COSA Xentaur Xentaur HDT User Manual

r

e

H

t

t

w

e

p

D

d

i

r

b

y

T

D

U

o

S

i

E

n

t

T

r

a

R

’

S

i

m

s

n

A

M

N

U

A

L

H

X

e

n

t

a

u

r

C

o

r

p

o

r

a

t

i

o

n

HDT User’s Manual

When calling your representative for technical support,

please have your serial numbers available.

The Sensor and Instrument Serial Numbers are

engraved on them.

Sensor Serial No.: _______________

Instrument Serial No.: _______________

Your Representative is:

Except as may be provided by contract, this document and all

specifications and drawings contained are the property of Xentaur Corporation, are issued in strict confidence, and shall not

be reproduced or copied or transmitted, in any form or by any

means, or used as the basis for the manufacture or sale of apparatus, programs, or services without permission.

Check the Internet for updates; the latest revision of this

manual is available in Adobe Acrobat format at:

http://www.xentaur.com

Document No.: DPT.00.D.1068 Rev.1 8/11/05

Copyright © 2005 by Xentaur Corporation

i

HDT User’s Manual

Xentaur reserves the right to change or modify the product

specification and / or appearance at any time without notice.

Therefore, the information in this document is subject to

change without notice and does not represent a commitment

on the part of Xentaur Corporation.

The customer agrees that in accepting and using this instrument Xentuar Corporation’s liability arising from or in any

way connected with this instrument shall be limited exclusively to performing a new calibration or replacement or

repair of the instrument or sensor, at Xentaur’s sole option,

as covered by Xentaur’s warranty. In no event shall Xentaur

be liable for any incidental, consequential or special damages of any kind or nature whatsoever, including but not

limited to lost profits arising from or in any way connected

with this instrument or items hereunder, whether alleged to

arise from breach of contract, express or implied warranty,

or in tort, including without limitation, negligence, failure to

warn or strict liability.

Swagelok, Cajon are trademarks of SWAGELOK Co.

Acrobat is a trademark of Adobe Systems Incorporated

Microsoft Windows is a registered trademark of Microsoft Corporation

HTF is a trademark of Xentaur Corporation

The Xentaur Logo is a trademark of Xentaur Corporation

ii

HDT User’s Manual

Examine the HDT package for damage or mishandling. If any damage is evident notify the carrier

and request an inspection.

Unpack the box, it should contain: The HDT with

sensor in desiccant container, a mating connector,

and this manual.

PLEASE READ THIS MANUAL IN WHOLE,

PRIOR TO INSTALLING OR REMOVING THE

SENSOR FROM ITS SHIPPING CONTAINER.

This manual is organized in three sections:

Section 1

Section 2

is an overview of the HDT.

describes the sensor and sampling techniques.

Section 3

describes the instrument’s electrical, and

mechanical interfaces.

This manual is intended for those already familiar

with the installation, use and maintenance of analytical or process instrumentation.

iii

HDT User’s Manual

Warranty

Xentaur instruments are warranted to be free from defects in

workmanship and materials. Liability under this warranty is limited to servicing, calibrating, and replacing any defective parts of

the instrument returned to the factory for that purpose. Fuses are

specifically excluded from any liability . This warranty is effective

from the date of delivery to the original purchaser. The equipment

must be determined by Xentaur to have been defective for the

warranty to be valid. This warranty applies as follows:

• one year for electronics

• one year for mechanical failures to the sensor

• six months for calibrations

If damage is determined to have been caused by misuse or abnormal conditions of operation, the owner will be notified and

repairs will be billed at standard rates after approval.

Maintenance Policy

In cases when equipment fault is suspected, please notify your

representative of the problem, be sure to provide them with

model and serial numbers. If the problem can not be resolved,

then ask for a Return Authorization Number (RAN) and shipping

instructions. Issuance of an RAN does not automatically imply

that the equipment is covered by our warranty, that will be determined after we receive the equipment. Pack the equipment in a

suitable box with sufficient padding, include the RAN number on

your paperwork, and send the equipment, prepaid, to the designated address. Xentaur will not accept equipment returned without an RAN, or with reversed shipping or import/export charges.

If the warranty has expired, or the damage is due to improper use

or exposure of the equipment; then Xentaur will provide an estimate and wait for approval before commencing repairs.

For your convenience a Return Authorization Request Form is

provided in appendix J, it must be filled out and sent back to Xentaur in order to obtain a RAN.

iv

HDT User’s Manual

HDT User’s Manual Table of Contents

1.0 Overview of the HDT ...................................................1

2.1 Precautions using the sensor .........................................3

2.2 Sensor Technical Specifications ...................................4

2.3 Sensor Installation & Sampling Techniques .................4

2.3.1 In-situ Installation ......................................................5

2.3.2 Extractive Installation ................................................6

2.4 Troubleshooting unexpected readings ..........................9

3.1 Precautions using the HDT .........................................13

3.1.1 Electromagnetic Compatibility Considerations .......13

3.2 Instrument Technical Specifications ...........................14

3.3 Installation ..................................................................15

3.3.1 Mechanical Installation ............................................15

3.3.2 Electrical Installation ...............................................15

3.4 Operating the Instrument ............................................17

3.4.1 Starting up ................................................................17

3.4.2 HART Interface .......................................................17

3.5 Troubleshooting the Instrument ..................................17

Appendix A: HDT power-on sequence, timing diagram ..19

Appendix B:HDT pin 3 timing diagrams .........................20

Appendix C: HDT Mechanical Drawing ..........................21

Appendix D: HDT Block Diagram & Connections ..........22

Appendix E: Certifications - Approvals - Conformity .....24

Appendix G: Current vs. Dewpoint ..................................28

Appendix H: Uncertainty in LBS & ppmV calculations ..31

Appendix I: Sensor Response Time ..................................32

Appendix J: Return Authorization Request ......................33

v

HDT User’s Manual

vi

Section 1: Introduction

1.0 Overview of the HDT

The HDT is a microprocessor based 4-20mA loop powered

(2 wire) hygrometer, for measuring moisture content in

gases or liquids in a wide range from -100°C to +20°C dewpoint in gases; and 0 ppmW to 1000 ppmW in liquids. The

measurement is transmitted by varying the current drawn

(4-20mA) from the power supply. The current varies linearly proportional to the selected measurement units. In

addition a digital output modulates/demodulates the 420mA loop line without interfering with its operation, and

adheres to the HART protocol. Thus the HDT is capable of

communicating with properly equipped Personal Computers

or other RS-232 or HART capable controllers. The HDT’s

advanced design allows it to be housed in a small stainless

steel enclosure behind the sensor probe, thus the instrument

and sensor are a single integrated unit.

The HDT uses the Xentaur HTF™ sensor which is encapsulated in sintered stainless steel, thus it is capable of coming

into contact with a wide variety of environments. However

one should keep in mind that the sensor is a sensitive device

and it should be handled accordingly.

page 1

HDT User’s Manual

page 2

Section 2: Sensor and Sampling Techniques

2.1 Precautions using the sensor

The Xentaur HTF™ Al2O3 sensor is designed and field

proven to be highly reliable, rugged and maintenance free.

However the user should consider the following precautions:

• To avoid the need for prolonged dry-down (when expecting to

measure dewpoints dryer than -65ºC), do not expose the sensor to

room air longer than necessary (1 - 2 minutes). Thus, do not open

the sensor container before you are ready to install the sensor.

• The sensor container has desiccant to keep the sensor dry during

shipping and to avoid damage due to condensation. Close the container immediately after removing the sensor to avoid degradation

of the desiccant.

• Do not throw away the sensor container, you may use it again to

transport the sensor between locations, to store it between uses or

to ship it back to the factory for certification. The container can

be attached to the loop cable, by trapping the cable with the lid

strap.

• Do not expose the sensor to corrosive gases or liquids such as

ones containing Chlorine, Ammonia or HCl. (SO

tored when the moisture content is low). Cyanide, Br

may harm the gold layer of the sensor, thus limiting sensor

HNO

3

life.

• Except for the XTR-60 and XTR-LQ sensors:

1. Do not expose the sensor to liquid water, as it may get damaged.

2. Do not breathe directly onto the sensor, as condensation may

form which could damage the sensor element.

• Do not install the sensor near heat sources such as radiators or

air ducts.

• Do not install the sensor in places subject to extreme mechanical

vibration or shock. If this is not avoidable, use resilient mounting.

If in doubt, call your representative.

• Do not disassemble the porous metal filter encapsulation, as this

will damage the sensor and void your factory warranty.

• Prior to installation of the probe, ensure that no contaminants are

present in the system (e.g. oil, liquid water).

can be moni-

2

, I2, and

2

page 3

HDT User’s Manual

2.2 Sensor Technical Specifications

Type:.................................Hyper Thin Film high capacitance Al2O3.

Dewpoint range:

XTR-100........................-148°F to +68°F (-100°C to +20°C)

XTR-65..........................-85°F to +68°F (-65°C to +20°C).

XTR-60..........................-76°F to +68°F (-60°C to +20°C).

XTR-LQ.........................for use in liquids.

Capacitance:......................15nF to 200nF.

Accuracy:..........................±5.5°F (±3°C).

Repeatability:................ ....±0.9°F (±0.5°C).

Response time:..................see graph in Appendix I.

Temperature range:...........-10°C to +70°C.

Sample Flow range: ..........(linear velocity @ 1ATM):Static to 100m/s.

Storage temperature:.........-40°F to+176°F (-40°C to +80°C).

Mechanical:.......................encapsulated in 100µ sintered stainless steel.

Calibration method: ..........NIST/NPL traceable multi-point factory calibration.

2.3 Sensor Installation & Sampling Techniques

Keep in mind that the moisture content at the sensor is not

only due to the moisture of the gas being measured, but also

due to desorption of water from tubing, trapped moisture (at

the interconnection points, valves, filters and other hygroscopic materials in the system), leaks in the system, and others. Thus the measurement may vary from the expectation,

and therefore care should be taken in choosing the sampling

technique utilized in the measurement. Factors such as gas

pressure, flow rate, materials of construction, length and

diameter of tubing, number of interconnecting fittings, dead

space in tubing and manifolds; will influence the measurement value and response time.

The high capacitance HTF™ sensors can be installed either

directly in the line to be sampled (in-situ), or in a slip stream

of a sample system (extractive).

To assure a long and accurate performance of the sensor, it

should be protected from contaminants such as liquids

page 4

Section 2: Sensor and Sampling Techniques

(water, oil etc.), and particulates. The sintered stainless steel

sensor encapsulation protects from particulates larger than

100 microns, finer particulates (e.g. from degraded desiccant or rust) should be filtered with a particulate filter with

suitable capability, do not use hygroscopic filter materials.

2.3.1 In-situ Installation

In-situ installation is recommended only for measurements

where the gas pressure is expected to vary little, the gas is

expected to be free of contaminants, the gas temperature is

within the operating specifications of the sensor, and there is

no chance of liquids coalescing. Examples of applications

suited for in-situ installations are: pure gases, output of desiccant dryers (for instrument air), glove boxes, etc. For most

other applications in-situ installation should be avoided for

the following reasons:

• Sample conditioning is almost always necessary to

avoid exposure of the sensor to liquid water and other

contaminants, such as hydrocarbons, which may damage the sensor or affect accuracy over time.

• Variations in line pressure affect the reading of the sen-

sor because dewpoint varies with pressure.

• If the gas line is under pressure, it is more likely that

water condensation occurs which may damage the sensor.

• Under a pressurized system removal of the sensor with-

out the installation of isolation valves can be dangerous.

If in-situ installation is required, bypass mounting is preferable. If in-line installation is required, make sure to install

the sensor at the upper surface of the gas line to minimize its

exposure to liquid water should condensation occur; the

XTR-60 sensor is best suited for these applications. Also

consider the need to isolate (depressurize) before installing

page 5

HDT User’s Manual

or removing the sensor.

4-20mA loop cable

Main

Gas Line

4-20mA loop cable

Safety shut-off Valve

HDT

HDT

)

Loop Power 5V-28V DC, will draw

Loop Power 5V-28V DC, will draw

E

; pin2= -V

E

4/20mA ( pin1= +V

)

E

; pin2= -V

E

4/20mA ( pin1= +V

In-Line Installation, Sensor

Measuring at Line Pressure

Xentaur Hybrid

Dewpoint Transmitter

NOT RECOMMENDED

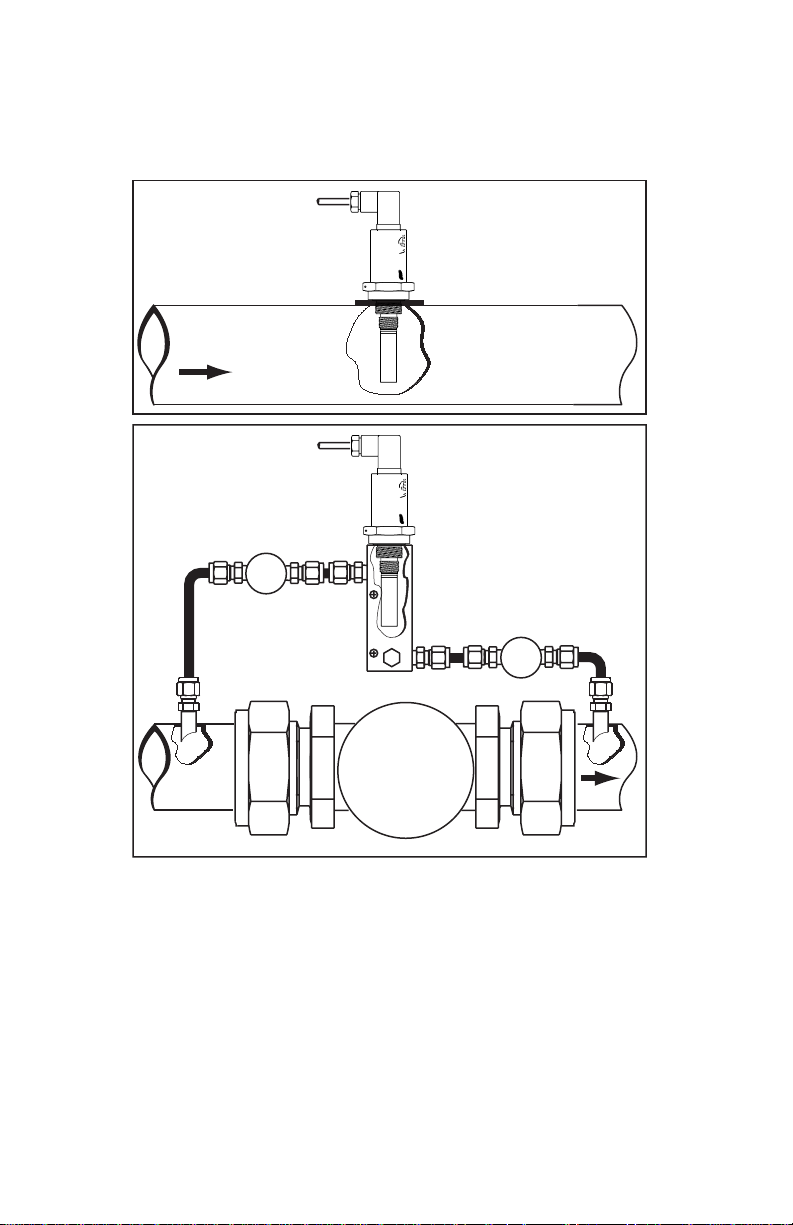

Bypass Installation, Sensor

Xentaur Hybrid

Measuring at Line Pressure

Dewpoint Transmitter

Safety shut-off Valve

Sample Cell

Bypass

Main

Gas Line

Control

Valve *

* maintain differential pressure to provide adequate flow through sample cell

2.3.2 Extractive Installation

For extractive installations we recommend our sample system ESS, which may be equipped with a variety of features,

such as: isolation valve, coalescing or particulate filter,

pressure regulator, calibration sample injection or extraction

port, pressure gauge, flow meter, weatherproof enclosure.

page 6

Loading...

Loading...