When calling for technica l su pport.....

........ please have your serial numbers ready.

The Sensor and Instrument Serial Numbers are on the rear of the instrument, also see section 5.2.4.

Sens o r Serial No .: _______________

Instrument Serial No.: _______________

Your Representativ e is:

COSA INSTRUMENT CORPORATION

55 Oak Street, Norwood, NJ 07648

Tel.: (201) 767-6600 - Fax.: (201) 767-6804

Except as may be provided by contract, this document and all specifica-

tions and drawings contained are the p roperty of COSA INSTRUMENT

Corporation, are issued in strict confidence, and shall not be reproduced

or copied, in any form or by any means, or used as the basis for the man-

ufacture or sale of apparatus, programs, or services without permission.

Check the Internet for updates; The latest revision of this manual is available in Adobe Acrobat

format at: http://www.xentaur.com

Rev.1 Document No. XD0.01.D.0000

page i

The customer agrees that in accepting and using this instrument Xentuar Corporation’s liability

arising from or in any way connected with this instrument shall be limited exclusively to performing a new calibration or replacement or repair of the instrument or sensor, at Xentaur’s sole

option. In no ev ent s hall Xentaur be liable for any incidental, consequential or special damages of

any kind or nature whatsoev er, including but not limited to lost profits arising from or in any way

connected with this instrument or items hereunder, whether alleged to arise from breach of contract, express or implied warranty, or in tort, including without limitation, negligence, failure to

warn or strict liability.

VCO is a trademark of Cajon.

Swagelok,Cajon are trademarks of SWAGELOK Co.

Acrobat is a trademark of Adobe Systems Incorporated

HTF is a trademark of Xentaur Corporation

TheXentaur Logo is a trademark of Xentaur Corporation

page ii

XPDM Manual Table of Contents

1. Introduction................................................................................................................... 1

2. Precautions................................................................................................................... 2

3. Principle of Operation................................................................................................... 3

4. Operating the XPDM..................................................................................................... 5

4.1. Sample Hook-up........................................................................................................ 5

4.1.1. Fittings .................................................................................................................... 5

4.1.2 Recommended Pipes........... .......................................................... .......................... 5

4.1.3. Sample conditioning................................................................................................ 5

4.2. Measuring.................................................................................................................. 5

5.0 The User Interface...................................................................................................... 7

5.1 Display Conventions................................................................................................... 7

5.2 Operating State........................................................................................................... 8

5.2.1 Viewing Dewpoint Mode ................. .......................................................... ............... 8

5.2.2 Viewing Temperature at the Sensor ................. ................................................ ....... 9

5.2.3 Start Autocal Mode .................................................................................................. 9

5.2.4 Viewing Serial Number Mode .......................................... ........................................ 9

5.3 Set-up State .............................................................................................................. 10

6. Options........................................................................................................................ 11

6.1 RS-232C................................................................................................................... 11

6.2 Current Loop Output................................................................................................. 12

6.3 Operating from an external Power Supply................................................................ 13

7. Automatic Calibration.................................................................................................. 14

8. Changing desiccant cartridge and/or battery.............................................................. 15

9. Special messages, warnings and error indications..................................................... 16

Appendix A: Flow diagram of User Interface in the Operating State .............................. 17

Appendix B: Flow Diagram of User Interface in the Set-Up State.................................. 18

Appendix C: Relationship of Instrument Reading and 4-20mA output when lbs of H20/million stan-

dard cft or ppmv engineering units are selected............................................................. 19

Appendix D: Uncertainty in LBS and PPMV calculations................................................ 20

Appendix E: Battery Life............... ............................................... ................................... 21

page iii

1. Introduction

The XPDM is a portable, hand-held, microprocessor controlled, battery operated dewpoint meter with buil t in dry-storage for the sensor. The instrument is ideally suited for all

applications, where quick and precise measurements are required.

Standard Equipmen t:

1. XPDM Portable Instrument with

sensor, desiccant cartridge and

lithium battery.

2. 2VCO® to Swagelok® fittings and

2 Swagelok® to barbed hose fittings.

3. Calibration bulb.

4. Shoulder strap.

8 6

3

Optional Equipment:

5. VCO® to VCO® Fittings.

6. Pig tail.

7. Flexible stainless steel hose.

8. Pressure regulator, all stainless

steel, (preset at 1.5 atm) with

mounting bracket.

9. Coalescing filter, all stainless steel

with mounting bracket.(not shown)

10.Wall transformer (with factory

installed I/O option).

11.Replacement desiccant cartridge.

12.Padded transport case.

5

7

12

10

11

2

3

4

1

page 1

2

2. Precauti on s

• Warranty limitation: The XPDM’s sample cell/piston assembly should not be disassembled except by factory trained personnel. The warranty is voided, if the sample

cell piston assembly is disassembled by the customer.

• Avoid contaminated sample streams: The XPDM has been designed to allow for fast

and precise mea surem ents o f de w po ints as lo w as -1 00 °C. Therefore, a ll surfaces in

contact with the sample stream are made from electropolished stainless steel. This

minimizes the time for the instrument to reach equilibrium with the sample stream,

thus speeding up the measurement. The introduction of corrosive gases or gases

contaminated with oils, solvents etc. may damage or coat the electropolished surfaces and slow down the measurement. Surfaces contaminated with oils etc. can be

cleaned by factory trained personnel (please contact your sales representative). Surfaces damaged by corrosive gases are damaged permanently, causing longer

response times. Gases containing chlorine, ammonia, HCl or SO2 may also cause

damage to the sensor. SO2 can be monitored when the moisture content is low.

• Avoid liquid water: Avoid the introduction of liquid water into the sample cell, as this

may damage the sensor. Do not breathe directly into the instruments sample ports,

as condensation may form which could damage the sensor element. If liquid water

can not be av oided, order the XTR-6 5W sensor which is water proof , but has a limited

range, and a slower dry down response.

• Avoid high pressure: The XPDM has been designed for operation at pressures

slightly above atmospheric, however each sample cell, sensor, piston, dry-storage

assembly has been tested for pressures up to 120 PSI. Do not introduce sample

streams, whi ch could cause pr essure rises abo ve 100 PSI. Mak e y our measu rements

at atmospheric pressures, and use the pressure calculation feature to calculate dewpoints at higher pressures. Ask your representative for a regulator installation kit.

• Exercise Caution with Hazardous Gases: Please use appropriate precautions if the

sample yo u ar e ab out t o me asure i s haza rdou s. Pla ce the unit i n a sa f e area , i f it is to

be used with hazardous gases. Please be aware that the possibility of a small leak

always exists. Such a leak will not influence the accuracy of the measurement, but

may represent a risk if the sample gas is of hazardous nature.

• Avoid Extreme temperatures: Do not install the unit near heat sources such as radiators or air ducts. The instruments’ operating temperature range is -10°C to 50°C.

• Avoid Mechanical Vibration: Do not install the unit in places subject to extreme

mechanical vibration or shock. Use resilient mounting, if shock and vibration are not

avoidable. Call your representative if in doubt.

• Avoid long exposures of sensor element to room air: For reasons explained later in

this manual (section 7), do not expose the sensor to room air for longer then necessary (1 - 2 Minutes). The sensor is exposed to room air, when the sensor actuator is

in the out position and no samp le line is connect ed, or the samp le gas is shut off. It is

best to push the sen sor bac k into dry-storage, afte r a measurement is completed and

whenever the instrument is not in use.

• Do not force the Actuator: Remove any port obstructions (such as shipping caps)

before operating the Actuator.

page 2

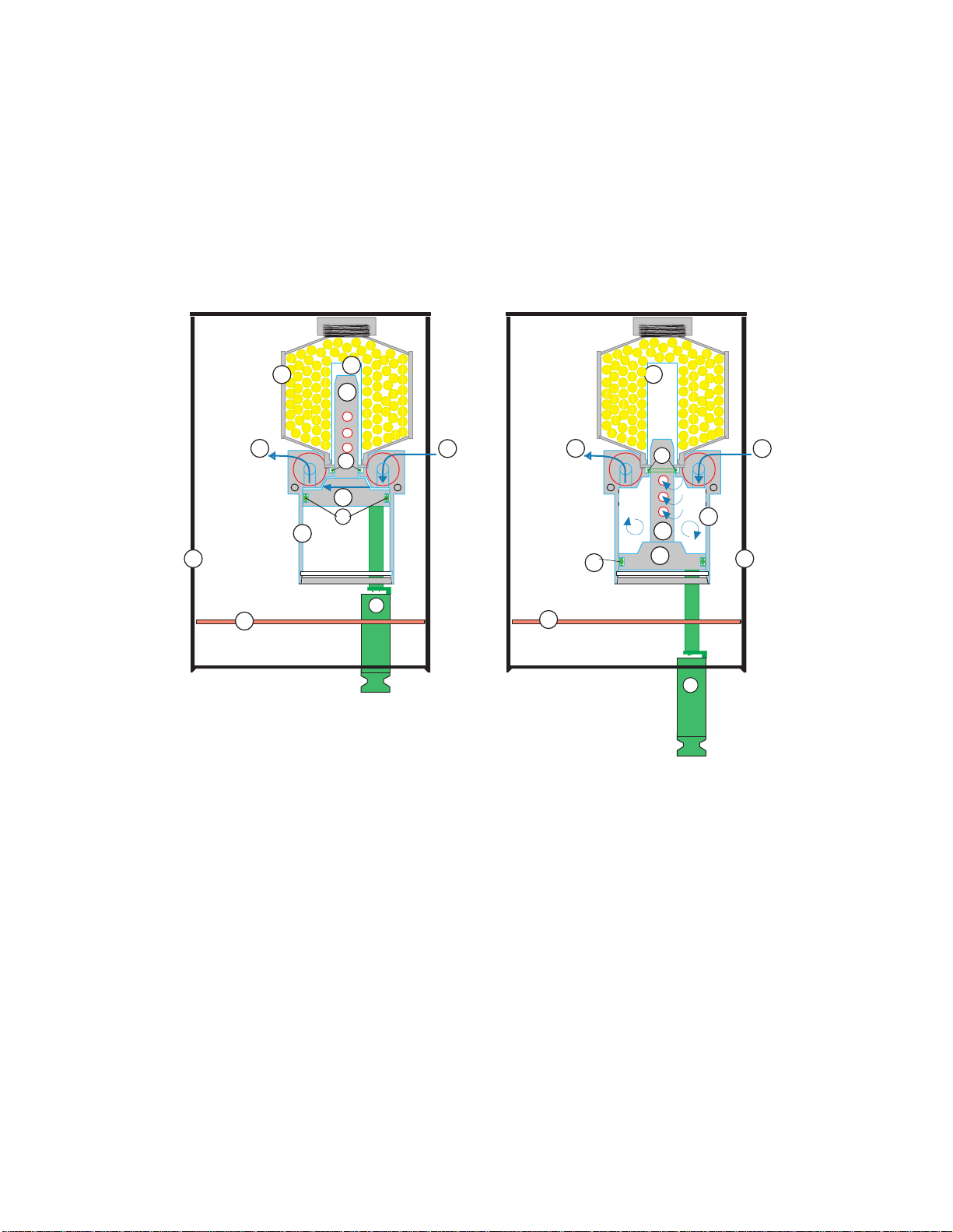

3. Principle of Operation

Dewpoint sensors, like all hygroscopic materials, adsorb much faster than they desorb.

Therefor e, an accurate measurement will be obtained much faster, if at the beginning of

the measurement, the sensor is at a dewpoint drier than the gas to be measured. The

XPDM design all ows the sensor to be mo ved directly betw een dry-storage and the sample

cell, without any exposure to ambient air.

Sensor in Sensor In

dry-storage position measuring position

8

2 2

4

10

9

5

1 1

6

3

6

7

6

10

9

6

4

5

3

7

1. Sample Gas In 7. Sensor Actuator

2. Sample Gas Out 8. Desiccant Chamber

3. Piston 9. Filter Mesh

4. Sample Cell 10.Electronic Board

5. Sensor 11.Instrument Case

6. Spring loaded PTFE seals

1111

The dra wing on the lef t show s the XPDM with the sens or in dry-storage position . The se nsor is enclosed in a gas-tight container and surrounded by desiccant. The sample gas

passes through the sample chamber and prepares the environment for measurement.

Blocking of the outlet port will pressurize the sample chamber and move the piston into

the position sho wn on the right. The sensor is no w exposed to the sample gas without e ver

having been exposed to ambient air. After the measurement is taken, pushing in the sensor actuator will return the sensor into dry-storage, where it will dry down and re ady itself

for another fast measurement.

page 3

A note about dry-storage

The dry-storage consist of a stainless steel container filled with desiccant. The electropolished stainless steel sensor guard slides between the dry-storage and the sample

cell through a spring energized PTFE seal, assuring maximum possible gas tightness

and minim um gas tr ansport between the two chambers when the sensor is moved. When

in dry-storage, the sensor guard is separated from the desiccant b y a stainless steel wire

mesh with a thickn ess of 127 µ (0.005”) and a m esh siz e of 100µ. Th is keeps the distance

between the sensor and the d esiccant t o a m inim um, whi ch is critica l f or fast and low drydowns, while protecting the sensor from contamination with desiccant particles.

The factory supplied desiccant provides dry-storage dewpoints as low as -80°C when

fresh. When the sensor is pushed into dry-storage it will take some time to dry down

completely and reach equilibr ium with the dewpoint in the dry-storage. The dry-down

time to equilibrium depends on how wet the sensor was before it was returned to drystorage, and in case that it was completely wet, how long it had remained in wet condition.

To take full advantage of the dry-storage, ma ke sure, that the dry-storage dewpoint is

below the expected dewpoint of the sample gas by periodically checking the indicated

dewpoint after the sensor has remained i n dry-storage for an e xte nded period of time, f or

exam ple o v e r nig ht. R epla ce the desi ccan t cartridge, if the dry-stora ge d e wpoint is m uch

higher than -80°C and above your expected sample dewpoints.

page 4

4. Operating the XPDM

4.1. Sample Hook-up

4.1.1. Fittings

The XPDM can be hooked up to the sample gas using a variety of fitt ings , depend in g on

the application. The instruments’ sample ports are 1/4” VCO® female, to assure proper

seals for even the lowest dewpoint measurements.

Depending on the application and needs, we recommend the use of one of the following

methods of attachment:

•VCO® ➜ VCO®: This method is i de al f or all applicati o ns , incl uding th e use of flexible

stainless steel hoses, available optionally.

•VCO® ➜ Swagelok®: This method is suitable for all applications where rigid pipe

connections are acceptable.

•VCO® ➜ Swagelok® ➜ Barbed Hose Fitting: This method is acceptable for dewpoints above -65°C and should in all cases be used only with PTFE tubing.

4.1.2 Recommended Pipes

Stainless steel pipes should be used exclusively, for dewpoints below -65°C. Your representative has a fle xib le stainless stee l hose a v ailabl e. The l ength of t he sample line to the

instrument should be k ept as short as possible, to assure f ast equilibrium. W e recommend

the attachme nt of at least 12" long stainless steel p ipe at the outle t port to av oid ba ck flow

of ambient air when sampling at low flow rates, ask your representative for the optional

pigtail.

PTFE tubes are perfectly accep table , a nd off er ad v antages d ue to their flexibility , f or de wpoints above -65°C. However, PTFE tubes should be kept as short as possible.

Under no circumsta nces use rubber or plastic tu bes, which are both, hyg roscopic and permeable. No valid measurements can be expected when such materials are used.

4.1.3. Sample conditioning

• Pre-filters: Do not use any pre-filters for oil, particles or liquid water when measuring

dewpoints b el o w -65 °C. Pre-filters store and release w a ter vapor, and slo w do wn a nd

distort the measurement at low dewpoints.

• Pressure regulators: Do not use a pressure regulator containing any materials other

than stainless steel, for dewpoints below -65°C. To ensure the use of the right product, use regulators provided by your sales representative.

4.2. Measuring

• Turn the unit on by pushing the Power button.

• Select the desired engineering units, using the up or down buttons.

• Take note of the indicated dewpoint while the sensor is still in dry-storage.

• Introduce the sample gas i nto the u nit whil e the outpu t port is unobstructed. Wait one

minute, for every 20°C below 0°C of expected dewpoint, to allow the interconnecting

hose or tube as well as the sample chamber to adapt to the sample dewpoint (eg. if

expecting -60°C, wait for 3 minutes).

• Block the outlet port. The small pressure build-up in the sample chamber should be

sufficient to push out the piston and move the sensor into the sample chamber. If no t

page 5

Loading...

Loading...