Countyline CLPT85, CLPT36, CLPT20H, CLPT20, CLPT52 User Manual

...

293 Wright Street, Delavan, WI 53115

Phone: 800-535-4950

Fax: 800-526-3757

www.tractorsupply.com

OWNER’S MANUAL

Pre-Charged

Pressure Tanks

MANUAL DEL USUARIO

Tanques de

presion precargada

CLPT20H

CLPT20

CLPT36

Installation/Operation/Parts

For further operating, installation, or

maintenance assistance:

Call 800-535-4950

English.................Pages 2-7

©2017 CL491 (Rev. 01/06/17)

CLPT52

CLPT85

CLPT119

Instalación/Operación/Piezas

Para mayor información sobre

el funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 800-535-4950

Español ............. Páginas 8-13

Safety 2

Important Safety

Instructions

SAVE THESE INSTRUCTIONS - This manual

contains important instructions that should be

followed during installation, operation, and

maintenance of the product. This is the

safety alert symbol. When you see this symbol

on your pump or in this manual, look for one of

the following signal words and be alert to the

potential for personal injury!

indicates a hazard which, if not

avoided, will result in death or serious injury.

indicates a hazard which, if not

avoided, could result in death or serious injury.

indicates a hazard which, if not

avoided, could result in minor or moderate injury.

NOTICE addresses practices not related to

personalinjury.

Carefully read and follow all safety instructions

in this manual and on pump.

Keep safety labels in good condition. Replace

missing or damaged safety labels.

California Proposition 65 Warning

This product and related

accessories contain chemicals known to the

State of California to cause cancer, birth defects

or other reproductive harm.

1. Read this manual carefully. Failure to follow

these Instructions could cause serious bodily

injury and/or property damage.

2. Consult installer or licensed plumber for

correct relief valve. Install system according to

local codes.

3. Always test water from well for purity before

using. Check local health department for

testing procedure.

4. Before installing or servicing tank, BE SURE

pump electric power source is disconnected.

Release all water pressure before working on

tank or system. Release air pressure before

removing cover flange.

5. Install relief valve in pump supply line to tank,

as close to tank as possible.

6. BE SURE pump electrical circuit is

properlygrounded.

7. Remove bleeder orifices, air volume controls

or other air charging devices in existingsystem.

8. DO NOT USE tank as a surge suppressor.

Risk of explosion. To prevent

possible serious or fatal injury and/or damage to

equipment, system pressure must be less than

100 pounds per square inch (PSI) (689kPa) under

any circumstances. Failure to follow instruction

can result in tank blowup. If system discharge

pressure can exceed 100 PSI (689kPa), install a

relief valve capable of passing the full pump

volume at 100 PSI (689kPa).

Risk of freezing. Do not allow

pump, tank, or piping system to freeze. Freezing

can severely damage equipment and may lead

to tank explosion and serious injury. Allowing

tank to freeze voids tank warranty.

Warranty 3

Retain Original Receipt for Warranty Eligibility

Limited Warranty

This Limited Warranty is effective January 1, 2013 and replaces all undated warranties and warranties dated before

January 1, 2013.

CountyLine warrants to the original consumer purchaser (“Purchaser” or “You”) that its products are free from defects in

material and workmanship for a period of twelve (12) months from the date of the original consumer purchase. If, within

twelve (12) months from the original consumer purchase, any such product shall prove to be defective, it shall be repaired or

replaced at CountyLine’s option, subject to the terms and conditions set forth herein. Note that this limited warranty applies

to manufacturing defects only and not to ordinary wear and tear. All mechanical devices need periodic parts and service to

perform well. This limited warranty does not cover repair when normal use has exhausted the life of a part or the equipment.

The original purchase receipt and product warranty information label are required to determine warranty eligibility. Eligibility

is based on purchase date of original product – not the date of replacement under warranty. The warranty is limited to repair

or replacement of original purchased product only, not replacement product (i.e. one warranty replacement allowed per

purchase). Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store. Contact CountyLine Customer Service

at 800-535-4950.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the retail outlet

where it was purchased immediately after the discovery of any alleged defect. CountyLine will subsequently take corrective

action as promptly as reasonably possible. No requests for service will be accepted if received more than 30 days after the

warranty expires. Warranty is not transferable and does not apply to products used in commercial/rentalapplications.

Sewage Pumps

DO NOT return a sewage pump (that has been installed) to your retail store. Contact CountyLine Customer Service. Sewage

pumps that have seen service and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wear rubber gloves when handling the pump;

• For warranty purposes, return the pump’s cord tag and original receipt of purchase to the retail store;

• Dispose of the pump according to local disposal ordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

CL106, CL108 90 days

CLTS33P, CLSU14 2 Years

4” Submersible Well Pumps 3 Years

CLVS50C, CLW750, Pressure Tanks 5 Years

General Terms and Conditions; Limitation of Remedies

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty does not

apply to the following: (1) acts of God; (2) products which, in CountyLine’s sole judgement, have been subject to negligence,

abuse, accident, misapplication, tampering, or alteration; (3) failures due to improper installation, operation, maintenance or

storage; (4) atypical or unapproved application, use or service; (5)failures caused by corrosion, rust or other foreign materials in

the system, or operation at pressures in excess of recommended maximums.

This warranty sets forth CountyLine’s sole obligation and purchaser’s exclusive remedy for defective products.

COUNTYLINE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDEDHEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an

implied warranty lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal

rights and You may also have other rights which vary from state to state.

CountyLine • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 800-535-4950 • Fax: 800-526-3757 • www.tractorsupply.com

Installation 4

WATER

WATER

ABCD

To serviceFrom well

General Information

Operating Cycle

Tanks listed below are pre-charged, or filled with

air at the factory, to 40 pounds per square inch

(PSI) (276kPa). When installing tank, set tank

pressure according to Chart 1. To do this, bleed

air from or add air to tank through valve on top

of tank.

NOTICE Always set or check tank pre-charge

with NO WATER in tank or water pressure

in system. If you have already pumped water

before setting or checking pre-charge pressure,

turn pump off. Open faucet until there is no

more water pressure. Set pre-charge in tank

according to Chart 1, then close faucet and turn

pump back on.

WATER

NOTICE Replace and tighten air valve cap after

pressure is adjusted correctly. Failure to replace

air cap may allow loss of air pressure and lead

to tank waterlogging and bladder failure.

When Pressure Switch

Setting Is:

Reduce Tank Precharge

(PSI) To:

20-40 PSI (138-276 kPa) 18 (124 kPa)

30-50 PSI (207-345 kPa) 28 (193 kPa)

40-60 PSI (276-414 kPa) 38 (262 kPa)

Chart I - Tank Precharge Settings

(The first number on the pressure switch is the

pump ‘ON’ setting; the second number is the

pump ‘OFF’ setting.)

Pre-charged storage tanks can be connected

together to increase the drawdown. Drawdown

is the actual amount of usable water available

from when the tank is full to when the pump

turns on. Installing two tanks of same size will

double the drawdown supply, three tanks will

triple the drawdown supply, (Figure 1). Locate

pressure switch as shown. Tank and pressure

switch cannot be more than 10’ (3M) apart.

Tanks

Figure 2 - Tank Operating Cycle

1. Tank nearly empty – air expands filling area

above bladder (Figure 2A).

2. Water enters tank – air is compressed above

bladder as it fills with water (Figure 2B).

3. Pump-up cycle completed – air compressed to

OFF setting of pressure switch (Figure 2C).

4. Water drawn from tank – compressed tank air

forces water out of bladder (Figure 2D).

5. Bladder empty – new cycle ready to begin

(Figure 2A).

Installation

Connect discharge pipe from pump to a tee.

Connect one side of tee to tank flange and the

other side of tee to service. Use plastic or steel

pipe as required. To prevent leaks, use PTFE

pipe thread sealant tape on male threads of all

threaded connections to tank.

NOTICE To be sure pipe joints are not crossthreaded and all threads are clean, make

connections by hand (without sealer) first. When

threads are clean, remove pipe, add PTFE tape,

and remake connection. Tighten by hand first;

finish with pipe wrench.

When installing an elbow or nipple in the plastic

Pressure

switch

tank flange, tighten it hand tight plus 1-1/2 turns

with a pipe wrench. DO NOT OVERTIGHTEN!

Standard Tank Replacement

When replacing standard tank in a water system

with pre-charged tank, no bleeder orifices or Air

Figure 1

NOTICE Tank capacity is different than

drawdown. Tank capacity is the actual physical

volume of the sheet metal that makes up

thetank.

Volume Control (AVC) are required. When sizing

a pre-charged tank to replace a standard tank,

the tanks should have equivalent drawdowns.

For example, model CLPT20 pre-charged tank

has a drawdown of 5.8 gallons (22L) and is

equivalent to a 42 gallon standard tank that has

a drawdown of 4.3 gallons (16.3L).

WATER

WATER

Installation 5

explosion. Disconnect all power to pump and

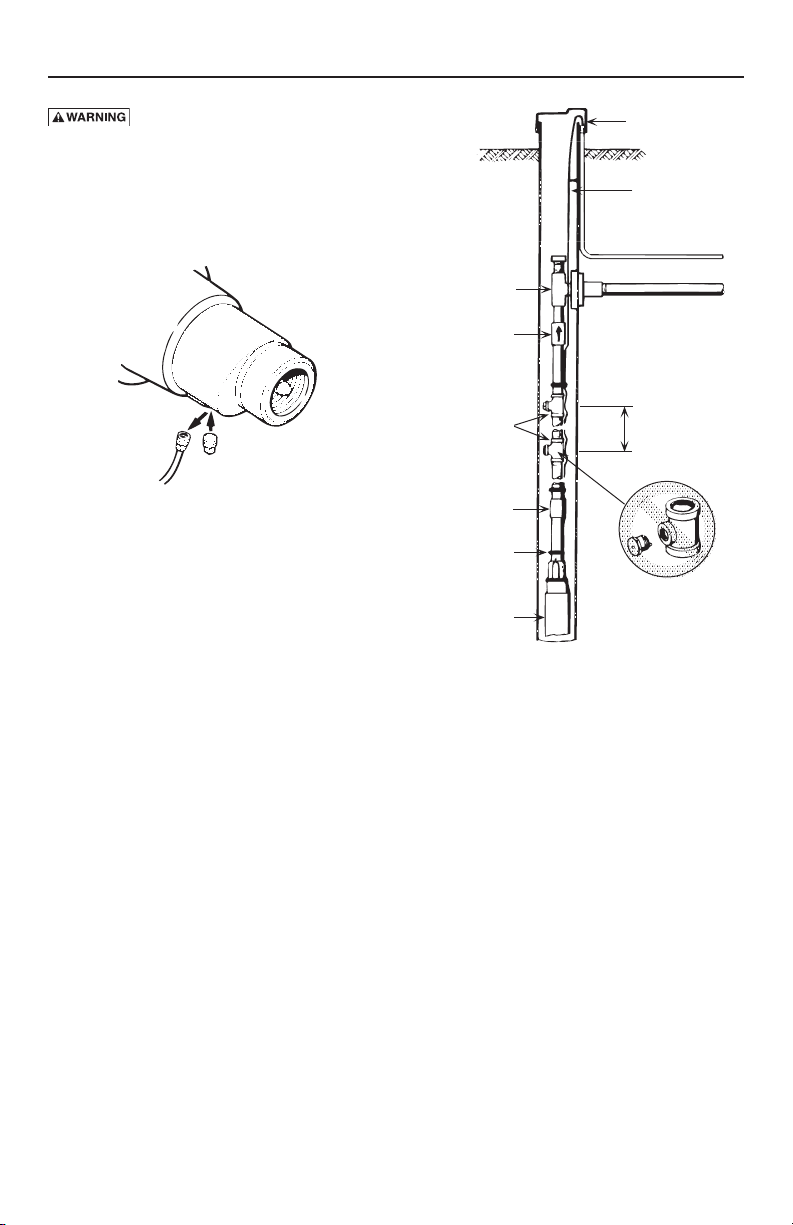

Risk of electric shock and

bleed all pressure from system before working

on pump, tank, or piping.

For jet pump installation, remove AVC tube

from port in pump body or jet body and plug

port (see Figure 3). New pumps come with

pluginstalled.

Figure 3 - Plug AVC Port when installing pre-

charged tank on existing pumps. New pumps

come with plug Installed.

NOTICE When working on submersible pumps

in wells, be sure safety rope is solidly connected

to pump and securely anchored at the well

head at all times. Do not drop the pump down

thewell!

Bleeder Orifices

For submersible pump installations, there may

be bleeder orifices in the vertical discharge

pipe. They must be removed and the tees

plugged when a pre-charged tank is installed

in the system. To do this, raise the pump and

discharge piping enough to bring the bleeder

orifices clear of the well. Remove the bleeder

orifices from tees and replace with plugs (see

Figure 4). Bleeder orifices may be any of several

sizes. Have a supply of 1/2”, 3/4”, and 1” plugs

available. Replace pump and reconnect the

discharge pipe.

Adjusting Tank Pre-charge

In areas where temperature is high for long

periods of time, tank pre-charge pressure may

increase. This may reduce tank drawdown

(amount of water available per cycle). If this

occurs, adjust pre-charge pressure according to

Chart 1.

Flush all air out of piping system and water

reservoir portion of pre-charged tank.

Adjustment of tank pre-charge is required on

new installations, pumps requiring re-priming,

and pumps disassembled for service.

Ventilated

well cap

Submersible

cable

Pitless

adaptor

Check valve

Bleeder orifice

and tee

Pipe coupling

Tape cable

to pipe

Pump

2 ft.

(.6m)

Figure 4

Adjust tank precharge asfollows:

1. Open faucets furthest from tank and run pump.

2. Run pump until sputtering stops and steady

stream of water flows.

3. Open and close faucets repeatedly until all air

has been removed.

4. If stream does not become steady, air may be

leaking into system; check for leaks in piping

on suction side of pump.

NOTICE To prevent waterlogging, check tank air

charge annually.

To Check Tank Air Charge

If drawdown decreases significantly, check

asfollows:

1. To check air charge in tank, shut off electric

power to pump, open faucet near tank, and

drain completely.

2. At air valve, check tank air pressure with tire

gauge. See

Chart 1

for correct pressure setting.

If needed, adjust tank pressure up or down.

3. Use soap or liquid detergent to check for air

leaks around air valve. Continuous bubbling

indicates leak. If necessary, release air pressure

and install new core in air valve, (same type

used for automobile tubeless tires.)

Loading...

Loading...