-01Page ii

Page 3

User Manual

CONTENTS

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Symbol Explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Typical Congurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring and Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

RM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

RM2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

XP1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

RM1 Conguration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

RM2 Conguration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

XP1 Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Using the IFC Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Password Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Establish Link Via RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Establish Link Via Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Prole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Creating, Saving and Loading Proles. . . . . . . . . . . . . . . . . . . . . . . . . 22

Uploading a Prole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Prole Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page iii CXX-UM-03060-EN-01April 2019

Page 4

Flow Processor, EC80

Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rotor Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pressure Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Temperature Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Conguring Flow processor Outputs and Inputs . . . . . . . . . . . . . . . . . . . . . 30

Frequency Outputs (1 and 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Analog Output (Channels 1, 2, 3 and 4). . . . . . . . . . . . . . . . . . . . . . . . 31

Conguring Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Conguring Liquid Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Temperature vs Viscosity Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Temperature vs Density Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Liquid Pressure Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Hardware Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Model Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

General Hardware Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Oscillation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Meter Selection (BUS ID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Real-time Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Real-Time Report Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Flow processor Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Downloading Proles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Locating Multiple EC80 Flow Processors . . . . . . . . . . . . . . . . . . . . . . . 41

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Conguration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Report Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Communication (Comm.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Database, Gator Display, Gator Report and Real Time Clock (RTC) . . . . . . . 43

Version Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

April 2019CXX-UM-03060-EN-01Page iv

Page 5

Description

DESCRIPTION

The EC80 Flow Processor provides a state-of-the-art interface for today’s flow

meters. With multiple frequency inputs and one temperature input in a compact

design, the flow processor is compatible with single and dual rotor turbine flow

meters for precise calculation and output of flow rate or accumulated flow.

The linearization, viscosity and density correction features improve flowmeter

accuracy to the highest levels available today. Our newest feature allows the flow

processor, with a Cox Auto Viscosity Turbine Meter, to automatically measure and

compensate for kinematic liquid viscosity.

SAFETY INFORMATION

The installation of the flow processor must comply with all applicable federal,

state and local rules, regulations and codes.

Failure to read and follow these instructions can lead to misapplication or misuse

of the flow processor, resulting in personal injury and damage to equipment.

Safety Symbol Explanations

DANGER

INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED WILL RESULT

IN DEATH OR SERIOUS PERSONAL INJURY.

INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED COULD

RESULT IN DEATH OR SERIOUS PERSONAL INJURY.

INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED COULD

RESULT IN MINOR OR MODERATE PERSONAL INJURY OR DAMAGE TO

PROPERTY.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable

accessories for any physical damage such as scratches, loose or broken parts, or

any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier's agent within 48

hours of delivery and file a claim with the carrier. A claim for equipment

damage in transit is the sole responsibility of the purchaser.

Page 5 CXX-UM-03060-EN-01April 2019

Page 6

Operating Principle

RTD

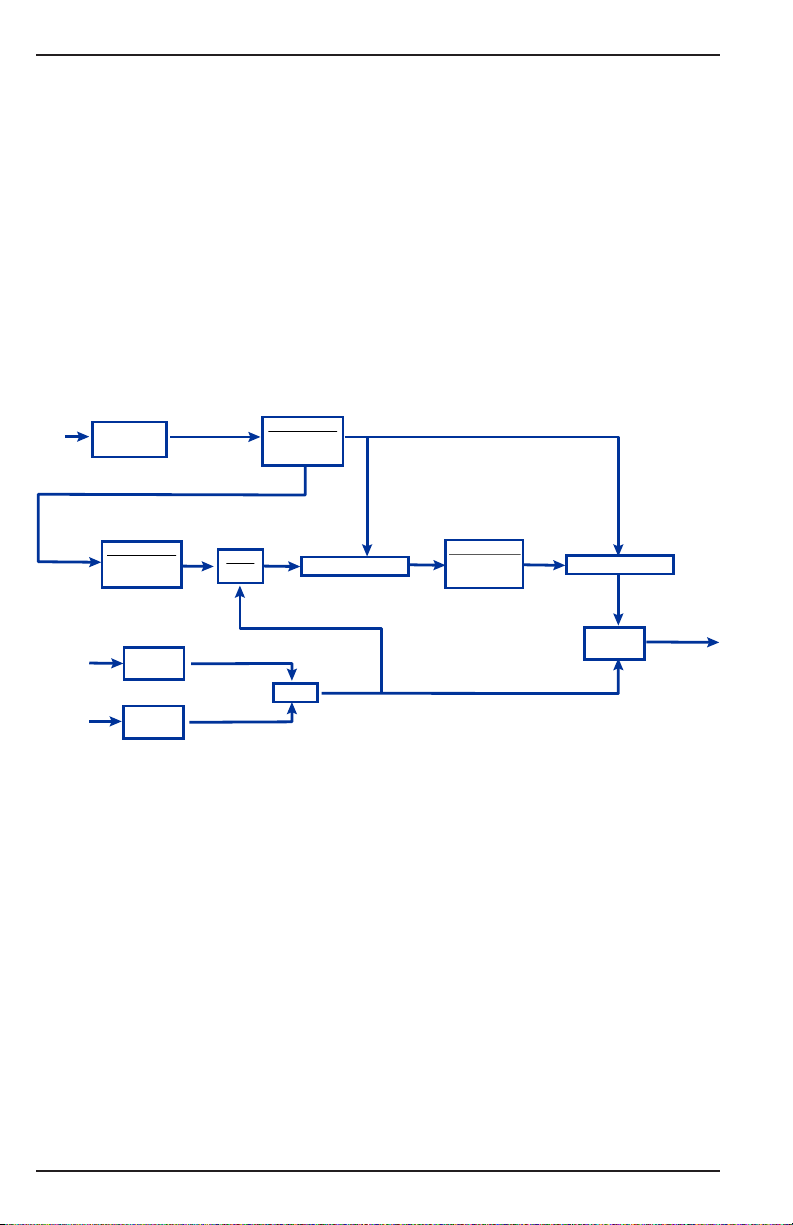

OPERATING PRINCIPLE

The EC80 Flow Processor accepts all types of square wave pulse inputs. Fully

compensated and linearized volumetric flow rates, totals and temperature are

examples of flow parameters that can be viewed through serial communications,

included software program or an embedded rate indicator (depending on

product configuration).

The EC80 Flow Processor can use a universal viscosity curve to compensate for

varying liquid temperature and viscosity conditions. It can also use

Strouhal-Roshko algorithms for a more comprehensive compensation method,

taking into consideration all the secondary effects to which the meter is sensitive

like the expansion and contraction of the meter bore diameter. The flow processor

extracts the density value of a known liquid from a stored temperature/density

table and multiplies by the volumetric flow rate to get the inferred mass flow rate.

Measure

Temperature

Counts

Lookup Table

Temperature

vs Counts

Temp

Temp

Rotor A

Rotor B

Lookup Table

Viscosity vs

Temperature

Measure

Frequency

Measure

Frequency

Ro

v

Fa

Fb

act

Fsum

v

1+2(alpha)(deltaT)

Fsum

Fa+Fb

Figure 1: Flow Processor Calculations

Ro

ref

Lookup Table

Strouhol vs

Roshko

St

ref

1-3(alpha)( delta T)

St

act

Calculate

Flow Rate

Q

supply

April 2019CXX-UM-03060-EN-01Page 6

Page 7

Installation

INSTALLATION

Precautions

• Turn off power supply prior to making any connections to the flow processor.

• Verify that the power supply is rated to deliver enough current for

your application.

• Do not submerge or place flow processor in moisture-prone environments.

• Do not place the flow processor in close proximity to high voltage and/or

current carrying lines. It is sensitive to Electro-Magnetic Interference (EMI).

• Verify that all terminations at the flow processor are free from frayed wires and

terminate with proper insulation at terminal blocks.

• Before applying supply power, make sure the power setting is not in excess

of the flow processor’s rating. A setting over the rating will cause the flow

processor to fail and not be covered under the warranty.

• Tighten all terminal block connections with reasonable firmness. Do not

over-tighten the screw down terminals.

• Use adequately gauged wires for transferring signals to and from the flow

processor printed circuit board (PCB).

• Make sure the PCB will not be exposed to excessive shock.

• Make sure the PCB will not be exposed to heat that exceeds the temperature

rating of the flow processor electronics.

• Pay careful attention to the grounding scheme for your application. Use low

impedance grounds, common to all electronics.

• If the PCB is exposed, be careful that debris, loose conductor strands or any

other foreign matter does not come in contact with terminals and/or electrical

components and connections.

Page 7 CXX-UM-03060-EN-01April 2019

Page 8

Installation

C

(NOT INCLUDED)

DETAIL N

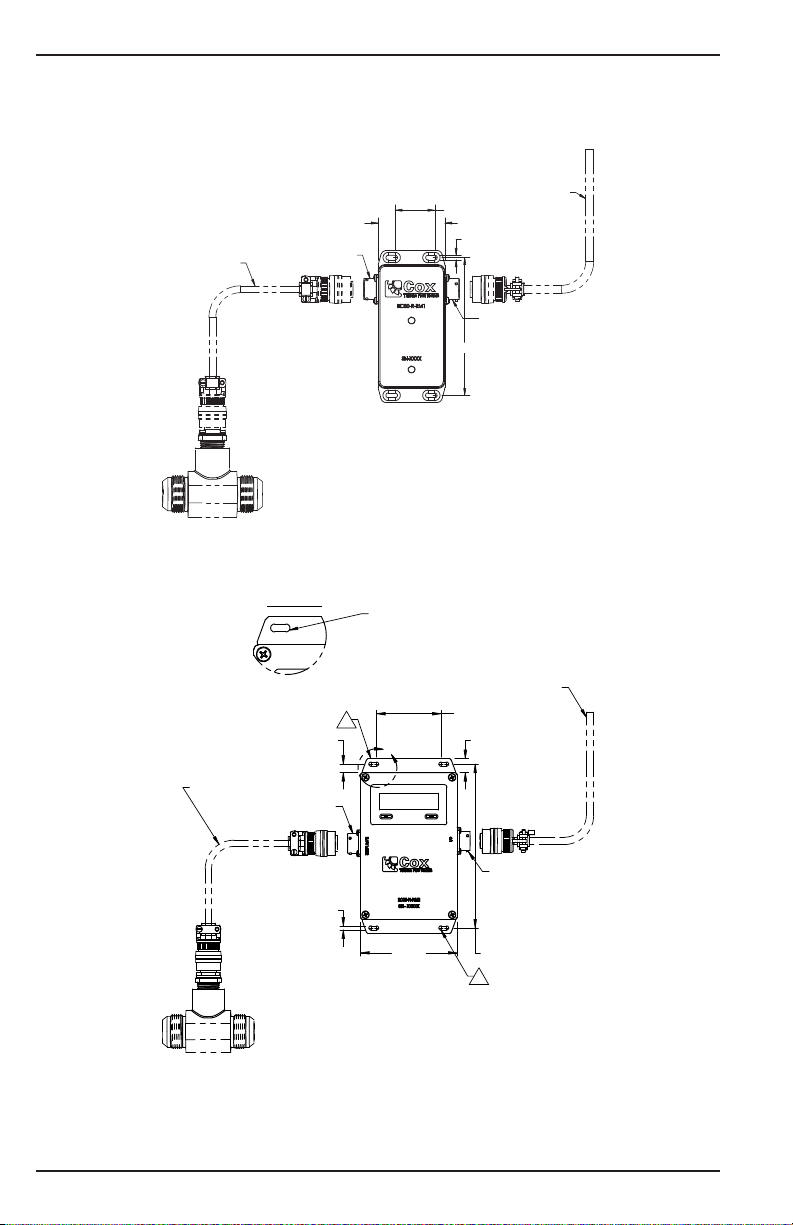

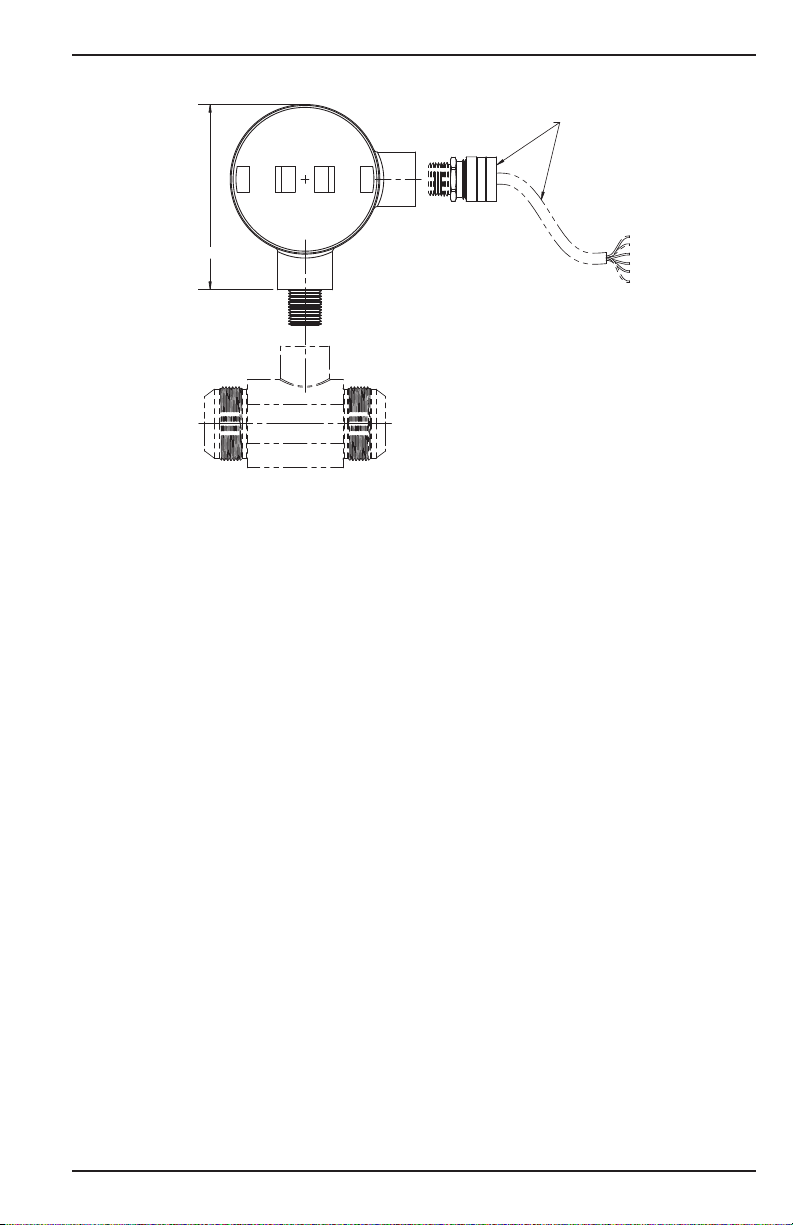

Typical Congurations

RM1

ABLE

* CONFIGURATION SHOWN

IS TYPICAL FOR RF INPUT.

RM2

PT02E-12-8P

Figure 2: RM1 Configuration

REMOVE ANODIZATION

TO EXPOSE ALUMINUM

2X 1.42

2.4

4X.17

2X 4.92

CABLE

(NOT INCLUDED)

PT02E-12-14P

2X .33

CABLE (NOT INCLUDED)

PT02E-12-8P

4X .16

* CONFIGURATION SHOWN

IS TYPICAL FOR RF INPUT.

Figure 3: RM2 Configuration

CABLE (NOT INCLUDED)

3

N

2X 2.50

.55

PT02E-12-14P

2X 6.37 3.74

3

April 2019CXX-UM-03060-EN-01Page 8

Page 9

XP1

2X 4.7

B-9541 CABLE WITH 6907K13

CORD GRIP. (NOT INCLUDED)

* CONFIGURATION SHOWN

IS TYPICAL FOR RF INPUT.

Figure 4: XP1 Configuration

Installation

Page 9 CXX-UM-03060-EN-01April 2019

Page 10

Input

INPUT

The flow processor has inputs for turbine meters (both single and dual rotor) and

temperature. The flow processor calculates mass flow rates based on volumetric

flow with temperature compensation.

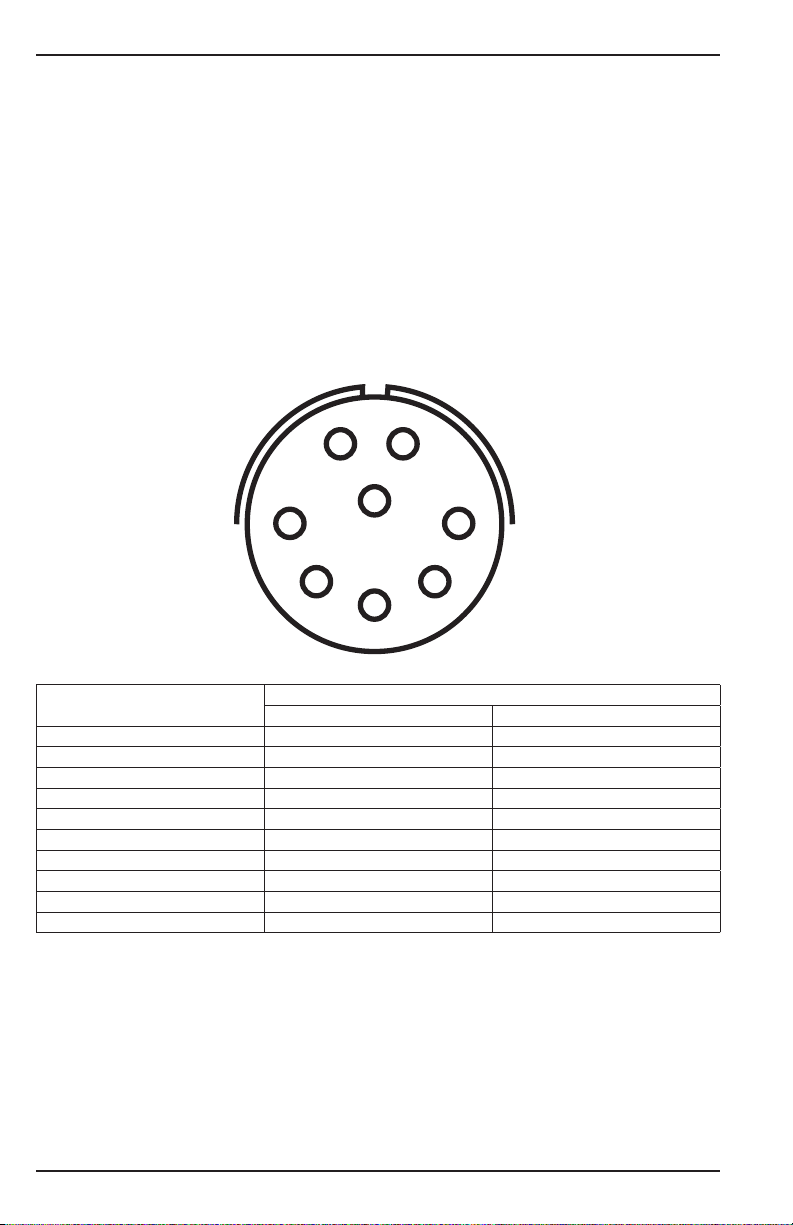

Analog Input

You can configure the analog input for different types of temperature transducers.

The flow processor is supplied with a 10 kΩ thermistor but can be

jumper-configured for 0…5V DC, 0…10V DC or 4…20 mA temperature

transducers. Consult the factory if you need to incorporate the analog input for

reasons other than temperature acquisition. See “Installation” on page7 and

“Wiring and Jumpers” on page12 to select a particular temperature transducer.

G

F

A

B

H

E

C

D

Figure 5: Input diagram

Function/Signal

RF PICKOFF A A A

RF A RETURN B B

RF PICKOFF B C C

RF B RETURN D D

RF PICKOFF Q N/A N/A

RF Q RETURN N/A N/A

RTD EX+ E E

RTD + F F

RTD – G G

RTD EX- H H

RM1 RM2

Pinout

April 2019CXX-UM-03060-EN-01Page 10

Page 11

Outputs

OUTPUTS

You can configure all flow processor outputs for different parameters, and can

do so independently of other channels. Use the IFC15 software to program the

following output parameters:

Frequency

• Linearized Flow Rate (Volumetric or Mass)

• Raw Frequency Rotor A

• Raw Frequency Rotor B

• Raw Sum; Frequency A + Frequency B (Dual Rotor Applications)

• Total Flow (Accumulation)

Analog

• Linearized Flow Rate

• Temperature

B

C

A

F

E

D

H

L

M

K

J

N

Figure 6: Output diagram

Function/Signal

PWR + A A

PWR RETURN B B

RS-485 + C C

RS-485 – D D

RAW A OUT E E

RAW B OUT F F

GND H H

FREQ 1 OUT J J

FREQ 2 OUT K K

GND L L

ANALOG 1 VOLTAGE OUT M M

ANALOG 2 VOLTAGE OUT N N

AGND P P

ANALOG 4-20 mA RETURN – P P

ANALOG 4-20 mA OUT + R R

RM1 RM2

R

P

Pinout

Page 11 CXX-UM-03060-EN-01April 2019

Page 12

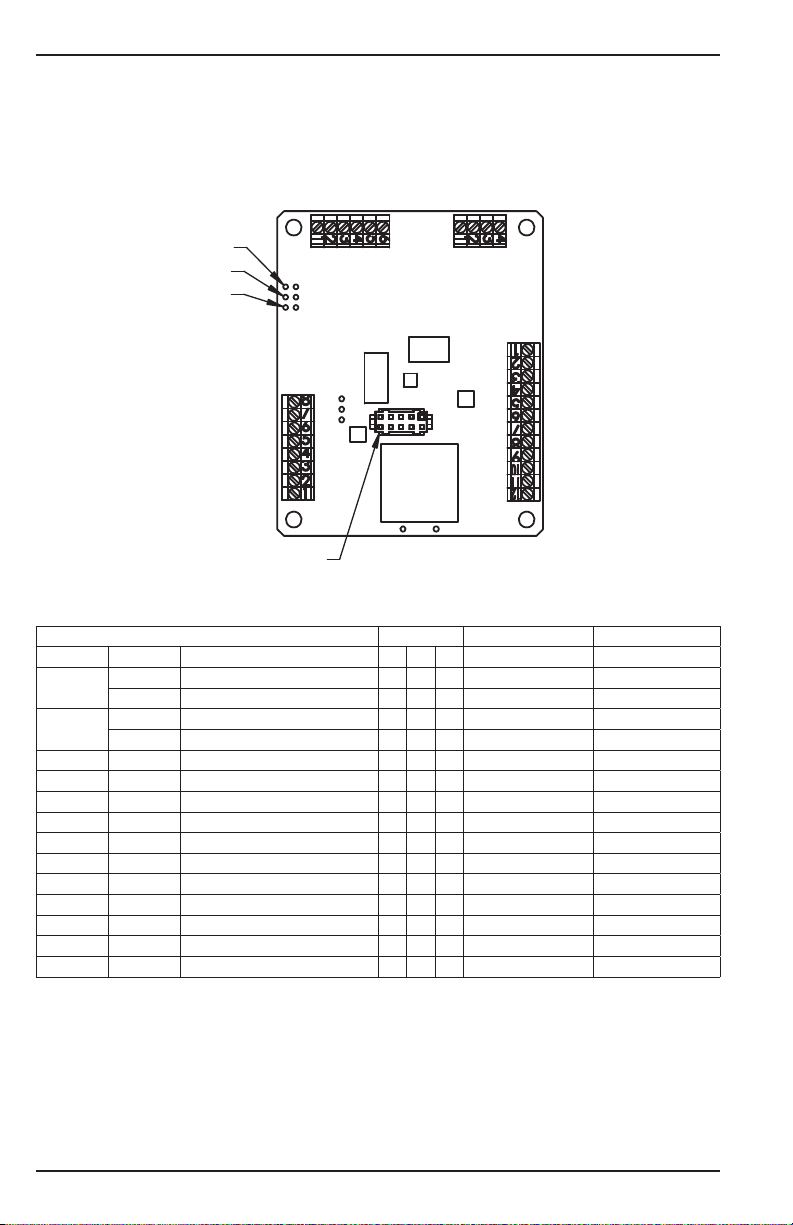

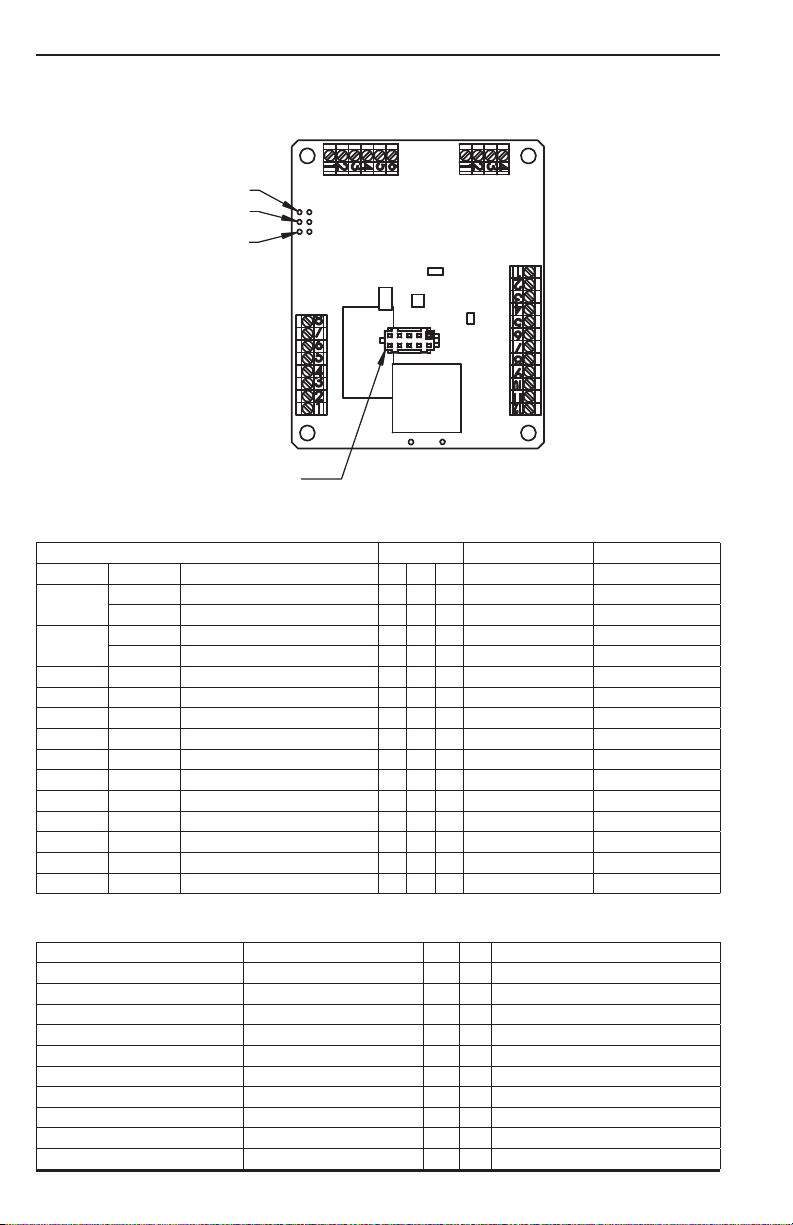

Wiring and Jumpers

JMP

EF4295 TERMINAL BLOCK LAYOUT

PGM PORT

JMP

JMP

WIRING AND JUMPERS

RM1

J2

J1

-C

-B

-A

JMP-1

J5

J4

EC80 Flow Computer to PT02E-12-14P

EC80 B-9541 CABLE PT02E-12-14P

SCALING UNITS FUNCTION/SIGNAL J1 J4 J5 WIRE COLOR PINOUT

N/A

N/A

N/A Hz RAW A OUT 1 ORG E

N/A Hz RAW B OUT 2 RED/WHT F

N/A Hz GND 3 ORG/BLK H

N/A Hz GND 6 GRN/BLK L

N/A N/A AGND 7 BLU/BLK P

N/A N/A ANALOG 4-20 mA RETURN – 3 RED/BLK P

VDC+ PWR + 1 RED A

VDC- PWR RETURN 2 BLK B

N/A RS-485 + 5 WHT C

N/A RS-485 – 6 WHT/BLK D

Hz FREQ 1 OUT 4 GRN J

Hz FREQ 2 OUT 5 GRN/WHT K

V ANALOG 1 VOLTAGE OUT 9 BLU M

V ANALOG 2 VOLTAGE OUT 8 BLU/WHT N

mA ANALOG 4-20 mA OUT + 4 BLK/WHT R

April 2019CXX-UM-03060-EN-01Page 12

Page 13

Wiring and Jumpers

Flow-Meter to EC80 Flow Computer

B-9541 WIRE COLOR FUNCTION/SIGNAL J2 J5 PT02E-12-8P PINOUT

WHT RF PICKOFF A 1 A

WHT RF A RETURN 2 B

BLU RF PICKOFF B 3 C

BLU RF B RETURN 4 D

GRN RF PICKOFF Q 5 N/A

GRN RF Q RETURN 6 N/A

ORG RTD EX+ 4 E

ORG RTD + 3 F

ORG RTD – 2 G

ORG RTD EX- 1 H

JMP-1 Pickoff Jumper Table

JMP-A ON ROTOR A 4 OHMS

JMP-A OFF ROTOR A 10 OHMS

JMP-B ON ROTOR B 4 OHMS

JMP-B OFF ROTOR B 10 OHMS

JMP-C ON ROTOR Q 4 OHMS

JMP-C OFF ROTOR Q 10 OHMS

Page 13 CXX-UM-03060-EN-01April 2019

Page 14

Wiring and Jumpers

PGM PORT

EF4295 TERMINAL BLOCK LAYOUT

RM2

JMP-C

JMP-B

J2 J1

JMP-1

JMP-A

J5

J4

EC80 Flow Computer to PT02E-12-14P

EC80 B-9541 CABLE PT02E-12-14P

SCALING UNITS FUNCTION/SIGNAL J1 J4 J5 WIRE COLOR PINOUT

N/A

N/A

N/A Hz RAW A OUT 1 ORG E

N/A Hz RAW B OUT 2 RED/WHT F

N/A Hz GND 3 ORG/BLK H

N/A Hz GND 6 GRN/BLK L

N/A N/A AGND 7 BLU/BLK P

N/A N/A ANALOG 4-20 mA RETURN – 3 RED/BLK P

VDC+ PWR + 1 RED A

VDC- PWR RETURN 2 BLK B

N/A RS-485 + 5 WHT C

N/A RS-485 – 6 WHT/BLK D

Hz FREQ 1 OUT 4 GRN J

Hz FREQ 2 OUT 5 GRN/WHT K

V ANALOG 1 VOLTAGE OUT 9 BLU M

V ANALOG 2 VOLTAGE OUT 8 BLU/WHT N

mA ANALOG 4-20 mA OUT + 4 BLK/WHT R

Flow-Meter to EC80 Flow Computer

B-954 WIRE COLOR FUNCTION/SIGNAL J2 J5 PT02E-12-8P PINOUT

WHT RF PICKOFF A 1 A

WHT RF A RETURN 2 B

BLU RF PICKOFF B 3 C

BLU RF B RETURN 4 D

GRN RF PICKOFF Q 5 N/A

GRN RF Q RETURN 6 N/A

ORG RTD EX+ 4 E

ORG RTD + 3 F

ORG RTD – 2 G

ORG RTD EX- 1 H

April 2019CXX-UM-03060-EN-01Page 14

Page 15

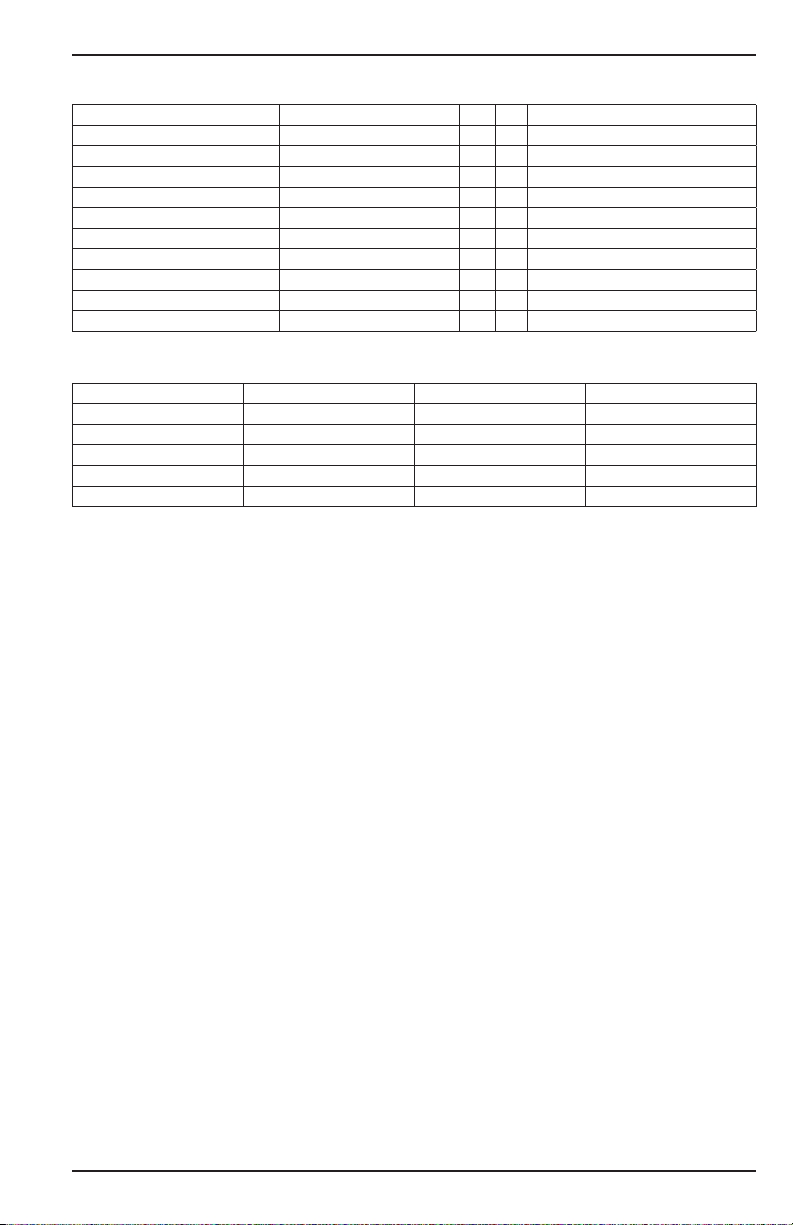

JMP-1 Pickoff Jumper Table

EF4295 TERMINAL BLOCK LAYOUT

PGM PORT

5

JMP-A ON ROTOR A 4 OHMS

JMP-A OFF ROTOR A 10 OHMS

JMP-B ON ROTOR B 4 OHMS

JMP-B OFF ROTOR B 10 OHMS

JMP-C ON ROTOR Q 4 OHMS

JMP-C OFF ROTOR Q 10 OHMS

XP1

Wiring and Jumpers

J2

J1

JMP-C

JMP-B

JMP A

JMP 1

J

J4

EC80 Flow Computer to B-9541 Cable

SCALING UNITS FUNCTION/SIGNAL J1 J4 J5 WIRE COLOR

N/A

N/A

N/A Hz RAW A OUT 1 ORG

N/A Hz RAW B OUT 2 RED/WHT

N/A Hz GND 3 ORG/BLK

N/A Hz GND 6 GRN/BLK

N/A N/A AGND 10 BLU/BLK

N/A N/A ANALOG 4-20 mA OUT – 3 BLK/WHT

VDC+ PWR + 1 RED

VDC- PWR RETURN 2 BLK

N/A RS-485 + 5 WHT

N/A RS-485 – 6 WHT/BLK

Hz FREQ 1 OUT 4 GRN

Hz FREQ 2 OUT 5 GRN/WHT

V ANALOG 1 VOLTAGE OUT 12 BLU

V ANALOG 2 VOLTAGE OUT 11 BLU/WHT

mA ANALOG 4-20 mA OUT + 4 RED/BLK

EC B-9541

Page 15 CXX-UM-03060-EN-01April 2019

Page 16

Wiring and Jumpers

JMP-1 Pickoff Jumper Table

JMP-A ON ROTOR A 4 OHMS

JMP-A OFF ROTOR A 10 OHMS

JMP-B ON ROTOR B 4 OHMS

JMP-B OFF ROTOR B 10 OHMS

JMP-C ON ROTOR Q 4 OHMS

JMP-C OFF ROTOR Q 10 OHMS

Flow-Meter to EC80 Flow Computer

WIRE COLOR FUNCTION/SIGNAL J2 J5

WHT RF PICKOFF A 1

WHT RF A RETURN 2

WHT RF PICKOFF B 3

WHT RF B RETURN 4

WHT RF PICKOFF Q 5

WHT RF Q RETURN 6

RED OR YLW RTD EX+ 4

RED OR YLW RTD + 3

WHT OR YLW RTD – 2

WHT OR YLW RTD EX- 1

April 2019CXX-UM-03060-EN-01Page 16

Page 17

DIMENSIONS

RM1 Conguration

Dimensions

A

B

A

B

C

A 3.40 in (86.36 mm) 1.22 in. (30.99 mm)

B 2.38 in. (60.45 mm) 5.43 in. (137.92 mm)

C — 0.16 in (4.06 mm)

RM2 Conguration

C

A 4.75 in (120.65 mm) 2.18 in. (55.37 mm)

B 3.74 in. (95.00 mm) 1.99 in. (50.55 mm)

C 5.71 in. (145.03 mm) 6.81 in. (172.97 mm)

D — 0.06 in. (1.52 mm)

Front View

Front View Side View

A

B

Front View

Front View Side View

Side View

A

B

Side View

C

D

Page 17 CXX-UM-03060-EN-01April 2019

Page 18

Dimensions

XP1 Conguration

A

A

B

B

C

C

Front View Side View

Front View Side View

A 4.70 in. (119.38 mm) 2.71 in. (68.83 mm)

B 2.80 in. (71.12 mm) 4.70 in. (119.38 mm)

C 2.80 in. (71.12 mm) 0.80 in. (20.32 mm)

April 2019CXX-UM-03060-EN-01Page 18

Page 19

Specications

SPECIFICATIONS

Linearized Frequency ± 0.1% of reading

Performance

Input Power

Temperature Environment

Flow Meter Input Type (A and B)

(Two Independent Channels)

RTD Temperature Input

4-Wire

Analog Input

(For Temperature)

Frequency Output

(Two Independent Channels)

Analog Outputs

(Two Independent Channels)

EIA-485 Serial Data

Raw Frequency Output

(Two Independent Channels)

Enclosure

Environmental Rating

Remote Cable Length

Software Conforms to SAE ARP4990 calculations for temperature

Linearized Analog

Output

Process Latency 100 s

Nominal 24V DC, 2w maximum

With Digital Output 7…32V DC

With Analog Output 12…32V DC

Operating –40…185° F (–40…85° C)

Storage –67…257° F (–55…125° C)

Humidity 0…80% RH, non-condensing

Pulse TTL Compatible

(A and B)

RF Carrier

4 or 10 Ohm Pickup

Type 100 Ohm platinum, 0.00385 alpha

Useable Range –65…365° F (–55…185° C)

5 Hz Sine Response

Voltage 0…5V or 0…10V DC

ADC Resolution 12 bit (1/4096)

Input Impedance >100k Ohms

0…5V, TTL, 1…20,000 Hz, square wave

50% duty cycle

Minimum Load

Impedance

16-bit resolution

Channel One 4…20 mA, 0…5V DC or 0…10V DC

Channel Two 0…5V DC or 0…10V DC

Load Impedance

(4…20 mA)

Baud 115k

Update Rate Selectable, 0.1 sec minimum

Data Bits 8

Stop Bit 1

Parity None

0…5V, TTL, 5…3500 Hz, square wave

5k Ohm minimum load

Remote

Remote with Display

Blind Integral

Flow Meter to EC80 20 ft (6.1 m)

EC80 to DAQ or Control

System

± 0.1% of full scale

Frequency range: 5 Hz…5.0 kHz

Carrier frequency range: 25…65 kHz

Frequency range: 5 Hz…5.0 kHz

10k Ohm

500 Ohms maximum

Aluminum enclosure with

weatherproof mounting flange

Aluminum enclosure with

weatherproof mounting flange

NEMA 4 (IP65)

Class 1, Groups C and D

Class 2, Groups E, F and G

Class 3, WET LOC — Cast Aluminum

100 ft (30.5 m)

Page 19 CXX-UM-03060-EN-01April 2019

Page 20

Using the IFC Software

USING THE IFC SOFTWARE

OTE:N When you first run the program, if any error messages display, close them

out. The IFC configuration has not been initialized yet.

Password Initialization

The Password feature allows only users with permission to access or manipulate

the data in the configuration profile and flow processor.

If multiple users are interfacing with the software, set a default User Name

and Password that is easily remembered. For example: User Name=admin;

Password=admin

Un-installing or re-installing does not erase any set users.

To set the password for the first time, or to add a user name later:

1. Click the Options icon in the upper left portion of the toolbar of the main

GUI screen.

Options Icon

Figure 7: Options icon

Options Icon

2. Select the General tab to view the password options.

OTE:N The General options are also available from File > Options > General.

Figure 8: General options

3. Enter a Company name and Technician name. These two elds remain the same

when opening the Options window, and are not protected.

4. Enter a Login name and Password to be associated with a specic prole.

April 2019CXX-UM-03060-EN-01Page 20

Page 21

Using the IFC Software

IMPORTANT

Be sure to write down the password or click the Remember Password checkbox.

Entering an incorrect password locks the software.

5. Click New User.

6. Enter the same password in the Conrm Password box, and click OK. After

conrmation a new user is created and you are returned to the options screen.

Figure 9: Confirm password box

7. Click Login to login with the user you just created. The currently logged-in

person can then access the Graphical User Interface (GUI), and make changes to

IFC proles.

OTE:N The first user to initialize the software can also choose to add new users.

Establish Link Via RS485

You need to establish communication between the PC and the flow processor

hardware before you can program the flow processor using IFC. Make sure the

cable is connected and the flow processor is powered on.

OTE:N You can see which com port you are connected to using your operating

system’s device manager.

To establish communications:

1. Click the Options icon in the upper left portion of the toolbar of the main

GUI screen.

2. Select the Comm tab to view the communications conguration options.

OTE:N The Comm tab is also available from File > Options > Comm.

3. From the drop-down menu, select the communication port.

4. Set the Baud Rate to 115200.

5. Click Apply.

6. Click OK.

7. View the status area for connection info.

Figure 10: Comm Section

Page 21 CXX-UM-03060-EN-01April 2019

Page 22

Prole

New

Save

Establish Link Via Ethernet

If the flow processor in use is capable of Ethernet communication you can connect

to the PC with an ethernet cable.

To establish communications:

1. Check the Use TCP/IP box.

2. Type the IP Address for the connected ow processor.

3. View the Status area for connection info.

PROFILE

A profile is all the information that is programmed into the software, including

Linearization tables, liquid properties, input and output settings, and others. You

can use a profile to program the EC80 Flow Processor. You can also upload a profile

from a previously programmed flow processor, save a profile for later use and copy

a profile.

The following sections describe how to work with profiles.

Creating, Saving and Loading Proles

Open

Figure 11: New, Load and Save buttons

Create a new profile by going to File>New or clicking the New button on the

toolbar. Save a new profile by selecting File>Save As and then choosing a save

location and filename. You can quickly save the file later by selecting File>Save,

or clicking the Save button on the toolbar. Open a previously saved profile by

selecting File>Open, or clicking the Open button on the toolbar.

Uploading a Prole

You can upload an existing profile from the EC80 Flow Processor and save it under

a different filename, then manipulate the data, yet still retrieve the old data if

necessary.

IMPORTANT

Always keep an OEM copy (original) of the profile, in case you want to restore the

factory configuration.

1. Click the Upload button in the toolbar of the main GUI screen. This retrieves

the prole currently stored in the ow processor (if previously downloaded)

and places all prole data from the ow processor in the GUI.

2. Click the File menu.

3. Click Save As.

April 2019CXX-UM-03060-EN-01Page 22

Page 23

Prole Programming

4. Click the Down Arrow the Save In: eld and browse to the directory in which

you want to save the le.

5. In the File name: eld, type a name for your le

(for example, YOUR FILE NAME.fdp).

6. Make sure the Save as Type: eld indicates Proles (*.fdp) and click Save.

Figure 12: Save profile

All tables and configuration information are now in the profile for ready access.

PROFILE PROGRAMMING

You can Enter data into a profile and use it to program the flow processor.

You can program profiles in two ways:

• Manually change each cell value to correspond with calibration data, or

• Import multiple values into the interface using Microsoft Excel®.

Although the Linearization table is the table most often modified, any of the data

entry look-up tables can be modified. Make sure to follow these guidelines when

importing or exporting the data.

• Always erase the cell(s) entirely before entering data so the new data does not

combine with prior profile data.

OTE:N To erase all cells of a grid, right-click the IDX button in the upper left

corner of the grid and select Clear Grid.

• The number of XY pairs imported from Excel must be less than or equal to the

available number of index numbers (IDX) for each respective look-up table.

• To avoid truncation or excessive interpolation of profile data, make sure the

Excel data tables match the maximum number of columns for each respective

look-up table. For example, if the table holds 100 XY pairs, then maximize the

resolution of the table by placing points at all 100 index points.

• Data obtained through independent testing needs to be manually entered,

cell by cell, or entered into Excel first and then copied into the profile.

Page 23 CXX-UM-03060-EN-01April 2019

Page 24

Prole Programming

• If the data collected is not formatted to use the maximum number of IDX

entries in the GUI, accuracy is jeopardized. For example, if independent testing

yields only 50 Roshko/Strouhal points (IDX linearization entries) the data will

not be as accurate as it would be by using all 100 points in the

Linearization table.

• Data tables interpolate between points.

• Data tables do not extrapolate beyond the minimum and maximum values.

The flow processor holds the last value in the table, if the threshold is

exceeded.

Flow processors with factory-created profiles have pre-formatted data in the cells

of each lookup table. Powerful software, in conjunction with highly repeatable

and accurate calibration systems, provides Badger Meter the ability to fit

accurate curves to calibration profiles. Using linear, exponential or logarithmic

interpolation, the flow computer can use and optimize the maximum number of

IDX entries.

April 2019CXX-UM-03060-EN-01Page 24

Page 25

Prole Programming

Table Data Entry

To manually modify or update a table in the IFC software (using the linearization

table as an example):

1. Navigate to the table.

2. Right-click the IDX button in the upper left corner of the grid and select Clear

Grid. The table may change appearance slightly.

Figure 13: IDX button

3. Click in each cell and type the new value.

IMPORTANT

Be careful when typing the values, as keystroke errors can occur. Verify all data entries

prior to downloading the profile into the EC80 Flow Processor.

Figure 14: Example table

A more convenient method is to copy and paste multiple data entries from

Microsoft Excel. This procedure saves time and provides data accuracy.

To import multiple values into the interface using Microsoft Excel:

1. In Excel, highlight a minimum of 2 (X,Y) pairs and a maximum of up to 200

(X,Y) pairs, and copy them to the clipboard.

a. For example, if we had a total of three Roshko/Strouhal (X,Y) pairs (for the

example Linearization table, other tables use different calculated values),

the Excel spreadsheet would be set up as below:

Roshko (X) Strouhal (Y)

1.7782794 1.77827941

1.9179102 2666.6081

2.068505 2776.4523

b. Click and drag over the data to be copied, but not the column or row labels.

Only grab the raw data from the Excel spreadsheet. Make sure that the

Roshko values are located on the left side as the X-axis variable, and the

Strouhal values are on the right side as the Y-axis variable (for the example

Linearization table, other tables have different calculated values).

Page 25 CXX-UM-03060-EN-01April 2019

Page 26

Prole Programming

c. With the Roshko/Strouhal values highlighted, right-click in the shaded area

and click Copy to place data onto the clipboard. Alternatively, with the data

highlighted, press Ctrl+C to copy the data to the clipboard.

2. Switch to or re-open the GUI and right-click IDX in the upper left corner of

the table.

3. Select Paste Grid to copy the raw data from the clipboard to the table.

Figure 15: Pasted table

Linearization

The Linearization process takes a raw, non-linear output from a turbine meter and

performs mathematical calculations to provide a linearized output. The EC80 Flow

Processor uses the Roshko/Strouhal method for correlating the meter’s volumetric

flow rate and reflects the sum of all rotors. In a single rotor application, the sum

Roshko and sum Strouhal equate to the correlation of a single rotor. In a dual rotor

application, the sum Roshko and sum Strouhal equate to the correlation of both

rotors, summed together.

The minimum number of IDX (X,Y) entries for the linearization table is 2. The

maximum number of IDX (X,Y) entries for the linearization table is 200. Fill out the

table according to instructions in “Table Data Entry” on page25.

In addition to the Linearization table itself, a number of additional fields on the

linearization tab can be changed. Although not typically modified from factory

settings, they perform additional advanced operations in the EC80 Flow Processor.

Field Function

Corresponds to the coefficient of thermal expansion of the flow meter housing. This field

Alpha

Reference

Temp

Rotor

Frequency

Cutoff

is factory configured for the thermal expansion of stainless steel. The thermal expansion

coefficient for stainless steel is 9.6 × 10-4 or 0.0000096. Other expansion coefficients are

available from the factory.

The reference temperature, in degrees Fahrenheit, in which the calibration data was

obtained. Typical calibration reports state the reference temperature in which the data

was obtained, and should be the same as the temperature in which the Roshko/Strouhal

calibration data was obtained.

These fields limit the output of the flow processor to a minimum and maximum

frequency threshold. If rotor frequency decreases below the minimum flow rate or over

the maximum flow rate, the flow processor stops outputting a flow rate. The left column

corresponds to the rotor frequency of the A rotor (Upstream), and the right column is for

the B rotor (Downstream). In single rotor applications, only the left field is used.

April 2019CXX-UM-03060-EN-01Page 26

Page 27

Prole Programming

Standard vs. Auto-Viscosity

The EC80 Flow Processor, when used with a dual rotor turbine meter, incorporates

the ability to determine liquid viscosity directly from the turbine meter. The Auto-

Viscosity feature is applicable only to liquid viscosities at or below 40 cStk. If you

are unsure as to what range of viscosity you are operating over, please contact

Badger Meter, as a large database of liquid properties has been generated.

To select the Auto-Viscosity feature:

1. Click the Linearization tab on the GUI interface main screen.

Figure 16: Linearization tab

2. Click on the drop-down menu.

Figure 17: Liquid drop-down menu

3. Highlight Turbine (Liquid - Auto Viscosity) and click to select:

Figure 18: Auto Viscosity option

The Linearization table displays, showing the Auto-Viscosity feature enabled.

Remember, the liquid being metered must be below 40 cStks to use this feature. If

you’re unsure of the liquid’s viscosity, call Badger Meter at 877-243-1010.

Page 27 CXX-UM-03060-EN-01April 2019

Page 28

Prole Programming

Load Rotor Table

Rotor Ratio

Figure 19: Ratio tab

The Rotor Ratio table provides a number of powerful diagnostic and analytical

features. In dual-rotor applications, the ratio of the upstream and downstream

rotors can be compared to provide self checks, diagnostic provision or

automatically determine the liquid viscosity.

Rotor ratio is typically configured at the factory; however it can be implemented

by the user as well. The flow processor obtain’s frequency data from each rotor

and calculates the frequency ratio. Once the flow processor calculates the ratio

it associates a high order polynomial and a Roshko number to the data. The

frequency ratio is calculated as follows:

RotorRatio =

Where, Fa = Frequency of Rotor A, and Fb = Frequency of rotor B.

Use this ratio function to address any potential failures in the meter. Because

the flow processor is comparing the frequency output of one rotor to the

other, you can determine if bearing failure, pickoff failure or even liquid

particulates are hindering meter performance. This same method is also used to

determine viscosity.

Fb

Fa

Figure 20: Load rotor table button

Upon editing any fields contained in the Rotor Ratio table, the Load Rotor Table

button appears in the menu bar as seen in Figure 20. This provides the ability to

write updated Rotor Ratio information to the EC80 Flow Processor.

OTE:N The Load Rotor Table button does not write the entire profile down to

the flow processor, it only writes the information contained in the Rotor

Ratio table.

Field Function

If the ratio is exceeded by the set percentage, the flow processor will output zero flow,

Error

therefore stating a malfunction has occurred. Further prognosis could lead to pickoff failure,

Range

bearing failure or flow processor failure

Once the ratio is exceeded, therefore indicating a failure of some kind, the error timer

Error

dictates how long the meter will have to stay in excess of the current set ratio percentage,

Timer

before an error condition occurs and zero flow results

April 2019CXX-UM-03060-EN-01Page 28

Page 29

Prole Programming

Pressure Calibration

Figure 21: Pressure tab

The Pressure table is used for calibrating pressure transducers. Pressure calibration

does not apply to the EC80 flow processor.

Temperature Compensation

Figure 22: Temperature tab

The Temperature table provides the necessary calibration of the flow

processor’s temperature input device. Obtain a temperature profile by testing

the temperature sensor being used. The temperature profile is unique to the

individual sensor. To calibrate the temperature sensor:

1. Place the temperature sensor in a temperature bath.

2. Enter the temperature vs. counts data into the Temperature

Compensation table.

Typical applications use either a 10k Thermistor or 100 Ohm Platinum

RTD. This provides the flow processor the look-up table necessary for

temperature acquisition.

Page 29 CXX-UM-03060-EN-01April 2019

Page 30

Conguring Flow processor Outputs and Inputs

CONFIGURING FLOW PROCESSOR OUTPUTS AND INPUTS

Frequency Outputs (1 and 2)

Figure 23: Frequency out tab

The Frequency Out table is used for configuring both of the EC80 Flow Processor’s

frequency outputs. All EC80 Flow Processors come with 2 frequency channels,

and the channels can be configured independently. Use this table to completely

configure the type of information to be output for each channel, and adjust the

output scaling. A few possible types are volumetric flow rates, mass flow rates,

temperature (both ° F and ° C), the sum of rotor frequencies (Rotor A + Rotor B),

pressure and differential pressure.

1. Click the down arrow to select the engineering unit. The engineering units for

Frequency 1 and frequency 2 do not need to be the same.

2. Fill the tables according to instructions in “Table Data Entry” on page25. The

rst entry typically corresponds to zero ow and is set to zero Hertz, while

the last entry is typically maximum ow. The maximum output frequency is

sixteen Hertz.

OTE:N Setting the maximum flow rate to a frequency greater than 16 kHz causes

the flow processor to output 16 kHz.

Click the summation check box to enable totalizing (accumulation) of the

frequency output. This feature is only applicable to special firmware editions.

The feature needs to be configured at the factory and is not available in standard

applications. The feature works by summing flow rates and outputting a frequency

proportional to total flow, not flow rate.

The test frequency button takes the value input as the scaling frequency and

outputs that frequency from the flow processor. Use this feature to verify that

the flow processor is outputting the appropriate frequency and to verify the

calibration of the flow processor.

April 2019CXX-UM-03060-EN-01Page 30

Page 31

Conguring Flow processor Outputs and Inputs

Analog Output (Channels 1, 2, 3 and 4)

Figure 24: Analog out 1 tab

Use the Analog Out tables to configure the EC80 Flow Processor’s analog channels.

Use this table to completely configure the type of information and scaling. Not

all EC80 Flow Processor boards have an analog output. If yours does, use this

procedure. You can select the engineering unit for things such as volumetric flow

rate, mass flow rate and temperature.

OTE:N The EC80 Flow Processor needs to be jumper-configured prior to selecting

the corresponding electrical type. See “Wiring and Jumpers” on page12

for more information.

The electrical waveform needs to match your board’s jumper configuration.

1. Select the bullet next to the waveform for which the ow processor’s analog

channel is jumper-congured (0…5V DC, 0…10V DC or 4…20 mA).

2. Select the engineering unit from the drop-down menu.

3. Fill the tables according to instructions in “Table Data Entry” on page25. The

rst entry typically corresponds to zero ow, and is set to 0V DC or mA.

Calibrate Analog Channels

In addition to adjusting the scaling and determining the unit of measurement,

you need to calibrate the analog channels. Typically, 10 points are performed in

calibration, evenly spaced throughout the range of the channel. For instance,

on a 0…10V channel, the output would be calibrated at 1, 2, 3, 4, 5, 6, 7, 8, 9 and

10V DC.

1. Use a multimeter to monitor the output.

2. Press the left or right arrows to adjust the Digital-to-Analog Converter (DAC)

counts until the multimeter reads the correct value.

3. Click Set Output to store the number of DAC counts and move on to the next

index point.

Use the summation check box for totalizing (accumulation) of the frequency

output. This feature is only applicable to special firmware editions. The feature

needs to be configured at the factory and is not available in standard applications.

The feature works by summing flow rates and outputting a frequency

proportional to total flow, not flow rate.

Page 31 CXX-UM-03060-EN-01April 2019

Page 32

Conguring Flow processor Outputs and Inputs

Conguring Analog Input

Figure 25: Analog input 1 tab

You can configure the analog inputs (Analog In 1, Analog in 2 and Analog In 3) to

accept external analog devices.

Typically, this applies to flow processors that use pressure compensation, where

an external pressure transducer is used. In special instances, analog inputs may

be used for other functions. Consult the factory if your application includes an

analog input.

The electrical waveform needs to match your board’s jumper configuration. See

“Wiring and Jumpers” on page12 for more information.

1. Select the bullet next to the waveform that the ow processor’s analog

channel is jumper-congured for (0…5V DC, 0…10V DC or 4…20 mA).

2. Select the engineering unit from the drop-down menu.

3. Fill the tables according to instructions in “Table Data Entry” on page25. The

rst entry typically corresponds to zero ow, and is set to zero V DC or mA.

April 2019CXX-UM-03060-EN-01Page 32

Page 33

Conguring Liquid Properties

Delete Selected Liquid

CONFIGURING LIQUID PROPERTIES

Figure 26: Liquid properties tab

Use the Liquid Properties table to correct for changes in liquid viscosity,

compute mass flow rate via density tables and provide pressure versus viscosity

compensation.

Use the drop-down menu to select a liquid and display the liquid properties that

were factory configured.

If needed, create a new liquid by following these instructions:

1. Click the text of the drop-down menu to highlight the text.

2. Type a new liquid name.

3. Fill the viscosity table through use of the viscosity calculator or import a table.

4. Click the Save Liquid Tables button to Save the new liquid.

When you change the data in the table or re-name an existing liquid, the software

shows additional options in the menu bar:

Load Liquid Tables

Figure 27: Liquid tables buttons

Save Liquid Tables

The teal cylinders buttons appear for modification of the liquid registry. The

choice is:

Field Function

Load Liquid

Tables

Save Liquid

Tables

Delete Selected

Liquid

Loads the currently stored liquid tables. The liquid tables are stored on the PC

Overwrites any existing liquids stored on the PC and creates a group of liquids

based on what is saved

Deletes the currently selected liquid from the liquid registry. Liquids are selected

via the drop-down box or placing your cursor in the corresponding liquids table,

which activates the liquid and allows for deletion from the liquid registry

Page 33 CXX-UM-03060-EN-01April 2019

Page 34

Conguring Liquid Properties

Temperature vs Viscosity Table

Figure 28: Temperature vs Viscosity Table

You can populate the entire viscosity table, all 100 index points, with the Viscosity

Calculator tool. You need to know two liquid viscosities and the corresponding

liquid temperature and enter them in the yellow cells.

OTE:N Please pay close attention to appropriate units when entering data into

the fields above. The temperature units are in Fahrenheit (° F), the Density

units are in Pounds per Gallon (Pounds/Gal) and Viscosity is in

Centi-Stokes (cStk). The temperature engineering unit (T1 and T2)

is degrees Fahrenheit (° F) and kinematic viscosity (V1 and V2) is in

centistokes (cStk).

To populate the table:

1. Type a liquid name in the white eld near the top of the table.

2. Click the bullet next to the ASTM or Andrade method for computation of

viscosity. The ASTM equation is typically more accurate.

3. Input the lesser temperature value and the corresponding viscosity value in

the top-most yellow data elds of the viscosity calculator (T1 and V1), and the

greater temperature value and the corresponding viscosity value in the middle

row of yellow data elds of the viscosity calculator (T2 and V2).

OTE:N Do not place the lesser temperature on the middle row of yellow cells

because that causes the viscosity calculator to fail and possibly corrupt

profile data.

4. Specify minimum and maximum temperature values. This tells the viscosity

calculator over which range in temperature to populate the temperature vs

viscosity table.

OTE:N Exceed your intended operating temperature by 5…10 degrees or more

so that temperature range is not exceeded and proper viscosity correction

takes place in the flow processor.

5. Click the Fill button to populate the temperature vs viscosity table.

April 2019CXX-UM-03060-EN-01Page 34

Page 35

Conguring Liquid Properties

The software calculates the viscosity across the entire specified temperature

range. The most commonly used and most accurate method for calculating

viscosity is the ASTM method. However, the Andrade method may be used.

OTE:N All calculations are done per ASTM D341 when ASTM is selected.

Temperature vs Density Table

Figure 29: Temperature vs Density Table

The density table is only applicable when a mass flow rate is needed. Using the

flow meters temperature sensor, density is calculated from the Temperature vs

Density table and then multiplied by the volumetric flow rate to obtain the mass

flow rate.

MassFlowRate = VolumetricFlowRate × Density

Leave these fields blank or clear the table using the IDX button (right-click the IDX

button and select Clear Grid), if a mass flow rate is not needed.

You will need to get the density properties from our factory or independently

in order to calculate mass flow rate. If difficulty arises in obtaining density

information regarding your liquid, have Badger Meter test the liquid properties in

our laboratory, and supply you with the temperature vs density information.

Liquid Pressure Compensation

Figure 30: Liquid Pressure Correction Coefficient table

Liquid pressure compensation is not available for the EC80 Flow Processor.

Page 35 CXX-UM-03060-EN-01April 2019

Page 36

Hardware Conguration

HARDWARE CONFIGURATION

Model Information

The model information is on the left side of the interface. It shows information

pertaining to the profile currently loaded (For example, if you upload a profile

from the flow processor, the hardware information is for that flow processor).

The model information is input at the factory and offers our technicians the base

information needed for troubleshooting or profile tracking. Do not change these

factory settings.

Figure 31: Model information

Field Function

IFC Model

IFC SN

Meter Model No Identifies the configuration and features of the flow meter

Meter SN Provides traceability and calibration information for the flow meter

Firmware Revision

Identifies the configuration of EC80 Flow Processor for which the profile

was designed

Provides traceability of an individual EC80 Flow Processor and

associated documentation

States the flow processors firmware configuration and provides historical

revision control

General Hardware Information

The general hardware information is on the left side side of the interface just

below the model information. It contains factory configuration information

regarding the Clock Frequency, Carrier Frequency, Input and Output Average, and

Low Flow Cutoff (in gpm).

Figure 32: General hardware information

April 2019CXX-UM-03060-EN-01Page 36

Page 37

Hardware Conguration

OTE:N The clock frequency and carrier frequency match the particular model of

flow processor in use. Do not change these factory settings.

Field Sub-Field Function

Frequency

Average

Low Flow

Cutoff

Clock (Hz) Configured at the factory to match individual EC80 Flow Processor.

Carrier (Hz)

Output

(Cycles)

Input

(Cycles)

Numeric

Entry (GPM)

Configured at the factory to optimize resonance curve when using RF

carrier pickoffs.

The number of output samples necessary before the flow processor yields

a single value at the output. If data obtained from the flow processor is

updating too fast, use this feature to smooth the data so more samples

are taken prior to outputting a value.

The number of input samples necessary before the flow processor yields

a single value at the processor. If data obtained from the flow processor

is updating too fast, use this feature to smooth the data so more samples

are taken prior to inputting a value to the processor.

The low flow cutoff omits erroneous data in the low flow region of a

turbine meter. Near zero state conditions or pulsating flow may cause

erratic readings near zero flow. In this case, the flow processor can be

told to not output a flow rate below the set flow rate. Low Flow Cutoff is

typically set to zero and not used.

Oscillation

The Oscillation tab is only used at the factory to calibrate the flow processor’s

internal clock. Do not change these factory settings.

Figure 33: Oscillation tab

Meter Selection (BUS ID)

The software has provisions for multi-drop applications, where multiple flow

processors need to communicate to one central location. In order to address

multiple meters, you must designate a different Bus ID# to each flow processor.

There are 256 available Bus IDs (0…FF). Each ID consists of a one- or two-digit

hexadecimal value, where 0 = 0, and 255 = FF. In order for the software to

search and display a particular flow processor, you must upload the Bus ID (see

instructions below). This tells the interface to attempt communication with that

particular Bus ID.

Page 37 CXX-UM-03060-EN-01April 2019

Page 38

Real-time Monitoring

The Bus ID information displays in the lower left corner of the main screen.

Figure 34: Bus ID information

To address an individual flow processor:

1. Click on the Current Bus ID # eld.

2. Change the value to correspond with the meter to be addressed.

3. Click the Upload icon on the toolbar of the main GUI screen.

The prole from the ow processor you addressed then populates the software

interface with the information stored in that particular ow processor.

4. (Optional) Click the Download icon to place another ow processor’s prole

into the currently selected ow processor.

REALTIME MONITORING

The EC80 Flow Processor outputs

real-time values via the established RS485

communication. Parameters and variables

can be viewed in the Status section of the

IFC15 GUI. The Status screen displays the

item (variable), the numerical value, the

engineering unit, and, if applicable, the

number of counts associated with that

particular variable.

You can select which parameters to view in

the options menu under the Report Display

tab. See “Report Display” on page43 for more

information. The Report Display is programmed

from the factory to display a core group of

variables. More variables can be applied to the

report format.

The status display is shown in Figure 35;

however it is necessary to follow the

instructions in “Real-Time Report Display” to

establish real-time update of the selected

variables.

Figure 35: Status section

April 2019CXX-UM-03060-EN-01Page 38

Page 39

Real-time Monitoring

Real-Time Report Display

To view the parameters in real-time, a flow processor must have established

communication with the PC and be communicating properly.

Once connected, click the Connect button below the Status window.

OTE:N See “Report Display” on page43 for all the variables for monitoring.

In addition to viewing all real time variables, you can also access the

following features:

The Show Graph button switches the logging information section to a small graph

of the currently selected table. To select another table, click somewhere in that

table’s data.

Use the IFC GUI data logging feature to create a log of selected data measured

over a period of time. The GUI sends information to a tab-delimited file. The

software measures the information either for a pre-programmed or manually

selected amount of time.

Figure 36: Log File field

To configure the IFC GUI to provide log reports:

1. Type or browse to a location on your computer to output data logging.

This designates the le name and location in which you wish to store

the information.

2. Type a numeric value in the Sample Rate eld to specify how often a new entry

should be placed in the data log.

3. Select either seconds (S) or milliseconds (mS).

4. Select the interval stop from the drop-down menu, by clicking the drop-down

menu, then clicking an option to select it.

Page 39 CXX-UM-03060-EN-01April 2019

Page 40

Flow processor Programming

Option Function

Manual Stop

Timed Stop

(Seconds)

Timed Stop

(Minutes)

Timed Stop

(Date)

Sample Stop

Manual stop begins data logging when you click Start and ends data logging when

you click Stop.

Timed stop (Seconds) begins data logging when you click Start and ends data logging

when it reaches the numerical value adjacent to the drop-down menu. For Example,

if 100 were placed in the time field adjacent to the drop-down menu, 100 seconds

would elapse before the data would cease to log.

Timed stop (Minutes) begins data logging when you click Start and ends data logging

when upon reaching the numerical value adjacent to the drop-down menu. For

Example, if 100 were placed in the time field adjacent to the drop-down menu, 100

minutes would elapse before the data would cease to log.

Timed stop (Date) begins data logging when you click Start and ends data logging

when upon reaching the numerical value adjacent to the drop-down menu. For

Example, if 1/1/20 were placed in the time field adjacent to the drop-down menu, the

GUI would continue to log data until January 1st 2020.

Sample stop begins data logging when you click Start. The software logs one sample's

worth of data and stops at the set interval in the sample rate field.

Viewing Log

To view the log being populated, click View. You will be transferred to the logging

file you have designated. Values update at the intervals set.

Watching Log

To watch the log being populated in real-time, click Watch. You will be transferred

to the logging file you have designated.

FLOW PROCESSOR PROGRAMMING

Connect all sensors, transducers, pickups and com-link cables to the EC80 Flow

Processor before powering up the computer. Communication needs to be

established with the EC80 Flow Processor prior to uploading or downloading

a profile. All flow processors, unless specially configured, communicate via an

RS485 connection to the PC. The PC, in conjunction with an RS485 converter is

required for communicating with the flow processor. Ask your sales representative

regarding purchase of USB-to-RS485 converters (PN EF I-7561).

Downloading Proles

Downloading a profile is how you use all the information you programmed into

the IFC GUI to program the flow processor. Follow this procedure to download the

current profile to the flow processor:

1. Click the white box next to Enable on the tool bar.

2. Click the Download icon . All information in the data tables, either blank or

populated, is written to the ow processor.

April 2019CXX-UM-03060-EN-01Page 40

Page 41

Flow processor Programming

Flow processor Programming

Locating Multiple EC80 Flow Processors

The Locate IFC function is for users who use many flow processors that all

communicate with a central PC. Daisy-chained flow processors, all communicating

via RS485, can be addressed individually via their corresponding Bus ID. You can

search to see which flow processors are currently connected in the loop. Since

each flow processor has its own Bus ID, each flow processor appears on this

display. Information such as the Bus ID, Firmware Revision and GUID hexadecimal

string can all be displayed in this screen.

To locate an EC80 Flow Processor:

1. Click the View menu.

2. Click Find IFC.

Figure 37: Locate IFC window

The Refresh button clears the display and begins searching again for EC80

Flow Processors.

The Get Profile button loads the currently selected flow meter’s profile into the

GUI tables so you can modify the tables.

Page 41 CXX-UM-03060-EN-01April 2019

Page 41 CXX-UM-03060-EN-01April 2019

Page 42

Conguration Options

Commands

The Commands feature is for specific applications where polling or Ethernet

configurations are being used. Do not use this feature unless the application

requires it. Consult your sales representative if this feature interests you.

Figure 38: Commands menu

CONFIGURATION OPTIONS

Access the options menu either by clicking the Options Icon, or navigating to

File>Options.

General

Figure 39: General tab

Use the General tab for user sign in. A company name, technician name, login

ID and password can be set here. See “Password Initialization” on page20 for

more information.

April 2019CXX-UM-03060-EN-01Page 42

Page 43

Version Information

Report Display

Figure 40: Report display tab

Use the Report Display tab to select which flow processor variables to view in the

Status window. Every variable the flow processor uses for computation of flow is

listed here. If you want to display all the variables, click Select All. To display none

of the variables, click Clear All. To view the old report style, click the box next to

Old Report Style.

Communication (Comm.)

Use the Communications tab to establish communications with the flow processor.

See “Establish Link Via RS485” on page21 or “Establish Link Via Ethernet” on

page22 for more information.

Database, Gator Display, Gator Report and Real Time Clock (RTC)

The Database, Gator Display, Gator Report and Real Time Clock (RTC) tabs are

currently used for Flow Gator products. They are not applicable to the EC80

Flow Processor.

VERSION INFORMATION

Figure 41: Version information window

Click the View menu bar and select About to display important information

regarding the software. The factory may ask for the version of software you

are using.

Page 43 CXX-UM-03060-EN-01April 2019

Page 44

Flow Processor, EC80

Control. Manage. Optimize.

Cox is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous

research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the

extent an outstanding contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 19-07 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 :

Loading...

Loading...