Country Flame DV 30, DV 46 User Manual

COUNTRY FLAME TECHNOLOGIES

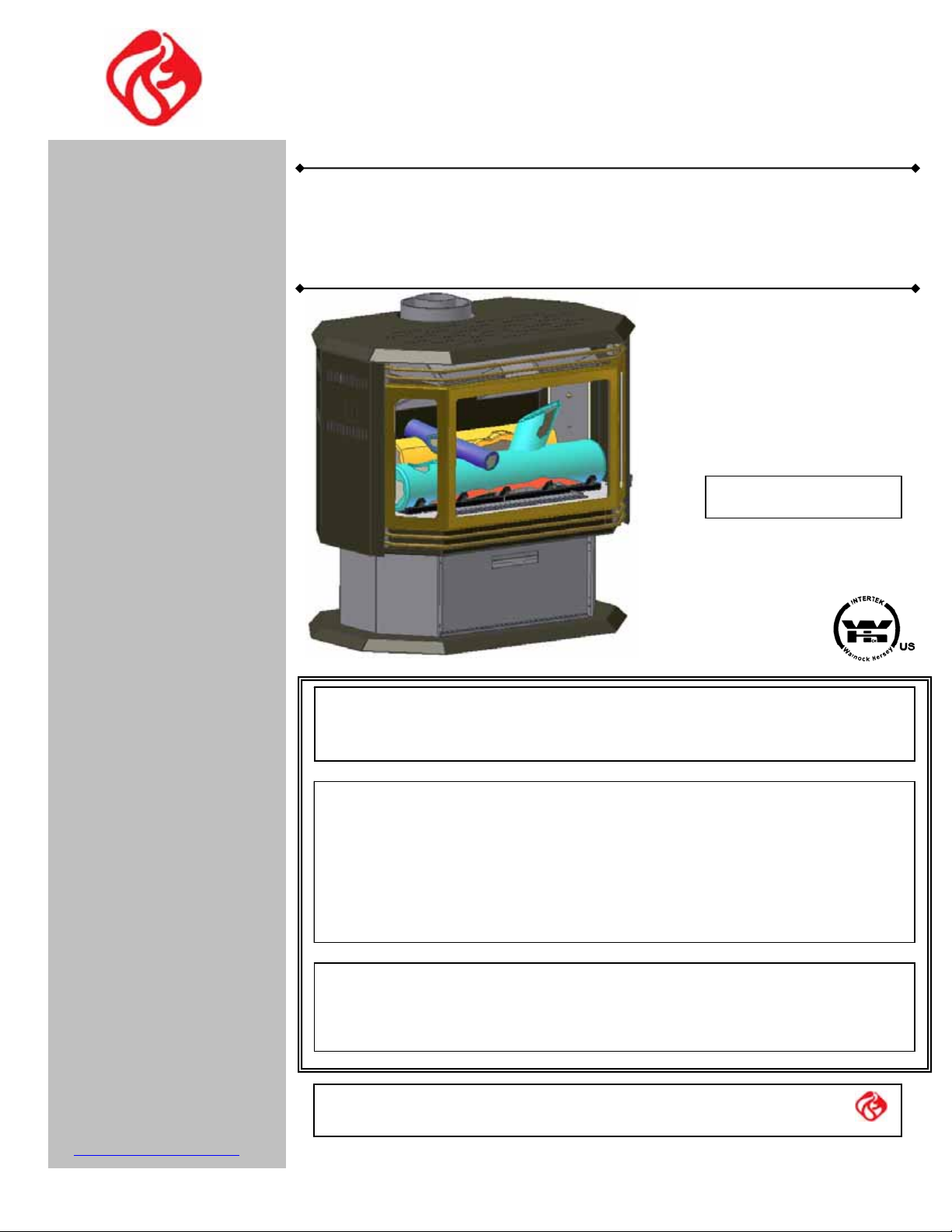

BAYVUE DIRECT VENT GAS STOVE

MODEL DV 30 & DV 46

NATURAL GAS OR PROPANE CAPABLE

USA & CANADA TEST STANDARD:

Harmonized ANSI Z21.50 - 2000

CSA 2.22 – 2000, CAN/CGA 2.17

TESTED BY:

WARNOCK HERSEY

Suitable for Bedroom

Installation

C

ountry Flame Technologies

A Division of American Products, LLC

900 George Street

Marshfield, MO 65706

417-859-0990

417-859-0192

www.countryflame.com

WARNING: If the directions contained in this manual are not followed

exactly, a fire or explosion may result causing property damage, personal injury

or loss of life.

•

Do not light any appliance.

•

Do not touch electrical switches; do not use the phone in your

building.

Immediately call the gas company from a neighbor’s phone.

•

Follow gas company instructions.

•

Call the Fire Department if Gas Company doesn’t answer.

•

IF YOU SMELL GAS

FOR YOUR SAFETY

Do not store or use gasoline or any flammables (vapors or liquids) in the vicinity of

this or any other appliance.

Installation and repair must be performed by a qualified service person or gas supplier.

FOR YOUR SAFETY

© 2004 COUNTRY FLAME

TABLE OF CONTENTS

INTRODUCTION...................................................................................................................3

SAFETY INFORMATION .....................................................................................................4

INSTALLATION, GENERAL................................................................................................5

PRESSURE TESTING....................................................................................................5

ALTITUDE LIMITATIONS ........................................................................................... 6

GAS SUPPLY CONNECTION ...................................................................................... 6

MINIMUM/MAXIMUM Btu RATES............................................................................ 7

CLEARANCES............................................................................................................... 7

MINIMUM CLEARANCES........................................................................................... 9

CEILING CLEARANCES..............................................................................................9

TOOL LIST.....................................................................................................................9

UNPACKING.................................................................................................................. 9

LOG PLACEMENT......................................................................................................10

CONTROL PANEL ACCESS ...................................................................................... 12

HEARTH REQUIREMENTS.......................................................................................12

VALVE ASSEMBLY REMOVAL............................................................................... 12

FUEL CONVERSION KITS......................................................................................... 13

PR CONVERSION KIT BV-4604 CONTENTS ..........................................................14

PR CONVERSION KIT BV-3004 CONTENTS ..........................................................14

NG CONVERSION KIT BV-4603 CONTENTS: ........................................................ 14

NG CONVERSION KIT BV-3003 CONTENTS ......................................................... 14

PROPANE CONVERSION KIT......................................................................... 15

NATURAL GAS CONVERSION KIT...............................................................15

PROPANE CONVERSION .......................................................................................... 15

INTAKE AND EXHAUST CONDITIONS.......................................................................... 18

SEALED VENTING SYSTEM ....................................................................................18

THERMOSTAT/FAN CIRCUIT .................................................................................. 18

FAN INSTALLATION .........................................................................................................19

DIRECT VENT INSTALLATION .......................................................................................19

GENERAL.....................................................................................................................19

INSTALLATION PRECAUTIONS.............................................................................. 20

INSTALLER SAFETY PRECAUTIONS..................................................................... 20

VENTING PARTS LIST.......................................................................................................20

BASIC VENT KITS...................................................................................................... 21

INSTALLATION PLAN....................................................................................................... 22

VENT (FRESH AIR) REQUIREMENTS.....................................................................22

DIRECT VENT TERMINATION ................................................................................24

VENT TERMINALS..................................................................................................... 24

STANDARD HORIZONTAL TERMINAL .................................................................24

SNORKEL TERMINAL (14" OR 36").........................................................................24

VERTICAL TERMINAL..............................................................................................24

CHIMNEY PIPE ........................................................................................................... 24

STANDARD HORIZONTAL VENT...........................................................................24

VERTICAL AND HORIZONTAL VENT....................................................................27

VENT GRAPHS............................................................................................................28

VENT GRAPH (cont'd).................................................................................................29

Version 1.0h

1

TABLE OF CONTENTS

SNORKEL VENT.........................................................................................................30

VERTICAL VENT........................................................................................................30

CATHEDRAL CEILINGS............................................................................................31

MAINTENANCE..................................................................................................................32

CLEANING BURNERS AND CONTROLS......................................................32

REPLACE OLD EMBERS .................................................................................32

CHECK FLAME AND PILOT ........................................................................... 33

GLASS CLEANING ........................................................................................... 33

CHECK VENT SYSTEM ...................................................................................33

GLASS-CERAMIC SPECIFICATIONS ...................................................................... 34

GLASS REPLACEMENT ............................................................................................34

GASKET SPECIFICATIONS.......................................................................................34

GENERAL VENT INSPECTION................................................................................. 36

GENERAL CLEANING...............................................................................................36

GENERAL SAFETY ....................................................................................................36

GENERAL PERIODIC INSPECTIONS....................................................................... 36

CLEANING A PAINTED SURFACE.......................................................................... 36

CLEANING PLATED SURFACES .............................................................................37

DOOR INSTALLATION.............................................................................................. 37

DOOR SEAL................................................................................................................. 37

MAIN ORIFICES..........................................................................................................38

GAS FLAME INSPECTION ........................................................................................ 38

RELIEF VALVE INSPECTON....................................................................................39

SIT 820 NOVA mV GAS CONTROL VALVE....................................................................40

WARRANTY ........................................................................................................................41

TROUBLE SHOOTING GUIDE ..........................................................................................42

TROUBLE SHOOTING GUIDE (cont’d) ............................................................................ 43

PARTS LIST ......................................................................................................................... 44

PARTS LIST (cont’d)............................................................................................................45

OPERATING INSTRUCTIONS........................................................................................... 46

LIGHTING INSTRUCTIONS ...................................................................................... 46

TO TURN OFF GAS TO BAYVUE DV......................................................................46

FIRST FIRE................................................................................................................... 46

SAFETY LABEL..........................................................................................................47

Version 1.0h

2

INTRODUCTION

THANK YOU and CONGRATULATIONS on the purchase of a new gas appliance manufactured by

Country Flame Technologies. This purchase makes you part of our family of literally tens of thousands of

previous customers who have bought Country Flame’s gas and wood products over the past several

decades. Country Flame shares our customer’s concerns to protect the environment, obtain value for their

purchase, and know that they have purchased one of the most reliable gas products the market has to offer.

Each and every employee at Country Flame pledges to ensure each and every one of our customers has our

commitment to product support. Product support is dedicated to ensuring our customers achieve the

greatest level of satisfaction from the proper use of our products. Thank you for selecting Country Flame.

We look forward to hearing from you as this product becomes part of your home heating solution.

This manual is written to provide information that will assure proper installation, proper maintenance, and

correct operation of an American made gas fireplace called the Bayvue DV (Direct Vent). It is imperative

that the certified professional installer and homeowner read, understand, and follow all information

included in this manual to ensure safety and correct operation. If there are questions on installation,

operation, or maintenance issues, please re-read and understand all directions and instructions contained in

this manual. In the event of any issues or confusion, contact Country Flame or a certified professional

before undertaking the installation or operation of this appliance. Installation must be in accordance with

local codes, gas supplier restrictions, and conform to current National Fuel Gas Code ANSI Z223.1 (USA)

or current CAN/CGA B149 Installation Codes (Canada).

Country Flame wishes you a lifetime of warmth and happiness.

Version 1.0h

3

SAFETY INFORMATION

- Do not store or use gasoline or other flammables in the vicinity of this appliance.

-

Do not place clothing or flammable material on or near this appliance.

-

Due to high operating temperatures, this appliance should be located out of high traffic areas and away

from furniture and draperies.

-

Children and adults should be alerted to the hazards of high surface temperatures and should maintain

safe clearances (stay away) to avoid burns or clothing ignition.

-

Always supervise young children playing in the same room as this operating appliance.

-

Any safety screen, guard or other parts removed for servicing this appliance must be replaced prior to

operation.

-

ALL INSTALLATION AND REPAIR SHOULD BE COMPLETED BY A CERTIFIED GAS

TECHNICIAN. THIS APPLIANCE SHOULD BE INSPECTED BEFORE USE AND AT LEAST

ANNUALLY, BY A CERTIFIED GAS PROFESSIONAL.

-

The interior of a gas stove is subject to surface rust due to moisture in the combustion air as well as

condensation created during the initial warm up and firing of the gas appliance. At a minimum,

annually clean and repaint the interior surfaces to prevent deterioration. More frequent cleaning may be

required due to carpet lint, bedding material, dust, etc. being drawn into the appliance. It is imperative

that this appliance’s control compartment, burners, circulating air system is kept clean.

-

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE INJURY OR PROPERTY DAMAGE. REFER TO THIS MANUAL

FOR ASSISTANCE OR FOR ADDITIONAL INFORMATION CONSULT A QUALIFIED

INSTALLER, SERVICE AGENCY, OR GAS SUPPLIER.

-

ALWAYS use high temperature rated silicone or sealing compound at 600OF (316OC) or higher.

-

This appliance was designed as a sealed unit and as such, the glass doors must be fully intact and closed

when operating this gas product.

-

This appliance was NOT designed, tested, or approved for installation in OEM mobile homes,

permanently installed mobile homes, or recreational vehicles and should not be used in such

applications.

-

This appliance was NOT d esigned, tested, or approved for installation as a fireplace insert. Do not use

this appliance in such applications.

Version 1.0h

PLEASE KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

4

INSTALLATION, GENERAL

The Bayvue DV installation must ensure adequate combustion air and ventilation air is available for proper

stove operation. Refer to the venting section for further combustion air requirements. Installation must

conform to local codes and gas supplier restrictions. In the absence of local codes, an installation must

conform to the current National Fuel Gas Code which at the writing of this manual is ANSI Z223.1

(reference NFPA-54 for natural gas or reference NFPA-58 for propane products). In Canada, an

installation must conform to CAN/CGA-B149 code.

This appliance must be electrically connected and grounded in accordance with local codes, or in the

absence of local codes, with the current NFPA 70 National Electric Code or in Canada, with CSA C22.1

Canadian Electrical Code.

IT IS IMPERATIVE THAT THIS APPLICANCE’S CONTROL COMPARTMENT, BURNER, AND

CIRCULATING AIR PASSAGE WAYS ARE KEPT CLEAN AND CLEAR OF OBSTRUCTIONS.

ALWAYS PROVIDE FOR ADEQUATE COMBUSTION AIR AND ENSURE PROPER OPERATION

AT ALL TIMES. PROVIDE ADEQUATE CLEARANCES AROUND AIR OPENINGS AND

NECESSARY ACCESSIBILITY FOR ROUTINE OPERATION AND SERVICE. NEVER OBSTRUCT

ANY OPENINGS ON THIS APPLIANCE OR NEVER OBSTRUCT THE DIRECT VENT

TERMINATION ON THE EXTERIOR OF THE BUILDING.

MINIMUM CLEARANCES TO COMBUSTIBLES MUST BE MAINTAINED DURING

INSTALLATION. THE HEATER MUST HAVE ADEQUATE SPACE FOR PROPER OPERATION

AND SERVICING. MAINTAIN MINIMUM CLEARANCES AND VENT/AIR INTAKE PIPE

CLEARANCES.

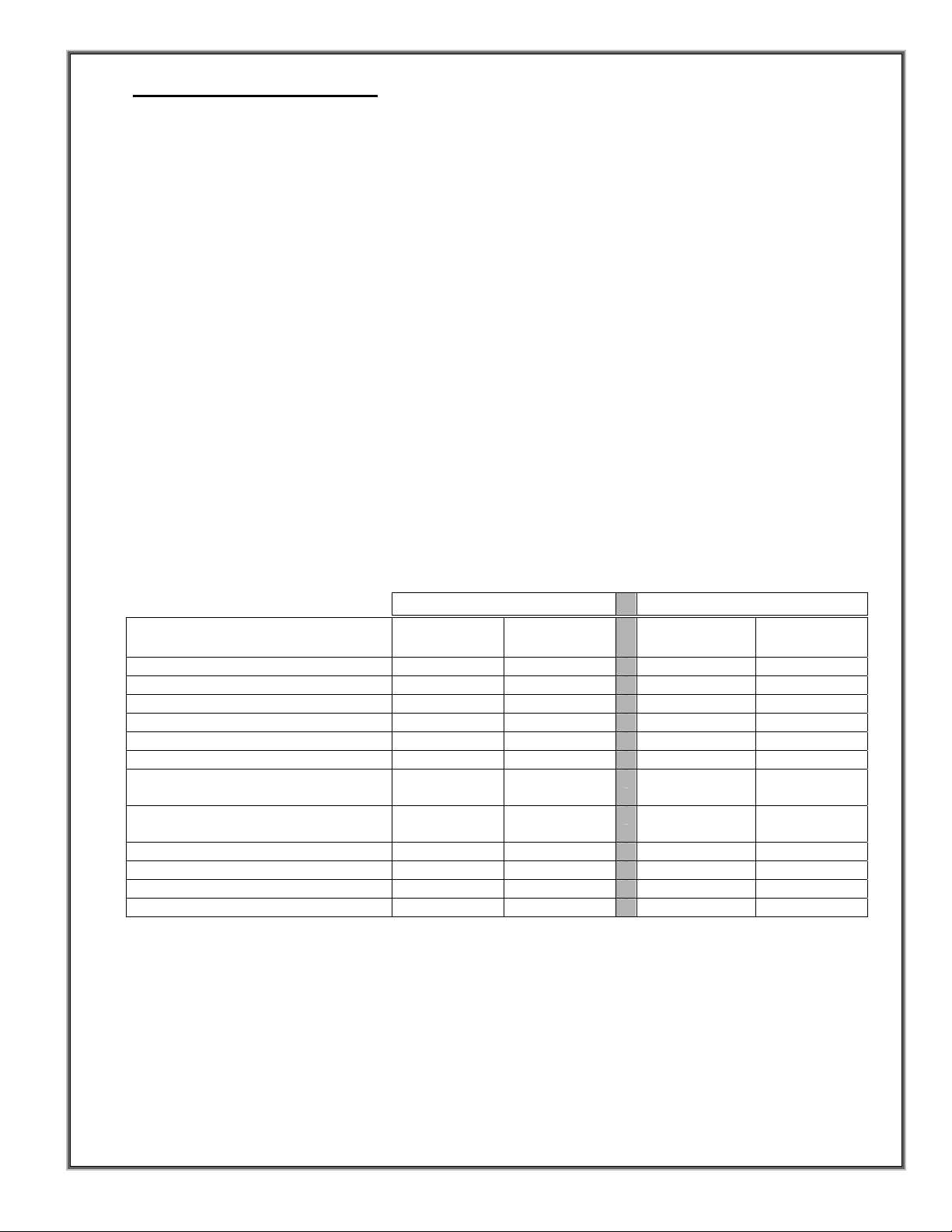

TABLE 1: BAYVUE DV SPECIFICATIONS

BAYVUE DV-46

NATURAL

PROPANE

GAS

Altitude 0 - 4500’ 0 - 4500’ 0 - 450 0’ 0 - 4500’

Manifold pressure 3.5” W.C. 10” W.C. 3.5” W.C. 10” W.C.

Minimum Inlet Gas Pressure 4.5” W.C. 11” W.C. 4.5” W.C. 11” W.C.

Maximum. Inlet Gas Pressure 7.0” W.C. 14.0” W.C. 7.0” W.C. 14.0” W.C.

BTU Input Rating (High) 46,000 46,000 BTUH 32,000 30,000 BTUH

BTU Input Rating (Low) 29,000 34,500 BTUH 21,000 21,500 BTUH

*Efficiency with fan (steady

state)

*Efficiency no fan (steady

state)

*A.F.U.E. 68.77% 70.67% 60.19% 62.22%

Front Burner Orifice 55 DMS 69 DMS 57 DMS 70 DMS

Middle Burner Orifice 45 DMS 55 DMS 50 DMS 59 DMS

Rear Burner Orifice 40 DMS 53 DMS 45 DMS 55 DMS

35,700 36,800 BTUH 24,000 23,100 BTUH

37,200 39,100 BTUH 22,800 22,000 BTUH

*ANSI standards are SAFETY STANDARDS not PERFORMANCE STANDARDS. A.F.U.E.

(efficiency standards) and efficiency test protocol are established by the U. S. Department of Energy.

BAYVUE DV-30

NATURAL

GAS

PROPANE

PRESSURE TESTING

This appliance MUST BE isolated from the gas supply piping system during any pressure testing of the

gas supply piping system at test pressures equal to or less than ½ pounds per square inch gauge (psig) (3.5

kPa or 14” W.C.) Isolate the appliance by closing the manual shutoff valve during pressure testing.

Failure to isolate the appliance will cause damage and can require replacement of the SIT 820 NOVA mV

gas control valve. If test pressures will be in excess of ½ psig, then the SIT 820 NOVA mV gas control

valve must be disconnected from the gas supply line. Refer to FIGURE 27 for SIT 820 NOVA mV valve

information.

Version 1.0h

5

Country Flame’s Bayvue DV stove must be vented vertically or horizontally through an outside wall. This

appliance and all its components are tested and safe to operate when installed in accordance with the

instructions contained in this manual. Read and understand all instructions before beginning installation to

ensure maximum efficiency and safety is achieved. Failure to follow the instructions contained in this

manual will void the warranty and may present a fire hazard. Immediately, upon unpacking the product,

report any glass or parts damaged, to both the shipping company and the local Country Flame Dealer.

Country Flame

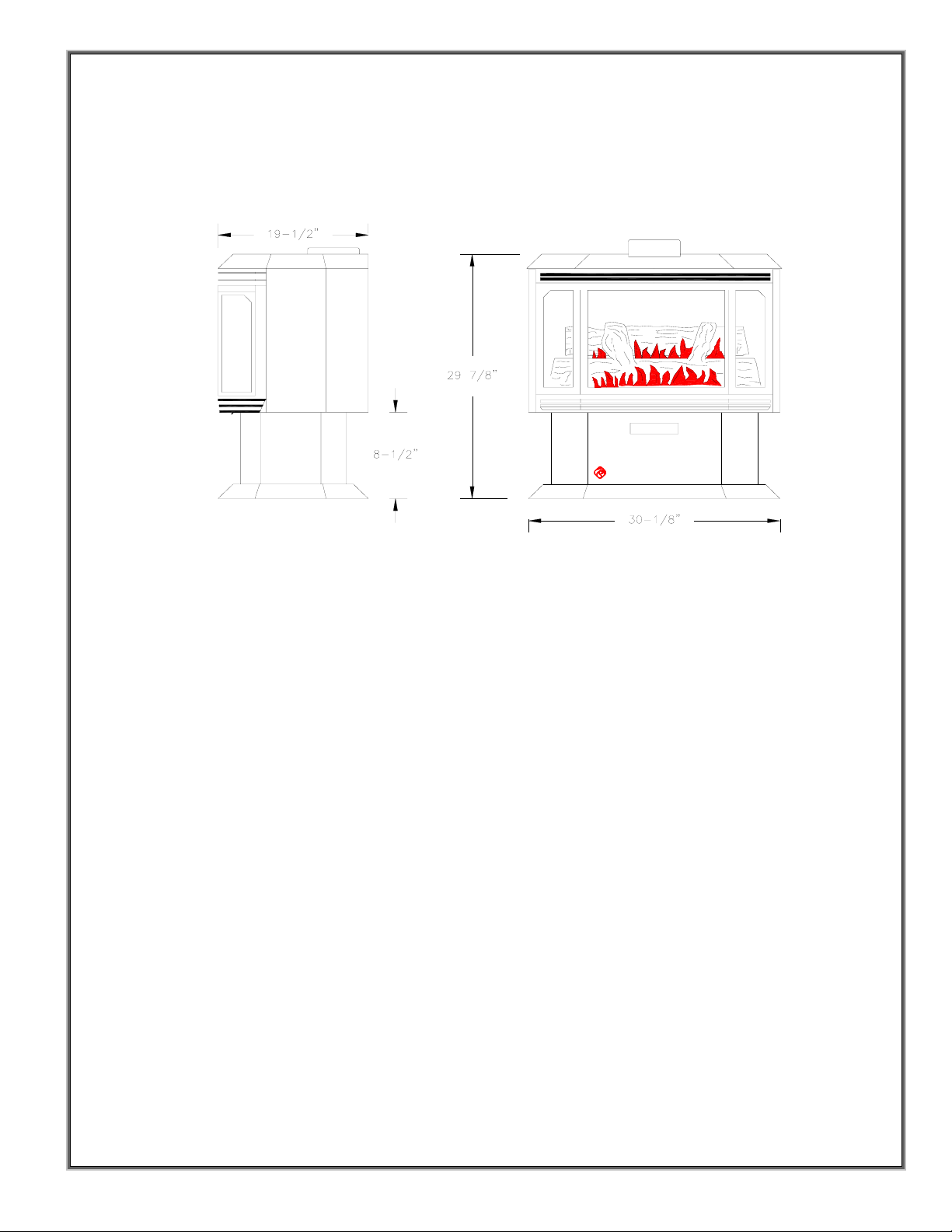

FIGURE 1: BAYVUE DV DIMENSIONS

ALTITUDE LIMITATIONS

United States input ratings of this unit are based on sea level operation. No appliance input rating needs to

be changed for any operation at elevations up to 2000 feet (600m). For operation at elevations above 2000

feet, the Bayvue DV’s input rating shall be reduced at the rate of 4% for each 1000 feet above sea level.

Exception: As permitted by the authority having jurisdiction.

Canadian input ratings of this unit are based on seal level operation. No appliance input rating needs to be

change up to 4500 feet above sea level in Canada. Installation of this appliance at altitudes above 4500

feet is subject to field test of the individual installation and approval by the local authority having

jurisdiction.

GAS SUPPLY CONNECTION

A gas supply line must be installed by a qualified professional and must conform to National Standards;

NFPA 54 (natural gas) or NFPA 58 (propane) as well as local codes. Connection of the gas supply line

shall be made near the lower rear of the appliance. The gas supply line shall be purged of air before

connection is made to the appliance. This shut-off valve must be located within 3 feet of the appliance or

to the existing local code standard. The Bayvue DV has been tested and approved for installation using a

(7/8" O.D. / 1/2" I.D.) Model #1650 N Dormont Flex Connector supplied with the unit. REMEMBER:

the gas supply line connection must be equipped with an easily visible shut-off valve. Do not run gas

supply lines through chimneys, gas vents, dumb waiters, elevator shafts, clothes chutes, or air ducts.

Piping should be sloped ¼” for every 12 feet of horizontal run. The slope will run from the gas meter

down to the appliance and the horizontal run shall be supported every 10 feet by suitable gas pipe hangars

or straps. Install gas supply line drip leg traps where condensate might accumulate. Sediment traps may

be required by code. Traps collect moisture and sediment that might block orifices or valves from

operating properly. Depending on the total length of gas supply line being run from the gas company

meter to the appliance, different size piping is required. Check with the local gas company for

requirements but NEVER use plastic or galvanized pipe.

Version 1.0h

6

The SIT 820 NOVA mV gas control value, installed in the Bayvue DV, is supplied with pressure test ports

for checking input and output fuel pressures. Refer to FIGURE 27 for valve test port locations. Valve test

ports are located below the off/pilot/on control knob. The right port is the OUT (Manifold Pressure) test

port and the left port is the IN test port. Pressure is checked by turning the capture screw counterclockwise

2 or 3 turns and then placing tubing from the manometer over the test point. WARNING: After taking

pressure readings, turn the capture screw clockwise to reseal. Do not over torque. The installer should

provide a 1/8" N.P.T. plugged tapped hole** immediately upstream of the gas supply line connection to be

used for a test gauge connection. **NOTE: N.P.T. means American Standard Taper Pipe Thread

MINIMUM/MAXIMUM Btu RATES

The Bayvue DV’s SIT 820 NOVA mV gas control valve has a HI/LOW knob that is used to regulate the

appliance’s manifold gas pressure. Refer to FIGURE 27 for location of this manifold control valve. When

a pilot flame has been established and the appliance’s OFF/PILOT/ON control knob is in the “ON”

position, the manifold HI/LOW control knob can be used to adjust the appliances Btu rates. Turning the

HI/LOW valve to “HI” allows the appliance to operate at its maximum Btu output rating. Turning the

HI/LOW valve to “LOW” allows the appliance to operate at its minimum Btu output rating.

CLEARANCES

The Bayvue DV will heat nearby surfaces when in operation. A safe Bayvue DV installation requires that

minimum or greater clearances be maintained between the stove and nearby combustible materials.

Failure to maintain proper minimum clearances will cause overheating of combustible materials that can

lead to personal property damage or loss of life. Clearances around the appliance must allow for proper

servicing of the product. If there is any question about clearances please contact Country Flame or a

certified professional. Never reduce clearances below the minimums stated in this manual.

1"

6"

1"

36"

6"

1"

6"

30"

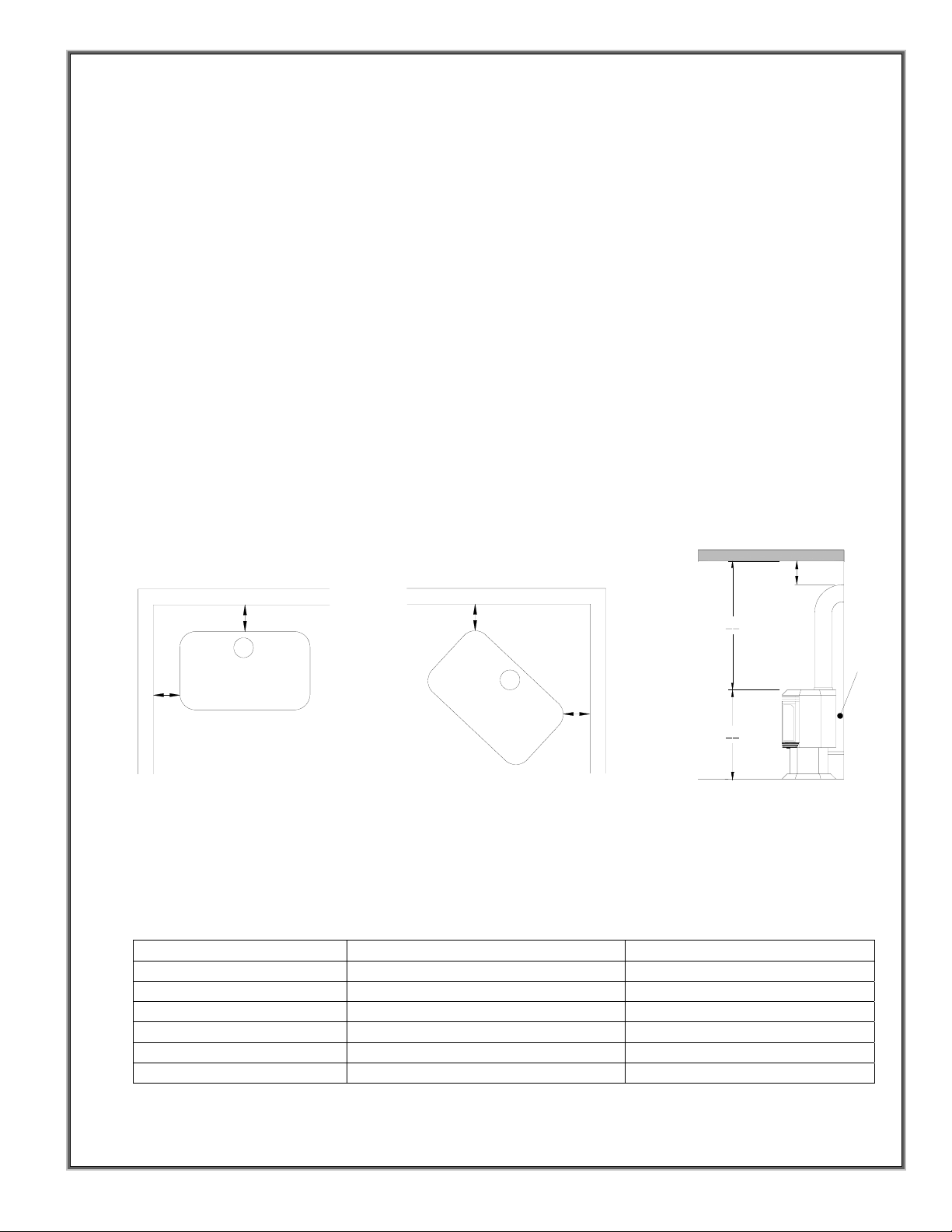

FIGURE 2: BAYVUE DV MINIMUM CLEARANCES

FIGURE 2 shows the minimum clearances required for back wall, side wall, corner, and ceiling

installations. These minimum clearances must be maintained in order to ensure proper service can be

accomplished and to ensure overheating of combustible materials does not occur. TABLE 2 lists the

minimum clearances.

TABLE 2: BAYVUE DV MINIMUM CLEARANCES

CLEARANCE FROM DISTANCE (INCHES) DISTA NCE (MILIME TERS)

LEFT/RIGHT SIDE WALL 6 152

FLOOR TO CEILING 66 1676

BACK WALL 6 152

UNIT TOP TO CEILING 36 914

HORIZONTAL FLUE 1 25

APPLIANCE CORNER 1 25

Version 1.0h

7

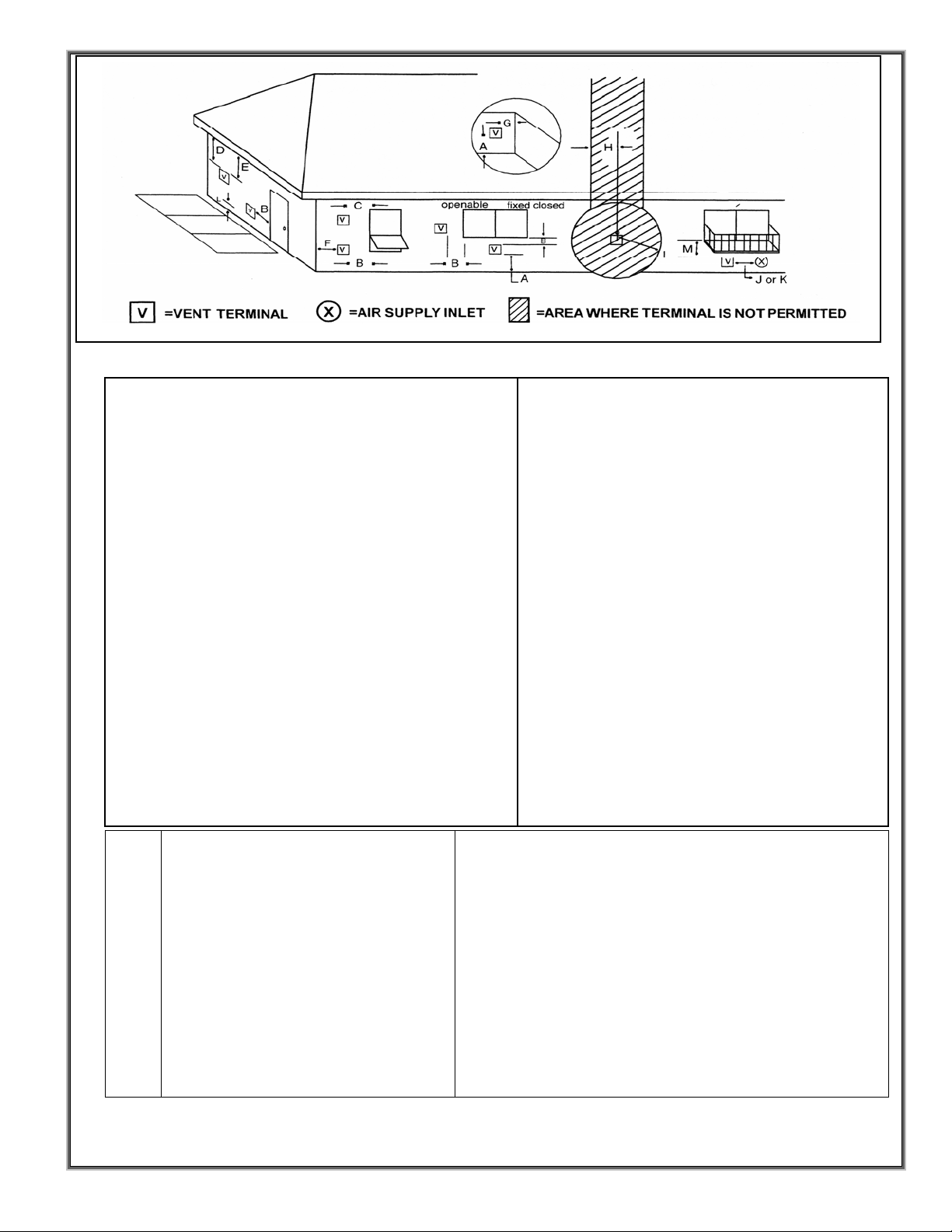

FIGURE 3: CLEARANCE REQUIREMENTS

A = 12 in. Clearances above grade,

veranda, porch, deck or balcony

B

C

D* = 18 in.

E*

F

G

H = 3 ft. (Canada) Not to be installed above a gas

*

**

***

= 12 in.

= 9 in. (U.S.A)

12 in(Canada)

= 18 in.

= 9 in.

= 6 in.

30 in. minimum for vinyl clad soffits

A vent shall not terminate directly above a

sidewalk or paved driveway that is located

between two single family dwellings and

serves both dwellings.

Only permitted if veranda, porch, deck or

balcony is fully open on a minimum of 2

sides beneath the floor.

NOTE: Local codes or regulations may

require different clearances.

Clearances to window or door

that may be opened

Clearance to permanently closed

window

Vertical clearance to ventilated

soffit located above the terminal

within a horizontal distance of 2

feet (60 cm) from the center-line

of the terminal

Clearance to unventilated soffit

Clearance to outside corner

Clearance to inside corner

meter/regulator assembly within

3 feet (90cm) horizontally from

the center-line of the regulator

WARNING: In the U.S.A.: Vent system termination is

NOT permitted in screened porches. Follow all sidewall,

overhang and ground clearances as stated in the instructions.

In Canada: Vent system termination is NOT permitted in

screened porches. Vent system termination is permitted in a

porch area with two or more sides open. Follow all

sidewalls, overhang and ground clearances as stated in the

instructions.

Country Flame Technologies assumes no responsibility for

the improper performance of the fireplace when the venting

system does not meet requirements.

I = 3ft. (U.S.A)

= 6ft (Canada)

J = 9 in.(U.S.A)

= 12 in. (Canada) Clearance to non

K

**L = 7 ft. Clearance above paved

***M = 18 in. Clearance under

= 3ft. (U.S.A)

= 6ft (Canada)

Clearance to service

regulator vent outlet

mechanical air supply

inlet to building or the

combustion air inlet to

any other appliance

Clearance to a mechanical

air supply inlet

sidewalk or a paved

driveway located on

public property

veranda, porch, deck

or balcony

Version 1.0h

TABLE 3: CLEARANCE DEFINITIONS

8

MINIMUM CLEARANCES

The Bayvue DV is installed by maintaining minimum clearances to all combustibles including any

projections such as shelves, window sills, or fireplace mantles that are located above or around the

appliance. Refer to FIGURE 2, FIGURE 3, TABLE 2, and TABLE 3 for clearances.

Sidewalls, both left and right sidewalls where applicable, must maintain minimum clearances to the

appliance. Overheating of sidewall material or framing material can occur without proper clearance.

All clearances listed in this manual are considered minimum clearances. All actual installation appliance

clearances MUST conform to local installation codes AND MUST conform to any clearance requirements

imposed by the local gas supplier.

CEILING CLEARANCES

The minimum ceiling height measured from the top of the appliance to the ceiling is thirty six inches (914

mm). The minimum clearance measured from any part of the horizontal vent pipe to the ceiling is one

inch (25 mm).

TOOL LIST

The following tools or equipment are recommended to the certified professional installer to be required

during the installation process. Other tools or equipment may be required depending on site specific

conditions:

- Various open end wrenches, including

- Various nut drivers’ and torx drivers, as required.

- Pipe wrenches.

- Phillips and flat bladed screw drivers.

- Proper gas pipe fitting sealant compound.

- Leak test fluid “U” tube manometer or pressure gauge (0 – 16” WC scale) test equipment.

- Volt/ohm meter.

7/16”, ½”, 9/16”, and crescent wrenches as needed.

UNPACKING

STEP 1 Unbolt the stove from the pallet. Discard pallet and packaging material.

STEP 2 Open the stove door on the unit and unpack all components located inside the firebox.

STEP 3 Inspect the interior and exterior of the stove for any shipping damage.

STEP 4 Review the materials list provided with the appliance to ensure all parts needed for

installation are present. This should include:

a) One set of ceramic fiber logs, (total 3 logs). Handle logs with care, extremely fragile.

b) One bag of ember material.

c) One installation, operation, and maintenance manual with warranty.

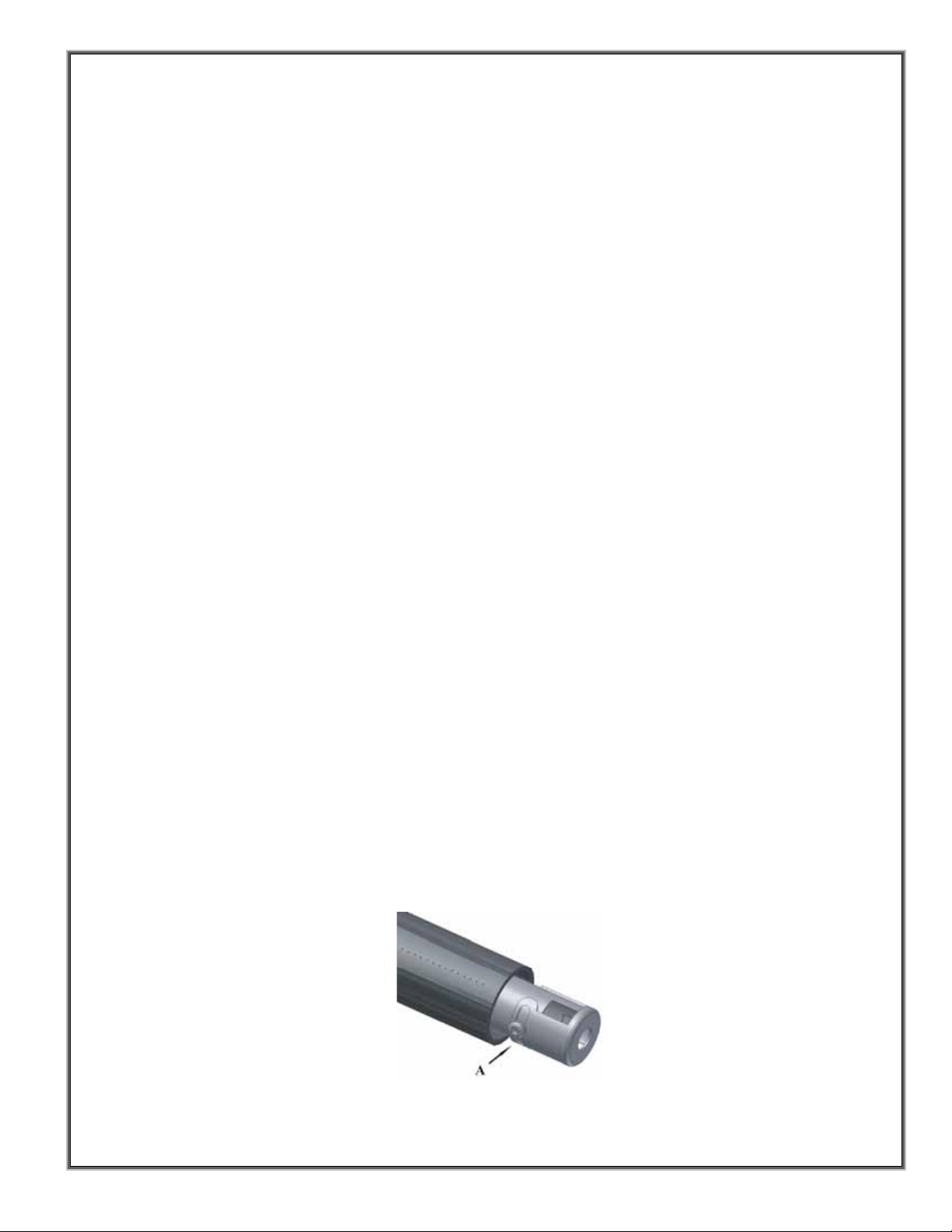

STEP 5 Verify the adjustable air shutter setting is correct per TABLE 4. FIGURE 4 shows the air

shutter welded into the end of each burner. There are three air shutters to be checked.

FIGURE 4, item A shows the location of the air shutter locking screw, if adjustment is

required.

Version 1.0h

FIGURE 4: ADJUSTABLE BURNER AIR SHUTTER

9

NATURAL GAS

0 – 2000 FEET > 2000 FEET 0 – 2000 FEET > 2000 FEET

FRONT BURNER 1/8 INCH SAME 1/8 INCH SAME

MIDDLE BURNER 3/16 INCH SAME 1/4 INCH SAME

REAR BURNER 3/8 INCH SAME 3/8 INCH SAME

PROPANE

0 – 2000 FEET > 2000 FEET 0 – 2000 FEET > 2000 FEET

FRONT BURNER 1/8 INCH SAME 1/8 INCH SAME

MIDDLE BURNER FULL OPEN SAME 5/32INCH SAME

REAR BURNER FULL OPEN SAME 3/8 INCH SAME

Bayvue DV-46 Bayvue DV-30

TABLE 4: AIR SHUTTER ADJUSTMENT

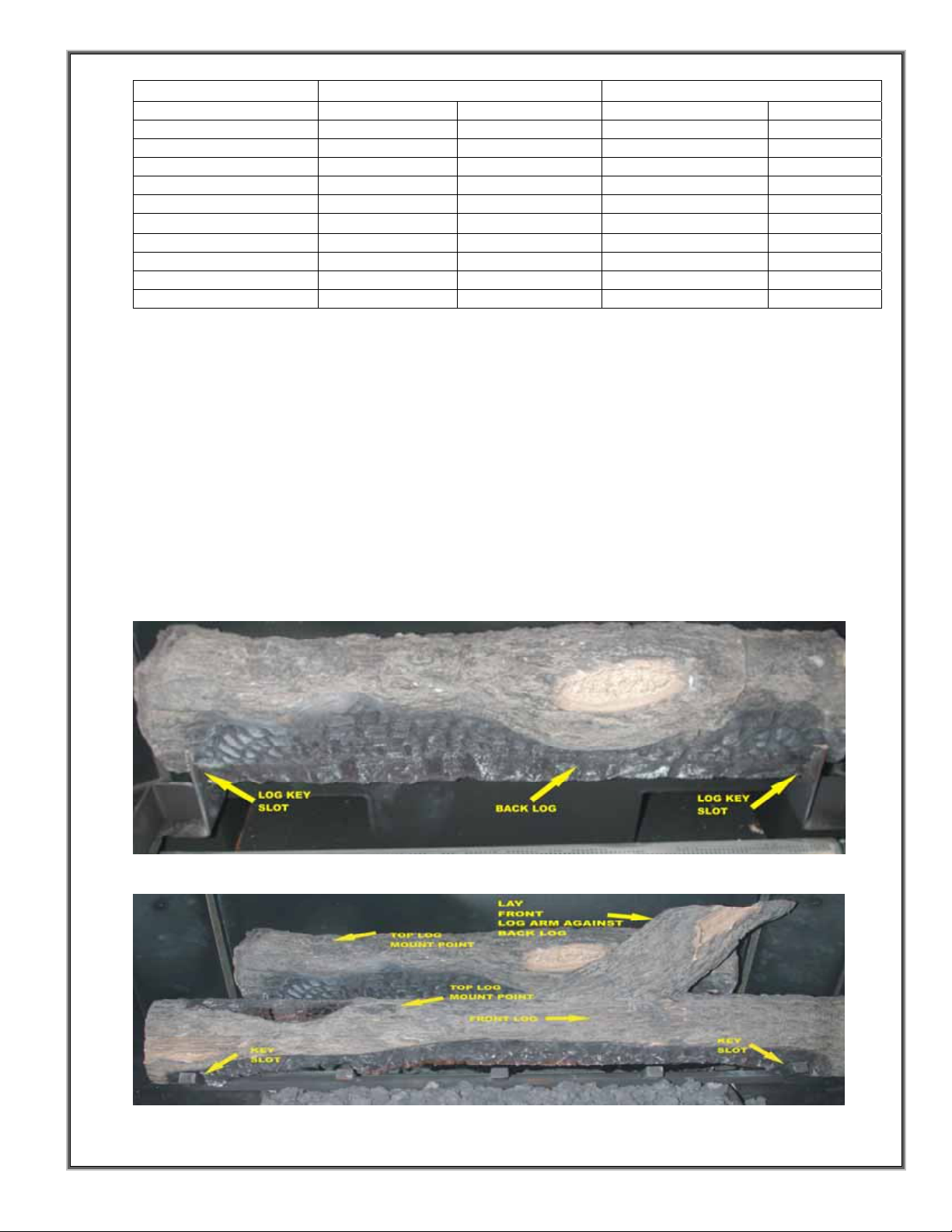

LOG PLACEMENT

The ceramic logs provided with this appliance are extremely fragile. Please handle these three logs with

the utmost care. Small chips off of the logs can be covered up using high temp paint. FIGURE 5 and the

following steps present log installation instructions. WARNING: IMPROPER LOG PLACEMENT

INSIDE THE FIREBOX CAN CAUSE IMPROPER FUEL BURN, EXCESSIVE CARBON

MONOXIDE (a colorless, odorless, toxic gas) PRODUCTION AND RESULT IN SOOTING AN

ENTIRE HOUSE. MONITOR THE FIRST FEW FIRES TO ENSURE NO SOOTING.

STEP 1 Center the rear log down onto the log retainer’s two keys into the log notches. See FIGURE 5a.

STEP 2 Set the front log into the log retainer using the two outside log grate arms as guides. See

FIGURE 5b. Rest front log arm against the back log. Note grooves for top log positioning.

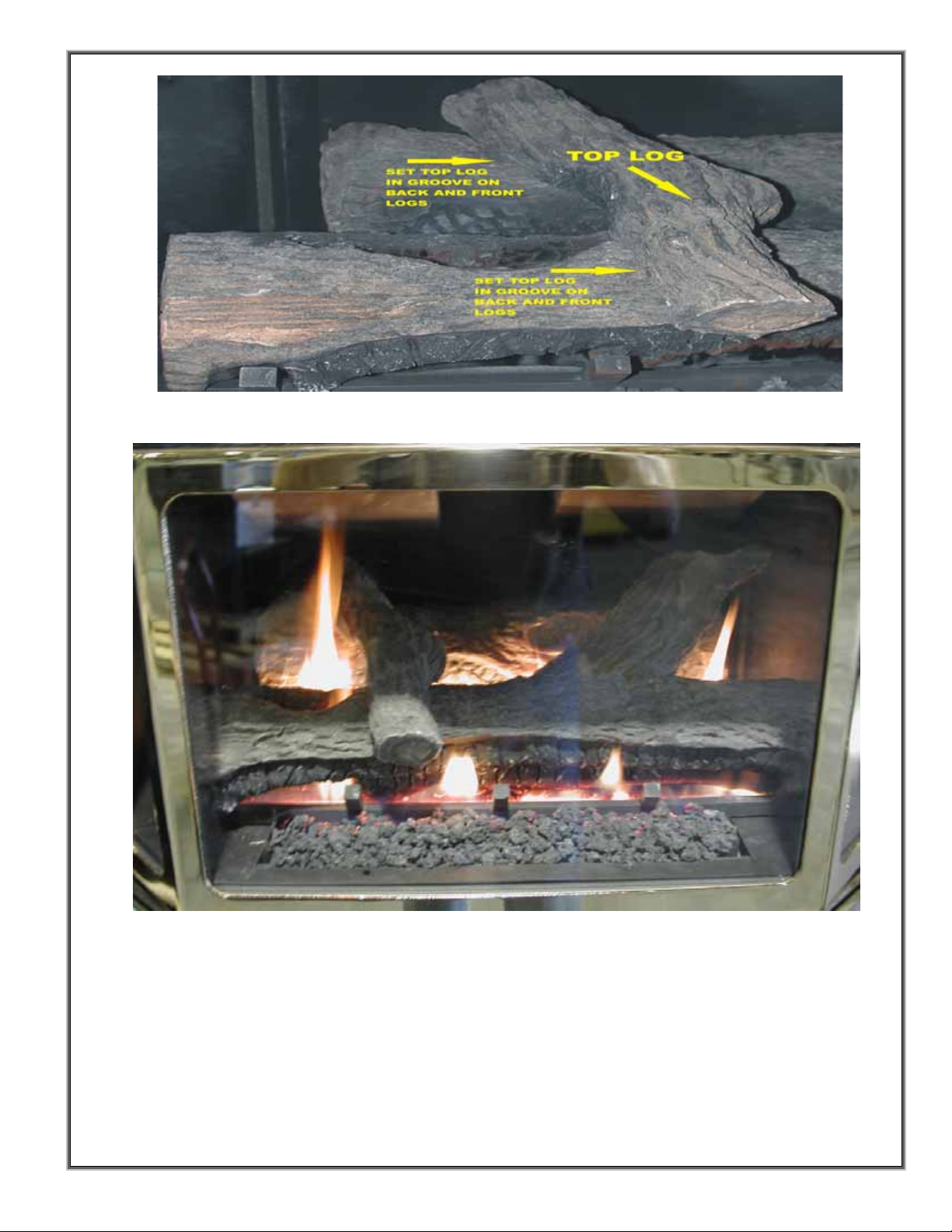

STEP 3 The top log lays on the left grooves nested on the back and front logs. See FIGURE 5c.

STEP 4 Embers are placed into and over the front of the "V" shaped front burner. See FIGURE 5d.

Version 1.0h

FIGURE 5a: REAR LOG PLACEMENT

FIGURE 5B: FRONT LOG PLACEMENT

10

FIGURE 5c: LOG SET (3 PIECES EACH)

FIGURE 5d: LOG SET WITH EMBERS

FIFGURE 5d also provides a view of a proper flame pattern for the Bayvue DV when the manifold

pressure is turned to high or its maximum Btu setting. Note that the embers that are close to the log grate

are glowing red. Further, these same embers have a blue flame being emitted from them. This “effect” is

because the front burner is designed not only to hold the embers but also to produce a small flame that

creates the burning ember effect. The middle and rear burner are designed to produce the “fire” and turn

the larger logs red. Note that a blue gas flame can be observed by looking down the front edge of the front

log. This flame should be touching “not floating above” the burner. The flame tips will be yellow but no

soot should be seen rising from the logs. It should be a very clean burn as shown in FIGURE 5d. Contact

a local Country Flame Dealer or certified professional if there is any issue with the flame appearance.

Version 1.0h

11

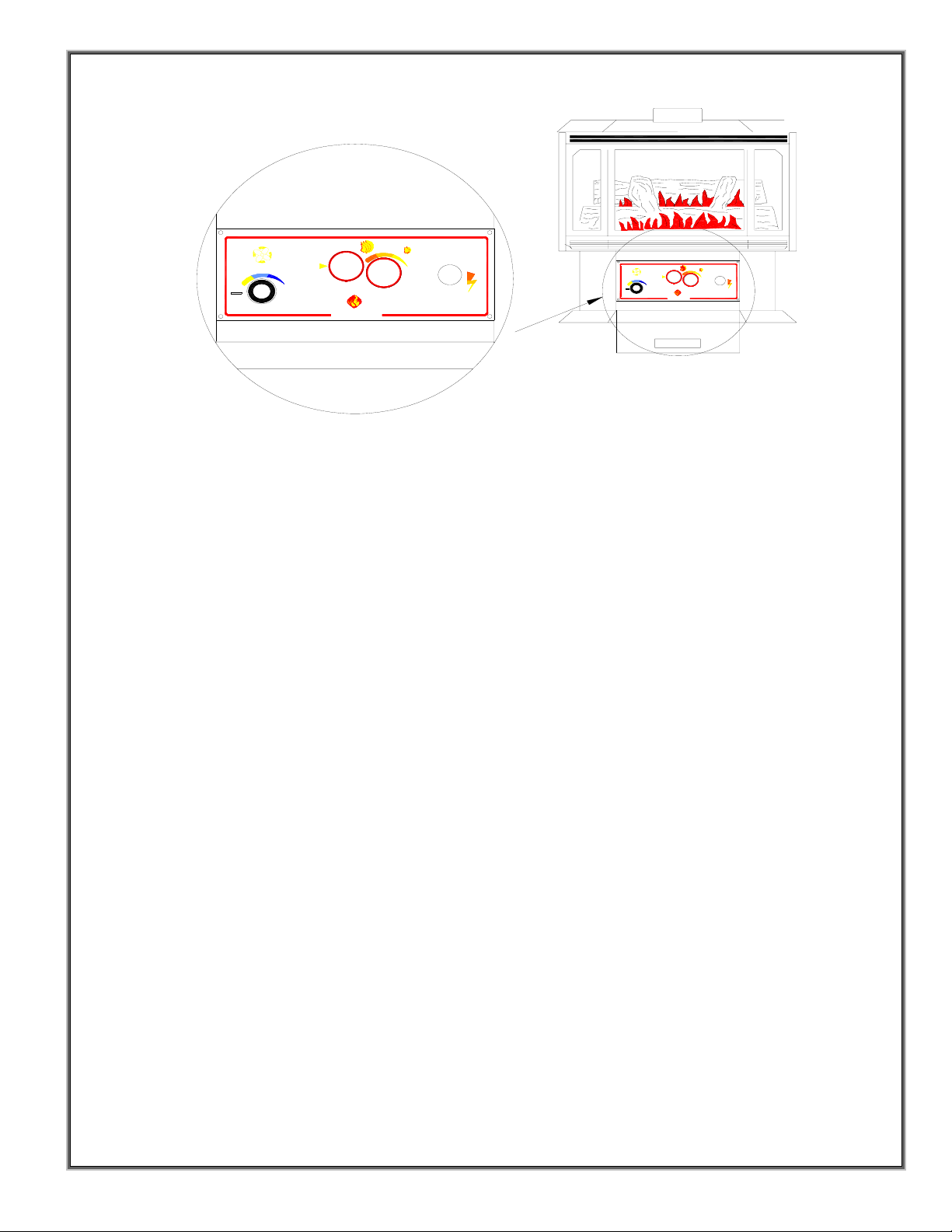

CONTROL PANEL ACCESS

HI

FLAME COMFORT

CONTROL

LO

FAN SPEED

HI

PIEZO

IGNITOR

35.0500.00

OFF

HI

LO

VALVE

CONTROL

LO

Country Flame

FLAME COMFORT

CONTROL

PIEZO

IGNITOR

35.0500.00

FAN SPEED

HI

OFF

VALVE

CONTROL

LO

Country Flame

FIGURE 6: CONTROL PANEL

The control panel is accessed through the front door of the Bayvue DV as shown in FIGURE 6. The

control panel has controls that adjust the blower fan speed, adjusts the burning setting, includes the burning

control, and the piezoelectric igniter control.

HEARTH REQUIREMENTS

When the Bayvue DV is to be installed directly on carpeting, combustible tile or other combustible

material other than wood flooring, the carpet or combustible material must be covered first. Other than

wood flooring, the floor must be covered with metal, non-combustible tile or wood paneling extending the

full width and depth of the appliance. The Bayvue DV can sit on a raised hearth as long as all chimney

pipe and all stove minimum clearances are maintained.

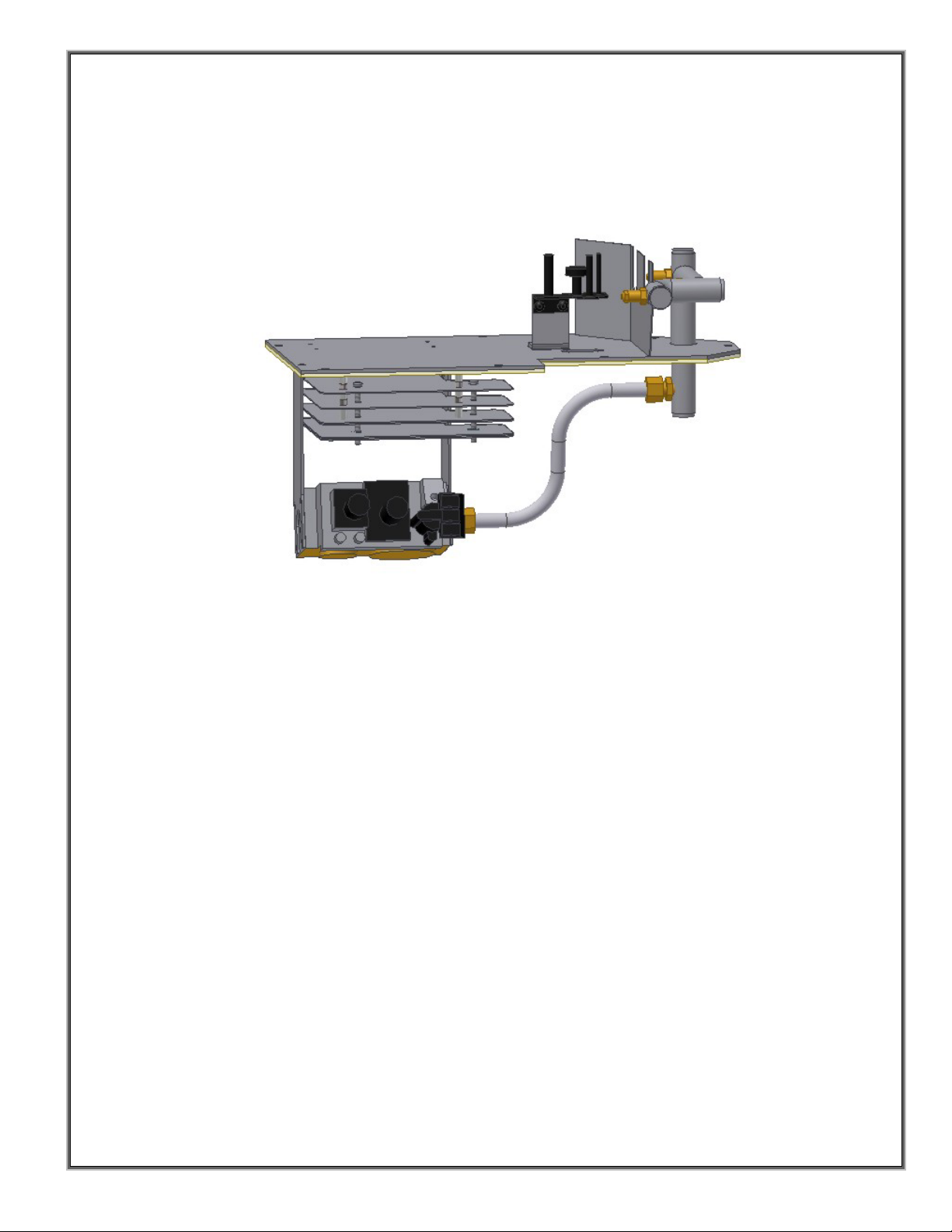

VALVE ASSEMBLY REMOVAL

From time to time, it may be necessary to remove the valve assembly. This assembly includes the SIT 820

control valve, the base mounting plate for the burner assembly, the pilot system, the three burner spud (a

spud is a removable cap or plug) orifice assemblies, and miscellaneous tubing. If it is ever necessary to

remove the valve assembly, take care not to damage any parts. Further, this system, once removed, should

be inspected by a certified professional before the valve assembly is reinstalled. The following steps

should be followed to ensure no damage occurs in removing the valve assembly. To reinstall the valve

assembly, reverse the steps as listed during the installation procedure.

STEP 1 Remove the control panel front access door by removing the screw hinge pins at the bottom

of the door.

STEP 2 Remove by pulling the rheostat knob off. Remove the four screws holding the control panel

front bezel in place and remove the bezel plate. Disconnect the piezoelectric igniter’s wire

from the igniter.

STEP 3 Remove the four screws holding the control panel support brackets.

STEP 4 Remove the two screws holding the heat shield that is directly above the valve access door

area.

Version 1.0h

12

STEP 5 Remove the glass door, logs, and embers. Refer to the specific section for each of these items

for further instructions on removal and installation of the glass door, logs, and embers.

Remove the three burner retaining screws and slide the burners off the burner spud orifice

holders and remove the front, middle, and rear burners. It is critical to ensure each burner is

marked so the correct burner is located in the same position it was removed from.

STEP 6 Remove the nine screws sealing the complete burner assembly to the bottom of the stove.

STEP 7 Disconnect the wiring to the terminal block and disconnect the gas.

STEP 8 Lift the complete gas valve assembly out of the stove. FIGURE 7 shows the assembly.

FIGURE 7: GAS VALVE ASSEMBLY

FUEL CONVERSION KITS

WARNING: Conversion kits shall be installed by a qualified service agency in accordance with

the manufacturer’s instructions and all applicable codes and requirements of the authorized

agency having juristriction. If the information in these manufacturer’s instructions are not

followed exactly, a fire, explosion or production of carbon monoxide may result causing property

damage, personal injury or loss of life. The qualified service agency is responsible for the proper

installation of this kit. The installation is not proper and complete until the operation of the

converted appliance is checked as specified in the owner instructions supplied with the

conversion kit.

The next several pages explain the conversion kits and step by step procedures to complete conversions.

This information is provided for homeowner reference but all conversions are to be completed by a certified

professional.

In the event of any problem with a Country Flame conversion kit or the installation of the kit, please contact

a local authorized Country Flame Dealer or contact Country Flame directly to obtain additional information

and assistance in properly resolving the problem.

Version 1.0h

13

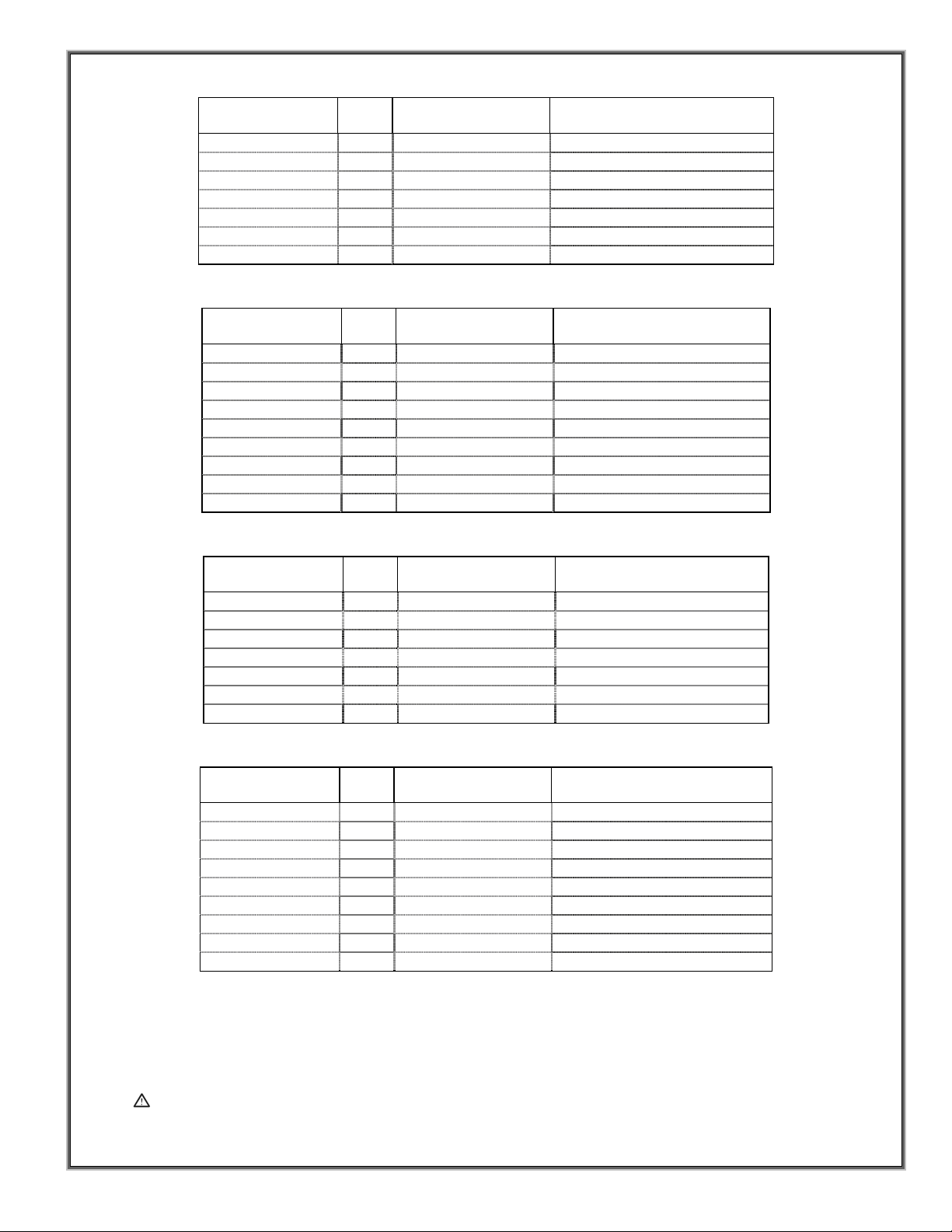

PR CONVERSION KIT BV-4604 CONTENTS:

ITEM QTY PART NUMBER ITEM DESCRIPTION

Regulator 1

Pilot Orifice 1

Front Spud Orifice 1

Middle Spud Orifice 1

Rear Spud Orifice 1

Conversion Label 1

Instructions 1

GC-3906-01

BV-4614

BV-4626

BV-4627

BV-4628

35-0500-01

BV-4650

PR CONVERSION KIT BV-3004 CONTENTS:

ITEM QTY PART NUMBER ITEM DESCRIPTION

Regulator 1

Pilot 1

Front Spud Orifice 1

Middle Spud Orifice 1

Rear Spud Orifice 1

Middle Burner 1

Rear Burner 1

Conversion Label 1

Instructions 1

GC-3906-01

BV-4614

BV-4632

BV-4633

BV-4634

BV-4620

BV-4622

35-0500-03

BV-4650

NG CONVERSION KIT BV-4603 CONTENTS:

ITEM QTY PART NUMBER ITEM DESCRIPTION

SIT 820 NOVA mV Gas Valve

#35 Pilot Injector Orifice

69 DMS LP Front Orifice Spud

55 DMS LP Middle Orifice Spud

53 DMS LP Rear Orifice Spud

Conversion NG to LP

Conversion Kit Instructions

SIT 820 NOVA mV Gas Valve

#35 Pilot Injector Orifice

70 DMS LP Front Orifice Spud

59 DMS LP Middle Orifice Spud

55 DMS LP Rear Orifice Spud

Middle Burner for 30,000Btu

Rear Burner for 30,000Btu

Conversion NG to LP

Conversion Kit Instructions

Regulator 1

Pilot 1

Front Spud Orifice 1

Middle Spud Orifice 1

Rear Spud Orifice 1

Conversion Label 1

Instructions 1

GC-3905-01

BV-4613

BV-4623

BV-4624

BV-4625

35-0500-02

BV-4650

SIT 820 NOVA mV Gas Valve

#51 Pilot Injector Orifice

55 DMS NG Front Orifice Spud

45 DMS NG Middle Orifice Spud

40 DMS NG Rear Orifice Spud

Conversion LP to NG

Conversion Kit Instructions

NG CONVERSION KIT BV-3003 CONTENTS

ITEM QTY PART NUMBER ITEM DESCRIPTION

Regulator 1

Pilot 1

Front Spud Orifice 1

Middle Spud Orifice 1

Rear Spud Orifice 1

Middle Burner 1

Rear Burner 1

Conversion Label 1

Instructions 1

GC-3905-01

BV-4613

BV-4629

BV-4630

BV-4631

BV-4620

BV-4622

35-0500-04

BV4650

:

SIT 820 NOVA mV Gas Valve

#51 Pilot Injector Orifice

57 DMS NG Front Orifice Spud

50 DMS NG Middle Orifice Spud

45 DMS NG Rear Orifice Spud

Middle Burner for 30,000Btu

Rear Burner for 30,000Btu

Conversion LP to NG

Conversion Kit Instructions

NOTE: Conversion kits are available only for natural gas and propane fuel.

NOTE: A Country Flame conversion kit is to be installed only by certified service technicians.

NOTE: Check kit contents for all parts. Do not attempt conversion with items missing.

NOTE: A Torx T20 Tamper-Proof screwdriver may be separately ordered if needed.

NOTE: D.M.S. (DMS is Drill Manufacturer's Standard) Standard twist drill or steel wire gauge number.

WARNING: The gas supply MUST BE SHUT OFF prior to disconnecting the electrical power and

before proceeding with ANY conversion kit installation.

Version 1.0h

14

Loading...

Loading...