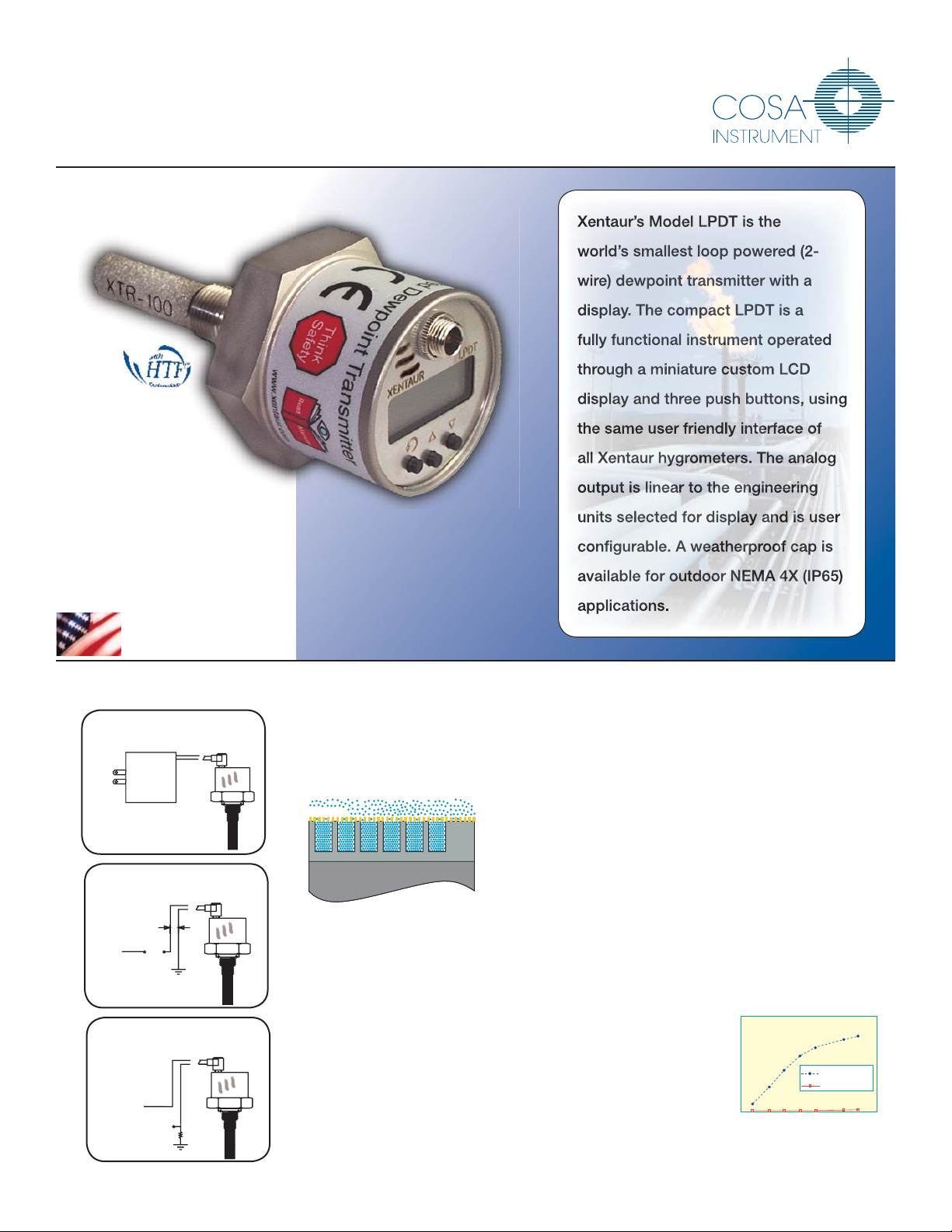

Loop Powered Transmitter

LPDT

-100°C TO +20°C DEWPOINT

Xentaur’s Model LPDT is the

world’s smallest loop powered (2-

wire) dewpoint transmitter with a

display. The compact LPDT is a

fully functional instrument operated

through a miniature custom LCD

display and three push buttons, using

the same user friendly interface of

all Xentaur hygrometers. The analog

output is linear to the engineering

units selected for display and is user

Manufactured with pride

in the USA

METHODS OF USING

AND INTERFACING THE LPDT

Operation with Wall Transformer

Dewpoint viewed on Instrument Display

10-33VDC

120V

or

220V

Wall Transformer

Operation with DC Power Supply

Dewpoint viewed on Instrument Display

and available as 4-20mA output

maintain

10-33VD here

4-20mA

VDC

Operation with DC Power Supply

Dewpoint viewed on Instrument Display

and available as Voltage output

12 - 33VDC

0.4 - 2V output

100 Ω

Xentaur

Xentaur

Xentaur

configurable. A weatherproof cap is

available for outdoor NEMA 4X (IP65)

applications.

XENTAUR HYPER-THIN-FILM (HTF) Al2O3™ MOISTURE SENSOR TECHNOLOGY

The model LPDT uses a Xentaur HTF™ Aluminum Oxide sensor. The breakthrough

HTF™ sensor technology represents advances in thin film and metal oxide sciences and

offers significant performance advantages over all other aluminum oxide sensors.

Operating Principle of Al2O3 Sensor

Gold layer

Aluminum Oxide film with Pores

Aluminum

result of the proprietary manufacturing method in which the aluminum oxide layer is made

to be hyper thin as well as extremely hygroscopic. This results in a very sensitive sensor

with fast response.

HIGH CAPACITANCE RESPONSE

HTF sensors have a capacitance change, several orders

of magnitude larger than that of conventional aluminum oxide

sensors due to the hyper thin film, a sharp transition layer and

a special pore geometry. Additionally, this change is quasi

linear and its sensitivity to temperature is negligible. The

advantages of a linear high capacitance response are: better

sensitivity, better repeatability and faster response times. Also,

the measurement system is less prone to noise and drift, and

signal conditioning is kept to a minimum.

The operating principle of the HTF™ aluminum oxide

sensors is that a hygroscopic layer of aluminum oxide adsorbs

or releases water molecules within its pores, depending on

the water vapor pressure in its environment. The electrical

capacitance of the aluminum oxide layer changes with the

surrounding water vapor pressure. The electrical capacitance

is measured between the aluminum core of the sensor and a

porous conductive gold layer on the outside.

The advantages of the HTF sensor technology are a

Hyper Thin Film vs. Conventional Al2O3 Sensor

Change of Capacitance with Dewpoint

200

150

100

nF

50

0

-90

-70

HTF Technology

Conventional

10

-10

-30

-50

200

150

100

50

0

30

www.cosa-instrument.com

TECHNICAL SPECIFICATIONS

Dewpoint Sensor Element

Type: .................................. Hyper-Thin-Film high capacitance

Al

Dewpoint Range:

XTR-100 ..................... -148°F to +68°F

XTR-65 .......................-85°F to +68°F

Capacitance: .....................15nF to 200nF

Accuracy: ...........................± 5.5°F (±3°C)

Repeatability: .....................±0.9°F (±0.5°C)

Temperature range: ............-14°F to -158°F

Sample Flow Range:

(linear vel. @ 1 atm.) ...Static to 100 m/s

Storage Temperature .........-40°F to +176°F

Calibration Method ...........Field span check.

NIST/NPL traceable

multipoint calibration.

Temperature Measurement

The instrument measures the sample temperature with a

precision integrated circuit sensor.

Electronics

Input resolution: .................0.1°C(dp)

Indicators ...........................3.5 digit LCD with

203

(-100°C to +20°C)

(-65°C to +20°C)

(-10°C to +70°C)

(-40°C to +80°C)

custom legends

Controls: ............................3 push buttons, all settings stored in

EPROM

Output: ..............................Analog 4-20mA

Alarms: ..............................The 4-20 mA of the digital output

may be used by an external device

to operate relays

Isolation: ............................Sensor and case are isolated from

the current loop and shunted with

33V transorbs.

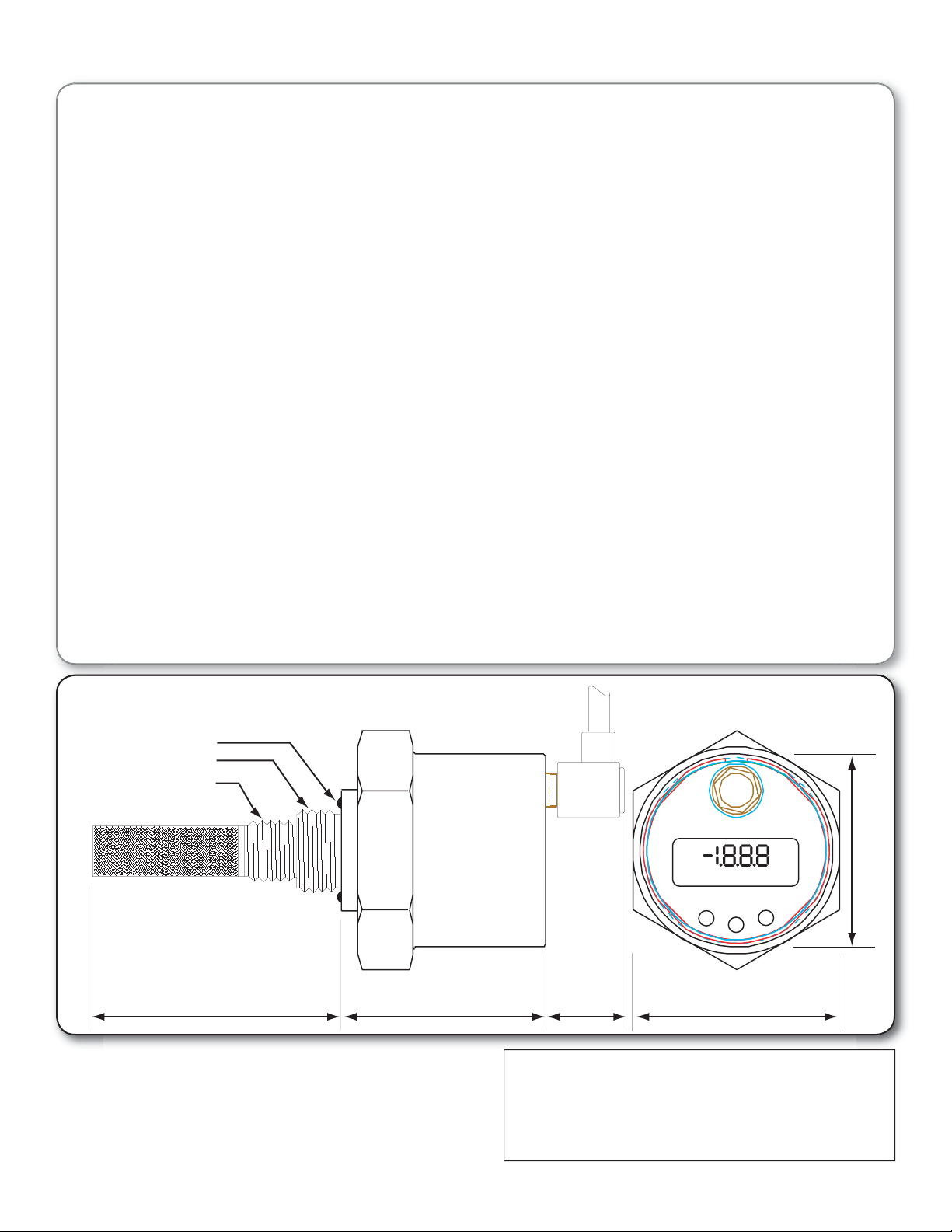

Mechanical

Enclosure ...........................Stainless steel

(Weather proof cover optionally

available)

Pressure operating range: .Standard: 500PSI (34bar)

...................................Optional: 5,000 PSI (340 bar)

Electrical connections: ......2.1 mm power jack with retainer

thread size 3/4”-16, 14mm x 12.5mm

Cable: ................................Two conductor cable

Power Requirements .........10 to 33 VDC, the instrument

draws 4-20mA depending

on measurement dewpoint.

Warranty ............................1 year

Engineering units: ..............°C, °F, ppmv, LBS H

gm H

O/M3

2

O/mm scf,

2

Viton A-O-ring

3/4" - 16

14mm x 12.5mm

2.230"

COSA INSTRUMENT CORPORATION

Texas Office: 7125 North Loop East, Houston, TX 77028

Tel: 713-947-9591, Fax: 713-947-7549

New Jersey Office: 55 Oak Street, Norwood, NJ 07648

Tel: 201-767-6600, Fax: 201-767-6804

Email: cosa@cosaic.com

www.cosa-instrument.com

1.850" 0.600"

Represented by:

ACTUAL SIZE

Flats for 1

1.750"

7/8" wrench

rev 2.804

Loading...

Loading...