COSA Xentaur Xentaur XDTL-HT User Manual

XTDL-HT™

Optical Moisture Dew Point Analyzer

User Manual

LAS.99.D.10027 Rev 1

September, 2013

COSA Xentaur Corporation

www.cosaxentaur.com

Copyright © 2013

All rights reserved.

The contents of this publication are presented for informational purposes only. While every effort has been made

to ensure this document error-free, it should not be construed as warranties or guarantees, expressed or implied,

regarding the product or services described herein or its use or applicability.

COSA Xentaur Corporation reserves the right to change or modify the product specification and/or appearance at

any time without notice. Therefore, the information in this document is subject to change without notice and

does not represent a commitment on the part of COSA Xentaur Corporation.

The customer agrees that in accepting and using this instrument COSA Xentaur Corporation’s

liability arising from or in any way connected with this instrument shall be limited exclusively to

performing a new calibration or replacement or repair of the instrument or sensor and at their

sole option, as covered by the warranty. In no event shall COSA Xentaur Corporation be liable for

any incidental, consequential or special damages of any kind or nature whatsoever, including but

not limited to lost profits arising from or in any way connected with this instrument or items

hereunder, whether alleged to arise from breach of contract, express or implied warranty, or in

tort, including without limitation, negligence, failure to warn or strict liability.

Table of Contents

Unpacking _________________________________________________________________________ 5

Warning Labels _____________________________________________________________________ 5

Overview __________________________________________________________________________ 6

Specifications ______________________________________________________________________ 7

Theory of Operation _________________________________________________________________ 8

Installation _______________________________________________________________________ 10

Enclosure Installation ____________________________________________________________________ 10

Extractive Installation____________________________________________________________________ 11

Electrical Connections ___________________________________________________________________ 12

Connecting Power ______________________________________________________________________ 13

Interfacing to Analog Output ______________________________________________________________ 13

Interfacing to RS-232/RS-485 ______________________________________________________________ 14

Interfacing to Ethernet ___________________________________________________________________ 14

Wiring Relay Contacts ___________________________________________________________________ 15

Startup _______________________________________________________________________________ 15

User Interface _____________________________________________________________________ 17

Status Indicators ________________________________________________________________________ 17

Display ________________________________________________________________________________ 17

Touch Keys ____________________________________________________________________________ 18

Chart Operation ________________________________________________________________________ 19

Readings ______________________________________________________________________________ 19

Menu Access ___________________________________________________________________________ 19

Main Menu ____________________________________________________________________________ 20

Measurements ____________________________________________________________________ 21

Moisture Measurement __________________________________________________________________ 21

TruTune™ _____________________________________________________________________________ 21

Setup Menu ___________________________________________________________________________ 22

Modbus Communication ____________________________________________________________ 23

Setup Menu ___________________________________________________________________________ 24

Modbus RTU ___________________________________________________________________________ 24

Modbus/TCP ___________________________________________________________________________ 25

3

Analog Outputs ___________________________________________________________________ 26

Current Output _________________________________________________________________________ 26

Voltage Output _________________________________________________________________________ 26

Setup Menu ___________________________________________________________________________ 27

Remote Controlled ______________________________________________________________________ 28

Relays ___________________________________________________________________________ 29

Setup Menu ___________________________________________________________________________ 30

Time Controlled ________________________________________________________________________ 31

Remote Controlled ______________________________________________________________________ 31

PID Controllers ____________________________________________________________________ 32

Setup Menu ___________________________________________________________________________ 32

Support Information ________________________________________________________________ 34

Restoring default values __________________________________________________________________ 34

Setting clock ___________________________________________________________________________ 34

Troubleshooting ___________________________________________________________________ 35

Maintenance______________________________________________________________________ 37

Warranty ______________________________________________________________________________ 37

Maintenance Policy _____________________________________________________________________ 37

Spare List ______________________________________________________________________________ 38

Appendix A: Enclosure Dimensional Drawing ____________________________________________ 39

Appendix B: Modbus Registers _______________________________________________________ 40

Coil Registers __________________________________________________________________________ 40

Discrete Input Registers __________________________________________________________________ 40

Input Registers _________________________________________________________________________ 41

Holding Registers _______________________________________________________________________ 43

Index ____________________________________________________________________________ 55

4

Unpacking

Unpack the XTDL-HT™ in a clean, dry area. Check the packing list for an itemized record of all

equipment shipped. Examine all packing material for miscellaneous parts before discarding. Save the

container until you determine that no shipping damage has occurred. Inspect the equipment for any

signs of damage that may have occurred during shipment. If any part is damaged during shipment, file

a claim against the carrier. Report the damage in detail, taking photographs if possible. Report any

shipping damage to COSA Xentaur at the address listed on the back of this manual.

Warning Labels

The symbols shown below or their likeness may appear on the instrument to alert the user of

potentially hazardous conditions.

Class 3B invisible laser radiation. When opened, avoid direct eye exposure. Class 1 laser

product.

Caution – Risk of Electric Shock

Caution – Hot surface

5

1

Overview

The COSA Xentaur XTDL-HT™ is a tunable diode laser moisture analyzer with a new proprietary

measurement cell designed for harsh environments, such as the dirty blanket gases in heat treating

applications, where high particulate counts and corrosive gases cause other measuring systems to fail.

It frees from the worry of cleaning the optics or frequently replacing sensing elements due to frequent

drift or failure. Once calibrated at the factory, no further recalibration is required. A reliable on-line

moisture system will improve the quality of the finished product and alert to process upsets, thus

preventing the costly reworking of parts.

The XTDL-HT™ employs proprietary backscatter GasScan™1 Wavelength Modulation Spectroscopy

(WMS) technique developed by Physical Sciences Inc. With no mirrors in the gas flow path, the XTDLHT™ can handle extreme gas stream conditions with high particulate without compromising the

measurement. This adaptive measurement method is also independent of the light level so

approximately 80% of the light intensity can be lost while still making an accurate measurement.

The integrated sample conditioning system aspires the sample from the low pressure furnace by

means of an eductor, eliminates particulates through a self-cleaning sintered stainless steel tube filter

and regulates the flow and pressure of the sample. The measurement cell is temperature and pressure

controlled to ensure measurement accuracy and consistent results from the analyzer. This instrument

software allows up to 6 different stored factory calibration curves based on the gas matrix or ambient

conditions. Real-time pressure correction is employed to further enhance measurement repeatability.

The instrument comes factory calibrated against a NIST traceable reference standard. Under normal

conditions, the instrument should not require calibration in the field due a proprietary algorithm,

TruTune™, which checks and aligns the light source automatically in the background ensuring the

instrument is properly tuned.

Up to three user-selected variables can be displayed: two in text form and a third in graphical form.

The interface is flexible and allows the end user to display any combination of available variables. Even

a single variable can be displayed in three different sets of engineering units.

GasScan™ is a trademark of Physical Sciences Inc.

6

Specifications

Measurement Range

3,000-25,000ppmV H2O

-8.2 to 20.9°C (at 14.696 psiA)

Accuracy

±2% or ±200ppm, whichever is greater

Pressure Range

Operating: 0-30psiA

Temperature Range

Operating: -20 to 50°C

User Interface

Ultra high contrast graphical display

Touch keys operation for user interface

Analog Output

1 standard, 1 optional

High resolution (16-bit)

4-20mA, 0-20mA, 0-24mA, 0-5V, 0-10V, ±5V, ±10V options

Isolated output option available

Alarm Contacts

1 standard, 2 optional

SSR and Class I Division 2 relays option available

Digital Communication

Modbus RTU and Modbus/TCP support

RS-232, RS-485 serial communication,

Isolated interface option available

Ethernet communication, 10/100 Mbps

Supply Voltage

110/220VAC 50-60Hz

Maximum power consumption: 700VA

Enclosure

Wall mounting or pipe mounting

Dimension

21”Wx37”Hx10"D

Weight

Approximately 20 kg (53lbs) depending on options

Specifications

7

Laser Diode

Sinusoidal

Generator

Sample Cell Photodetector

Demodulator

Calibration Curve

Reading

f

f

f

1, f2

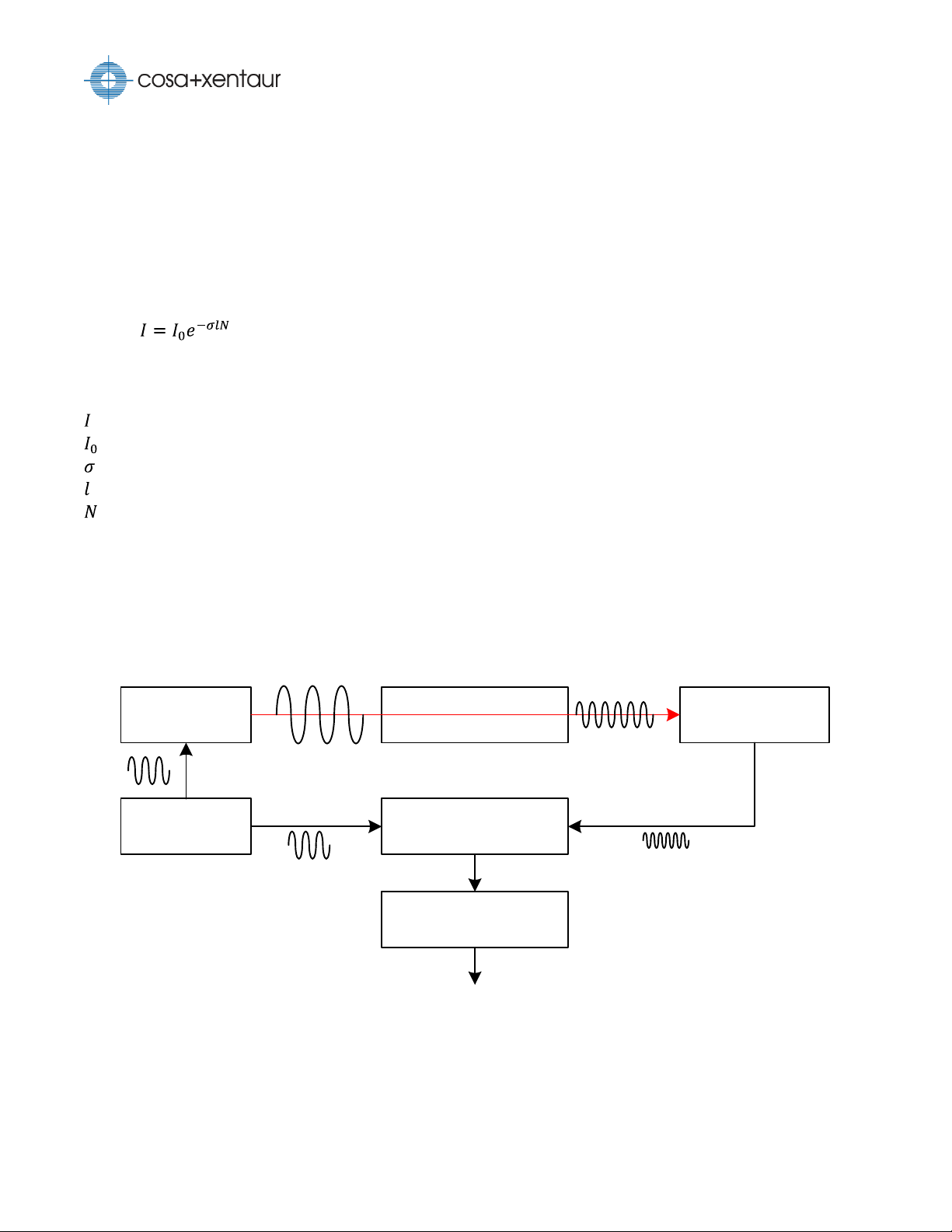

Theory of Operation

Atoms and molecules have absorption spectra that are distinctive to their species. The XTDL-HT™

measures water vapor in a sample by measuring an absorption line (wavelength) from the water vapor

absorption spectrum. As a near-infrared laser beam passes through the sample cell, a photodetector

measures the reduction in light intensity due to interaction with the sample. By Beer-Lambert law,

where

is the intensity of the transmitted light

is the intensity of the incidental light

is the instrument-dependent absorption coefficient

is the beam pathlength

is the density of the absorbing particles

the instrument can calculate the water concentration. To improve the signal-to-noise ratio, the XTDLHT™ employs the wavelength modulation spectroscopy (WMS) technique. In WMS, wavelength of the

laser light is continuously modulated with a sinusoidal waveform with the target wavelength at the

center, and the signal is detected as harmonics of the modulation frequency. The measurement value

is computed using the harmonic amplitudes over the stored calibration curve.

The absorption coefficient in the Beer-Lambert law is a function of sample temperature and pressure.

To ensure stable and accurate reading, the XTDL-HT™ maintains the sample temperature with a heated

enclosure and the sample pressure is fixed with a back pressure regulator.

8

Theory of Operation

In typical laser absorption instruments, light beam is reflected on one or two mirrors inside the sample

cell before reaching to the photodetector. When the mirror becomes fouled due to particulates or

contamination, measurement will no longer be possible. The angle of reflection may change and the

received light intensity may decrease too much affecting the calibration. Unlike these instruments, the

XTDL-HT™ does not use any mirror in its sample cell; it uses a black body target allowing light to scatter

inside the cell. It measures the water vapor concentration as a ratio of the harmonic amplitude to the

absorbed light intensity. This allows accurate measurement regardless of how much light is received

from scattering.

9

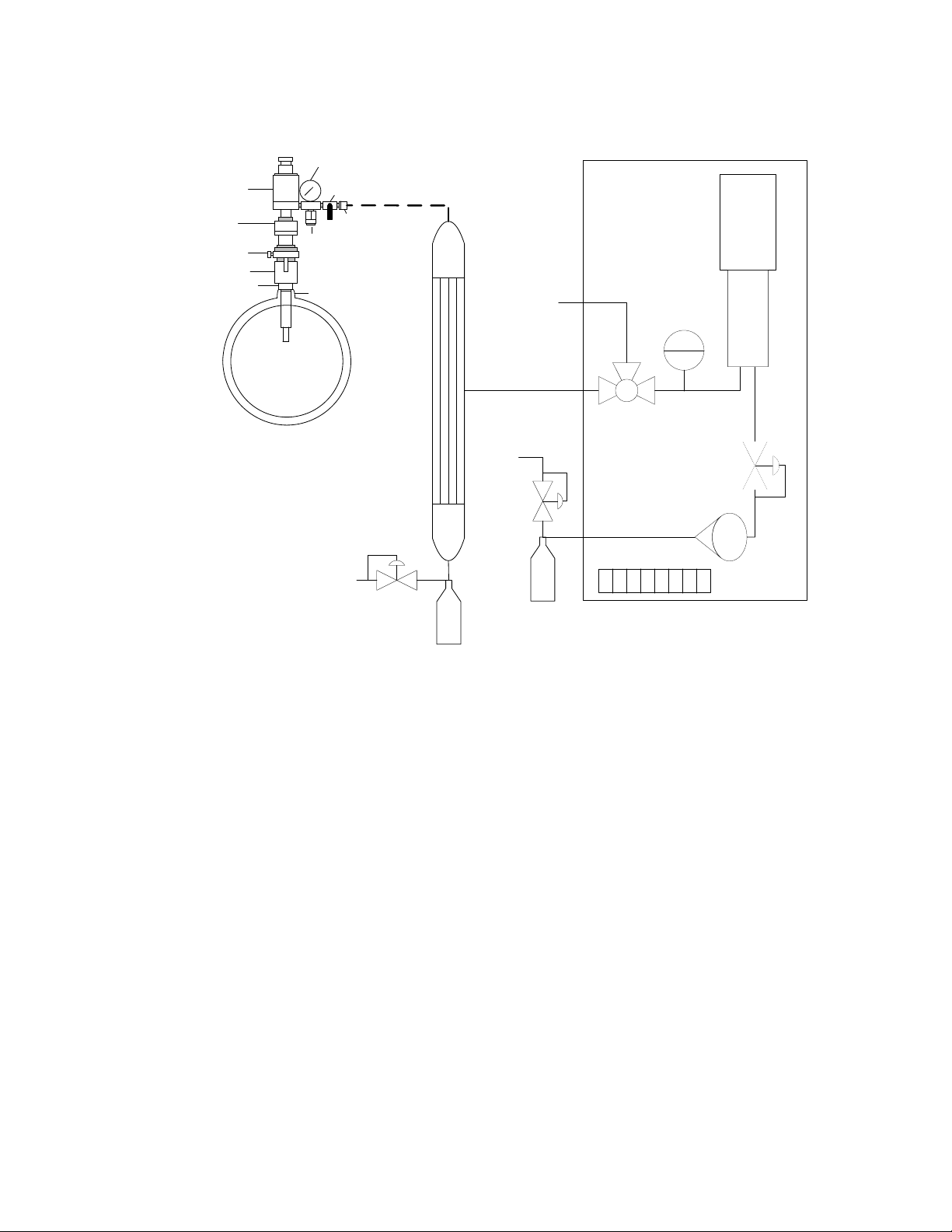

Calibration Gas

Inlet

Process Gas Inlet

Instrument Air

Inlet

Electrical Wiring Cable Grips

Vent

Pressure

Gauge

Flow Meter

Keypad

Display

Mounting Plate

Mounting Bracket

Status

Indicators

Instrument Air

Inlet

Outlet

Eductor

Inlet

Eductor

Gas Sampling

Filter

Inlet Air

Regulator

Outlet Air Regulator

Installation

Enclosure Installation

For wall mounting installation, remove the top and bottom mounting plates and bolt the four

mounting brackets to the wall. For pipe mounting installation, install pipe clamps (p/n ESS.98.M.0205)

over the top and bottom mounting plates. Sunshade (p/n ESS.S2.M.9365) is recommended for outdoor

installation.

10

Installation

Enclosure

1

6

4

8

9

Calibration

Gas Inlet

Process

Gas Inlet

Sample

Gas

Exhaust

7

pipeline

Pipe Nipple

Thredolet

Ball Valve

Baseplate

Housing

Regulator

Relief Valve

Ball Valve

Outlet Connector

Pressure Gauge

Notes:

Enclosure insulated on all sides to

maintain nomially 34°C ± 1°C in a

temperature range of -20°C to 50°C.

Inlet rated to 6000 psig maximum.

Flow rate is 2 l/min nominal.

All ¼” Swaglok fittings and tubing.

Shop Air

Inlet

Shop Air

Inlet

Sample

Gas

Exhaust

5

5

2

2

10

1. Back pressure regulator

5. Adjustable regulator

9. Pressure gauge (0-30 psig)

2. Eductor

6. 3-way valve

10. Gas sampling filter

3. All ¼” stainless steel tubing

7. XTDL-HT™ laser cell

4. Flow meter

8. Enclosure heater

Extractive Installation

The instrument should be installed in a slip stream of process gas. Please make sure that:

The sample is taken from the upper surface of the main gas line to avoid problem of

contamination.

The sample is taken away from the pipe wall where flow rates may be low, and dewpoint change

may lag.

If regulators or shut-off valves are used up stream of the instrument, make sure that these do not

contain rubber or other hygroscopic materials.

Stainless steel tubing is preferred. Copper tubing is acceptable. Do not use plastic, rubber, or

Tygon tubing due to water retention in these materials.

Use small diameter pipes (1/4” or 1/8” OD).

Do not install other devices up stream of the instrument, such as other measurement systems,

which are not absolutely necessary as these are potential leak sources.

11

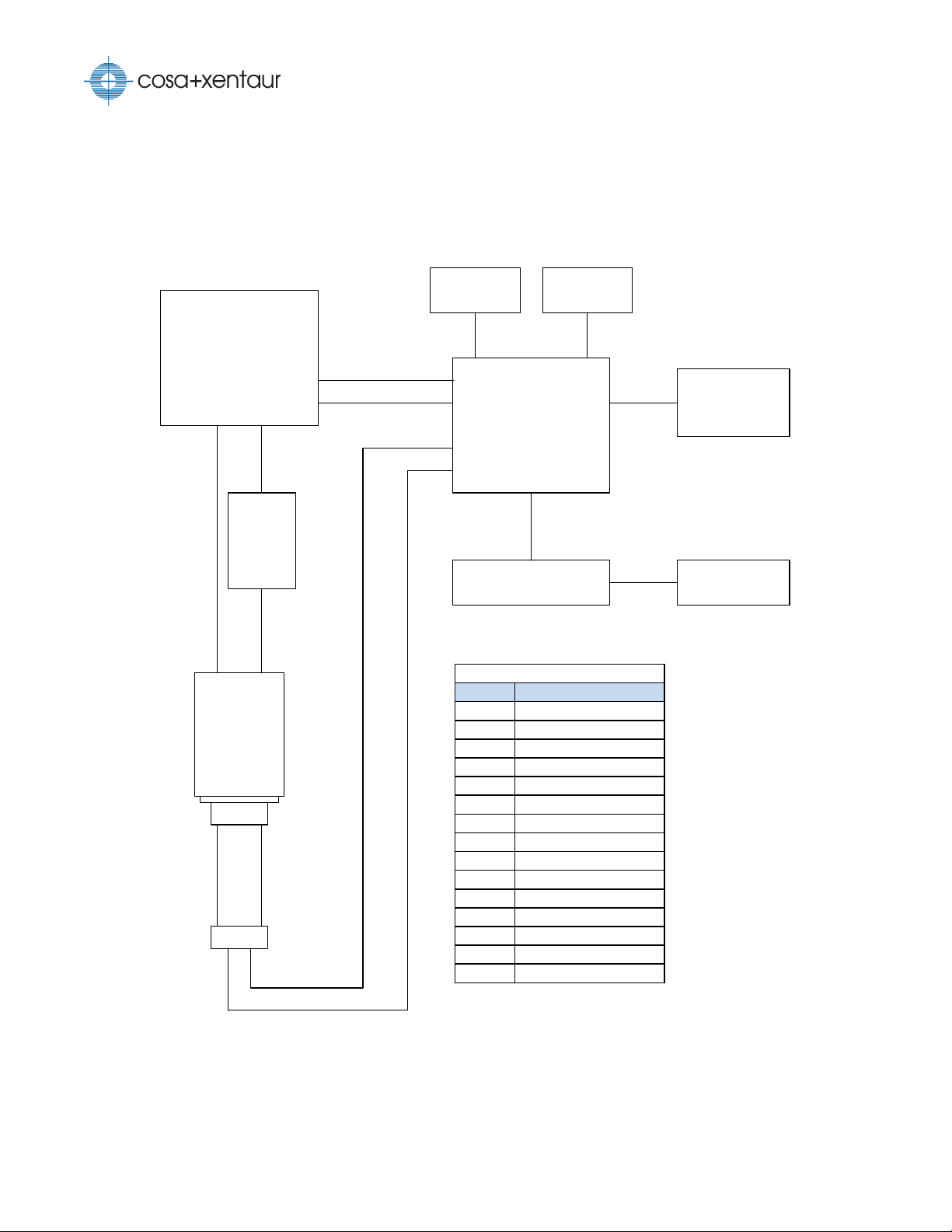

Control Board

Laser Cell

Display Keypad

Terminal Block Fan Heater

Thermistor

Pressure Transducer

Detector Signal

Optical Fiber

J4

J5

J7

J2

J10 J13

J6

J12

J8

Ethernet

RJ45

(optional)

USB-A

Connector

(optional)

WMS Board

J3

J7

J25

Attenuator

Optical Fiber

Terminal Block Layout

Terminal Signal

1 AC Live In

2 AC Live

3 AC Neutral In

4 Fan Heater AC Neutral

5 Ground

6 Fan Heater Ground

7 Relay 1 Common

8 Relay 1 NO

9 AC Live

10 Fan Heater AC Live

11 RS-485-, RS-232 TX

12 RS-485+, RS-232 RX

13 RS-485/RS-232 Common

14 Analog Output

15 Analog Ground

Laser

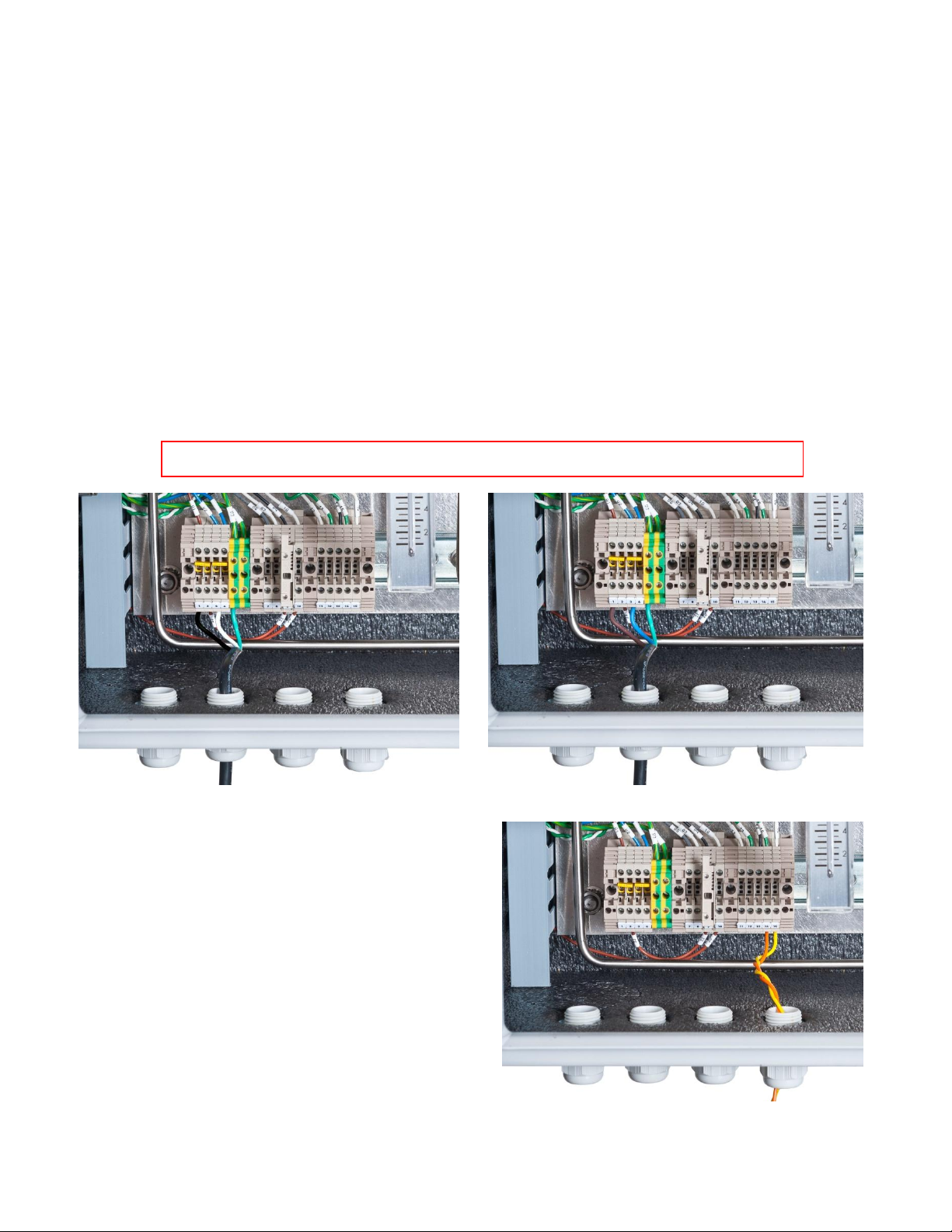

Electrical Connections

There are four watertight cable grips on the bottom of XTDL-HT™ enclosure. They accommodate cables

with diameter between 0.197” (5mm) and 0.472” (12mm).To install a cable, loosen the nut, and feed

the cable through the grip. After connecting the cable, tighten the nut. Unused cable grips should be

plugged to maintain integrity of the enclosure.

12

Electrical and optical connections

Installation

CAUTION: Do not connect to AC power without a proper grounding connection.

Analog output cable installation

North American power cable installation

European and other international power cable installation

Connecting Power

The XTDL-HT™ requires AC power of 110/230VAC, 50/60 Hz. The voltage rating should be specified on

the order and it is marked on the front panel label. Each instrument is provided with an international

approved AC power cable, terminated with a connector according to the ordered option. This cable is

provided strictly for testing the instrument; it should not be used in the final installation. For

installation, the instrument must be field wired permanently connected and installed according to local

and nationally recognized procedure for equipment of this type and stated power requirements. For

North American installations, use UL 62 and/or CSA C22.2 No 49, 16AWG cable with black, white, and

green color codes. For European and other international installations, use CENELEC harmonized type

cable, with 1.31 mm² wire size or equivalent, with brown, light blue, and green/yellow stripe color

codes. Power cable must be wired to the DIN-mounted terminal blocks marked 1 (AC live In), 3 (AC

neutral In), and 5 (AC ground). The cable must be fed through one of the cable grips (second cable grip

is recommended).

Interfacing to Analog Output

The optional analog outputs can be voltage or

current depending on the ordered configuration. The

analog output cable should be fed through one of

the cable grips (fourth cable grip is recommended).

Channel 1 output should be wired to the DINmounted terminal blocks marked 14 (positive) and

15 (negative). Isolation option on the analog outputs

is available upon request. Refer to Analog Output

chapter for setup information.

13

Serial cable installation

Ethernet cable installation

Interfacing to RS-232/RS-485

Depending on the ordered configuration, the

XTDL-HT™ supports RS-232 or half-duplex RS-485

serial interface option. The serial cable should be

fed through one of the cable grips (fourth cable

grip is recommended). For RS-232, TxD, RxD, and

Common Ground signals should be wired to the

DIN-mounted terminal blocks marked 11, 12, and

13, respectively. For RS-485, the inverting signal

(TxD-/RxD-) should be wired to the terminal

block marked 11, non-inverting signal

(TxD+/RxD+) to the block marked 12, and

common signal to the block marked 13. Isolation

option is available on either interface. Refer to

Modbus RTU section for setup information.

Interfacing to Ethernet

To use the optional Modbus/TCP communication,

Ethernet cable once fed through a cable grip (first

cable grip is recommended) should be hooked up to

the RJ-45 connector on the Control Board. Make

sure that there is enough cable slack to allow the

door fully opened. Cat-5 or compatible cabling

should be used. Refer to Modbus/TCP section for

setup information.

14

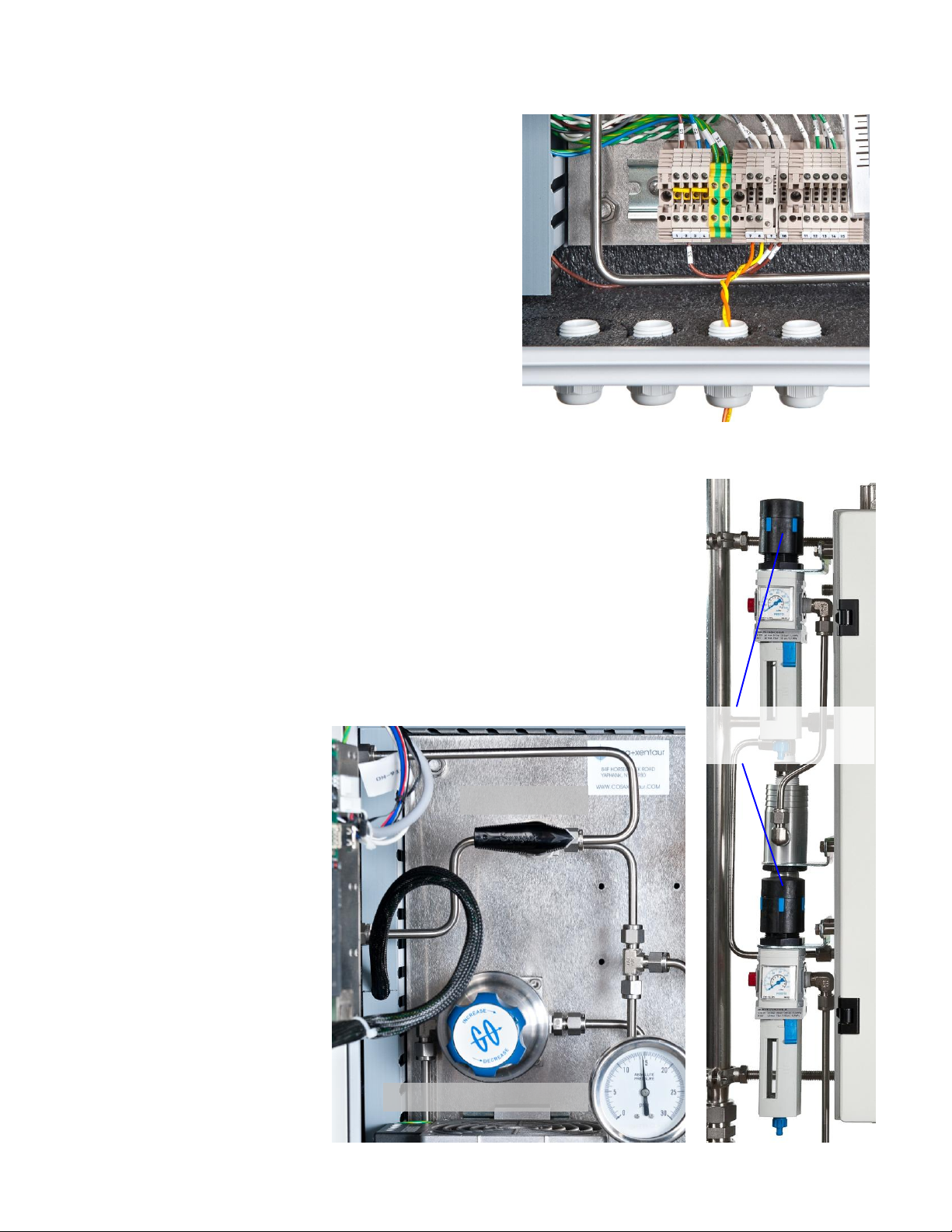

Installation

Relay cable installation

3-way valve

Back pressure regulator

Lift and Turn knob to

set regulator pressure

Wiring Relay Contacts

Standard XTDL-HT™ has one mechanical relay for user

control. Two more relays are available when optional

I/O board is installed. Depending on the ordered

option, the instrument can be installed with:

Mechanical relays (250VAC, 10A max. rating)

Solid state relays (240VAC, 5A max. rating)

Class I Division 2 relays (250VAC, 6A max. rating)

Use wiring appropriate for the voltage and current that

will be switched by the relays. Wires to the relays

should be fed through one of the cable grips (third

cable grip is recommended). For relay 1, connect the

wires to the DIN-mounted terminal blocks marked 7

and 8. Refer to Relays chapter for setup information.

Startup

The instrument air pressure should be set at 60-70 psi on both regulators to

allow sufficient pulling force to the eductors. The sample pressure should be

held at a fixed value in order to maintain the measurement accuracy. This is

accomplished by setting the back pressure regulator inside the enclosure. Any

value in the operating range can be used as the instrument has pressure

compensation on measurement. 1-2 psi below atmospheric pressure is

recommended. To set the pressure:

1. Set the 3-way valve to

process gas.

2. Set the back pressure

regulator until the sample

pressure is at the desired

setpoint.

Close the enclosure door after

the pressure is set. It will take

about 1 ½ hours to reach the

desired internal temperature

depending on the ambient

environment. Measurement

reading may fluctuate until

then. Monitor the sample

temperature for stability if

15

TIP: Flow rate has no impact on instrument accuracy. Low flow rate increases the response

time slightly. Therefore, it is more important to control the pressure than the flow rate.

unsure whether accurate measurement is ready. If the instrument has been inactive for more than a

month, run TruTune™ once before using measurement.

16

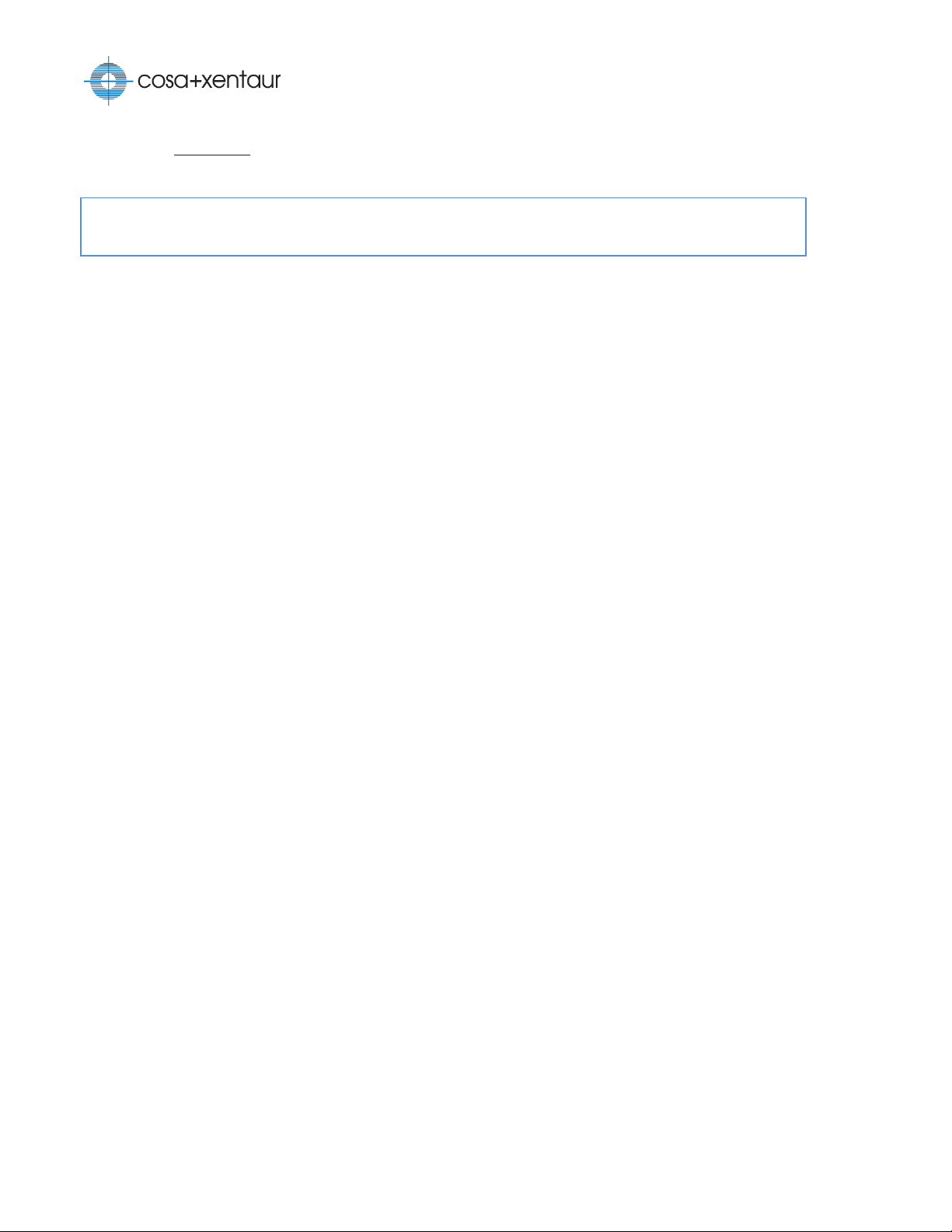

User Interface

Primary Reading

Secondary Reading

Secondary Reading

Type

Primary Reading Type

Relay Status

Chart

Error

Condition

User Interface

The user interface consists of a graphical display, status indicators, and a keypad.

Status Indicators

There are two LED indicators between the display and keypad. The green LED is lit when power is

applied to the instrument. The red LED is lit when an error condition is detected.

Display

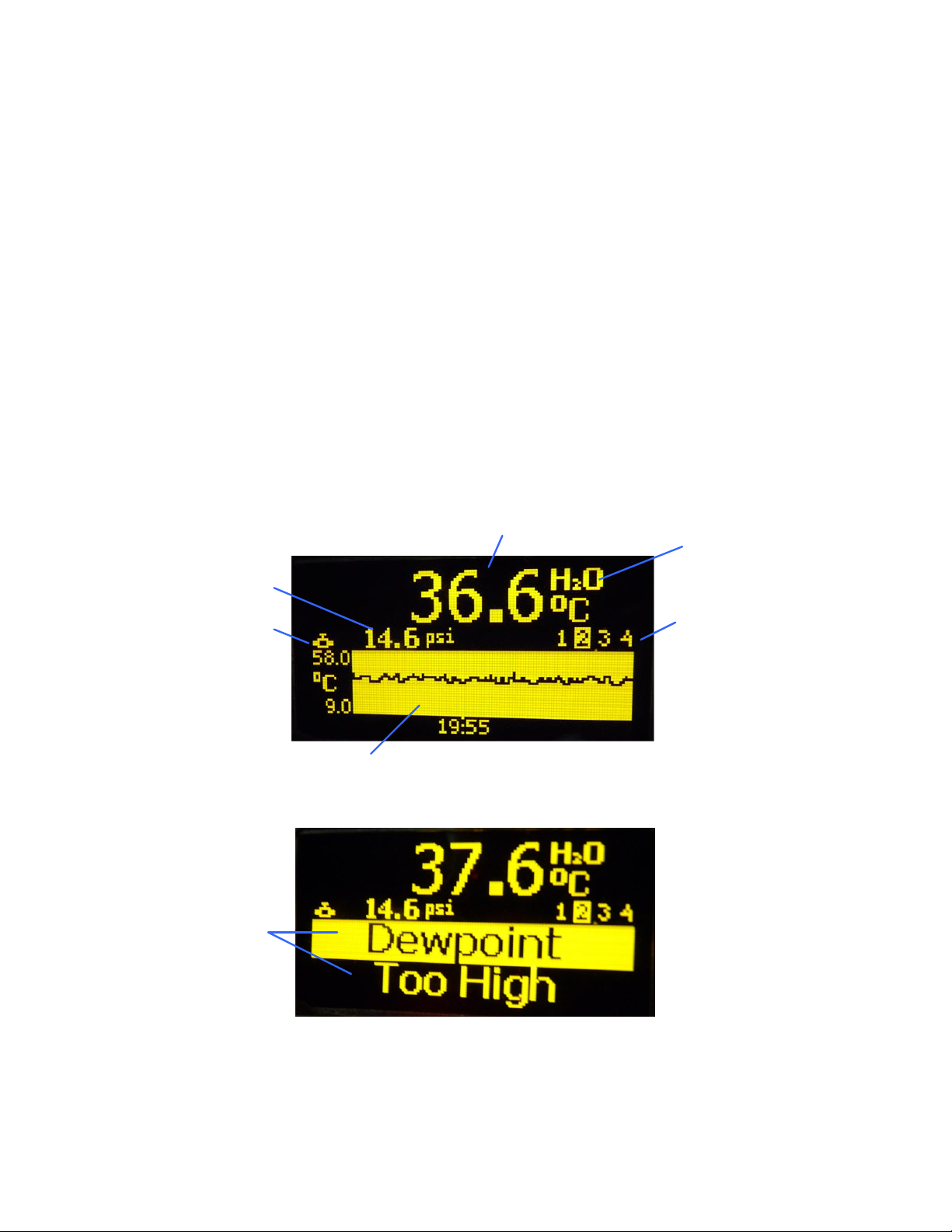

The XTDL-HT™ uses a high contrast OLED display. This allows both indoor and outdoor operation. The

main screen shows two measurement readings (primary and secondary), a chart, and the states of the

relays. The readings and chart are customizable via the menu system and the Modbus communication

protocol.

In the event of a fault, the chart would be replaced with the flashing error information.

17

Loading...

Loading...