TM

FOCUS

INSTALLAT I O N A N D M A I N T E N A N C E

MANUA L

REVISION 2

P RO B E

Focus TM Probe – OFM

Installation Manual

Contents:

1.0

Focus

1.1 Procedure – Installing Pipe Fittings ....................................................................................3

2.0 Focus TM Probe Pipe Fitting Installation – Hot Tap.......................................................4

3.0 Focus TM Probe Installation..............................................................................................6

3.1 Procedure – Installing the Safety Chain Clip:.....................................................................6

3.2 Procedure – Calculating Insertion Depth – 6” and Larger Pipes:........................................7

3.3 Procedure – Calculating Insertion Depth – 4” Pipe: ...........................................................8

3.4 Procedure – Installing the Focus TM Probe:.........................................................................9

3.5 Multi-fiber Cable Attachment...........................................................................................11

3.6 Heater Cable Attachment - Optional.................................................................................11

4.0 Focus TM Probe Removal ................................................................................................12

TM

Probe Pipe Fitting Installation.........................................................................3

4.1 Procedure – Removing the Focus TM Probe: .....................................................................12

5.0 Focus TM Probe Maintenance .........................................................................................13

2 Making Light Work ~ Photon Control Inc.

1.0 Focus TM Probe Pipe Fitting Installation

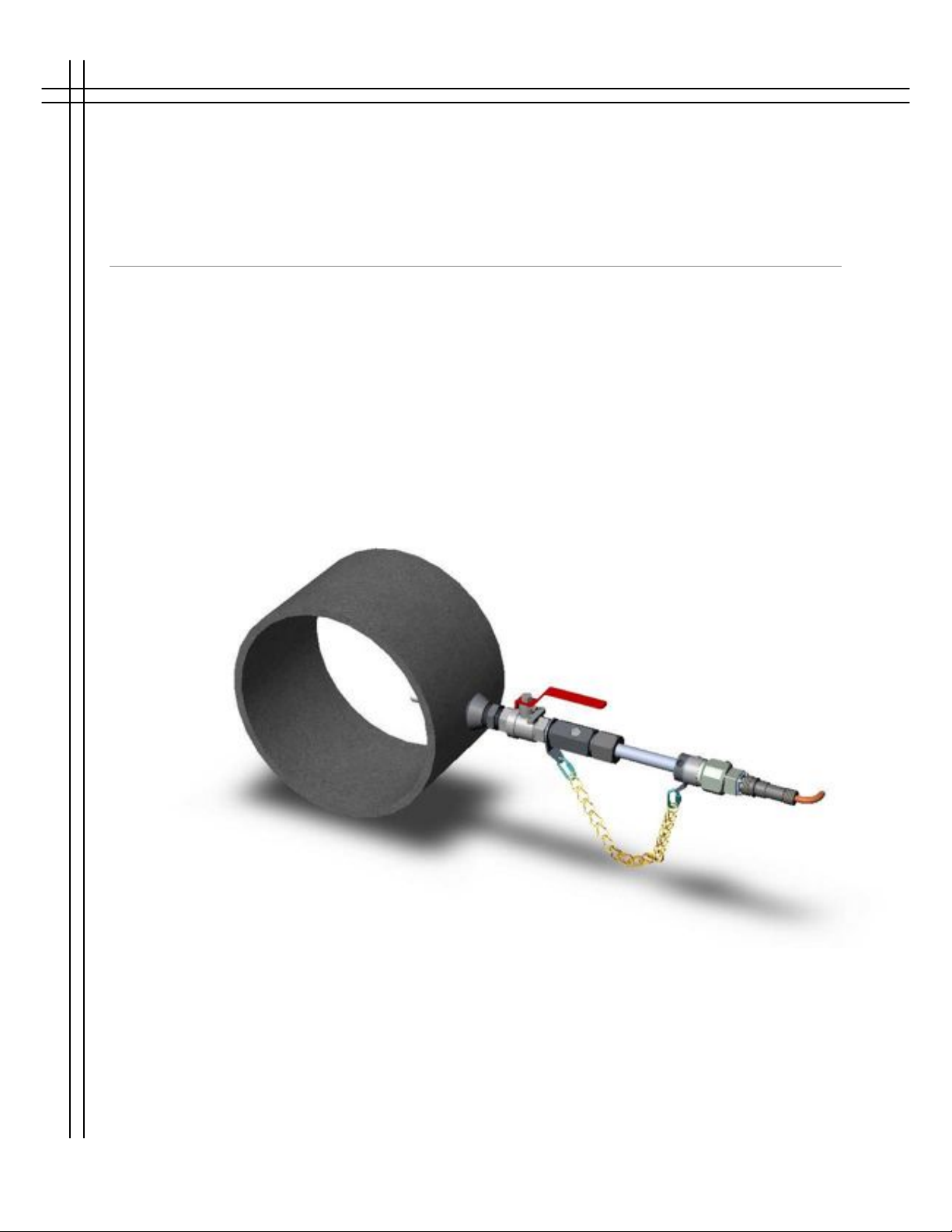

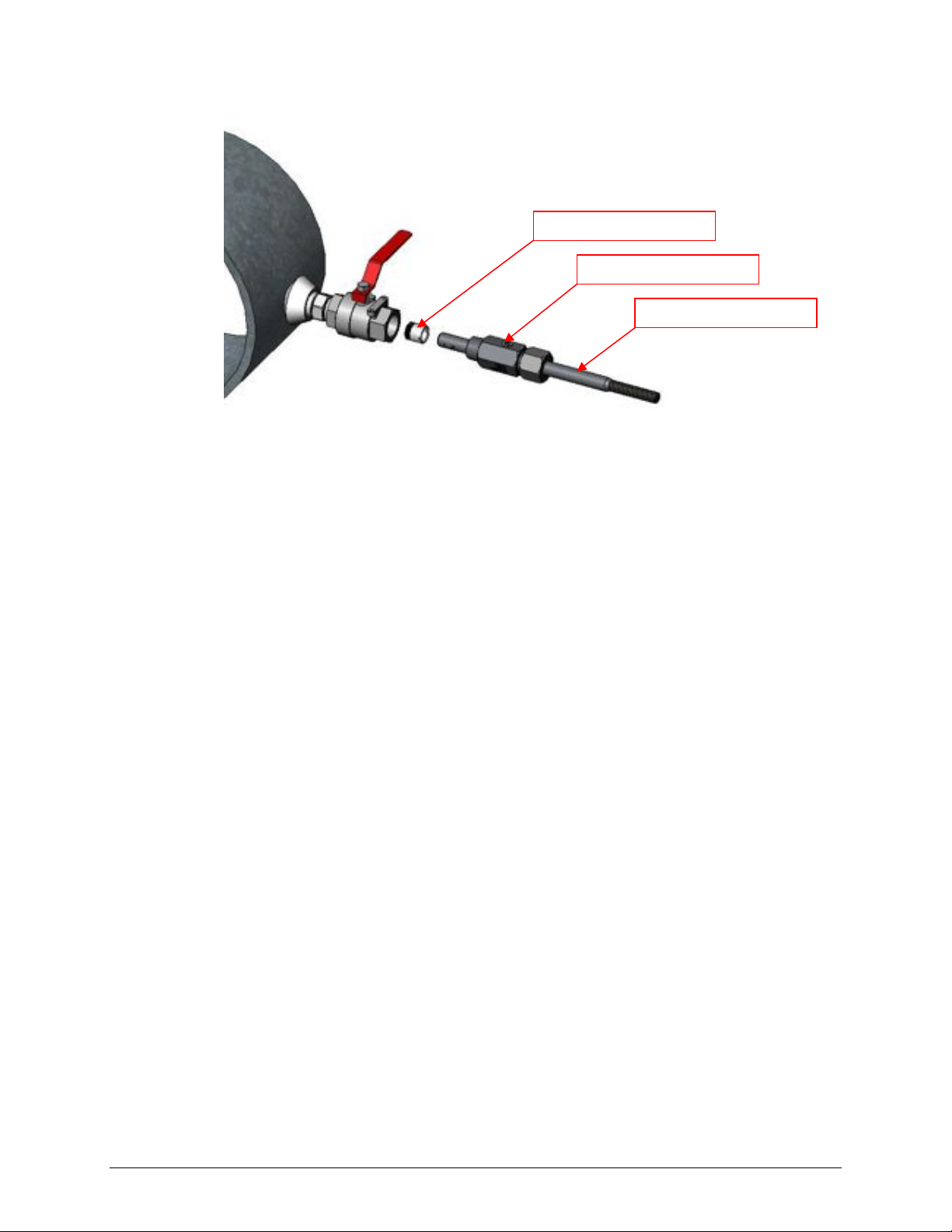

The instructions that follow are for installing the necessary fittings that will support the Focus

Probe flow meter. Figure 1 shows the components and may be used as a visual reference while installing

the fittings. The Focus

TM

Probe must never be installed in a vertical position where debris or moisture is

likely to settle on the optics. When installing into horizontal runs, position the fittings so that the probe

will be inserted at the 3 o’clock position. (Refer to

Figure 8) Mounting the probe horizontally will

minimize window-cleaning maintenance. Ensure that there is sufficient room around the pipe to install

and remove the insertion probe.

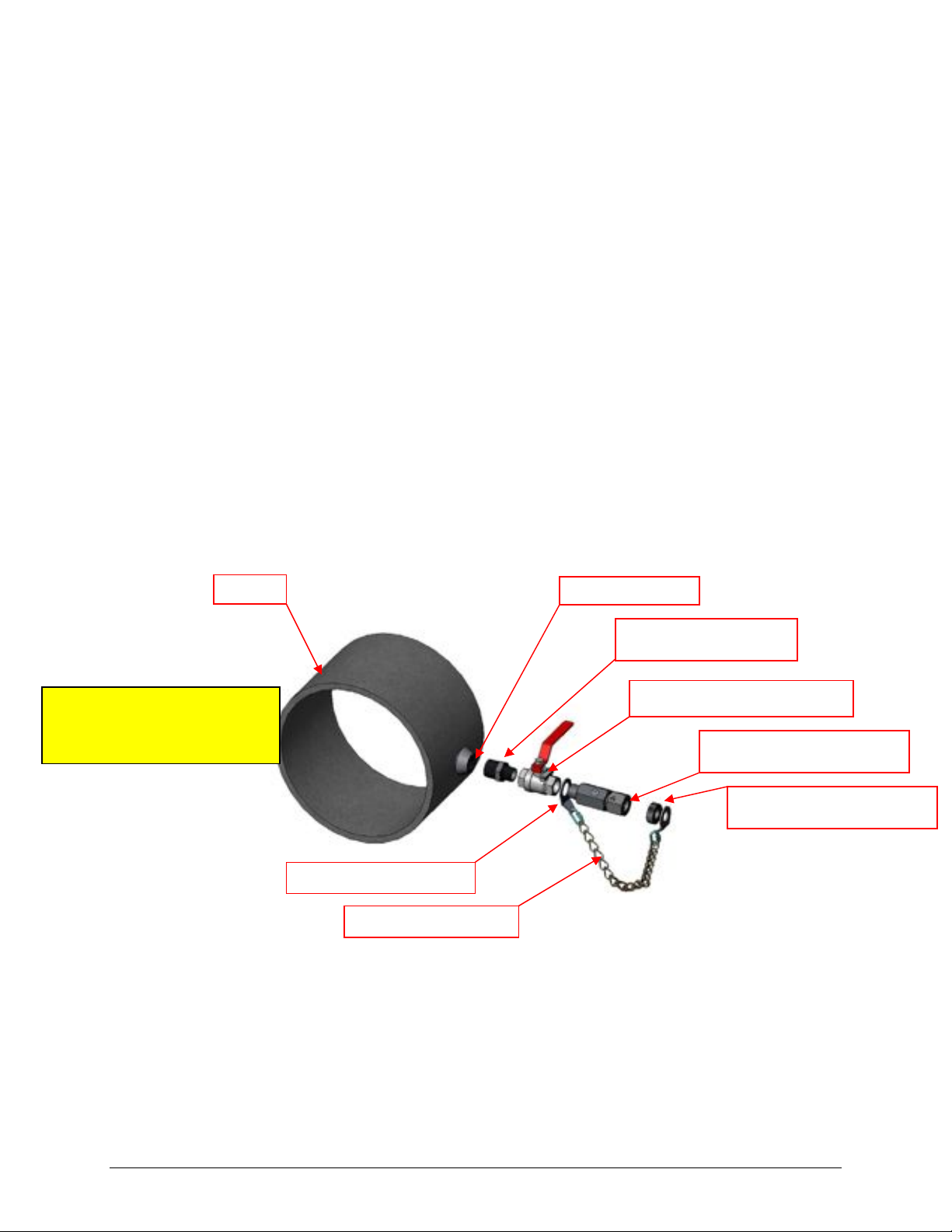

1.1 Procedure – Installing Pipe Fittings

1. Choose the location in the pipe that you want to install the Focus

2. Install a Threadolet with a 1” NPT thread.

3. Apply an appropriate pipe sealant and thread the 1” to ¾” Adapter into the weldolet and tighten.

4. Apply an appropriate pipe sealant and, holding the Ball Valve so the mounting holes and lever

point away from the pipe, thread the ¾” Ball Valve on to the Adapter and tighten.

5. Turn the Ball Valve to the off position. (Handle perpendicular to Ball Valve as shown)

6. Slide the Safety Chain Ring over the threading of the Packing Gland.

7. Apply an appropriate pipe sealant and thread the ¾” NPT Packing Gland into the Ball Valve and

tighten.

TM

Probe.

PIPE

1” Threadolet

1” TO ¾” ADAPTER

TM

NOTE:

1) Apply sealant to NPT threads

before installing.

Figure 1: Install Fittings as Shown in Diagram

¾” NPT ISOLATION VALVE

¾” NPT PACKING GLAND

¾” CLAMP COLLAR

SAFETY CHAIN RING

SAFETY CHAIN

Photon Control Inc. ~ Making Light Work 3

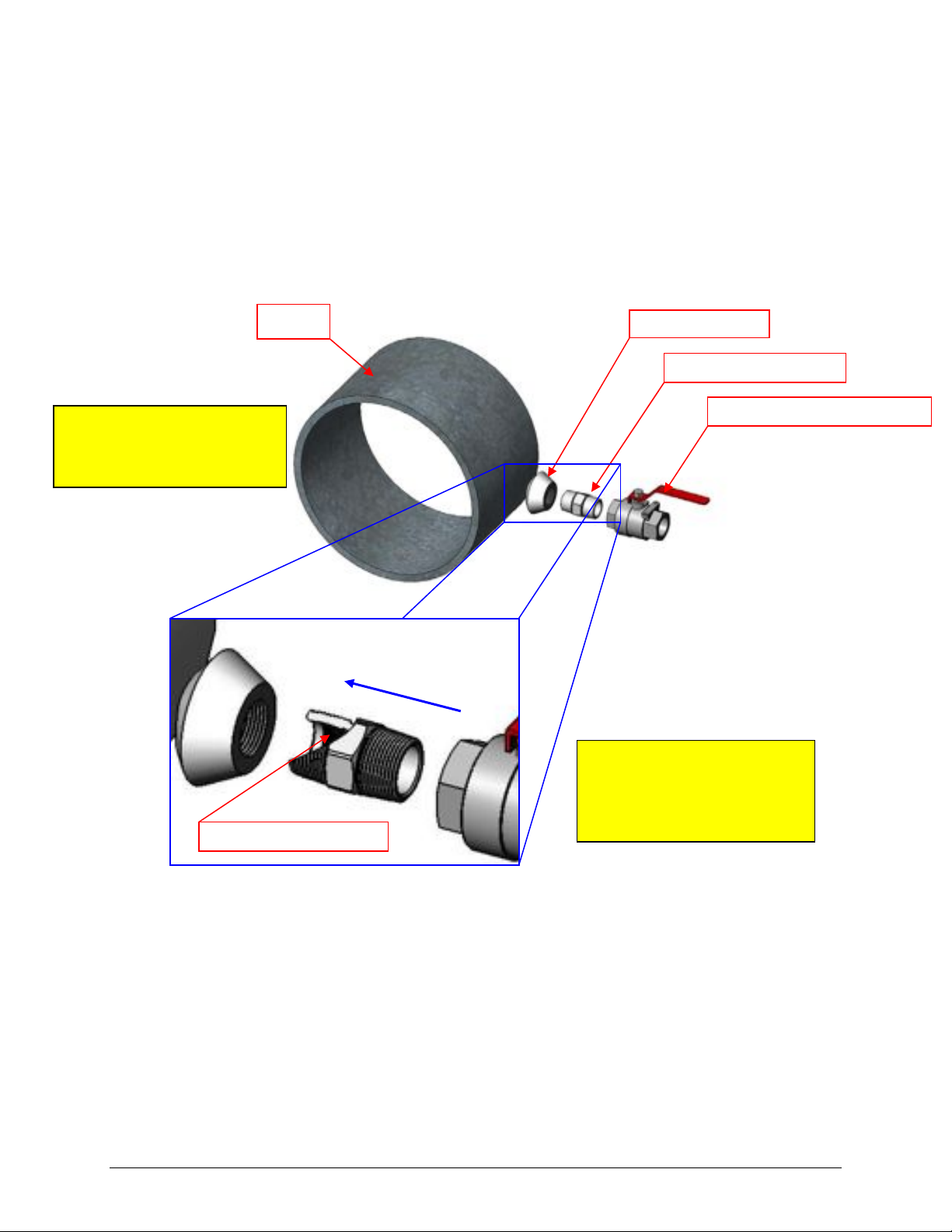

2.0 Focus TM Probe Pipe Fitting Installation – Hot Tap

1. Choose the location in the pipe that you want to install the Focus

2. Install a Threadolet with a 1” NPT thread.

3. Apply an appropriate pipe sealant and thread the 1” to 1” Nipple into the Threadolet and tighten.

4. Apply an appropriate pipe sealant and, holding the Ball Valve so the mounting holes and lever

point away from the pipe, thread the 1” Ball Valve on to the Nipple and tighten.

TM

Probe.

NOTE:

1) Apply sealant to NPT

threads before installing.

PIPE

1” Threadolet

1” TO 1” NIPPLE

1” NPT ISOLATION VALVE

NOTE:

Internal threads on 1” to 1” nipple

towards pipe

INTERNAL THREADS

Figure 2: Hot Tap Fitting Installation

5. Hot Tap Drill a 7/8” hole through the pipe wall.

6. Turn the Ball Valve to the “Off” position (handle perpendicular to valve body) when removing the

Hot Tap Drill from the pipe fittings.

7. Slide the Hot Tap Tool into the Packing Gland with the dowel pin protruding on the threaded end.

4 Making Light Work ~ Photon Control Inc.

SUPPORT SLEEVE

PACKING GLAND

HOT TAP TOOL

Figure 3: Inserting the support sleeve

8. Slide the Support Sleeve onto the Hot Tap Tool so the sleeves threads are toward the pipe as

shown in Figure 3.

9. Apply an appropriate pipe sealant and thread the Packing Gland into the Ball Valve and tighten.

10. Turn the Ball Valve to the “On” position (handle parallel to valve body)

11. Insert the hot tap tool through the valve and rotate it clockwise to thread the Support Sleeve into

the 1” to 1” Nipple until tight.

12. Back the Hot Tap Tool out of the pipe fittings until it stops against the Packing Gland.

13. Turn the Ball Valve to the “Off” position.

14. Unthread the Packing Gland from the Ball Valve to remove the Hot Tap Tool.

15. Slide the Safety Chain Ring over the threading of the Packing Gland. (Refer to Figure 1 for Safety

Chain placement)

16. Reapply an appropriate pipe sealant and thread the 1” NPT Packing Gland into the Ball Valve and

tighten.

17. Refer to Section 3.0 for flow meter installation.

Photon Control Inc. ~ Making Light Work 5

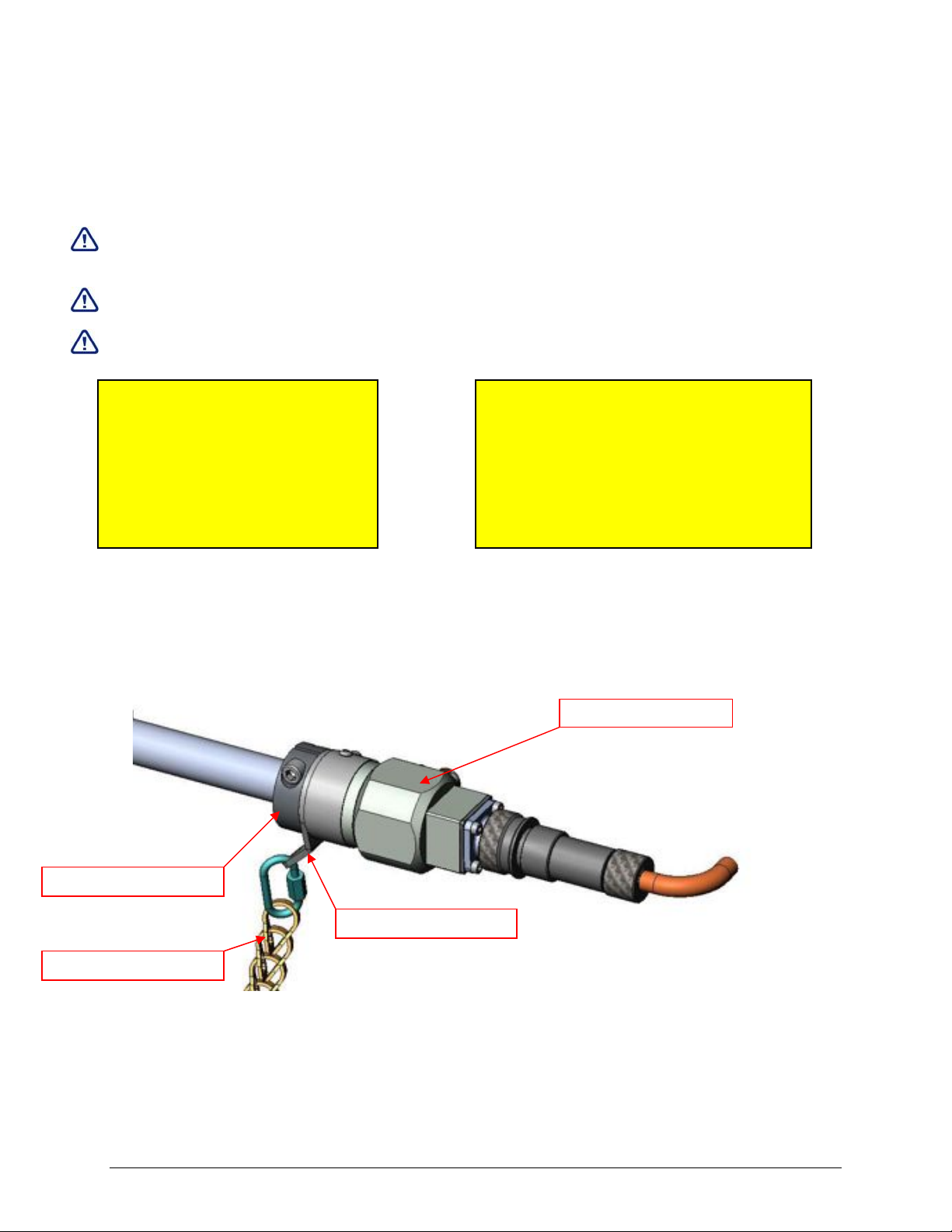

3.0 Focus TM Probe Installation

The instructions in this section cover the installation of the Focus

to retain the probe. Figure 4 through

Diameters

provide visual aids for the installation procedures.

Figure 6: Insertion Depth Calculations for 4" and Smaller Pipe

At no time during the installation should any person position any part of their body in line with the probe.

A pressurized pipe could cause the probe to accelerate outwards causing bodily harm.

Small leakages may occur during installation. Take appropriate safety precautions.

Install only under minimal operating pressure or with the line shut off to prevent large forces acting on the

probe.

NOTE:

Maximum Force Acting on Probe =

Line Pressure (psig) x 0.44

Examples:

30psig x 0.44 = 13lbs

100psig x 0.44 = 44lbs

NOTE:

Process operating pressure and temperature

restrictions:

Max Pressure: 100psig

Temp. Range: -40ºF to +302ºF (-40ºC to +150ºC)

3.1 Procedure – Installing the Safety Chain Clip:

TM

Probe and the safety hardware used

1. Undo the Quick Link connector and remove the Safety Chain from the Safety Chain Clip.

2. Slide the Safety Chain Clip on to the probe so the tab points away from the Fiber Connector at the

3. Slide a Clamp-On Collar on to the probe and position it so it secures the Safety Chain Clip against

4. Tighten the screw on the Clamp-On Collar with a 3/16” Allen wrench.

CLAMP-ON COLLAR

SAFETY CHAIN

Figure 4: Install Safety Chain Clip and Clamp-On Collar as Shown

end of the probe.

the Fiber Connector.

FIBER CONNECTOR

SAFETY CHAIN CLIP

6 Making Light Work ~ Photon Control Inc.

Loading...

Loading...